- Balancing mechanical strength and surface texture in porous ceramics for handicraft design

Zhenpeng Zhao*

Huanghe Science and Technology University, Zhengzhou, Henan 450006, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Porous ceramic structures are perfect for contemporary craft applications where both functionality and aesthetics are needed because they combine strength and surfaces that can be customized. This study investigates the effects of controlled porosity and pore size distribution (50-300 µm) on the surface characteristics and structural performance of ceramic forms meant for artisanal use. According to conceptual analysis, compressive strengths of 20 to 50 MPa are adequate for both functional and ornamental applications. The creation of complex shapes and textured finishes is made possible by the interconnected pore network, which lowers bulk density and improves tactile qualities. The results provide a framework for optimizing ceramic designs for modern craft practices by highlighting the connection between porosity, pore geometry, and mechanical behavior. In order to create lightweight, long-lasting, and adaptable products that combine traditional artistry and material engineering, this work offers design guidelines for incorporating porous ceramics into craft applications.

Keywords: Modern craft, Porous ceramics, Handicraft design.

Porous ceramics have emerged as a versatile class of materials that combine mechanical integrity with distinctive structural and aesthetic properties. They have gained value in a variety of engineering domains due to their lightweight nature, adaptable surface morphology, and capacity to accommodate interconnected pore networks [1]. Their ability to allow fluid transport, promote chemical interactions, and replicate natural tissue environments has long been exploited in applications like filtration, catalysis, thermal insulation, and biomedical scaffolds [2]. Controlled porosity and pore architecture, which directly control strength, density, permeability, and surface properties, are the main sources of these functional qualities [3]. Porous ceramics have long been used in the industrial and biomedical fields, but relatively little research has been done on their potential applications in artisanal and decorative design [4]. In modern craft practice, materials are being assessed more and more for their capacity to communicate aesthetic expression, tactile engagement, and cultural value in addition to their structural performance. Given their longstanding connection to craftsmanship, ceramics offer an ideal setting for this investigation [5]. However, the emphasis on hardness, rigidity, and polished finishes in traditional dense ceramics may limit design diversity and creative material expression. Porous ceramics, on the other hand, present special opportunities like translucency, ease of handling, complex surface textures, and lower raw material usage, that closely correspond with contemporary trends in sustainable and artistic design [6].

Specifically, regulating porosity (30-60%) and pore

size distribution (50-300 µm) gives designers and artists a range of adjustable parameters to strike a balance between aesthetics and functionality. While higher porosity allows for expressive textures and lighter material weight, lower porosity levels may result in smoother surfaces ideal for delicate decorative objects. In a similar vein, coarser pores add rough, organic visual and tactile characteristics, while fine pores can produce elegant, minimalist designs. Crucially, porous ceramics in this range continue to have compressive strengths of 20 to 50 MPa, which are adequate for a variety of functional and aesthetic applications [7]. Porous ceramics are an appealing but underutilized option in craft applications because of their dual ability to preserve utility while enhancing artistic versatility. Additionally, porous ceramics provide environmental benefits as sustainability becomes a crucial aspect of design [8]. Because of their lower bulk density, they require less energy and materials to manufacture and transport. Green design principles, which emphasize reducing ecological impact without compromising creativity, are strongly aligned with this property. Porous ceramics may therefore be a crucial component in promoting sustainable craft practices by bridging the gap between the fluidity of artistic expression and the accuracy of materials engineering [9].

A conceptual framework for directing the incorporation of porous ceramics into decorative and craft applications is presented in this work. This method, in contrast to conventional experimental research, is based on published mechanical data and established theoretical connections between structural performance, pore geometry, and porosity. The goal is to offer design-oriented insights and useful guidelines that can benefit material scientists, designers, and artisans alike, rather than to duplicate laboratory-based characterization. By doing this, this study aims to highlight the cultural, aesthetic, and sustainable potential of porous ceramics in modern craft, expanding their application beyond technical domains.

Instead of using experimental methods, this study uses a conceptual framework to investigate the functionality and aesthetics of porous ceramics for craft applications. Porosity, pore size distribution, and compressive strength are the main design parameters taken into account because they collectively control surface properties and structural integrity. In order to balance mechanical strength and weight reduction, porosity in the range of 30 to 60% is used, allowing ceramics to maintain their robustness while being simpler to handle and transport. Pore sizes ranging from 50 to 300 µm are chosen to allow for different tactile and visual effects; coarser pores produce expressive, organic textures that are appropriate for decorative detailing, while finer pores contribute to smooth, refined surfaces.

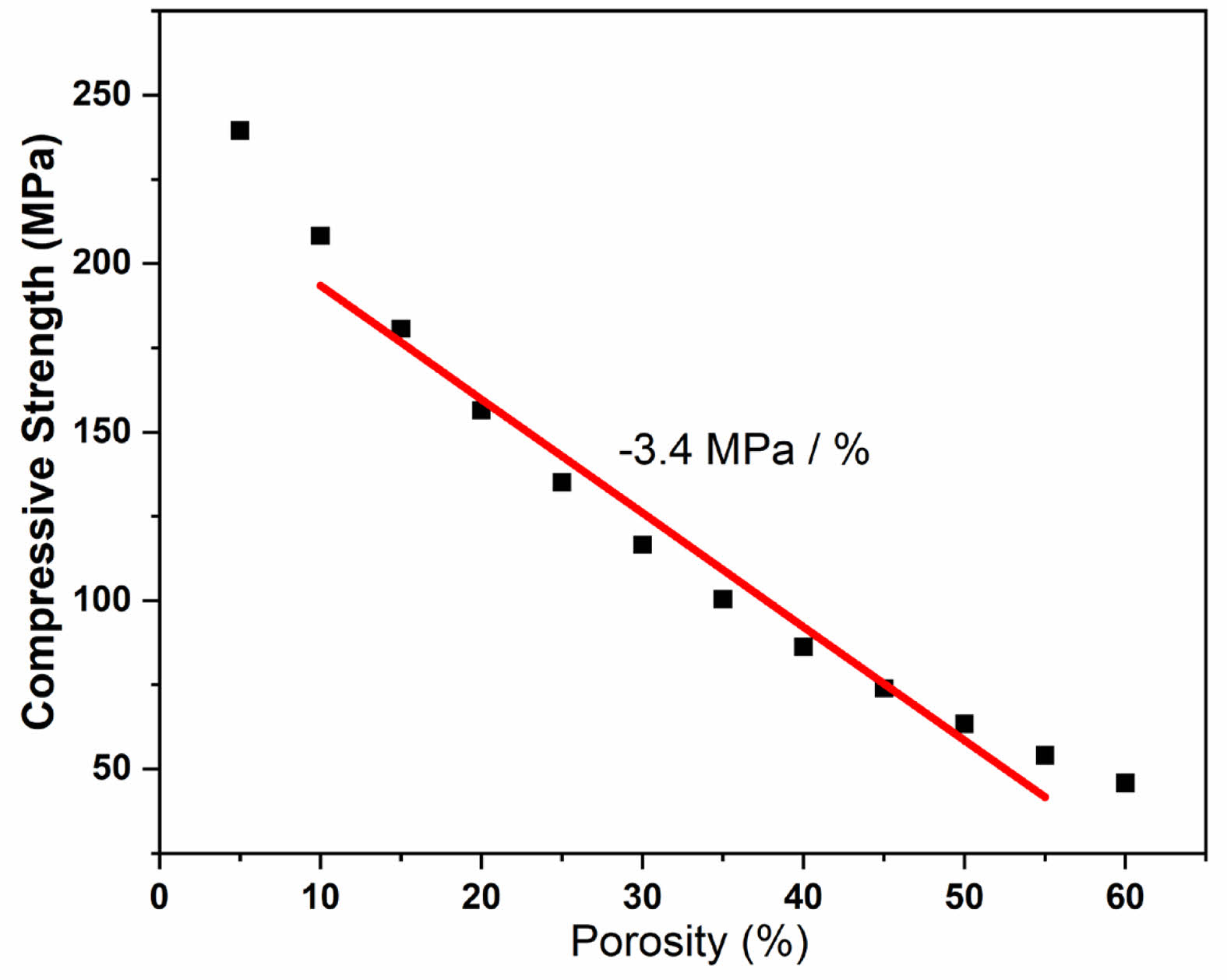

In porous ceramics intended for craft applications, the findings shown in Figs. 1-3 illustrate the interdependence of porosity, pore size distribution, and mechanical performance. In line with well-established models of porous ceramics, a pronounced inverse relationship between porosity and compressive strength was found (Fig. 1). Structural performance is extremely sensitive to changes in porosity, according to the slope analysis (3.375 MPa per % porosity, averaged across the studied range). Interestingly, the mid-porosity range (20-60%) is where strength degradation is most noticeable, with small increases in porosity leading to significant strength decreases. In porous ceramics intended for craft applications, the findings shown in Figs. 1-3 illustrate the interdependence of porosity, pore size distribution, and mechanical performance. In line with well-established models of porous ceramics, a pronounced inverse relationship between porosity and compressive strength was found (Fig. 1). Structural performance is extremely sensitive to changes in porosity, according to the slope analysis (3.375 MPa per % porosity, averaged across the studied range). Interestingly, the mid-porosity range (20-60%) is where strength degradation is most noticeable, with small increases in porosity leading to significant strength decreases [10, 11].

The slope flattens above 50% porosity, suggesting that since the ceramic is already structurally limited, more porosity has less of an impact on further weakening. This behavior gives artisans a quantitative guideline: porosities between 30 and 40 percent represent the ideal balance where adequate strength is maintained while achieving the aesthetic and functional benefits of porosity. For purely decorative items, this asymptotic behavior offers a design safe zone where minimal structural requirements are met while lightweight construction and aesthetic variation are preferred [12].

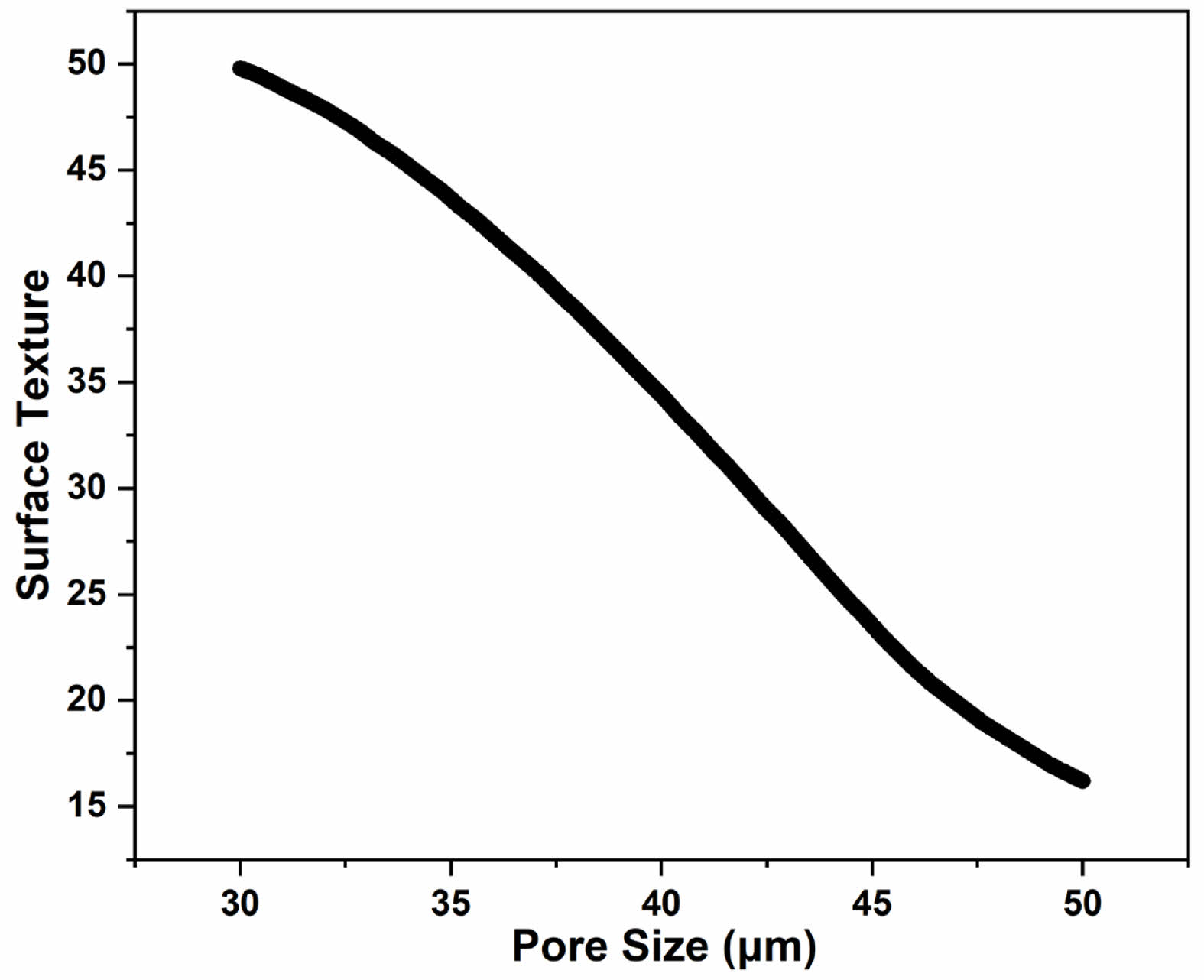

The relationship between pore size and surface texture, as depicted in Fig. 2, further demonstrates the multipurpose function of porosity in influencing the sensory attributes of ceramics. Higher surface texture indices are produced by pores smaller than 100 μm, which results in more tactile definition and finer visual details. In artisanal crafts that prioritize ornamentation, engraving, or complex geometric motifs, these qualities are highly prized [13]. On the other hand, designs aiming for translucency, visual minimalism, or polished finishes may benefit from smoother surfaces with lower texture indices produced by larger pore sizes (>200 μm). This demonstrates the dual nature of porous ceramics from the standpoint of craft design: depending on the chosen pore size distribution, they can either enhance fine details or encourage smoothness. Expanding creative expression while maintaining structural coherence is made possible by the conceptual tuning of this property through material design.

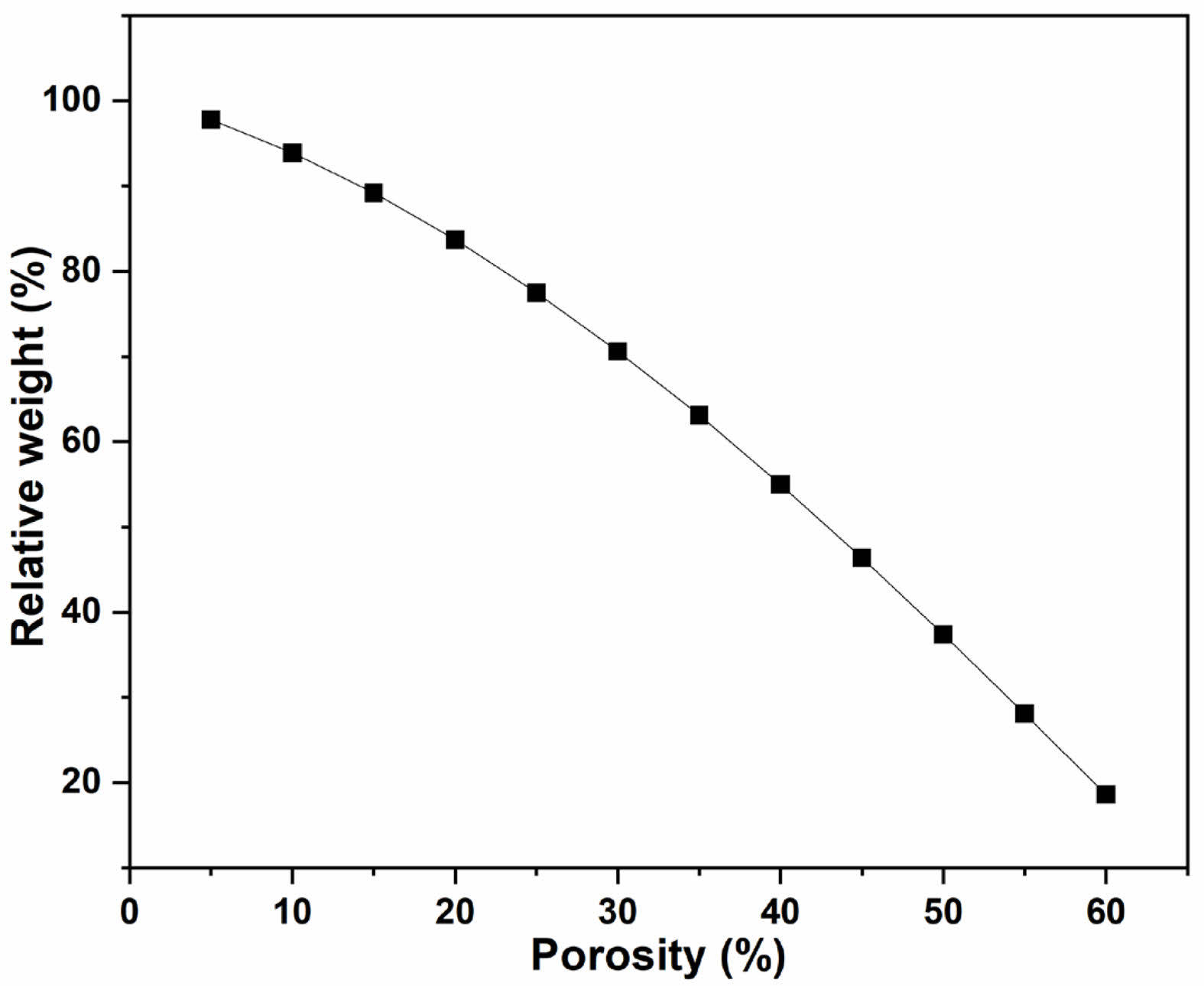

Another crucial aspect of porous ceramic design is weight reduction, as seen in Fig. 3. The direct decrease in bulk density is reflected in the nearly linear decrease in relative weight with increasing porosity, which has both environmental and practical advantages. Lighter ceramics are more manageable to shape, fire, and finish, reducing the physical strain on craftspeople and increasing the practical size of handcrafted items. Additionally, by consuming fewer raw materials and using less energy for transportation, lighter weights promote sustainability. In sustainable craft practices, where reducing ecological impact is becoming more and more important, this weight-porosity relationship offers quantifiable proof that porous ceramics can adhere to green design principles without completely sacrificing durability.

Together, these three relationships, porosity versus relative weight, pore size versus surface texture, and porosity versus strength, are taken into account. The findings show that designers and artisans must make careful trade-offs: pore size regulates tactile quality but can change translucency and detail resolution; porosity increases lightness and aesthetic versatility but reduces strength; and weight reduction increases sustainability but must be weighed against the final object’s functional needs [14]. These trade-offs highlight the benefits of a methodical approach, in which the choice of material is guided by predictable correlations backed by data on mechanical and aesthetic performance rather than by trial and error.

Crucially, the current analysis draws attention to the underutilized potential for transferring engineering knowledge into craft and design settings. Although porous ceramics have been thoroughly researched for use in biomedical scaffolds, filtration, and catalysis, their use in artisanal and decorative applications is still relatively new. This study offers a framework for closing this gap by quantifying the connections between structural and aesthetic qualities. For instance, a functional serving plate may need porosity below 30% and smaller pores to preserve strength and surface refinement, while a ceramic lamp with high translucency could be optimized by choosing a porosity above 45% with pore sizes exceeding 200 μm. For designers looking to combine contemporary material engineering with traditional artistic practices, these mappings are useful resources.

|

Fig. 1 Relationship between porosity and compressive strength of porous ceramic samples. The results indicate a negative correlation, where increasing porosity leads to a systematic reduction in strength. The slope (3.375 MPa per % porosity) highlights the sensitivity of structural performance to porosity changes. |

|

Fig. 2 Variation of relative weight with porosity in porous ceramic structures. As porosity increases, bulk density and relative weight decrease significantly, enabling the production of lightweight components suitable for both functional and decorative applications. The trend underlines the advantage of porosity for sustainable material use. |

|

Fig. 3 Effect of pore size on surface texture index. Larger pores correspond to smoother tactile surfaces and reduced surface detail, while smaller pores provide higher texture indices that enhance decorative intricacy. This relationship emphasizes the trade-off between aesthetic resolution and tactile smoothness in ceramic design. |

This work emphasis on sustainability and cultural innovation has wider implications. The ability to create ceramics that are lightweight, strong, and aesthetically pleasing promotes resource-efficient production, which

is especially important for artisanal industries with modest scale but significant cultural value. Placing porous ceramics in this context advances the conversation between technology and craftsmanship as well as material science. By encouraging collaborative innovation, this integrated viewpoint can help material scientists and artisans create ceramic products that are both environmentally conscious, functional, and artistically expressive.

- 1. H. Xiong, A. Shui, Q. Shan, S. Zeng, X. Xi, and B. Du, Mater. Chem. Phys. 267 (2021) 124699.

-

- 2. M. Maréchal, E. del Campo Estrada, G. Moulin, G. Almeida, P. Lv, G. Cuvelier, and C. Bonazzi, Mater. Sci. Eng., A 780 (2020) 139153.

-

- 3. A. Tığlı and T. Çağın, in A case study on metal-ceramic interfaces: wetting of alumina by molten aluminum2018 (Trans Tech Publ, 2018) p. 185-189.

-

- 4. X. Tang, Z. Zhang, X. Zhang, W. Huo, J. Liu, S. Yan, and J. Yang, J. Polym. Res. 25[6] (2018) 136.

-

- 5. J. Liu, Y. Li, S. Yan, Z. Zhang, W. Huo, X. Zhang, and J. Yang, Int. J. Appl. Ceram. Technol. 15[3] (2018) 643-652.

-

- 6. C. Feng and H. Janssen, Build. Environ. 134 (2018) 21-34.

-

- 7. X. OuYang, F. Yin, J. Hu, Y. Liu, and Z. Long, J. Ph. Equilibria Diffus. 38[6] (2017) 874-886.

-

- 8. Z. Wang, X. Liu, B. Xu, and Z. Wu, Int. J. Refract. Met. Hard Mater. 51 (2015) 130-136.

-

- 9. Q.-J. Hong and A. Van De Walle, Phys. Rev. B 92[2] (2015) 020104.

-

- 10. L.Y. Yin, X.G. Zhou, J.S. Yu, H.L. Wang, S. Zhao, Z. Luo, and B. Yang, Key Eng. Mater. 519 (2012) 281-286.

-

- 11. J. Yu, J. Yang, H. Li, and Y. Huang, J. Porous Mater. 19[5] (2012) 883-888.

-

- 12. L.J. Gibson, MRS Bull. 28[4] (2003) 270-274.

-

- 13. G. Kaptay, G. Csicsovszki, and M.S. Yaghmaee, in An absolute scale for the cohesion energy of pure metals2002 (Trans Tech Publ, 2002) p. 235-240.

-

- 14. G. Fairbank, C. Humphreys, A. Kelly, and C. Jones, Intermetallics 8[9-11] (2000) 1091-1100.

-

This Article

This Article

-

2025; 26(5): 839-842

Published on Oct 31, 2025

- 10.36410/jcpr.2025.26.5.839

- Received on Sep 15, 2025

- Revised on Oct 2, 2025

- Accepted on Oct 2, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- Zhenpeng Zhao

-

Huanghe Science and Technology University, Zhengzhou, Henan 450006, China

Tel : +86-18790287656 Fax: +86-0371-88857000 - E-mail: zhaozhenpeng2024@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.