- Optimization of rice husk ash (RHA) as partial replacement of cementing material in structural ceramic composite concrete using response surface methodology (RSM) statistical experimental design

Aliff Akhmal Mohd Fazlia, Siti Koriah Zakariaa, Nur Iman Najwa Abd Rahmana, Siti Zuliana Salleha,

Abdul Hafidz Yusoffa, Nurul Azita Sallehb, Mustaffa Ali Azhar Taibc, Faisal Budimand, Arlina Alia and Pao Ter Teo1,*aAdvanced Materials Research Cluster, Faculty of Bioengineering and Technology, Universiti Malaysia Kelantan, Jeli Campus, 17600 Jeli, Kelantan, Malaysia

bSchool of Technology Management and Logistics, Universiti Utara Malaysia, 06010 Sintok, Kedah, Malaysia

cDivision of Advanced Ceramic Materials Technology, Advanced Technology Training Center (ADTEC) Taiping, 34600 Kamunting, Perak, Malaysia

dSchool of Electrical Engineering, Telkom University, Bandung 40257, West Jawa, Indonesia

Rapid development in the

concrete industry leads to a higher demand for cement consumption worldwide.

Due to this, the production of cement has become very crucial, resulting in a

high carbon footprint and pollution along the process. Therefore, the

utilization of agricultural by-products as cement replacement will help to

reduce pollution caused by conventional cement production and therefore reduce

the unsystematic waste management. Rice husk ash contains high silica content

that makes it a potential material to partially replace cement in concrete

production. This is because, the reaction between rice husk ash and cement can

improve the compressive strength of the concrete. With the aid of response

surface methodology, the optimization of utilizing rice husk ash as a partial

replacement of cement in concrete can be achieved. Therefore, concrete

incorporated with rice husk ash with high and optimum compressive strength can

be produced.

Keywords: rice husk ash (RHA), Concrete, Cement

The growth of cement production around the world is

expected to keep increasing with the infrastructure development due to

increment of population. The progress of this production making researchers to

find alternative material as a replacement of cement due to high

possibly of shortcoming natural resource. Moreover, the cement

production caused the emission of CO2 and high energy used which

results in negative effect in environment [1]. The replacement of

cement from waste material is vital in order to increase the

sustainability in green construction [2]. For example, the utilization of waste

materials such as fly ash [3-5], recycled copper slag [6], sugarcane bagasse

ash [7, 8], and corncob ash [9] have been reported. These wastes are

considered as alternative for cement because they possess pozzolanic properties

[10].

Besides that, there are numerous reports that suggest the

utilization of rice husk ash (RHA) as a partial replacement

in body formulation of concrete production [11-13]. The

source of RHA is abundant and highly generated annually because 90% of rice plantation

are produced and consumed in Asian Region [14, 15]. Hence, RHA is the best

option as supplementary cementitious material (SCM) due to widely available

resource. In addition, the utilization of rice husk ash as a pozzolanic

material in cement and concrete provides several advantages, such as improved

strength and durability properties, reduced materials cost due to cement

savings and environmental benefits related to the disposal of waste materials

and to reduced carbon di oxide emissions [16]. In the other

work, Zareei et al. (2017) have reported that concrete with high compressive

strength compared to standard concrete could be produced by substituting 10% of

cement with RHA [17]. The pozzolanic properties of RHA which caused a reaction

between SiO2 and Ca(OH)2 during cement hydration process

and thus enhanced the properties of RHA-mixed cement [18].

The other factors that enhanced the RHA-mixed cement properties can be

associated to the formation rate of calcium silicate hydroxide (C-S-H) from the

reaction between Ordinary Portland Cement (OPC) and water [19]. The positive

utilization effect of RHA will be able to reduce the problem arise by the

abundant of RHA generated [20].

Although the replacement of RHA into cement production can

increases the performance of cement but a further increment of RHA would reduce

the compressive strength of concrete due slight cementitious

properties of RHA than conventional cement [17]. In a work reported by Hwang et

al. (2011) where they observed a decrement performance of concrete when the

addition of RHA beyond 20% [12]. Hence, the optimum percentage of RHA need to

be determined because it will influence the performance of cement-mixed with

RHA.

Most of the utilization of RHA in cement production are

reported without the use of response surface methodology (RSM). Aydar et al.

(2018) mentioned that RSM is helpful for creating, improving, and enhancing the

reaction variable [21]. In addition, RSM can be used to optimize one or more

responses for examples maximize strength and also to minimize cost [22].

In this work, the compressive strength of a concrete

affected by RHA replacement (10, 20 and 30 wt%) and curing time (3, 5 and 7

days) is reported. The statistical analysis including model adequacy checking,

analysis of variance (ANOVA), main effect and interaction plots as well as the

regression analysis were performed for each response. The aim of this work is

to obtain a correct body formulation of concrete incorporated with RHA with the

aid of statistical design.

Material

Ordinary Portland Cement (OPC) was produced by one of the

local cement manufacturers in Malaysia. Sand aggregate is used as a structural

filler for the concrete. Black and Grey RHAs were obtained from BERNAS Paddy

Processing Centre, Penang, Malaysia.

Method

The concrete was formulated based on M-20 concrete,

which composed of cement, sand, and aggregate with a ratio of 1:1.5:3 [23]. For

this study, the cement ratio consisted of a combination of cement and RHA (10

wt.%, 20 wt.%, and 30 wt.%). Two types of RHA (black RHA and grey RHA) were

used throughout the study. The raw materials (RHA and OPC) were also

characterized in terms of chemical composition (XRF) and mineralogical property

(XRD).

Firstly, raw materials are mixed in a dry condition for 2

minutes, then water was added and mixed for another 3 minutes using Heidolph

mixer at constant mixing speed. The fresh concrete was then poured into the

plastic mold with a dimension of 10 cm × 10 cm × 5 cm. The

concrete was de-molded after 24 hours and cured in a tank of water. The

concrete samples were tested at the concrete age of 3, 5 and 7 days after

curing.

The final cured concrete is then characterized in terms

of compressive test, porosity test, water absorption test, and

also surface and phase analysis. Compressive test (ASTM C109), effective

porosity, and water absorption (ASTM C642-97) tests were performed to determine

the mechanical properties of the concrete samples.

Chemical

Composition of Raw Materials

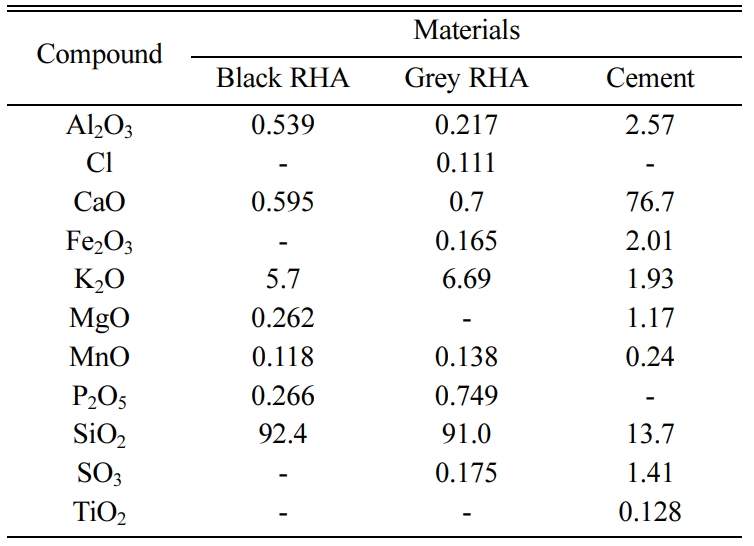

Table 1 listed the composition of raw materials that were

determined by XRF. Black RHA shows a high concentration of silicon dioxide,

which is 92.4%, and grey RHA is 91.0%. Cement has a high concentration in

calcium oxides, which is 76.7%. The usage of RHA as a partial replacement for

cement is important because it has a high content of silicon dioxide (SiO2)

that will react with calcium oxides from the cement to enhance the strength of

concrete by the formation of calcium silicate hydrate (C-S-H) gel.

Mineralogical

Analysis

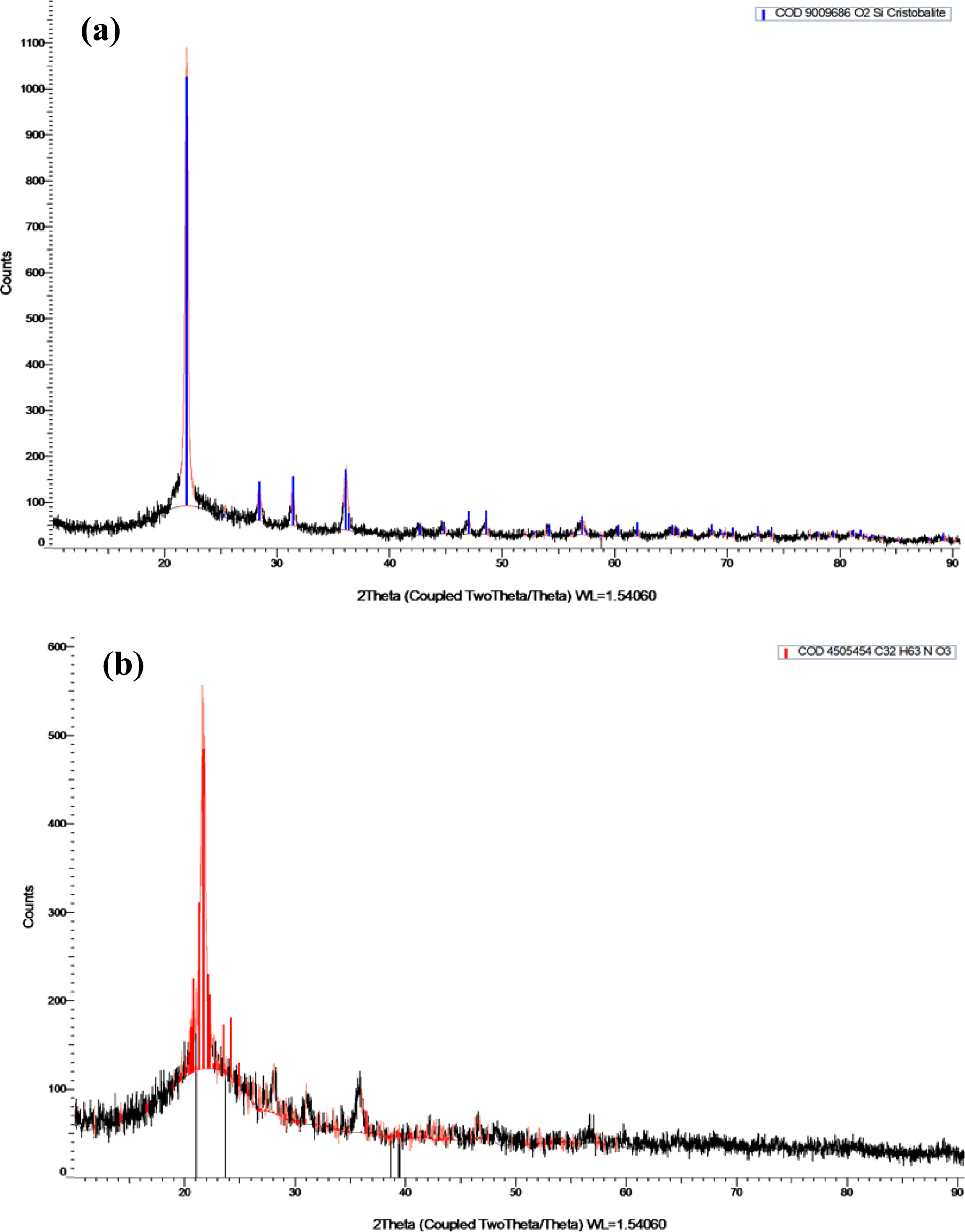

Fig. 1(a) shows the XRD pattern of black RHA. The

crystallinity of black RHA is 53.9% showing that black RHA being incinerated at

a temperature below 700 °C. The color of black RHA was formed due to

incomplete combustion of rice husk [24].

On the contrary, Fig. 1(b) reveals the XRD pattern for

Grey RHA that forms an amorphous region where its crystallinity is 44.7% that

indicates Grey RHA being incinerated above 700 °C. As the temperature of

incineration increase above 700 °C, the mineralogy of silica in RHA

started to change to crystalline [25]. The purity of silica is highly affected

by chemical treatment compared to thermal treatment. The grey color of RHA was

formed due to the strong interaction between potassium and silica ion that

causes the formation of potassium silicate combined with carbon. Therefore, the

grey color of RHA was formed during incineration [26].

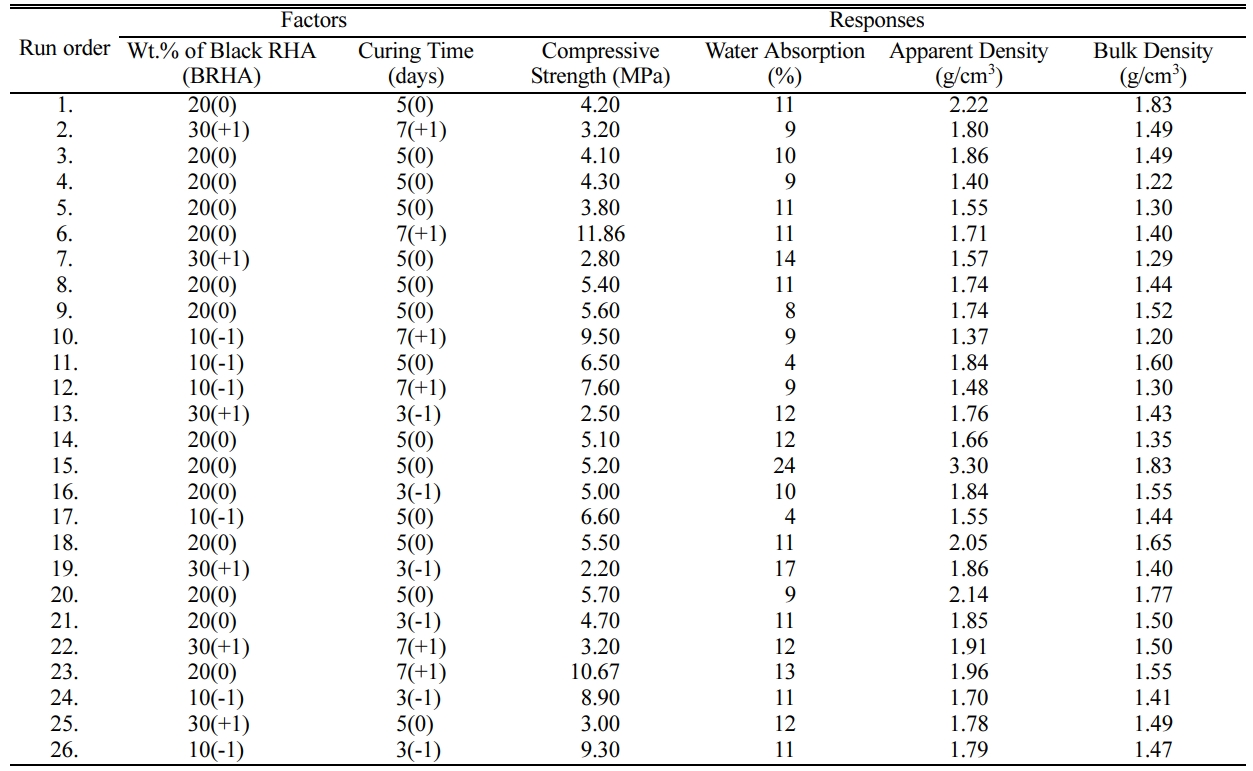

Central Composite Design

Central Composite Design is an experimental design, useful

in response surface methodology for building a second-order (quadratic) model

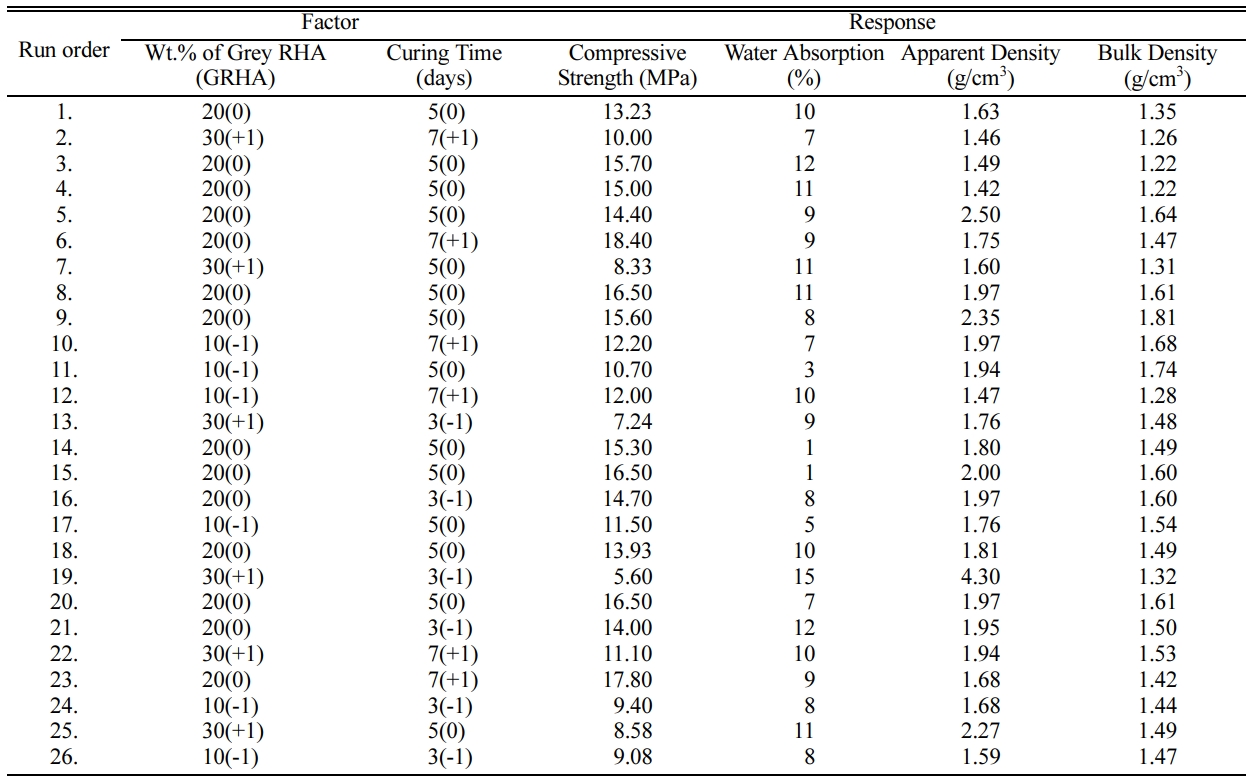

for the response variable. Table 2 and Table 3 show the experimental design

matrix and response for black and grey RHA, which sum up to a total of 26

experimental runs in random order with 2 replications, using MINITAB 16. After

that, coding was used to denote the level or range of each evaluated factor on

scale ‘-1’ for 10% and 3 days, ‘0’ for 20% and 5 days, and ‘+1’ for 30 % and 7 days.

Subsequently, statistical analysis, including model adequacy

checking, analysis of variance (ANOVA), main effect and

interaction plots and regression analysis were performed for each response.

Model Adequacy Checking

Khan et al. (2017) have reported that the assumption of

residuals by statistical analysis can be proven by model adequacy check [22].

In general, statistical subject residuals can be described as the difference

between actual and prediction value. In this study, the actual response values

were obtained from Table 2 and Table 3.

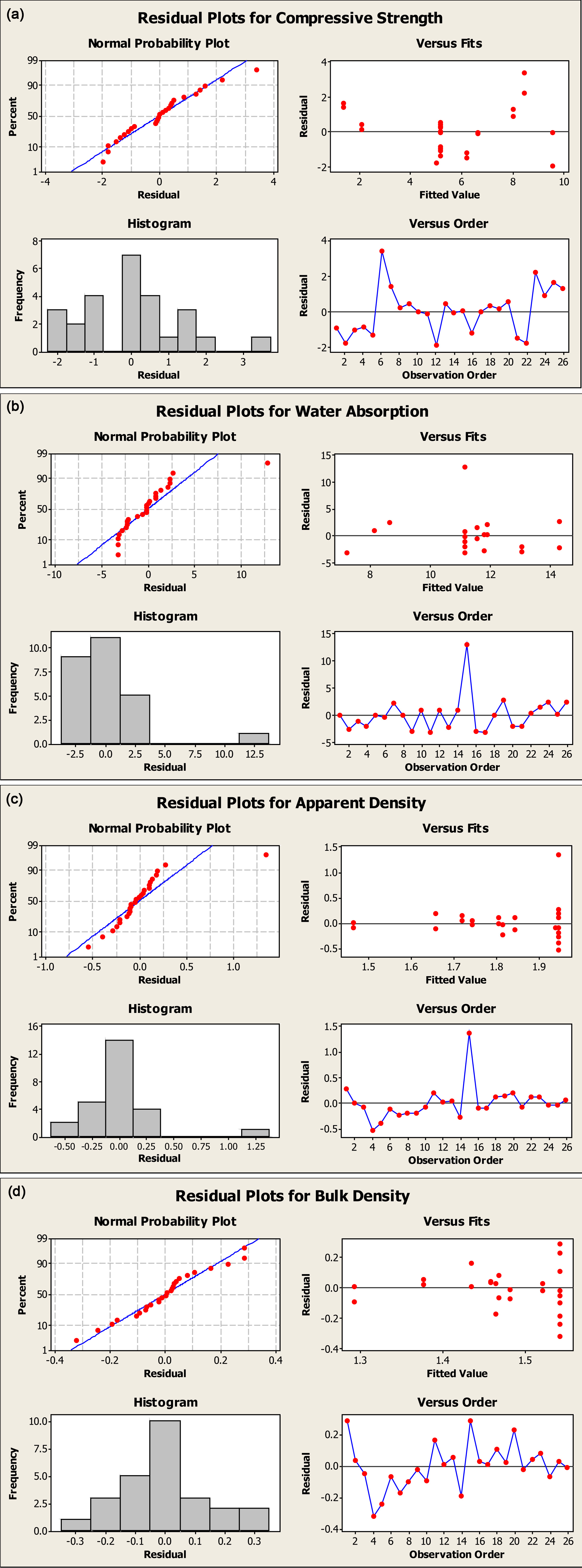

Fig. 2(a)-(d) shows the residual plots for compressive

strength, water absorption, apparent density, and bulk density of concrete that

incorporated with black RHA. By analyzing all the normal probability plot from

graph present from black RHA, it was observed the residual plots shows two

types of pattern which is light tail distribution for compressive, water

absorption and apparent density that indicate this side of the

distribution produces outliers at a reduced rate from what

expect with a normal distribution, a light tail often means that all the

observations are piled up near a boundary for the distribution [27]. This

pointed out that compressive strength, water absorption, apparent density, and

bulk density fulfilled the first criteria of model adequacy checking and were

normally distributed [28].

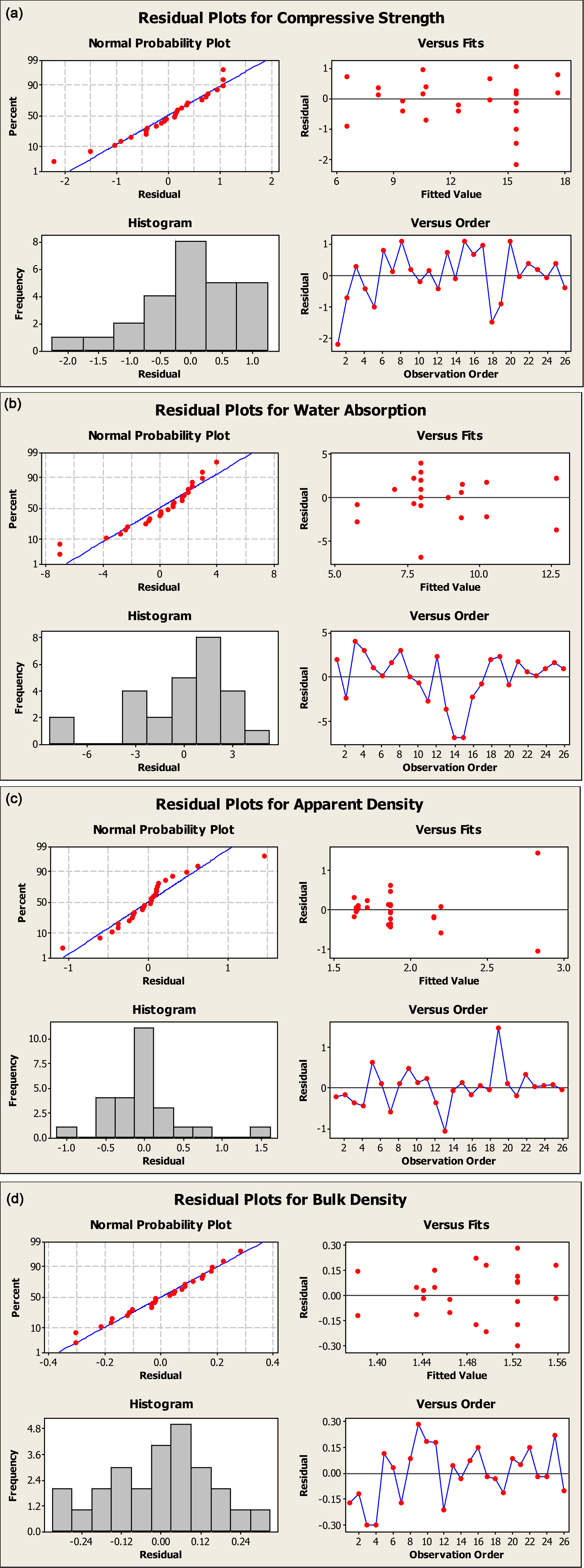

Meanwhile, Fig. 3(a)-(d) show residual plots for compressive

strength, water absorption, apparent density, and bulk

density of concrete containing grey RHA. The normal probability plots of grey

RHA were scattered along the straight line indicating normal distribution of

the evaluated properties. Thus, the first criteria of model adequacy checking

were fulfilled. Next, all the histogram plots show bell-shaped patterns which

indicates that all of the data were normally distributed, and this further

supports the normal distribution data of compressive

strength, water absorption, apparent density, and bulk

density.

After that, residuals versus fitted value plots

illustrated that the data points for compressive strength, water

absorption, apparent density, and bulk density that use black and grey RHA are

distributed randomly, ensuring that constant variance criteria of residuals

[29]. The residual versus observation order plots indicate that residual

points are completely random despite observation order. This

implies that residual was independent with each other obeying the third

assumption.

Analysis

of Variance

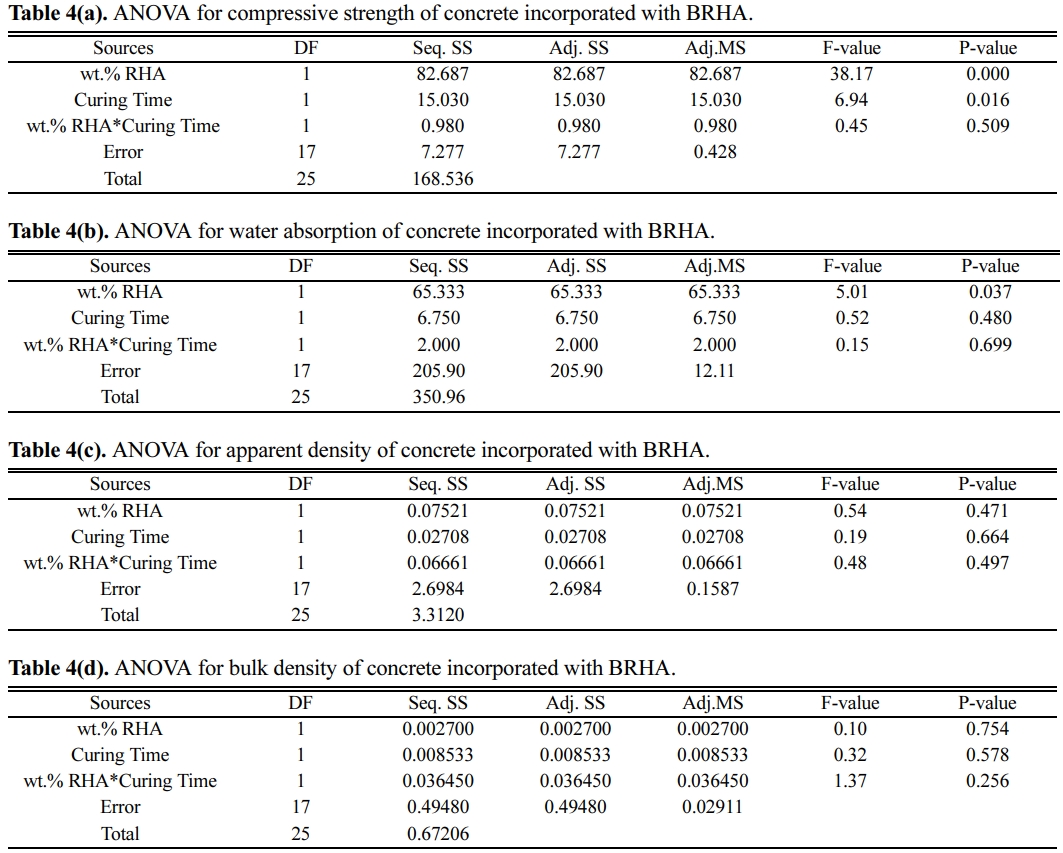

Analysis of Variance or commonly known as ANOVA is a test

of the hypothesis that the means of two or more populations are equal [30]. It

is conducted in order to observe the significant effect of operating factors on

responses of a particular developed product. In this study, the significant

effect of weight percentage of black and grey rice husk as and curing time to

the responses such as compressive strength, water absorption,

apparent density, and bulk density could be determined by observing the

probability value or known as ‘p-value’. Most of the researcher has agreed that

the p-value has to be equal or smaller than 0.05 so that operating factor is

statically significant in investigating response leading to rejection of the

null hypothesis of ANOVA.

Table 4(a)-(d) present ANOVA for compressive strength,

water absorption, apparent density, and bulk density for black RHA. From the

analysis, it was found that the p-value for wt.% of RHA replacement and curing

time linear factor and also wt.% * curing time interaction factor is zero

(0.000) for compressive strength response by black RHA. The smaller p-value

than 0.05 indicates that factor could be regarded to have a higher effect on

response [31]. However, the p-value for other response such as water

absorption, apparent density, and bulk density are higher than 0.05, which

mean it is not statistically significant and indicates weak

evidence against the null hypothesis. For water absorption,

Saraswathy and Song (2007) have mentioned in their

study where concrete that uses RHA is slightly low compared to concrete that

fully uses cement [32].

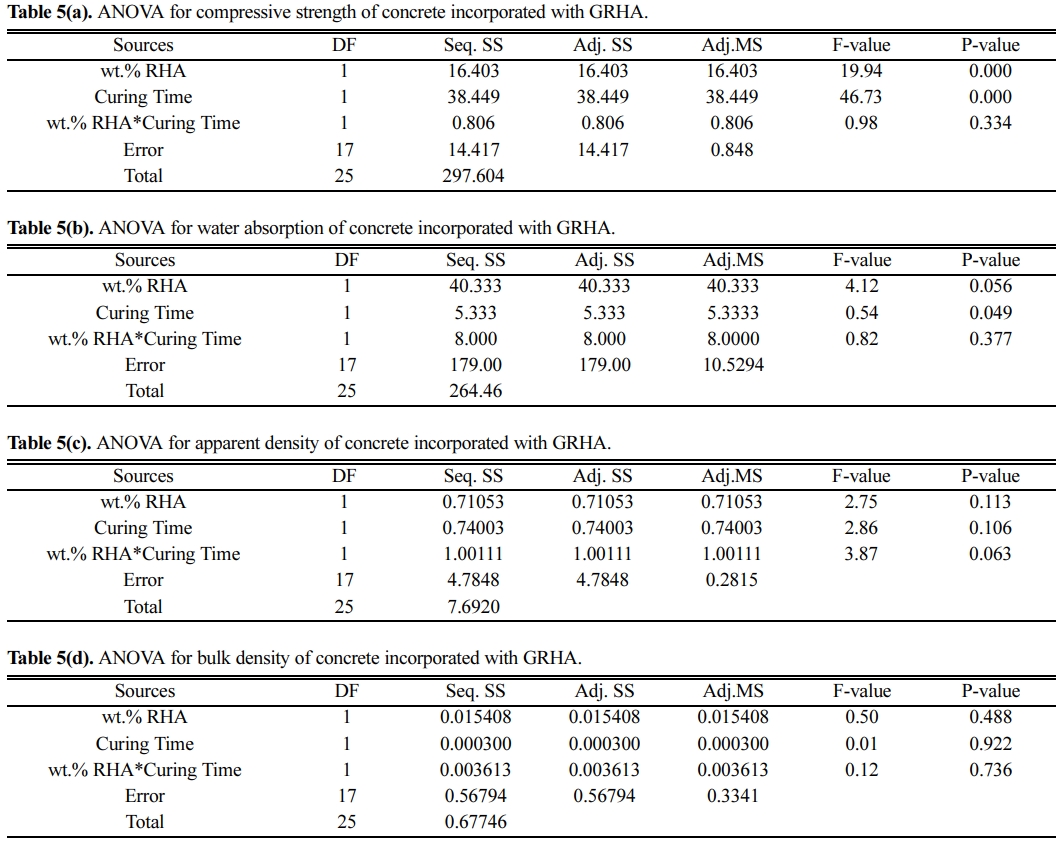

Meanwhile, Table 5(a)-(d) present ANOVA for compressive

strength, water absorption, apparent density, and bulk density for grey RHA. It

was found that the p-value for wt.% of RHA replacement and curing time linear

factor is zero (0.000) for compressive strength response by grey

RHA. This indicates that wt.% and curing time have a significant effect on

compressive strength of concrete that incorporated with grey RHA as [31] have

reported that if the p-value is 0.05 and lower. The p-value for water

absorption is 0.056 for wt.% RHA and 0.049 for curing time, these p-values

indicate also indicate that wt.% RHA and curing time have a significant effect

toward water absorption of grey RHA.

However, the p-value for water absorption, apparent

density, and bulk density of black RHA and apparent density and bulk density of

grey RHA were not significant. This is because all of the p-values from the

responses mentioned have exceeded the minimum limit of the p-value, which is

0.05. The insignificant of the p-value for all responses due to the factor

which is wt.% RHA and curing time do not affect the responses in this study.

This due to the factor that the replacement of cement by RHA only affecting the

compressive strength of the concrete due to the reaction between SiO2 in

RHA and OPC, which produced the addition of C-S-H that responsible to the

strengthening of the concrete. Hence, it can be concluded that addition of RHA

in concrete does not affect the water absorption, bulk density, and apparent

density as the role of RHA in concrete only affecting the compressive strength

of the concrete.

Main

Effect and Interaction Plots

Main effect plot demonstrates the effect of factor (with

different levels) to the changes in a particular response. In this general

factorial design, the main factor that evaluated were weight percentage (wt.%)

of black and grey RHA and curing time. Meanwhile, the interaction plot

illustrated the combination of effects of both main

factors (with different levels) to the particular response

(compressive strength, water absorption, apparent density, and bulk density).

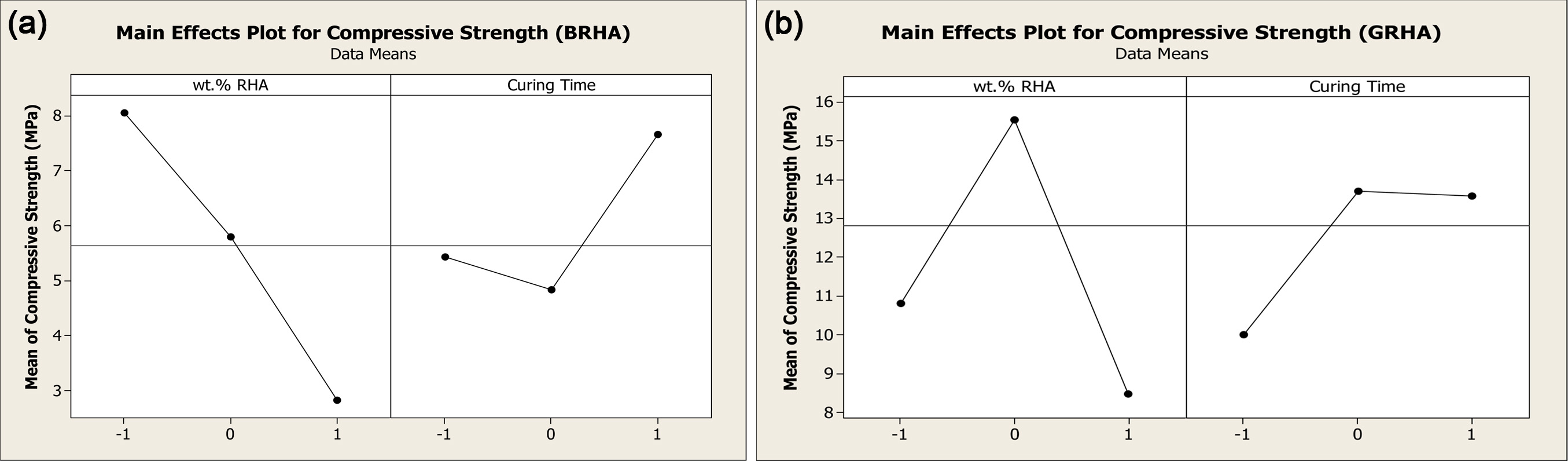

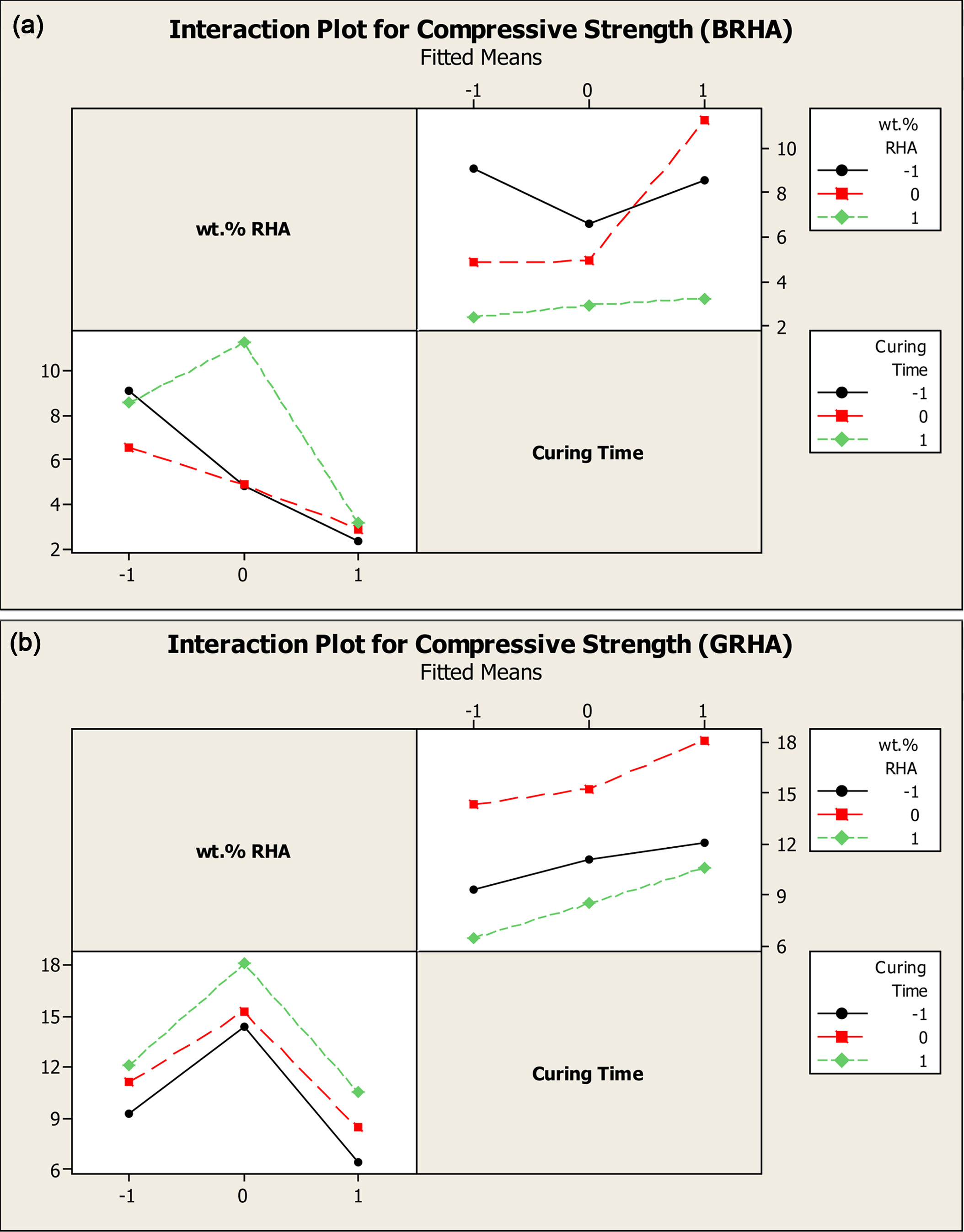

Compressive Strength

Fig. 4(a) and Fig. 4(b) show main effects plots for

compressive strength for black and grey RHA. From the main effects plot, it was

observed that by increasing weight percentage of black RHA from 10 wt.% (coded as

‘-1’) to 30 wt.% (coded as ‘1’) it shows the decreasing trend due to

black RHA is incomplete combustion of rice husk and mostly has lower amorphous

silica, higher loss of ignition (LOI) and lower SiO2 content than

grey RHA [24]. For curing time, it shows a decreasing trend from 3 days (coded

as ‘-1’) to 5 days (coded as ‘0’).

However, the trend suddenly increases when curing time

increase to 7 days (coded as ‘1’). Fig. 4(b) show the main effects of

compressive strength for grey RHA. From the main effects plot, it was observed

that increasing the weight percentage of grey RHA from 10 wt.% (coded as ‘-1’)

to 20 wt.% (coded as ‘0’) show an increasing trend. However, further increasing

to 30 wt.% (coded as ‘1’) reduced the compressive strength of the concrete.

Curing time for grey RHA show an increasing trend from 3 days (coded as ‘-1’)

to 5 days (coded as ‘0’) and finally show a constant trend for 7 days (coded as

‘1’).

Fig. 5(a) shows that the interaction plots for black RHA

are not parallel, which means strong interaction among factor (weight percentage

of grey RHA and curing time). It is observed that the lesser weight percentage

of black RHA replacement resulting in the higher compressive strength of the

concrete. At the same time, the interaction plot for grey RHA in Fig. 5(b) show

that the lines were not parallel, which is suggesting that there is a strong

interaction among factor (weight percentage of grey RHA and curing

time). Further analysis of the plot has revealed that for all

weight percentage of RHA added, the compressive strength of the concrete

increase with longer curing time. Concrete added 20 wt.% of grey RHA combine with

7 days of curing time show the highest compressive strength.

The effect of curing time toward the concrete also shows that decreasing trend

where the more prolonged the curing time, the lower the compressive strength of

the concrete.

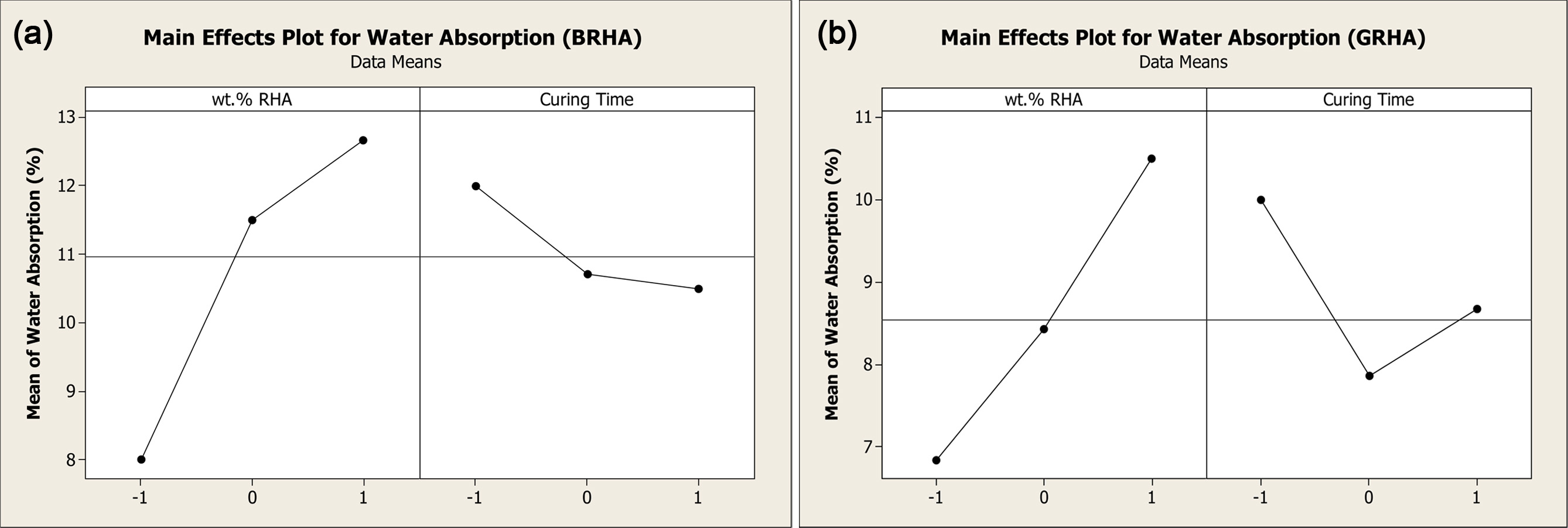

Water Absorption

Fig. 6(a), Fig. 6(b), show the main effect, while Fig.

7(a) and Fig. 7(b) interaction plot for water absorption for both black and

grey RHA. By observing the main effect plot of water absorption, it is revealed

that increasing the weight percentage of both types of RHA contributes to

higher water absorption for the concrete. The main effect plots show a

decreasing trend from 3 days (coded as ‘-1’) to 7 days (coded as ‘1’) for both

black and grey RHA.

From the interaction plot of water absorption, the highest

water absorption is concrete that incorporated with 30 wt.% of RHA, while 7

days of curing time show the highest result of water absorption for black RHA.

However, the interaction plot of water absorption for grey RHA show an

increasing pattern for curing days but a decreasing pattern for weight

percentage. The highest water absorption is concrete incorporated with 30 wt.%

of grey RHA due to the higher RHA replacement in cement the

higher porous of the concrete products, which lead to higher water

absorption [33].

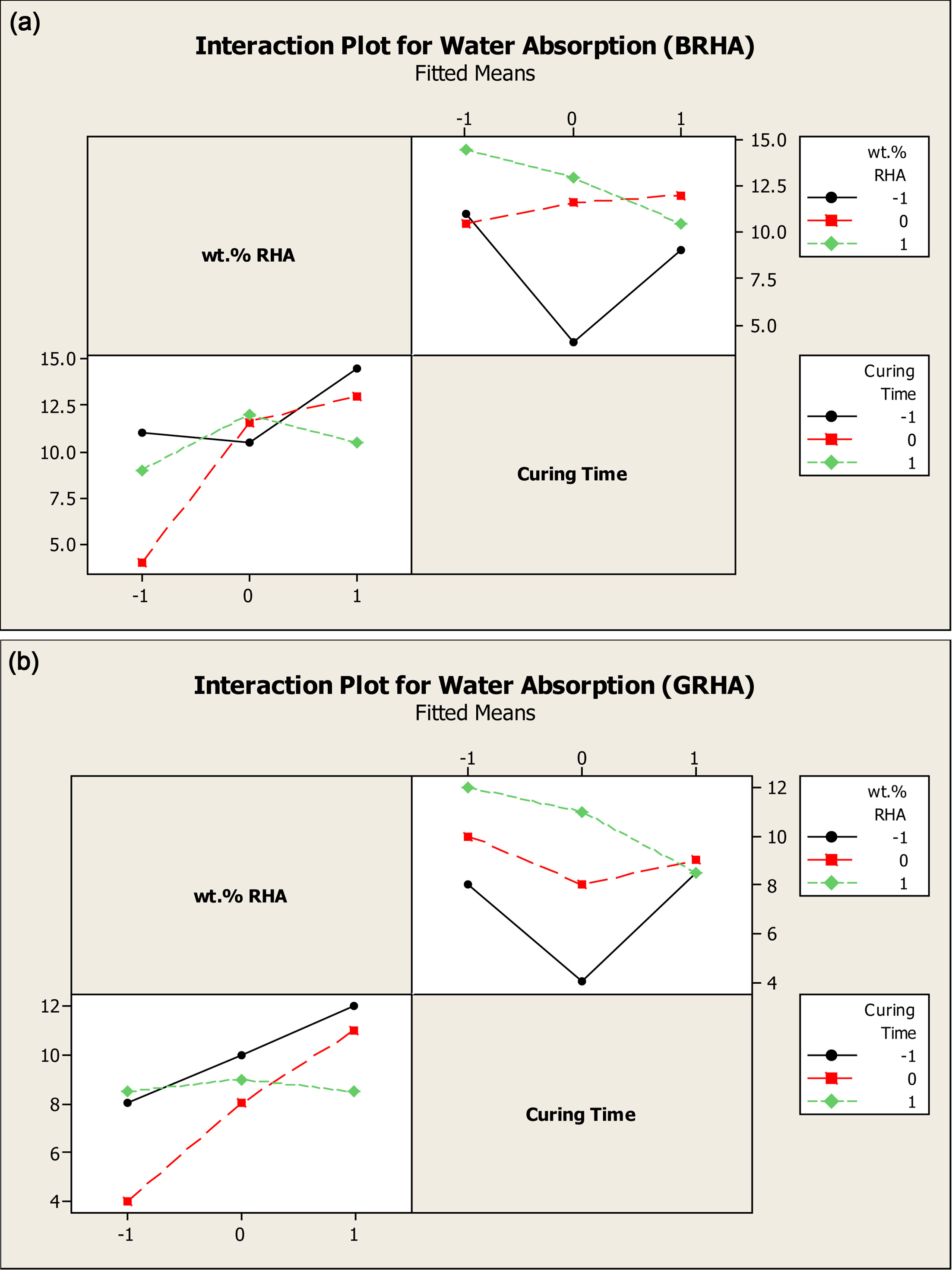

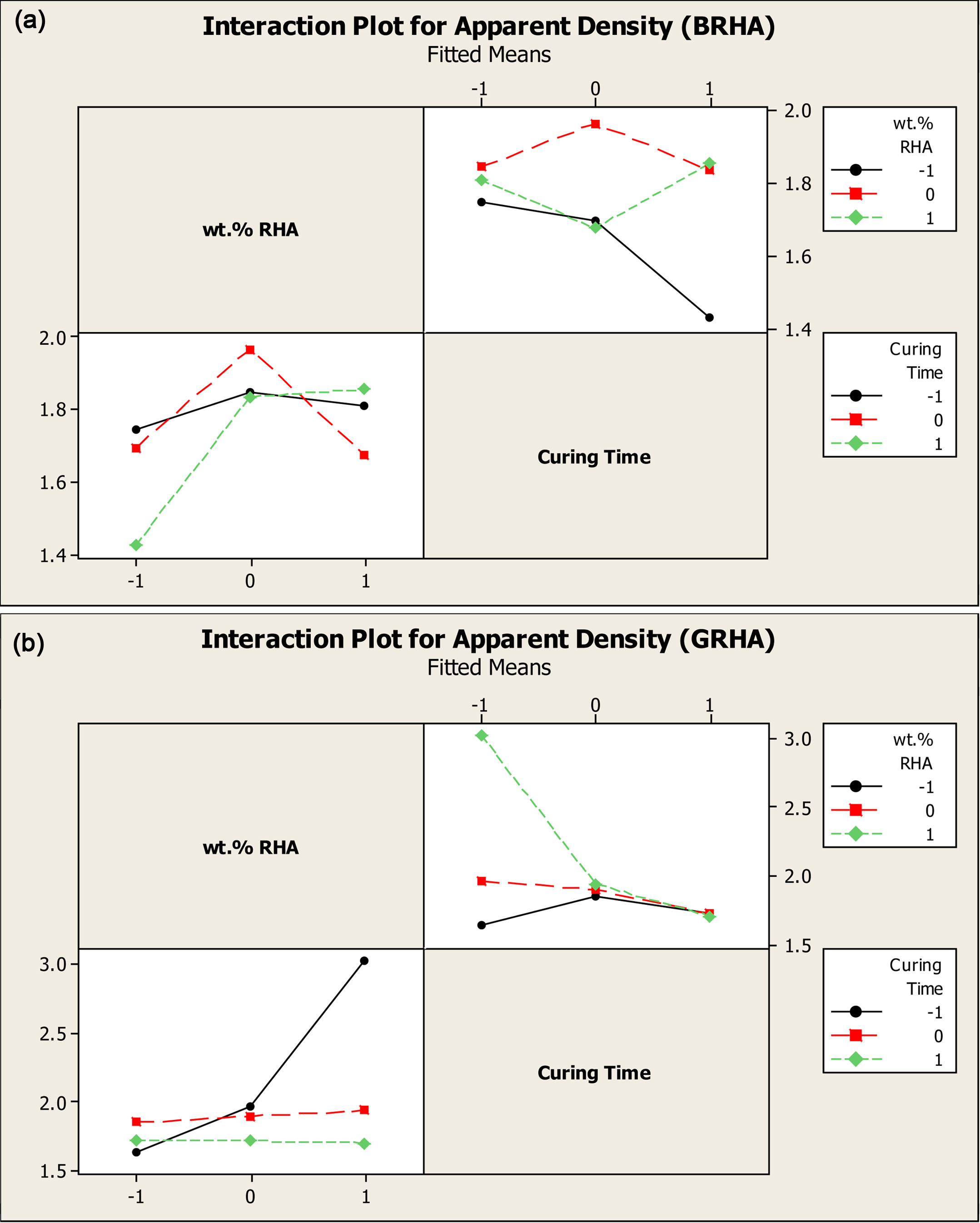

Apparent Density

Fig. 8(a) and Fig. 8(b) show the main effect plot for

black and grey RHA while Fig. 9(a) and Fig. 9(b) show interaction plot for both

types of RHA. From the observation of the main effect plot, black and grey RHA

show an increasing trend, but for black RHA, it started to decrease when the

weight percentage of RHA is 20 wt.% to 30 wt.%. The curing time shows a

decreasing pattern for grey RHA as the day’s increase form 3 days (code as

‘-1’) to 7 days (coded as ‘1’). Conversely, black RHA shows an increasing trend

from 3 days (coded as ‘-1’) to 5 days (coded as 0). After that, the trend

started to decrease to 7 days (coded as ‘1’).

Fig. 9(a) and Fig. 9(b) show the interaction plot for

black and grey RHA for apparent density. From the observation for black RHA, it

shows 20 wt.% (coded as ‘0’) and 5 days (coded as ‘0’) show the highest

reading. Meanwhile, from observation of grey RHA, the line is parallel to each

other. This indicates that no interaction occurs among the response, whether

weight percentage or curing time [34].

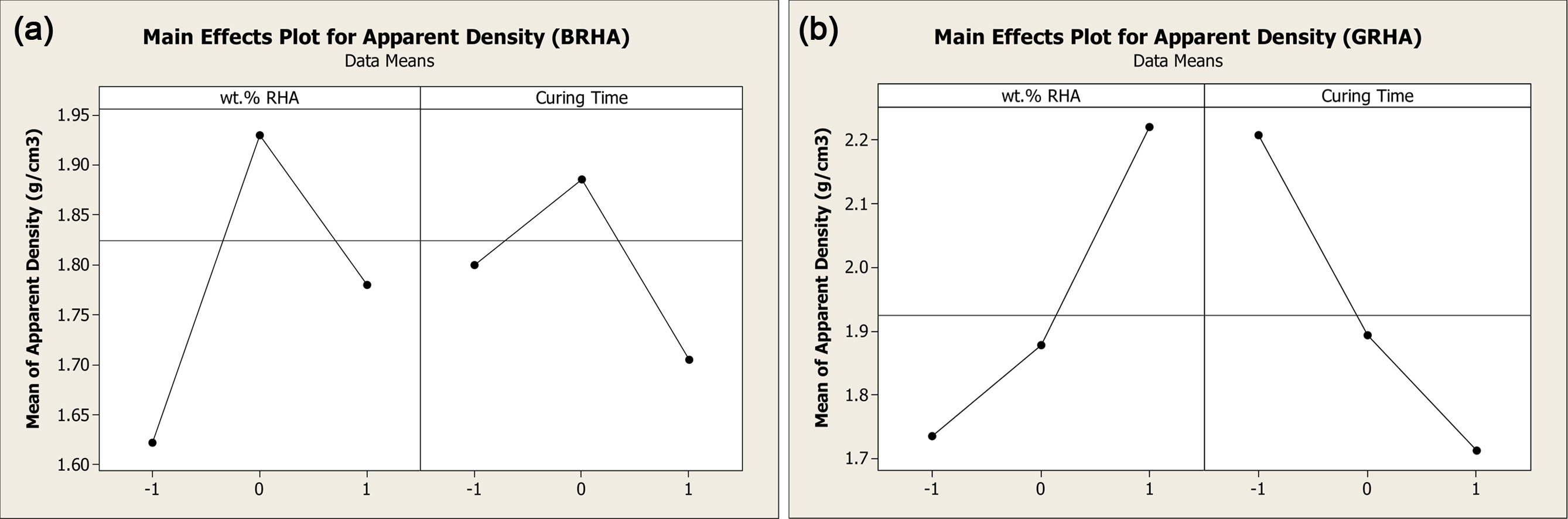

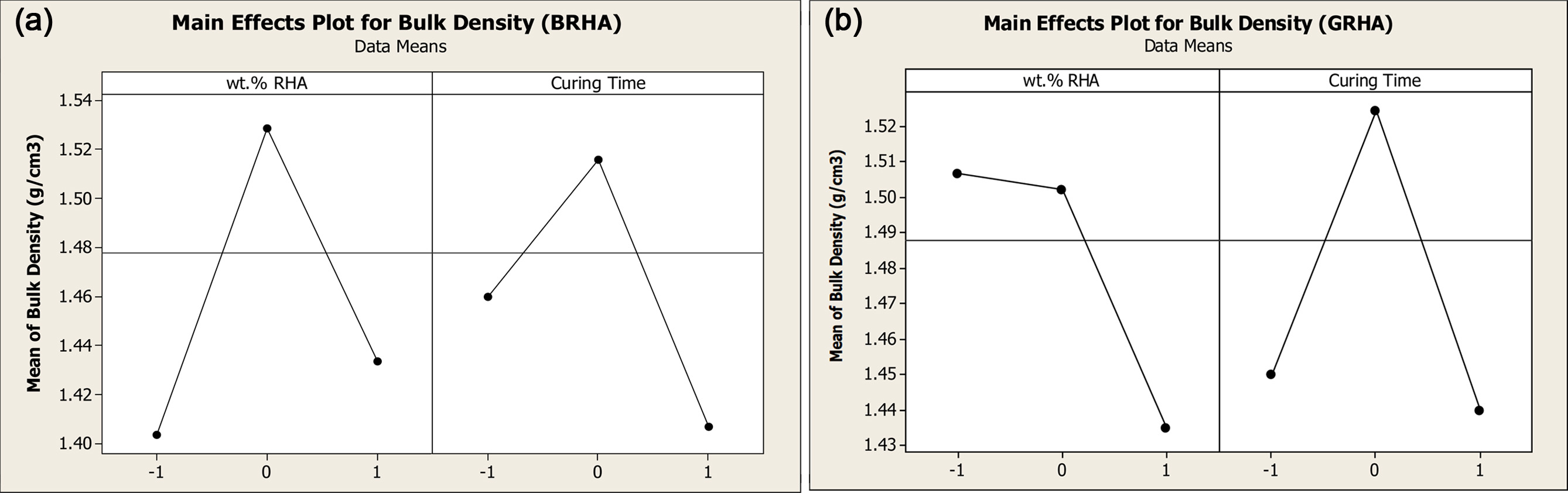

Bulk Density

Fig. 10(a) and Fig. 10(b) show the main effect plot for

bulk density for black and grey RHA. From the observation, the main effect plot

for black RHA show an increasing trend from 10 wt.% to 20 wt.% for weight

percentages and 3 days to 5 days for curing time. Then, it shows a decreasing

trend to 30 wt.% and 7 days. From the results of grey RHA, the weight

percentage of RHA show a decreasing pattern, while for curing time show both

increase and decrease pattern. It starts to increase from 10 wt.% to 20 wt.%

and decrease from 20 wt. % to 30. wt.%.

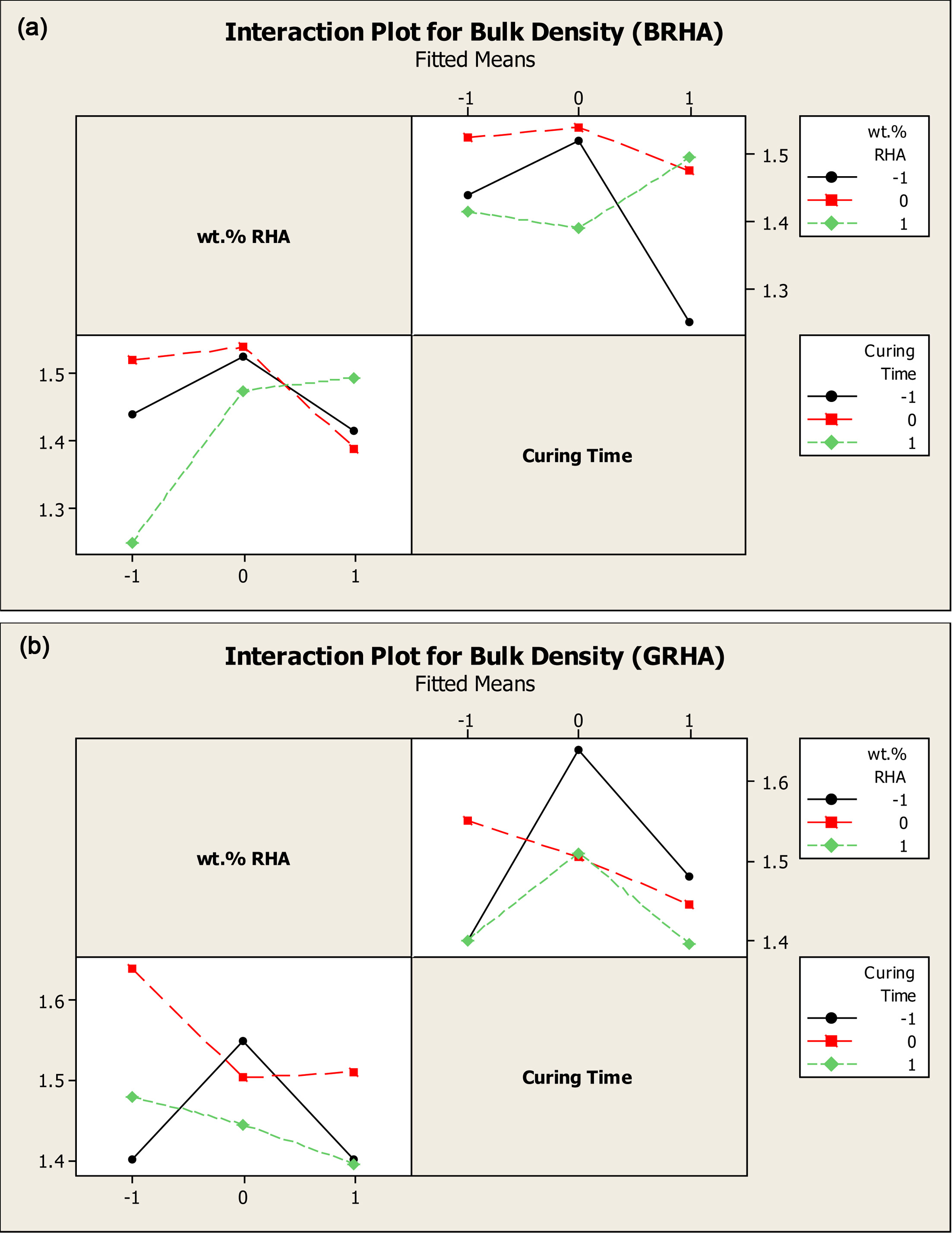

For the interaction plot in Fig. 11(a), 20 wt.% of RHA and

5 days of curing time show the highest reading. After that, Fig. 11(b) for grey

RHA show that 10 wt.% and 5 days of curing time show the highest reading, among

others variable response.

|

Fig. 1 XRD Pattern of (a) Black RHA and (b) Grey RHA. |

|

Fig. 2 (a) Residual plots for compressive strength of black RHA; (i) Normal probability plot, (ii) Histogram of frequency versus residual,

(iii) Residual versus fits, (iv) Residual versus observation order of data. (b) Residual plots for water absorption black RHA; (i) Normal

probability plot, (ii) Histogram of frequency versus residual, (iii) Residual versus fits, (iv) Residual versus observation order of data. (c)

Residual plots for apparent density black RHA; (i) Normal probability plot, (ii) Histogram of frequency versus residual, (iii) Residual versus

fits, (iv) Residual versus observation order of data. (d) Residual plots for bulk density black RHA; (i) Normal probability plot, (ii) Histogram

of frequency versus residual, (iii) Residual versus fits, (iv) Residual versus observation order of data. |

|

Fig. 3 (a) Residual plots for compressive strength grey RHA; (i) Normal probability plot, (ii) Histogram of frequency versus residual, (iii)

Residual versus fits, (iv) Residual versus observation order of data. (b) Residual plots for water absorption grey RHA; (i) Normal probability

plot, (ii) Histogram of frequency versus residual, (iii) Residual versus fits, (iv) Residual versus observation order of data. (c) Residual plots

for apparent density grey RHA; (i) Normal probability plot, (ii) Histogram of frequency versus residual, (iii) Residual versus fits, (iv)

Residual versus observation order of data. (d) Residual plots for bulk density grey RHA; (i) Normal probability plot, (ii) Histogram of

frequency versus residual, (iii) Residual versus fits, (iv) Residual versus observation order of data. |

|

Fig. 4 (a) Main Effects Plots for Compressive Strength (BRHA). (b) Main Effects Plots for Compressive Strength (GRHA). |

|

Fig. 5 (a) Interaction Plot for Compressive Strength (BRHA). (b) Interaction Plot for Compressive Strength (GRHA). |

|

Fig. 6 (a) Main Effects Plots for Water Absorption (BRHA). (b) Main Effects Plots for Water Absorption (GRHA). |

|

Fig. 7 (a) Interaction Plots for Water Absorption (BRHA). (b) Interaction Plots for Water Absorption (GRHA). |

|

Fig. 8 (a) Main Effects Plots for Apparent Density (BRHA). (b) Main Effects Plots for Apparent Density (GRHA). |

|

Fig. 9 (a) Interaction Plots for Apparent Density (BRHA). (b) Interaction Plots for Apparent Density (GRHA) |

|

Fig. 10 (a) Main Effects Plot for Bulk Density (BRHA). (b) Main Effects Plot for Bulk Density (GRHA). |

|

Fig. 11 (a) Interaction Plot for Bulk Density (BRHA). (b) Interaction Plot for Bulk Density (GRHA). |

|

Table 2 Experimental design matrix of central composite design for BRHA. |

Factor I: Wt.% of BRHA; ‘(-1)’ represents 10 wt.%, ‘(0)’ represents 20 wt.%, ‘(+1)’ represents 30 wt.% |

|

Table 3 Experimental design matrix of central composite design for GRHA. |

Factor I: Wt.% of GRHA; ‘(-1)’ represents 10 wt.%, ‘(0)’ represents 20 wt.%, ‘(+1)’ represents 30 wt.% |

In this study, the utilization of RHA as a partial

replacement of cementing material in concrete by using a statistical

experimental design was successfully done. Based on the

result obtained from compressive strength, water

absorption, bulk density, apparent density also from XRD and XRF results, which

show positive finding where it indicated that the suitability of RHA to partially

replace cement in concrete. This results further supported by

analysis through statistical experimental design that shows the p-value of all

responses that indicated responses have a significant effect on the factor.

From the data, the best RHA replacement for black RHA was the combination of 20

wt.% RHA and 7 days of curing time due to it have higher compressive strength,

which is 11.86 and 10.67 MPa compared to another sample. A similar result also

can be observed for grey RHA that shows the highest compressive strength of

17.80 and 18.4 MPa. According to Bahri et al. (2018), the difference between

the compressive strength of grey and black RHA was affected by their

crystallinity in which amorphous silica has a higher pozzolanic reaction

compared to crystalline silica. Higher pozzolanic reaction means more C-S-H

were produced during the reaction, which leads to higher compressive strength

[24].

The authors would like to thank the Faculty of

Bioengineering and Technology, University Malaysia Kelantan (UMK), for

providing the research facilities in order to complete this project.

- 1. E. Khankhaje, M. Rafieizonooz, M.R. Salim, R. Khan, J. Mirza, H.C. Siong, and Salmiati, J. Clean. Prod. 172 (2018) 1476-1485.

-

- 2. H. Mohammadhosseini and J.M. Yatim, J. Clean. Prod. 144 (2017) 8-21.

-

- 3. F. Rivera, P. Martínez, J. Castro, and M. López, Cem. Concr. Compos. 63 (2015) 104-112.

-

- 4. J.B. Lee, S.S. Kim, J.Y. Lee, and J.S. Ryou, J. Ceram. Process. Res. 18[4] (2017) 291-300.

- 5. S.K. Seo, Y.S. Chu, and K.B. Shim, J. Ceram. Process. Res. 18[3] (2017) 177-182.

- 6. C.W. Hong, J. Il Lee, and J.H. Ryu, J. Ceram. Process. Res. 17[7] (2016) 768-772.

- 7. A. Bahurudeen, D. Kanraj, V. Gokul Dev, and M. Santhanam, Cem. Concr. Compos. 59 (2015) 77-88.

-

- 8. S.A. Mangi, N. Jamaluddin, M.H. Wan Ibrahim, A.H. Abdullah, A.S.M. Abdul Awal, S. Sohu, and N. Ali, IOP Conf. Ser.: Mater. Sci. Eng. 271[1] (2017) 012001.

-

- 9. S.A. Memon, U. Javed, and R.A. Khushnood, Constr. Build. Mater. 195 (2019) 165-177.

-

- 10. A. Ayinde Raheem and M. Abiodun Kareem, Int. J. Sustain. Constr. Eng. Technol. 7[2] (2017) 77-93.

- 11. D.D. Bui, J. Hu, and P. Stroeven, Cem. Concr. Compos. 27[3] (2005) 357-366.

-

- 12. H. Chao-Lung, B. Le Anh-Tuan, and C. Chun-Tsun, Constr. Build. Mater. 25[9] (2011) 3768-3772.

-

- 13. S.K. Antiohos, V.G. Papadakis, and S. Tsimas, Cem. Concr. Res. 61-62 (2014) 20-27.

-

- 14. S. Muthayya, J.D. Sugimoto, S. Montgomery, and G.F. Maberly, Ann. N. Y. Acad. Sci. 1324[1] (2014) 7-14.

-

- 15. A. Maryoto and G. Heri Sudibyo, MATEC Web Conf. 258 (2019) 01005.

-

- 16. V. Saraswathy and H.W. Song, Constr. Build. Mater. 21[8] (2007) 1779-1784.

-

- 17. S.A. Zareei, F. Ameri, F. Dorostkar, and M. Ahmadi, Case Stud. Constr. Mater. 7 (2017) 73-81.

-

- 18. A.A. Ramezanianpour, M. Mahdi Khani, and G. Ahmadibeni, Int. J. Civ. Eng. 7[2] (2009) 83-91.

- 19. B.K. Ngun, H. Mohamad, E. Sakai, and Z.A. Ahmad, J. Ceram. Process. Res. 11[3] (2010) 311-315.

- 20. G.H.M.J. SubashiDe Silvaa and B.V.A.Perera, J. Build. Eng. 18 (2018) 252-259.

-

- 21. A.Y. Aydar, in “Statistical Approaches With Emphasis on Design of Experiments Applied to Chemical Processes” (InTech, 2018) p 157.

-

- 22. A. Khan, J. Do, and D. Kim, J. Constr. Eng. Manag. 143[4] (2017) 04016108.

-

- 23. I.K. Ejiogu, P.A. Mamza, P.O. Nkeonye, and A.S. Yaro, Pac. J. Sci. Technol. 19[1] (2018) 22-36.

- 24. S. Bahri, H.B. Mahmud, and P. Shafigh, Sadhana43[2] (2018) 22.

-

- 25. S. Memon, I. Wahid, M. Khan, M. Tanoli, and M. Bimaganbetova, Sustainability 10[5] (2018) 1322-1343.

-

- 26. C.D. Igwebike-Ossi, Int. J. Appl. Chem. 12[3] (2016) 281-291.

- 27. K. Burnecki, A. Wylomanska, and A. Chechkin, PLoS One 10[12] (2015) e0145604.

-

- 28. L. Foglia, S.W. Mehl, M.C. Hill, and P. Burlando, Water Resour. Res. 49[1] (2013) 260-282.

-

- 29. A.F. Zuur and E.N. Ieno, Methods Ecol. Evol. 7[6] (2016) 636-645.

-

- 30. H.-Y. Kim, Restor. Dent. Endod. 39[1] (2014) 74-77.

-

- 31. S. Greenland, S.J. Senn, K.J. Rothman, J.B. Carlin, C. Poole, S.N. Goodman, and D.G. Altman, Eur. J. Epidemiol. 31[4] (2016) 337-350.

-

- 32. V. Saraswathy and H.-W. Song, Constr. Build. Mater. 21[8] (2007) 1779-1784.

-

- 33. M.M. Ahmad, F. Ahmad, M. Azmi, and M.Z.A. Mohd Zahid, Appl. Mech. Mater. 802 (2015) 267-271.

-

- 34. A. Thejas Shetty and S.D. Kularni, Int. Res. J. Eng. Technol. 4[7] (2017) 482-488.

This Article

This Article

-

2020; 21(6): 667-682

Published on Dec 31, 2020

- 10.36410/jcpr.2020.21.6.667

- Received on Jul 8, 2020

- Revised on Aug 30, 2020

- Accepted on Sep 4, 2020

Services

Services

- Abstract

introduction

methodology

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Pao Ter Teo

-

Advanced Materials Research Cluster, Faculty of Bioengineering and Technology, Universiti Malaysia Kelantan, Jeli Campus, 17600 Jeli, Kelantan, Malaysia

Tel : +609-9477427 Fax: +609-9477402 - E-mail: teopaoter@umk.edu.my

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.