- Parametric optimization for maximization of material removal rate in turning of mild steel using taguchi six sigma technique

Senthil Kumar Natarajana,*, Karthick Sekarb, Dhanenderan Natesanc and Senthil Kumar Kuppuswamid

aDepartment of Mechanical Engineering, Ganesh College of Engineering, Salem, India

bDepartment of Mechanical Engineering, Excel Engineering College, Komarapalayam, India

cDepartment of Automobile Engineering, Government College of Engineering, Erode, India

dDepartment of Agricultural Engineering, Nehru Institute of Technology, Coimbatore, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The Six Sigma practice is applied to increase the quality of the machined surface and in this work six sigma practice is used to determine the optimal level of parameters. Six sigma technique is combine with Taguchi technique for optimizing the turning process parameters. Mild steel is used as a work piece to optimize the material removal rate. The primary objective of this research work is maximizing the material removal rate during turning of mild steel using single point cutting tool. The turning process parameters considered in this work are cutting speed, feed rate and depth of cut. The optimal parameters combination for signal to ratio values for turning process is A3-B4-C2, which gives cutting speed as 1000rpm, feed rate 0.20 mm/rev and depth of cut 0.8mm. The validation experiments are also conducted and the optimal turning parameters are observed to provide maximum material removal rate.

Keywords: Taguchi technique, Six sigma technique, Material removal rate, Optimization.

The essential quality of all manufacturing industries is to produce high quality components with low cost at a very minimum period of time. Several operations are performed in industries and in majority of industry; the turning process seems to be highly predominant. In turning process the process parameters are cutting speed, feed rate and depth of cut. These process parameters affect directly on the material removal rate of the material. The main objective of this research work is maximization of material removal rate during turning a mild steel rod. Taguchi Six Sigma technique is used for the Optimisation process and optimal parameters are selected for turning mild steel. The removal of metal from the outer diameter to decrease the diameter of the work piece to generate a smooth finish on the metal is called as a turning process. The basic operation in the late is the turning process, in which the process output depends on operating conditions used on the too. It becomes a very difficult process to determine the optimum output in a turning process and in this work, a unique approach to achieve a better quality is used.

The materials are generated by extrusion process, drawing process, casting process etc., and the required finishing and shape of the object is obtained by turning process. The signal to noise and orthogonal array are the tools which are used to determine the optimal process parameters in maximizing the material removal rate. The machining of mild steel are demonstrated with response surface methodology and modified deep neural network for optimizing the material removal rate, cutting force and cutting time [1]. Since coated carbide tool have high elastic modulus, it will provide better machining when compared to other materials. It is concluded that the cutting spped is the most influencing parameter in machining the mild steel. Machining process are highly effected by several factors such as tool geometry, work materials, cutting speed, depth of cut, feed rate, machine vibrations and so on [2]. Among the alternatives available to determine the best machining conditions to provide high production rate with low manufacturing cost, Taguchi techniques are found to be best suited for better optimization. The dry and wet turning of mild steel with High speed steel tool is carried out with the objective to reduce the tool flank wear and improving the material removal rate to evaluate the optimized cutting conditions that will provide both high quality turning and better productivity [3]. It is observed that better machining is observed during wet turning instead of dry turning. The energy consumption during the turning operation to remove the material has becoming an environmental problem in several industries [4]. Models are developed for turning carbon steel, aluminium and ductile iron materials and experiments are conducted with high accuracy to investigate the power consumption. The turning of EN24 alloy steel using coated carbide inserts and empirical relationship between the cutting parameters cutting speed, depth of cut and feed rate are carried out [5]. It is concluded that cutting speed and depth of cut has high influence on material removal rate. Response surface models are created to study the significant effects of the surface roughness and material removal rate in turning EN24 alloy steel. Taguchi six sigma techniques are used to optimize cutting parameters in turning of mild steel for maximization of material removal rate. The six sigma approach is incorporated in this work to assess the process capability and variation in the machining process. In this work L18 orthogonal design is selected and material removal rate is maximized using larger the better formula.

Experiments for cylindrical and rectangular workpieces of varied geometries to study the surface roughness characteristics are conducted [6]. It is observed that when there is an increased surface area exposure, the surface roughness will be also increased with cylindrical geometries. With higher pulse duration and current, the surface roughness increases because of the formation of deep crater due to higher discharge energies [7]. Experiments are conducted to study the machining conditions for optimal material removal rate in WEDM process [8]. It is observed that peak current is the most influencing parameter and contributes significantly in electrode wear. Taguchi-grey relational analysis is demonstrated for investigating the machining parameters during milling of 17-4 PH stainless steel [9]. 18 experiments are selected as per the orthogonal array with three factors at several levels. The process parameters considered in this work are cutting speed, depth of cut and feed rate. The Taguchi and Grey relational analysis are discussed for optimizing the friction characteristics and wear characteristics of Al-7.5% SiC material [10]. The mechanical and tribological parameters are evaluated and design of experiments are used to conduct and L27 orthogonal array is selected to conduct 27 experiments with several combinations of process parameters viz. axial load, time and speed.

Taguchi design are used to determine the surface roughness characteristics while machining aluminium alloy and grey cast iron [11]. The work is focussed on minimization of surface roughness and the most influencing parameters are determined. Response surface methodology are used for optimizing the impact toughness for boride steel [12] and used Taguchi technique to optimize the material removal rate using L9 orthogonal array for EN19 steel [13]. EN31 steel are optimized using Taguchi design and Grey Relational Analysis [14]. Hybrid optimization is used by combining these two techniques to investigate and determine the most influencing process parameters while machining under MQL technique for minimising the surface roughness and vibration of the tool. The machinability parameters of Al/SiC metal matrix composite are discussed against the machining responses considered in this work are surface roughness and material removal rate [15]. The minimization of surface roughness and maximization of material removal rate are optimized using ANN. The experiments are designed using design of experiments and ANOVA analysis is also carried out to find the adequacy of the process. The green machining characteristics of Al 6063 in CNC milling using Taguchi and Grey relational method are studied [16]. Green machining is performed in two conditions viz. dry conditions and MQL conditions. It is concluded that industries should practice dry machining conditions since it causes no pollution, lower disposal and cleaning cost and non-toxic for health and environment. Several optimization process are in existence to determine the optimal machining process parameters such as Taguchi technique, Response surface methodology, Taguchi Grey relational analysis, Desirability function analysis and so on [17-20].

The objective of the work is to maximize the material removal rate in turning mild steel using Taguchi six sigma technique. The six sigma methodology is integrated to evaluate the process capability, performance improvement, etc. The optimized parameters are evaluated and validated to ensure reproducibility. This work combines Taguchi technique and six sigma methodology to enhance productivity in turning mild steel and maintains stability and quality in the turning process.

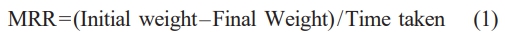

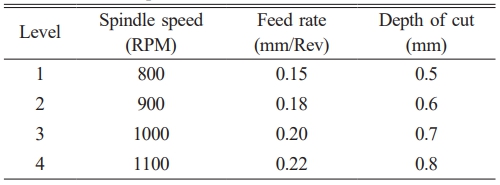

All the experiments are conducted on a CNC Turning machine using a high speed steel single point cutting. Mild steel is used as a work piece to optimize the material removal rate. The primary objective of this research work is maximizing the material removal rate during turning of mild steel using single point cutting tool. Dry machining is performed to enhance the green manufacturing to reduce the pollution. The turning operation is carried out using a single cutting tool in a CNC machine having a spindle speed of 2500 rpm. The turning operation tool used for turning of mild steel is carbide tipped general purpose tool. The workpiece used in this work is Mild steel (AISI 1020). The mild steel possess Tensile strength of 350–450 MPa, Yield Strength of 250–300 MPa, Hardness of 110–140 BHN. The workpiece of cylindrical bars with 25 mm in diameter and 150 mm in length are turned to measure material removal rate. A single point cutting tool typically a high speed steel is used to turn the wok piece material. The single point cutting tool with the tool nomenclature 8-15-8-10-15-15-0.8 is used to turn the workpiece. The turning operation is carried out for 30 mm length. CNC machines are used for attaining high correctness and low preparing time and the material removal rate is considered to be the response against the cutting parameters. The machining is performed on a CNC machine of varying speeds. The turning process parameters considered in this work are cutting speed, feed rate and depth of cut. Surface roughness are usually measured using Mitutoyo surface tester. This work focuses on material removal rate only and in the future the surface roughness analysis will be carried out. The parameters are selected based on the literature review and manufacturer recommendations for turning of mild steel. Levels are chosen to cover the entire feasible range used in the manufacturing process. The process parameters and its level are show in Table 1. Material removal rate is measured as per the relation given below

Taguchi technique is used by several researchers and six sigma process is applied to increase the quality of the surface part. This work combines Six Sigma approach with Taguchi technique to determine the optimal turning process parameters. Signal to noise ratio is characterized by three categories namely; nominal the best, smaller the better and larger the better. The Six Sigma practice is applied to increase the quality of the machined surface and in this work six sigma practice is used to determine the optimal level of parameters. Six sigma technique is combine with Taguchi technique for optimizing the turning process parameters.

The general steps followed in the Taguchi six sigma technique are as follows;

a) Problem definition

b) Selection of process parameter and its levels

c) Experimental design using Taguchi method

d) Conducting Experiments

e) Calculation of S/N ratio

f) Analysis of Variance (ANOVA)

g) Integration of six sigma tools

h) Determination of optimal combination

i) Validation experiment

j) Process capability analysis

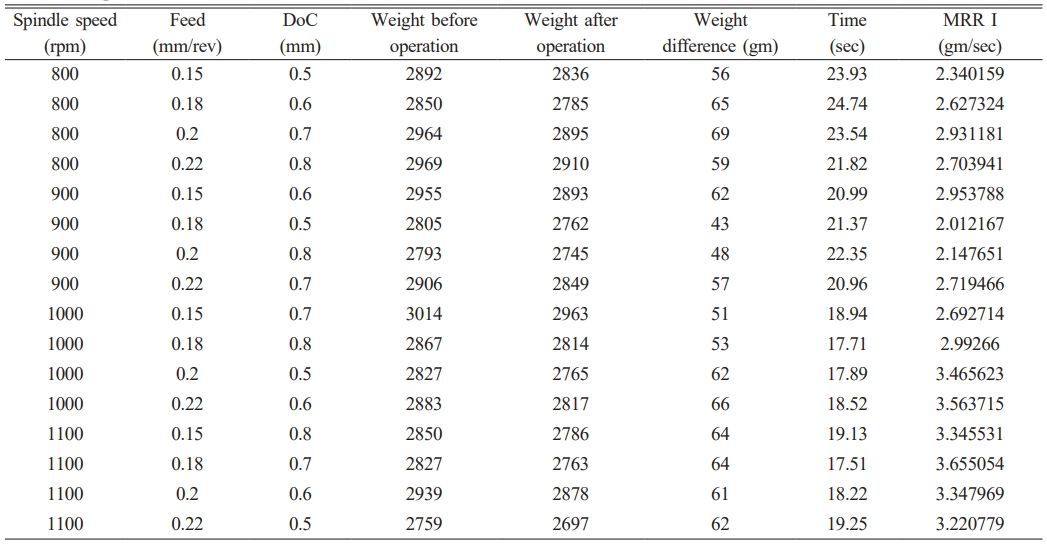

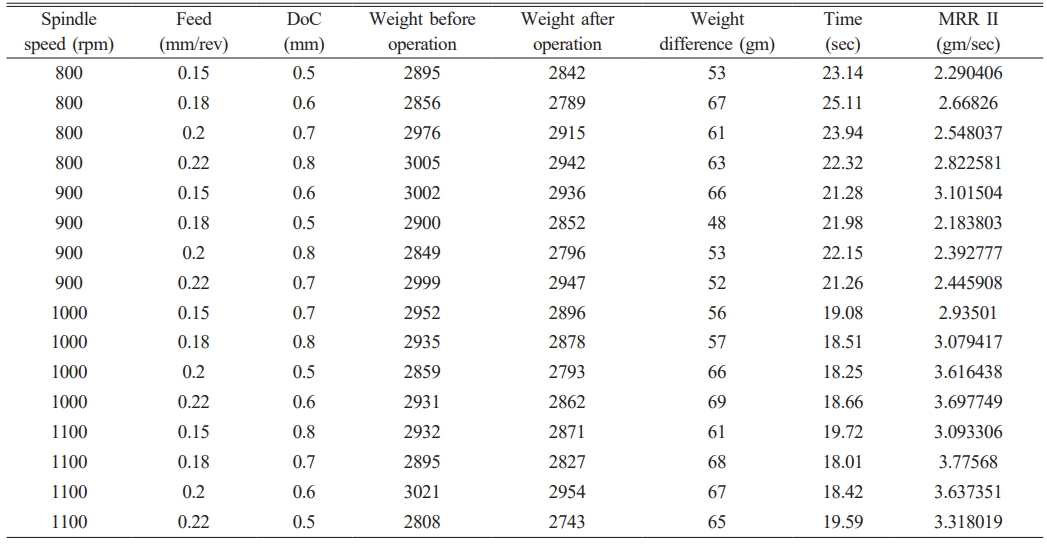

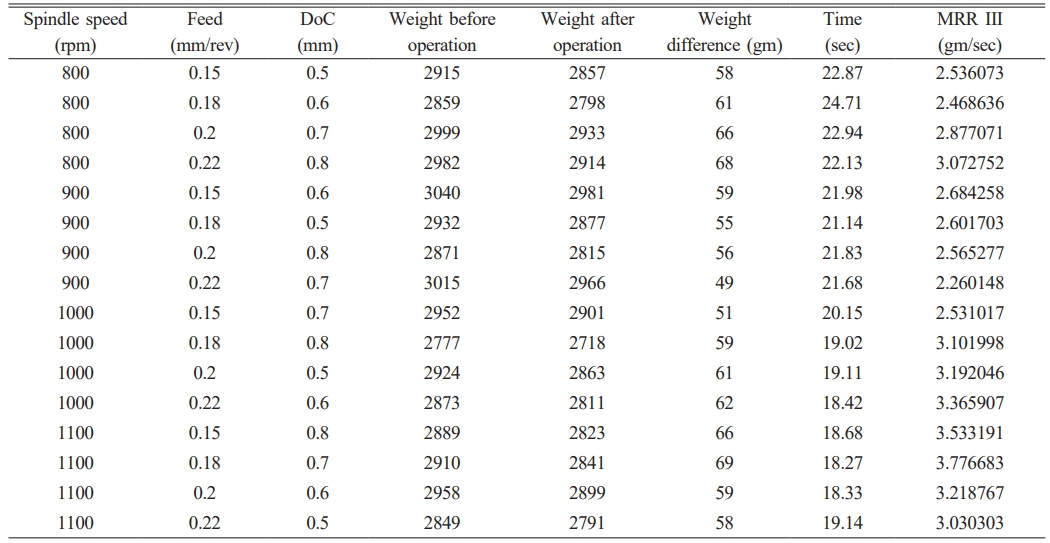

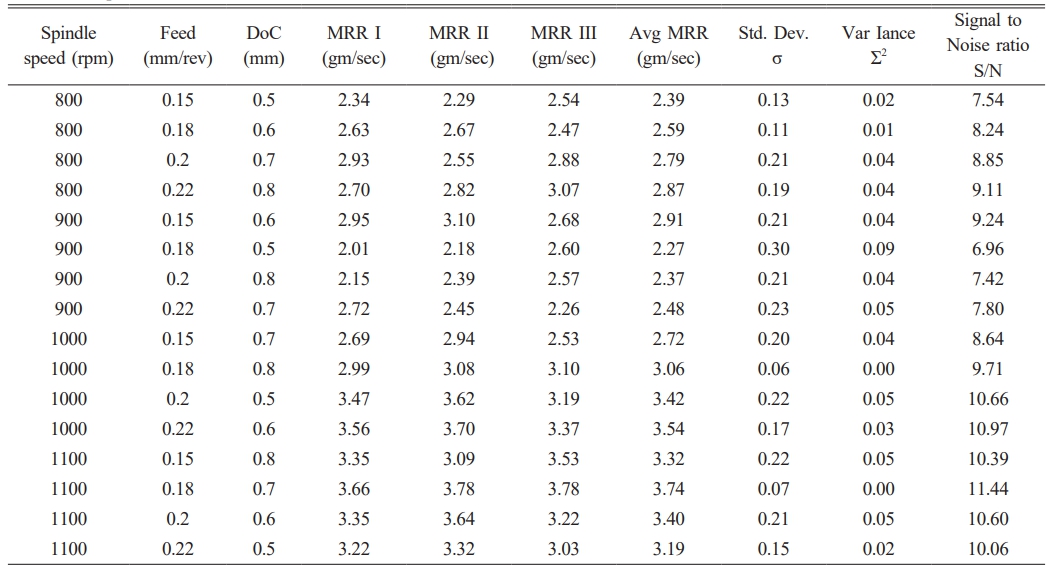

Design of experiments is used to reduce the number of experiment and to determine the optimum value that provides the maximum material during turning of mild steel. As per the orthogonal array of experiments, sixteen experiments are conducted with four levels of different speed, depth of cut and feed rate. L16 can handle upto 15 degrees of freedom. L16 provides a good compromise between the accuracy and feasibility and it is statistically accurate to process multiple process parameters and reduces the number of experiments without losing the ability to analyse factor effects. For each parameter combination, three runs are performed and the average of material removal rate is recorded and presented in Table 2, Table 3 and Table 4 respectively. MRR is measured in volume based or weight based. A digital balance is used to measure the weight of the workpiece before machining and after machining. The difference in this weigh will give the amount of material removed during the turning process. In volume based measurement, the product of cutting speed, feed rate and depth of cut will provide the amount of material removed during the turning process. In this work, the weight based measurement is used to calculate the MRR during turning of mild steel. The larger the better characteristic is used in this work to maximize the material removal rate during turning of the mild steel bar. S/N ratio characteristics are determined and presented in Table 5.

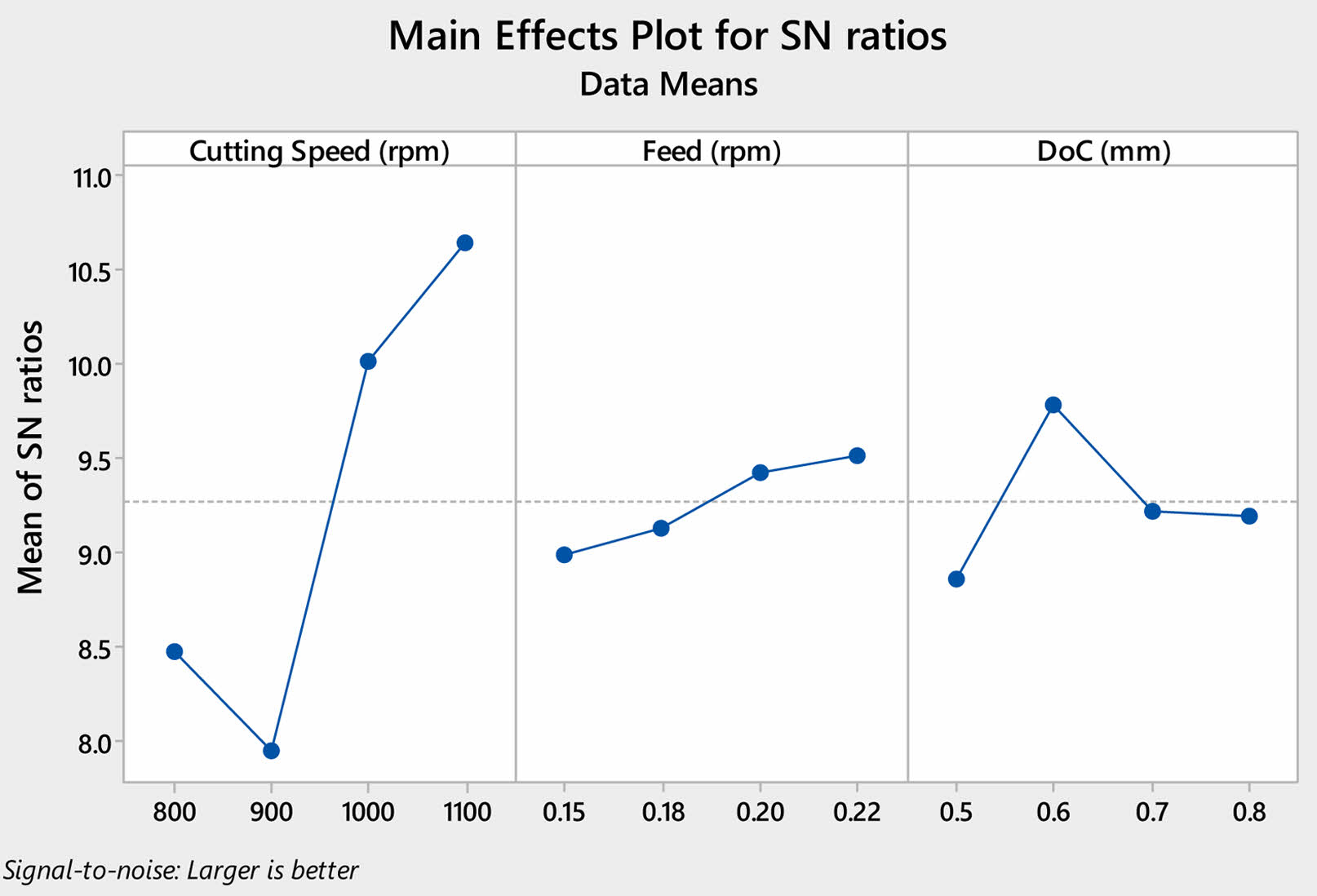

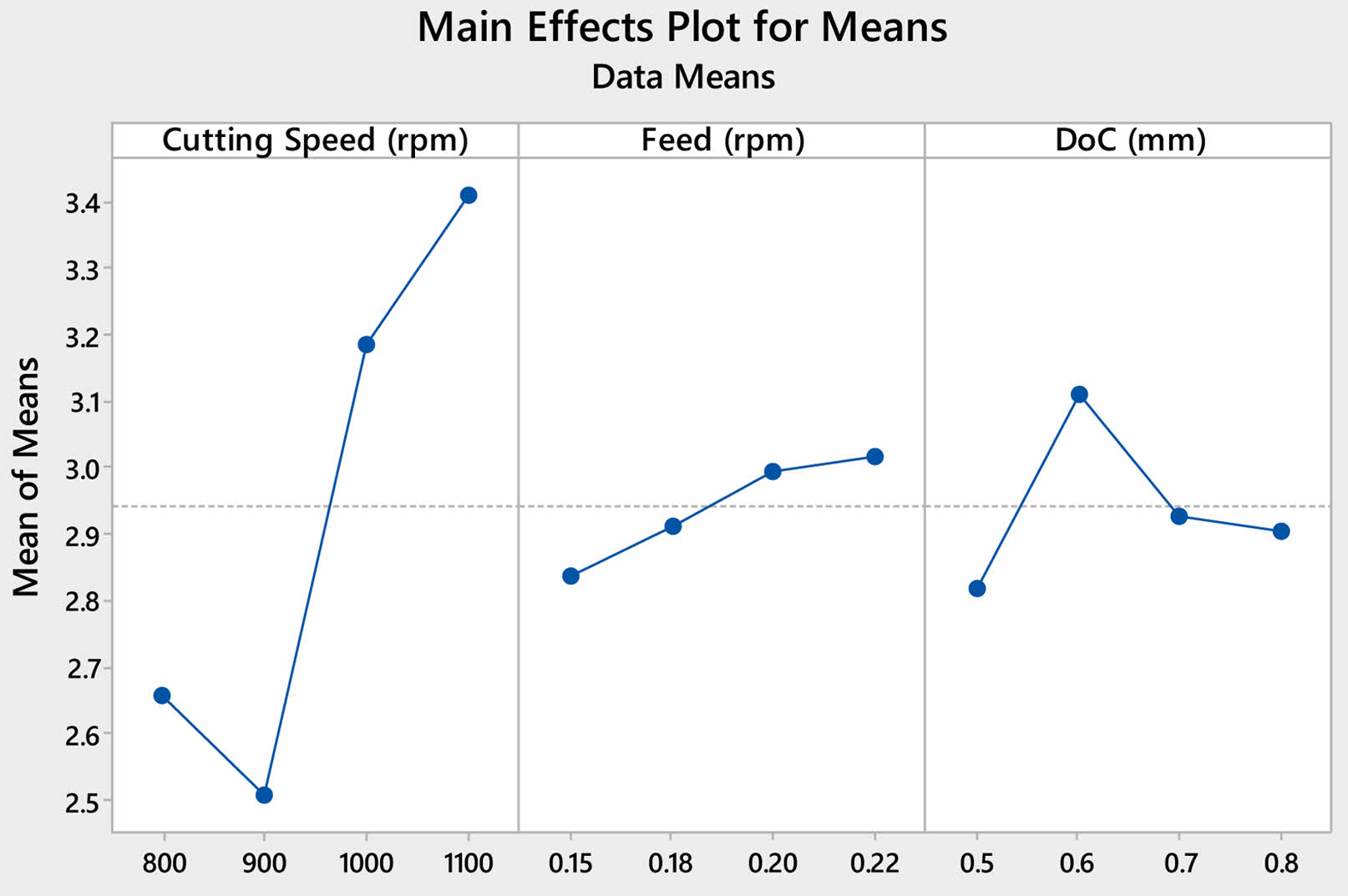

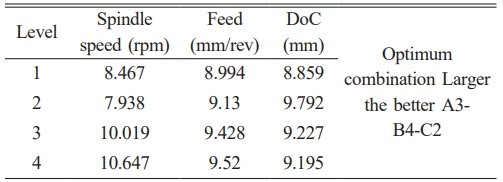

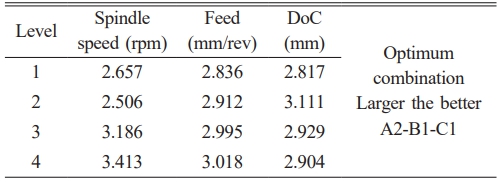

Figure 1 and Figure 2 represents the Main effects plots for signal to ratio for material removal rate and means for material removal rate respectively. The optimal parameters combination for signal to ratio values for turning process is A3-B4-C2, which gives cutting speed as 1000 rpm, feed rate 0.20 mm/rev and depth of cut 0.8 mm. Similarly the from the response table for means, the optimum parameters for maximum material removal rate is observed as A2-B1-C1, which gives cutting speed 900 rpm, feed rate 0.15 mm/rev and depth of cut 0.5 mm. A confirmation test is also validated for the turning process after obtaining the optimal results and is observed that the standard deviation and mean value of data are improved. Validation experiments are conducted for the optimal combinations A3-B4-C2 and it is observed that the maximum material rate is 3.9 gm/sec is calculated. The optimal parameters will provide the best insights to the industrial applications for improving the production rate. The average material removal rate is recorded to be 3.95235 gm/sec and it is observed to be the best result providing the maximum material removal rate. Table 7

|

Fig. 1 Main effects plots for S/N ratio for Material removal rate. |

|

Fig. 2 Main effects plots for Means for Material removal rate. |

Taguchi optimization technique is used in this work to determine the optimal turning parameter while turning mild steel. Six sigma analysis is used to reduce the production cost and to improve the manufacturing process quality. L16 orthogonal array is used to conduct the experiments and three trials are carried out. Totally 48 experiment are conducted as per the combinations given by the experimental design and material removal rate is calculated and recorded. Taguchi Six sigma technique is used to optimize the optimal turning process parameters and it is observed that A3-B4-C2 combination provides the best optimal process parameter to provide maximum material removal rate. The optimal parameters for cutting speed are 1000 rpm, feed rate is 0.2 mm/rev and depth of cut is 0.8 mm and the validation experiments are conducted and the material removal rate is found to be improved in the turning process.

- 1. T. Palaniappan and P. Subramaniam, Mater. Today Comm. 38 (2024) 108425.

-

- 2. C. Mgbemena, G. Etebenumeh, and F. Ashiedu, Niger. J. Technol. 35[4] (2016) 847-854.

-

- 3. R. Butola, Jitendrakumar, Vaibhavkhanna, P. Ali, and V. Khanna, Mater. Today Proc. 4[8] (2017) 7892-7902.

-

- 4. J. Lv, R. Tang, W. Tang, S. Jia, Y. Liu, and Y. Cao, J. Cleaner Prod. 193 (2018) 128-139.

-

- 5. S. Dinesh, K. Rajaguru, and V. Vijayan, Mech. Mech. Eng. 20[4] (2016) 451-466

- 6. D.B. Arulappan and V. Durairaj, Matéria (Rio de Janeiro), 29[4] (2024) e20240255.

-

- 7. G. Narendranath and J. Udaya prakash, Mater. Today. Proc. 92[1] (2023) 424-429.

-

- 8. M. Kumar, S.K. Tamang, D. Devi, M. Dabi, K.K. Prasad, and R. Thirumalai, J. Ceram. Process. Res. 23[3] (2022) 373-382.

-

- 9. K. Fuat, B. Nurettin, and A. Mahir, Eng. Sci. 26 (2023) 961.

- 10. S. Poria, P. Sahoo, and G. Sutradhar, Silicon. 8 (2016) 591-599.

-

- 11. M.W. Azizi, O. Keblouti, L. Boulanouar, and M.A. Yallese, Struct. Eng. Mech. 73[5] (2020) 501-513.

-

- 12. S.R.G. Krishnan, P. Muthiah, and M. Jaganathan, Matéria (Rio de Janeiro) 28[2] (2023) e20230086.

-

- 13. M.N. Akhtar, T. Sathish, V. Mohanavel, A. Afzal, K. Arul, M. Ravichandran, I.A. Rahim, S.S.N. Alhady, E.A. Bakar, and B. Saleh, Materials (Basel) 14[16] (2021) 4470.

-

- 14. T. Singh, V.K. Sharma, M. Rana, K. Singh, and A. Saini, Mater. Today Proc. 50[2] (2022) 2288-2293.

-

- 15. M. Mia, P.R. Dey, M.S. Hossain, M.T. Arafat, M. Asaduzzaman, M.S. Ullah, and S.M.T. Zobaer, Measurement 122 (2018) 380-391.

-

- 16. P.J. Reddy and D. Vinodh, J. Phys. Conf. Ser. 2484 (2023) 012037.

-

- 17. S. Kumar, S. Gurusamy, V. Sivakumar and S.M. Vaiyapuri, J. Ceram. Process. Res. 23[6] (2022) 869-877.

-

- 18. M. Sivaperumal, R. Thirumalai, S. Kannan, and Y.K.S. S. Rao, J. Ceram. Process. Res. 23[3] (2022) 404-408.

-

- 19. R. Thirumalai, J.S. Senthilkumaar, P. Selvarani, and S. Ramesh, Proc. Inst. Mech. Eng., Part C: J. Mech. Eng. Sci. 227[9] (2013) 1889-1897.

-

- 20. R. Thirumalai, J.S. Senthilkumaar, P. Selvarani, R.M. Arunachalam, and K.M. Senthilkumaar, Aust. J. Mech. Eng. 10[2] (2012) 157-168.

-

This Article

This Article

-

2025; 26(5): 864-869

Published on Oct 31, 2025

- 10.36410/jcpr.2025.26.5.864

- Received on Jul 23, 2025

- Revised on Aug 11, 2025

- Accepted on Sep 2, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- Senthil Kumar Natarajan

-

Department of Mechanical Engineering, Ganesh College of Engineering, Salem, India

Tel : +91 9994322766 - E-mail: Senthilnatarajanpdd@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.