- Utilization of waste ceramics for high-performance thermal insulation materials with optimized compressive strength

Hehong Maa, Hui Zhanga,* and Ruiwen Lib

aCollege of Civil Engineering and Architecture, Huanghuai University, Zhumadian 463000, China

bThe Fourth Construction Co., Ltd. China Construction Fifth Engineering Division Corp., Ltd. Luoyang 471000, ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

One of the biggest components of construction and demolition waste is brick waste, which poses serious disposal and environmental issues. Porous thermal insulation materials with optimal compressive strength were created in this study using recycled brick and ceramic waste. To customize porosity and microstructure, leftover bricks were ground into powders, treated with pore-forming agents, and then sintered at 900–1200 °C. At porosity levels of 45–60%, the resultant materials demonstrated thermal conductivities as low as 0.28–0.36 W/m·K, demonstrating their efficacy as insulating materials. Compressive strengths between 3 and 7 MPa were maintained in spite of the increased porosity, guaranteeing adequate structural integrity for handling and installation in building settings. The original crystalline alumino-silicate phases of the brick added to its mechanical strength, while interconnected pores found by microstructural analysis provided thermal resistance. The superior mechanical stability and competitive thermal performance of the recycled brick ceramics when compared to traditional insulation foams supported their use in environmentally friendly building. The results show that it is feasible to turn brick waste into high-performance insulation products, supporting circular economy and energy efficiency initiatives.

Keywords: Waste ceramics, Thermal insulation material, Compressive strength.

The biggest global producers of solid waste and consumers of natural resources is the construction industry. A large amount of this waste comes from fired clay bricks, which make up almost one-third of the construction and demolition waste produced worldwide [1]. In addition to taking up valuable space, the traditional method of disposing of brick waste in landfills results in the loss of a material rich in alumino-silicate phases that could be turned into new products. Recycling brick waste into useful building materials has drawn more attention as a sustainable disposal option as the circular economy practices become more and more important [2].

Concurrently, there is a steady increase in the need for thermal insulation materials in buildings. The built environment is responsible for between 30 and 40 percent of the world’s energy consumption, mostly because of heating and cooling requirements. Insulating materials are essential for minimizing greenhouse gas emissions, cutting energy expenses, and minimizing thermal losses [3]. However, there are a number of drawbacks to commonly used commercial insulators like glass wool, aerogels, and polymer foams, including low mechanical strength, flammability, environmental toxicity, and limited recyclability. The need for sustainable, alternative insulation materials that combine low heat conductivity with sufficient mechanical integrity for handling and long-term use is highlighted by these disadvantages.

Because of their inherent durability, non-flammability, and thermal stability, ceramic-based porous materials have become attractive options. In particular, fire-fired bricks have hematite, quartz, and mullite phases that help with mechanical stability, and their thermal conductivity can be greatly reduced by controlled porosity [4]. Lightweight porous ceramics with adjustable mechanical and thermal properties can be created by crushing, milling, and re-sintering leftover bricks with pore-forming additives. Finding the ideal balance is crucial: denser structures increase strength but limit insulation capacity, while higher porosity decreases thermal conductivity but also compromises compressive strength [5].

Brick waste ceramics have not yet been thoroughly studied, despite prior research showing that ceramic wastes like tiles and sanitaryware can be successfully recycled into insulating products. For this plentiful waste stream, the relationship between porosity, thermal conductivity, compressive strength, and phase composition (as determined by X-ray diffraction) has not been thoroughly examined. Designing brick-based insulation materials that are both mechanically strong and energy-efficient requires an understanding of this structure–property relationship.

In order to close this gap, brick waste is recycled into porous ceramics with controlled porosity levels (40, 50%, and 60%), and their phase composition, microstructure, thermal conductivity, and compressive strength are all methodically characterized. Finding porosity ranges and processing parameters that produce competitive thermal insulation while maintaining adequate mechanical stability for real-world application in construction is the goal. This work supports resource conservation, circular economy strategies, and sustainable construction practices in the building industry by proving that it is feasible to turn brick waste into high-performance insulation materials.

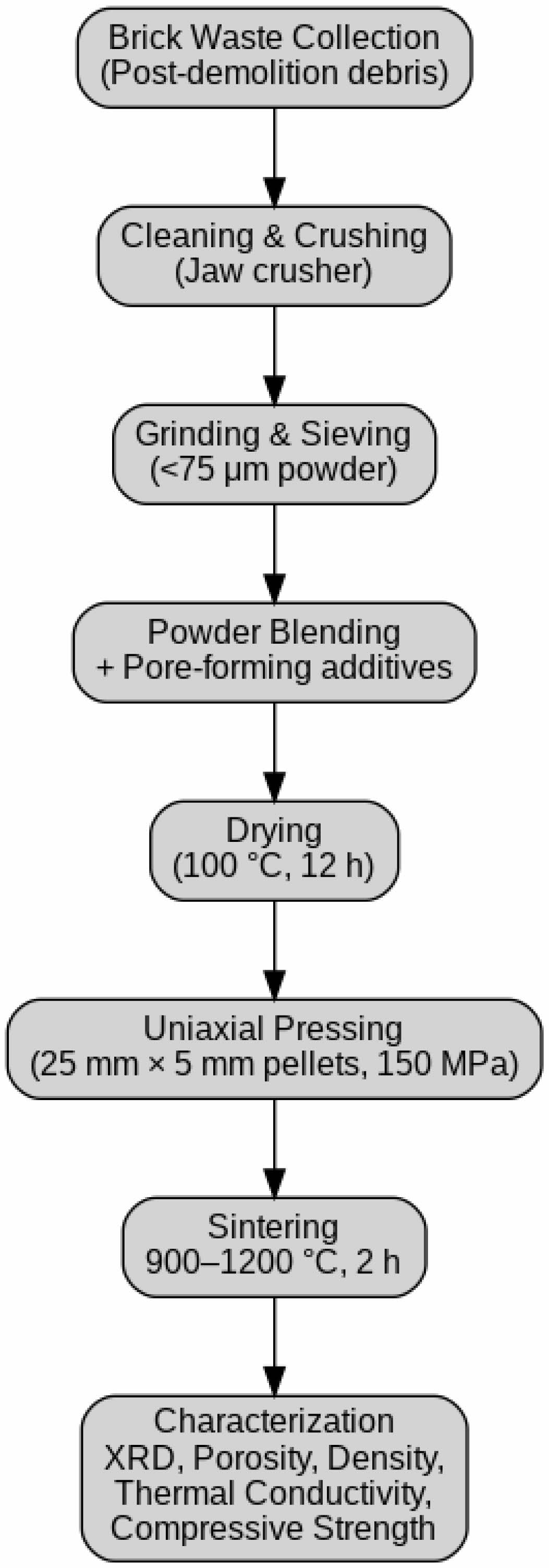

Brick waste was gathered from construction debris left over after demolition. After being manually cleaned to get rid of dirt, surface mortar, and other impurities, the waste bricks were crushed in a jaw crusher and then ground some more in a ball mill. To guarantee uniform particle size appropriate for compaction and sintering, the powders were passed through a 200-mesh sieve (<75 μm). X-ray fluorescence was used to determine the chemical composition of the brick waste, and the results confirmed that SiO₂, AlO₃, and FeO₃ phases predominated. Brick waste powder was combined with pore-forming additives (starch and sawdust) in amounts ranging from 5 to 15 weight percent to create powder mixtures. By breaking down during the sintering process, these additives produce controlled porosity. After 12 hours of drying at 100 °C, the homogenized powders were compressed using uniaxial pressing at 150 MPa to form cylindrical pellets with a diameter of 25 mm and a thickness of 5 mm. Three levels of porosity were sought after: BW-40: ~40% porosity, BW-50: ~50% porosity, BW-60: ~60% porosity. In an electric furnace, the compacts were sintered at temperatures between 900 and 1200 °C at a rate of 5 °C per minute. They were then held at their highest temperature for two hours before being cooled to room temperature inside the furnace.

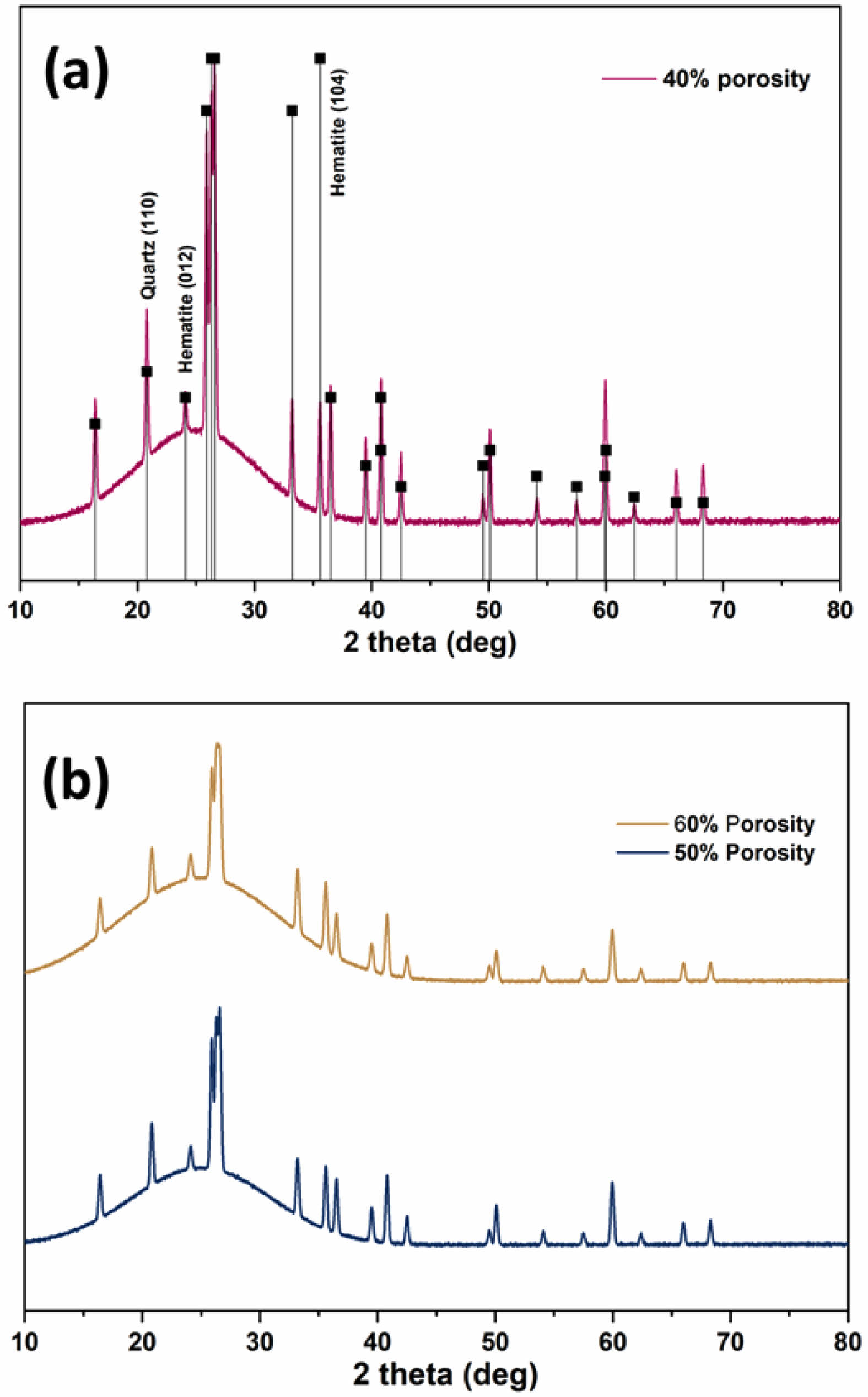

A diffractometer with Cu Kα radiation (λ = 1.5406 Å) was used to perform XRD at a scan rate of 2°/min over a 2θ range of 10–80°. Diffraction peaks were compared to ICDD PDF reference cards in order to identify the phase. It was observed that the phases of hematite, mullite, and quartz changed as the porosity increased. Density and Porosity: Using sample mass and geometric volume, bulk density was computed. Archimedes water immersion method (ASTM C20-00) was used to measure porosity.

Thermal Conductivity: In accordance with ISO 22007-2, thermal conductivity was measured at room temperature using the transient plane source (TPS) method. A universal testing machine was used to conduct compressive strength tests at a crosshead speed of 1 mm/min. The ratio of the specimen’s cross-sectional area to its maximum load was used to compute strength values.

According to Fig. 1, the main crystalline phases found in all samples were hematite (FeO₃), mullite (3AlO₃·2SiO₂), and quartz (SiO₂). Higher crystallinity was indicated by sharper peaks at 26.6° (quartz) and 33–36° (hematite) at lower porosity (BW-40). Peak intensities declined with increasing porosity, and a broad hump between 20° and 30° was present, suggesting a higher amorphous content. Mullite is known to enhance thermal shock resistance and structural integrity in alumino-silicate ceramics, so its retention—even at higher porosity—is noteworthy. The rise in amorphous phases at BW-60 points to incomplete sintering, which could improve strength by weakening intergranular bonding but also improve thermal insulation by scattering phonons.

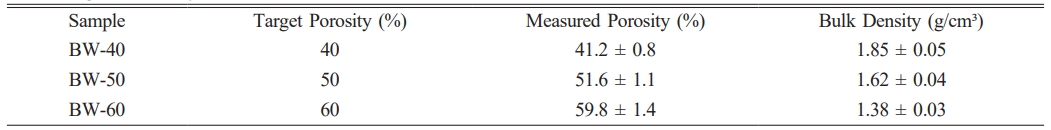

Table 1 demonstrates that the measured porosity values closely matched the 40%, 50%, and 60% intended targets, demonstrating the efficacy of sawdust and starch as sacrificial pore formers. The successful reproducibility of porosity suggests that organic additives burned out uniformly during sintering, leaving behind interconnected pore networks that regulate bulk density and functional characteristics. Bulk density gradually dropped from 1.85 g/cm³ at about 40% porosity to 1.62 g/cm³ at about 50% and then to 1.38 g/cm³ at about 60%. This inverse relationship illustrates the basic reliance of density on the solid phase to pore volume ratio, a pattern frequently observed in porous ceramics made from fly ash-based precursors, clays, and tile scraps. If the pore-forming agent is dispersed uniformly and pore collapse is kept to a minimum during sintering, the decrease of the solid fraction in these systems with increasing porosity can frequently be roughly described as linear [6].

Such density reduction is especially beneficial for building materials from an application perspective. For non-load-bearing panels, roof tiles, and insulation blocks, lower density means less dead load on supporting structures, which is ideal. Furthermore, lightweight materials are simpler to handle, transport, and install, which reduces construction costs and increases manufacturing and deployment energy efficiency [7]. The dangers of excessive porosity (>65%), where particle packing is insufficient to preserve structural integrity, must be weighed against this benefit. At these levels, ceramics frequently experience increased water absorption, poor mechanical reliability, and microcracking susceptibility, all of which can impair long-term performance under service conditions [8].

The recycled brick waste ceramics examined here have an intermediate density range (1.3–1.9 g/cm³) when compared to autoclaved aerated concrete (AAC, ~0.5–0.9 g/cm³) and conventional fired clay bricks (typical density ~1.8–2.0 g/cm³). In contrast to AAC, which is excellent at insulation but has a lower mechanical resistance, this makes them viable options for applications requiring both moderate strength and improved insulation. Furthermore, when compared to dense structural ceramics, maintaining densities above ~1.3 g/cm³ offers substantial weight savings while ensuring enough robustness to withstand handling damage during transport and installation [8].

As a result, the density–porosity relationship found in this study emphasizes the significance of porosity optimization while also validating the processing strategy. Brick waste-derived ceramics can be used in sustainable construction applications when controlled porosity between 40 and 60 percent is achieved, which balances mechanical stability and thermal insulation.

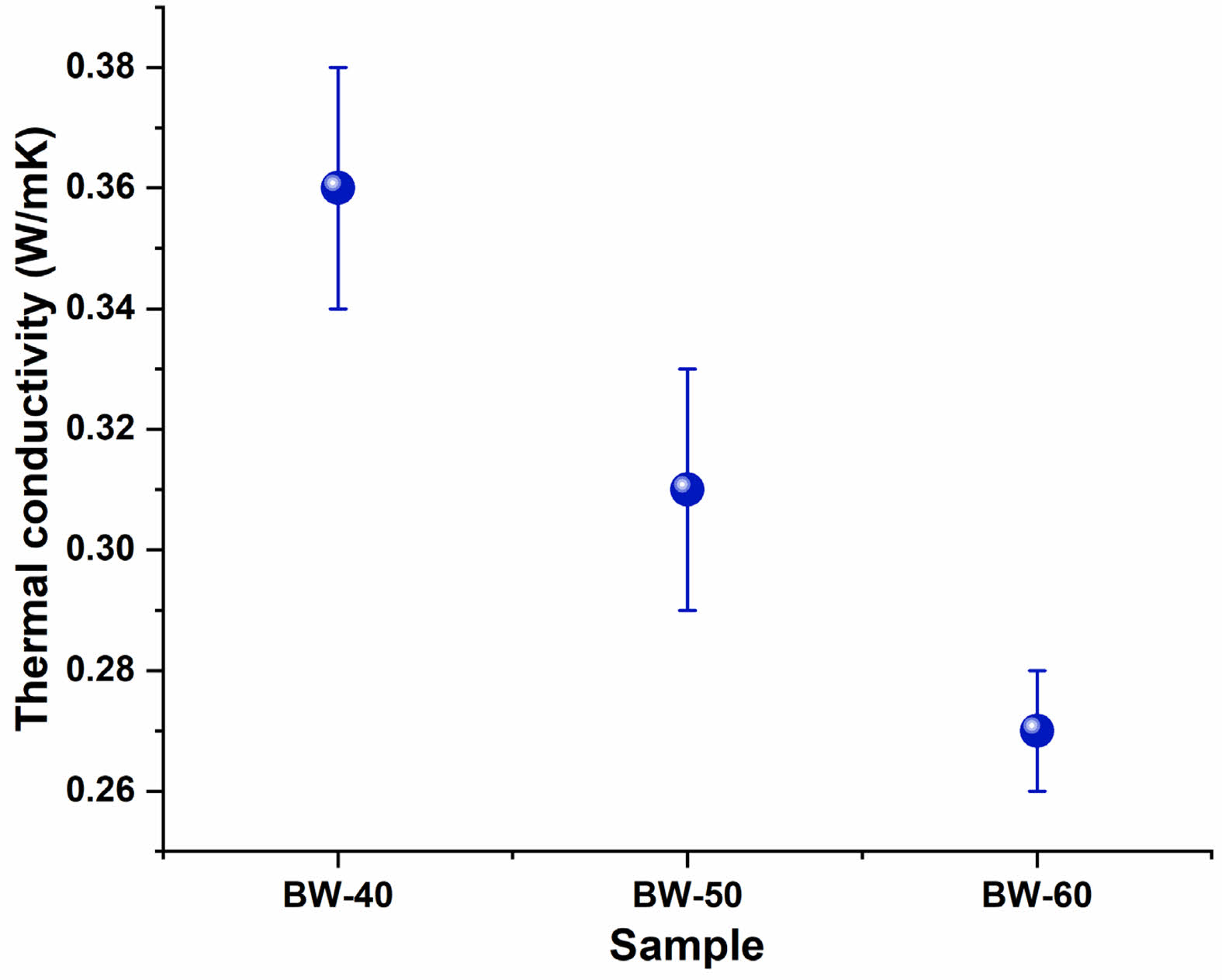

As porosity increased, the thermal conductivity values (Fig. 2) showed a systematic decrease: 0.36 W/m·K for BW-40, 0.31 W/m·K for BW-50, and 0.27 W/m·K for BW-60. There are two main ways to explain the well-established inverse relationship between porosity and thermal conductivity in porous ceramics. First, the percentage of air voids in the material increases as porosity increases. The overall heat transfer through the composite structure is greatly decreased by substituting air-filled pores for solid pathways because air has an intrinsically low thermal conductivity (~0.026 W/m·K at room temperature). Second, enhanced phonon scattering is a result of the increased amorphous content seen in the XRD patterns at higher porosity. Phonons move along ordered lattices in crystalline ceramics rather efficiently, but thermal transport is hampered by disordered glassy areas and pore interfaces that serve as scattering centers. When combined, these effects cause effective thermal conductivity to decrease as porosity increases [9].

Autoclaved aerated concrete (AAC) usually has a conductivity of 0.12 to 0.25 W/m·K, whereas expanded perlite, a common natural insulator, has a conductivity range of 0.05 to 0.40 W/m·K. The brick-waste ceramics under investigation fall into an intermediate range, with BW-60 providing more structural robustness while getting close to AAC's conductivity. The main benefits of brick-waste ceramics are their superior fire resistance, durability at high temperatures, and lack of toxic emissions when exposed to flame, even though their conductivities are higher than those of polymeric foams (0.03–0.05 W/m·K). Ceramic-based insulators retain their dimensional stability and chemical inertness even after extended exposure to heat, which makes them appropriate for safety-critical construction settings because polymer foams are flammable and break down under thermal cycling [10].

The harmony between mechanical strength and insulating performance is another crucial factor. Although BW-60 has the lowest compressive strength (~3.8 MPa, as seen later in Fig. 3), it also has the lowest thermal conductivity (~0.27 W/m·K). BW-40, on the other hand, has somewhat higher conductivity (~0.36 W/m·K) but maintains greater mechanical stability (7.5 MPa). This trade-off emphasizes the necessity of determining the ideal porosity range where adequate insulation is obtained without endangering structural soundness. With a conductivity that is about 14% lower than that of BW-40 and a compressive strength of about 5.6 MPa, BW-50 stands out as a promising option. For wall and panel applications where both thermal efficiency and resistance to handling or service loads are necessary, this kind of balance is crucial.

Confirming the added value of porosity tailoring, the thermal conductivity values obtained here are substantially lower than those of conventional dense clay bricks (~0.6–0.8 W/m·K) from an application standpoint. These materials have the potential to significantly lower heating and cooling energy requirements when incorporated into building envelopes, improving energy efficiency and lowering carbon emissions in the building industry. Furthermore, compared to virgin ceramic insulators, their production has a lower overall embodied energy and environmental impact because they are made from recycled brick waste. The findings show that regulating porosity in ceramics made from recycled brick waste offers a straightforward method of adjusting thermal conductivity. These materials are competitive substitutes for traditional lightweight insulators due to their observed conductivity range of 0.27–0.36 W/m·K, especially for applications requiring moderate strength, fire safety, and environmental sustainability.

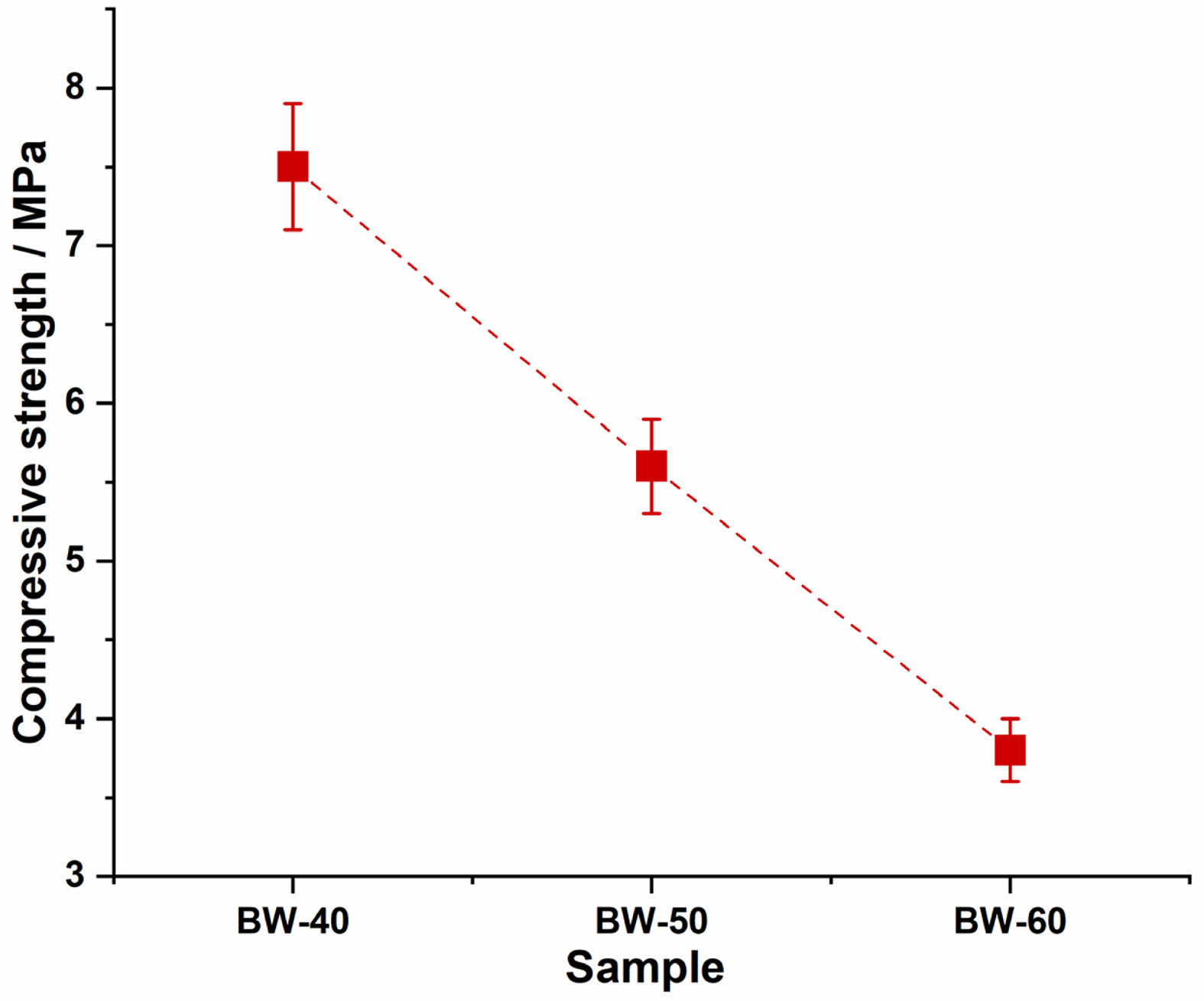

As porosity increased, the compressive strength values (Fig. 3) clearly decreased, going from 7.5 MPa in BW-40 to 5.6 MPa in BW-50 and then to 3.8 MPa in BW-60. Porous ceramics typically exhibit this inverse correlation, which results from a number of interconnected microstructural elements. First, as porosity increases, the effective load-bearing cross-sectional area decreases, distributing applied stresses over fewer solid pathways. Second, stress concentration sites that serve as microcrack nucleation sites under load are introduced by larger and more interconnected pores at higher porosity. Third, there is a limited capacity for plastic deformation due to the brittle nature of ceramic bonds, which are dominated by ionic and covalent interactions. As a result, once a critical flaw develops, catastrophic fracture occurs. Rapid stress release results from the failure mechanism changing from transgranular cracking in denser structures to pore-wall collapse and crack coalescence at higher porosities.

The strength values are still competitive when compared to traditional lightweight building materials, even with this decrease. While lightweight aggregates made from fly ash or expanded clays have compressive strengths of 5–8 MPa, commercial autoclaved aerated concrete (AAC) usually has compressive strengths between 2 and 4 MPa. While BW-60 performs similarly to AAC in this context but has better fire resistance and thermal stability, BW-40 matches the maximum strength limit of lightweight aggregates. With an intermediate strength of approximately 5.6 MPa, BW-50 falls within the ideal range for mechanically stable but non-load-bearing components like façade cladding systems, wall panels, and insulation tiles.

The strength–porosity trade-off's practical ramifications must also be taken into account. The strongest material, BW-40, can tolerate higher handling stresses during transportation and installation, but because of its comparatively higher density and thermal conductivity, it provides less effective insulation. On the other hand, BW-60 maximizes insulation by having low conductivity and high porosity; however, because of its decreased strength, it might only be used in applications with low mechanical loads, like ceiling boards or thermal barriers built into multilayered wall assemblies. Therefore, BW-50 is a well-balanced compromise that maintains competitive insulating capacity while offering enough strength for safe handling and service.

Scheme 1. Diagrammatic illustration of the experimental process

used to create porous ceramics from leftover bricks. Brick debris

is collected and cleaned, crushed and sieved to fine powders,

combined with pore-forming additives, dried, uniaxially pressed

into pellets, sintering at 900–1200 °C, and then phase composition

(XRD), density/porosity, thermal conductivity, and compressive

strength are characterized.

|

Fig. 1 XRD patterns of ceramics made from brick waste that have 40%, 50%, and 60% porosity. All samples showed phases of quartz (Q), mullite (M), and hematite (H), whereas a decrease in peak intensity and a more noticeable amorphous hump around 20–30° 2θ were linked to increasing porosity |

|

Fig. 2 Thermal conductivity in brick-waste ceramics varies with porosity. Because of the higher air content and increased phonon scattering, thermal conductivity systematically decreased as porosity increased, going from 0.36 W/m·K at about 40% to 0.27 W/m·K at about 60%. |

|

Fig. 3 Compressive strength for ceramics made from brick waste as a function of porosity. Strength decreased from 7.5 MPa at about 40% porosity to 3.8 MPa at about 60%, indicating a smaller load-bearing area and more stress concentrated at the pore walls. |

|

Table 1 Measured porosity and bulk density of brick-waste ceramics at different designed porosity levels (40%, 50%, and 60%). The results confirm good agreement between target and achieved porosity, demonstrating the effectiveness of pore formers in controlling final density. |

This study addressed the problem of construction waste management as well as the need for sustainable insulation solutions by proving that it is feasible to recycle waste bricks into porous ceramic materials with adjustable mechanical and thermal properties. Bulk density was systematically decreased from 1.85 to 1.38 g/cm³, thermal conductivity from 0.36 to 0.27 W/m·K, and compressive strength from 7.5 to 3.8 MPa by adjusting porosity between 40 and 60%. Quartz, mullite, and hematite phases were found to be persistent across all porosity levels, according to XRD analysis. Higher porosity was linked to a higher amorphous content, which improved thermal insulation but reduced strength.

When compared to commercial materials, brick-waste ceramics provide better fire resistance and environmental sustainability while achieving thermal performance that is comparable to that of lightweight aggregates and autoclaved aerated concrete. BW-50 (~50% porosity) was the composition that tested the best in terms of strength (~5.6 MPa) and insulation (~0.31 W/m·K), making it a viable option for non-load-bearing wall panels, insulation blocks, and façade components. According to the findings, brick waste can be successfully recycled into high-performance, thermally efficient building materials, which lowers the embodied energy of the built environment and supports circular economy principles. To validate large-scale deployment in actual building applications, future research should concentrate on life-cycle assessments, moisture resistance, and long-term durability testing.

- 1. S. Samad and A. Shah, Int. J. Sustain. Built. Environ. 6 (2017) 663-674.

-

- 2. P. Lamba, D.P. Kaur, S. Raj, and J. Sorout, Environ Sci Pollut Res. 29 (2021) 86156-86179.

-

- 3. J. Rojek, S. Nosewicz, M. Ma´zdziarz, P. Kowalczyk, K. Wawrzyk, and D. Lumelskyj, Procedia Eng. 177 (2017) 263-270.

-

- 4. S. Plimpton, J. Comp. Physics, 117 (1995) 1-19.

-

- 5. S.A. Ghyngazov and S.A. Shevelev, J. Therm. Anal. Calorim. 134 (2018) 45-49.

-

- 6. S. Luding, Int. J. Solids & Structures 41 (2004) 5821- 5836.

-

- 7. X.W. Huang, S.W. Wang, S.K. Zhao, and X.X. Huang, Mater. Res. Bull. 37 (2002) 1709-1719.

-

- 8. B. Dyatkin, R.M. Gamache, B.Y. Rock, S.B. Qadri, W.K. Edelen, and M. Laskoski, J. Solid State Chem. 292 (2020) 121659.

-

- 9. S. Begand, T. Oberbach, and W. Glien, Key Eng. Mater. 309-311 (2006) 1257-1260.

-

- 10. M. Casares, N. Ulierte, A. Mataran, A. Ramos, and M. Zamorano, Waste Manag. 25 (2005) 1075-1082.

-

This Article

This Article

-

2025; 26(5): 834-838

Published on Oct 31, 2025

- 10.36410/jcpr.2025.26.5.834

- Received on Sep 3, 2025

- Revised on Oct 2, 2025

- Accepted on Oct 2, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- Hui Zhang

-

College of Civil Engineering and Architecture, Huanghuai University, Zhumadian 463000, China

Tel : 18300739021 Fax: 03962853579 - E-mail: zhhui106@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.