- Study on cobalt-blue pigment of blue-and-white porcelain from the Zhengde imperial kiln of Ming Dynasty (AD 1506-1521)

Xiaolong Lia,b, Weixia Donga,*, Qifu Baoa,*, Zhipeng Chena, Yulong Yanga, Kun Liuc and Jianer Zhoua

aMaterials science and engineering, Jingdezhen Ceramic University, Jingdezhen, Jiangxi, 333000, PR China

bJiangxi arts and ceramics technology institute, Jingdezhen, Jiangxi, 333400, PR China

cKey Laboratory of Inorganic Coating Materials CAS, Shanghai Institute of Ceramics, Chinese Academy of Sciences (SICCAS), Shanghai, 200050, PR ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Blue-and-white porcelain is a kind of famous underglaze color porcelain in Chinese ceramic history. However, during the same period, blue-and-white porcelain exhibited different tones and “color dispersion” distances, such as during the Zhengde period. Energy Dispersive X-Ray Fluorescence (EDXRF), colorimetry, Optical Microscope (OM), etc, were used to study on the blue-and-white porcelain from the Hongzhi, Zhengde and Jiajing imperial kiln of Ming Dynasty. The results show that the cobalt-blue pigment of Zhengde imperial Kiln can be divided into three stages. The early years of Zhengde were similar to those of Hongzhi period, the blue-and-white porcelain showed blue tone due to use “Pingdengqing” cobalt-blue pigment with high Mn, low Co and high Al2O3 contents, “color dispersion” distance about 100 μm. In the middle period of Zhengde, the blue-and-white porcelain showed gray blue tone due to use “Shiziqing” cobalt-blue pigment with higher Mn, lower Co and similar Al2O3 content, compared with that of “Pingdengqing” cobalt-blue pigment, “color dispersion” distance about 100 μm. The later period of Zhengde was similar to the period of Jiajing, blue-and-white porcelain showed vivid slightly purplish-blue tone due to use “Huiqing” cobalt-blue pigment with low Mn, high Co and low Al2O3 contents, “color dispersion” distance about 180~650 μm. It can be known from archaeological experiments that the “color dispersion” distance and the crystal structure of the interaction layer of blue-and-white porcelain can be used to infer the content of Al2O3 in blue pigment. The experimental results enrich the historical documents of cobalt-blue pigment of Zhengde imperial Kiln in Ming Dynasty.

Keywords: Blue-and-white porcelain, Color dispersion, Co-spinel crystal, Cobalt-blue pigment.

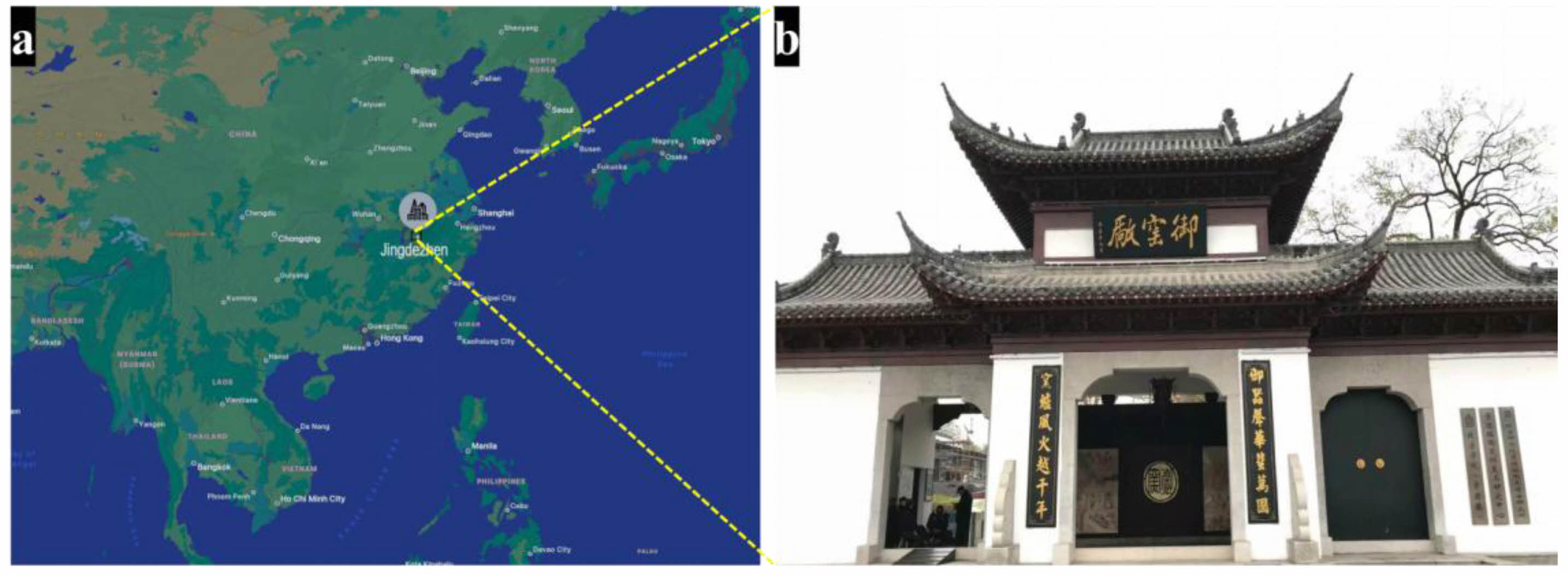

The blue-and-white porcelain of imperial kiln is favored by people because of its the elegant blue-white picture and exquisite manufacturing techniques. The existing archaeological materials show that the origin of blue-and-white porcelain can be traced back to the Tang Dynasty. In the Yuan Dynasty, blue and white porcelain began to be produced on a large scale in Jingdezhen [1]. The Ming Dynasty was the golden period for the development of blue-and-white porcelain. During the reign of Hongwu, an imperial kiln factory was set up in the Zhushan District of Jingdezhen to fire imperial porcelain, which was called “imperial kiln” porcelain, as shown in Fig. 1. It was the earliest imperial kiln in Jingdezhen in the Ming Dynasty [2, 3]. During the Zhengde period of the Ming Dynasty, as the imported “Smalt” blue pigment was nearly exhausted [2, 4-6], the use of domestic blue pigment became a common practice in the market. However, due to the different origins and composition of domestic blue pigment, their tones and “color dispersion” (i.e. fuzzy) often varied. Previous technological research on ancient ceramics has mainly focused on their composition, ionic valence, and microstructure [7-11]. The earliest research on chemical composition can be traced back to Academician Zhou Ren's chemical analysis of Southern Song imperial Kiln porcelain pieces in “Jiaotan”, Hangzhou in the early 1930s, after which the Shanghai Institute of Ceramics of the Chinese Academy of Sciences published the element content data of 700 ancient porcelain bodies and 462 ancient porcelain glazes, including blue and white porcelain from Jingdezhen [12]. In 1978, Chen et al. [13] tested the chemical composition of blue-and-white porcelain bodies, glazes and blue pigments in the past dynasties through electronic probe, and compared Fe2O3/CoO and MnO/CoO in blue-and-white porcelain to determine the types, ages and colors of cobalt-blue pigment used in blue-and-white porcelain. Later, Yu [14-16], Wu [1, 17, 18], Zhu [19, 20], Pinto [21] and others conducted similar studies through nondestructive test analysis.

According to the literature [6], during the reign of Zhengde of the Ming Dynasty, three types of cobalt blue pigments were used. In the early period of the Zhengde reign, the cobalt blue pigment used was “Pingdengqing”. In the middle period of the Zhengde reign, it was Gao'an “Shiziqing”. In the late period of the Zhengde reign, it was “Huiqing” mixed with “Shiziqing”. Why were mixed cobalt-based pigments used in the late period of Zhengde? According to historical records [4, 22], if only “Huiqing” is used alone, the “color dispersion” effect of the blue-and-white porcelain is quite significant. If only “Shiziqing” is used alone, the blue-and-white porcelain will appear dull and lack luster. From this, it can be inferred that the blending of the two kinds of blue pigments can solve the problem of “color dispersion”. To our knowledge, due to the disappearance of cobalt ore raw materials as cobalt-blue pigment in ancient dynasties, [22] it is difficult to trace back to ancient times. There are few reports on the relationship between chemical composition and “color dispersion”. In this study, by comparing the chemical composition of blue pigments and the microstructure of blue and white porcelain during the Hongzhi, Zhengde, and Jiajing periods, the relationship between the color, “color dispersion” and crystal structure of blue-and-white porcelain in Zhengde period was revealed.

|

Fig. 1 (a) Location of Jingdezhen City, Jiangxi Province (world map). (b) Photograph of imperial kiln factory (taken by me) |

Samples

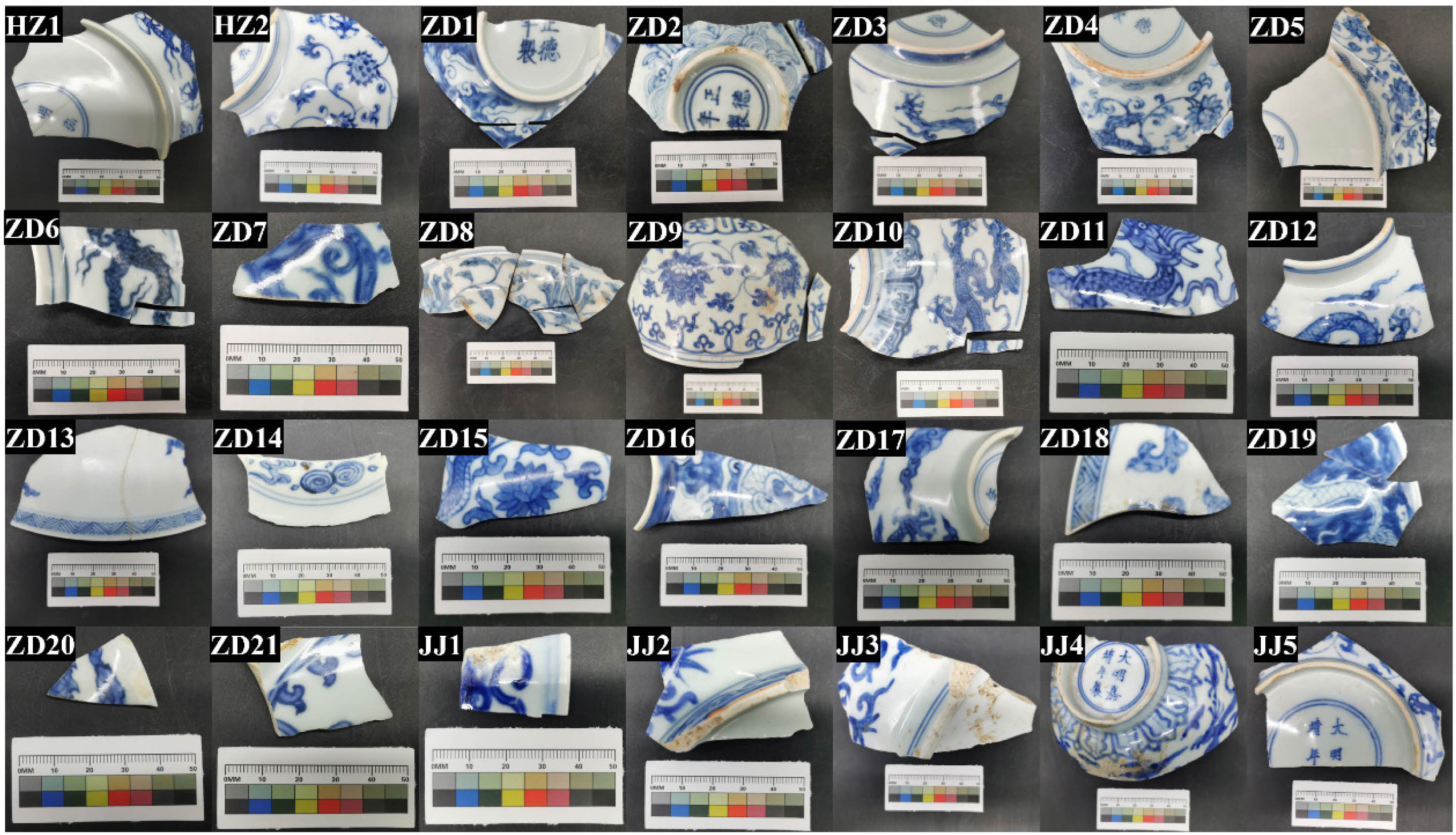

The typical blue-and-white porcelain sherds were collected from Imperial Kiln Museum in China. Two pieces of blue-and-white porcelain sherds (named as HZ1 and HZ2, respectively) are from Hongzhi period in the Ming Dynasty (AD 1488–1505), twenty-one pieces of blue and white porcelain sherds (named as ZD1~ZD21, respectively) are from Zhengde period in the Ming Dynasty (AD 1506–1521), five pieces of blue-and-white porcelain sherds (named as JJ1~JJ5) are from Jiajing period in the Ming Dynasty (AD 1522–1566). Photos of the typical blue and white porcelain sherds are shown in Fig. 2.

Testing methods

Blue color zones of the blue and white porcelain were measured using a Konica Minolta CM-700d spectrometer with a 10° angle. Small zones were adapted by a 3 mm aperture. Each zone underwent 3 measurements. The colorimetric data was exploited using the CIE Lab 1976 system (NIPPON DENSHOKU). Each color is defined by three values: a*, b*, L* expresses the green (-100) and red (+100) components, the blue (-100) and yellow (+100) components and the brightness between black (0) and white (100), respectively. EDXRF (energy-dispersive X-ray fluorescence) was employed for quantitative analysis of chemical composition of the porcelain glaze and cobalt-blue pigment. The energy-dispersive X-ray fluorescence (EDXRF) technique is now well established as a powerful tool for studying ancient ceramics by analyzing element composition, which provides quick, non-destructive analysis, involving easy sample preparation and good reproducibility. The EDXRF spectrometer used was a Philips DX-95, with excitation provided by a target X-ray tube and an Si (Li) detector. An exposure time of 600 s was used for all samples. In order to observe the ‘color dispersion’ phenomenon of the blue-and-white porcelain, digital microscope (VHX-6000, Japan) was applied (OM). The surface of the porcelain pieces was observed. The cross-sections of the porcelain shards etched in 8 wt% HF at the room temperature were performed on cross sections using a scanning electron microscope (SU8010, HITACHI, Kyoto, Japan) equipped with an energy-dispersive X-ray spectrometer (SEM-EDS). The samples were analyzed by using the X-Ray diffractometer (XRD, DX-2700B, China) with the radiation wavelength of Cu-Kα is 0.154 nm, 2θ=5 °~80 °, and the step length is 0.02 °.

Methods of experimental archeology

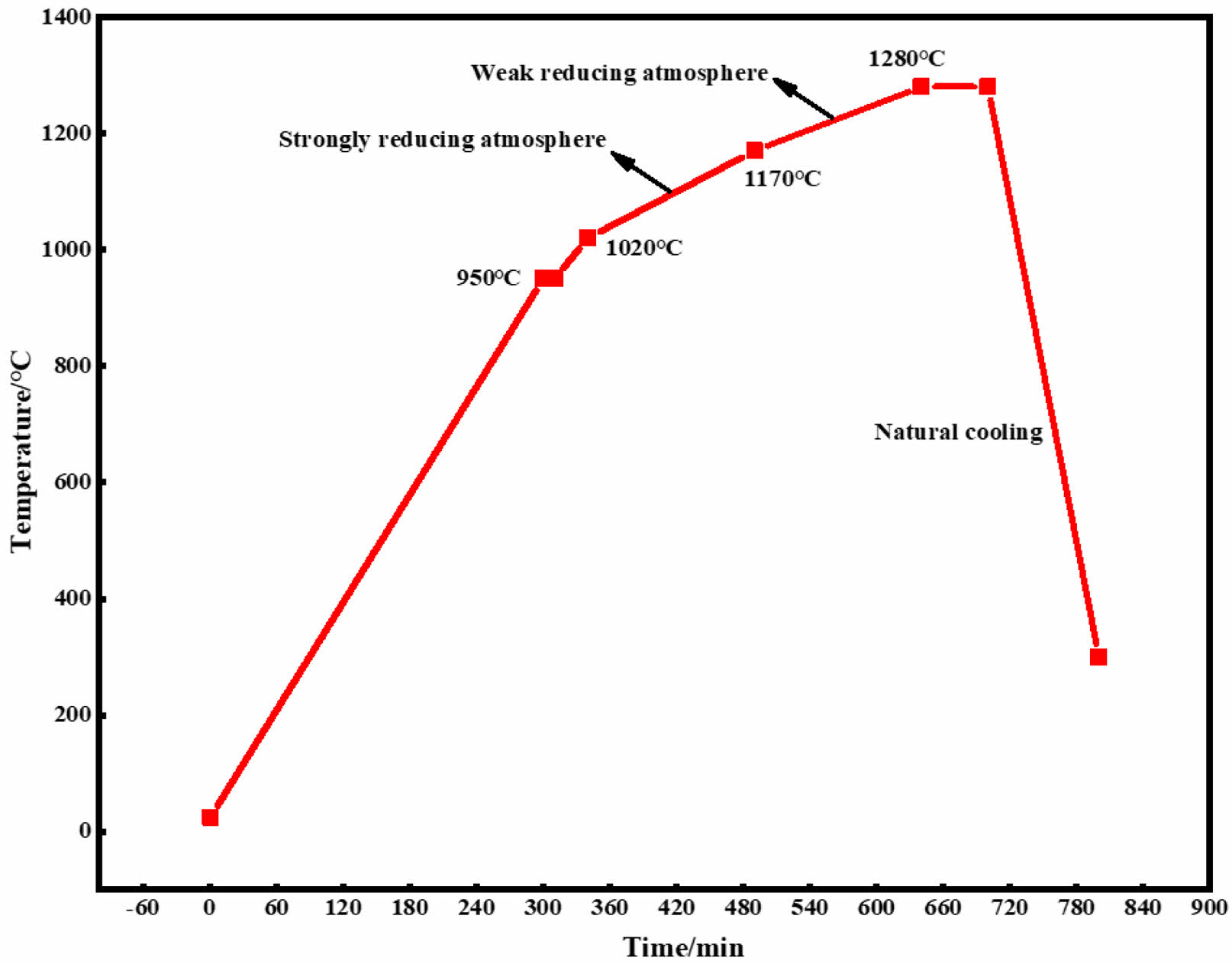

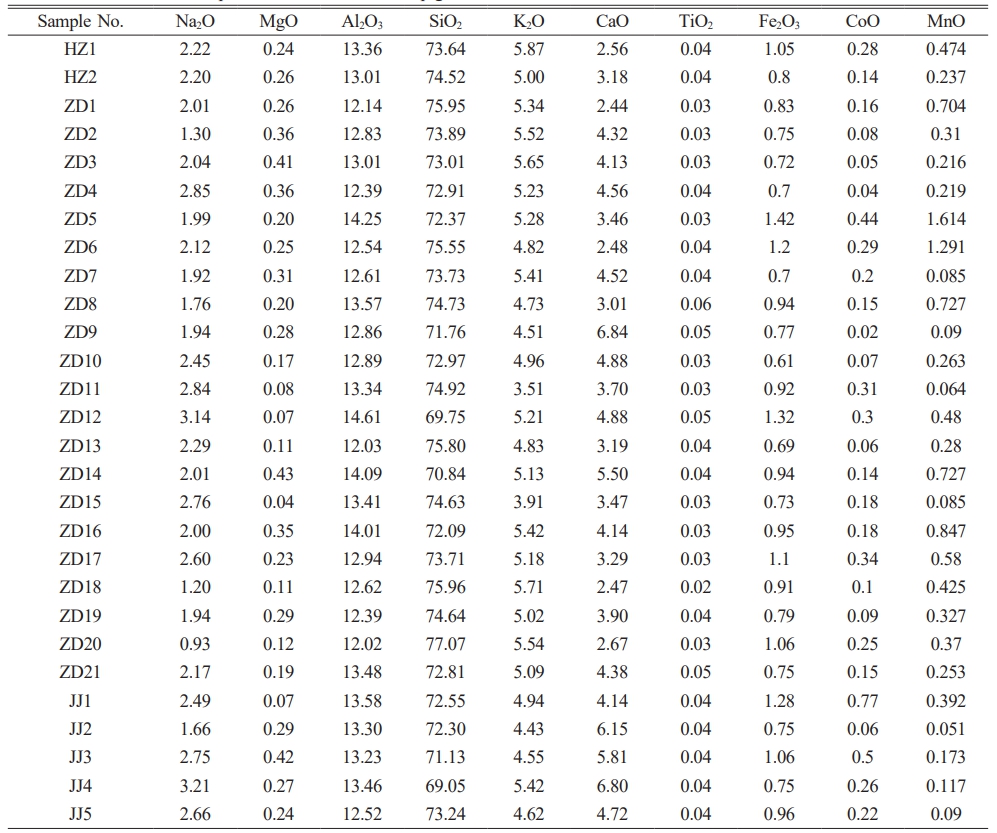

The chemical composition of raw materials for experiments is shown in Table 1. The archaeological experimental study investigated the influence of the content of Al2O3 (added at 5 wt% and 10 wt%) in the cobalt-blue pigment on the “color dispersion” of blue-and-white porcelain. The body and glaze were prepared based on Zhengde period chemical composition by the traditional ceramic firing process. The samples are fired based on the certain firing system by the gas shuttle kiln (Fig. 3).

|

Fig. 2 Photos of blue-and-white porcelain samples. HZ1 and HZ2 sherds (Hongzhi in Ming Dynasty, AD 1488-1505), ZD1~ZD21 sherds (Zhengde in Ming Dynasty, AD 1506-1521), and JJ1~JJ5 sherds (Jiajing in Ming Dynasty, AD 1522-1566). |

|

Fig. 3 Firing system |

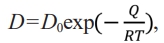

The colorimetric measurements on blue decorations are presented in Appendices (Table S1) and the a* and b* values are shown in Fig. 4. The colorimetric values of Group 1 (ZD7, ZD11, ZD15, JJ1, JJ2, JJ3, JJ4, JJ5) are characterized by negative b* and positive a* value corresponding. This group corresponds to the later period of Zhengde and the period of Jiajing. Its b* value is lower than -20.6. The blue-and-white porcelain specimens show a vivid slightly purplish blue. Group 2 includes seven samples (HZ1, HZ2, ZD9, ZD12, ZD17, ZD20, ZD21). The colorimetric values are characterized by a negative b* and a negative a* values corresponding to blue. This group corresponds to the period of Hongzhi and the early years of Zhengde, and includes blue samples with b* values ranging from -14.86 to -20.23. Group 3 includes thirteen samples (ZD1, ZD2, ZD3, ZD4, ZD5, ZD6, ZD8, ZD10, ZD13, ZD14, ZD16, ZD18, ZD19). The colorimetric values are characterized by a negative b* and a negative a* values corresponding to gray blue. This group contains the gray blue samples with a b* value between -4.09 and -13.43.

In terms of mineralogy; manganese, iron, copper, arsenic, nickel, and zinc, as well as other related elements, typically correspond with particular cobalt ore sources [5]. Due to the different pigment ores origins, the types and quantities of paragenetic elements are also changeable. Therefore, examining the variability in symbiotic elements is presently the universal method for provenance study of blue pigment [2]. Iron, manganese and cobalt are considered to be the elements with the most significant impact on blue coloration [23]. The MnO/CoO and Fe2O3/CoO ratios could potentially be characteristic of particular cobalt rich materials [5, 24, 25], thus the comparative results can often approximately discern the provenance. The research results show that the MnO/CoO ratio of imported cobalt-blue pigments from abroad is generally less than 1, while the MnO/CoO ratio of domestic cobalt-blue pigments is greater than 1 [13].

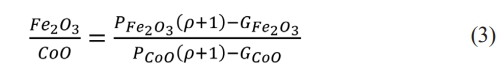

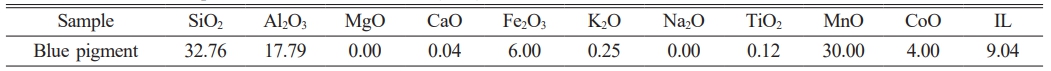

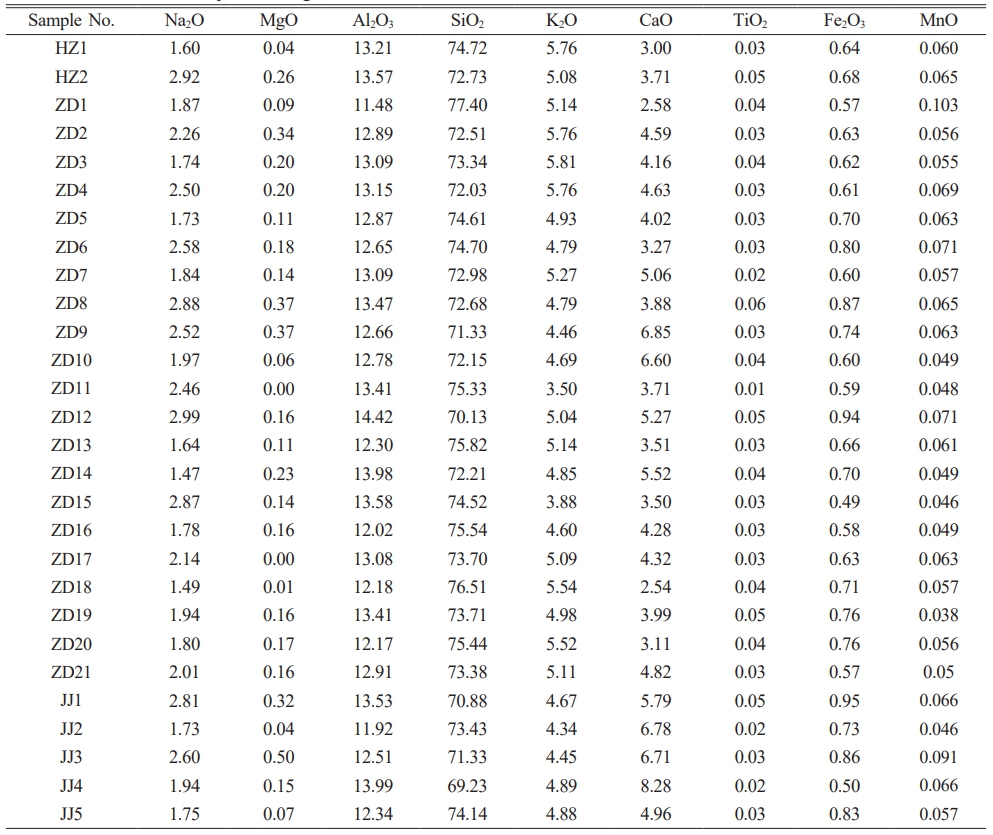

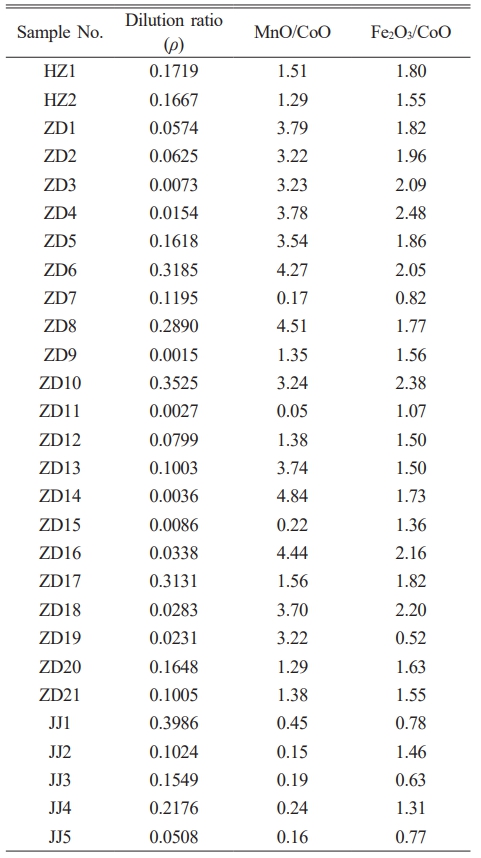

The composition of actually in cobalt-blue pigment is a difficult problem in this work, because cobalt-blue pigment is only a very thin middle layer between the glaze and body, even if the body grinding method is used, but the blue decoration part of blue-and-white porcelain cannot be separated from the glaze. In this situation, the chemical compositions of the glaze and the blue decoration part are analyzed separately. Then, through calculation, the ratios of MnO/CoO and Fe2O3/CoO in the blue decoration part can be derived. The calculation method is as follows. The chemical analyses of the glaze and the blue decoration part are presented in Table 2 and Table 3. The chemical analysis of the cobalt-blue pigment is shown in Appendices Table S2 [13], it can be seen from Table 2, Table 3 and Appendices Table S2 that the content of calcium oxide in cobalt-blue pigment is very small, and the content of calcium oxide in the glaze is up to ten times more than that of cobalt-blue pigment, so when cobalt-blue pigment is combined with the glaze, the calcium oxide in cobalt-blue pigment can be ignored. In this way, each sample can obtain the calcium oxide content change value between them by analyzing the composition of the glaze and the blue decoration part two parts, The dilution ratios (ρ) of the ‘blue and white’ to the ‘glaze’ can then be calculated using formula (1) [7, 13], with the results given in Table 4.

* ρ = dilution ratio, C = CaO concentration, Cp = CaO in pigment, Cg = CaO in glaze.

Element percentage in cobalt-blue pigment can be obtained from the dilution ratio based on the formula (2):

where A - element percentage content, G (glaze), P (pigment).

The dilution factors are then used, in combination with the ratios of MnO, Fe2O3 and CoO, to determine the dilution corrected ratios. These corrected ratios should better represent the characteristics of cobalt-blue pigment, allowing for a more representative comparison. The calculation methods are as shown in formula (3) and (4), and the thus results are presented in Table 4.

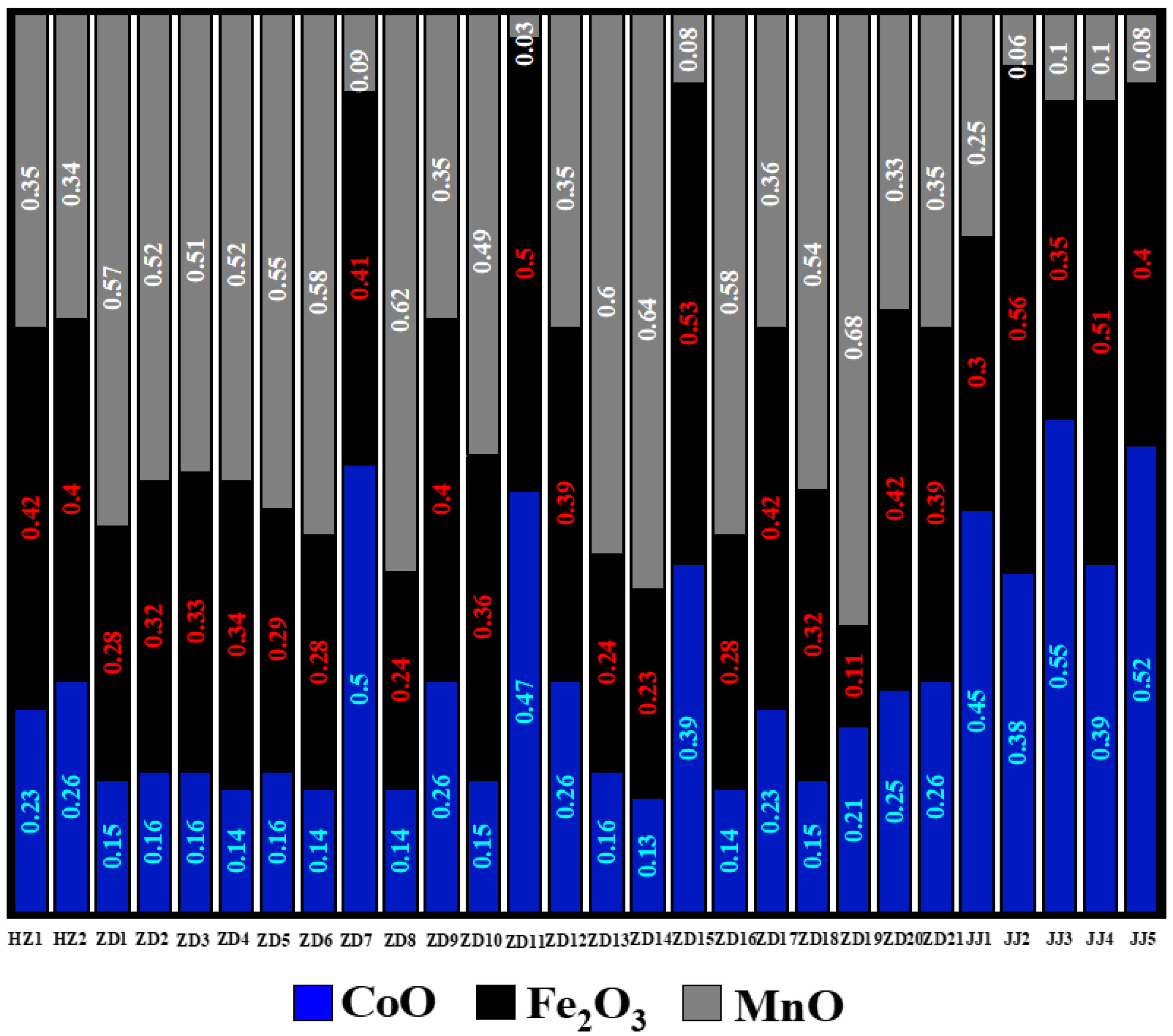

The calculated MnO, CoO and Fe2O3 proportion in the blue decorations of the samples is shown in Fig. 5. As can be seen from the Fig. 5, during the Zhengde period, the cobalt-blue pigments could be divided into three categories. The first category, including seven samples (HZ1, HZ2, ZD9, ZD12, ZD17, ZD20, ZD21), the CoO and MnO content in the cobalt-blue pigments used in these samples was 25% and 35%, respectively. According to the literature [4, 6] that Hongzhi inherited the characteristics of Chenghua blue-and-white porcelain, in the early years of the Zhengde period, the materials and techniques of the Hongzhi period were continued. From the Ming Dynasty scholar Gao Lian's “Yan Xian Qing Appreciation note”, it was recorded that “to the Chenghua kiln are ‘Pingdengqing’ [26]”. The “Pingdengqing” mentioned by Gao Lian refers to the “Potangqing” cobalt ore produced in Leping County, Jiangxi Province. So, in the early Zhengde period, one type is similar to the cobalt-blue pigment (Pingdengqing) used during the Hongzhi period of the Ming Dynasty, the b* value of blue-and-white porcelain with “Pingdengqing” cobalt-blue pigment is between -14.8 and -20.23 (Fig. 4), and the color is blue. The second category includes thirteen samples (ZD1, ZD2, ZD3, ZD4, ZD5, ZD6, ZD8, ZD10, ZD13, ZD14, ZD16, ZD18, ZD19), with a CoO content of about 15% and MnO content of about 60% in cobalt-blue pigment, which indicate a lower cobalt and higher manganese type. According to the Jiangxi Ruizhou Annals of Zhengde ten years of the Ming Dynasty (1515) “Tianzegang in Shanggao County has ‘Shiziqing’, and Jingdezhen is used to paint porcelain.” This is a clear record that Jingdezhen used Ruizhou blue pigment ‘Shiziqing’ in the Zhengde period [4]. So, during the middle period of Zhengde, the “Shiziqing” was used, the b* value is between -4.09 and -13.43 (Fig. 4), and the color is gray blue. The third category consists of eight samples (ZD7, ZD11, ZD15, JJ1, JJ2, JJ3, JJ4, JJ5), exhibits the CoO content of about 50%, and the MnO content of about 10% in cobalt-blue pigment, which belongs to a high CoO and low MnO type of cobalt-blue pigment. According to Wang Shimao’s “kuitianwaichen”, “‘Huiqing’ is from abroad, Zhengde period, Dadang Town, Yunnan Province got it and as a gem, whose price is twice that of gold, by that time we already knew that it could be used to make porcelain, and it worked very well [27].” According to the records Jiangxi Provincial da zhi volume seven Pottery Book · Huiqing [22], “ceramic used ‘Huiqing’, which was originally a foreign tribute item. During the Jiajing period, it was used to produce imperial kiln porcelain.” According to this, the imported ‘Huiqing’ had begun to be used in Zhengde, but it was greatly popular in the Jiajing Dynasty. Therefore, during the late period of Zhengde, one type is similar to the cobalt-blue pigment (Huiqing) used during the Jiajing period of the Ming Dynasty, the b* value is below -20.6 (Fig. 4), and the color is vivid slightly purplish blue. Combined with the chemical composition of the cobalt-blue pigment and chromaticity value analysis, it can be seen from the cobalt content of cobalt-blue pigment that the b* value decreases as the cobalt content increases, as described by Chen [13], Zhou [28] and pinto [21], the main colorant element of the blue decoration was usually cobalt. Moreover, according to the literature [28], it is mentioned that as the manganese content in the cobalt-blue pigment increases, the a* value decreases the b* value increases, the blue-and-white porcelain turns gray blue.

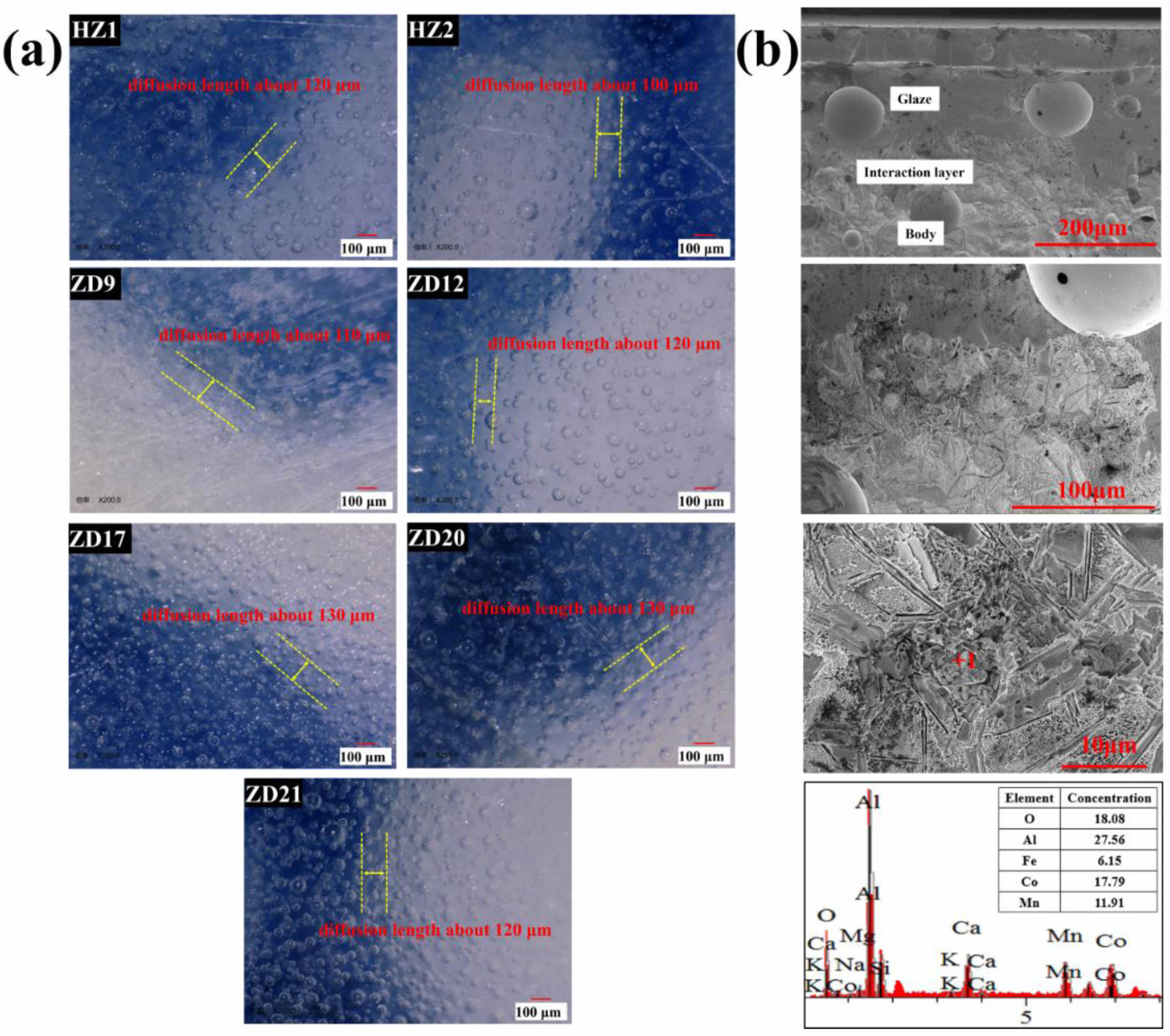

In order to determine the relationship between cobalt-blue pigment and “color dispersion”, the optical photographs and microscopic structures of the samples from the Hongzhi period and the early years of the Zhengde are shown in Fig. 6. As can be seen from Fig. 6(a) the diffusion distance of blue-and-white porcelain are about 100 μm. Fig. 6(b) shows the SEM-EDS results of the typical sample ZD9. It can be seen from Fig. 6(b) the sample are divided into three layers: a dense glaze layer, an interaction layer and relatively loose body. In the interaction layer exhibit many needle-like crystals and particles with the different shapes. EDS results at point 1 in Fig. 6(b) show that the particles are composed of Co+Fe+Mn, Al and O elements with an atomic ratio of about 1: 2: 4, which are close to the stoichiometry of Co-spinel crystals.

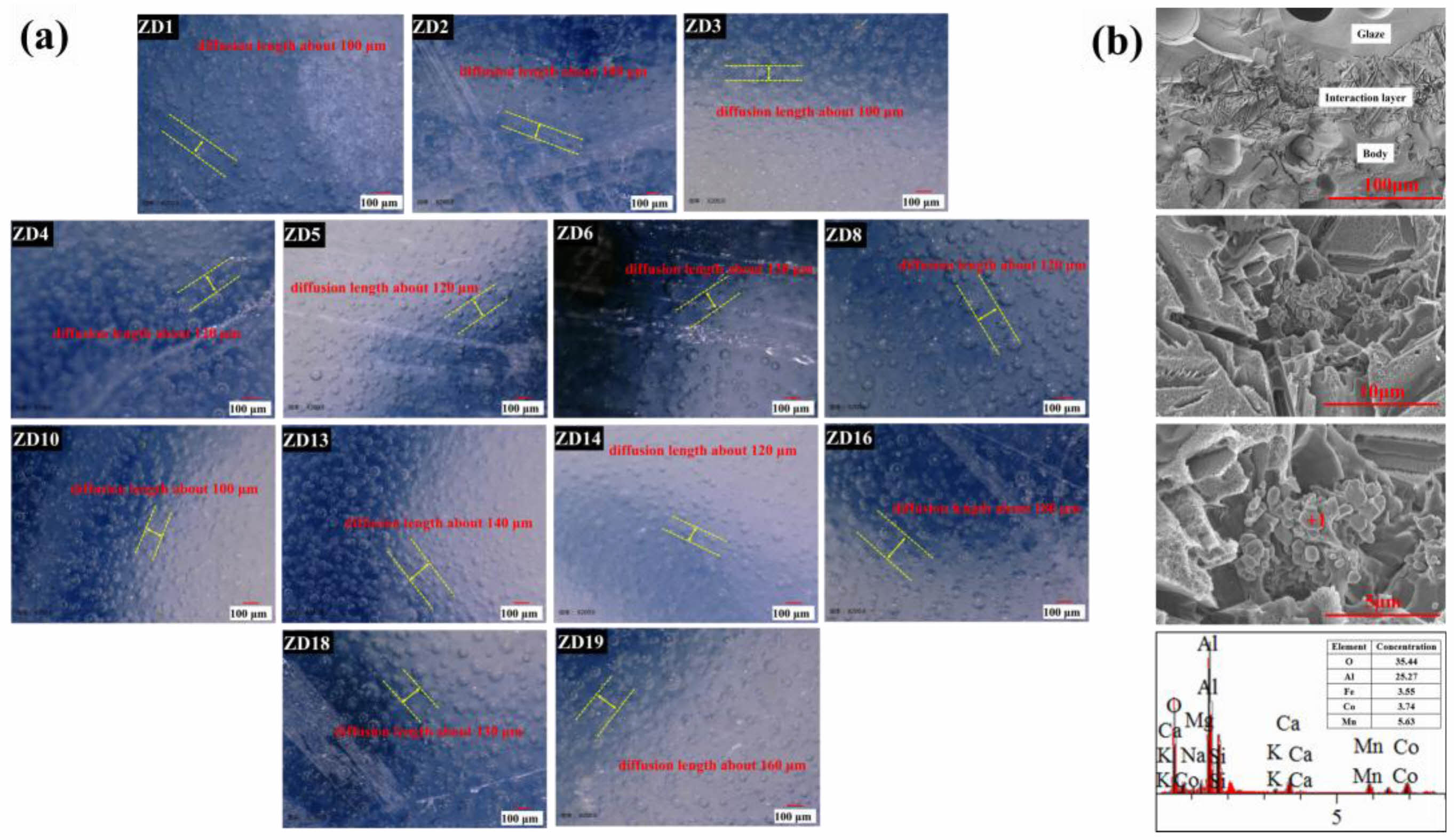

The optical photographs and microscopic structures of the samples from the middle period of Zhengde are shown in Fig. 7. As can be seen from Fig. 7(a) the diffusion distance of blue-and-white porcelain are about 100 μm. Fig. 7(b) shows the SEM-EDS results of the typical sample ZD16. It can be seen from Fig. 7(b) the sample are divided into three layers: a dense glaze layer, an interaction layer and relatively loose body. In the interaction layer exhibit many needle-like crystals and particles with the different shapes. EDS results at point 1 in Fig. 7(b) show that the particles are composed of Co+Fe+Mn, Al and O elements with an atomic ratio of about 1: 2: 4, which are close to the stoichiometry of Co-spinel crystals.

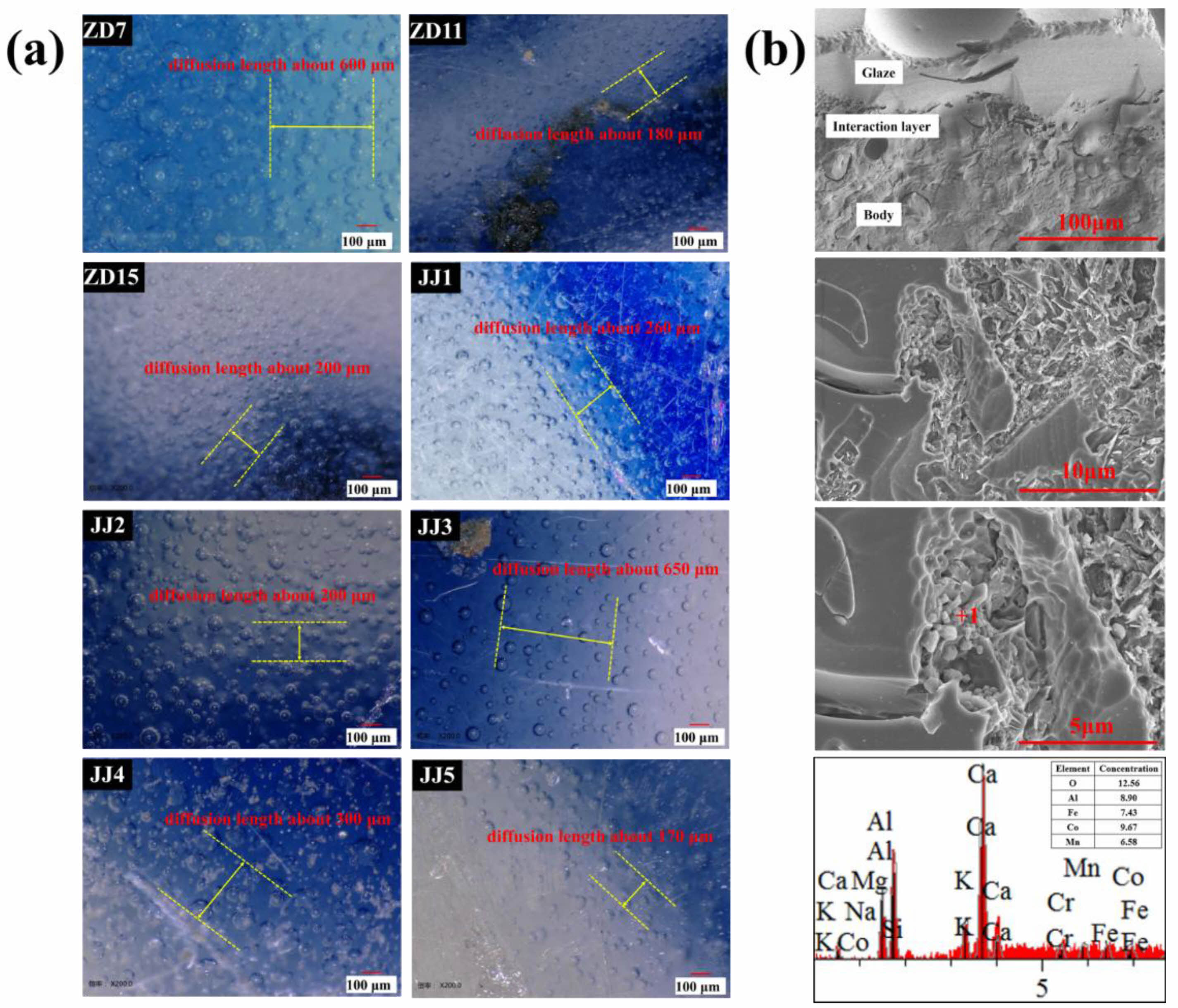

The optical photographs and microscopic structures of the samples from the late Zhengde and Jiajing period are shown in Fig. 8. As can be seen from Fig. 8(a) the diffusion distance of blue-and-white porcelain are about 180~650 μm. Fig. 8(b) shows the SEM-EDS results of the typical sample JJ4. It can be seen from Fig. 8(b) the sample are divided into three layers: a dense glaze layer, an interaction layer and relatively loose body. In the interaction layer exhibit only many needle-like crystals and few particles with the different shapes. The EDS results at points 1 in Fig. 8(b) indicate that the ratio of Co+Fe+Mn, Al and O elements in the particles is not 1:2:4, from this, it can be concluded that there are no Co-spinel crystals in the interaction layer.

Based on the experimental result (Fig. 6, Fig. 7, Fig. 8), more interesting is that the use of “Huiqing” cobalt-blue pigment of blue-and-white porcelain (ZD7, ZD11, ZD15, JJ1, JJ2, JJ3, JJ4, JJ5) “color dispersion” distance are relatively large (Fig. 8(a)) and thus the interaction layer of blue-and-white porcelain has very few Co-spinel crystal particles or no Co-spinel crystal particles at all (Fig. 8(b)). While the “color dispersion” distance of blue-and-white porcelain using “Shiziqing” (ZD1, ZD2, ZD3, ZD4, ZD5, ZD6, ZD8, ZD10, ZD13, ZD14, ZD16, ZD18, ZD19) and “Pingdengqing” (HZ1, HZ2, ZD9, ZD12, ZD17, ZD20, and ZD21) cobalt-blue pigment is relatively small (Fig. 6(a) and Fig. 7(a)), the interaction layer of the sample has a large number of Co-spinel crystals (Fig. 6(b) and Fig. 7(b)). According to the records Jiangxi Provincial da zhi volume seven Pottery Book · Huiqing [22] “the more ‘Hui Qing’ cobalt-blue pigment, blue-and-white porcelain diffusion distance is larger and not collected; If there is more ‘Shiziqing’ cobalt-blue pigment, the color is heavy and not bright; Therefore, the ‘Hui Qing’ cobalt-blue pigment is often mixed with ‘Shiziqing’ cobalt-blue pigment.” It can be seen that the type of cobalt-blue pigment affects the “color dispersion” distance. It can be well known that sufficient Al2O3 sources and CoO sources are helpful for the formation of CoAl2O4 spinel crystals, CoAl2O4 is a double oxide with a spinel structure [29], stable at high temperatures. So, the fewer Co-spinel crystals in the interaction layer, the greater the “color dispersion” distance will be. It can be seen from Table 1 that Al2O3 content in the glazes of the four typical samples (ZD9, ZD16, JJ4) is 12.66 wt%, 12.02 wt%, 13.99 wt%, respectively. Therefore, the Al2O3 content in the residual particles of the interaction layer for ZD9 and ZD16 is approximately 25%, while Al2O3 content in JJ4 is approximately 10%. From this, we can make the following speculation the Al2O3 content of “Huiqing” cobalt-blue pigment is very small, while the Al2O3 content of “Shiziqing” and “Pingdengqing” cobalt-blue pigment is more. In order to verify the inferred results, the archaeological experiment was designed to investigate the effect of different Al2O3 contents on the “color dispersion” of the blue-and-white porcelain.

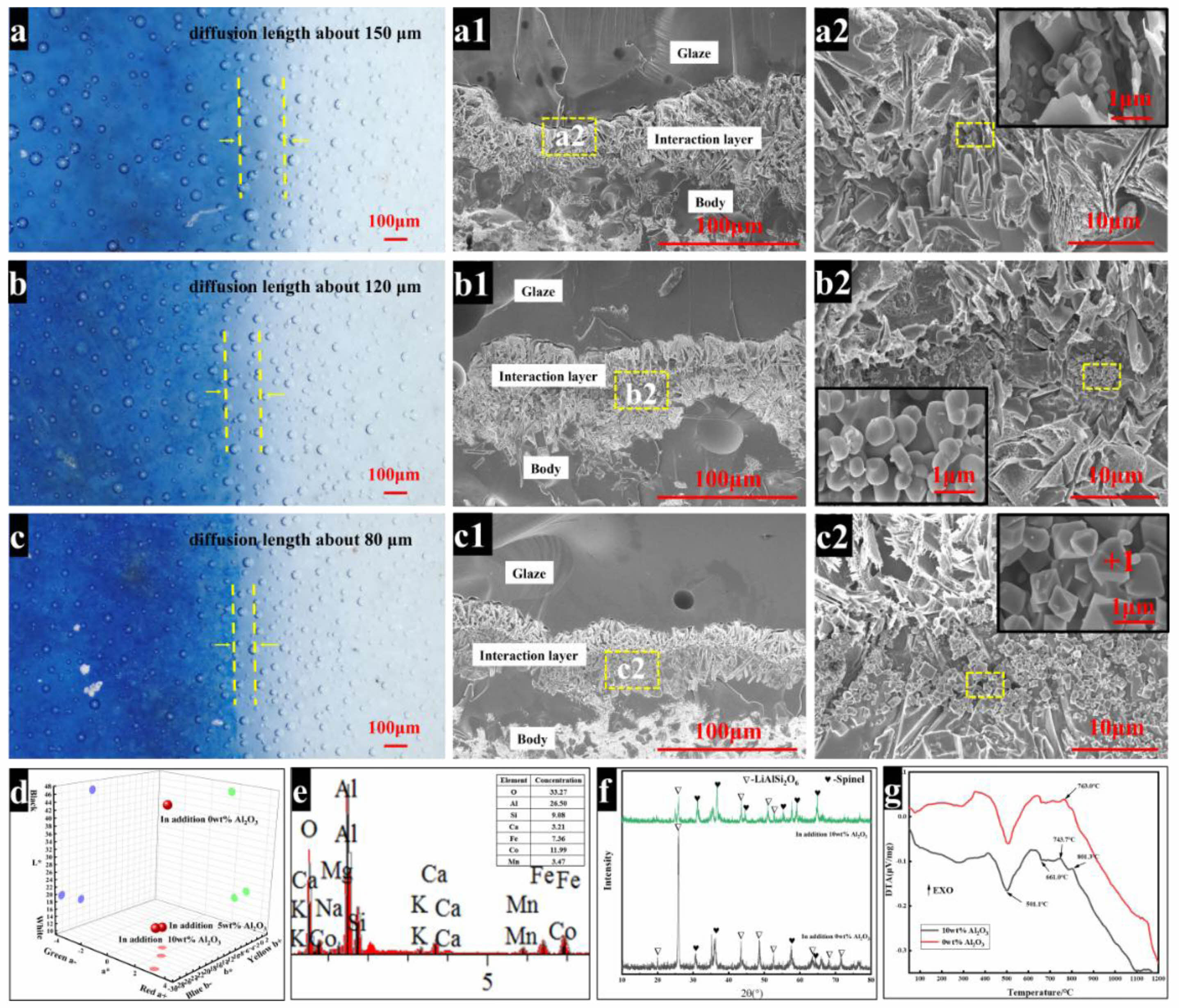

Fig. 9 shows the results of the archaeological experiment. Fig. 9(a, b, c) shows the photos of samples with different Al2O3 contents of the cobalt-blue pigment. As can be seen from the Fig. 9(a, b, c), as the Al2O3 content in the cobalt blue pigment increases, the diffusion distance of the blue-and-white porcelain samples decreases from 150 μm to 80 μm. The value of b* decreased from -19.4 to -28.16 (Fig. 9(d)). Fig. 9(a1, b1, c1) shows the microstructure of the interaction layer. It can be seen from Fig. 9 (a1, b1, c1) the samples are divided into three layers: a dense glaze layer, an interaction layer and relatively loose body. In the interaction layer exhibit many needle-like crystals and particles with the different shapes Fig. 9(a2, b2, c2), moreover, as can be seen from the inset images of Fig. 9(a2, b2, c2), with the increase in Al2O3 content, the number of residual particles in the interaction layer increases, and their shapes gradually transform into octahedrons. EDS results at point 1 in the inset image of Fig. 9(c2) show that the particles are composed of Co+Fe+Mn, Al and O elements with an atomic ratio of about 1: 2: 4 (Fig. 9(e)), which are close to the stoichiometry of Co-spinel crystals. From the XRD analysis of the cobalt-blue pigment (Fig. 9(f)), it can also be seen that as the Al2O3 content increases, the amount of Co-spinel crystal phase (PDF card: 70-0753) increases. The DTA graph (Fig. 9(g)) also shows an increase in Al2O3 content. There is a very obvious exothermic peak at 801.3 °C, which proves the formation of spinel. It can be seen from that the Al2O3 content in the cobalt-blue pigment is the key factor for the formation of Co-spinel.

According to Fick's second law diffusion equation  [30] where the concentration (C) and time(t) are constant, the diffusion coefficient (D) is an important parameter that determines the diffusion distance. According to the diffusion coefficient formula

[30] where the concentration (C) and time(t) are constant, the diffusion coefficient (D) is an important parameter that determines the diffusion distance. According to the diffusion coefficient formula  the diffusion coefficient is mainly determined by temperature (T) and diffusion activation energy (Q). At a certain temperature, the diffusion activation energy is related to the crystal structure stability. Spinel crystal is a stable cobalt-blue pigment at high temperature [31-33]. Therefore, the “color dispersion” distance of blue-and-white porcelain is related to the formation of Co-spinel crystals in cobalt-blue pigment. This also explains why during the Jiajing period and the later years of the Zhengde reign, the “Huiqing” cobalt-blue pigment and the “Shiziqing” cobalt-blue pigment were used in combination. This was because the Al2O3 content in the “Huiqing” cobalt-blue pigment was relatively low, unable to form Co-spinel crystals, resulting in a larger “color dispersion” distance. In contrast, the domestic cobalt-blue pigment was due to its high Al2O3 content, which was more likely to form Co-spinel crystals, with a smaller “color dispersion” distance. After mixing the “Huiqing” cobalt-blue pigment with the domestic cobalt-blue pigment, the Al2O3 content would increase, resulting in an increase in the number of Co-spinel crystals, thereby reducing the “color dispersion” distance and enhancing the clarity of the blue pattern on the blue-and-white porcelain.

the diffusion coefficient is mainly determined by temperature (T) and diffusion activation energy (Q). At a certain temperature, the diffusion activation energy is related to the crystal structure stability. Spinel crystal is a stable cobalt-blue pigment at high temperature [31-33]. Therefore, the “color dispersion” distance of blue-and-white porcelain is related to the formation of Co-spinel crystals in cobalt-blue pigment. This also explains why during the Jiajing period and the later years of the Zhengde reign, the “Huiqing” cobalt-blue pigment and the “Shiziqing” cobalt-blue pigment were used in combination. This was because the Al2O3 content in the “Huiqing” cobalt-blue pigment was relatively low, unable to form Co-spinel crystals, resulting in a larger “color dispersion” distance. In contrast, the domestic cobalt-blue pigment was due to its high Al2O3 content, which was more likely to form Co-spinel crystals, with a smaller “color dispersion” distance. After mixing the “Huiqing” cobalt-blue pigment with the domestic cobalt-blue pigment, the Al2O3 content would increase, resulting in an increase in the number of Co-spinel crystals, thereby reducing the “color dispersion” distance and enhancing the clarity of the blue pattern on the blue-and-white porcelain.

|

Fig. 4 The a* and b* values of blue decorations. |

|

Fig. 5 The curves of the calculated iron, cobalt and manganese proportion in blue pigment. |

|

Fig. 6 The optical photographs and microscopic structures of the samples from the middle period of Zhengde. (a) optical photographs. (b) The SEM-EDS of typical sample ZD9. |

|

Fig. 7 The optical photographs and microscopic structures of the samples from the middle period of Zhengde. (a) optical photographs. (b) The SEM-EDS of typical sample ZD16. |

|

Fig. 8 The optical photographs and microscopic structures of the samples from the middle period of Zhengde. (a) optical photographs. (b) The SEM-EDS of typical sample JJ4. |

|

Fig. 9 The results of archaeological experimental. (a, b, c) optical photographs. (a1, b1, c1) The SEM image of interaction layer (a, b, c). (a2, b2, c2) The magnified photo of the rectangular area in Fig. 9 (a1, b1, c1). (d) L*a*b* value. (e) SEM-EDS of points 1 the inset images in Fig. 9 (c2). (f) XRD of the cobalt-blue pigment. (g) DTA of the cobalt-blue pigment. The inset images in Fig. 9 (a2, b2, c2) are the enlarged parts marked with the rectangular area in Fig. 9 (a2, b2, c2), respectively. |

By analyzing of the chemical composition, color change and ‘color dispersion’ of blue-and-white porcelain, the following conclusions are as follows.

Three kinds of cobalt-blue pigments were used in the Zhengde period of the Ming Dynasty. In the early years of the Zhengde period, “Pingdengqing” cobalt-blue pigment with high Mn and low Co contents was used, similar to that in the Hongzhi period, the color showed blue tone. In the middle period of Zhengde, ‘Shiziqing’ cobalt-blue pigment with higher Mn and lower Co content was used, the color showed gray blue tone. The later period of Zhengde was similar to the period of Jiajing, blue-and-white porcelain showed vivid slightly purplish-blue tone due to use ‘Huiqing’ cobalt-blue pigment with low Mn and high Co contents. The Al2O3 content in “Huiqing” cobalt-blue pigment is less than that of “Shiziqing” and “Pingdengqing” cobalt-blue pigment, respectively. Therefore, the “color dispersion” distance of the sample using “Huiqing” cobalt-blue pigment is larger than that of the samples using “Shiziqing” and “Pingdengqing” cobalt-blue pigment, respectively. The results provide a method to judge the blue-and-white porcelain with different history Dynasty by the color and “color dispersion” of blue-and-white porcelain. A technical route for imitating blue and white porcelain are provided for blue-and-white porcelain in Zhengde period.

Our research work presented in this paper was supported by Inorganic Membrane Key Laboratory, Museum of blue-and-white Porcelain from the Yuan Dynasty at the Jingdezhen Ceramic University, Imperial Kiln Museum and Jiangxi Provincial Department of Education program (GJJ2205609), Major Project of Natural Science Foundation of Jiangxi Province (20232ACB204017), Jingdezhen Technology Bureau (20212GYZD009-18 and 20224GY008-16), Project of Jiangxi Province department of Education (GJJ2201048).

- 1. J.Z. Li, J. Wu, Z.Q. Deng, and C. Wang, Sci. China. Ser. E Technol. Sci. 47[003] (2004) 366-375.

- 2. J.Z. Li, China Sci. Publ. & Media. Beijing, 1998.

- 3. J.Y. Chen and N.L. Chen, Jingdezhen Ceram. 03 (2022) 87-91.

- 4. Q.Z. Wang, Cultural Relic. 08 (1982) 59-64.

- 5. F.K. Zhang, People's Fine Arts Press. Shanghai, 2000.

- 6. B. Xue, Identif. Appreciat. Cult. Relics. 17 (2019) 41-43.

- 7. R. Zhang and P. Gethin, Ceram. Int. 47[18] (2021) 25763-25768.

-

- 8. M. Hao, M. Zhang, Y. Weng, and Z. Xiong, J. Ceram. Process. Res. 25[5] (2024) 827-841.

-

- 9. Z. San, F. Wang, X. Yuan, S. Shen, J. Wang, and X. Wei, J. Ceram. Process. Res. 23[6] (2022) 758-765.

-

- 10. Z. Cheng, Z. Zhang, H. Yu, K. Liu, Y. Xu, W. Dong, J. Zhou, and Q. Bao, J. Ceram. Process. Res. 26[2] (2025) 248-256.

-

- 11. C. Jiang, J. Wu, H. Y, T. Lu, Z. Ya, F. Jiang, and X. Qiu, J. Ceram. Process. Res. 26[3] (2025) 463-471.

-

- 12. H. J. Luo, China Light Ind. Press. 1997.

- 13. Y.C. Chen, Y.Y. Guo, and Z.G. Zhang. Ceram. Soc. 04 (1978) 225-241.

- 14. K.N. Yu and J.M. Miao, Appl. Radiat. Isot. 48[7] (1997) 959-963.

-

- 15. K.N. Yu and J.M. Miao, Appl. Radiat. Isot. 51[3] (1999) 279-283.

-

- 16. K.N. Yu and J.M. Miao, X Ray Spectrom. 28[1] (1999) 19-23.

-

- 17. J. Wu, P.L. Leung, J.Z. Li, M.J. Stokes, and Mike T.W. Li, X Ray Spectrom. 29[3] (2000) 239-244.

-

- 18. J. Wu, P.L. Leung, and J.Z. Li, Stud. Conserv. 52[3] (2007) 188-198.

-

- 19. T.Q. Zhu, X. Ding, C.M. Kusimba, and Z.Y. Feng, Ceram. Int. 41[8] (2015) 9878-9884.

-

- 20. T.Q. Zhu, Y.C. Zhang, H. Xiong, Z.Y. Feng, Q. Li, and B.L. Cao, Archaeometry. 58[6] (2016) 966-978.

-

- 21. A. Pinto, J. Groenen, B. Zhao, T.Q. Zhu, and P. Sciau, J. Eur. Ceram. Soc. 40[15] (2020) 6181-6187.

-

- 22. Z.M. Wang and W.G. Lu, Beijing thread-bound book Bureau. 2003.

- 23. R. Wen, C.S. Wang, Z.W. Mao, Y.Y. Huang, and A.M. Pollard, Archaeometry. 49[1] (2007) 101-115.

-

- 24. R. Wen and A.M. Pollard, Archaeometry. 58[1] (2016) 1-16.

-

- 25. Q. Ma, A.M. Pollard, J. Jiang, and Y. Weng, Archaeometry. 63[1] (2021) 194-203.

-

- 26. L. Gao, Zhejiang People's Fine Arts Publishing House. 2012.

- 27. S.M. Wang, the first edition of the series is integrated. Ming Dynasty.

- 28. J. Zhou, Jingdezhen Ceramic Inst. 2014.

- 29. S. Salem, S. Jazayer, F. Bondiol, A. Allahverd, and M. Shirvani, J. Ceram. Process. Res. 12[6] (2011) 677-681.

-

- 30. L.M. Z, Wuhan Univ. of Technol. Press. 2008.

- 31. L. Torkian and M. Daghighi, Adv. Powder Technol. 25[2] (2014) 739-744.

-

- 32. S. Salem, J. Ind. Eng. Chem. 20[3] (2014) 818-823.

-

- 33. N. Srisawad, W. Chaitree, O. Mekasuwandumrong, P. Praserthdam, and J. Panpranot, J. Nanomaterials. 2012[1] (2012) 108369.

-

This Article

This Article

-

2025; 26(5): 742-753

Published on Oct 31, 2025

- 10.36410/jcpr.2025.26.5.742

- Received on Jul 10, 2025

- Revised on Jul 31, 2025

- Accepted on Aug 29, 2025

Services

Services

- Abstract

introduction

samples and methods

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Weixia Dong, Qifu Bao

-

Materials science and engineering, Jingdezhen Ceramic University, Jingdezhen, Jiangxi, 333000, PR China

Tel : 0798-8480007 Fax: 0798-8480007 - E-mail: dwxbqf0727@163.com (Q.B.); weixia_dong@sina.com (W

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.