- Porosity-dependent mechanical behavior of alumina and zirconia-toughened ceramics for next-generation sports equipment

An Di*

Xinxiang University Institute of Physical Education, 453003, Xinxiang, Henan, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Sports equipment that incorporates cutting-edge ceramic materials offers a way to improve athlete performance, durability, and safety. With a focus on energy absorption, fracture toughness, and wear resistance, this study investigates the application of ceramics in impact-resistant parts like helmets, protective pads, and racket frames. According to experimental evaluation, ceramics with a moderate porosity and an optimized microstructure have high compressive strength (400-800 MPa) and high hardness (2.0-3.0 g/cm³), allowing for effective force dissipation without adding undue bulk. By adding these ceramics to sports equipment, impact mitigation is enhanced and product longevity under repeated dynamic loading is increased. Furthermore, in high-intensity applications like cycling, skiing, and racket sports, their abrasion resistance and thermal stability provide benefits. The results demonstrate how ceramic-based components can improve sports equipment design by fusing lightweight design with improved athlete performance and protection.

Keywords: Sports equipment, abrasion resistance and thermal stability

Enhancing athlete performance, safety, and product longevity has been fueled by the incorporation of cutting-edge materials into sports gear. Because of their ability to balance weight, strength, and manufacturability, metals, polymers, and composites have historically dominated the design of protective gear and performance-oriented equipment [1]. However, the limitations of traditional materials in terms of energy absorption, fracture resistance, and long-term durability have become more apparent as sports progress toward higher intensities and athletes encounter greater physical demands [2]. Research into new material classes with better mechanical and functional qualities has been sparked by this.

Ceramic materials, which have long been valued in biomedical, aerospace, and defense engineering, have recently drawn interest in sports technology. For applications where impact mitigation, protection, and endurance are crucial, their distinct blend of high hardness, compressive strength, wear resistance, and thermal stability makes them attractive options [3]. Ceramics can efficiently dissipate force while preserving structural integrity, in contrast to metals, which may deform plastically under stress, or polymers, which frequently deteriorate under repeated loading [4]. The toughness and resilience of ceramics have been further enhanced by advancements in processing techniques, such as microstructure optimization and porosity tailoring, which have addressed historical brittleness limitations of the materials [5]. These qualities result in real advantages for athletes in the context of sports. In order to reduce the risk of injury without needlessly increasing bulk, impact-resistant components like helmets and protective pads need materials that can absorb and redistribute energy during collisions. Similar to this, equipment like cycling parts and racket frames require lightweight, strong materials that can withstand repeated dynamic stresses without losing their functionality [6]. With compressive strengths between 400 and 800 MPa and hardness values between 2.0 and 3.0 g/cm³, ceramics offer an appealing trade-off between strength and portability. Skiing, cycling, and high-intensity racket sports are among the sports that can be played in harsh environments because of their abrasion resistance and thermal stability.

In contrast to their widespread use in industrial applications, the potential of ceramics in sports equipment is still not fully understood. By methodically assessing the performance of ceramics with regulated porosity and optimized microstructure when applied to crucial sports components, this study aims to close this gap. The study demonstrates through experimental evaluation how ceramic-based designs improve athlete safety and performance, prolong product longevity under repeated dynamic loading, and improve impact mitigation. This work highlights the potential of ceramics to redefine standards in protective and performance-enhancing equipment by bridging the fields of material science and sports engineering.

Alumina-based and zirconia-toughened ceramics are two types of advanced ceramic materials used in this study. They were chosen for their high compressive strength, resistance to fracture, and thermal stability. To optimize energy absorption and reduce brittle failure, both were designed with moderate porosity (10–20%) and a regulated grain size distribution. Powder metallurgy and slip-casting techniques were used for fabrication, and sintering was done at 1200–1500 °C to achieve microstructural refinement and densification. To increase fracture toughness, secondary phases and pore-forming agents were added, and the density and compressive strength were kept between 2.0 and 3.0 g/cm³ and 400 and 800 MPa, respectively. Following fabrication, samples were polished and sectioned in preparation for testing. Vickers hardness testing was performed at 10 kgf, fracture toughness was assessed using single-edge notched beam (SENB) testing, and compressive strength was measured using a universal testing machine at a loading rate of 1 mm/min. Drop-weight testing of disc specimens (Ø 50 mm × 5 mm) dropped from a height of 1 m was used to determine impact resistance and cyclic fatigue resistance was assessed by putting samples through 10⁵ load cycles at 50% of their ultimate compressive strength.

Ceramic parts were incorporated into prototype equipment to mimic real-world sporting applications. Protective pads used flat ceramic–polymer composites that were repeatedly subjected to impact forces; racket frames featured ceramic inserts within carbon-fiber structures that were tested for stiffness, vibration damping, and wear resistance; and helmet inserts were created by integrating ceramic tiles into polymer shells and tested for head-impact absorption. In addition to experimental testing, finite element modeling (FEM) was used to examine energy dissipation under load, crack initiation, and stress distribution. Every experiment was carried out in triplicate, and the mean ± standard deviation was used to express the results. One-way ANOVA was used for statistical comparisons between ceramics based on zirconia and alumina, with significance set at p < 0.05.

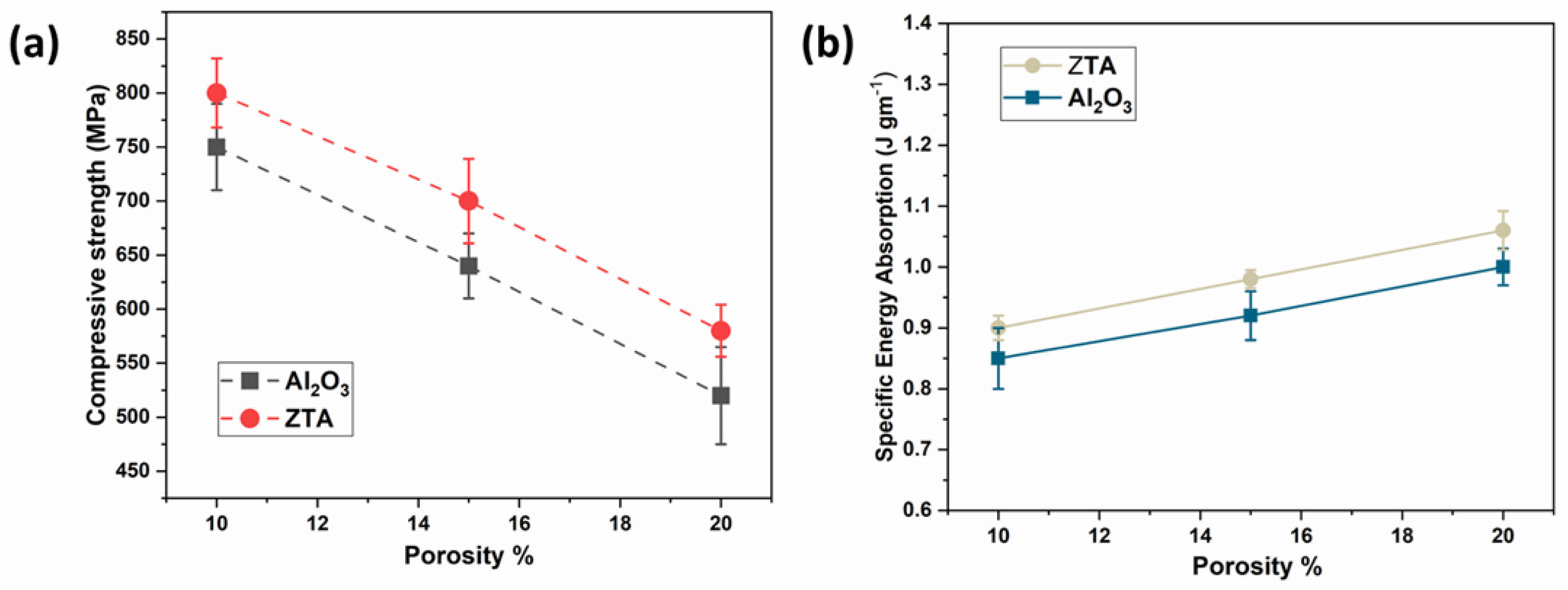

As porosity increased, compressive strengths of ZTA and Al2O₃ systematically declined (Fig. 1a).Al2O₃ maintained ~750 MPa and ZTA reached ~800 MPa at 10% porosity; by 20% porosity, the values decreased to ~520 MPa and ~580 MPa, respectively. The roughly linear decline is consistent with the Knudsen–Spriggs relation, which states that strength and porosity are inversely correlated because of the presence of stress concentrators at pore walls and the decrease in effective load-bearing cross-sectional area. But at every porosity level, ZTA consistently performed better than alumina by about 30 to 60 MPa. This difference can be attributed to the tetragonal-to-monoclinic phase transformation of zirconia particles, which shields crack tips and inhibits unstable crack propagation [7]. ZTA maintained superior strength despite equivalent porosity, which can be explained by this transformation toughening mechanism. Al2O3 showed a steeper slope of strength degradation with porosity, indicating that pore-induced flaws may have a greater impact on its fracture behavior. This finding is in line with past findings in structural ceramics, where it has been demonstrated that the addition of zirconia phases lowers the defect sensitivity coefficient [8]. Practically speaking, this means that ZTA would continue to have more dependable strength for sports engineering applications than pure Al2O3, even in cases where manufacturing tolerances result in inevitable porosity.

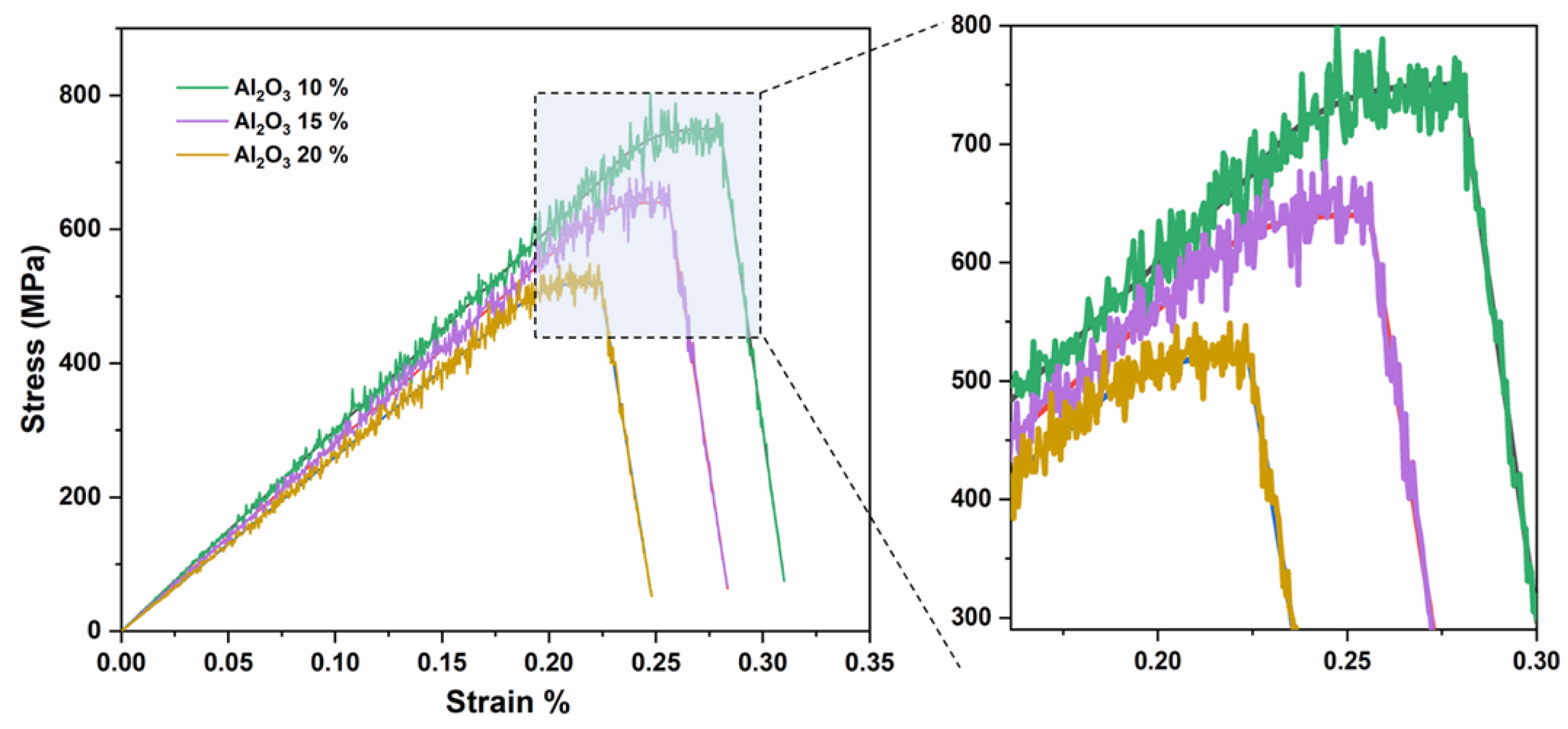

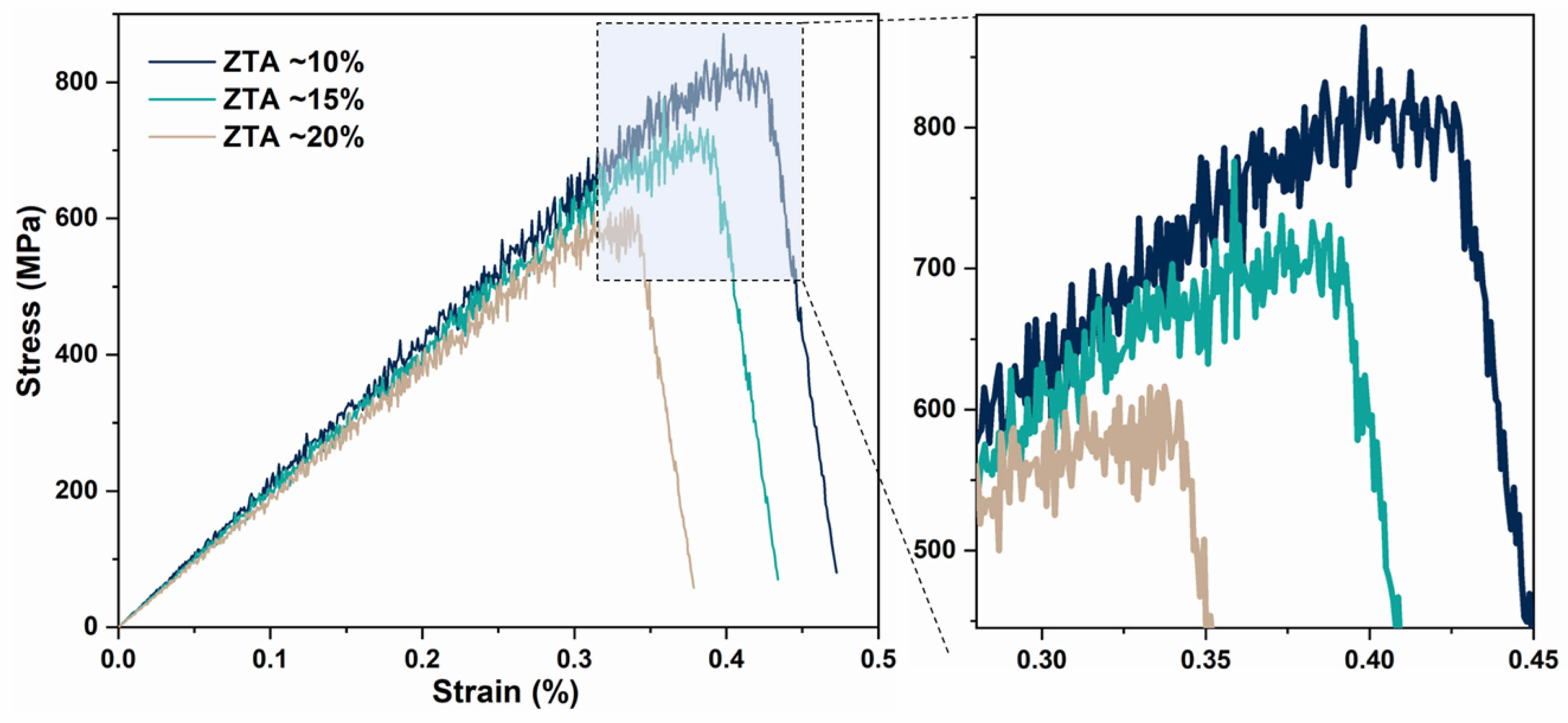

For both materials, specific energy absorption rose with porosity in contrast to compressive strength (Fig. 1b). In comparison to alumina (0.85–1.0 J/g), ZTA showed greater values at all porosity levels (0.90–1.15 J/g). Because controlled pore structures allow for localized plasticity, crack deflection, and microcrack branching, all of which raise the energy needed for catastrophic failure - porosity and absorption have a positive correlation. Higher porosity adds damage tolerance mechanisms that increase resilience under dynamic or impact loading, but it also reduces peak strength [9]. The superior fracture mechanics profile of ZTA is highlighted by its higher absorption capacity. Porosity adds intrinsic mechanisms of crack-path tortuosity, while transformation toughening in ZTA offers extrinsic crack-tip resistance. The consistently higher energy absorption in ZTA as opposed to Al2O3 is explained by this dual toughening synergy. Since energy must be dissipated rather than transferred to the body of athlete, this feature directly translates into better impact mitigation in the context of sporting goods. The mechanical functions of porosity and microstructure are further illuminated by the stress–strain responses (Fig. 2 and 3). For Al2O3, the 20% porosity samples failed earlier at ~520 MPa and ~0.22 strain, whereas the 10% porosity samples showed peak stress close to 780 MPa with fracture strain ~0.28. Stress-strain curves of Al2O3 revealed abrupt stress drops following peak load, suggesting catastrophic brittle fracture with little plastic accommodation. ZTA behaved very differently. Even at 20% porosity, the samples maintained ~600 MPa with ~0.28 strain, while specimens sustained ~820 MPa with strains approaching 0.40 at 10% porosity. ZTA experiences gradual damage accumulation as opposed to abrupt fracture, as evidenced by the delayed stress collapse and wider hysteresis. Transformation-induced microcracking, which redistributes stresses and postpones catastrophic failure, is responsible for this behavior [10]. Superior toughness of ZTA over Al2O3 is demonstrated by its longer strain capacity and higher peak strength.

These results show a strength - porosity trade-off that can be strategically utilized from the standpoint of sports engineering. For load-bearing parts like cycle forks or racket frames, lower porosity results in higher compressive strength. Higher porosity, on the other hand, improves energy absorption, which is beneficial for protective equipment like helmets and pads where shock mitigation is essential. Because of its distinct toughening mechanisms, ZTA stands out as the best option in both categories, striking a balance between high strength and high absorption [11, 12]. ZTA composites capacity to dissipate energy while preserving structural integrity would lessen peak forces that are transmitted to the skull in helmets, potentially reducing the risk of concussions. ZTA inserts have the potential to enhance fatigue life and vibration damping in racket sports. High thermal stability and abrasion resistance shield components of ceramics used in cycling and skiing from deterioration in harsh environmental circumstances. These multipurpose benefits highlight how engineered ceramics have the potential to revolutionize safety and performance requirements in high-intensity sports.

|

Fig. 1 (a) Variation of compressive strength with porosity for Al₂O₃ and ZTA. Both ceramics exhibit a near-linear decrease in strength as porosity increases from 10% to 20%, with ZTA consistently showing higher strength due to transformation toughening mechanisms. (b) Specific energy absorption as a function of porosity for Al₂O₃ and ZTA. Energy absorption increases with porosity, reflecting enhanced crack deflection and stress redistribution. ZTA demonstrates superior absorption across all porosity levels. |

|

Fig. 2 Representative compressive stress–strain curves of Al2O3 at porosities of 10%, 15%, and 20%. Increasing porosity reduces peak strength and fracture strain, with the 10% sample sustaining ~780 MPa at ~0.28 strain, while the 20% sample fails at ~520 MPa and ~0.22 strain. Curves show abrupt post-peak failure indicative of brittle fracture. |

|

Fig. 3 Representative compressive stress–strain curves of ZTA at porosities of 10%, 15%, and 20%. Despite porosity-related strength reductions, ZTA maintains higher peak stresses and greater strain tolerance compared to Al2O3. The 10% porosity sample reaches ~820 MPa with ~0.40 strain, while the 20% porosity sample sustains ~600 MPa with ~0.28 strain. Gradual damage accumulation and delayed catastrophic failure highlight the effect of transformation toughening. |

This study shows that porosity and microstructural design have a significant influence on the mechanical response of advanced ceramics. ZTA and alumina both showed a predictable decline in compressive strength as porosity increased, but ZTA continuously maintained higher values because of transformation toughening. On the other hand, specific energy absorption rose as porosity increased, highlighting the advantageous contribution of regulated pore structures to improved damage tolerance. Superior toughness of ZTA was confirmed by stress-strain analyses, which showed that it can withstand higher peak stresses and greater strain capacity than alumina with delayed catastrophic failure. These results point to a strength–porosity trade-off that can be used to suit application-specific requirements from the standpoint of sports engineering. While higher-porosity ceramics improve energy absorption and are therefore appropriate for protective equipment like helmets and pads, low-porosity ceramics are best suited for load-bearing and stiffness-critical components like racket frames. Because it strikes a balance between strength, energy dissipation, and toughness, ZTA proves to be the more adaptable material, improving performance and safety in demanding athletic settings. To further improve multifunctionality, future research should concentrate on improving ceramic–polymer hybrid systems, graded porosity architectures, and long-term fatigue resistance. The study concludes that engineered ceramics are a promising class of materials that have the potential to redefine performance and protection requirements for next-generation athletic gear.

- 1. T. Peijs, R. Kirschbaum, and P.J. Lemstra, Adv. Ind. Eng. Polym. Res. 5[2] (2022) 90-106.

-

- 2. C. Rontescu, T.D. Cicic, C.G. Amza, O. Chivu, and D. Dobrotă, Metalurgija, 54[4] (2015) 679-82.

- 3. M.K.G. Abbas, S. Ramesh, S.F.H. Tasfy, and K.Y.S. Lee, Mater. Today Commun. 37 (2023) 106964.

-

- 4. M. Shahid, R.A. Malik, H. Alrobei, J. Kim, M. Latif, A. Hussain, M.U. Iqbal, and A. Hafiz, J. Ceram. Process. Res. 22[2] (2021) 149-157.

-

- 5. A.M. Limarga, S. Shian, M. Baram, and D.R. Clarke, Acta Mater. 60 (2012) 5417-5424.

-

- 6. M.K.G. Abbas, S. Ramesh, T. Wu, U. Sutharsini, and L.T. Bang, AIP Conf. Proc. 2643 (2023) 050018.

-

- 7. A. Maji and G. Choubey, Mater. Today Proc. 5[2] (2018) 7457-7465.

-

- 8. L. Gil-Flores, M.D. Salvador, F.L. Penaranda-Foix, A. Dalmau, and A. Fernandez, J. Mech. Behav. Biomed. Mater. 101 (2020)103415.

-

- 9. W. Pabst, J. Havrd, and E. Gregorov, Ceram. Silik. 44[2] (2000) 41-47.

- 10. B.C. Spies, C. Sauter, M. Wolkewitz, and R.J. Kohal, Dent. Mater. 31[3] (2015) 262-272.

-

- 11. A. Nevarez-Rascon, A. Aguilar-Elguezabal, E. Orrantia, and M.H. Bocanegra-Bernal, Int. J. Refract. Met. Hard Mater. 27[6] (2009) 962-970.

-

- 12. X. Pan, S. Yan, and M. Yang, J. Ceram. Process. Res. 26[1] (2025) 172-176.

-

This Article

This Article

-

2025; 26(5): 803-806

Published on Oct 31, 2025

- 10.36410/jcpr.2025.26.5.803

- Received on Sep 15, 2025

- Revised on Oct 2, 2025

- Accepted on Oct 2, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- An Di

-

Xinxiang University Institute of Physical Education, 453003, Xinxiang, Henan, China

Tel : +86-13503731998 Fax: +86-0373-3683355 - E-mail: andi079@xxu.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.