- Sustainable interlocking ash bricks with green waste lime - ceramic fines: improving performance and longevity

S. Manishankar* and K. Vidhya

Department of Civil Engineering, Mahendra Engineering College, Namakkal, Tamil Nadu 637503, India

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This study presents a comprehensive investigation into the feasibility of incorporating Ceramic Fines (CF), a calcium-rich industrial byproduct from the cement manufacturing process, as a partial replacement for Ordinary Portland Cement (OPC) in the production of fly ash-based interlocking bricks. CF was substituted at incremental levels ranging from 0% to 20%, and its influence on the physical, mechanical, and durability properties of the bricks was systematically evaluated. The results indicate that 10% replacement of OPC with CF yields optimal performance, achieving a peak 28-day compressive strength of 11.72 MPa. A substantial reduction in bulk density, upto 13.36%, was observed with increasing CF content, indicating the potential for lightweight applications. Water absorption exhibited a strong inverse correlation with weight density and a decrease in the initial rate of absorption further confirmed the refinement of pore structure. Durability studies under prolonged seawater and sodium chloride immersion demonstrated superior chemical resistance, with minimal weight gain and strength degradation in CF specimens.XRD Analysis revealed dominant hexagonal crystalline phases, contributing to enhanced matrix stability and reduced ion permeability. The findings substantiate the viability of Ceramic Fines as a sustainable supplementary cementations material, promoting circular economy principles while enhancing the performance and durability of interlocking masonry units.

Keywords: Ceramic fines, Fly ash, Interlocking brick, Durability, Sustainability.

Masonry is primarily used in the construction of historical buildings, residential homes, sewers, drinking water facilities, and ancient monuments. The key materials that make up masonry composites are brick and mortar. Annually, approximately 1.4 trillion bricks are produced globally for masonry construction [1]. Burnt clay bricks have been the primary building material for centuries, valued for their mechanical strength and long lifespan. The alkalis in the bricks improve their binding properties, while the silica content contributes to their strength. However, the continuous extraction of fertile topsoil is depleting natural resources, and the high-temperature kiln firing process results in increased carbon emissions, which adversely affect the environment. Given these negative impacts, there is a need for an alternative production method using sustainable raw materials for masonry construction.

Interlocking bricks focus on the structural efficiency of bricks made from fly ash. The research includes tests for dimensional stability, water absorption, compressive strength, and efflorescence. The results suggest that the interlocking bricks produced are suitable replacements for conventional bricks [2]. Fly ash, a byproduct of energy production, is abundant and recognized as an additional cementitious material with properties similar to cement. In response to this, the Indian government issued a directive encouraging the use of fly ash-based products instead of conventional clay-based ones, particularly near national thermal power plants. Research has been conducted on the use of coal fly ash in the production of both fired and unfired bricks [3]. The study's authors highlight that incorporating 20% coal fly ash into burnt bricks results in strength comparable to that of the control bricks. However, strength declines with higher additions, particularly when the fly ash content reaches 30–50%. Non-fired bricks, with 40–60% coal fly ash, achieve a maximum compressive strength of 46 MPa [4].

Adding approximately 20% fly ash to clay bricks results in strength similar to that of bricks made without fly ash. The authors also found that incorporating fly ash reduces the weight of the bricks. The study then focused on producing fly ash bricks without clay, exploring two methods for their production. One method uses cement as the binding agent, while the other utilizes gypsum and lime. Published literature indicates that the cement-based method results in significantly higher mechanical strength compared to the gypsum-based method. When making bricks, natural sand is an optional ingredient. Given how quickly natural sand is being depleted, a substitute fine aggregate is needed. Fly ash, cement, and fine aggregate are the raw ingredients used to make cement-based fly ash bricks. Cement serves as a binding agent and improves strength characteristics when employed in manufacturing. However, for brick manufacture to be environmentally and sustainably viable, less cement must be used.

One waste product from the cement industry is ceramic fines, which contain a considerable amount of calcium. Green waste lime–ceramic fines (GWL-CF) is obtained through the semi-wet process of cement and tile manufacture. Yoon et al. [5] demonstrated that ceramic waste powder improves the strength and durability of blended cement mortars, supporting its potential as a supplementary binder. Previous research demonstrated the effectiveness of incorporating ceramic waste materials in the development of eco-friendly construction products, supporting their reuse as supplementary cementitious materials in concrete and bricks [6]. A related study confirmed that ceramic sludge enhances hydration behavior and compressive strength when blended with cement, further reinforcing the material's potential in sustainable construction [7]. A study was made to develop geopolymer bricks using incinerated bottom ash, coal ash, and ecosand, optimizing activator ratios and curing conditions. A peak compressive strength of 21.45 MPa was achieved at 60°C. The results demonstrate enhanced microstructure and sustainability in construction.[8].Another research investigates geopolymer bricks with 40% municipal incinerated ash, achieving 12.35 MPa strength and superior durability. Advanced testing confirmed reduced water absorption and improved chemical resistance. The study validates MI ash as a sustainable alternative to clay bricks[9].Other researches has shown that ceramic industrial sludge—chemically similar to ceramic fines—can be successfully used in the production of sustainable construction bricks, achieving good mechanical performance and durability [10].

There is silica and other chemicals in the green lime waste. These kinds of waste materials could lead to a good change and standardization in manufacturing when bricks are produced. The qualities of green lime waste as a building material must be investigated because there is currently little research on this topic. Recent research highlighted the potential of waste tile powder to improve the compressive strength and durability of fly ash-based geopolymer bricks, reinforcing the relevance of similar ceramic byproducts in sustainable brick manufacturing [11]. Traditional clay bricks, also known as fly ash bricks, are produced in uniform sizes with smooth surfaces [12]. These bricks are more effectively able to bear the force of gravity. Nonetheless, the composite bonding between the brick and the mortar resists the out-of-plane loading in the event of extreme events like earthquakes.

Hence, the newest technology to support both gravitational and lateral loads is mechanically interconnecting fly ash bricks. The mortar-free interlocking bricks have become more and more popular in the last few years. It requires less labour, is constructed more quickly, and is self-aligned [13]. Interlocking bricks are manufactured at a rate that is two to five times higher than that of regular bricks, and they save 60 to 80 percent of labour costs [14]. The significance of using the interlocking approach for building brick walls is emphasized in recent research [15]. The current bricklaying technique is challenging and takes longer to complete. Additionally, it is much more expensive than using the interlocking building approach because of the additional mortar. A study by shi et al. [16] conducted experimental and numerical investigations on the compressive properties of interlocking blocks, validating their effectiveness under structural loads.

In the current study, an attempt is made in the production of fly ash interlocking bricks with ceramic fines as a partial substitution for cement. The physical, mechanical and durability properties are investigated, and the optimum addition of ceramic fines is evaluated. Recent literature reported that global waste generation in a year reaches up to 2.2 billion tons, and it may increase to 15.6 million tons by the year 2050 [17]. Various industrial byproducts, such as paper sludge, incinerated municipal ash, and others, are increasingly being utilized in the production of brick masonry. Research using fly ash and bottom ash-based brick production with a non-conventional method of self-compacting mixture without any heat and pressing techniques but with cement incorporation was conducted. The best optimum combination of cement, bottom ash, and fly ash of 0.45:1:1 provides the best result [18]. Other studies investigated geopolymer bricks incorporating waste foundry sand and furnace slag, concluding that the optimum ratio of fly ash, foundry sand, and slag is 30:30:40, with a compressive strength of 26 MPa. The strongest bricks passed the leaching test and were environmentally feasible [19]. Additional studies showed that adding 20% coal fly ash to fired bricks matched the strength of control bricks, while 40–60% addition in non-fired bricks achieved up to 46 MPa compressive strength [20]. Energy assessments indicated that the production of one clay brick consumes 2 kwh of electricity and emits 0.41 kg of CO2 [21]. Glass waste and granite tailings were also studied as raw materials, showing improved mechanical and durability characteristics in ash-based bricks [22]. Palm oil clinker has been tested as a substitute for sand in fly ash cement bricks, with 30% clinker replacement identified as optimal [23]. Recycled carbon fibre from wind turbines was tested in porous brick production. While micropores formed during firing, the approach supports circular economy goals [24]. Studies also tested the inclusion of sawdust, marble dust, compost, and spent earth, identifying 1050 °c as the optimum sintering temperature [25]. Sewage sludge ash, comprising mostly 60% silica and 10% alumina, has shown potential in brick manufacturing [26]. Sawdust and limestone dust can reduce brick weight by up to 65% compared to concrete bricks [27]. Finally, textile sludge blended with quarry dust, lime, and slag was evaluated. Even with 15% sludge content, the bricks retained structural integrity with proper optimization [28].

Green waste lime-Ceramic Fines -Ceramic Fines - Ceramic Fines (GWL)

Green waste lime-Ceramic Fines - Ceramic Fines (GWL) is a calcium-Clay and alumina rich industrial byproduct generated during the semi-wet process of tile and stone flooring manufacturing process. This material, predominantly composed of calcium compounds, silica and alumina, derived from Marble industry waste streams and holds potential for reuse in construction applications, particularly in the production of inter locking bricks. Due to its fine particle size and reactive chemical composition, GWL exhibits pozzolanic activity, which can enhance the performance of cementitious systems. It also contains a variety of oxidizing compounds that contribute to secondary hydration reactions, thereby improving the microstructure of the final product.

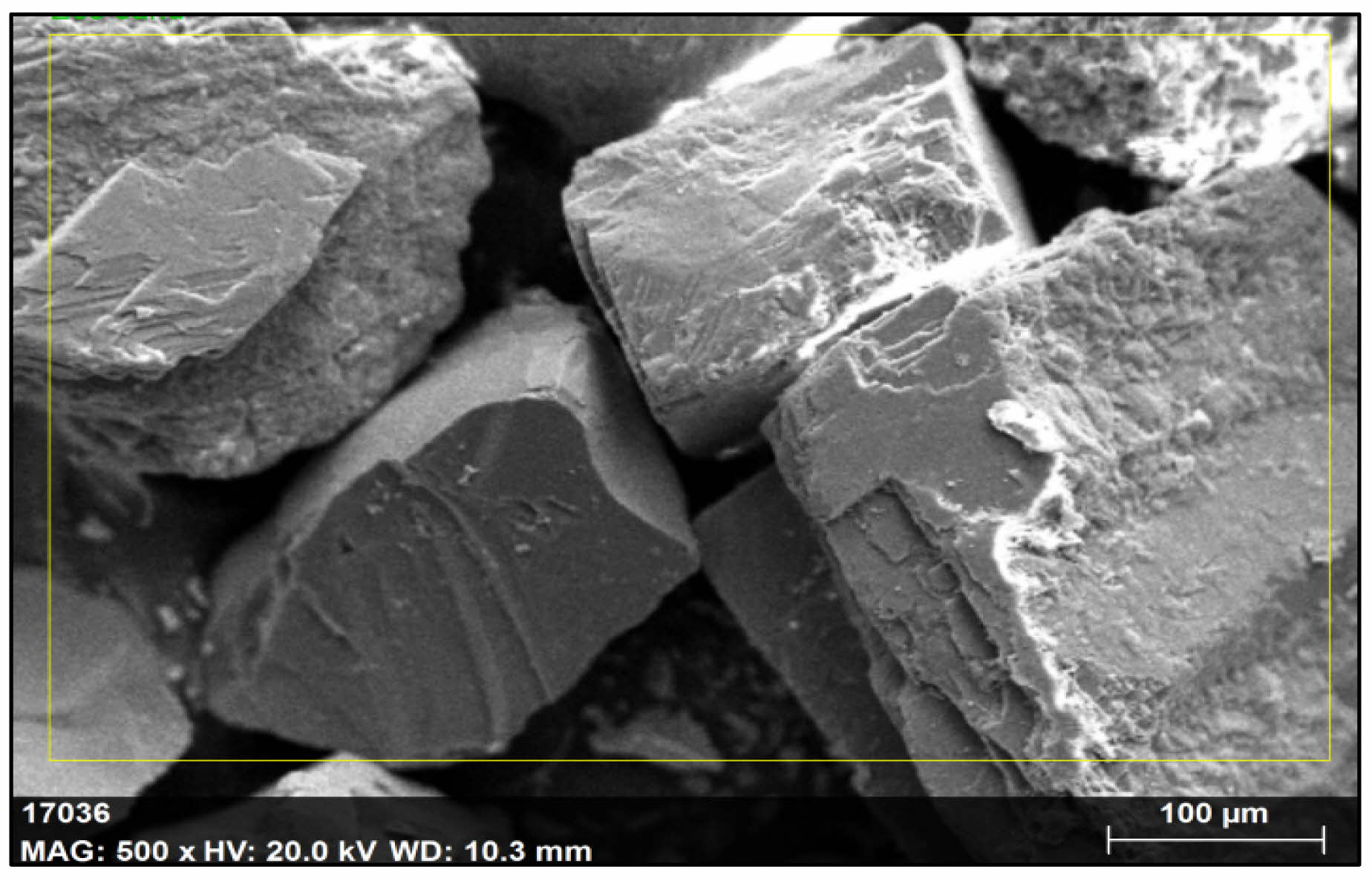

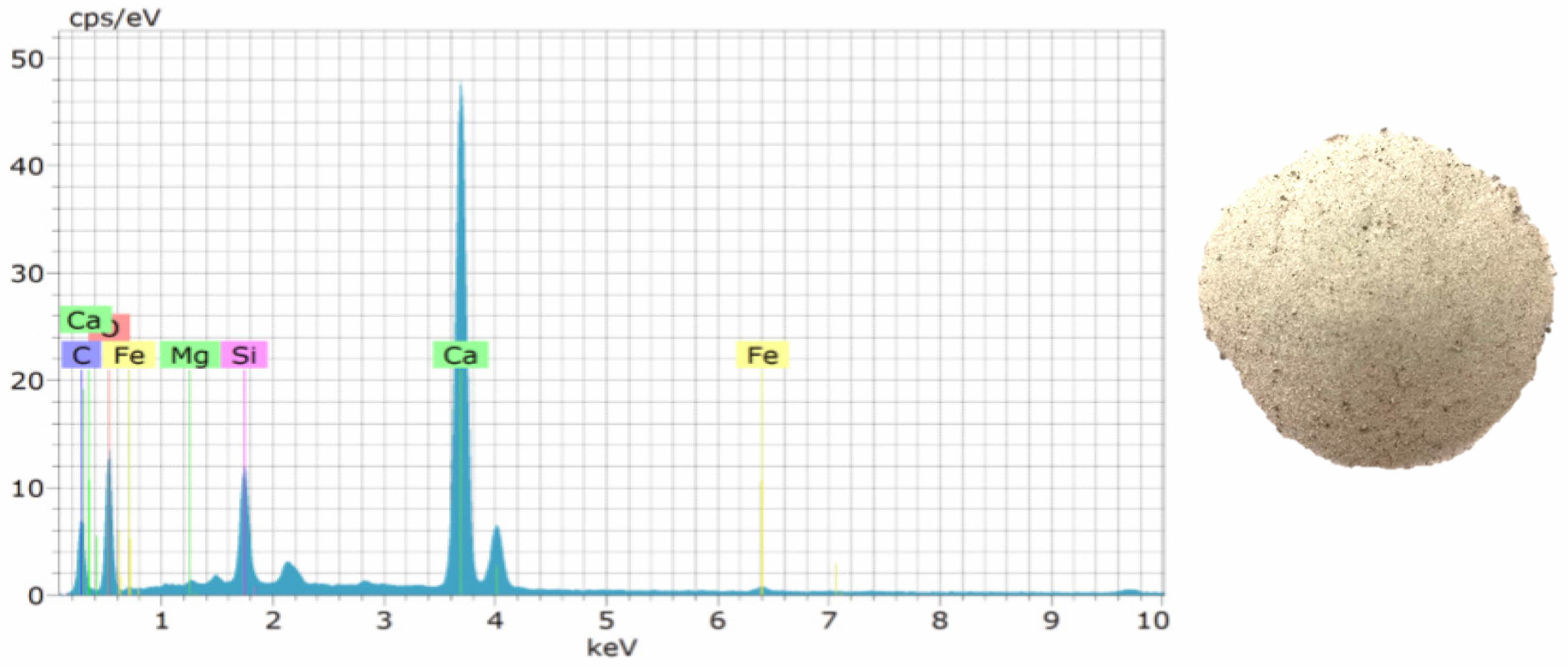

For this study, GWL was sourced from local Marble and tile manufacturing units, Salem, Tamil Nadu. The morphology and elemental composition of the material were analyzed using Scanning Electron Microscopy (SEM) and Energy Dispersive X-ray Spectroscopy (EDS), as illustrated in Figs. 1 and 2. The EDS results confirm that GWL is primarily composed of calcium, with minor constituents including magnesium, silica, and iron. These elemental components support the material’s suitability for use as a supplementary cementitious material.

The ceramic fines possess a specific gravity of 2.48 and a bulk density of 1510 kg/m³, indicating a moderately dense material. With a fineness modulus of 4.32 and particle sizes ranging from 140 to 150 µm they are coarser than typical fine aggregates, suggesting potential suitability for specific construction applications.

Fly Ash

Fly ash is a finely divided residue generated from the combustion of pulverized coal in thermal power plants. In the context of sustainable construction materials, it is increasingly utilized as a partial replacement for cement due to its favorable pozzolanic activity and micro-filler behavior. Upon hydration, the reactive silica present in fly ash combines with calcium hydroxide [Ca(OH)₂], a byproduct of cement hydration, to form secondary calcium silicate hydrate (C–S–H), thereby enhancing the strength and durability of cementitious matrices. Fly ash is classified into two types: Class F and Class C, based on the ASTM C618 standard. Class C fly ash, used in this study, is distinguished by its higher calcium oxide (CaO) content (typically >20%), which iMParts both pozzolanic and self-cementing properties, making it particularly suitable for applications in low-cement or blended cement systems. In contrast, Class F fly ash contains lower CaO and relies entirely on pozzolanic reactions.

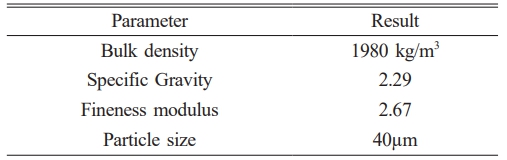

The fly ash employed in this research was obtained from the Mettur Thermal Power Station, Tamil Nadu, and falls under Class C classification. It exhibits a fine particle size distribution (predominantly <45 µm), low specific gravity (2.29), and a spherical morphology, which collectively enhance the mix workability, reduce water demand, and improve the homogeneity of the interlocking brick matrix. Table 1 presents the detailed physical properties of the fly ash used.

Cement

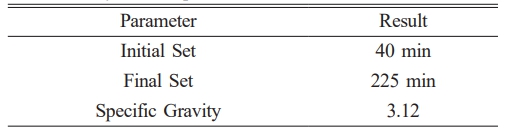

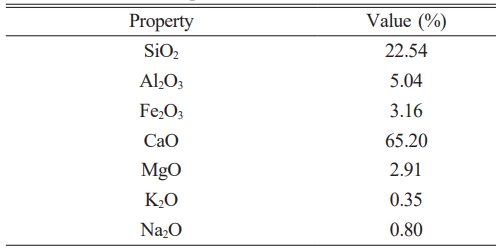

The experiments use UltraTech OPC 53-grade cement that is sourced locally in accordance with BIS 12269-2013. Table 2 and Table 3 respectively, list the physical and chemical properties of cement.

Manufactured Sand

As a sustainable substitute for river sand, manufactured sand is available. Artificial sand has become more and more popular as a building ingredient because real sand is scarce and quickly disappearing. Man-made products formed from crushed huge granite rocks are called manufactured sand. Because of their angular shape, the manufactured sand particles in mortar offer a stronger link between them. Comparable to actual sand, it has a particular gravity. For the purposes of this investigation, a local source provided manufactured sand.

Mix Compositions and casting of Interlocking bricks

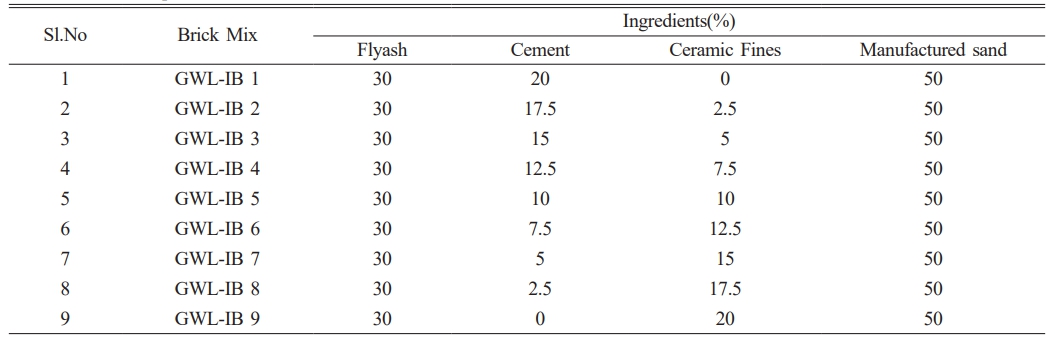

Table 4 presents the Mix compositions for the investigations. Flyash and Manufactured sand ratio are kept constant for the production of the interlocking bricks. The Ceramic Fines in incorporated from 0 to 20% with an interval of 2.5% as the Cement substitution material. The interlock brick of size 275 mm × 150 mm × 120 mm is manufactured in an industrial Set up. The Fig. 3 shows a view of Manufacturing of Interlocking brick at the industrial setup.

|

Fig. 1 Morphology of Green waste lime-Ceramic Fines -Ceramic Fines. |

|

Fig. 2 Energy Dispersive x-ray spectroscopy of Green waste lime-Ceramic Fines -Ceramic Fines. |

|

Fig. 3 Interlocking brick production in an industrial setup. |

The current study focused on the evaluation of the physical, mechanical and durability characteristics of the interlocking bricks with Green waste lime-Ceramic Fines as a partial substitution material. The Weight density, water absorption, Initial Rate of Absorption, Chemical resistance against the Seawater immersion and the Sodium Chloride immersion for the weight gain and the strength loss and XRD analysis of optimum brick samples Test results are presented and discussed. The tests are conducted as per the ASTM Standards (ASTM C67).

Weight density and Water absorption

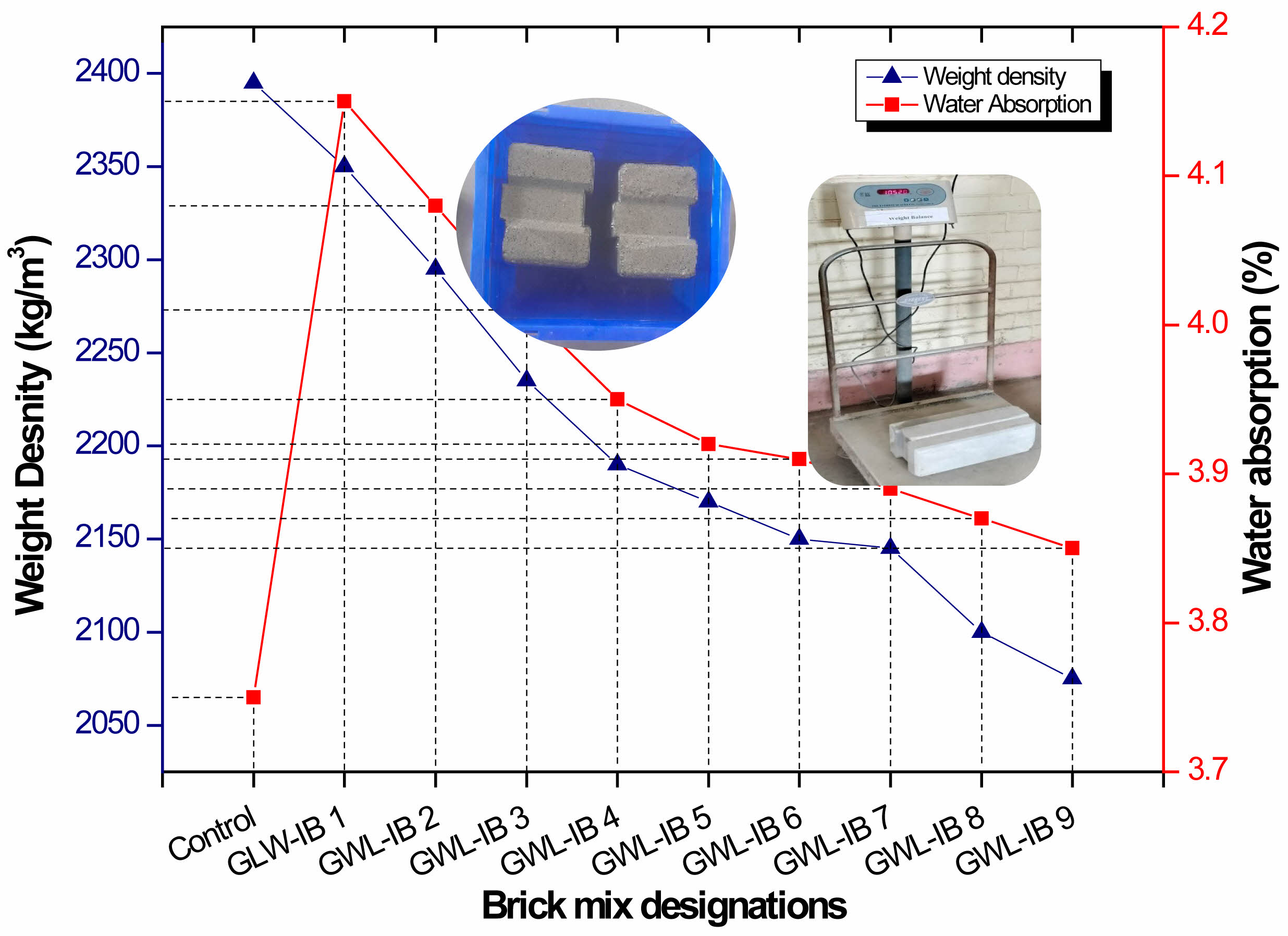

Figure 4 illustrates the experimental results for weight density and water absorption characteristics of sustainable interlocking bricks incorporating Ceramic Fines (CF) as a partial cement replacement. A clear downward trend is observed in weight density as the proportion of Ceramic Fines increases across the mix series GWL-IB 1 through GWL-IB 9. The measured weight densities span from 2350 kg/m³ to 2075 kg/m³, confirming a gradual reduction in bulk density with higher CF content.

Among all modified brick specimens, GWL-IB 1 exhibited the highest weight density, whereas GWL-IB 9 showed the lowest. When compared to the maximum density mix (GWL-IB 1), the other combinations exhibited progressive density reductions of 2.34% upto 11.70%, respectively. Furthermore, in comparison to the control brick (fly ash-based interlocking brick without ceramic substitution), the CF-modified bricks GWL-IB 1 through GWL-IB 9 demonstrated weight density reductions from 1.88% upto 13.36%, respectively. This systematic reduction in density is attributed to the unique particle morphology and microstructural characteristics imparted by the inclusion of Ceramic Fines. The finer particles and porous nature of CF influence the packing density and internal voids of the matrix, resulting in lighter composite structures. Notably, even at higher substitution levels (up to 25%), the bricks maintained structural coherence while offering the added advantage of reduced weight, making them well-suited for lightweight construction applications.

Thus partial replacement of cement with Ceramic Fines yields a measurable decrease in weight density, ranging from 1.88% to 13.36%, depending on the substitution level. The results underscore the potential of CF as a sustainable cement substitute that not only contributes to waste valorization but also facilitates the production of lightweight masonry units without compromising performance.

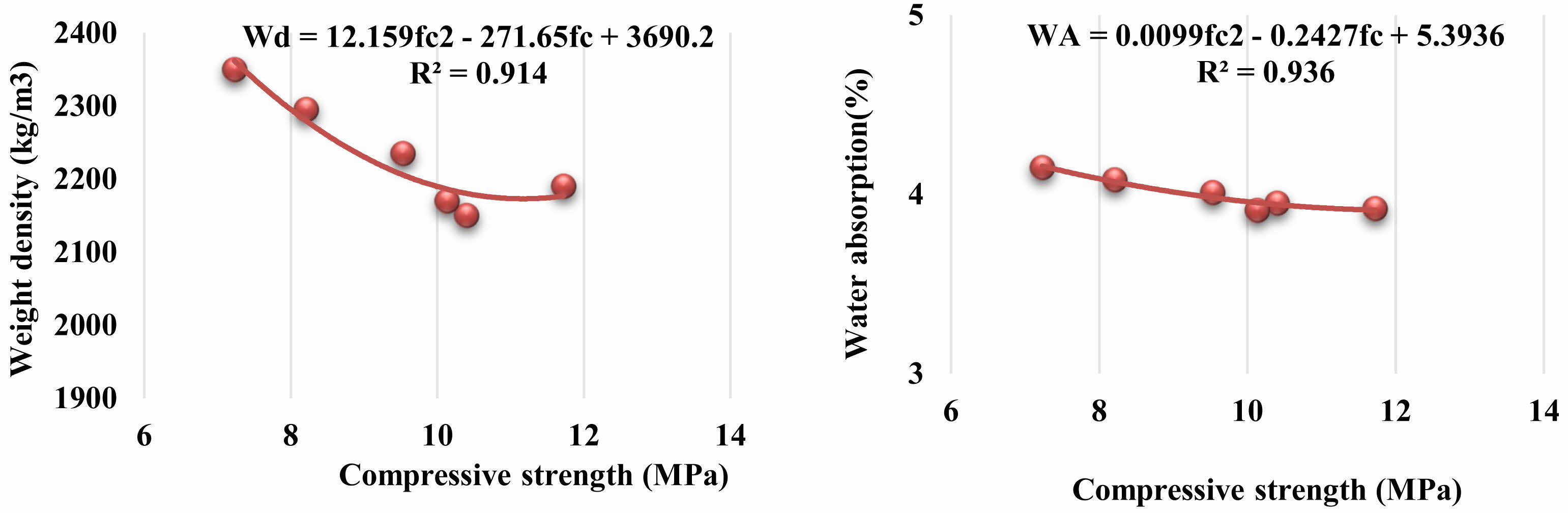

Figure 5 illustrates the water absorption (WA) characteristics of interlocking bricks incorporating Ceramic Fines (CF) as a partial cement replacement. All CF-modified mixes (GWL-IB 1 to GWL-IB 9) exhibited higher water absorption than the control, with values ranging from 10.67% to 6.93%, coMPared to 5.33% for the control brick.

Despite this, progressive reductions in absorption were noted across the series. Relative to GWL-IB 1, the mixes showed decreasing water absorption by 9.64% upto 7.23%, respectively. The initial increase in absorption is attributed to the finer, porous nature of CF, while the gradual decline at higher replacement levels may result from improved particle packing and reduced capillary porosity.

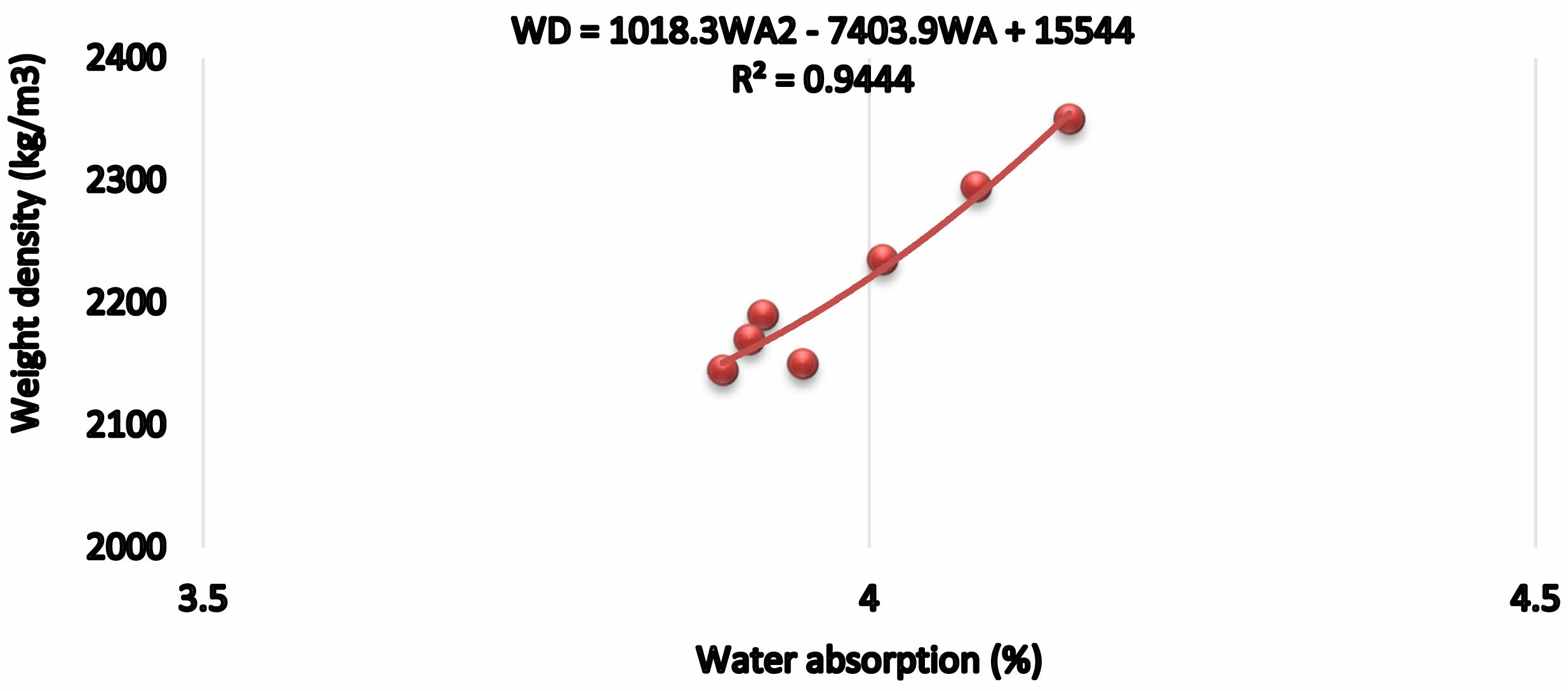

A regression analysis between WA (independent) and weight density (WD, dependent) reveals a strong inverse relationship, with a correlation coefficient of R² = 0.94. This indicates that as water absorption decreases, the weight density increases—a trend consistent with the microstructural densification induced by ceramic fines.

In summary, although CF initially increases water absorption, optimized levels mitigate this effect, balancing durability with lightweight performance. The strong WA–WD correlation underscores the suitability of CF in sustainable brick formulations.

Compressive strength

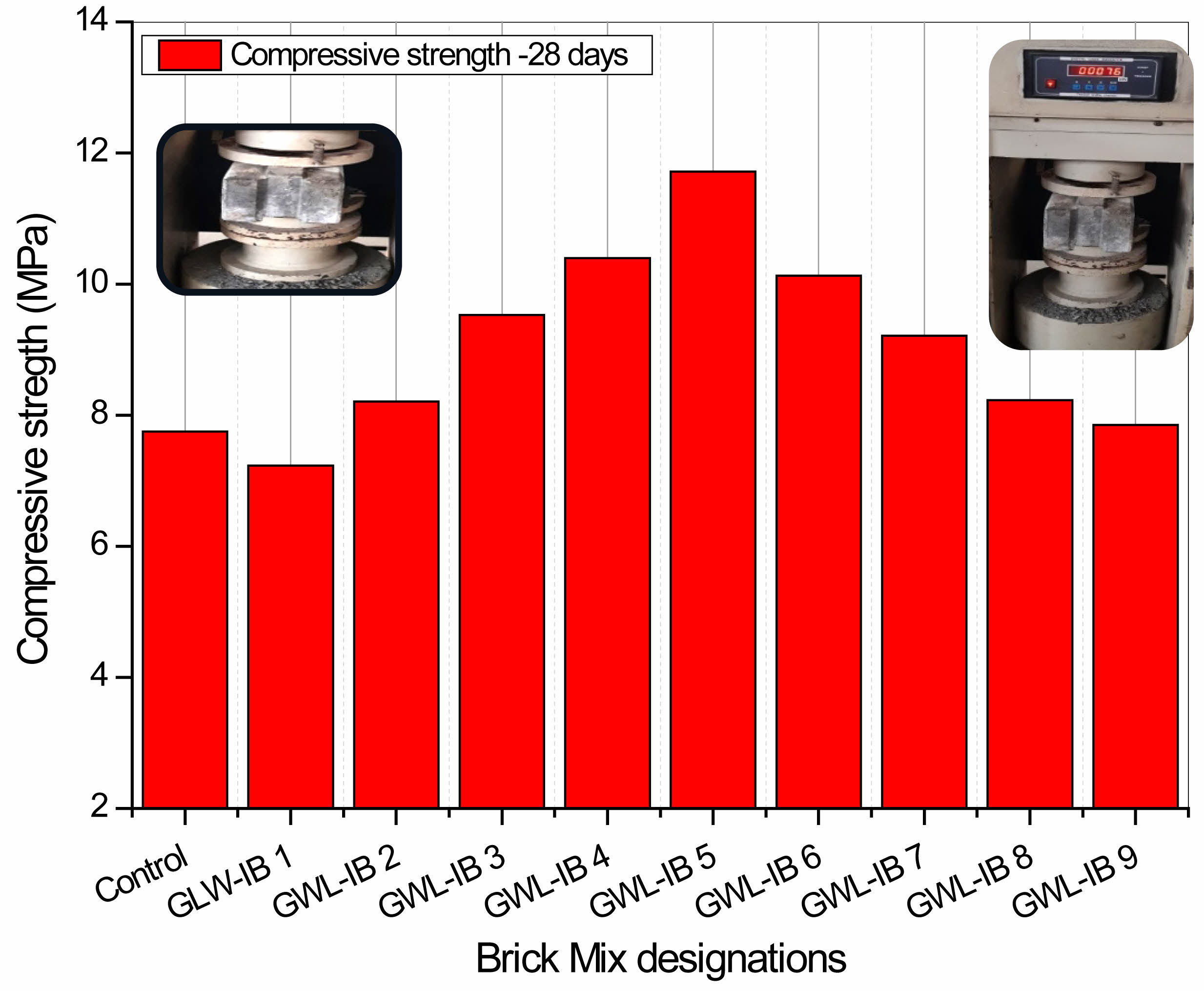

Figure 6 presents the compressive strength trends of interlocking brick specimens incorporating Ceramic Fines (CF) as a partial replacement for lime. The test results clearly indicate that the inclusion of CF at a 10% replacement level significantly enhances compressive strength at both 14-day and 28-day curing periods, attributable to improved particle packing, pozzolanic activity, and enhanced bond structure within the matrix.

From the graph, Beyond this optimum level, further additions of CF particularly up to 20%resulted in a measurable reduction in strength. This decline is likely due to the dilution of reactive lime content and the presence of excessive fines, which may disrupt the continuity of the binder matrix and contribute to increased porosity.

The optimum formulation, GWL-IB 5, recorded the highest compressive strengths of 8.2 MPa and 11.72 MPa at 14 and 28 days, respectively. When benchmarked against the other mixes (GWL-IB 1 through GWL-IB 9), the 28-day strength of GWL-IB 5 showed marked improvements respectively. These gains underscore the effectiveness of CF at moderate replacement levels in enhancing structural performance.

From a materials science standpoint, a negative correlation is observed between weight density and compressive strength, indicating that as density decreases due to the incorporation of lightweight CF the microstructural efficiency increases, resulting in strength gains. Furthermore, water absorption and compressive strength exhibit an inverse relationship, where reduced water ingress correlates with enhanced matrix densification and durability. This relationship is quantitatively supported by a correlation coefficient (R) of 0.93, suggesting a strong statistical alignment between compressive strength and both physical characteristics.

Figure 7 presents the relation between physical and mechanical characteristics of the interlocking bricks.

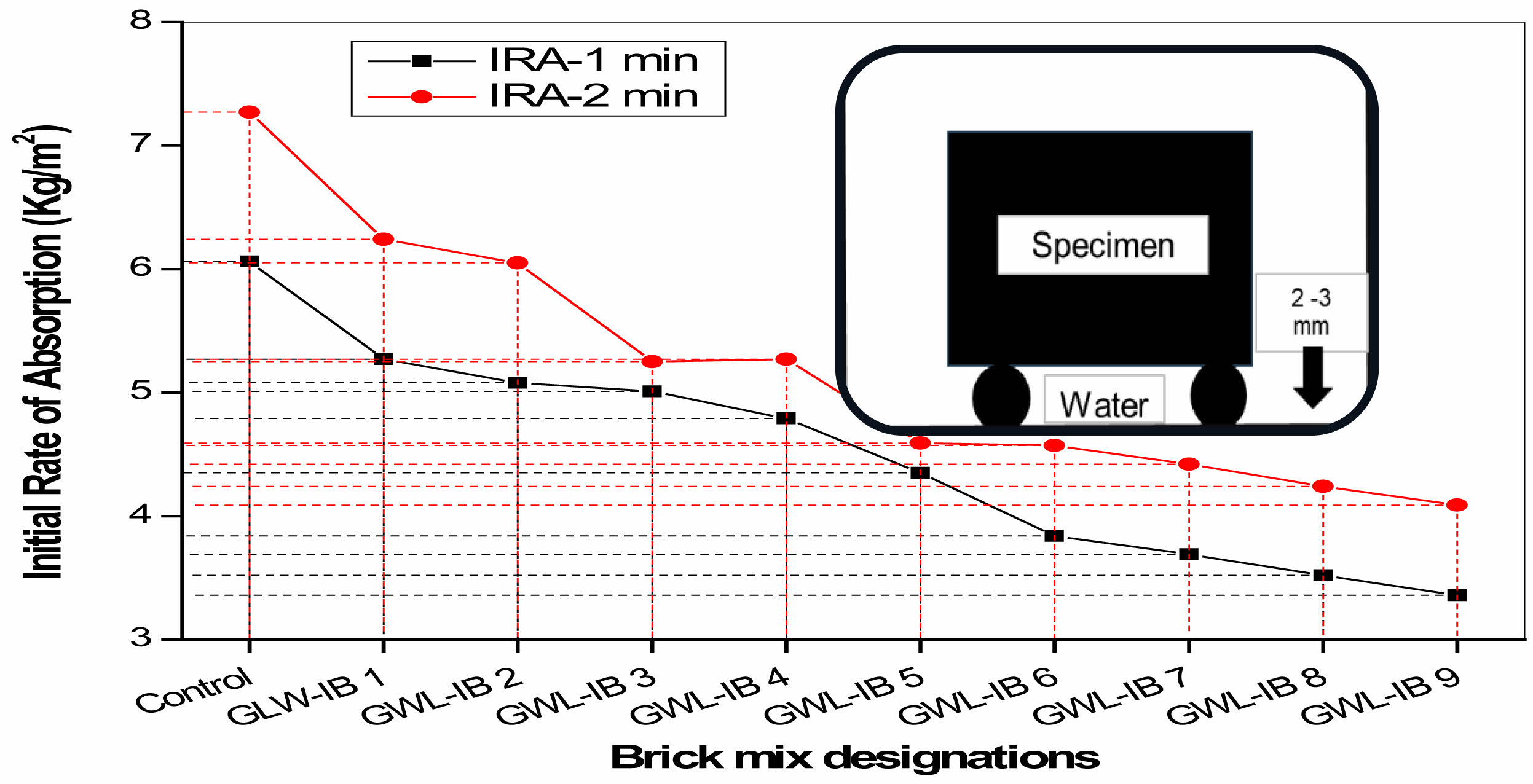

Initial Rate of Water Absorption (IRA) of Interlocking Bricks Incorporating Ceramic Fines

Figure 8 illustrates the Initial Rate of Water Absorption (IRA) characteristics of interlocking bricks formulated with varying proportions of Ceramic Fines (CF). The test outcomes indicate a progressive reduction in IRA values with increasing CF content, reflecting an improvement in surface densification and reduced capillary suction. For the 1-minute absorption period, the bricks GWL-IB1 and GWL-IB9 exhibited the highest and lowest IRA values of 5.27 kg/m² and 3.36 kg/m², respectively. A similar trend persisted during the 2-minute observation, where the maximum and minimum values recorded were 6.05 kg/m² and 4.09 kg/m², corresponding to the same mix designs.

This consistent behavior across both time intervals demonstrates that the incorporation of CF effectively imparts hydrophobic resistance and reduces pore connectivity within the matrix. Furthermore, all CF-modified bricks exhibited lower IRA values coMPared to the control specimen, highlighting the positive influence of CF on minimizing surface permeability.

The observed decline in IRA with Ceramic Fines addition underscores the potential of Ceramic Fines to produce interlocking bricks with enhanced durability characteristics, particularly suited for applications requiring low water ingress and high surface impermeability.

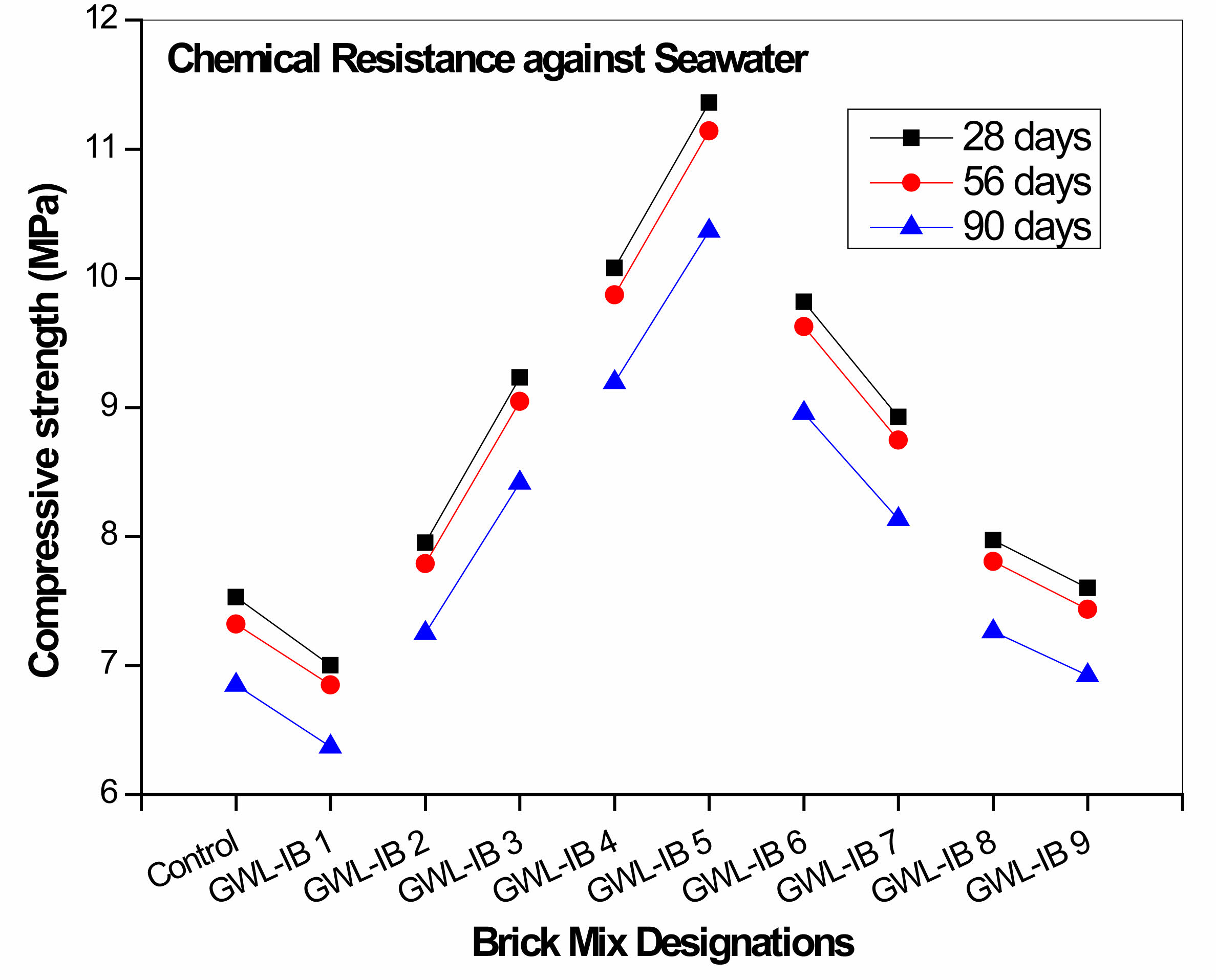

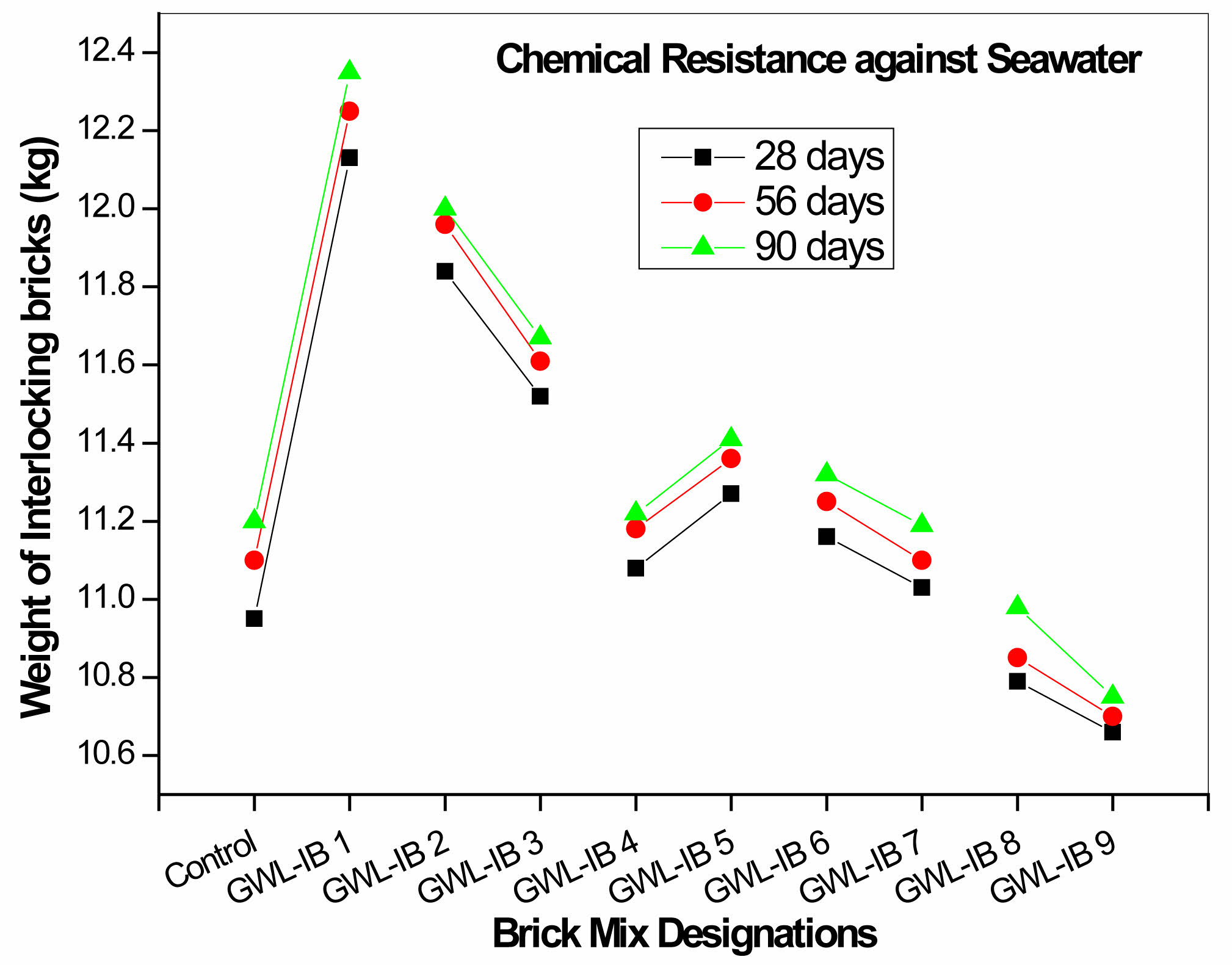

Chemical resistance study under seawater immersion

Figure 9 displays the weight variation of interlocking bricks immersed in seawater over 28, 56, and 90 days. The study evaluated weight gain and compressive strength loss to assess chemical resistance. Weight increase is primarily due to salt crystal deposition within the pore structure, inducing internal pressure. When this pressure exceeds the tensile strength of the pore walls, microcracking occurs, compromising the material. This degradation mechanism aligns with previous findings [8], highlighting salt crystallization pressure as a key factor in marine deterioration. The results confirm that Ceramic Fines-modified bricks exhibit measurable changes under long-term saline exposure, relevant for coastal durability applications.

Figure 9 summarizes the weight gain of interlocking brick blends with ceramic fines substituting cement, tested after 28, 56, and 90 days of seawater immersion. The control bricks exhibited weight increases of 4.29%, 5.71%, and 6.67% at these respective ages.

For the sustainable mixes GWL-IB 1 through GWL-IB 9, weight gains at 28 days ranged between 3.78% and 4.28%. At 56 days, gains increased to 4.17%–5.31%, and at 90 days, they further rose to between 4.66% and 6.17%. Notably, GWL-IB 5 consistently showed the lowest weight gain across all periods, indicating superior resistance to seawater-induced salt ingress.

The incremental weight gains from 28 to 56 days varied between 0.38% and 1.37%, while from 56 to 90 days the increase ranged from 0.33% to 1.20%. This steady pattern reflects ongoing salt accumulation within the pore structure, causing internal crystallization pressure that may lead to microstructural damage over time. However, the inclusion of ceramic fines helps refine the pore structure by reducing porosity and enhancing the packing density, which limits salt ingress and improves resistance to chemical attack. Furthermore, ceramic fines contribute to the formation of a denser microstructure through pozzolanic reactions, enhancing durability and mechanical stability under seawater exposure.

Figure 10 illustrates the strength loss of interlocking brick blends incorporating ceramic fines as a partial substitute for cement, evaluated after curing periods of 28, 56, and 90 days. The results reveal a consistent pattern of strength degradation over time. At 28 days, the control bricks exhibited strength losses of 2.85%, 5.56%, and 11.65% corresponding to the 28, 56, and 90-day marks, respectively. For the 56-day curing age, the mixes GWL-IB 1 through GWL-IB 9 demonstrated strength losses ranging narrowly between 4.95% and 5.27%, reflecting improved resistance relative to the control. By 90 days, all mixes experienced increased strength loss, with values from 11.55% to 11.89%. Notably, GWL-IB 5 recorded the lowest strength loss at 11.55%, underscoring its superior durability.

The incremental increase in strength loss between 28 and 56 days was modest, between 1.94% and 2.15%, while the increase from 56 to 90 days ranged from 6.90% to 7.01%. The incorporation of ceramic fines contributes to refining the microstructure via pozzolanic reactions, promoting a denser matrix that enhances resistance against chemical degradation. This improved matrix densification limits deleterious ion penetration and microcrack propagation under seawater immersion, thereby mitigating long-term strength loss. Consequently, ceramic fines play a critical role in sustaining mechanical integrity and prolonging the lifespan of interlocking bricks in aggressive marine environments.

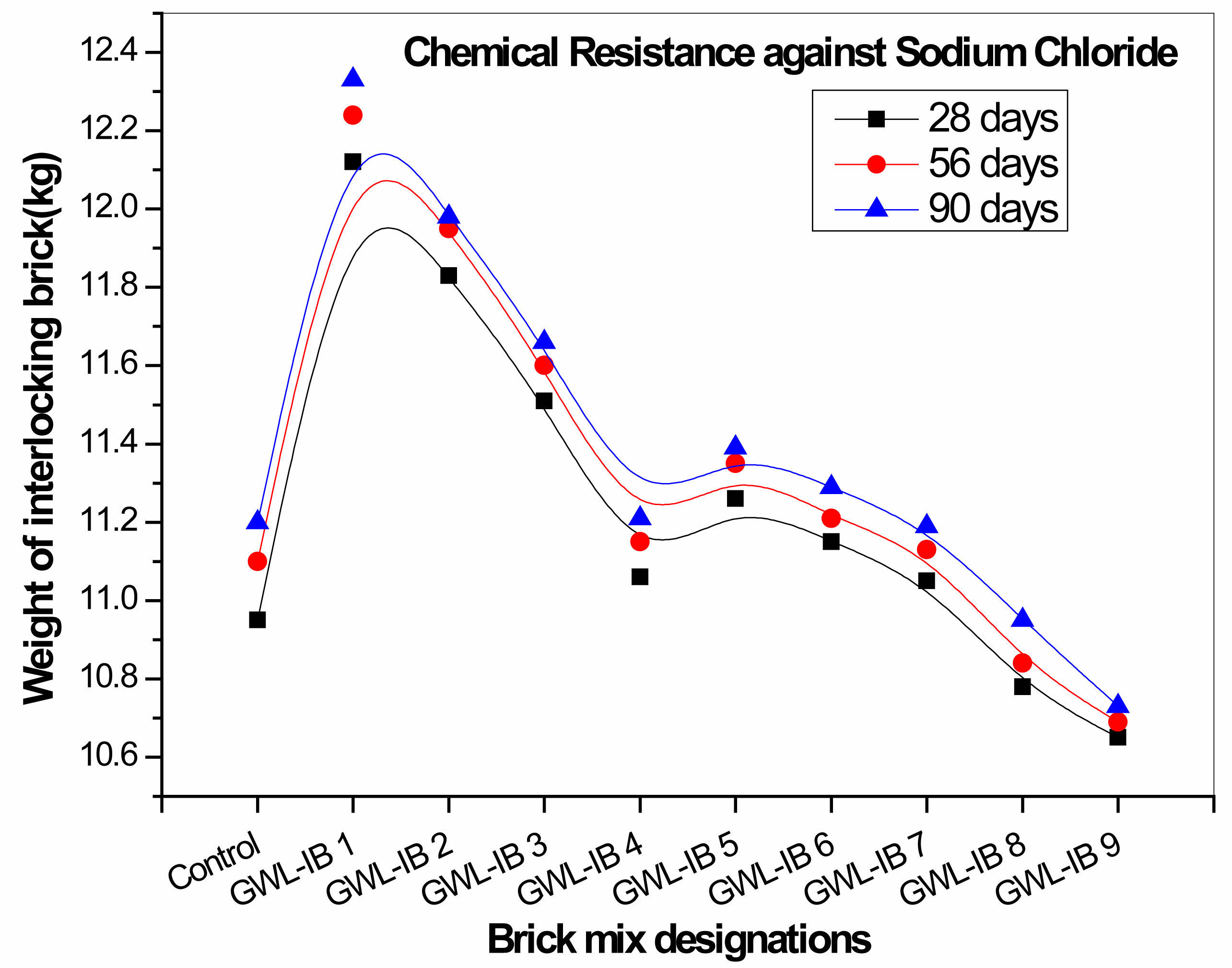

Chemical resistance study under Sodium Chloride immersion

Figure 11 shows the chemical resistance of interlocking bricks with ceramic fines as partial cement replacement, tested under sodium chloride immersion for 28, 56, and 90 days. Weight gain, indicating salt ingress and potential deterioration, was measured at each interval. Control bricks exhibited weight increases of 4.29%, 5.24%, and 6.57% at 28, 56, and 90 days, respectively. In contrast, ceramic fines-modified mixes (GWL-IB 1 to GWL-IB 9) showed consistently lower gains, ranging from 3.69% to 4.19% at 28 days, with GWL-IB 5 recording the lowest value, suggesting enhanced microstructural density and reduced permeability.

At 56 and 90 days, weight gains remained subdued, with increments between intervals under 1.37% and 1.01%, respectively, indicating limited salt diffusion and stable mass uptake. This improved durability is due to ceramic fines acting as micro-fillers and exhibiting partial pozzolanic activity, which refine pore structure and reduce ion transport pathways, thereby mitigating salt crystallization pressure and microcracking. Overall, ceramic fines enhance the chemical resistance of interlocking bricks in chloride-rich environments, supporting their use in sustainable construction exposed to marine conditions.

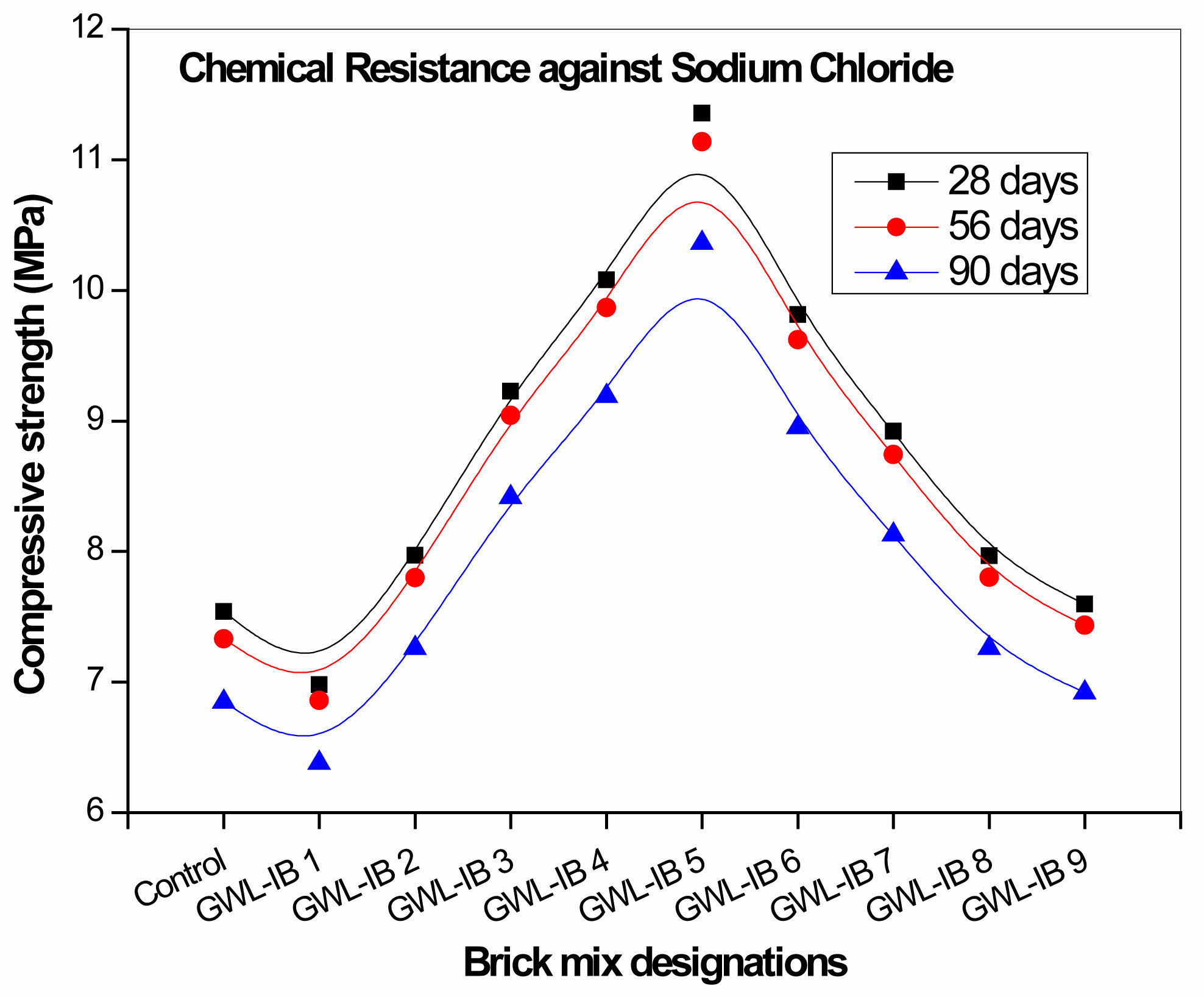

Figure 12 presents the strength loss of sustainable interlocking bricks with ceramic fines as a partial cement substitute, subjected to sodium chloride immersion over curing periods of 28, 56, and 90 days. The control bricks exhibited strength losses of 2.75%, 5.36%, and 11.59% at these intervals, respectively.

The ceramic fines-modified mixes (GWL-IB 1 to GWL-IB 9) demonstrated strength losses ranging from 2.92% to 3.46% at 28 days, and between 4.98% and 5.30% at 56 days. After 90 days, strength loss for these mixes increased to between 11.57% and 11.90%, with GWL-IB 5 showing the lowest degradation, indicating superior chemical resistance.

The incremental strength loss from 28 to 56 days varied between 1.72% and 2.16%, while the increase from 56 to 90 days ranged from 6.84% to 7.01%, suggesting a consistent degradation trend across mixes. The improved durability is attributed to the ceramic fines’ micro-filling effect and potential pozzolanic reactions, which refine the pore structure, reduce chloride ingress, and enhance long-term resistance to salt-induced deterioration.

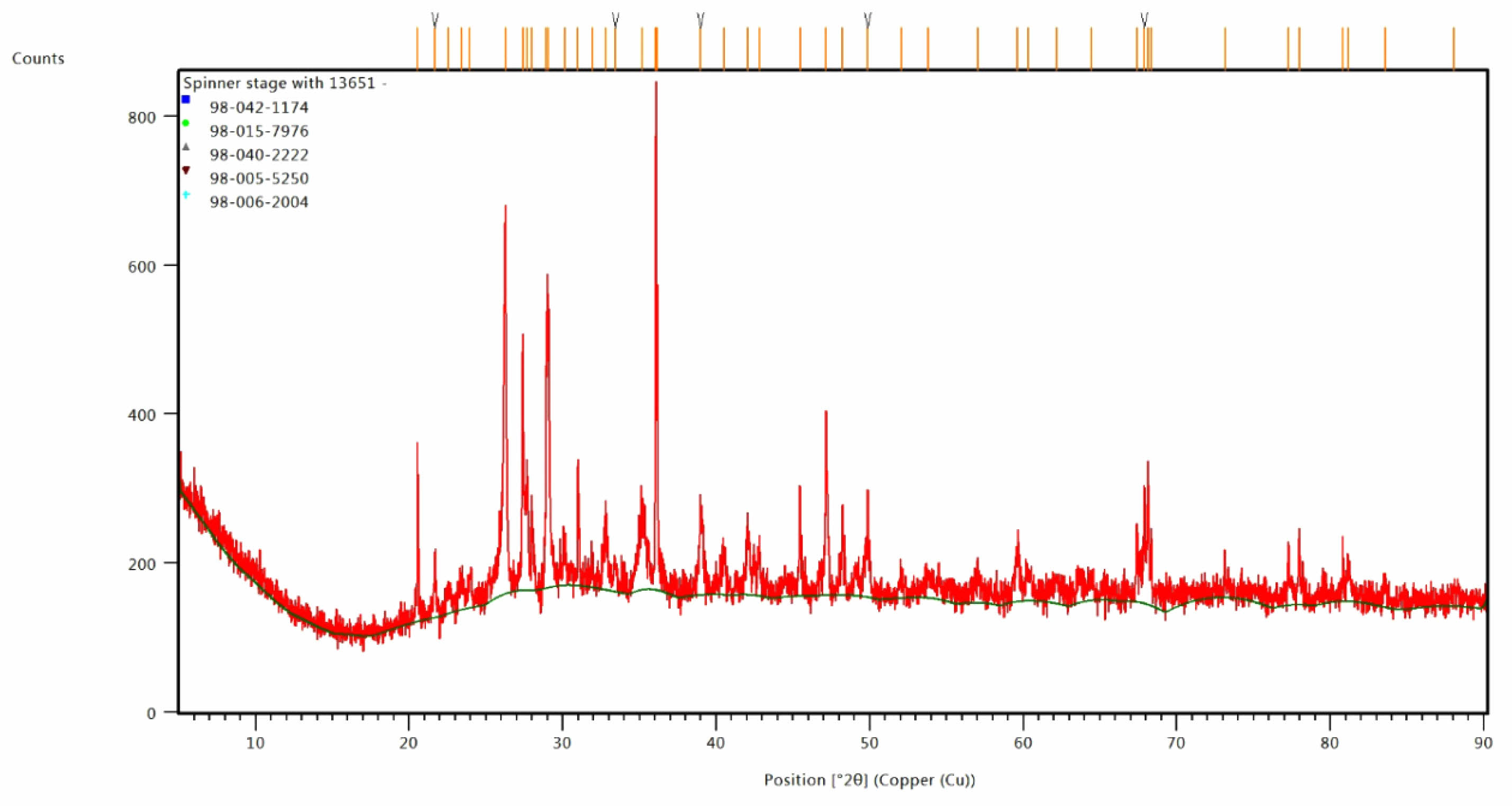

X Ray Diffraction studies

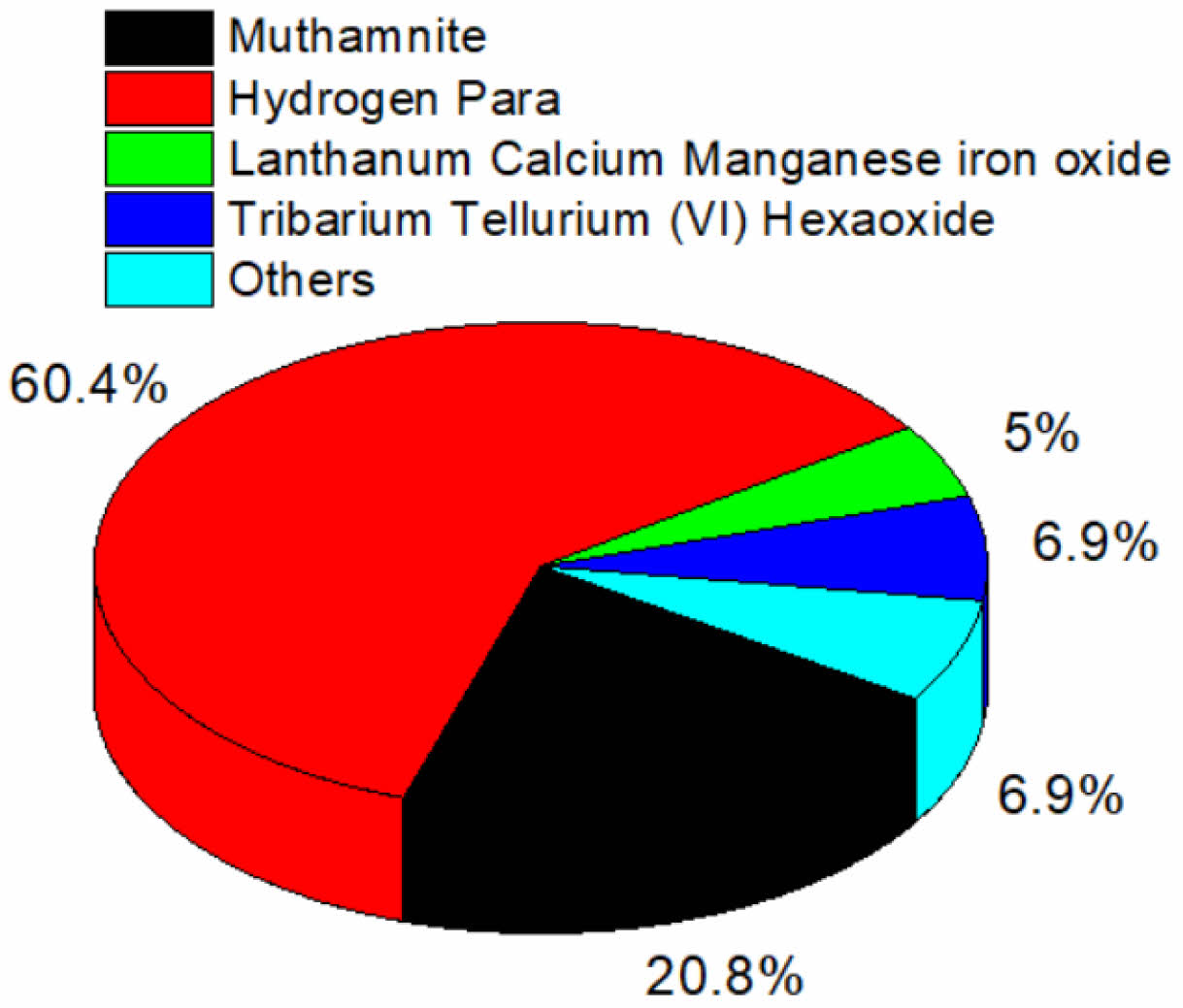

Figure 13 shows the XRD pattern of the optimum brick mix GWL-IB 5, while Fig. 14 presents the quantitative XRD analysis highlighting the various crystalline components in the optimum mixes.

From the results,the dominant hexagonal crystals, primarily Hydrogen-Para structures, constitute about 61% of the peak intensity. These hexagonal phases are characteristic of the ceramic fines used in the mix, reflecting their inherent mineralogical composition. The high presence of hexagonal crystals indicates that ceramic fines contribute significantly to the crystalline framework, promoting enhanced packing density and chemical stability within the brick matrix. Furthermore, the detection of calcium mercury gallium selenide within the hexagonal crystal system suggests that ceramic fines introduce beneficial trace elements or compounds, which may play a role in enhancing the chemical resistance of the bricks, especially under aggressive environments like sodium chloride exposure.

Overall, the mineralogical characteristics of ceramic fines significantly influence the crystalline microstructure of the bricks. The synergy of hexagonal and monoclinic phases derived from ceramic fines not only boosts mechanical strength but also enhances durability and chemical resistance, validating the use of ceramic fines as an effective partial substitute for cement in sustainable interlocking bricks.

|

Fig. 4 Weight density and Water absorption test results. |

|

Fig. 5 Regression analysis of weight density and Water absorption. |

|

Fig. 6 Compressive strength Test results. |

|

Fig. 7 Regression analysis of relation between Physical and mechanical properties. |

|

Fig. 8 Initial Rate of Absorption Test results. |

|

Fig. 9 Weight gain results under seawater immersion. |

|

Fig. 10 Strength loss study under seawater immersion. |

|

Fig. 11 Weight gain study under sodium chloride immersion. |

|

Fig. 12 Strength loss study under seawater immersion. |

|

Fig. 13 XRD for the optimum brick mix GWL-1B 5. |

|

Fig. 14 Quantititative results of XRD for the optimum brick mix GWL-1B 5. |

This study rigorously evaluates the incorporation of Ceramic Fines as a supplementary cementitious material in cement-based interlocking ash bricks, utilizing a composite blend of Ordinary Portland Cement (OPC), Ceramic Fines, fly ash, and manufactured sand.

Experimental results demonstrate a systematic reduction in bulk density of the bricks from 2350 to 2075 kg/m³ with increasing Ceramic Fines content, attributable to the lower specific gravity and improved particle packing density of Ceramic Fines, which optimizes the microstructural matrix.

Water absorption tests conducted over 24 hours reveal a progressive decline from 4.15% to 3.85%, indicating significant refinement of pore structure and a decrease in capillary porosity due to the pozzolanic activity and filler effect of Ceramic Fines.

Compressive strength analysis identifies an optimal substitution level at 10% Ceramic Fines, where the bricks achieve a peak strength of 11.72 MPa at 28 days curing, underscoring enhanced hydration kinetics and improved interfacial transition zone (ITZ) density through effective nucleation sites provided by Ceramic Fines.

An inverse correlation between density and compressive strength highlights that mechanical performance is predominantly governed by microstructural integrity rather than mere mass, with Ceramic Fines promoting a denser and more cohesive matrix.

Statistical correlation confirms a negative relationship between compressive strength and water absorption, substantiating the role of Ceramic Fines in reducing permeability and enhancing durability by mitigating microcrack propagation and moisture ingress.

Initial rate of absorption (IRA) measurements indicate a marked decrease in capillary suction with increasing Ceramic Fines, reflecting enhanced surface characteristics and pore refinement that limit water transport pathways.

Durability assessments under aggressive chemical environments, specifically seawater and sodium chloride immersion, reveal minimal strength loss and weight gain in the mix containing 10% Ceramic Fines substitution (GWL-1B), demonstrating superior resistance to chloride-induced degradation and ion ingress.

Collectively, these findings substantiate the potential of Ceramic Fines as a viable, sustainable cementitious additive that not only valorizes ceramic waste but also significantly improves the mechanical robustness, impermeability, and chemical durability of interlocking ash bricks, aligning with principles of green construction materials and circular economy.

The Principal and Civil Engineering Department, Mahendra Engineering College, Namakkal, Tamil Nadu, India.

No potential conflict of interest was reported by the author(s).

- 1. R. Selvapriya and R. Thanigaivelan, Matéria (Rio de Janeiro), 29[2] (2024) 1-16.

-

- 2. B. Al-Fakih, B.S. Mohammed, M.S. Liew, and E. Nikbakht, J. Build. Eng. 21 (2019) 37-54.

-

- 3. S. Abbas, R. Hameed, M.A. Baig, M. Kashif, and S. Shaukat, J. Build. Eng. 95 (2024) 110288.

-

- 4. D. Eliche-Quesada, J.A. Sandalio-Pérez, S. Martínez-Martínez, L. Pérez-Villarejo, and P.J. Sánchez-Soto, Ceram. Int. 44[4] (2018) 4400-4412.

-

- 5. S. Yoon, K.J. Lee, and J.H. Kim, J. Ceram. Process. Res., 19[1] (2018) 45-50.

- 6. J.H. Kim and H.K. Lee, J. Ceram. Process. Res. 15[2] (2014) 103-107.

- 7. S.D. Park and S.J. Lim, J. Ceram. Process. Res. 22[4] (2021) 376-382.

- 8. H. Choi and J.S. Kim, J. Ceram. Process. Res. 18[6] (2017) 491-495.

- 9. S.W. Lee and B.H. Han, J. Ceram. Process. Res. 20[3] (2019) 220-225.

- 10. S. Naganathan, A.Y.O. Mohamed, and K.N. Mustapha, Constr. Build. Mater. 96 (2015) 576-580.

-

- 11. S. Narayanasamy, G. Aruna, and S. Praburanganathan, AIP Conf. Proc. 3146 (2024) 050006.

-

- 12. V. Kumarasamy, R. Sampath, and S. Kandasamy, Iran. J. Sci. Technol. Trans. Civ. Eng. 46 (2021) 1929-1936.

-

- 13. G. Xie, X. Zhang, H. Hao, and J. Thomas, J. Build. Eng. 83 (2023) 108415.

-

- 14. T. Shi, X. Zhang, H. Hao, and C. Chen, Eng. Struct. 228 (2021) 111561.

-

- 15. M.N. Arisiketty and D. Cruze, Matéria (Rio de Janeiro), 29[3] (2024).

-

- 16. S. Saari, B.H.A. Bakar, and N.A. Surip, Dev. Built Environ., 5 (2021) 100042.

-

- 17. S. Apithanyasai, N. Supakata, and S. Papong, Heliyon, 6[3] (2020) e03577.

-

- 18. S. Abbas, M.A. Saleem, S.M.S. Kazmi, and M.J. Munir, J. Build. Eng. 14 (2017) 7-14.

-

- 19. M.H. Nguyen and P.H. Trong, Constr. Build. Mater. 321 (2022) 126385.

-

- 20. S. Praburanganathan, S. Chithra, and Y.B.S. Reddy, Environ. Sci. Pollut. Res. 29 (2022) 54193-54218.

-

- 21. K. Muthusamy et al., Mater. Today Proc. 46[4] (2021) 1652-1656.

-

- 22. L. Crespo-López, C. Coletti, S. Morales-Ruano, and G. Cultrone, Ceram. Int. 50[6] (2024) 9682-9696.

-

- 23. D. Eliche-Quesada et al., Ceram. Int. 38[4] (2012). [Please insert page numbers if available.]

- 24. M. Smol, J. Kulczycka, A. Henclik, K. Gorazda, and Z. Wzorek, J. Clean. Prod. 95 (2015) 45-54.

-

- 25. P. Turgut and H.M. Algin, Build. Environ. 42[9] (2007) 3399-3403.

-

- 26. W.V.D.C. Bezerra and G.A.A., Constr. Build. Mater. 95 (2015) 45-54.

This Article

This Article

-

2025; 26(4): 618-627

Published on Aug 31, 2025

- 10.36410/jcpr.2025.26.4.618

- Received on Jun 9, 2025

- Revised on Jul 23, 2025

- Accepted on Aug 24, 2025

Services

Services

- Abstract

introduction

materials and experimental program

results and discussion

conclusion

- Acknowledgements

- Disclosure Statement

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- S. Manishankar

-

Department of Civil Engineering, Mahendra Engineering College, Namakkal, Tamil Nadu 637503, India

Tel : +91 9788647755 - E-mail: shankarmani1986@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.