- Improving long-term corrosion resistance of high-performance concrete through the incorporation of micro silica and chemical admixtures

Sivakumar Arunachalama,*, Anandakumar Subbaiyanb, Sampathkumar Velusamyc and Hema Sudhakard

aDepartment of Civil Engineering, Kangeyam Institute of Technology, Tirupur – 638108, India

bDepartment of Civil Engineering, Meenakshi College of Engineering, Chennai – 600078, India

cDepartment of Civil Engineering, Kongu Engineering College, Perundurai – 638060, India

dDepartment of Civil Engineering, Ramakrishna Engineering College, Coimbatore – 641022, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This study investigates the long-term corrosion resistance and mechanical strength of high-performance concrete (HPC) using micro silica and chemical admixtures, including Rheobuild 1100, Glenium Ace 30, Sika Viscocrete 20 HEC, Ecmas HP-901 and Varaplast PC 100. The grade of the concrete adopted was M60 which comprises OPC 53 grade, fly ash, micro silica and fine aggregate and coarse aggregates were used. This study seeks to enhance the workability, strength in mechanics, and longevity of mixtures of concrete characterized by a low water-cement ratio. The results revealed significant improvements in compressive, tensile, flexural and bond strengths compared to control mixes. Durability tests revealed superior resistance to chloride ion penetration, salt ponding, sorptivity, water permeability, and accelerated corrosion for HPC mixes with micro-silica and chemical admixtures. Microstructural inspection using SEM and EDX revealed the densified matrix and increased C-S-H gel formation, which contributed to enhanced durability. Among all the admixtures, Glenium Ace 30 demonstrated superior performance, rendering it an exemplary selection for durable infrastructure.

Keywords: High-performance concrete (HPC), Micro silica, Chemical admixtures, Mechanical properties, SEM, EDX.

In tropical regions such as India, characterized by an extensive coastline exceeding 5,000 km and receiving approximately 80% of its annual precipitation within a just two months, the corrosion of reinforced concrete structures presents a significant issue. The dilemma is exacerbated in urban regions, where emissions of carbon and nitrogen oxides hasten the degradation of concrete by diminishing the efficacy of the cover. Consequently, reinforced concrete structures frequently require substantial repair and rehabilitation approximately 15 years post-construction [1]. Much of the nation's infrastructure is now antiquated, with numerous concrete structures surpassing their designed service life, rendering their ongoing utilization hazardous unless appropriate reinforcement measures are implemented to satisfy contemporary requirements [2]. After analyzing all the data, we still need to protect RCC from Corrosion. The following methodology for my research will provide a better solution for long-term aspects [3].

Concrete structures employed in marine building must endure exceptionally adverse circumstances for prolonged durations. As demonstrated by several facts and practices in engineering, the structure of concrete deteriorates significantly even before its life span, mainly in the construction engineering of the ocean [4]. With mineral admixtures, high-performance concrete (HPC) has a higher cementitious content than water content [5]. As it is more resistant than regular concrete to all types of harmful ions, it is frequently employed in ocean construction engineering [6, 7]. To improve and refine the distribution of the pore size of concrete, a calculated amount of admixtures can be added to the cement paste [8], thereby reducing the large number of pores, which eventually increases the number of connected small pores that fill in the cement and aggregate pores in different amounts. These required actions help to improve the performance of concrete by increasing its density [9]. Numerous studies have demonstrated that the addition of mineral admixtures to concrete increases its durability. Chalee demonstrated that replacing more micro silica and fine aggregates in concrete significantly reduces steel corrosion and chloride penetration [10, 11]. In this study, the long-term corrosion resistance of high-performance concrete (HPC) was investigated using various mineral and chemical admixtures, including Rheobuild 1100, Glenium ACE 30, Sika Viscocrete 20 HEC, Ecmas HP-901 (p), and Varaplast PC 100 [12, 13]. The objective was to develop concrete mixes capable of resisting long-term corrosion under extreme environmental conditions, as typically encountered in ocean construction. The mix design aims to achieve a water-cement ratio lesser for M60 grade concrete to enhance workability, mechanical strength, and durability [14-16].

To assess the mechanical properties of the concrete, split tensile strength, compressive strength, flexibility, and pull-out tests were conducted in line with IS requirements. Additional assessments, including the Rapid Chloride Penetration test, Salt Ponding, Sorptivity, permeation of water evaluations, and Accelerated Chloride Migration tests, have been performed to ascertain the durability of concrete and its resilience against hostile situations [17]. Additionally, SEM and EDX analyses were performed to analyze the microstructure of the concrete [18]. Furthermore, to evaluate the uniformity and integrity of the concrete, the Ultrasonic Pulse Velocity (UPV) was assessed. This study seeks to illustrate the capacity of micro silica and additives to improve the corrosion resistance and durability of high-performance concrete in marine environments.

Materials Used

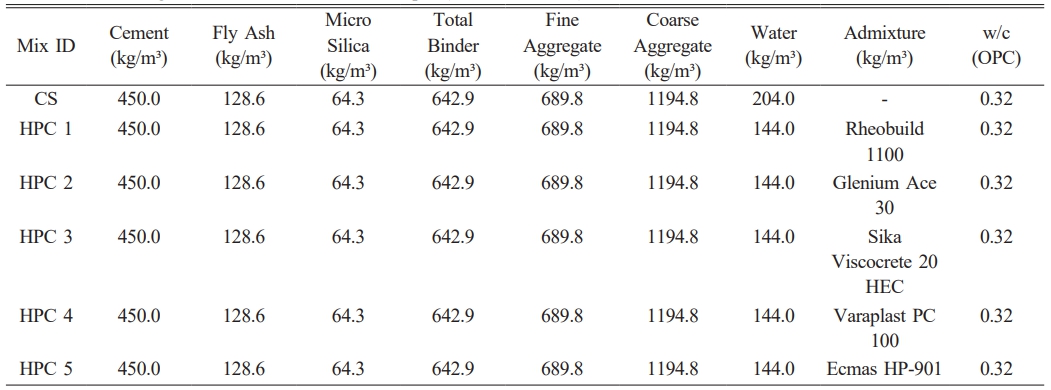

Materials such as Ordinary Portland Cement of grade 53, micro silica, and fly ash along with M sand were used as fine aggregates with a specific gravity of 2.76, a fine modulus of 2.85, and coarse aggregates of size 12.5 mm and 20 mm in a ratio of 60:40 were utilized for the production of concrete. Fe500 grade reinforcing steel was utilized in high-performance concrete. Rheobuild 1100, Glenium Ace 30, Sika Viscocrete 20 HEC, Varaplast PC 100, and Ecmas HP-901 (P) are chemical admixtures used in the preparation of HPC. Following the process outlined in IS 10262, M60 grade concrete was used [19, 20]. The water-cement ratio was consistently maintained at 0.32 throughout all samples. The mix design utilized for the M60 mix graded concrete is 1:1.07:1.85.

Steps involved in concrete preparation

Concrete samples for the five different admixtures and a control sample were prepared. These samples were labeled as CS (Control Specimen), HPC 1 (Rheobuild 1100), HPC 2 (Glenium Ace 30), HPC 3 (Sika Viscocrete 20 HEC), HPC 4 (Varaplast PC 100), and HPC 5 (Ecmas HP-901). All components, including cement, fly ash, micro silica, M-sand, and coarse aggregates (20 mm and 12.5 mm), were weighed separately and then combined in a mixer in the laboratory to prevent the loss of water and aggregate. A slump cone test was performed to determine the workability of the concrete [21]. To measure the mechanical properties of the concrete, cubes measuring 150 mm on each side, cylindrical specimens, and beams were cast at standard sizes. In this process, a steel rod that was rounded at one end and had a diameter of 16 mm was used as the reinforcement [22]. Concrete was poured into cube samples in three layers, and the layers of concrete were properly compacted using a table vibrator. The prepared samples were left undisturbed for 24 h after casting and maintained at room temperature [23]. They were then removed from the mold and cured by immersion in water for 28 days at a temperature of 23 ± 2 ᵒC.

Testing Methodology

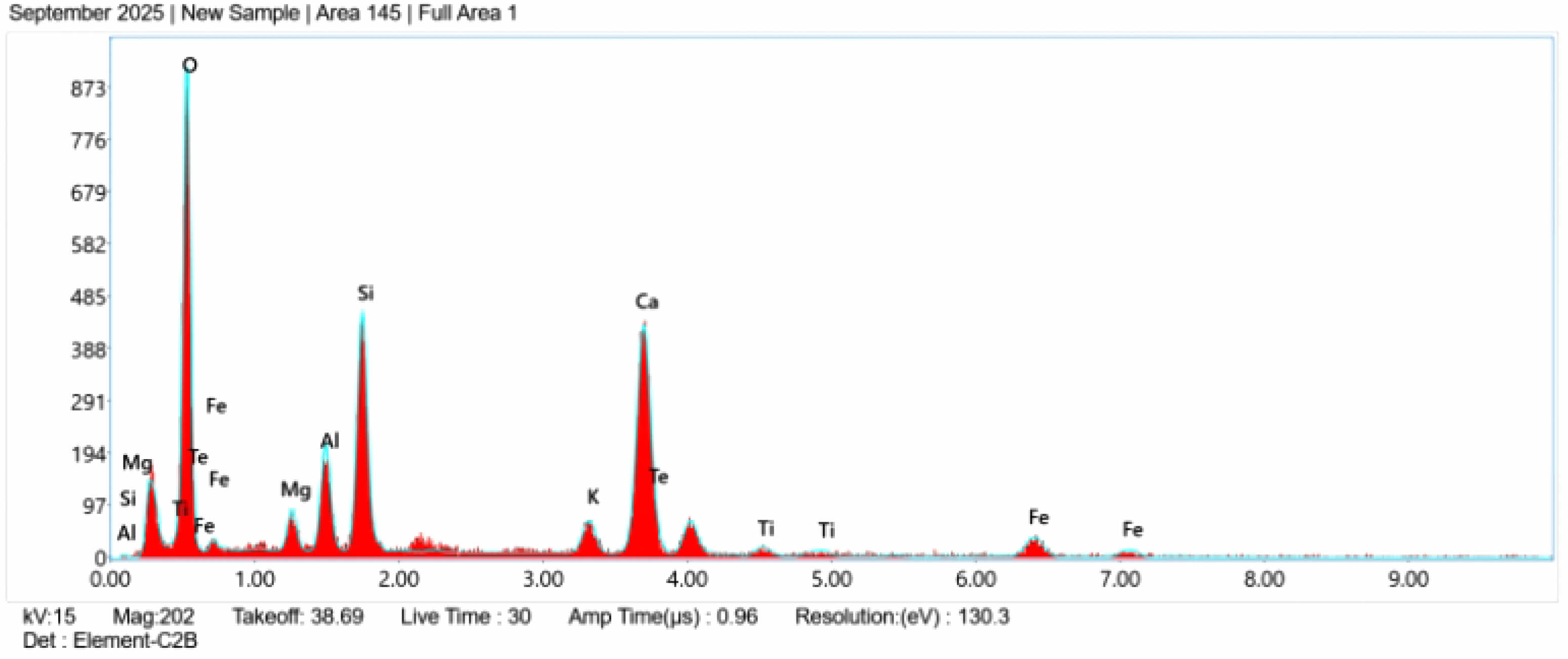

This study entailed performing a series of evaluations on the mechanical properties and durability of High-Performance Concrete specimens including various mineral and chemical admixtures. Concrete cubes were evaluated for compressive strength at 7 and 28 days in accordance with IS 516:1959 utilizing a compression testing machine [24]. The split tensile strength was determined using IS 5816:1999, and cylindrical specimens were used for tensile testing. The pull-out test was performed according to the ASTM C234-91 guidelines, as shown in Fig. 1. The flexural strength was determined by testing the beam specimens under a three-point loading system with respect to IS 516:1959, as shown in Fig. 2. The durability properties were assessed through various tests: in order to measure the chloride ion permeability, Rapid Chloride Penetration test was carried out in accordance with ASTM C1202-97 is showed in Fig. 3, the salt ponding test was carried out as per ASTM C 1543-02, sorptivity test was carried out following ASTM C1585 so as to assess the capillary suction and water permeability test was carried out using DIN 1048-5 respectively is showed in Fig. 4. NT BUILD 492 was used to carry out the Accelerated Chloride Migration Test (ACTM), and ASTM G109 was used for conducting the accelerated corrosion tests on concrete [25, 26]. To examine the elemental composition and morphological structure of the concrete matrix, Scanning Electron Microscopy and Energy Dispersive X-ray Analysis (EDX) were carried out according to ASTM E1508. The Ultrasonic Pulse Velocity (UPV) test was conducted according to IS 13311 (Part 1):1992 to assess the integrity and homogeneity of the concrete sample. All tests were carried out with strict adherence to the aforementioned standards to ensure accurate and reliable results, contributing to a comprehensive analysis of the performance of concrete. Table 1

|

Fig. 1 Casting of Specimen. |

|

Fig. 2 Flexural strength test. |

|

Fig. 3 Rapid Chloride Penetration test. |

|

Fig. 4 Water Permeability test. |

Mechanical Properties

Test for Compressive Strength

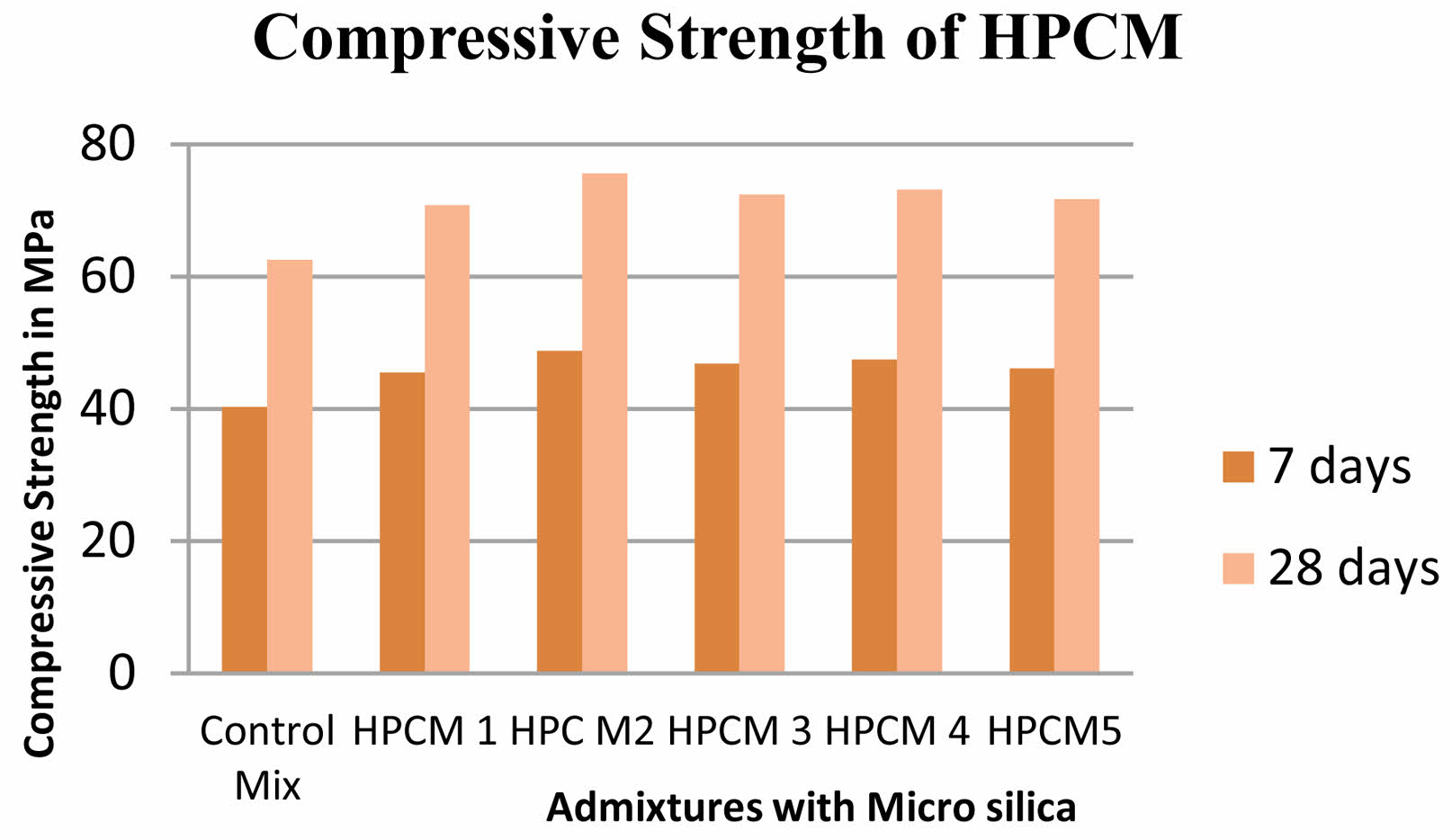

Figure 5 illustrates the compressive strength of both the control mix and the concrete with admixtures after 7 and 28 days of curing. It is evident from the chart that at 7 days, all samples of HPC along with micro silica exhibited higher strength in comparison to conventional concrete. The technique for compressive strength, including specimen size, curing, and measurement data, is referenced according to IS Standards. From the results, it was found that the mix containing micro silica and the Glenium Ace 30 admixture demonstrated the highest compressive strength of 75.60 N/mm2 [27]. Suggested that Glenium ACE 30 (HPC 1) significantly increases the compressive strength of concrete, with a 28-day strength reaching 75.05 MPa, which is consistent with our observation of 75 MPa. Additionally, it was noted that the concrete containing the Rheobuild 1100 admixture (HPC 2) enhanced the compressive strength, achieving values of approximately 70.02 MPa at 28 d, aligning with the observed 70.02 MPa [28].Also achieved a compressive strength of approximately 20.10 MPa after 28 d. The percentage increase in the strength of the compressive test of HPC 2 and HPC 3 mixes containing Varaplast PC 100 and Sika Viscocrete 20 HEC admixtures was 17.70% and 16.10%, respectively. Glenium ACE 30 concrete (HPC 1) demonstrated the highest improvement, followed by Varaplast PC 100 (HPC 4) and Sika Viscocrete 20 HEC (HPC 3), and it was concluded that all HPC mixes exhibited greater compressive strength than the Control Concrete.

Test for Split Tensile Strength

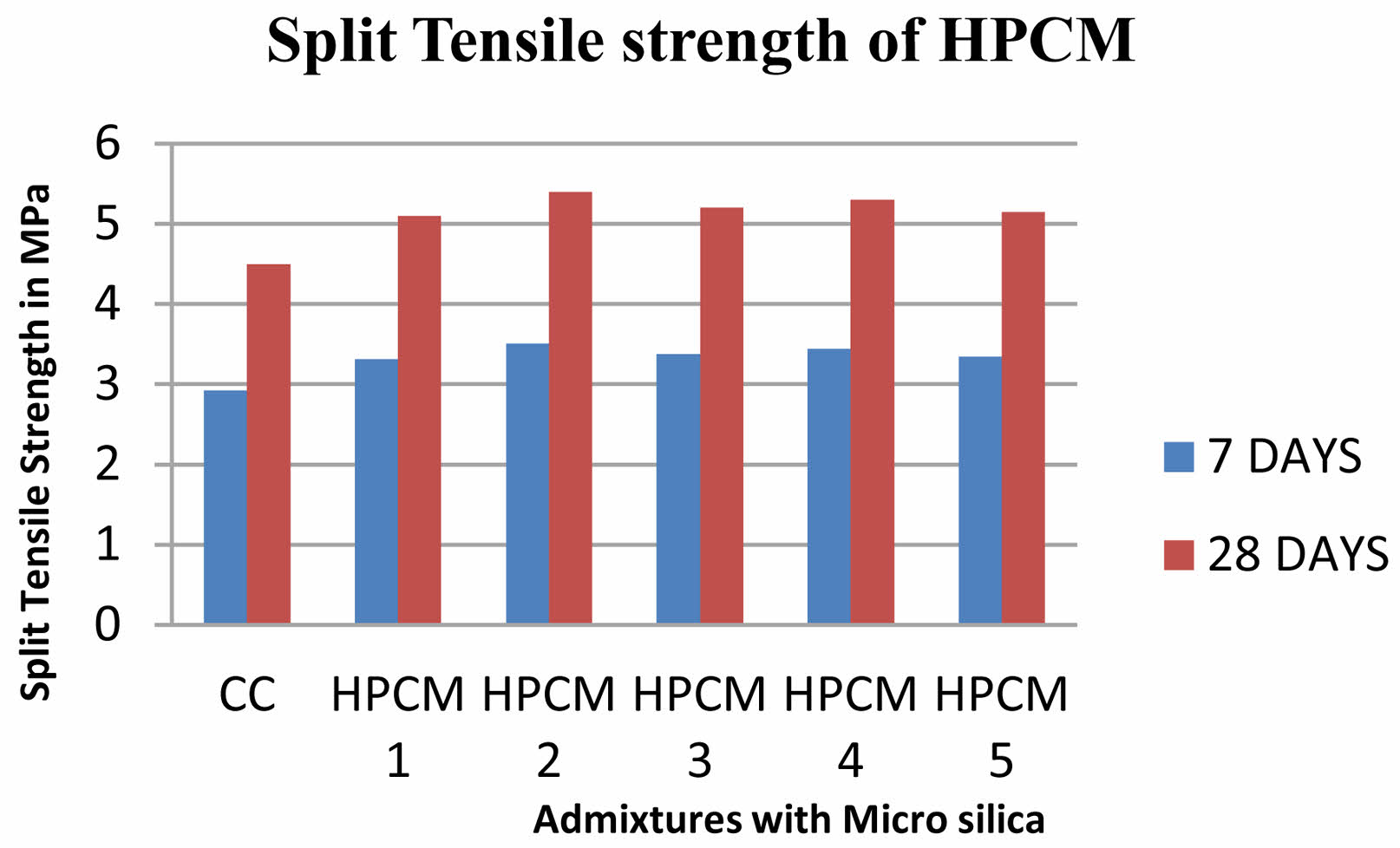

Figure 6 illustrates the split tensile strength of high-performance concrete specimens following 7 and 28 days of cure. The high-performance concrete samples exhibited superior split tensile strength relative to ordinary concrete, mostly attributable to the incorporation of water reducers and superplasticizers, leading to enhanced concrete strength [29, 30]. The technique, specimen dimensions, curing, and measurement specifications for Split Tensile strength are in accordance with IS Standards. From the Fig. 7, it is evident that HPC 2 exhibits the highest split tensile strength among the samples. Specifically, the split tensile strength for HPC 2 was 3.51 MPa and 5.40 MPa at 7 days and 28 days of curing, while for conventional concrete it was 2.925 MPa and 4.50 MPa, respectively. A comparison with conventional concrete revealed an 18.18% and 20% increase in the split tensile strength for HPC 2, respectively. The addition of admixtures to concrete improves bonding and reduces porosity, resulting in increased strength compared to conventional concrete that indicated high-performance concrete with micro-silica and chemical admixtures can achieve a split tensile strength of 5.00–5.40 MPa, supporting the values observed for almost all high-performance concrete mixes.

Flexural Strength test

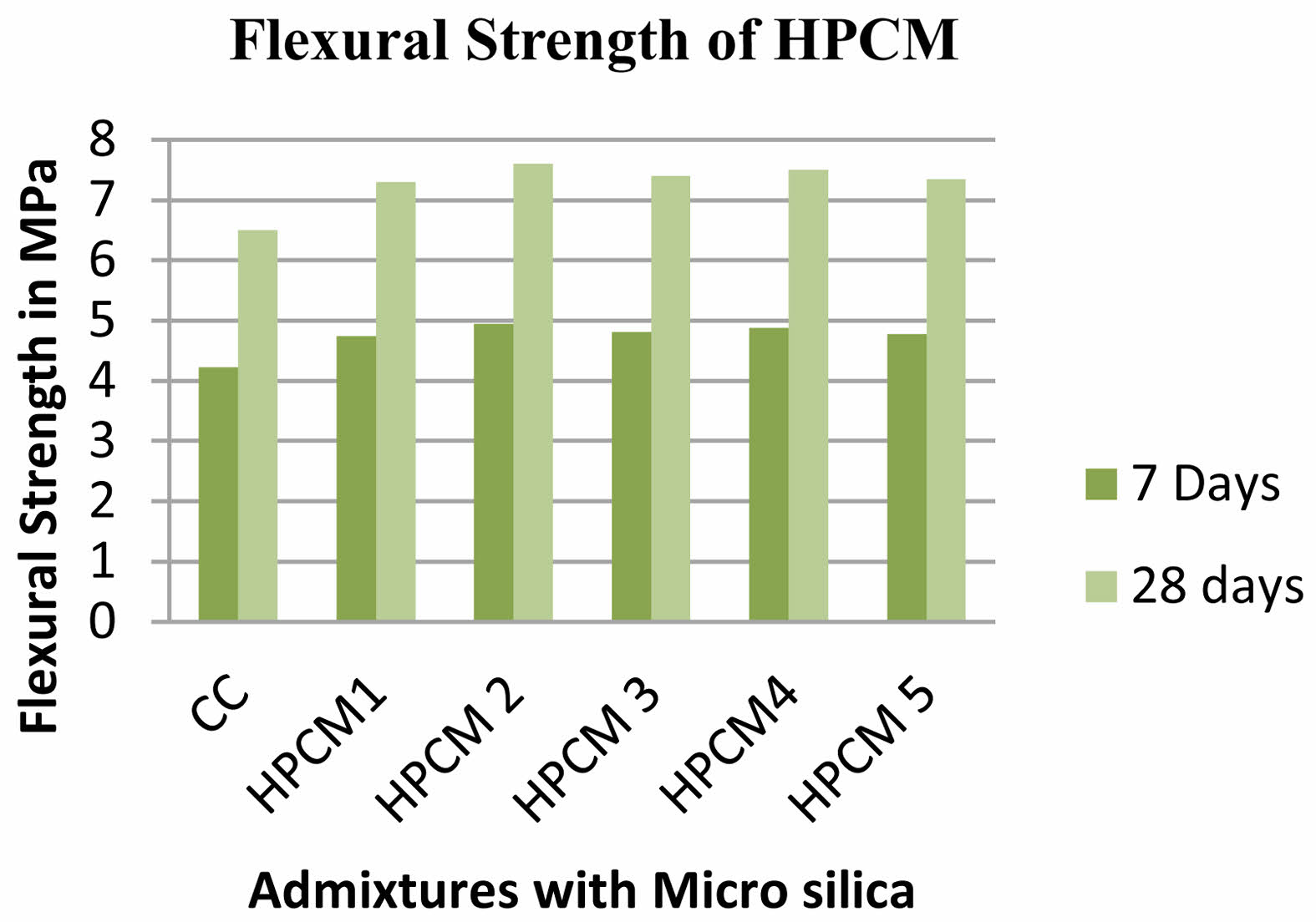

The technique for flexural strength, including specimen size, curing, and measurement data, is referenced according to IS Standards. In Fig. 7, the flexural strengths of various HPC samples are illustrated after 7 and 28 d of curing. Compared to CC, all HPC samples displayed superior flexural strength. At 7 days and 28 days, HPC 2 along with micro silica exhibited the highest flexural strength, measuring 4.94 MPa and 7.60 MPa, demonstrating exceptional tensile strength and crack resistance. HPC 3 and HPC 4 also displayed notable enhancements over the control mix, indicating that these admixtures effectively improved the flexural strength of the concrete. [32] Conducted research to prove that incorporating micro silica and chemical admixtures can significantly boost the flexural strength of concrete by improving particle packing and hydration products.

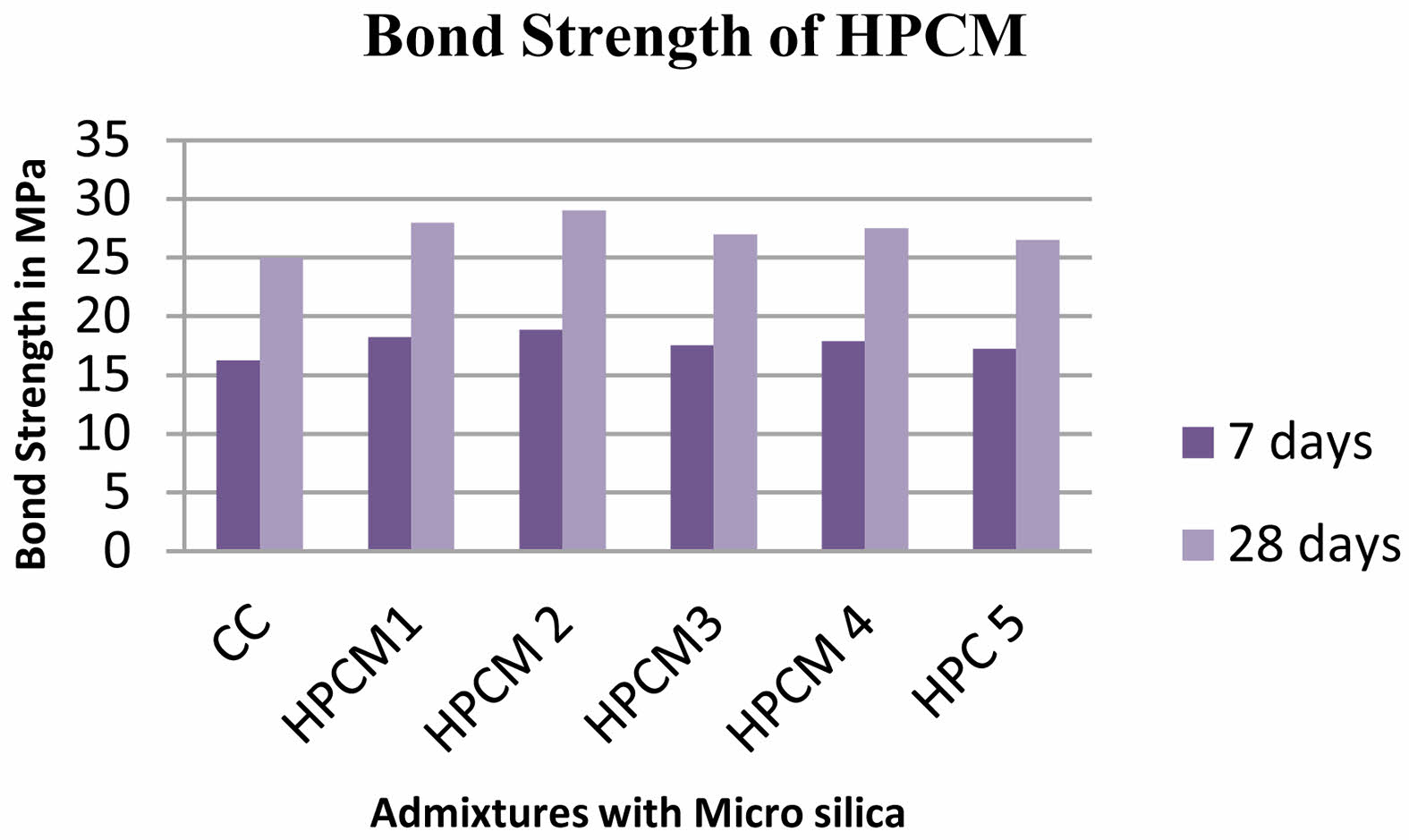

Pull Out Test

The process, specimen size, curing, and measurement specifications of the Pull Out test are referenced according to IS Standards. The bond strengths of various HPC samples at 7 d and 28 d of curing are shown in Fig. 8. The concrete containing micro silica and Glenium ACE 30 admixture demonstrated the highest bond strength with a value of 18.85 MPa for 7 days and 29.20 MPa for 28 days, indicating superior adhesion and durability. The presence of Rheobuild 1100 and Varaplast PC 100 admixtures in the concrete also exhibited significant enhancements, implying that these admixtures improved the bond strength and contributed to the overall structural performance. By improving the wetting and dispersion of cement particles, the inclusion of micro silica, super plasticizers, and other chemical admixtures can boost the bond strength of concrete, resulting in better hydration and improved bonding with reinforcing steel [33].Demonstrated that the incorporation of micro silica and specific chemical admixtures in high performance concrete led to improved bond strength owing to the creation of a denser matrix and enhanced adhesion.

Durability Properties

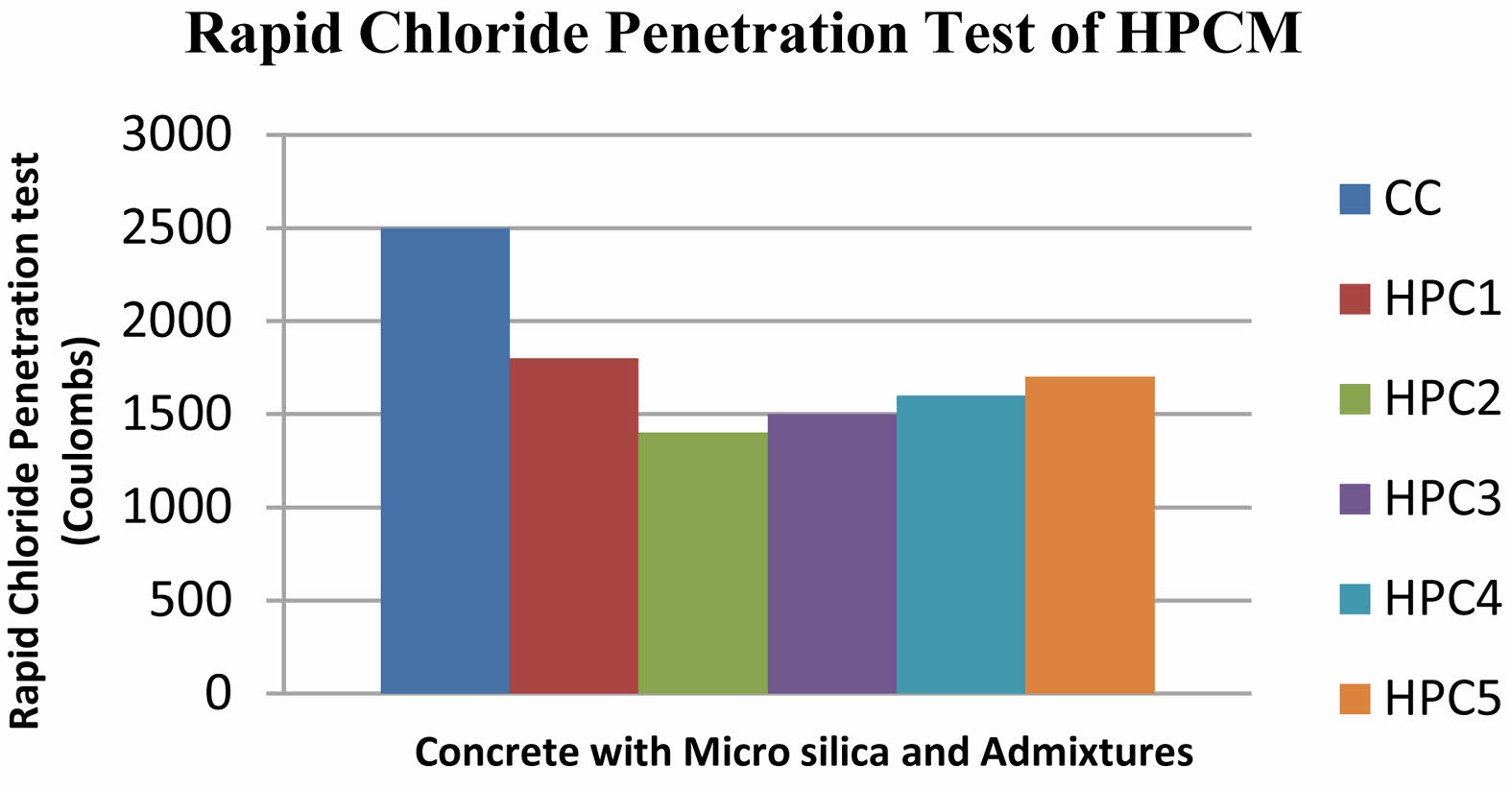

Properties related to durability, such as Rapid Chloride Penetration Test (RCPT), salt ponding, sorptivity, water permeability, accelerated chloride migration test (ACMT), and accelerated corrosion tests, were carried out. The Rapid Chloride Penetration (RCPT) test results for the control concrete were 2500 Coulombs, 1800 Coulombs for HPC 1, 1400 Coulombs for HPC 2, 1500 Coulombs for HPC 3, 1600 Coulombs for HPC 4, and 1700 Coulombs for HPC 5. From the results obtained from the test, it is clear that there is a significant reduction in the charge passed with the use of micro silica and chemical admixtures, indicating lower chloride ion permeability. HPC 2 was effective in enhancing the chloride resistance [34, 35]. The inclusion of micro silica significantly reduces the permeability of chloride ions in concrete, which aligns with the reduced RCPT values for mixes with admixture as shown in Fig. 9.

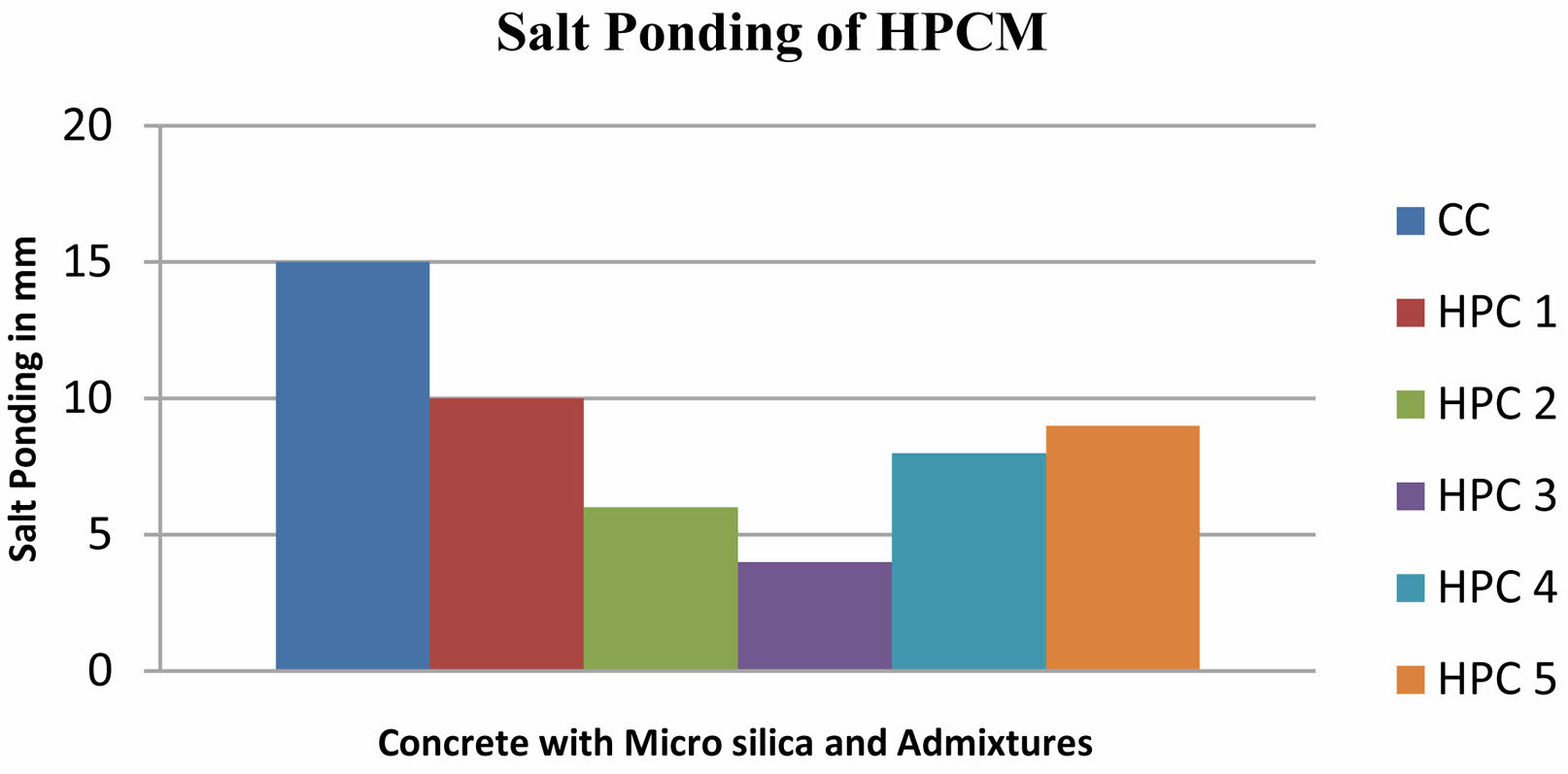

The salt-ponding values for CC were 15, 10, 6, 4, 8, and 9 mm for HPC 1, HPC 2, 4 mm for HPC 3, 8 m for HPC 4, and 9 mm for HPC 5, respectively. The depth of chloride ion penetration was considerably lower for the concrete mixes with admixtures. Glenium Ace 30 (HPC 2) and Sika Viscocrete 20 HEC (HPC 3) exhibited the lowest penetration depths, highlighting their superior performance in preventing chloride ingress, as shown in Fig. 10.

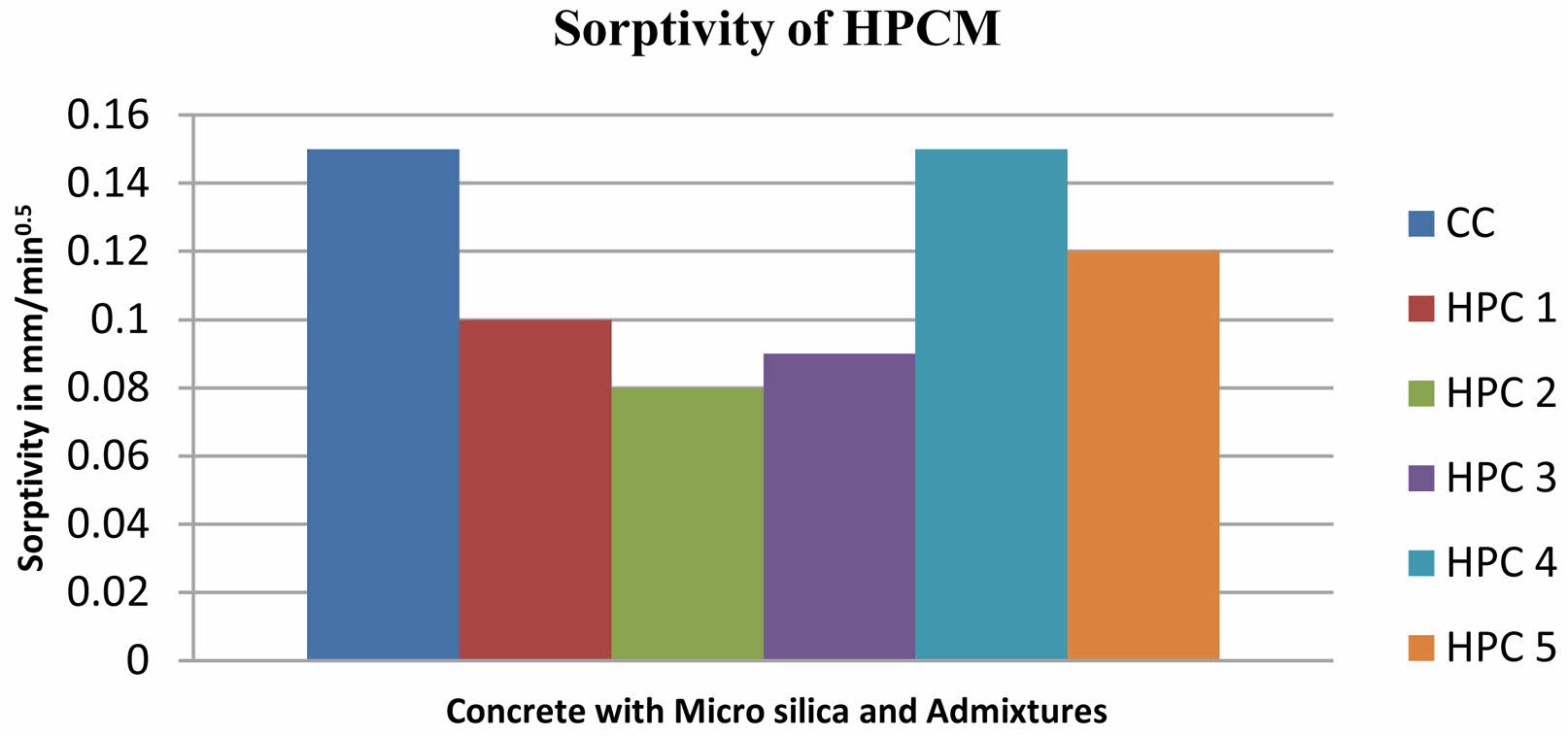

The sorptivity test results for CC was 0.15 mm/min0.5, 0.10 mm/min0.5 for HPC 1, 0.08 mm/min0.5 for HPC 2, 0.09 mm/min0.5 for HPC 3, 0.15 mm/min0.5for HPC 4 and 0.12 mm/min0.5for HPC 5 which indicated that the water absorption’s rate was reduced with the inclusion of admixtures. The concrete with micro-silica and Glenium Ace 30 admixture (HPC 2) showed the lowest sorptivity, which is beneficial for reducing water uptake and subsequent deterioration [36, 37]. Showed that the incorporation of cementitious materials, such as fly ash and micro silica, reduces the sorptivity of concrete, which is consistent with the values provided for admixture-enhanced mixes, as shown in Fig. 11.

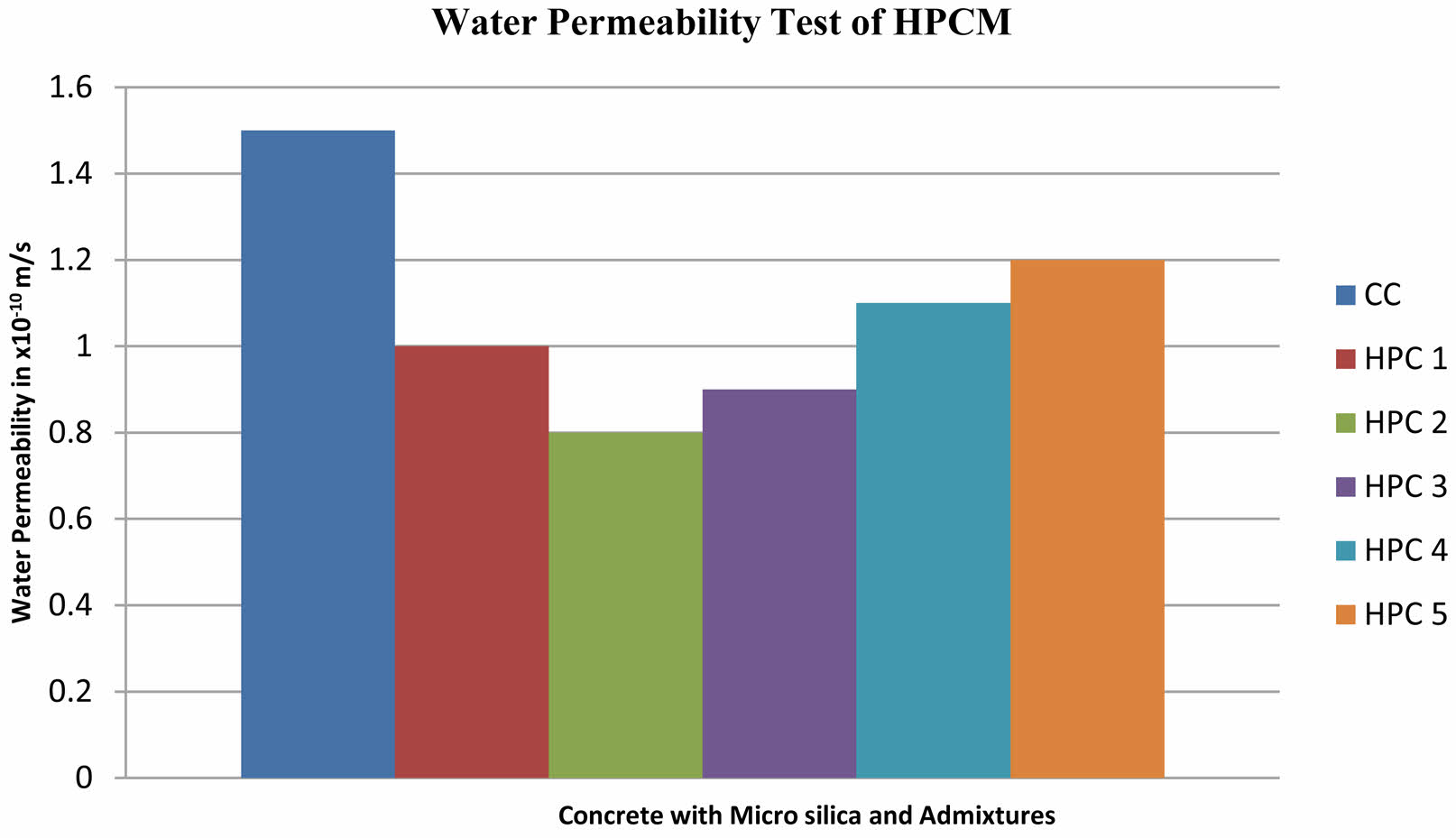

From the water permeability test, the co-efficient of water permeability for CC was 1.5 × 10-10 m/s, HPC 1 was 1.0 × 10-10 m/s, HPC 2 was 0.8 × 10-10 m/s, HPC 3 was 0.9 × 10-10 m/s, HPC 4 was 1.1 × 10-10 m/s, and HPC 5 was 1.2 × 10-10 m/s. From the test results, it was observed that the coefficient of permeability was significantly decreased for concrete mixes with micro-silica and chemical admixtures. The coefficient of permeability diminished as a result of pore refinement and the denser microstructure attained by the incorporation of micro silica and the dispersive effects of admixtures. These admixtures enhance packing density, diminish linked capillary holes, and promote secondary C-S-H gel formation, thus limiting water transport [38]. From the study conducted by [39, 40] it was found that the use of high-performance chemical admixtures and micro silicaled to reduced water permeability, as shown in Fig. 11.

An Accelerated Chloride Migration Test (ACMT) revealed that the admixtures improved the resistance to chloride migration. HPC 2, along with micro silica, showed the lowest chloride migration depth of 12 mm, reinforcing its effectiveness in enhancing durability. The time to corrosion initiation was calculated from the accelerated corrosion test and was found to be extended with the use of admixtures [41]. In this study, micro silica, Glenium Ace 30, and Sika Viscocrete 20 HEC provided the largest protection period, as shown in Fig. 12.

SEM and EDX Analysis

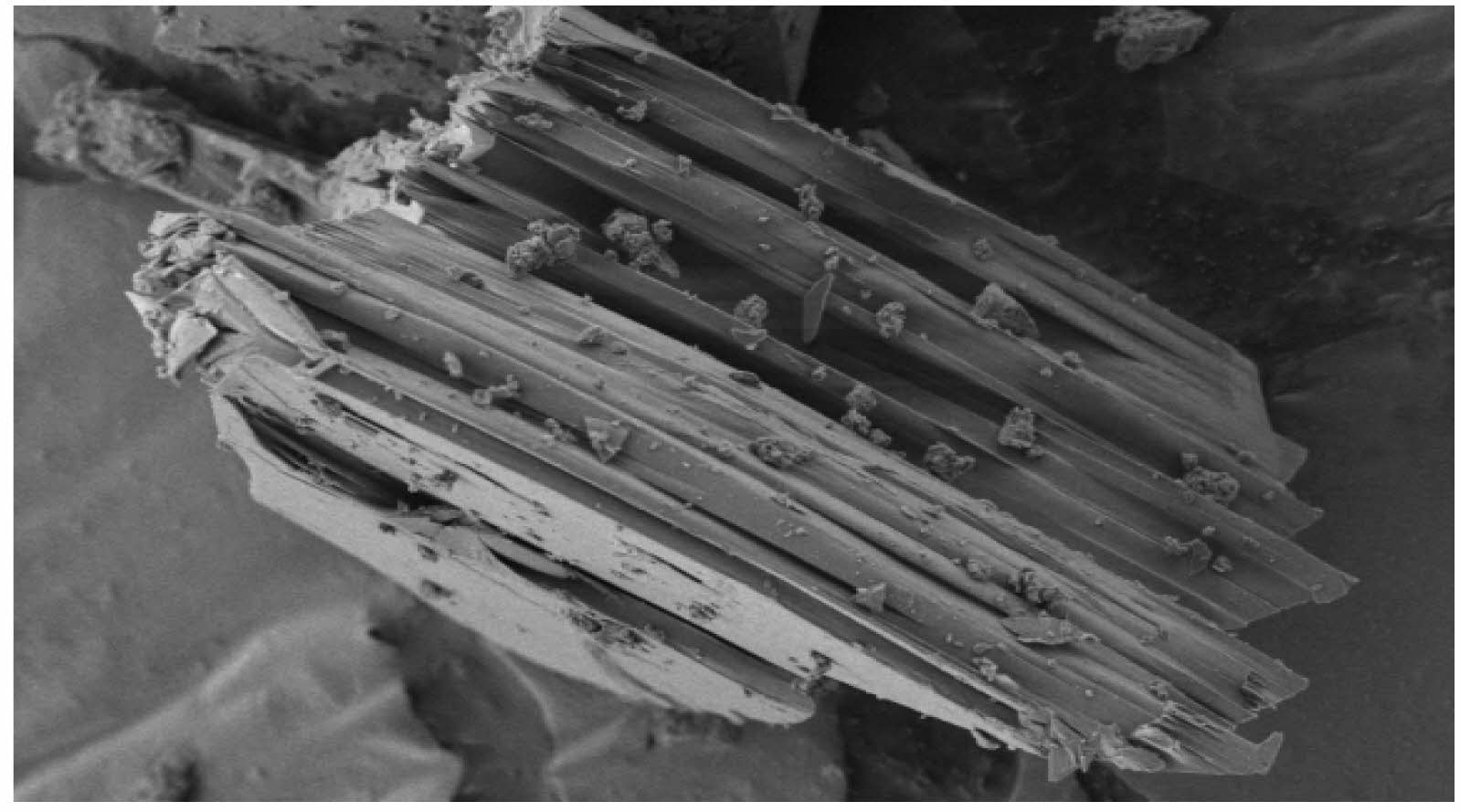

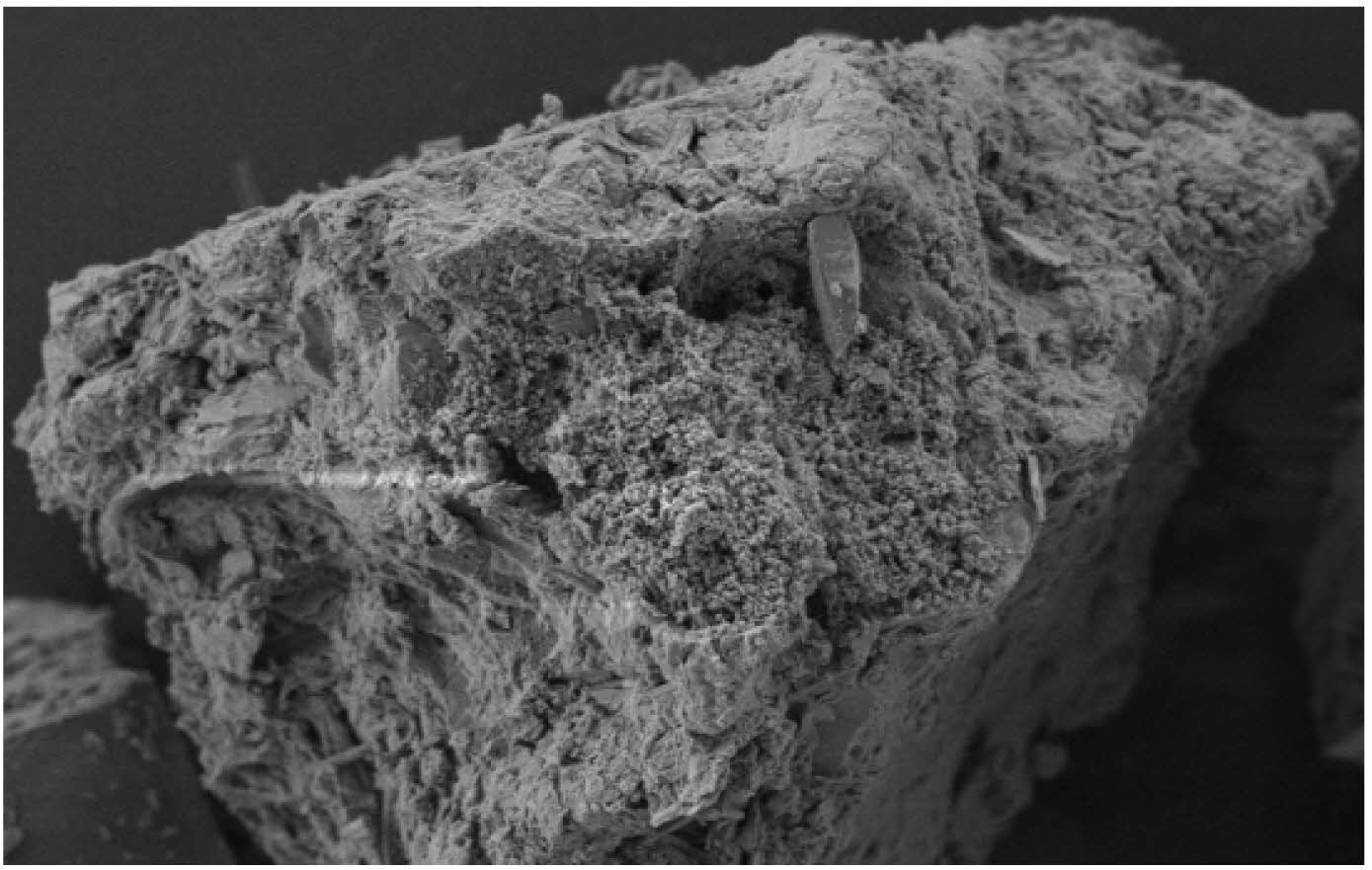

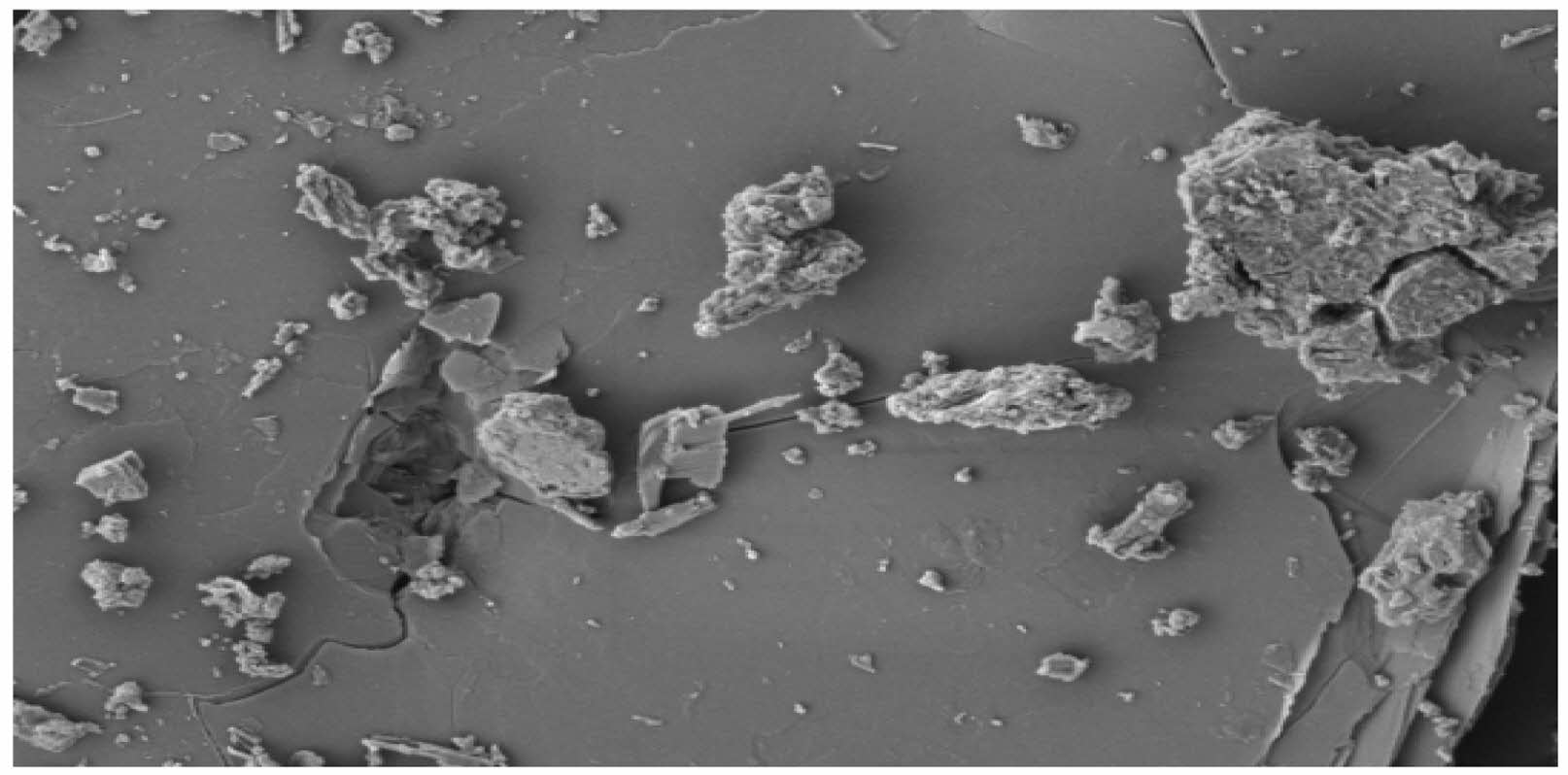

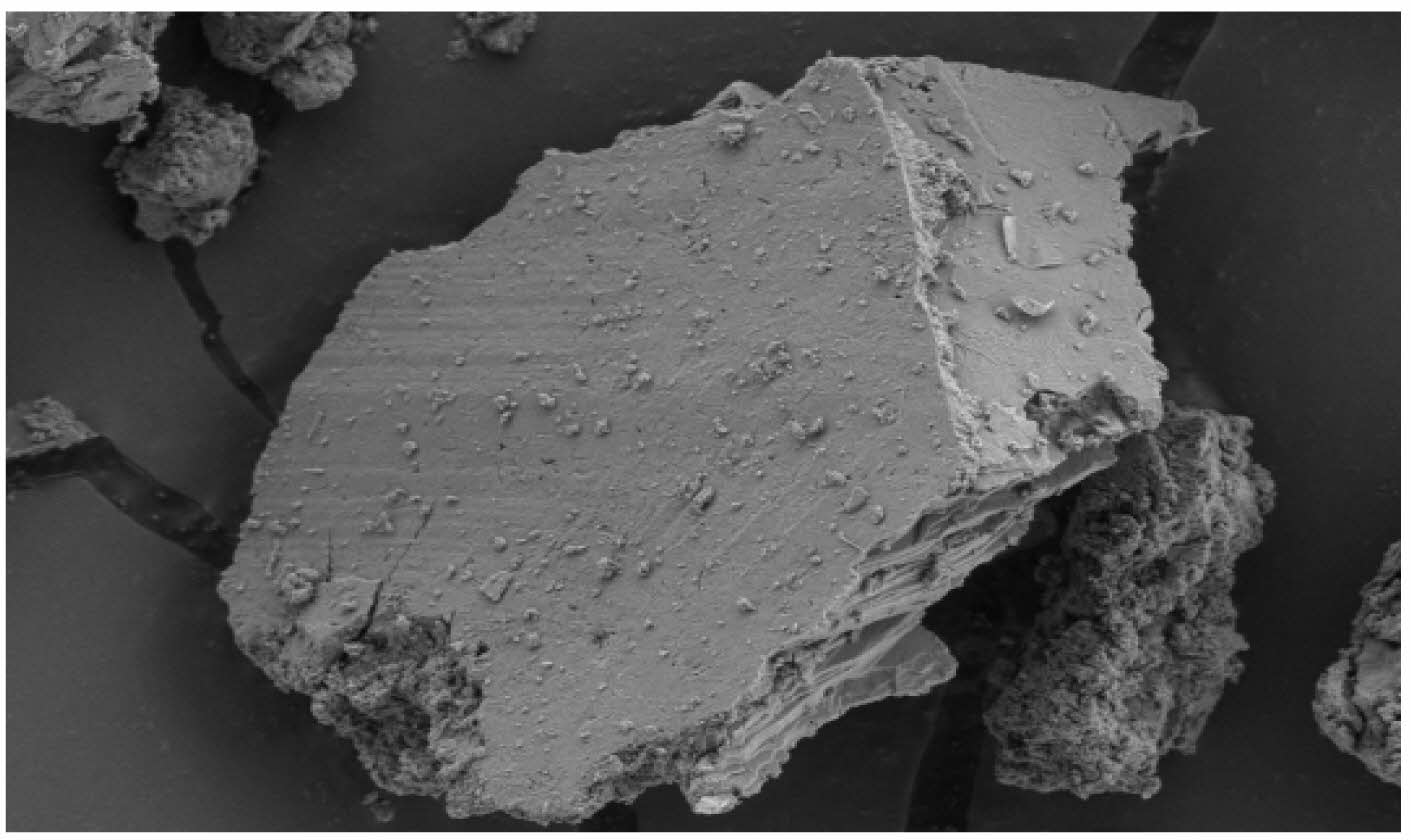

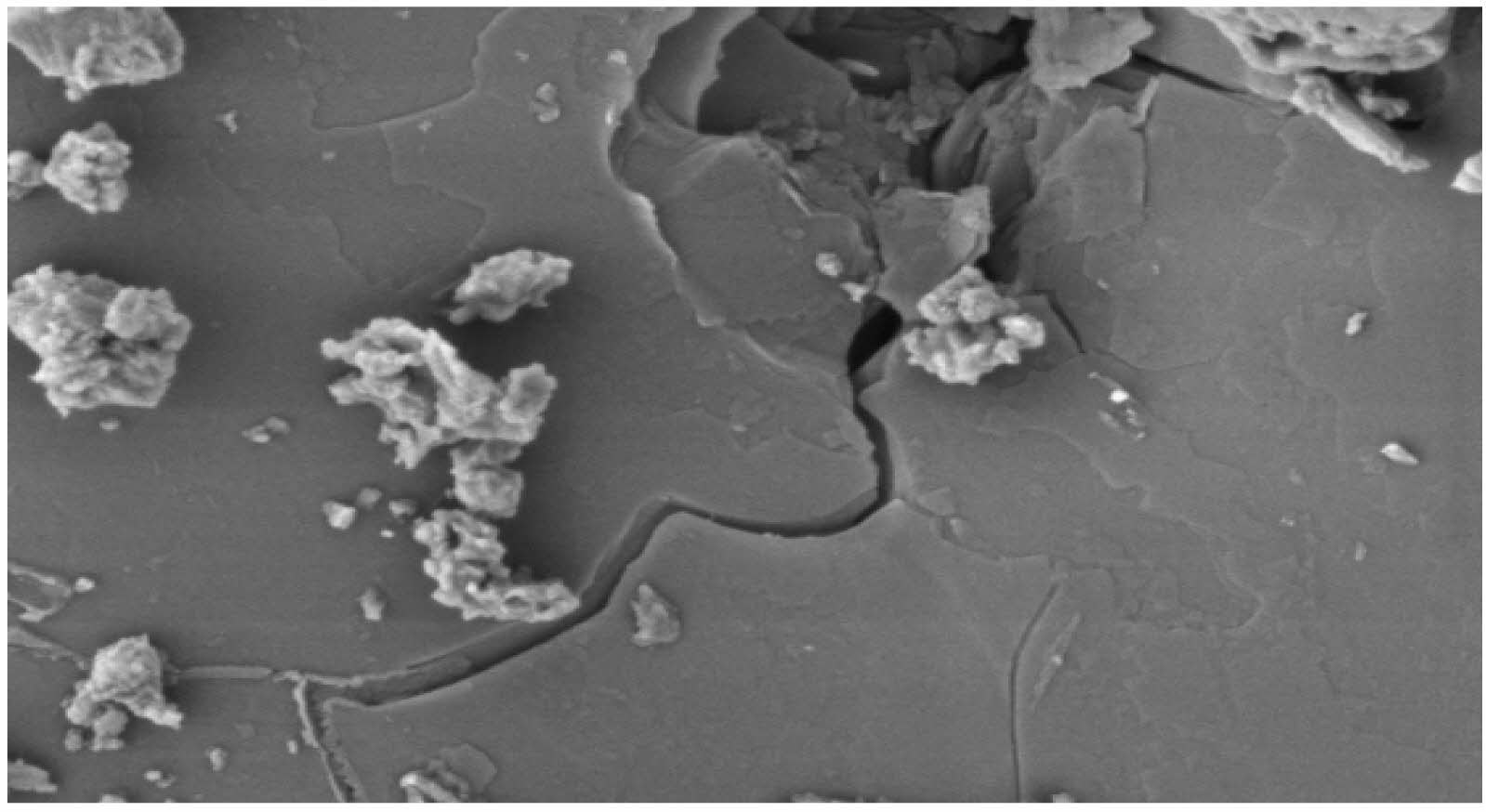

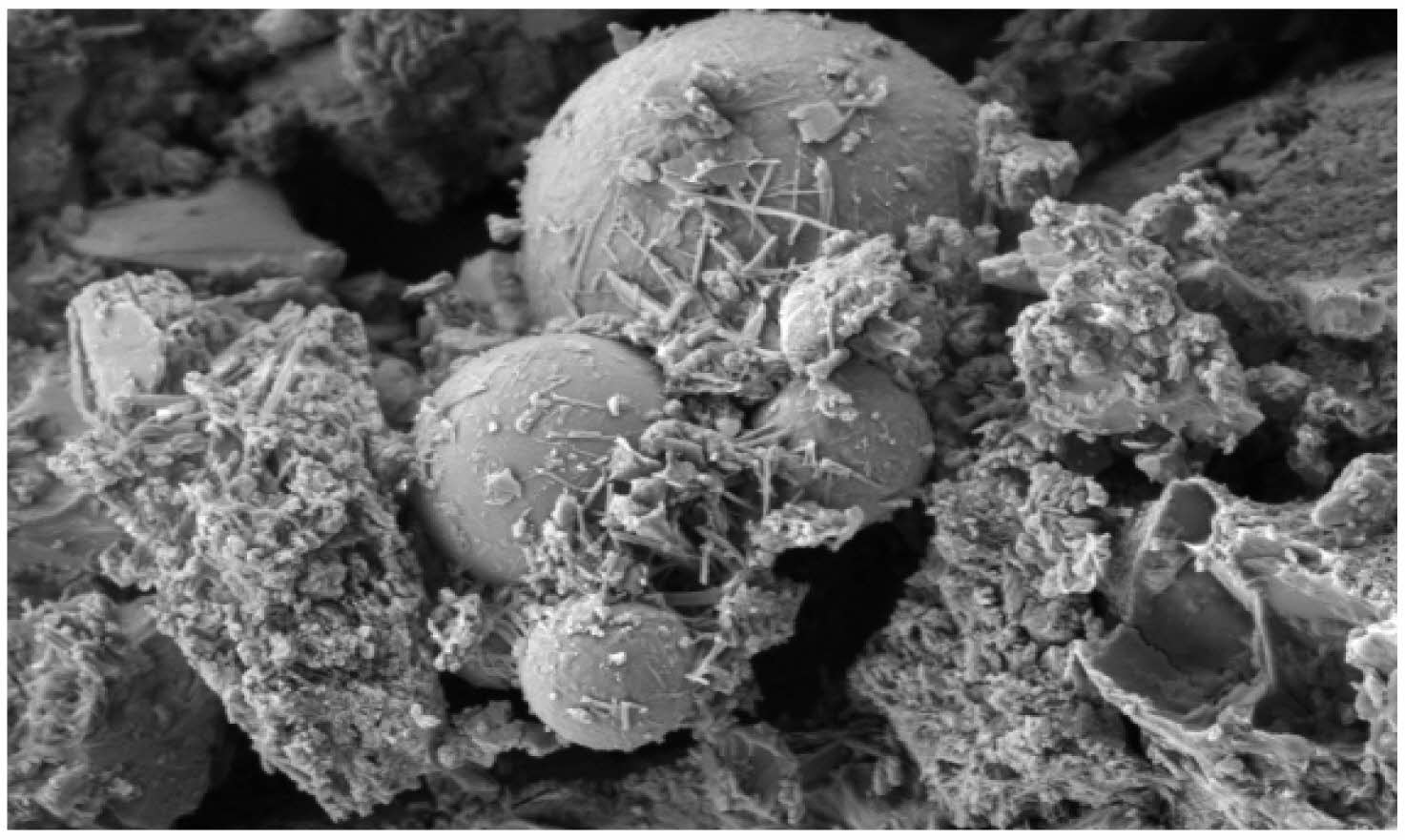

The SEM images provide visual evidence of the microstructure of HPC, showing the structure of the products of hydration, the distribution of different phases, and the quality of the Interfacial Transition Zone (ITZ). The SEM control mix image in Fig. 13 shows a relatively porous microstructure with larger and more interconnected pores. The hydration products were less dense and there were noticeable micro cracks. The micro-silica and HPC 1 mix with Rheobuild 1100, as shown in Fig. 14, has a denser microstructure with fewer and smaller pores. The hydration products are more uniform and compact, indicating better hydration and reduced porosity. The micro silica and Glenium Ace 30 mix HPC 2 in Fig. 15 exhibits a highly dense microstructure with minimal pores and a very compact matrix. The ITZ appears to be well-bonded, and the hydration products are highly crystalline. The mix of micro-silica and HPC 3in Fig. 16 shows a dense microstructure with well-formed and closely packed hydration products. The ITZ was improved, indicating better bonding between the cement paste and the concrete aggregate. The SEM images of micro-silica and Varaplast PC 100 in Fig. 17 concrete typically show a dense microstructure with fewer pores and micro cracks in comparison to the Conventional Concrete. The microstructure was compact because of the efficient packing of the particles facilitated by the admixture [42]. At higher magnification, calcium silicate hydrate (C-S-H) gel was well distributed, filling the voids and reducing porosity. The presence of uniformly dispersed fine particles contributed to the enhanced strength and durability. The SEM images of micro-silica and ECMAS HP-901 in Fig. 18 concrete exhibit a dense and well-hydrated microstructure [43]. The admixture promoted–the H gel formation and reduced the presence of capillary pores. Higher magnification reveals a continuous network of C-S-H gel formation with minimal micro cracks. Fine particles of the admixture fill the gaps, enhancing the overall microstructure.

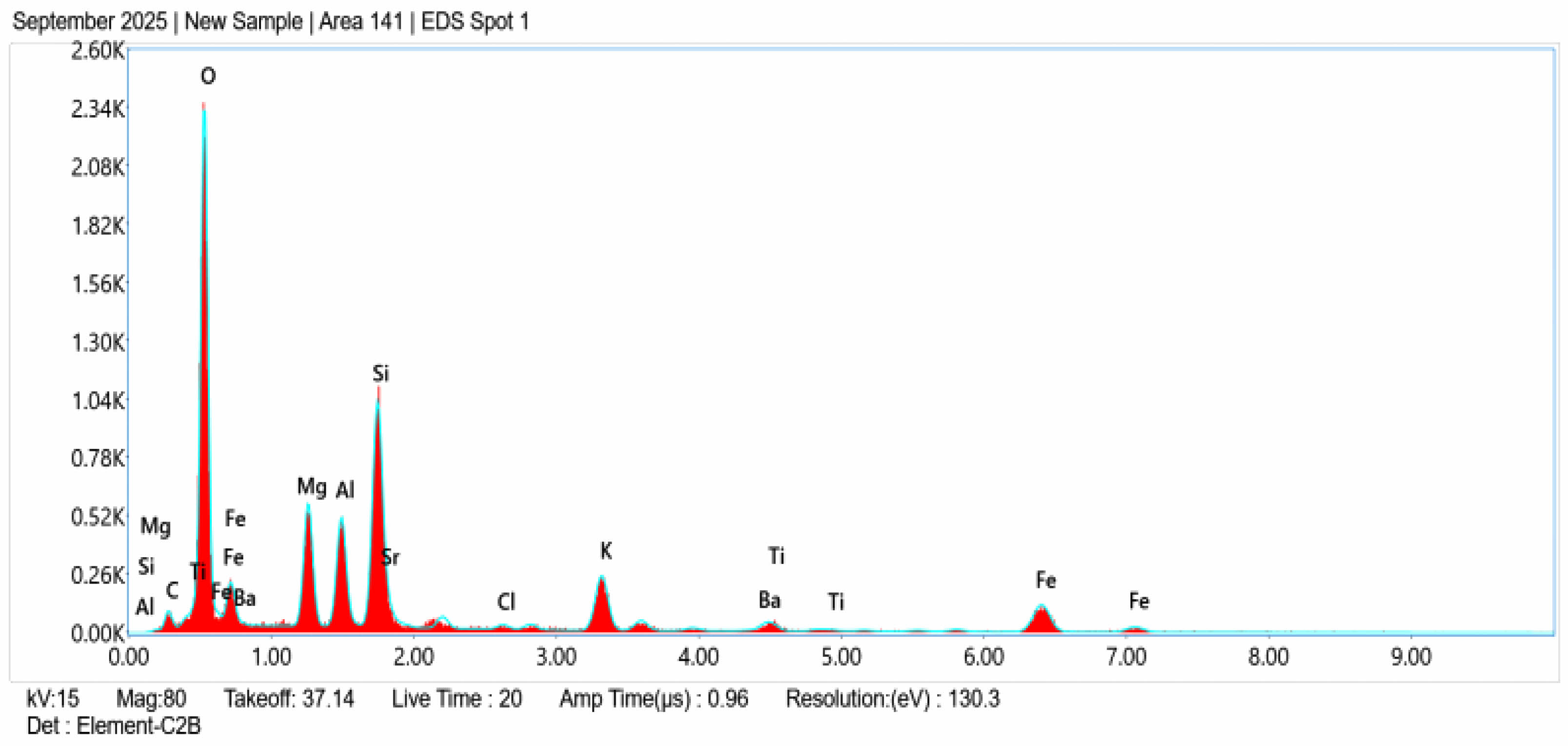

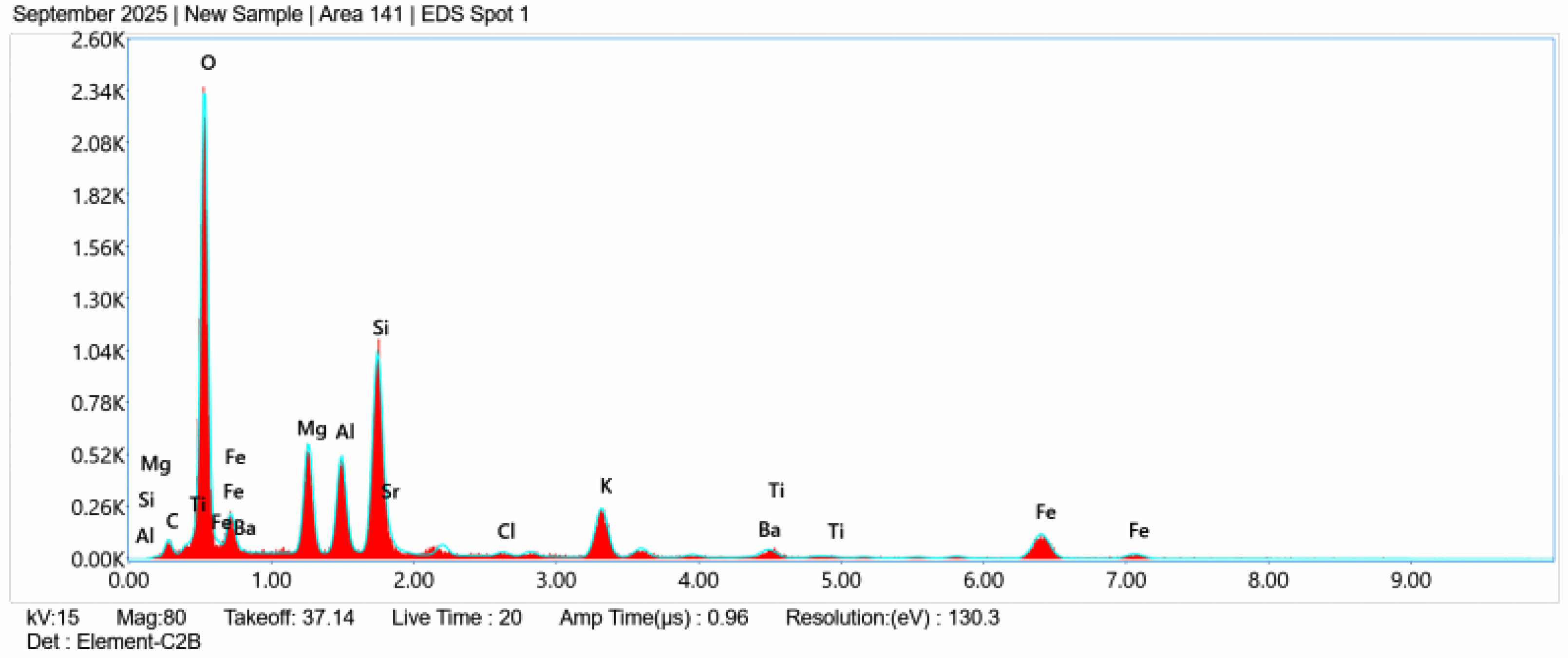

Energy Dispersive X-ray Spectroscopy (EDX) was conducted on hardened conventional concrete to evaluate its elemental composition and confirm the existence of cement hydration products. Fig. 19 illustrates the EDX spectrum of the Conventional Concrete sample, highlighting predominant peaks for O, Si, and Ca, which signify C–S–H gel and hydrated cement phases characteristic of standard concrete.

The EDX spectrum displays significant peaks for oxygen (O), silicon (Si), and calcium (Ca), validating the production of calcium silicate hydrate (C–S–H) gel as the primary hydration product. An unequivocal aluminum (Al) peak signifies the existence of calcium aluminate hydrates, whereas iron (Fe) and magnesium (Mg) peaks relate to minor clinker phases (C₄AF and MgO). Trace elements include potassium (K), chlorine (Cl), strontium (Sr), titanium (Ti), and barium (Ba) derive from cement raw materials and aggregates. The Ca/Si ratio, derived from the quantitative weight percentages, was determined to be roughly 1.9–2.0, which is characteristic of standard concrete and signifies a balanced production of C–S–H gel. This composition indicates that the matrix is adequately hydrated although comparatively less dense than HPC mixtures.

The overall elemental profile reflects the normal composition of OPCbased concrete. Compared to M60 concrete with other admixtures, this spectrum exhibits a comparatively lower Ca concentration and less apparent densification, indicating a higher proportion of capillary holes and a less polished microstructure [44]. Microstructural development and hydration behavior of M60-grade concrete adding Rheobuild 1100 (HPC 1), EDXwas conducted on the hardened paste. The EDX spectrum (Fig. 20) exhibits strong peaks for oxygen (O), calcium (Ca), and silicon (Si)—confirming the development of calcium silicate hydrate (C–S–H) gel, the major hydration product responsible for mechanical strength in Portland cement systems.

A significant aluminum (Al) peak indicates the production of calcium aluminate hydrates, possibly AFt (ettringite) and/or AFm phases, which enhance early strength and volume stability. Iron (Fe) and magnesium (Mg) are associated with minor components of cement clinker, specifically C₄AF (tetracalciumaluminoferrite) and MgO. Trace elements such as potassium (K) and cobalt (Co) are associated with raw cement components and admixture additives. The Ca/Si weight ratio is around 2.07, marginally exceeding the average range of 1.5–2.0 for well-structured C–S–H gel. This increased ratio signifies a calcium-rich hydration product, either resulting from the incomplete reactivity of silicate phases or the existence of free calcium hydroxide (portlandite). A high Ca/Si ratio correlates with increased early strength but may also indicate a less refined microstructure with elevated capillary porosity relative to highly densified high-performance concrete systems.

The overall elemental profile corresponds with that of OPC-based systems; however, the lower calcium concentration seen in comparison to other admixed concrete may indicate diminished densification. HPC 1, a superplasticizer based on polycarboxylate ether (PCE), is recognized for improving workability; yet, its influence on microstructural compaction is diminished in this instance—possibly attributable to dosage, curing conditions, or interactions with cement mineralogy [45].

Figure 20, EDX spectrum of M60 grade concrete using HPC 1. The spectrum displays significant peaks for Ca, Si, and O, signifying the presence of calcium silicate hydrate (C–S–H) gel, as well as peaks for Al, Fe, Mg, and trace elements, indicative of cementitious phases and admixture components [46]. EDX was conducted on hardened M60 grade concrete containing Glenium ACE 30 (HPC 2) to assess the elemental composition and verify the development of hydration products. Fig. 21 presents the EDX spectrum of the sample, whereas Table X encapsulates the quantitative elemental analysis.The EDX spectrum displays prominent peaks of oxygen (O), calcium (Ca), and silicon (Si), confirming the presence of calcium silicate hydrate (C–S–H) gel and portlandite [Ca(OH)₂] as the principal hydration products. The presence of aluminum (Al) signifies the production of ettringite and calcium aluminate hydrates (AFt/AFm phases), which enhance dimensional stability. Trace elements including magnesium (Mg), iron (Fe), sodium (Na), and potassium (K) are associated with clinker components and aggregate contaminants. The Ca/Si ratio of 2.36, derived from weight percentages, is marginally elevated compared to the commonly reported range for well-formed C–S–H gel, which is 1.7–2.3. This signifies a calcium-rich hydration product, aligned with a densely compacted microstructure and enhanced strength development in M60 grade concrete.The use of HPC superplasticizer markedly affected the microstructure by enhancing the dispersion of cement particles, resulting in more thorough hydration and increased production of C–S–H. This is evidenced by the elevated peaks of Ca and Si and the diminished presence of unhydrated residues. The microstructural data substantiates matrix densification, elucidating the observed enhancements in mechanical strength and durability performance, including increased compressive strength, reduced permeability, and enhanced resilience to harsh environments [47]. The EDX spectrum of M60 grade concrete with HPC 2 exhibits prominent peaks of Ca, Si, and O, hence validating the existence of C–S–H gel and a compact microstructure.The EDX results confirms that HPC2 enhances microstructural densification by augmenting the relative amount of calcium silicate hydrate and diminishing unhydrated clinker phases. The microstructural enhancement elucidates the observed increases in compressive strength, diminished permeability, and enhanced long-term durability, as illustrated in Fig. 21.

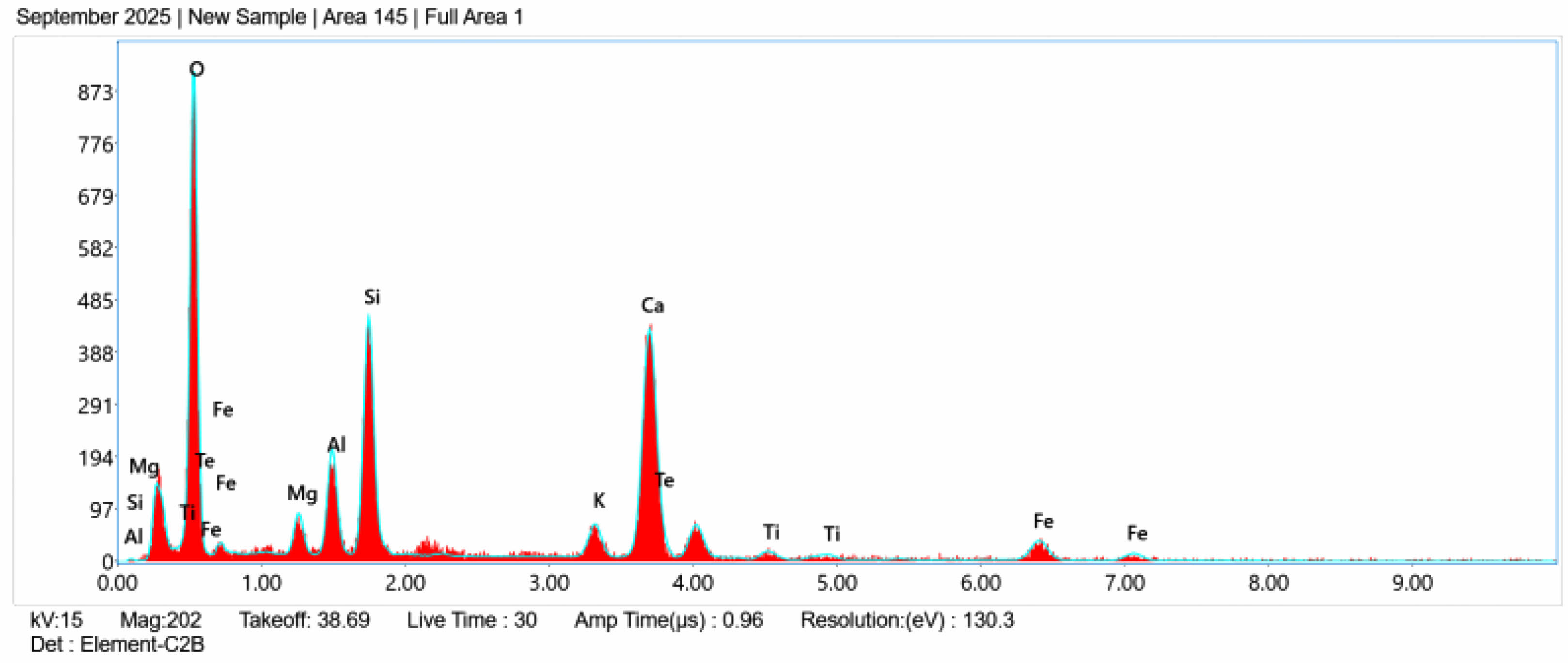

The chemical composition of the Sika Viscocrete 20 HEC (HPC 3) admixture was analyzed using Energy Dispersive X-ray Spectroscopy (EDX). The acquired spectrum, illustrated in Fig. 22, displays prominent peaks for oxygen (O), calcium (Ca), and silicon (Si), alongside minor contributions from magnesium (Mg), aluminum (Al), potassium (K), titanium (Ti), iron (Fe), and tellurium (Te). Quantitative research reveals that oxygen (46.30 wt.%) and calcium (23.88 wt.%) are the principal elements, with silicon contributing 9.46 wt.%. The determined Ca/Si weight ratio is 2.52, which is nearer to the stoichiometric range generally seen for calcium silicate hydrate (C–S–H) phases (1.2–2.0), but marginally elevated. In contrast to the HPC 3 admixture (Ca/Si = 6.86), HPC 3 demonstrates a more equilibrated Ca/Si ratio, indicating a composition that may more effectively facilitate C–S–H gel formation instead of excessive portlandite precipitation.

A Ca/Si ratio of 2.52 is advantageous for maintaining long-term strength via stable C–S–H gel formation.HPC 3, possessing a more balanced silicate composition, may improve microstructural refinement and reduce the excessive leaching of Ca(OH)₂. This enhances chemical resistance and dimensional stability in high-strength concretes such as M60.The presence of Al (4.27 wt.%), Fe (6.27 wt.%), and trace Te (4.28 wt.%) may affect hydration kinetics and phase stability. Specifically, Al can facilitate the development of calcium aluminate hydrates, whereas Fe oxides can serve as nucleation sites for hydration products. The composition of HPC 3 corresponds with its function as a superior water-reduction compound for concrete with a high strength. Its Ca/Si ratio, which aligns closely with C–S–H stoichiometry, renders it an advantageous additive for M60 concrete, facilitating both rapid strength development and enduring performance.

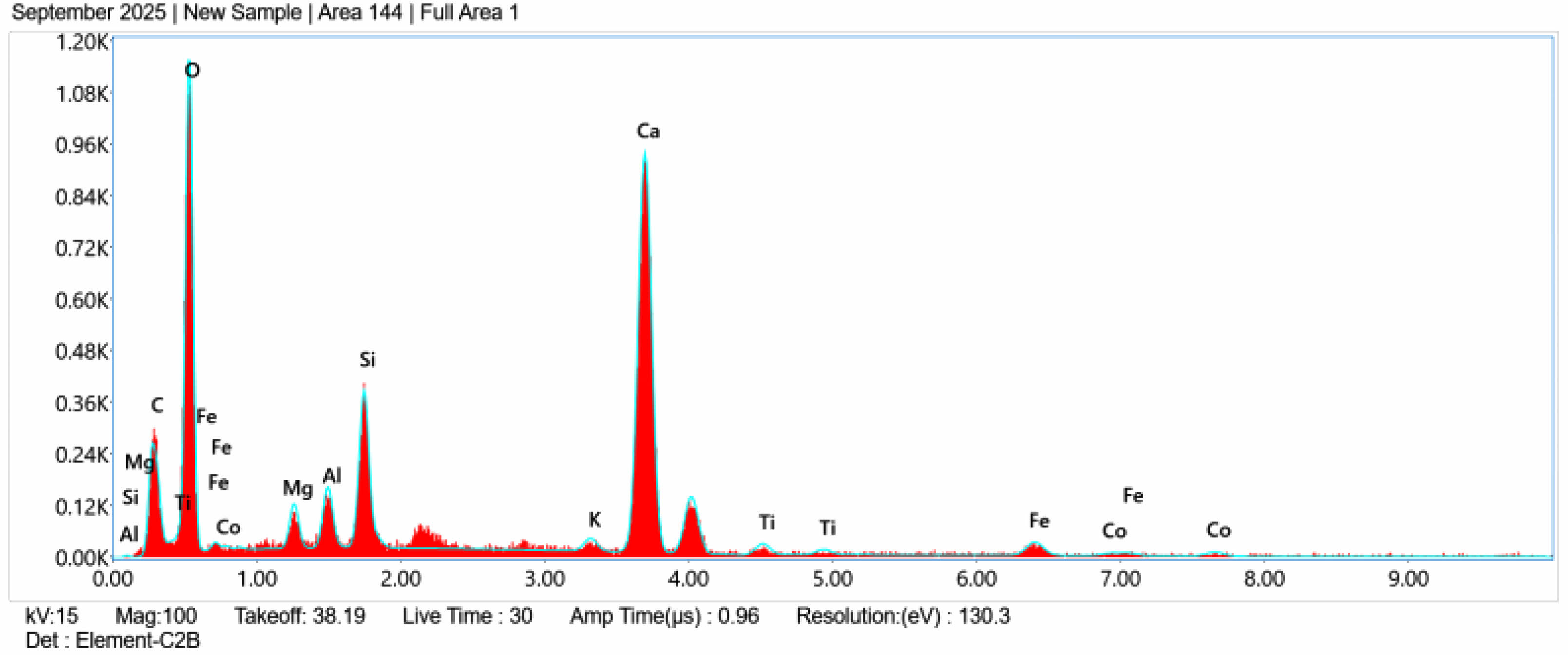

The chemical composition of the Ecmas HP-901 (HPC 4) admixture was analyzed using EDX. The spectrum illustrated in Fig. 23 has distinct peaks mostly associated with oxygen (O), calcium (Ca), and silicon (Si). Secondary signals were detected for magnesium (Mg), aluminum (Al), potassium (K), iron (Fe), and mercury (Hg). Oxygen (49.91 wt.%) and calcium (28.61 wt.%) are the predominant elements, whereas silicon constitutes 8.22 wt.%. The resultant Ca/Si weight ratio is 3.48, significantly exceeding the conventional C–S–H stoichiometric range (1.2–2.0) although remaining inferior to that of HPC 4 (Ca/Si = 6.86). This intermediate number indicates that HPC 4 offers a relatively higher calcium environment, however not to the same degree as HPC 3. The admixture, rich in calcium, can expedite the hydration of silicate phases and enhance the early availability of Ca⁺ ions. This facilitates accelerated setting and initial strength development in high-performance concretes.M60 grade concrete is typically formulated with micro silica, where the excess calcium from HPC 4 can actively interact with these supplementary cementitious materials to generate additional C–S–H. This pozzolanic combination enhances microstructural densification and long-term efficacy. The formulation of HPC 4 reveals a calcium-rich blend that may facilitate swift strength enhancement in M60 concretes, while simultaneously utilizing supplementary cementitious materials to improve durability by mitigating excess portlandite.

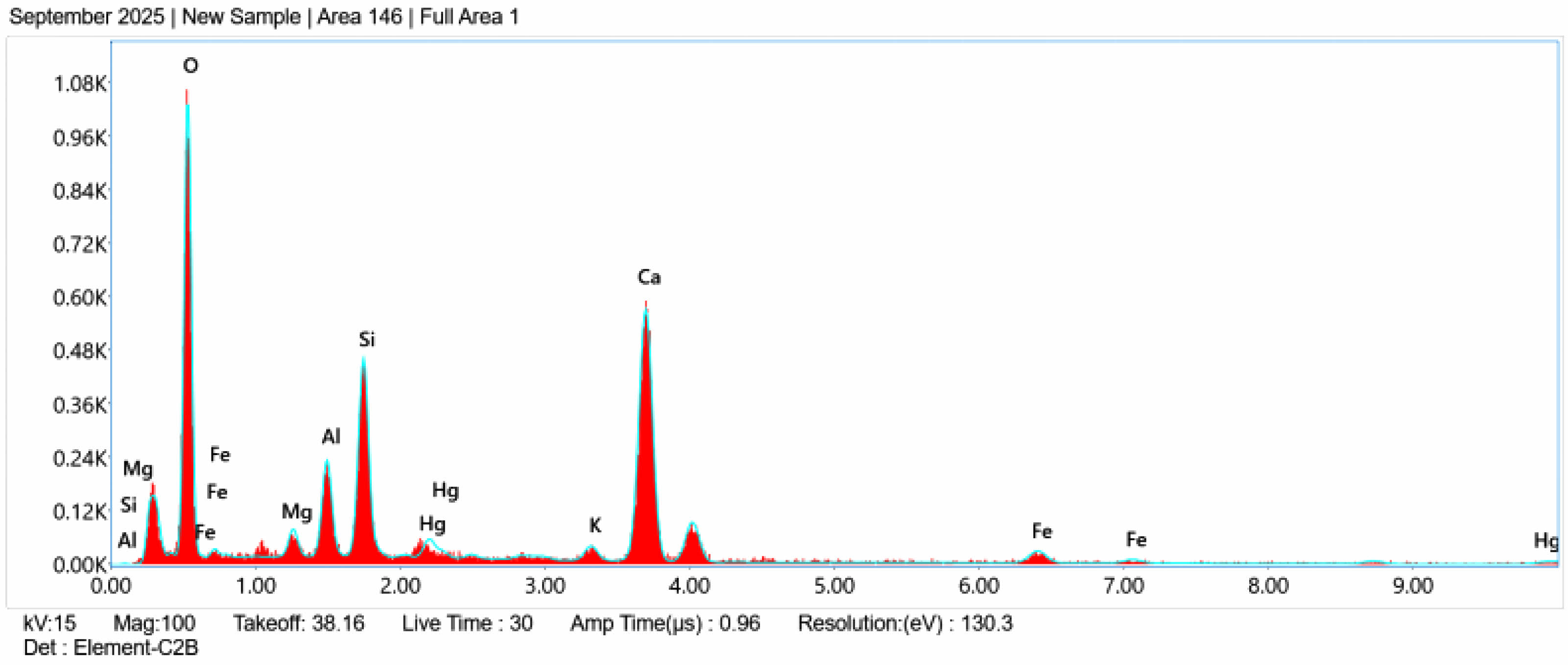

The elemental composition of the Varaplast PC 100 (HPC 5) chemical admixture was examined by EDX analysis. The spectrum depicted in Fig. 24 exhibits significant peaks attributed to oxygen (O), calcium (Ca), and silicon (Si), with additional small contributions from magnesium (Mg), aluminum (Al), potassium (K), titanium (Ti), iron (Fe), and cobalt (Co). EDX spectrum of the HPC 5 chemical admixture displaying principal and secondary elemental ingredients.

The quantitative data reveal that oxygen and calcium predominate in the composition, with weight percentages of 48.51% and 34.86%, respectively. Silicon, despite its lower concentration (5.08 wt.%), is noteworthy due to its crucial involvement in silicate phases and Ca–Si interactions within cementitious systems. The Ca/Si weight ratio was determined to be approximately 6.86, significantly exceeding the stoichiometric Ca/Si ratio of conventional calcium silicate hydrate (C–S–H) phases (1.2-2.0). This indicates that the admixture delivers a surplus of calcium, potentially affecting hydration kinetics, improving setting properties, and facilitating the production of portlandite (Ca(OH)₂) during hydration. Minor constituents, including Fe, Ti, and minor Co identified in the mixture, may function as inert fillers or nucleation sites during hydration. Although their concentrations are minimal, they may affect microstructural stability and crack resistance. The elevated oxygen concentration indicates the prevalence of oxide phases, aligning with standard admixture chemistry. The chemical profile of HPC 5 indicates its potential to enhance the hydration processes in M60 grade concrete by supplying ample calcium for early hydration, while also synergistically interacting with SCMs to attain the necessary strength and durability equilibrium of high-performance concretes [48].

The SEM images reveal that the inclusion of chemical admixtures leads to a denser and more homogeneous microstructure [49]. The reduction in pore size and improved ITZ contributed to enhanced mechanical and durability properties, and EDX analysis showed a higher Si/Ca ratio in mixes with chemical admixtures, indicating increased C-S-H formation, leading to an increase in the strength and durability of concrete. The reduced presence of CH suggests better utilization of calcium in the formation of durable hydration products.

NON Destructive Testing for High Performance Concrete

In the nondestructive testing, the ultrasonic sonic pulse velocity was conducted, as shown in Fig. 25. This non-destructive testing method indicates that the speed of an ultrasonic pulse passing through control concrete was found to be 3.9 km/s, HPC 1 and micro silica was found to be 4.4 km/s, HPC 2 and micro silica was found to be 4.6 km/s, HPC 3 and micro silica was found to be 4.5 km/s, HPC 4 and micro silica was found to be 4.3 km/s, and HPC 5 and micro silica was found to be 4.4 km/s. The UPV values for the mixtures with admixtures were higher than those of the control mix, indicating a dense and homogenous microstructure. This supports the SEM findings and enhances the durability. From the analysis it was observed that the concrete with chemical admixtures and micro silica has higher UPV values indicating better density and homogeneity.

|

Fig. 5 Compressive Strength of conventional and High Performance Concrete Mix. |

|

Fig. 6 Split Tensile Strength of Conventional and High Performance Concrete Mix. |

|

Fig. 7 Flexural Strength of Conventional and High Performance Concrete Mix. |

|

Fig. 8 Bond Strength of Conventional and High Performance Concrete Mix. |

|

Fig. 9 Rapid Chloride Penetration Test of High Performance Concrete Mix. |

|

Fig. 10 Salt Ponding of High Performance Concrete Mix. |

|

Fig. 11 Sorptivity of High Performance Concrete Mix. |

|

Fig. 12 Sorptivity of High Performance Concrete Mix. |

|

Fig. 13 SEM micrograph of control concrete. |

|

Fig. 14 SEM micrograph of HPC 1. |

|

Fig. 15 SEM micrograph of HPC 2. |

|

Fig. 16 SEM micrograph of HPC 3. |

|

Fig. 17 SEM micrograph of HPC 4. |

|

Fig. 18 SEM micrograph of HPC 5. |

|

Fig. 19 EDX image of Control Concrete. |

|

Fig. 20 EDX image of HPC 1. |

|

Fig. 21 EDX image of HPC 2. |

|

Fig. 22 EDX image of HPC 3. |

|

Fig. 23 EDX image of HPC 4. |

|

Fig. 24 EDX image of HPC 5. |

|

Fig. 25 Ultrasonic Pulse Velocity Test. |

This study showed that the addition of micro silica and specific chemical admixtures markedly enhanced the mechanical and durability properties of M60 grade high-performance concrete (HPC). The compressive strength of the control mix was approximately 62 MPa at 28 days, whereas the mix containing Glenium Ace 30 attained 75.6 MPa, indicating a 22% enhancement. The split tensile strength increased from 4.5 MPa in conventional concrete to 5.4 MPa in HPC mixes, demonstrating an approximate 20% improvement. The flexural strength of HPC with Glenium Ace 30 attained 7.6 MPa, in contrast to 6.0 MPa for the control, reflecting a 27% enhancement. Bond strength values increased significantly, with the optimal mixture attaining 29.2 MPa compared to 22.5 MPa for ordinary concrete, demonstrating a 30% improvement in reinforcement-concrete adhesion. Durability studies further validated the exceptional performance of HPC mixtures. The Rapid Chloride Penetration Test (RCPT) values diminished from 2500 Coulombs for the control to 1400 Coulombs for HPC 2, indicating a 44% decrease in chloride permeability. Salt ponding depths diminished from 15 mm in ordinary concrete to 4 mm in the most effective high-performance concrete, indicating substantial resistance to chloride penetration. Sorptivity measurements decreased from 0.15 mm/min0.5 to 0.08 mm/min0.5, signifying a reduction of approximately 47% in water absorption. Water permeability decreased from 1.5 × 10⁻¹⁰ m/s to 0.8 × 10⁻¹⁰ m/s, indicating a 46% enhancement in pore refinement. Accelerated chloride migration tests demonstrated minimum penetration depths of 12 mm in high-performance concrete (HPC), in contrast to 20 mm for the control specimen. Microstructural investigations utilizing SEM and EDX validated the presence of denser matrices, less porosity, and increased C-S-H gel formation in HPC mixtures. The non-destructive ultrasonic pulse velocity (UPV) measurements rose from 3.9 km/s for the control to 4.6 km/s for high-performance concrete (HPC), indicating a uniform and dense structure.

- 1. S. Abbas, A.M. Soliman, and M.L. Nehdi, Constr. Build. Mater. 75 (2015) 429-441.

-

- 2. S. Ahmad, Cem. Concr. Compos. 25 (2003) 459-471.

-

- 3. S. Ahmad, A.A. Bahraq, A. Al-Fakih, M. Maslehuddin, and M.A. Al-Osta, Arab. J. Sci. Eng. 48 (2023) 1-15.

-

- 4. M.H. Akeed, S. Qaidi, H.U. Ahmed, R.H. Faraj, A.S. Mohammed, W. Emad, B.A. Tayeh, and A.R.G. Azevedo, Case Stud. Constr. Mater. 17 (2022) e01271.

-

- 5. ASTM International, ASTM C494: Standard Specification for Chemical Admixtures for Concrete, ASTM Int. (2017).

- 6. A.A. Bahraq, M.A. Al-Osta, S. Ahmad, M.M. Al-Zahrani, S.O. Al-Dulaijan, and M.K. Rahman, Int. J. Concr. Struct. Mater. 13 (2019) 1-19.

-

- 7. J.P. Broomfield, Corrosion of Steel in Concrete: Understanding, Spoon Press (2003).

-

- 8. Y. Dong, Constr. Build. Mater. 167 (2018) 414-425.

-

- 9. L. Fan, W. Meng, L. Teng, and K.H. Khayat, Compos. Part B Eng. 177 (2019) 107445.

-

- 10. F. de Larrard and T. Sedran, Cem. Concr. Res. 32 (2002) 1699-1704.

-

- 11. P. Lambert, C.L. Page, and P.R.W. Vassie, Mater. Struct. 24 (1991) 351-358.

-

- 12. V. Sampathkumar, S. Manoj, and S. Anandakumar, J. Ceram. Process. Res. 25[4] (2024) 633-642.

-

- 13. K.B. Krishnan, K. Nirmalkumar, V. Sampathkumar, and P.C. Murugan, J. Ceram. Process. Res. 24[4] (2023) 714-722.

-

- 14. S. Saleh, A.H. Mahmood, E. Hamed, and Z. Zhao, Constr. Build. Mater. 372 (2023) 130815.

-

- 15. C.M. Tibbetts, J.M. Paris, C.C. Ferraro, K.A. Riding, and T.G. Townsend, Cem. Concr. Compos. 107 (2020) 103491.

-

- 16. C. Wen, P. Zhang, J. Wang, and S. Hu, J. Build. Eng. 52 (2022) 104370.

-

- 17. C. Andrade and C. Alonso, Constr. Build. Mater. 10 (1996) 315-328.

-

- 18. J.P. Broomfield, Corrosion of Steel in Concrete: Understanding, Investigation and Repair, Taylor & Francis (2007).

- 19. H. Yu, K.K. Chiang, and L. Yang, Constr. Build. Mater. 26 (2012) 723-729.

-

- 20. J. Dils, G. De Schutter, and V. Boel, Mater. Struct. 45 (2012) 1673-1683.

-

- 21. S. Pyo, T. Koh, M. Tafesse, and H.K. Kim, Constr. Build. Mater. 223 (2019) 206-213.

-

- 22. S. Ahmad, I. Hakeem, and M. Maslehuddin, Eur. J. Environ. Civ. Eng. 19 (2015) 1106-1126.

-

- 23. M.A. Al-Osta, Adv. Civ. Eng. 2018 (2018) 8678124.

-

- 24. C.E. Chalioris, G.E. Thermou, and S.J. Pantazopoulou, Constr. Build. Mater. 53 (2014) 257-273.

-

- 25. F.A. Farhat, D. Nicolaides, A. Kanellopoulos, and B.L. Karihaloo, Eng. Fract. Mech. 74 (2007) 151-167.

-

- 26. X. Shi, N. Xie, K. Fortune, and J. Gong, Constr. Build. Mater. 30 (2012) 125-138.

-

- 27. W. Cao, X. Wan, and T. Zhao, Adv. Mater. Res. 250-253 (2011) 202-206.

-

- 28. B. Junyig, A. Hongmei, and L. Puguang, Key Eng. Mater. 477 (2011) 398-403.

-

- 29. O. Mazanec and D. Lowke, Mater. Struct. 43 (2010) 357-365.

-

- 30. D. Chopin, F. de Larrard, and B. Cazacliu, Cem. Concr. Res. 34 (2004) 2237-2243.

-

- 31. S. Bhanja and B. Sengupta, Cem. Concr. Res. 35 (2005) 743-747.

-

- 32. K.H. Tan, T.Y. Wang, Z.H. Zhou, and Y.H. Qin, J. Mater. Civ. Eng. 33 (2021) 03121001.

-

- 33. E. Yasar, C.D. Atis, A. Kilic, and H. Gulsen, Mater. Lett. 57 (2003) 2267-2270.

-

- 34. B. Chen and J. Liu, Constr. Build. Mater. 22 (2008) 1108-1113.

-

- 35. K.L. Scrivener, Mater. Sci. Eng. (2024) 229-242, CRC Press.

-

- 36. S.A. Khedr and M.N. Abou-Zeid, J. Mater. Civ. Eng. 6 (1994) 357-375.

-

- 37. S. Arunachalam, S. Anandakumar, R. Ranjani, A.R. Varma, and G. Rajkumar, Mater. Today Proc. 47 (2021) 5297-5301.

-

- 38. B. Gong and H. Li, Struct. Eng. Mech. 91[3] (2024) 239-250.

- 39. L. Yang, Y. Gao, H. Chen, H. Jiao, M. Dong, T. A. Bier, and M. Kim, Adv. Cem. Res. 36[12] (2024) 567-586.

-

- 40. M. Wang, S. Zhu, F. Jiang, Y. Feng, X. Zhang, Y. Wang, and C. Zhu, Rock Mech. Rock Eng. (2025).

-

- 41. H. Li, M. Duan, X. Yang, R. Wang, and Z. Ouyang, Eng. Geol. 356 (2025) 108273.

-

- 42. J. Wang, Z. Wu, J. Han, G. Wang, and S. Lv, Tunn. Undergr. Space Technol. 165 (2025) 106864.

-

- 43. G. Kong, G. Sun, H. Liu, and J. Li, J. Test. Eval. 49[3] (2021) 1691-1704.

-

- 44. Y. Niu, W. Wang, Y. Su, F. Jia, and X. Long, Acta Mech. 235[1] (2024) 255-266.

-

- 45. D. Xu, S. Zhang, and Y. Qin, J. Geophys. Res. Solid Earth. 129[11] (2024) e2024JB029131.

-

- 46. H. Huang, M. Huang, W. Zhang, S. Pospisil, and T. Wu, J. Struct. Eng. 146[8] (2020).

-

- 47. L. Sun, C. Wang, C. Zhang, Z. Yang, C. Li, and P. Qiao, Adv. Struct. Eng. 26[3] (2023) 533-546.

-

- 48. D. Mani, G.S. Rampradheep, S. Velusamy, and H. Sudhakar, J. Ceram. Process. Res. 25[6] (2024) 997-1006.

-

- 49. P. Subashree, V. Sampathkumar, S. Gowtham, A.A. AlObaid, and I. Warad, J. Ceram. Process. Res. 25[2] (2024) 220-227.

-

This Article

This Article

-

2025; 26(5): 767-778

Published on Oct 31, 2025

- 10.36410/jcpr.2025.26.5.767

- Received on Jul 11, 2025

- Revised on Sep 24, 2025

- Accepted on Oct 2, 2025

Services

Services

- Abstract

introduction

investigation of the experiment

results and discussion

conclusions

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Sivakumar Arunachalam

-

Department of Civil Engineering, Kangeyam Institute of Technology, Tirupur – 638108, India

Tel : +91 8903486090 - E-mail: sivadevi6224@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.