- Stress and strain behavior of cementitious composites with epoxy/urea-formaldehyde microcapsules under uniaxial tests

Tielin Hana,b, Xianfeng Wanga,*, Dawang Lia, Ningxu Hana, Dongfeng Lic and Feng Xinga

aGuangdong Key Laboratory of Durability in Coastal Civil Engineering, College of Civil Engineering, Shenzhen University, Shenzhen, Guangdong 518060, P.R. China

bSchool of Civil Engineering and Architecture, Xian University of Technology, Shaanxi Xi’an 710048, P.R. China.

cSchool of Science, Harbin Institute of Technology (Shenzhen), The University Town of Shenzhen, Nanshan, Shenzhen, P.R. China

The effects of different dosages of microcapsules, proportion of prepressing stress and curing days on the mechanical properties, pore structure and healing efficiency of the specimens were studied through uniaxial compression test and mercury intrusion porosimetry (MIP) test. The results indicate that the uniaxial strength of the specimens decreased to a certain extent with an increase of dosage of the microcapsules. Meanwhile, the pore structure parameters (pore volume; porosity; critical pore size; capillary porosity), as well as the self-healing rate and recovery rate of the mechanical properties increased with increasing the dosage of microcapsules. The microcapsules have a significant influence on the deformation characteristics of the specimens and may improve the brittleness characteristics and strengthen the ductility of the ordinary concrete.

Keywords: Microcapsules, Cementitious material, Mechanical properties, Deformation, Pore structure, Self-healing rate, Recovery rate

Since Aspdin invented Portland cement in 1824, concrete materials have been widely used in the construction field, and have gradually become to be the largest and mostly used construction material due to superior performance and low cos [1]. However, internal local damage and micro-cracks are inevitably caused in the cement-based materials owing to its own defect of the high brittleness, low tensile strength and easy cracking characteristics, which will negatively impact on the durability and usability of the concrete structures [2], and so as to reduce the service life of the building and bring new threats to the environment. Therefore, it is very necessary to extend the service life of concrete structures for consideration of structural safety and rationality of resource utilization.

Meanwhile, to meet the guiding ideology of “Resource Saving and Environment Friendly” for economic construction, research and development of new concrete materials with higher performance and more complete functions has become the research focus and development trend of modern concrete production technology. In field of new concrete research and development, the research and application of self-healing concrete has become a hot research topic.

In 1925, Abrams [3] found that the compressive strength of damaged concrete after 8 years of outdoor exposure was more twice than that of the concrete specimens measured with 28 days, then he first proposed the self-repairing property of cement materials. The reasons for the increase in strength, some scholars believe that there are about 30% of cement clinker exists in concrete for a long time [4-5], the self-healing of cement matrix is the result of continuous hydration based on anhydrate cement particles. In addition, some scholars believe that a hydrated product calcium hydroxide (Ca(OH)2) reacts with CO2 in the cracks to form crystals with self-healing capacity (CaCO3), and gradually precipitates and seals the cracks, and finally repairs cracks [6].

With the development of intelligent materials, the self-healing and self-repairing function cementitious materials have been gradually developed. There is a new repair material, the self-healing cementitious material, has been put forward to heal the cracks in the cementitious composite materials [7-10]. The self-repair of the microcapsules refers to uniformly mix the microcapsules wrapped with repair agent and curing agent into the material matrix. When cracks occur inside the material, the microcapsules near the cracks will break under the stress of the tip and release the repair agent. When the repair agent meets with the curing agent dispersed in the matrix, then polymerize and fill the crack, which repairs or inhibits the crack further expand, restore or even improve the mechanical properties and durability of materials. Therefore, the microcapsules are widely used in the development and application of new self-repairing materials due to their advantages.

In recent years, there are lots of self-healing materials made with mineral admixtures and expansive agents, etc. for example, microorganism self-healing, shape memory alloy self-healing, minerals self-healing and microcapsule self-healing. One of the important research directions is to prepare self-healing cementitious materials through adding microcapsules. Ou and Kuang [11] established the distribution and orientation function of microcapsules in concrete through studying the effects of the microcapsules on the self-healing behavior of cracks inside concrete. Nishiwaki et al. [12] pointed out the ways to improve the self-healing effect, on the one hand, the microcapsules need to be large enough to wrap enough repair agents; On the other hand, it is necessary to improve the interfacial bonding strength between the microcapsules and the cement matrix to ensure that the microcapsules will crack rather than flake off. Yang et al [13] evaluated the self-healing performance of the microcapsules through permeability and uniaxial compression cyclic loading fatigue tests, and observed and confirmed by means of surface analysis tools and electron microscopy.

To obtain better self-healing effect, many researchers have carried out the organic microcapsule based self-healing by changing the mixture proportion of the microcapsules and concrete ratio [14-16]. In addition, the roughness surfaces and shapes of the microcapsule are decisive influence in the self-healing efficiency, researches show that it is well fulfill this in cementitious composite made with the spherical microcapsules [7-8]. The microcapsules are broken along the crack tip after crack propagating, subsequently and immediately released healing agents, when finally mended the crack inside cementitious composite and achieved the healing influence by the capillary action [17]. Consequently, cementitious composite with epoxy/ urea-formaldehyde microcapsules, which autonomously and partially repair and detect, have gradually attracted more and more attentions from researchers [18-27].

Meanwhile, according to the performance of cementitious material itself, many researchers have used different shell material [8, 28-39] to the parcel of different types of healing agent [17, 31-33], and mixed into cementitious material with different proportion. They also evaluated the performance of microcapsules and the self-healing restoration of microcapsules on the cement-based material. At present, regarding the microcapsule technology, even not fully developed, it does not affect the application of its widespread use in concrete engineering in future.

In summary, although the theoretical research on self-repairing concrete material has achieved remarkable results, and most of these are limited to the research of strength, durability and microstructure. There still are a lot of research in the engineering application needs to be researched. Therefore, to better apply microcapsules based self-healing cementitious composite concrete engineering, it is necessary to study the deformation characteristics, also evaluate the healing effects of the microcapsules and deformation characteristics, and summarize the repair mechanism of strength and de-formation of microcapsule self-repair concrete, which will lay the foundation for the better service of the microcapsule self-repair material to the concrete engineering.

In this study, the microcapsules were mixed into cement with different proportion to produce the microcapsule-based self-healing cementitious composites. The dosage of microcapsules, proportion of prepressing stress and curing days on the strength properties, deformation properties, pore structure and self-healing effects of the specimens were investigated by the uniaxial compression test. And the healed efficiency of the specimens was investigated based on the strength, strain and elastic modulus. Meanwhile, the influences of dosage of microcapsule on the pore structure parameters of the intact, damaged and healed specimens and its self-healing efficiency were carried out by the mercury intrusion porosimetry (MIP) test. In addition, the relationship between the strength properties and pore structure of cementitious composite material was established.

In this paper, the microcapsules were made by in situ polymerization. Epoxy resin was used as core enclosed in a urea-formaldehyde resin shell [22]. The average particle size of the microcapsules is 205.62 μm, its Shell thickness is 7.54 μm and the standard deviations of shell thickness is 2.2. (as shown in Fig. 1).

|

Fig. 1 SEM image of organic microcapsules. |

By referring the previous literatures and trying many times [15-16, 22, 34], test specimens’ water to cement ratio and cement to sand ratio are 0.5 and 1: 2, respectively; and the dosage of MC120D is mixed with half of the dosage of microcapsules. We use China Portland Cement GB-175-2007 P II 42.5R type from Shanxi Qinling Cement L. td Company (Shanxi, China); drinkable tap water and GB/T17671-1999 ISO standard sand from Xiamen Isiou Ltd Company (Xiamen, China).

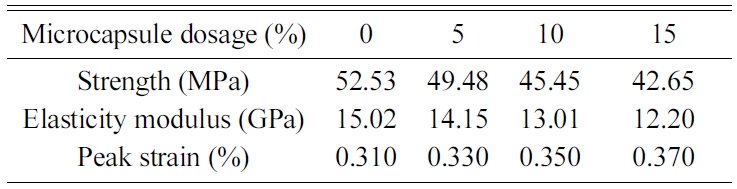

The specimens were processed into cylindrical specimens of 50 mm × 100 mm. The 130 specimens for each proportion of the microcapsule dosages (0%, 5%, 10%, and 15%) were divided into groups A, B, C, and D, each of which has at least 12 specimens except group A, group A contains 3 specimens. Group A was subjected to uniaxial tests using the WDT-1500 universal testing machine (MTS Systems Co., Ltd.). The average compressive strength of group A is shown in Table 1. Group B was subjected to uniaxial compression directly to failure without preloading treatment. Group C were pre-loaded to 40%, 60% and 80% of compressive strength and then unloaded, the damaged specimens were immediately carried out the penetration tests. Group D were pre-loaded to 40%, 60% and 80% of compressive strength and then unloaded, and damaged specimens were placed in the rapid maintenance kit (50 ℃) for 0, 3, 7 and 14 days, and then healed specimens were carried out the uniaxial tests. The average mechanical characteristics of four specimens in each group was regarded as final experimental data.

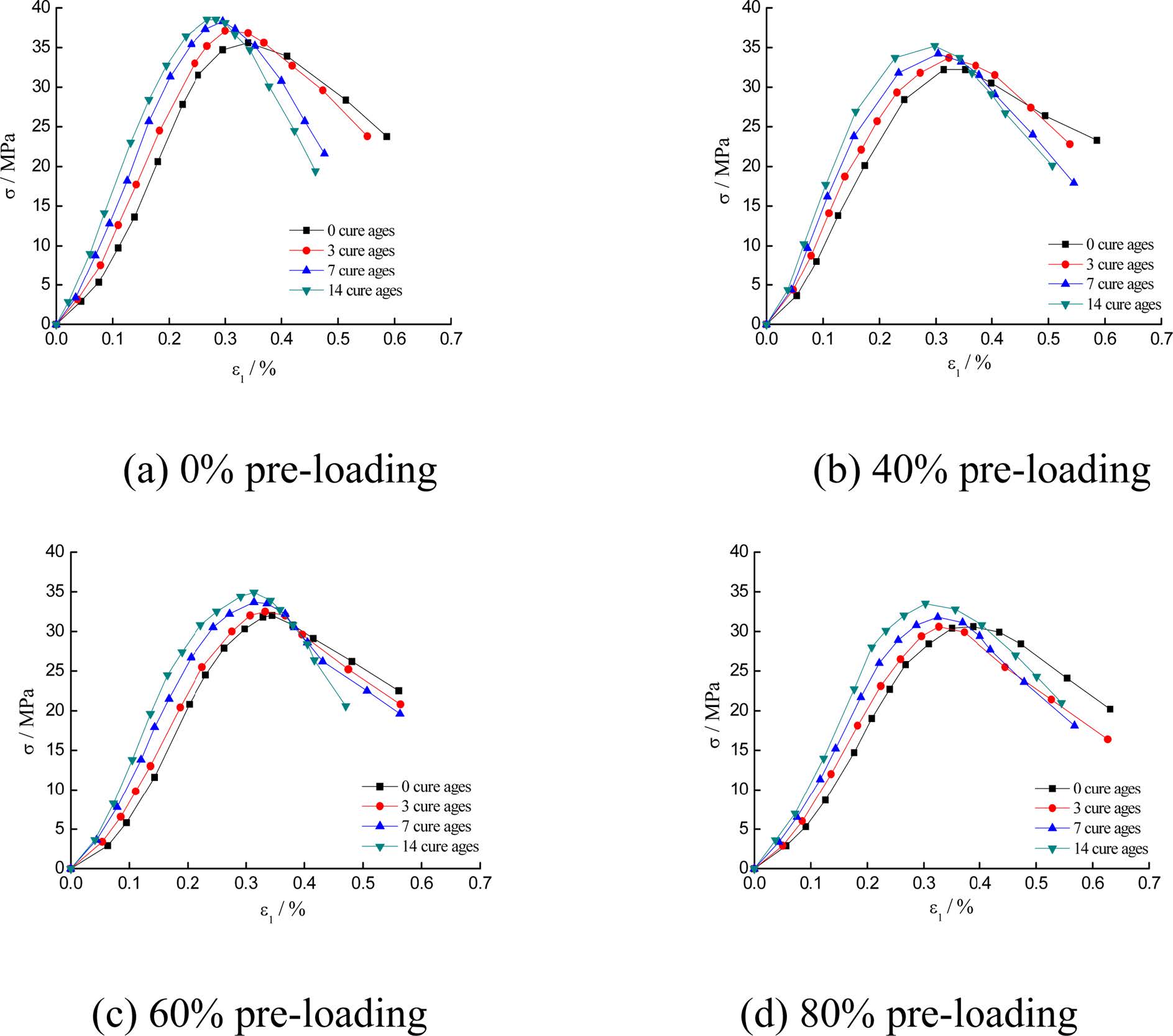

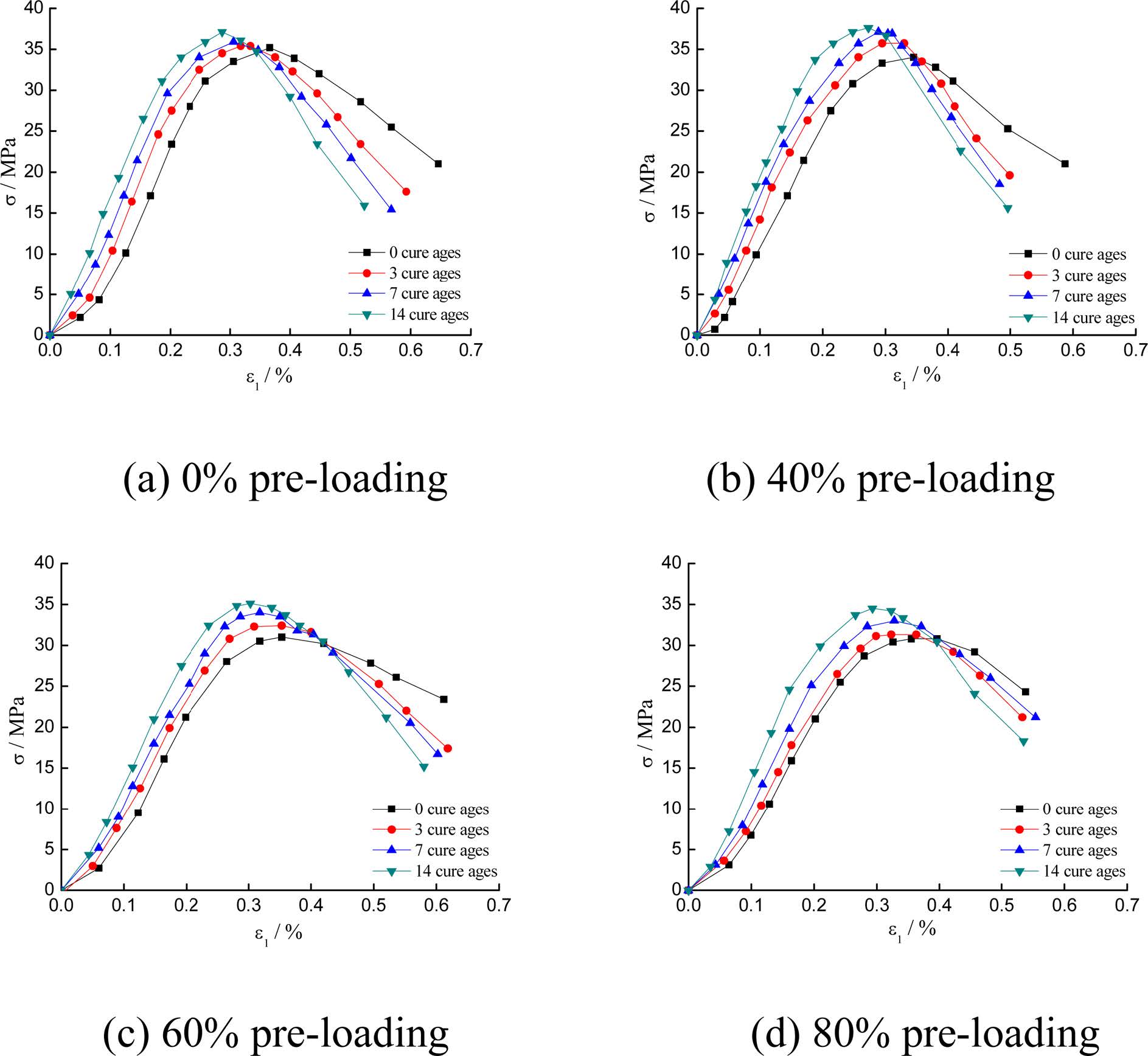

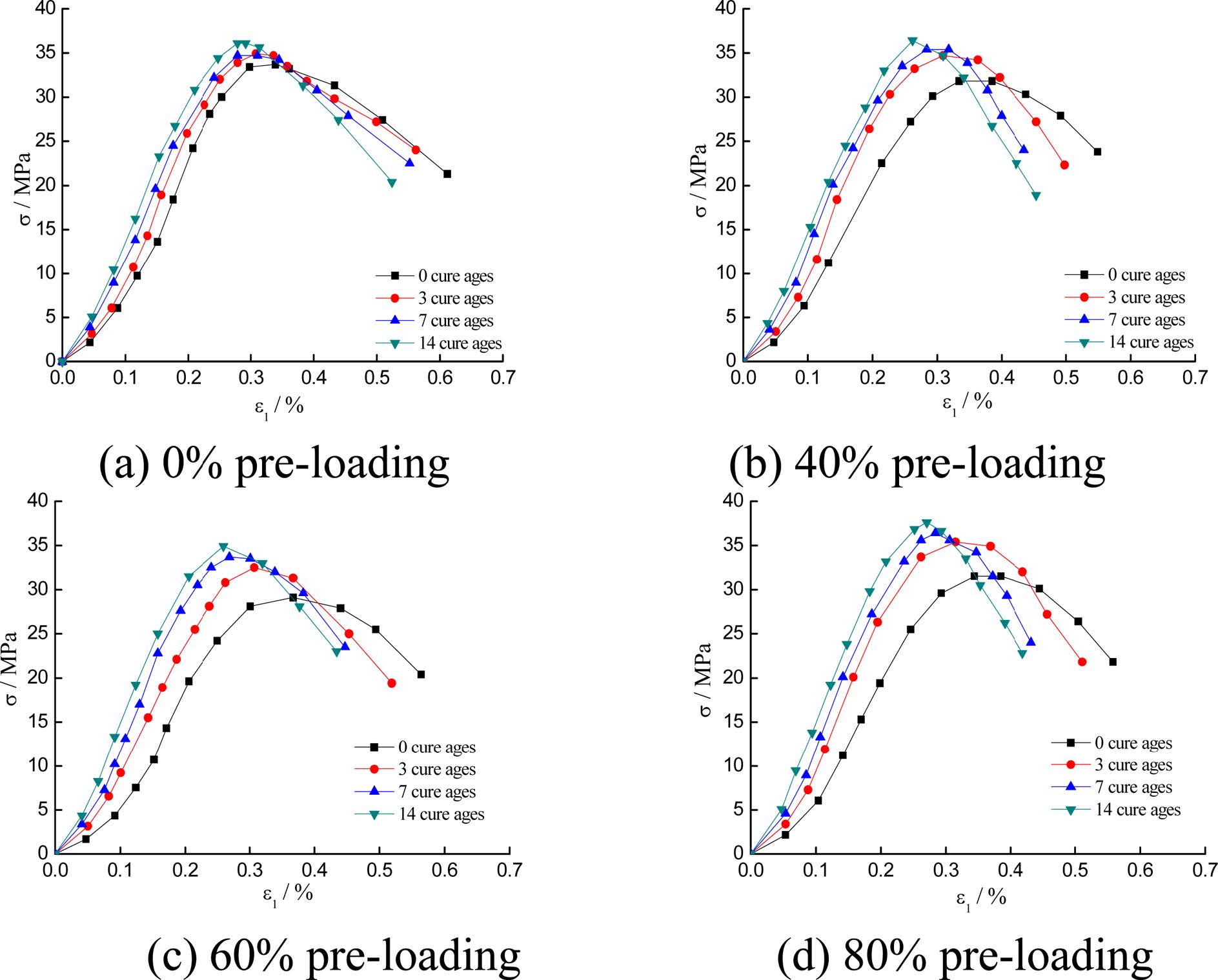

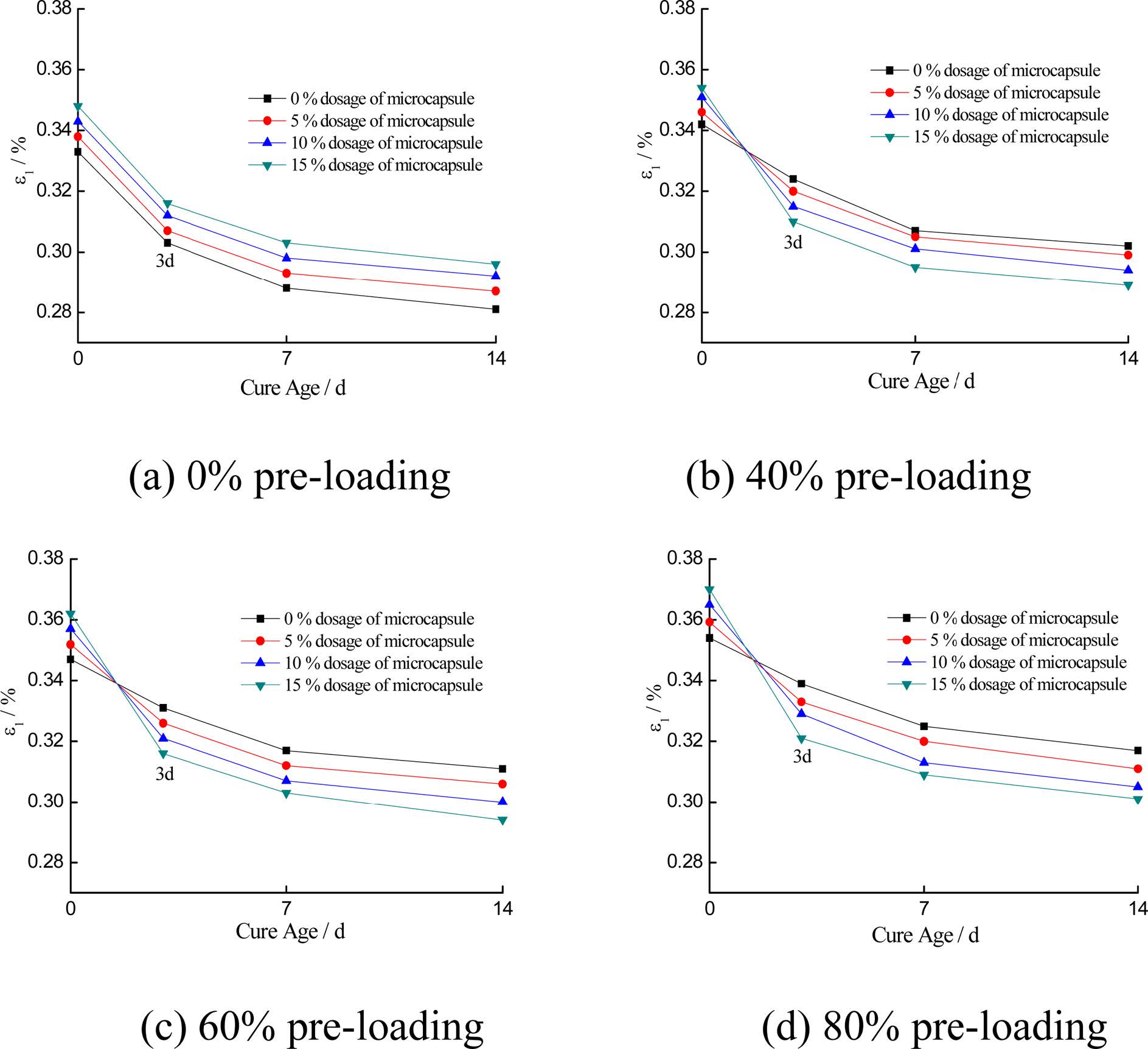

The stress-strain (σ ~ ε1) curves of the cement mortar specimens with different dosage of microcapsule under different preloading conditions are shown in Fig. 2 ~Fig. 4. The relationships between curing ages and peak strain under different dosage of the microcapsule, and the relationships between curing ages and peak strain under different pre-loading are shown in Fig. 5.

As can been seen from the Fig. 2 ~ Fig. 4, the “soft” trend of the σ ~ ε1 curves of the specimens gradually decrease with an increasing of the curing ages or with a decreasing of dosage of the microcapsules, and the brittle features of the specimens gradually also enhance, but its plastic features significantly decrease, accompanying by the trend of transition from ductile to brittle.

The compaction section of curves of the specimens with the microcapsules is more obvious compared with that of the ordinary concrete, and the compaction section is extended to different degrees with the increase of the microcapsule dosage, which indicates that the self-repairing specimens with the microcapsules have more initial pores. The slope of elastic stage of the σ ~ ε1 curves, i.e. elastic modulus, decreased to different degrees, and its degree of decrease amplitude increases with the increase of the dosage of the microcapsules, this indicates that the elastic modulus of the specimens decreased after the microcapsules was added into the concrete. With the increase of curing time, the strength and elastic modulus of the self-repairing concrete specimens are restored to different degrees under the same dosage of the microcapsules, but the peak strain gradually decreases. On the one hand, the self-healing products of the microcapsule self-repair system fills the micro cracks and pores, and changes the pore structure; on the other hand, the strength and stiffness of the healing products increase with an increasing of the curing ages, which increases the strength and stiffness of the damaged specimen.

In the yield stage, the yield section of the specimens is longer than that of the ordinary concrete, and the yield section is lengthened to varying degrees with the increase of the dosage of the microcapsules, but the failure strain of the healed specimens reduced, this also indicates that the stiffness of the damaged specimens is gradually restored, and the σ ~ ε1 curve shows a tendency of shortening in the yield section. Which indicates that the microcapsule self-repairing system may help to improve the ductility of concrete. The descending section of the σ ~ ε1 curves of the specimens is gentler than that of the normal specimens.

By observing the curves of the damaged specimens after self-repair under different dosages of the microcapsules, it can be seen that the curves of the healed specimens tends to move upward to the left compared with the σ ~ ε1 curves of the initial specimens; and this degree of healed influences of left shift becomes more and more obvious with an increasing of the curing ages, that is, the stress-strain relationship curves gradually moves upward to the left. Which indicates that the self-repairing system of the microcapsules has a certain influence on the deformation characteristics of the specimens.

It can be seen from Fig. 5 that, compared to the σ ~ ε1 curves of the damaged specimen, the left shift degree of the healed specimen is more obvious with the increase of pre-loading stress. Mainly because that the more pre-loading pressure, the more crack will produce inside the specimens, the more to activate the microcapsules. However, due to the limited repair agent encapsulated by the microcapsules, and results in limiting the repair ability of the microcapsules. Although the repair effect of the microcapsules on damaged specimens is more obvious with the increase of preloading pressure, the mechanical properties of healed specimens with excessive damage may not be restored to the intact state.

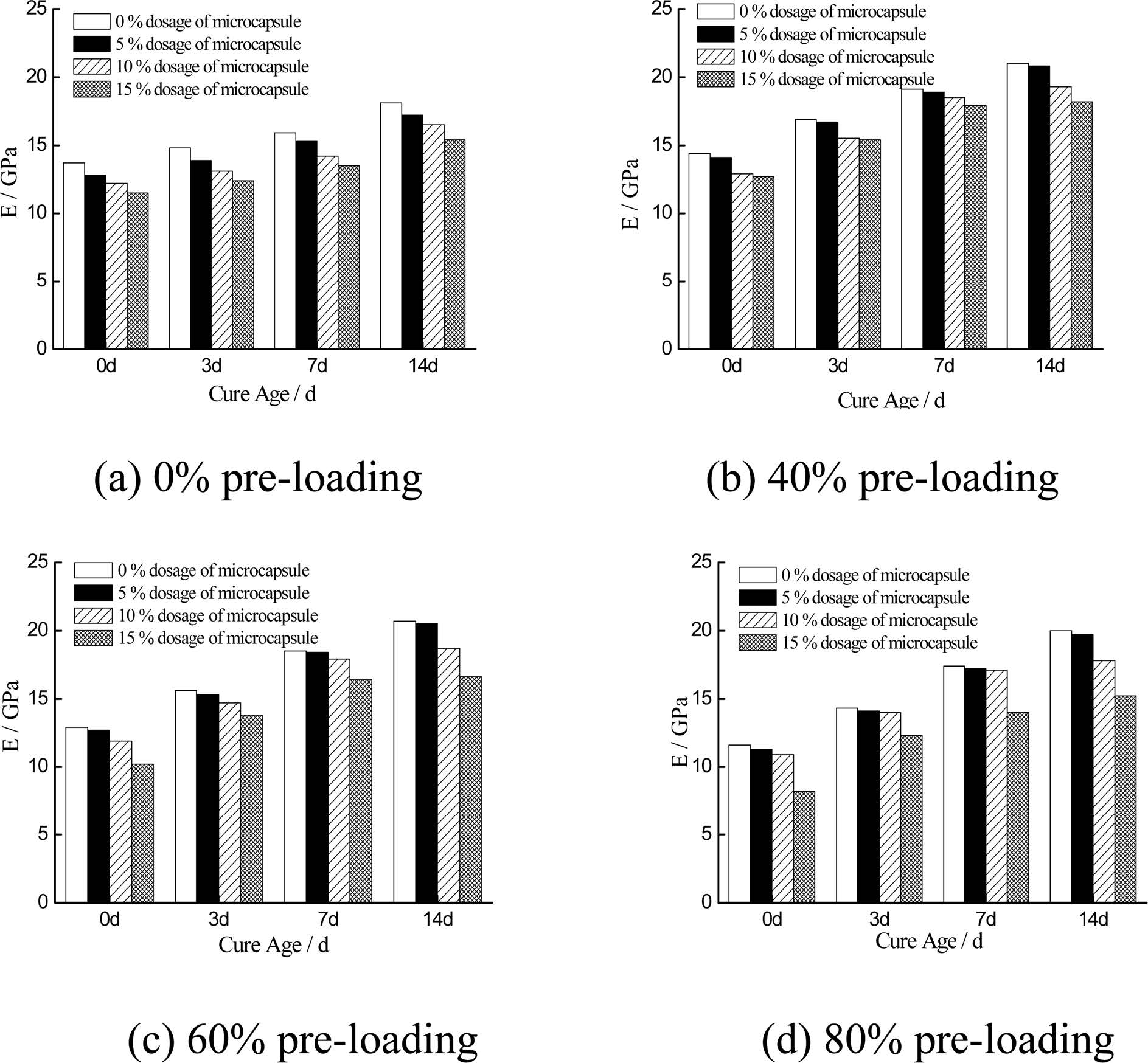

In general, the healed influence of microcapsules on the deformation properties of the specimens is limited under the dosage of microcapsules, which mainly shows that the elastic modulus gradually decreases with the increase of the dosage of the microcapsules, and the degree of decrease amplitude gradually decreases (shown in Fig. 6); the peak strain gradually increases with the increase of the dosage of microcapsules, and the degree of increase amplitude gradually decreases (shown in Fig. 5). It is concluded that the microcapsules can increase plastic deformation capacity of concrete combined with the stress-strain curves, and improve the brittleness characteristics of ordinary concrete when it damages, and strengthens the ability of concrete to resist vibration and impact load [35].

|

Fig. 2 The stress ~ strain curves of the specimens with 0% dosage of the microcapsules under different pre-loading conditions. |

|

Fig. 3 The stress ~ strain curves of the specimens with 5% dosage of microcapsules under different pre-loading conditions. |

|

Fig. 4 The stress ~ strain curves of the specimens with 15% dosage of the microcapsules under different pre-loading conditions. |

|

Fig. 5 The relationship between the peak strain and curing age of the specimens with different dosages of microcapsules under different pre-loading conditions. |

|

Fig. 6 The relationship between the elastic modulus and curing age of the specimens with different dosages of microcapsules under different pre-loading conditions. |

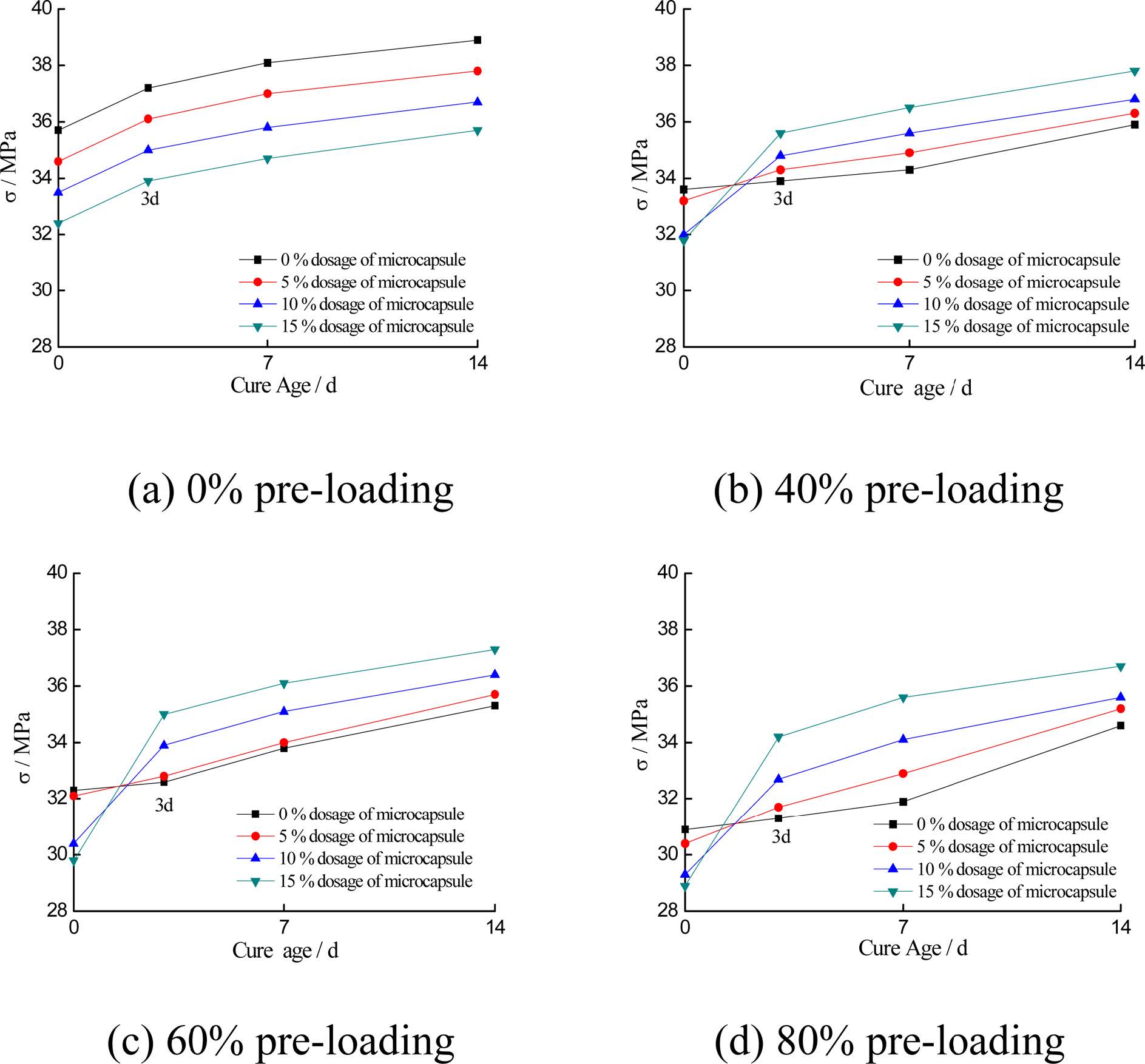

The relationships between curing ages and peak strength of the specimens under different pre-loading conditions and under different dosage of microcapsule are shown in Fig. 7. The strength of the specimens mixed with microcapsules degraded to some extent, and the more dosage of the microcapsules, the more the decreasing degree of the strength. Meanwhile, the strength decreased to different degrees with the increase of pre-pressing stress under the same dosage of microcapsule.

In addition, the peak strength gradually decreased with an increasing of dosage of microcapsule, but gradually increased with increasing of the curing ages. The strength of the damage specimens decreased compared with the initial condition. However, the strength has been recovered to different degrees compared with that of the damage specimens.

Taking initial states of specimens as an example, initial peak strengths were 34.61, 33.68 and 32.20 MPa when the dosage of microcapsule are 5%, 10% and 15%, respectively. Compared with the peak strength by 35.70 MPa when the 0% dosage of microcapsule, the initial peak strength decreased by 3.08%, 5.60% and 9.81%, respectively. And the reduction of the strength of specimens mixed with range from 10% to 15% dosage of microcapsules is more than that range from 0% to 5% and 5% to 10% dosage of microcapsules, this indicates that there is no linear relationship between the dosage of microcapsules and strength. Which may be related to the changes of holes structure in self-healing specimens, that is, the internal defects inside the specimens increase after mixing with microcapsule, and the strength and rigidity of microcapsules wall are both smaller than that of the cement material, which leads the strength and rigidity of the cement material to reduce, and this phenomenon is more and more obvious with increasing of dosage of the microcapsules.

In addition, taking 10% dosage of the microcapsules, 40% pre-loading and curing for 7days as an example, the initial, damage and healed peak strength are 33.52, 32.01 and 35.58 MPa, respectively. The damage peak strength decreases by 4.47% compared with the initial ones, but the healed peak strength increases by 6.26% compared with the initial ones. Meanwhile, the healed peak strength increases by 11.25% compared with the damaged ones. It indicates that the microcapsules have a positively effect on the mechanical properties of the specimens.

Under the same dosage of the microcapsules, the strength gradually increases with an increasing of curing ages. Taking the 10% dosage of microcapsule and 40% pre-loading as an example, the initial strength is 32.02 MPa. When curing ages are 3, 7, 14 days, the strength are 34.78 MPa, 35.60 MPa and 36.78 MPa, respectively. And the strengths are increased by 8.75%, 11.25% and 14.94% compared with that of specimens mixed with 0% dosage microcapsules (initial state). It can be seen that the elastic moduli of damaged specimens have been improved to varying degrees after a period of curing age. The longer the curing age, the more sufficient the healed of specimens’ defect, and the higher the strength. There is rapid reaction between the restorer and curing agent released from the microcapsules at the initial stage of curing ages, which leads the strength of the specimens to rapidly increase. The release of the restorer gradually solidifies after a period of reaction, and the strength of the specimens gradually increases.

|

Fig. 7 The relationship between the strength and curing age of the specimens with different dosages of microcapsules under different pre-loading conditions. |

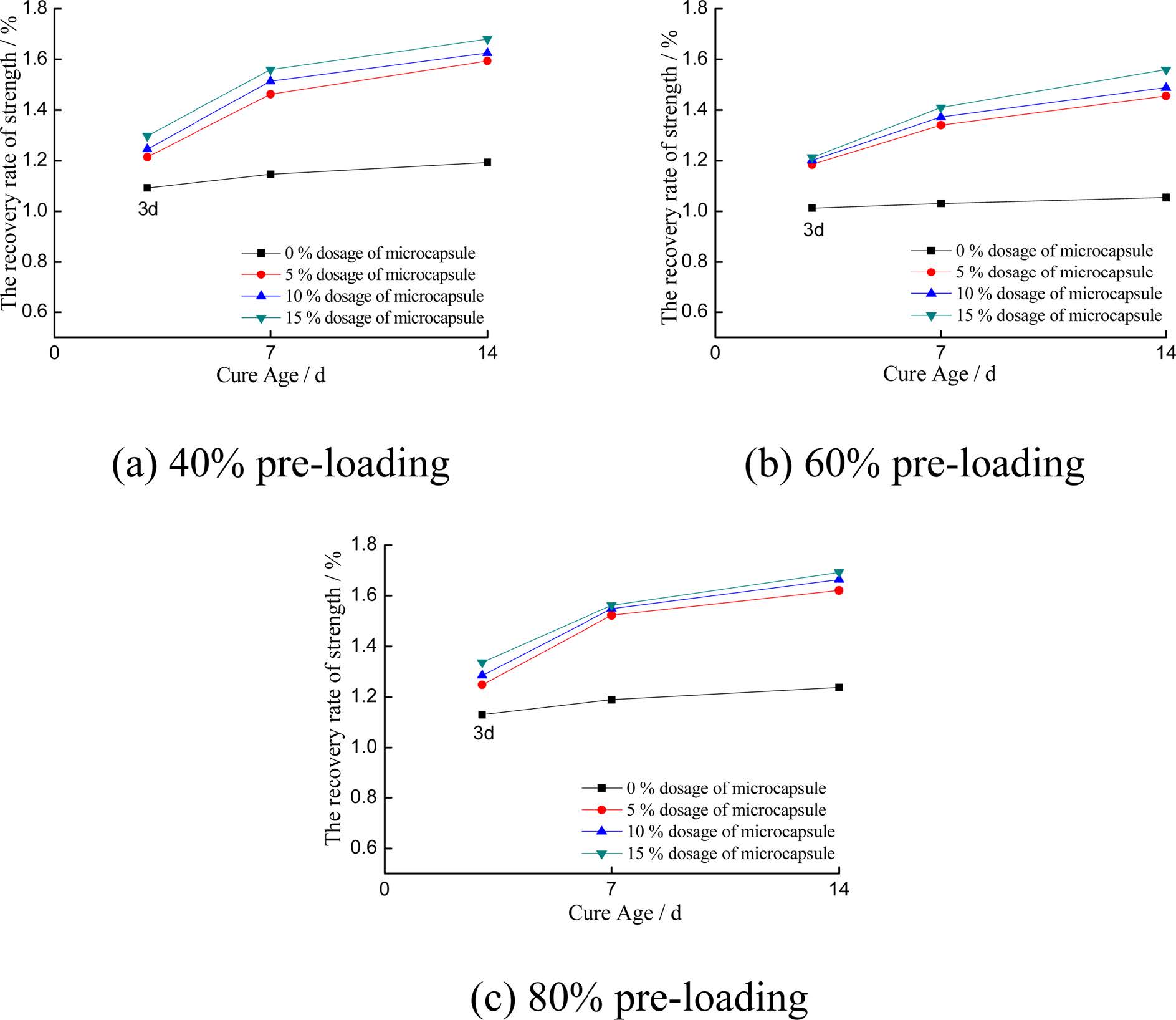

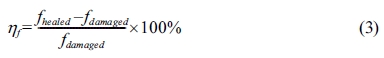

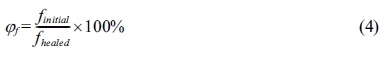

To investigate the healing effects in the relationships to strength and strain properties, the definitions for the healing rate and recovery rate of mechanical properties are given as following:

where η is the healing rate of the mechanical properties (%); φ is the recovery rate of the mechanical properties (%); Finitial denotes the initial mechanical properties; Fdamaged is the damaged mechanical properties; Finitial is the healed mechanical properties.

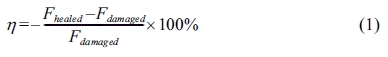

As can be seen from Fig. 8 ~ Fig. 9, the microcapsules have a positive and significant influences on the healed rate and recovery rate of peak strength and peak strain of the specimens. The healed rate of strength is greater than that without the microcapsules, which indicates positive healing influences due to the microcapsules. Meanwhile, the recovery rate of strength of the specimens is more than 100%, which means full recovery performances. The healed rate and recovery rate of strength of the specimens gradually increase with the increasing dosage of the microcapsule under the same states, but their healing and recovery rates gradually decrease with increasing of curing ages under the same dosage of the microcapsules.

Taking 40% pre-loading and curing for 7days as an example, the healed and recovery rate of the specimens without microcapsules are at a low level. Compared with the 0% dosage of microcapsule, the healed rate of strength increases by 3.04%, 9.14% and 12.70% when the dosages of microcapsule are 5%, 10% and 15%, respectively. Compared with the 0% dosage of microcapsule, the recovery rate of strength increases by 0.03%, 0.09% and 0.13% when the dosages of microcapsule are 5%, 10% and 15%, respectively. This indicates that the specimens made with the microcapsules have played a healing role, and the strength increases to different degrees from the macroscopic manifestations.

And the more the dosage of the microcapsules, the more the increasing degree of the strength. The mainly reason is that the reaction product between the curing agent and the epoxy fills the pores inside cementitious composite [36], which enhances the compressive strength of the specimens. This self-healing effects will be improved with an increasing dosage of the microcapsules [38]. On one hand, more microcapsules participate in the self-repair influences; on the other hand, the probability of cracks passing through microcapsules increases. The results show that more repairing agents and greater probability of rupture will naturally have a higher repair effects on the strength.

Under the same dosage of microcapsules, the healed and recovery rate of the specimen’s strength gradually increased with an increasing of curing ages. Taking 10% dosage of microcapsule and 40% pre-loading as an example, compared with the strength of specimens with 10% dosage of microcapsule under the initial state, the healed rate of strength increased by 8.75%, 11.25% and 15.00% when the curing ages are 3, 7 and 14 days, respectively. And compared with the strength of initial specimens with 10% dosage of microcapsule, the recovery rate of strength increased by 0.09%, 0.11% and 0.15% when the curing ages are 3, 7 and 14days, respectively.

The self-healing of strength is relatively fast in the initial stage of curing, and the latter growth is gradually decreasing until not increasing at all. This is because the bond strength and stiffness of the cured product gradually increases with the curing time, and eventually approach or even exceed the elastic modulus of cement matrix. As a result, the elastic modulus of the damaged specimen increases with the curing age.

|

Fig. 8 The relationship between the healed rate of strength and curing age of the specimens with different dosages of microcapsules under different pre-loading conditions. |

|

Fig. 9 The relationship between the recovery rate of strength and curing age of specimens with different dosages of microcapsules after different preloading conditions. |

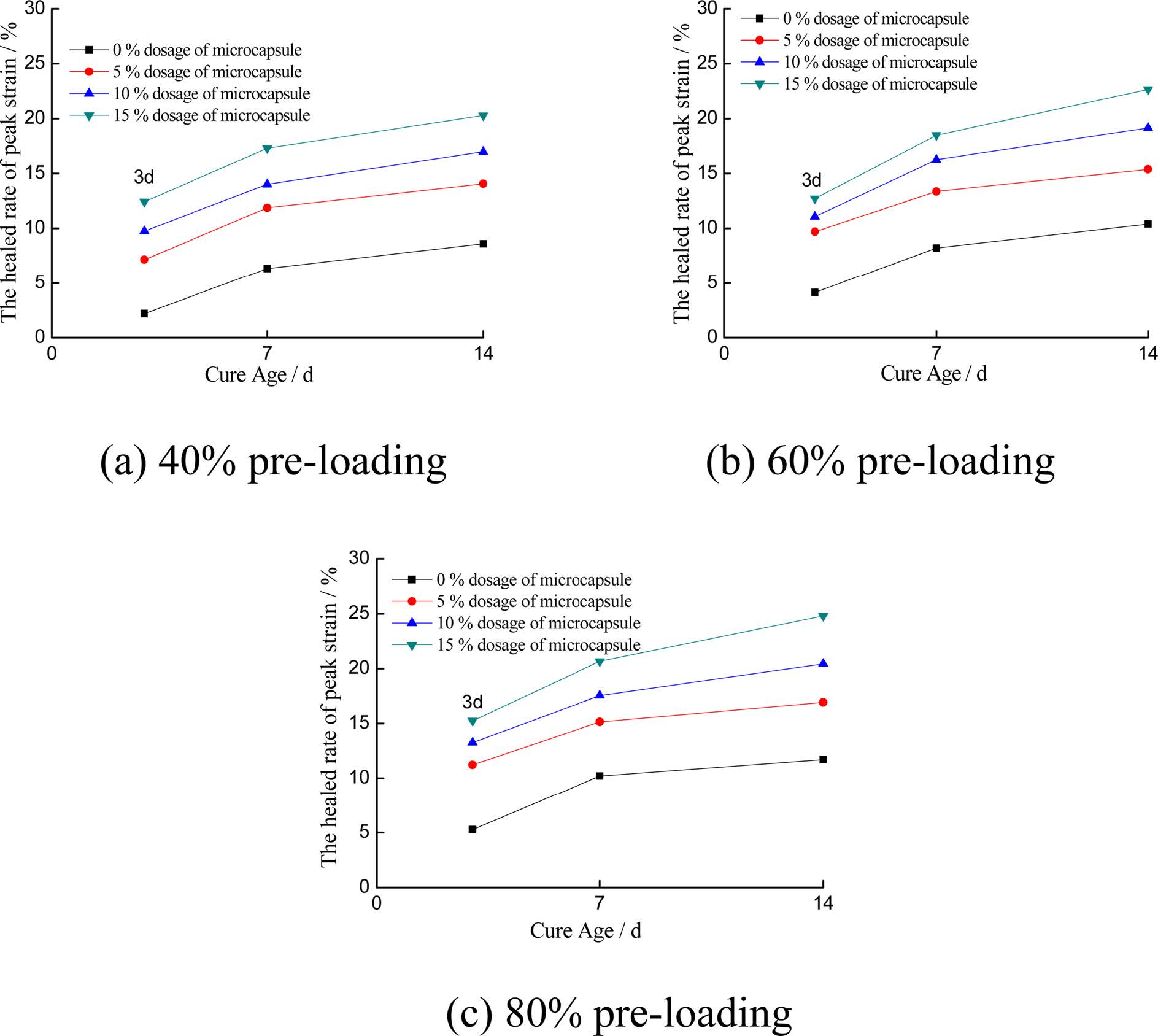

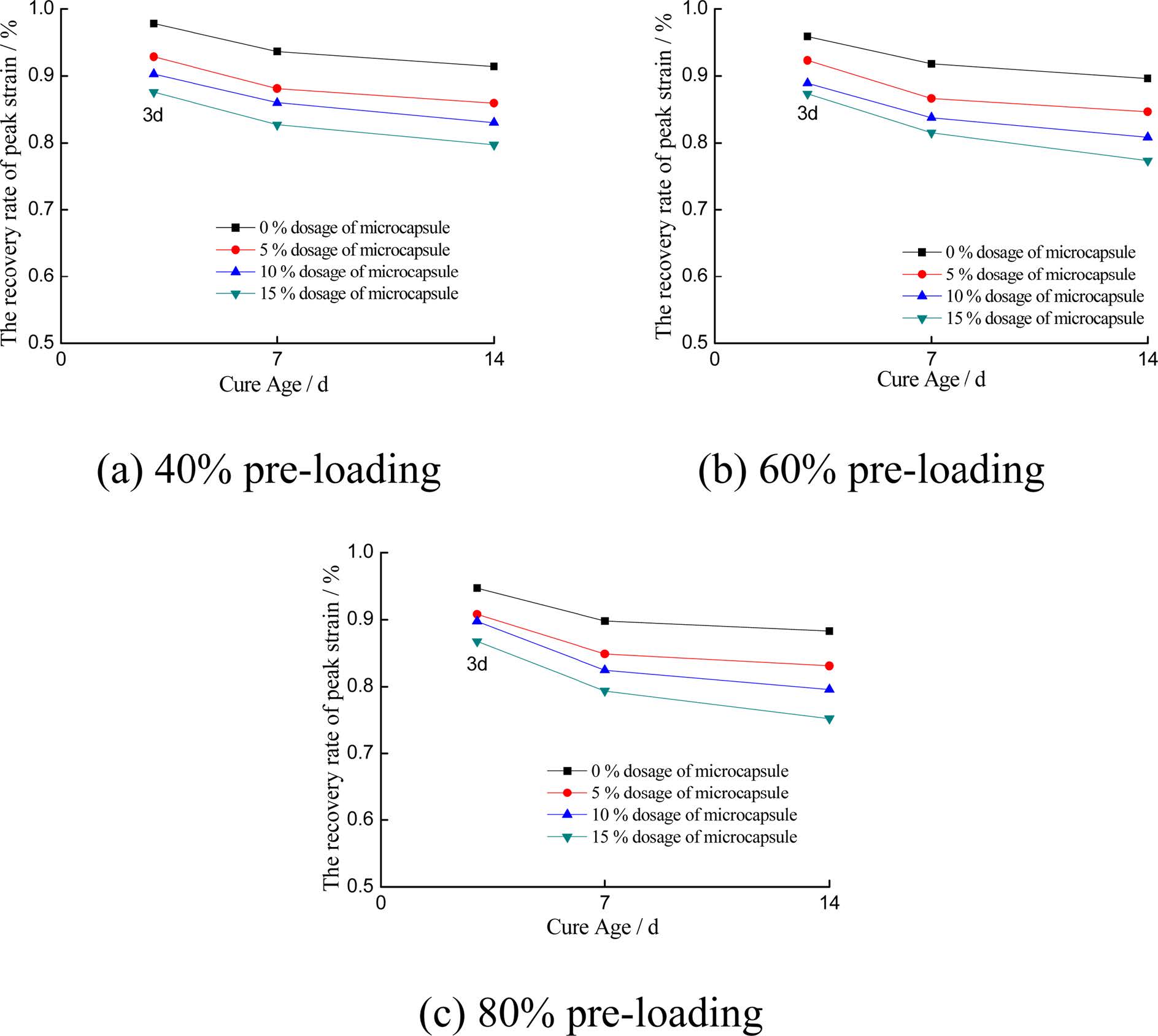

As can be seen from Figs. 10 and 11, the microcapsules also have a significant influence on the healed rate and recovery rate of the peak strain of the specimens. The healed rate and recovery rate of peak strain of the specimens gradually increase with an increasing of curing days and pre-loading under the same dosage of microcapsule, and their healed rate of peak strain gradually increase with increasing the dosage of microcapsules under the same preloading conditions, but the recovery rate of the peak strain gradually decreases with increasing the dosage of microcapsules under the same preloading conditions.

Taking 40% pre-loading and curing for 7days as an example, the healed and recovery rate of peak strain of the specimens without microcapsules are at a low level. Compared with the 0% dosage of microcapsule, the healed rate of peak strain increased by 5.52%, 7.67% and 10.96% when the dosage of microcapsules are 5%, 10% and 15%, respectively; and the recovery rate of peak strain increases by 0.06%, 0.08% and 0.11% when the dosage of microcapsule were 5%, 10% and 15%, respectively. This indicates that the microcapsules played a healing influences on the cement-based materials, and generally manifests as the peak strain decreases to different degrees on the macro level. And the more the dosage of the microcapsules, the more increasing of peak strain. Although the reaction products between epoxy resin and curing agent filled the pores and other defects inside the specimens, the plastic properties of the healed specimens reduce, the improvement degree is far less than the deformation characteristics of the specimens after the addition of microcapsules. Therefore, the dosage of microcapsules has a significant influence on the deformation characteristics [34].

Under the same dosage of microcapsules, the healed rate of peak strain gradually increases with an increasing of curing days, but the recovery rate of peak strain gradually decreases with an increasing of curing days. Taking the 10% dosage of microcapsule and 40% pre-loading as an example, compared with the peak strain of the specimens with 10% dosage of microcapsule under the initial states, the healed rate of peak strain increases by 9.75%, 14.01% and 16.97% when the curing ages are 3, 7 and 14days, respectively. And recovery rate of strength increases by 0.90%, 0.86% and 0.83% when the curing ages are 3, 7 and 14days, respectively. The self-healing of peak strain is relatively fast in the initial stage of curing, and the latter reduce is gradually decreasing.

|

Fig. 10 The relationship between the healed rate of peak strain and curing age of the specimens with different dosages of microcapsules under different preloading conditions. |

|

Fig. 11 The relationship between the recovery rate of peak strain and curing age of the specimens with different dosages of microcapsules under different preloading conditions. |

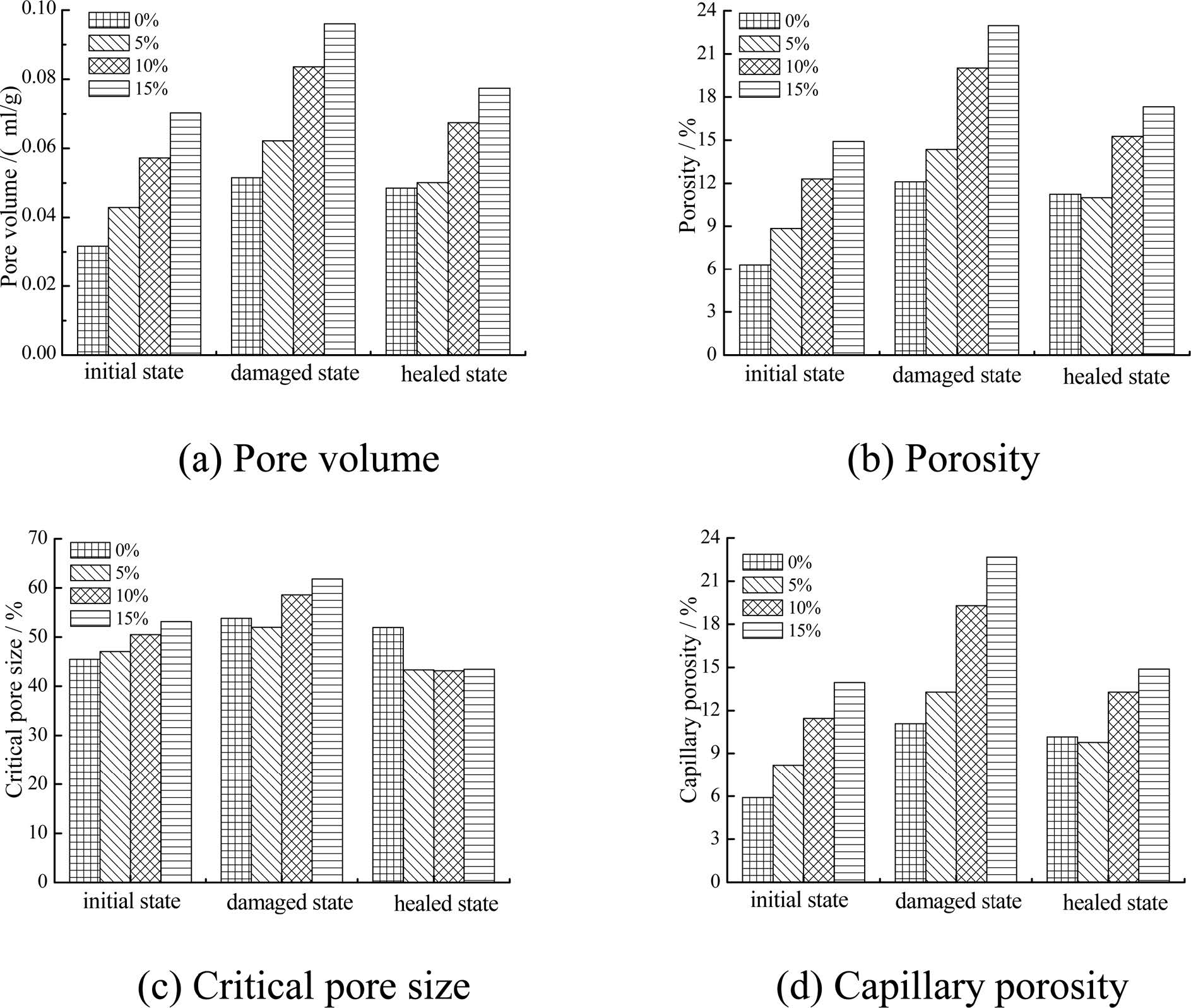

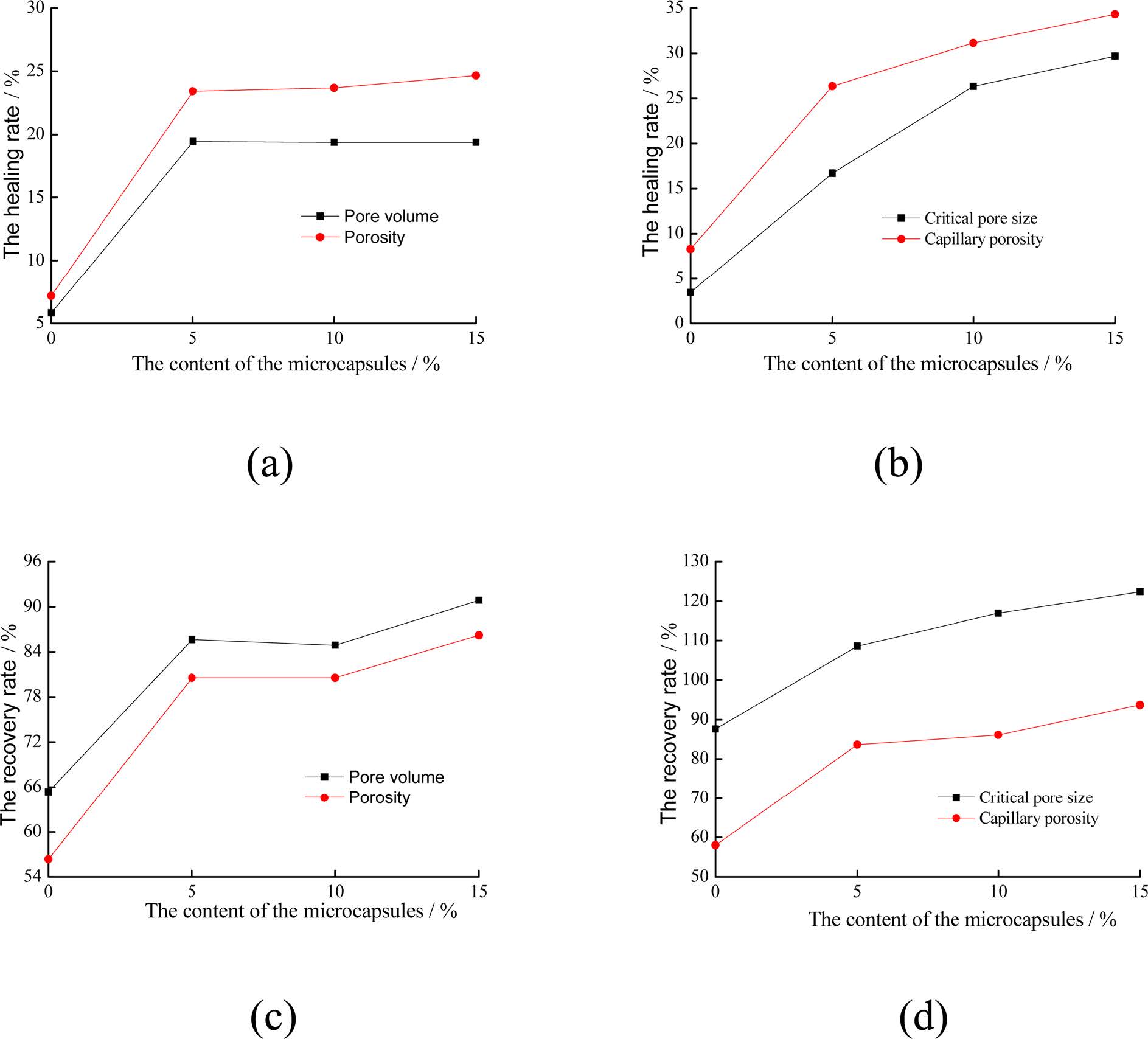

And the variation of the healing rate and recovery rate of the pore structure parameters of specimens with dosage of microcapsules is shown in Fig. 13.

As can been seen from Fig. 12, the pore structure parameters gradually increase with increasing the dosage of microcapsules. And there are also obvious influences of the specimens' state (initial, damaged and healed) on the pore structure parameters. The pore structure parameters of the damage specimens were more than that of the initial specimens, but these parameters had been repaired compared with that of the damage specimens after 7 days rapid curing [16]. That is mainly for the defects inside cement base material, caused by the microcapsules, increases with an increasing dosage of the microcapsule. The difference among the capsule wall of microcapsule, strength and stiffness of cement base material, increases the combination of the two interface produces pore [31]. Which indicates that even a small dosage admixture of the microcapsules can cause pores in the specimens. Moreover, the so-called crowding phenomenon will occur in the capsule particles with the increasing dosage of microcapsules. And the microcapsule particles will hinder the movement of surrounding fluid and make the mortar material more viscous [37-38], which leads to the poor compaction of the specimen and the increase of material pore parameters to varying degrees.

There are a series of physical variables that indicated the self-healing status are defined, as shown following:

where ηf represents healing rate of the pore structure parameters (%); φf represents recovery rate of the pore structure parameters (%); finitial denotes the initial pore structure parameters; fdamaged is damaged pore structure parameters; fhealed is healed pore structure parameters.

The self-healed effects of the microcapsules on the capillary porosity and critical pore size is very remarkable, and the healed rate of capillary porosity and critical pore size can reach 34.32% and 29.69% (15% dosage of microcapsules), respectively, the their recovery are 93.69% and 122.39%, respectively; but the healed rate and recovery rate of porosity and the pore volume are relatively small, their healed rate are only 23.86% and 18.26%, and their recovery rate are only 86.64% and 82.18%, respectively. This indicates that the effect of microcapsule on the pore size and porosity are relatively smaller than that on the capillary porosity and critical pore size, and confirms the healed effects of the microcapsules on the microcracks and microspore in cementitious composite material. However, it is worth mentioning that although self-healing effects increases with an increasing of the microcapsules, the effects of the microcapsules on the microstructure of the initial cementitious composite material cannot be ignored. Therefore, the dosage of the microcapsules should be optimally determined and balanced by the actual situation when the microcapsules are applied.

|

Fig. 12 Variation in pore structure parameters with dosage of microcapsules (60% pre-loading of the peak strength and 14 days of curing age). |

|

Fig. 13 Variation of the healing rate and recovery rate of the pore structure parameters of specimens with dosage of microcapsules. |

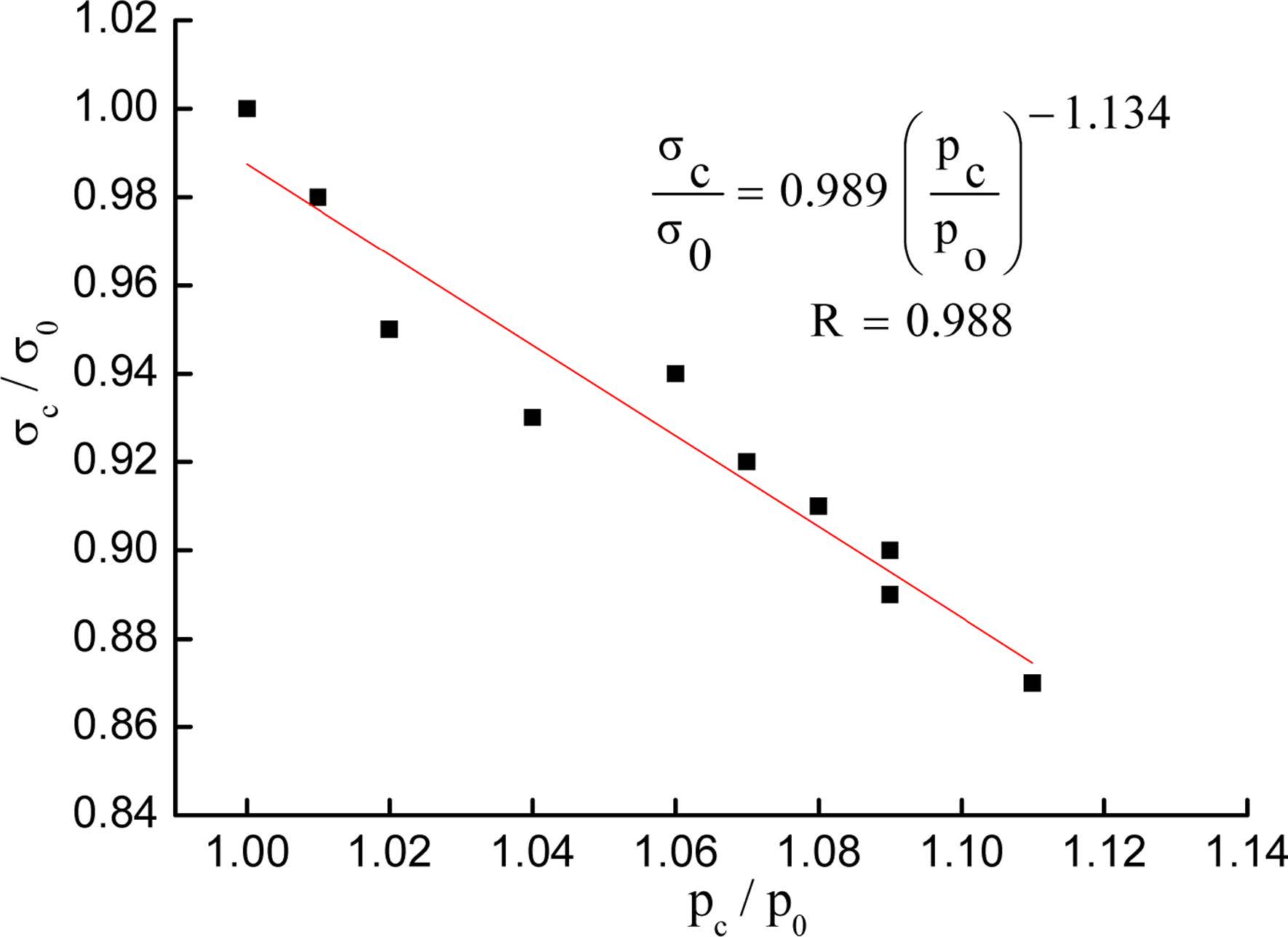

The difference of pore structure has a great impact on the mechanical properties of concrete. For the microstructure of the concrete, to study the relationship between pore structure and macroscopic properties of concrete is usually analyzed by means of models. The strength of concrete is essentially a function of pore volume in concrete, that is, the strength of concrete is determined by the volume of the defects (pore, capillary porosity, gel hole, etc.) of concrete. In view of previous studies [39-42], to analyze the relationship between the change of pore structure and strength of cement-based materials after adding the microcapsules.

The relationship between relative strength and porosity of the initial specimens, as shown in Fig. 14. As can be seen from Fig. 14, the strength of the microcapsules based on self-healing specimens decreases with the increase of porosity.

Linear regression was done on the results shown in Fig. 14. The relationship between the strength and porosity of the specimens was obtained as follows:

where σc is strength of the specimens with microcapsules under the initial state; σ0 is the strength of the specimens without the microcapsules under the initial state; pc is the porosity of the specimens with microcapsules under the initial state; p0 is the porosity of the specimens without the microcapsules under the initial state.

|

Fig. 14 Relationship between the relative strength and the porosity of the initial specimens. |

In this paper, the dosage of microcapsules, pre-loading stress and curing days on the mechanical properties, pore structure and self-healing effects of the cementitious composite materials were investigated through the uniaxial compression test and MIP tests. The main conclusions can be drawn as followings:

1) The “softening” trend of the stress ~ strain curves of the specimens gradually decreased with an increasing of the curing ages or with a decreasing of dosage of microcapsules, and the brittle features of mortar specimens gradually also enhanced, but its plastic features significantly decreased, accompanying by the trend of transition from ductile to brittle.

2) The strength of the specimens mixed with microcapsules degraded to some ex-tent, and the dosage of microcapsules has a significant influence on the deformation characteristics of the specimens. Under the same conditions, the strength decreased gradually with an increasing of the microcapsule dosage, but the peak strain gradually increased. Meanwhile, under the same dosage of microcapsule, the strength decreased to different degrees with the increase of pre-pressing stress, but its peak strain in-creased to different degrees. And with the increase of curing ages, the peak strength gradually has been repaired to different degrees, showing a gradual increasing trend, but the peak strain shows a gradual decrease trend.

3) The microcapsules played a healing action on the cement-based materials, and generally manifested as the deformation characteristic of the specimens decreased to different degrees on the macro level. And the more the dosage of the microcapsules, the more increasing of plastic deformation characteristics. Although the reaction products between epoxy resin and curing agent filled the pores and other defects inside the specimens, the plastic properties of the healed specimens reduced, the improvement degree was far less than the deformation characteristics of the specimens after the addition of microcapsules.

4) Microcapsules have different healing effects on different pore structure parameters (the pore volume, porosity, critical aperture and capillary porosity) of the cementitious composite materials.

The research described in this paper was financially supported by the General Program of the National Natural Science Foundation of China (No.51478272, 51378312), the joint funds of the National Natural Science Foundation and Guangdong Province of China (U1301241), the Science and Technology Foundation for the Basic Research Plan of Shenzhen City (JCYJ20160422095146121), and the Collaborative Innovation Research Centre for Environment-Friendly Materials and Structures in Civil Engineering, Southeast University.

- 1. M.F. Montemor, A.M.P. Simoes, and M.G.S. Ferreira, Cement. Concr. Compos. 25[4-5] (2003) 491-502.

-

- 2. L. Marsavina, K. Audenaert, G.D. Schutter, N. Faur, and D. Marsavina, Constr. Build. Mater. 23[1] (2009) 264-274.

-

- 3. A. Abrams, Concrete [10] (1925) 50.

- 4. K. Van Breugel, in “Proceeding of the first international conference on self-healing materials” (Dordrecht Springer, 2007) p.48.

- 5. K. Sisomphon, O. Copurogli, E.A.B. Koenders, Cement Concr. Compos. 34[4] (2012) 566-574.

-

- 6. C. Edverdsen, ACI Mater. J. 96 (1999) 448-454.

- 7. J.Y. Wang, H. Soens, W. Verstraete, and N. De Belie, Cem. Concr. Res. 56 (2014) 139-152.

-

- 8. Z.X. Yang, J. Hollar, X.D. He, and X.M. Shi, Cem. Concr. Compos. 33[4] (2011) 506-512.

-

- 9. V. Wiktor, and H.M. Jonkers, Cem. Concr. Compos. 33[7] (2011) 763-770.

-

- 10. J.F. Hu, H.Q. Chen and Z.B. Zhang, Mater. Chem. Phys. 118[1] (2009) 63-70.

-

- 11. J.P. Ou, and Y.C. Kuang, Acta. Mech. Solida. Sin. 25[2] (2004) 320-324.

- 12. T. Nishiwaki, in “Fundamental study on development of intelligent concrete with self-healing capability. Sendai: Depart-ment of Architecture and Building Science” (Tohoku University Press, 1997). p.33.

- 13. Y.Z. Yang, M.D. Lepech, E.H. Yang, and V.C. Li, Cem. Concr. Res. 39[5] (2009) 382-390.

-

- 14. K.V. Tittelboom, N.D. Belie, D.V. Loo, and P. Jacobs, Cem. Concr. Compos. 33[4] (2011) 497-505.

-

- 15. W. Xiong, J.N. Tang, G.M. Zhu, N.X. Han, E. Schlangen, B.Q. Dong, X.F. Wang, and F. Xing, Sci. Rep. 5 (2015) 10866.

-

- 16. B. Hilloulin, K.V. Tittelboom, E. Gruyaert, N.D. Belie, and A. Loukili, Cem. Concr. Compos. 55 (2015) 298-307.

-

- 17. N.X. Han, and F. Xing, Mater. 10[1] (2017) 2.

- 18. X.F. Wang, J.H. Zhang, W. Zhao, R. Han, N.X. Han, and F. Xing, Constr. Build. Mater. 165 (2018) 149-162.

-

- 19. D.G. Bekas, K. Tsirka, D. Baltzis, and A.S. Paipetis, Compos. Part. B-Eng. 87 (2016) 92-119.

-

- 20. B.Q. Dong, Y.S. Wang, G.H. Fang, N.X. Han, F. Xing, and Y.Y. Lu, Cem. Concr. Compos. 56 (2015) 46-50

-

- 21. X.F. Wang, F. Xing, M. Zhang, N.X. Han N and Z.W. Qian, Mater. 6[9] (2013) 4064-4081.

-

- 22. X.F. Wang, P.P. Sun, N.X. Han and F. Xing, Mater. 10[1] (2017) 1-18.

-

- 23. X.F. Wang, F. Xing, Q. Xie, N.X. Han, T. Kishi and T.H. Ahn, J. Ceram. Proc. Res. 16 (2015) 74-82.

- 24. X.F. Wang, Y.D. Guo, J.F. Su, X.L. Zhang, N.X. Han and X.Y. Wang, Nanomaterials-Basel. 8[6] (2018) 364.

-

- 25. X.F. Wang, C. Fang, D.W. Li, N.X. Han and F. Xing, Cem. Concr. Comp. 92 (2018) 216-229.

-

- 26. X.F. Wang, R. Han, T.L. Han, N.X. Han and F. Xing, Mater. Chem. Phys. 215 (2018) 346-354.

-

- 27. X.F. Wang, R. Han, J. Tao, T.L. Han, G.M. Zhu, J.N. Tang, N.X. Han and F. Xing, Compos. Part. B-Eng. 158 (2019) 249-258.

-

- 28. Y.G. Tian, S.F. Shi, K. Jia, and S.G. Hu, Constr. Build. Mater. 93 (2015) 1151-1156.

-

- 29. H.J. Wu, Q.M. Zhang, F.L. Huang, and Q.K. Jin, In. J. Impact. Eng. 32[1] (2005) 605-617.

-

- 30. G. Perez, J.J. Gaitero, E. Erkizia, I. Jimenez, and A. Guerrero, Cem. Concr. Compos. 60 (2015) 55-64.

-

- 31. D.A. Abrams, ASTM. J. 17[2] (1917) 70-78.

- 32. A.H.H. Al-Masoodi, A. Kawan, M. Kasmuri, R. Hamid, and M.N.N. Khan, Constr. Build. Mater. 104 (2016) 247-262.

-

- 33. G. Perez, E. Erkizia, J.J. Gaitero, I. Kaltzakorta, I. Jimenez, and A. Guerrero, Mater. Chem. Phys. 165 (2015) 39-48.

-

- 34. L.L. Shi, L.C. Wang, Y.P. Song, and L. Shen, Constr. Build. Mater. 66 (2014) 181-191.

-

- 35. S.R. White, N.R. Sottos, P.H. Geubelle, and J.S. Moore, Nature. 409[6822] (2001) 794-797.

-

- 36. M. Zhang, in “A study on microcapsule based self-healing meth-od and mechanism for cementitious composites” (Central South University Press, 2013) p.112.

- 37. A. Akhavan, S.M.H. Shafaatian, and F. Rajabipour, Cem. Concr. Res. 42[2] (2012) 313-320.

-

- 38. P. Sukontasukkul, P. Nimityongskul, and S. Mindess, Cem. Concr. Res. 34[11] (2004) 2127-2134.

-

- 39. M. Balshin, Dokl. Akad. Nauk. (SSSR). 67[5] (1949) 831-834.

- 40. E. Ryshkewitch, J. Amer. Ceram. Soc. 36[2] (2006) 65-68.

-

- 41. K. Schiller, Cem. Concr. Res. 1[4] (1971) 419-422.

-

- 42. D. Hasselman, J. Amer. Ceram. Soc. 45[9] (1962) 452-453.

-

This Article

This Article

-

2019; 20(S1): 46-55

- Received on Dec 9, 2018

- Revised on Jan 11, 2019

- Accepted on Jan 11, 2019

Services

Services

- Abstract

introduction

experimental materials and specimens

results and discussion

pore structure analysis

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Xianfeng Wang

-

Guangdong Key Laboratory of Durability in Coastal Civil Engineering, College of Civil Engineering, Shenzhen University, Shenzhen, Guangdong 518060, P.R. China

Tel : +86-755-2673-2830

Fax: +86-755-2653-4021 - E-mail: xfw@szu.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.