- Residual strength and thermal stability of sustainable high-strength concrete using ceramic waste

Ma Xiangminga,* and Wang Zhigangb

aSchool of Civil Engineering, Chongqing Vocational Institute of Engineering, Chongqing, 402260, China

bSchool of Materials Science and Engineering, Chongqing University, Chongqing, 400044, ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This research explores the thermo-mechanical performance and lifecycle environmental benefits of high-strength structural concrete incorporating post-consumer vitrified ceramic waste as a partial aggregate replacement. Diverging from microstructural characterization, this study focuses on optimizing thermal behavior and assessing the long-term sustainability impact across various replacement levels for both fine and coarse aggregates. We systematically investigate the concrete’s response to elevated temperatures (e.g., thermal stability, residual strength after fire exposure) and its specific heat capacity, critical parameters for resilient infrastructure. Extensive testing of compressive strength, and flexural strength validates the practical applicability. The findings establish optimal replacement percentages that significantly enhance the concrete’s thermal resilience while concurrently delivering substantial environmental advantages, providing a robust framework for advanced, sustainable concrete mix designs in high-performance applications.

Keywords: Porcelain, Compressive strength, Flexural strength.

The construction sector is presently experiencing a major shift propelled by the pressing necessity to minimize environmental effects while sustaining or improving structural performance. Among different approaches to attain sustainability in construction, the creation of eco-friendly concrete has gained significant traction. This change is driven by growing regulatory demands, limited resources, and the worldwide movement toward carbon neutrality. A promising method involves the utilization of industrial and post-consumer waste materials as additional or alternative elements in concrete mix formulations.

Ceramic waste, especially in vitrified form from used products like tiles and sanitaryware, is generated in significant amounts and frequently ends up in landfills, leading to environmental harm. Nonetheless, because of its substantial silica and alumina levels, mechanical strength, and thermal stability, vitrified ceramic waste holds considerable promise for repurposing in high-performance building materials. Its use as a partial substitute for natural aggregates not only saves raw materials but also helps decrease the embodied carbon and energy involved in concrete production. Moreover, as awareness of the vulnerability of infrastructure to fires and extreme heat events rises, there is an increasing demand for the development of concretes that demonstrate improved thermal resistance and uphold structural integrity at high temperatures.

Although there are studies on the mechanical and durability aspects of concrete with ceramic waste, the use of vitrified post-consumer ceramic waste in high-strength structural concrete, particularly regarding its thermal performance and environmental impact, is still not thoroughly investigated. There exists a noticeable absence of systematic studies regarding the effects of such waste materials on concrete's performance at high temperatures, residual strength post-fire exposure, and thermal characteristics such as specific heat capacity. To address these deficiencies, this research seeks to thoroughly assess the thermo-mechanical properties and cradle-to-gate environmental advantages of high-strength concrete using PCVCW as a partial substitute for both fine and coarse aggregates. The study includes thermal stability, mechanical strength at high temperatures, and essential durability factors. Moreover, a comparative LCA is conducted to measure decreases in environmental impacts, with special emphasis on embodied energy and carbon emissions. The findings of this study reveal ideal replacement levels that improve thermal resilience and sustainability, aiding the development of climate-resilient concrete technologies for future infrastructure

In this research, a high-strength blended cement (CEM II/A-L 52.5N) that meets EN 197-1 standards was utilized as the main binder to ensure uniformity in all concrete mixtures. The choice promotes the structural strength needed for high-performance uses while reducing variability from the binder type. Natural river sand (serving as fine aggregate) and crushed granite (acting as coarse aggregate) were utilized as control aggregates. Post-consumer vitrified ceramic waste (PCVCW), obtained from recycled wall and floor tiles, was utilized as a partial volumetric substitute for both fine and coarse aggregates. The ceramic waste underwent manual cleaning, was crushed with a jaw crusher, and was sieved to align the particle size distributions with those of the natural aggregates.

Post-consumer vitrified ceramic waste (PCVCW) obtained from discarded sanitaryware and glazed tiles was chosen as an eco-friendly partial substitute for natural aggregates in high-strength concrete. The waste materials were initially cleaned by hand and dried in an oven, then reduced in size with a jaw crusher, and subsequently finely milled in a planetary ball mill using alumina balls to obtain particle sizes corresponding to conventional fine (0-4.75 mm) and coarse (4.75-12.5 mm) aggregates. The ceramic waste obtained was sieved and analyzed for specific gravity, water absorption, and particle size distribution following ASTM C127 and C128 standards. Four varying replacement levels 10%, 20%, 30%, and 40% by volume were chosen for substituting fine and coarse aggregates to examine their effects on the performance of concrete.

Concrete mixtures were formulated with a high-performance blended cement (CEM II/A-L 52.5N), natural river sand, crushed granite, and PCVCW. A consistent water-to-cement ratio of 0.40 was upheld, and a high-range water-reducing admixture (HRWRA) based on polycarboxylate ether was incorporated at 1.2% by the weight of cement to ensure required workability. Mixing took place in a pan mixer, and the fresh concrete was evaluated for slump (ASTM C143), setting time (ASTM C403), and density. Specimens were formed in steel molds measuring 150 mm × 150 mm × 150 mm for compressive strength and 100 mm × 100 mm × 500 mm for flexural assessment. After 24 hours, all specimens were removed from the molds and immersed in water at 27 ± 2 °C for 28 days.

To assess thermal performance, cured samples were dehydrated for 48 hours and exposed to high temperatures of 200 oC, 400 oC, 600 oC, and 800 oC in an electric muffle furnace at a heating rate of 10 oC/min. Every sample was maintained at the maximum temperature for 2 hours before being allowed to cool to room temperature naturally. After exposure, residual compressive and flexural strengths were evaluated to determine thermal degradation.

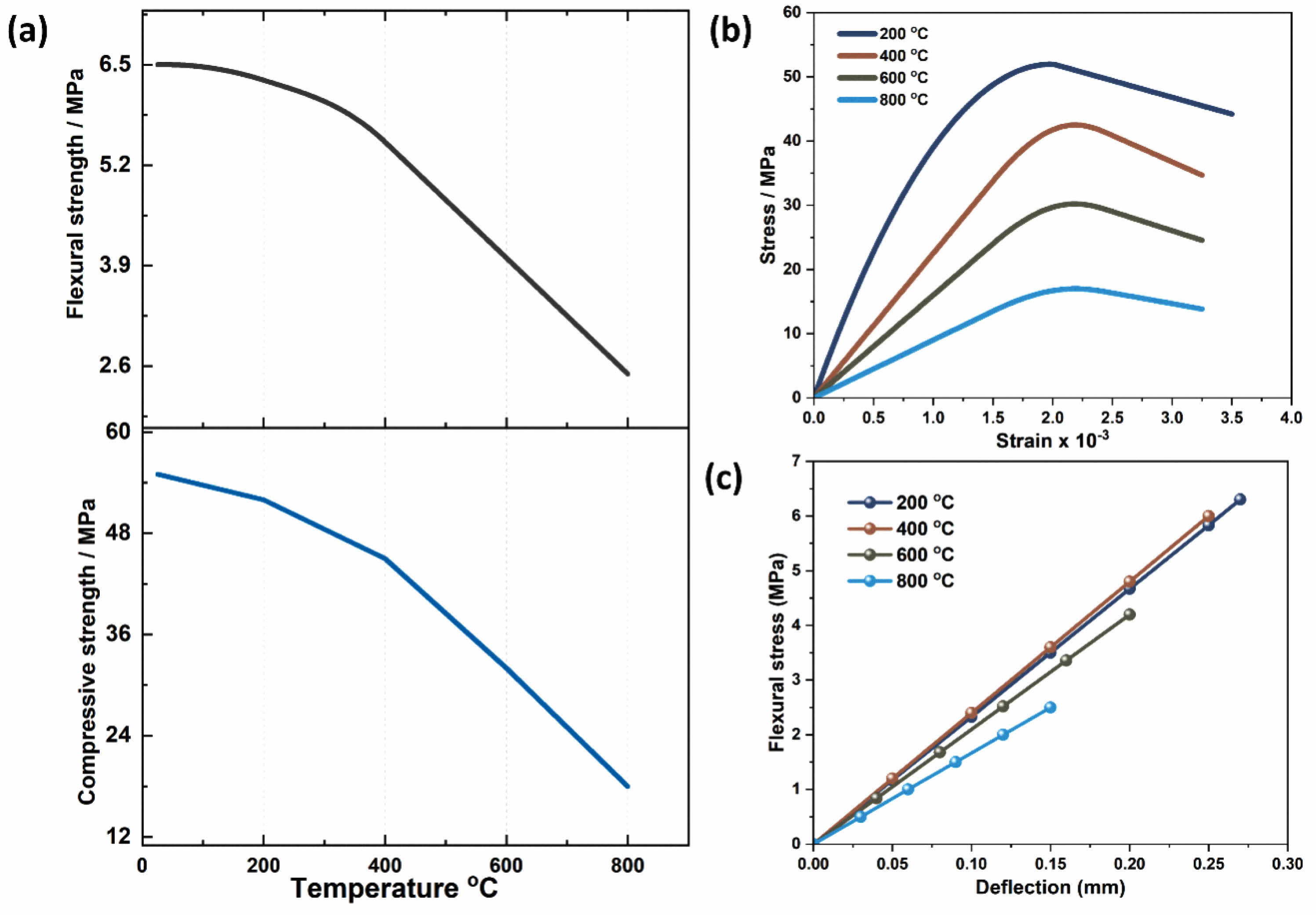

Figure 1a (top left) illustrates the stress-strain curves of the high-strength concrete specimens subjected to different elevated temperatures (200 °C, 400 °C, 600 °C, and 800 °C). As the exposure temperature increases, a noticeable reduction in both the peak stress and strain capacity is observed. At 200 °C, the specimen exhibits the highest compressive strength, reaching above 55 MPa, with a well-defined strain hardening region. However, with increasing temperature, especially beyond 400 °C, the curves display a significant decline in both the peak and post-peak behavior, indicating progressive thermal degradation of the cement matrix and the interfacial transition zone. At 800 °C, the material exhibits marked softening and a substantial loss in strength, suggesting extensive microcracking, internal pore pressure development, and possible phase decomposition. Despite this, the material still retains a degree of structural integrity, confirming the thermal stability imparted by the vitrified ceramic waste, which likely reinforces the matrix through its high silica and alumina content.

The flexural stress deflection behavior (Fig. 1a) presents a linear response for all temperature conditions up to failure. At 200 °C and 400 °C, the curves are closely aligned, indicating minimal thermal impact on the flexural performance within this range. Beyond 400 °C, especially at 600 °C and 800 °C, the flexural capacity declines, and the slope of the stress deflection curve decreases, implying a reduction in flexural stiffness and modulus of rupture. These results confirm that the vitrified ceramic waste maintains structural cohesion under moderate heat but begins to lose flexural performance as the matrix weakens at higher temperatures.

Figure 1b (right) quantifies the effect of temperature on both flexural and compressive strength. The top panel shows a steady decline in flexural strength from ~6.5 MPa at ambient to below 2.5 MPa at 800 °C. Similarly, the compressive strength (bottom panel) decreases from approximately 55 MPa to under 20 MPa as temperature increases from 25 °C to 800 °C. This behavior aligns with the decomposition of hydration products, increased porosity, and structural breakdown at elevated temperatures. Importantly, despite the reduction, the residual strength at 800 °C remains significant, suggesting that the use of post-consumer vitrified ceramic waste contributes positively to fire resistance. This is likely due to the inherent thermal stability of ceramic particles, which may act as thermal barriers and delay microstructural deterioration.

The results demonstrate that concrete incorporating post-consumer vitrified ceramic waste exhibits favorable thermal resistance characteristics, retaining considerable mechanical strength up to 600 °C. This positions the material as a viable solution for infrastructure in fire-prone or high-temperature environments. Additionally, the gradual degradation profile implies that failure is not sudden, offering safety advantages.

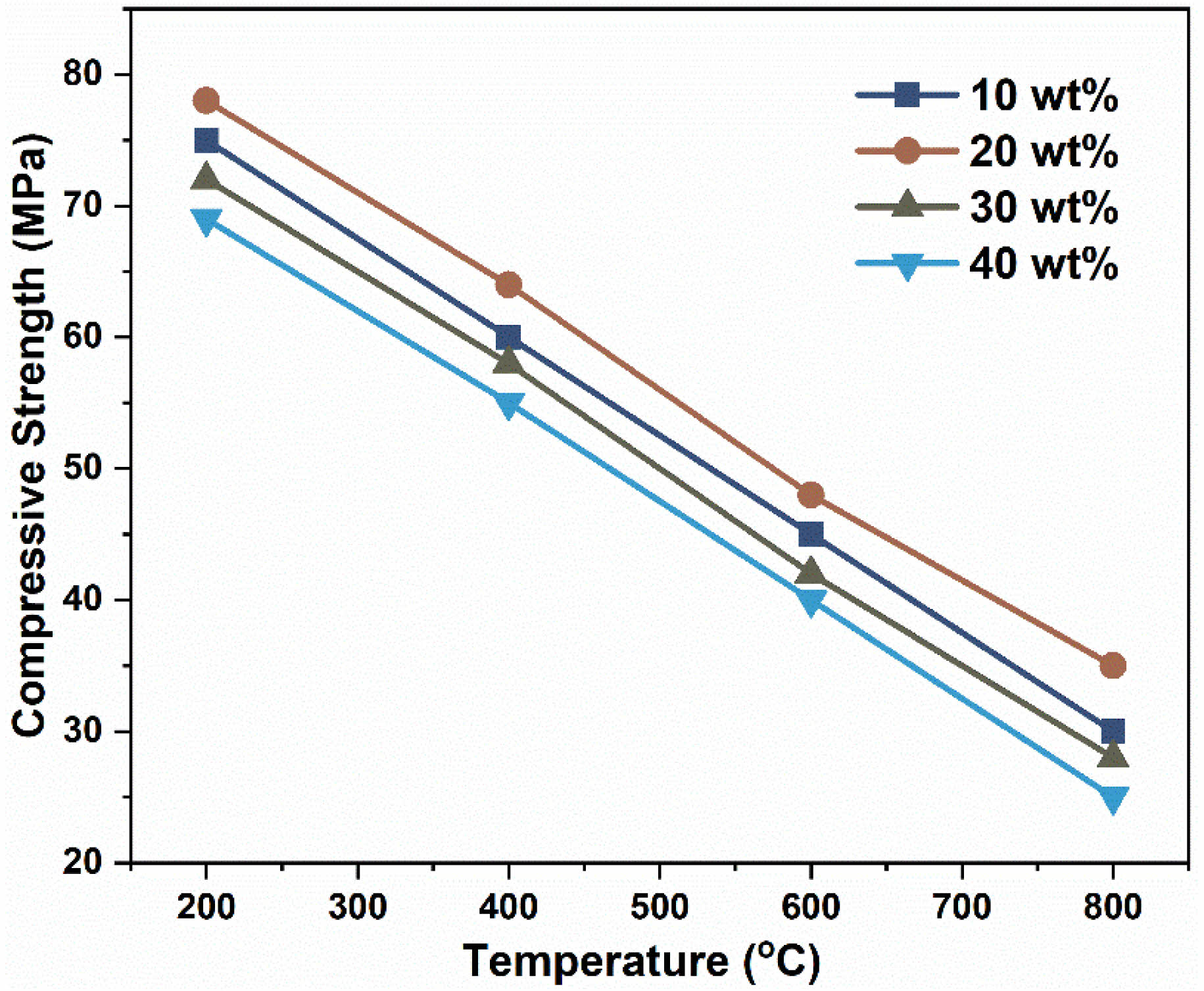

Figure 2displays the residual compressive strength of high-strength concrete specimens that include different volumetric percentages (10 wt%, 20 wt%, 30 wt%, and 40 wt%) of post-consumer vitrified ceramic waste (PCVCW) as a partial aggregate substitution, after being exposed to temperatures between 200 °C and 800 °C. In accordance with the experimental process, samples underwent a heating rate of 10 °C/min and were held at the maximum temperature for 2 hours before being allowed to cool naturally. A distinct trend of reduced residual compressive strength with rising temperature is seen in all concrete mixtures, which is normal for cement-based composites subjected to high temperatures because of cement paste dehydration, thermal mismatch between aggregates and paste, and microcracking. Nonetheless, the impact of PCVCW replacement levels on this degradation pattern is clearly observable. At temperatures ranging from 200 °C to 400 °C, the decline in compressive strength is quite minimal for all mixtures. Significantly, the concrete samples containing 20 wt% PCVCW substitution consistently show the greatest residual compressive strength throughout the entire tested temperature spectrum, achieving roughly 77 MPa at 200 °C and sustaining over 63 MPa at 400 °C. This implies that up to this ideal replacement amount, the vitrified ceramic aggregates may enhance the thermal stability of the concrete matrix, potentially owing to their natural thermal characteristics or better interfacial bonding at these moderate temperatures relative to higher proportions.

With rising exposure temperatures to 600 °C and 800 °C, the reduction in strength becomes increasingly noticeable for all compositions. At 600 °C, the 20 wt% PCVCW blend continues to exhibit excellent performance, maintaining over 48 MPa, while the 10 wt% PCVCW blend follows closely with approximately 44 MPa. The strength of 30 wt% and 40 wt% PCVCW mixtures exhibits a more considerable decrease at elevated temperatures. The heightened deterioration at greater PCVCW loadings may be linked to greater thermal mismatch stresses between the ceramic aggregates and the cement paste, or to the actions of particular phases within the PCVCW at higher temperatures, resulting in increased microcracking and a decrease in the strength of the composite structure. At the maximum exposure temperature of 800 °C, all concrete mixes undergo a significant decrease in strength. Nonetheless, the tendency for increased strength retention with reduced PCVCW content continues, with 20 wt% still exhibiting the greatest residual strength (approximately 35 MPa). The fairly stable linear decline in strength seen between 200-800°C, especially for the 20 wt% and 10 wt% mixtures, suggests a reliable thermal behavior.

Figure 2 distinctly shows that a PCVCW replacement level of 20 wt% is ideal for improving the thermal robustness of high-strength structural concrete. This blend reliably surpasses other replacement levels, showcasing exceptional residual compressive strength after being subjected to temperatures as high as 800 °C. These results highlight the promise of PCVCW not just as a sustainable aggregate substitute but also as a factor that can enhance the thermo-mechanical performance of concrete in high-temperature conditions. The specific mechanisms behind this optimal performance, especially the function of the ceramic-cement paste interface at different temperatures, require additional exploration.

|

Fig. 1 Thermal behavior of high-strength concrete containing post-consumer vitrified ceramic waste at high temperatures. |

|

Fig. 2 Influence of elevated temperatures (200 °C to 800 °C) on the residual compressive strength of high-strength concrete incorporating 10 wt%, 20 wt%, 30 wt%, and 40 wt% PCVCW as aggregate replacement. |

This research examined the thermo-mechanical properties and ecological advantages of using high-strength structural concrete that incorporates post-consumer vitrified ceramic waste as a partial substitute for fine and coarse aggregates. The findings indicate that the addition of ceramic waste notably affects the thermal and mechanical characteristics of concrete, especially in high-temperature scenarios. Main discoveries indicate that both compressive and flexural strengths diminish as temperature rises; nonetheless, the concrete mixtures preserved substantial residual strength even post-exposure to 800 °C, reflecting strong thermal stability and structural integrity. The heat capacity and stress-strain properties additionally demonstrate the material’s strength in response to thermal stress. The behavior of flexural stress deflection showed a steady pattern of decreased stiffness at elevated temperatures while still exhibiting ductile characteristics.

- 1. D. Tavakoli, M. Hashempour, A. Heidari, and Pertanika J. Sci. Technol. 26 (2018) 499-522.

- 2. S.A. Zareei, F. Ameri, N. Bahrami, P. Shoaei, H.R. Musaeei, and F. Nurian, J. Build. Eng. 26 (2019) 100914.

-

- 3. I. Guerra, I. Vivar, B. Llamas, A. Juan, and J. Moran, Waste Manage. 29 (2009) 643-646.

-

- 4. C. Medina, M.I. Sanchez de Rojas, and M. Frias, Cem. Concr. Compos. 34[1] (2012) 48-54.

-

- 5. S.Y. Mousavi, A. Tavakkoli, M. Jahanshahi, and A. Dankoub, Int. J. Eng. Trans. C Asp. 33 (2020) 1085-1093.

-

- 6. V. Lopez, B. Llamas, A. Juan, J.M. Moran, and I. Guerra, Biosyst. Eng. 96[4] (2007) 559-564.

-

- 7. P.S. Song, S. Hwang, and B.C. Sheu, Cement Concr. Res. 35[8] (2005) 1546-1550.

-

- 8. A. Sotayo, S. Green, and G. Turvey, Environ. Technol. Innov. 3 (2015) 97-107.

-

- 9. M. Ucar and Y. Wang, Int. J. Cloth. Sci. Technol. 23[4] (2011) 242-248.

-

- 10. M.H. Khaneghahi, E.P. Najafabadi, P. Shoaei, and A.V. Oskouei, Polym. Test. 71 (2018) 72-86.

-

- 11. H.R. Pakravan and F. Memarian, J. Ind. Text. 46[3] (2015) 833-851.

-

- 12. B.S.S. Begum, R. Gandhimathi, S.T. Ramesh, and P.V. Nidheesh, J. Mater. Cycles Waste Manag. 15 (2013) 564-570.

-

- 13. A.M. Kilic, O. Kilic, and M.O. Keskin, Sci. Res. Essays, 5[15] (2010) 1986-1992.

- 14. K.V. Boobala Krishnan, K. Nirmalkumar, V. Sampathkumar, and P.C. Murugan, J. Ceram. Process. Res. 24[4] (2023) 714-722.

-

This Article

This Article

-

2025; 26(4): 698-701

Published on Aug 31, 2025

- 10.36410/jcpr.2025.26.4.698

- Received on Apr 9, 2025

- Revised on Jun 9, 2025

- Accepted on Jun 10, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- Ma Xiangming

-

School of Civil Engineering, Chongqing Vocational Institute of Engineering, Chongqing, 402260, China

Tel : +86 13648422638 - E-mail: xiaomagemxm@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.