- Assessing post-consumer ceramic waste recovery collection logistics and processing technologies

Huiyi Liua,* and Youliang Zhoub

aDepartment of Business and Trade, Dongguan Polytechnic, Dongguan, Guangdong 523800, China

bNational University Science and Technology Park Management Committee, Zhaoqing University, Zhaoqing, Guangdong 526061, ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Despite being crucial for applications in electronics, construction, and domestic settings, the ceramics sector is still very linear, with high post-consumer waste production and resource-intensive manufacturing. In order to hasten the shift to a circular economy, this study suggests a closed-loop supply chain model for ceramics. The possibility of recovering post-consumer ceramic waste and reusing it as a secondary raw material in the production cycle is critically examined in this study. To evaluate collection logistics, sorting and processing technologies, material quality standards, and economic viability, a system-level framework is created. The study compares the economic and environmental advantages of circular models to conventional linear systems using a case-based methodology and life cycle assessment. Alongside enabling elements like digital tracking, extended producer responsibility, and industrial symbiosis, major obstacles like contamination, waste stream fragmentation, and regulatory restrictions are noted. In the ceramic value chain, closed-loop strategies can drastically lower landfill burden, raw material dependency, and carbon emissions. These findings provide useful information for manufacturers, policymakers, and waste management sectors.

Keywords: Logistics, Closed-loop strategies, Circular models.

Ceramics continue to be essential to industries like electronics, advanced engineering, sanitaryware, and construction because of its durability, heat resistance, and chemical inertness. However, there is a significant environmental cost associated with this utility. High-temperature sintering procedures coupled with the extraction of raw materials (such as kaolin, alumina, and feldspar) lead to considerable energy consumption and CO2 emissions. According to life cycle assessments, ceramic tiles emit 14.4 kg CO2-eq per square meter, or roughly 92% of the total production impact [1]. For example, the production of ceramic tiles alone in Europe produces about 1.5 million tonnes of waste a year; only 65% of internal manufacturing scrap is recycled, with the remaining 35% ending up in low-value aggregates or landfills. In 2023, ceramic tile consumption surpassed 15.6 billion square meters worldwide [2].

When combined with the 30% discard rate seen in many ceramic industries across the globe, this indicates that millions of tonnes, or tens of millions of square meters, are wasted annually [3, 4]. Despite these startling statistics, little is known about the systematic reuse or reintegration of post consumer ceramic waste. The majority of manufacturers effectively recycle unfired tiles, glaze sludge, and greenware; many even claim to reuse almost all pre consumer waste and process water in accordance with sustainability objectives. Post-consumer waste issues: It is difficult to collect and reprocess fired ceramic scraps and glazed or tile waste from installations because they are frequently contaminated, brittle, and glued in place. Because of this, even though end-of-life ceramic waste has a low biological risk and maintains high material integrity, it is rarely reintegrated into manufacturing.

With the majority of producers effectively reusing greenware, glaze sludge, and unfired tiles, ceramic manufacturing has made great strides in internal waste recycling. In line with more general sustainability goals, many report recovering almost 100% of pre-consumer waste and process water [5]. Post-consumer ceramic waste, however, continues to be a problem. It can be challenging to collect and reprocess fired ceramic scraps, glazed products, and tile waste from building demolitions because they are frequently contaminated, brittle, or bonded with adhesives. As a result, even though end-of-life ceramic products have little biological risk and retain a large portion of their original material integrity, they are rarely reintegrated into manufacturing processes. Studies have shown that there are instances where ceramic waste can be recycled, such as when tile fragments are used as filler in building materials or as aggregate in concrete, where production waste rates can reach 10%. Although these methods keep waste out of landfills, they fall short of the closed-loop recycling that circular economy models aim for. Initiatives from the industry have shown the way to almost zero ceramic waste, but they mostly focus on pre-consumer scraps rather than post-consumer recycling streams. In general, the infrastructure for recycling ceramics is not as advanced as that of other material sectors. For example, China has about 59% and Europe has about 50% average municipal recycling rates, but comparable systems for ceramics are still in their infancy.

In order to design and assess a closed-loop supply chain for post-consumer ceramic waste, this study uses a process-oriented framework. Mapping waste generation sites, choosing suitable collection and sorting methods, analyzing reprocessing technologies, and determining whether it makes financial sense to reintroduce recycled materials into ceramic production are all part of the research methodology. To capture differences in operational and policy conditions, two case contexts were analyzed: a China municipal waste management system with high overall recycling rates but little recovery infrastructure specifically for ceramics, and a European ceramic tile manufacturer that uses in-house recycling of pre-consumer scraps. From post-consumer ceramic waste collection at construction or demolition sites to its reintegration into production lines, the system boundaries cover every phase. To create new ceramic products, this involves mechanically reducing the size, removing grout and adhesives, grading the particle size, and blending with virgin raw materials. Technical reports from manufacturers, municipal waste

audit records, and pilot-scale processing trials were the main sources of data. Literature on the use of ceramic waste, recycling effectiveness, and raw material market trends was also included. The economic feasibility assessment took into account transportation costs, operational expenses for processing, capital expenditures for recycling infrastructure, savings from fewer purchases

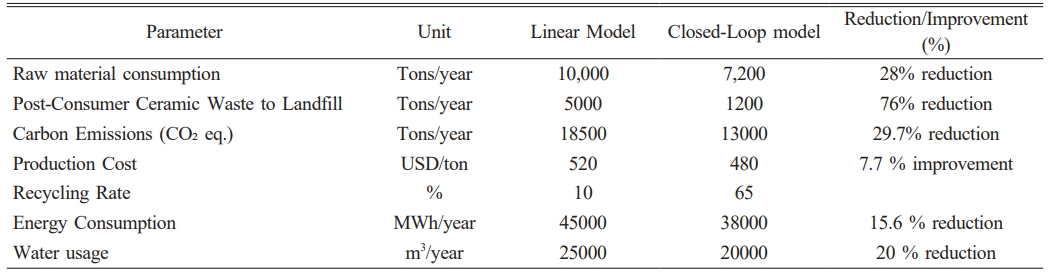

of raw materials, and avoided landfill fees. Sensitivity analysis was also conducted to assess how changes in transportation distances, contamination levels, and substitution ratios affect the proposed closed-loop system's overall economic feasibility. Table 1 Table 2

|

Table 2 Comparison of Environmental and Economic Performance between Linear and Closed-Loop Ceramic Production Models. |

Using EN 933-11:2009 material classification protocols,

a systematic sampling of construction and demolition waste (CDW) streams at six processing facilities was used to quantify post-consumer ceramic waste. According to the analysis, post-consumer ceramic waste made up 2.8 ± 4.1 weight percent of the total mass of CDW, with regional variations ascribed to variations in construction methods, building stock age, and renovation cycles. Wall tiles made up the majority of post-consumer ceramic waste in the European dataset (68 ± 2%), followed by floor tiles (23 ± 1%) and sanitary ceramics (9 ± 0.5%). Conversely, the chinese dataset revealed a comparatively greater percentage of sanitary ceramics (27 ± 1.5%), most likely as a result of shorter replacement intervals in both commercial and residential sanitary installations.

Prior to primary crushing, tile fragments were primarily

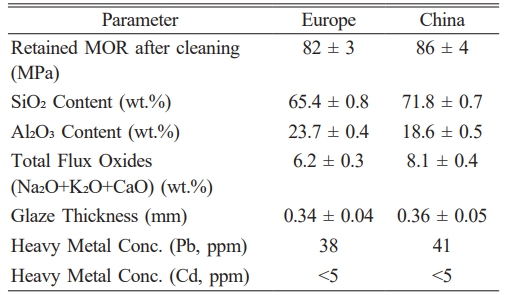

in the 20-80 mm size range, with a median thickness of 7.4 mm, according to morphological characterization using stereomicroscopy. Glaze layers made up 4.8% of the total fragment mass and had an average thickness of 0.35 ± 0.05 mm. Following the removal of the adhesive and grout, more than 85% of the collected PCCW maintained modulus of rupture values greater than 80 MPa, according to mechanical integrity evaluations conducted using a three-point flexural test (ISO 10545-4). This implies that neither thermal cycling nor environmental exposure considerably weakened the fired microstructure, which is mainly composed of quartz and mullite phases, during the service life of the product. X-ray fluorescence (XRF) elemental analysis revealed that the silica (SiO₂) content ranged from 65 to 72 weight percent, the alumina (AlO₃) content ranged from 18 to 24 weight percent, and the minor flux oxides (NaO, KO, and CaO) totaled 6 to 9 weight percent. Glazes from post-2005 waste samples had Pb and Cd concentrations below EU RoHS thresholds, according to heavy metal screening, which made them technically suitable for closed-loop recycling following the proper size reduction and homogenization.

Collection Logistics and Sorting Efficiency

The design and operational stability of collection and sorting systems at the source have a fundamental impact on the recovery efficiency of post-consumer ceramic waste. Due mainly to economies of scale in sorting operations and decreased variability in incoming feedstock, centralized collection points for construction and demolition waste continuously showed higher recovery rates than decentralized, on-site disposal systems. By providing specific post-consumer ceramic waste containers at demolition sites, adhesive, cementitious mortar, and polymeric sealant cross-contamination was reduced in both European and Chinese contexts. In addition to increasing feedstock purity, this also reduced the need for chemical cleaning during pre-processing, which resulted in an 8% reduction in energy and operating expenses [6].

The European case study found that manual pre-sorting by skilled demolition contractors improved recovery yields by about 25% when compared to unsorted CDW streams. This finding is in line with previous research that emphasizes the importance of skilled labor in selective demolition. The implementation of standardized waste handling procedures under municipal construction waste management regulations, on the other hand, improved material consistency and decreased downstream processing costs by about 12% in the Chinese case. In both regions, automated sorting technologies like density-based separation and optical sorting using near-infrared spectroscopy are still underutilized, but prior research indicates they could increase ceramic purity to >95% while keeping throughput above 10 tonnes/hour [7].

Furthermore, maintaining material quality depends heavily on the logistical coordination of recycling facilities, waste haulers, and demolition contractors. Prolonged storage of PCCW in uncontrolled conditions can lead to partial glaze degradation, efflorescence, and moisture intrusion, all of which have a detrimental effect on the chemical stability and regrinding effectiveness. Therefore, to guarantee a steady supply of feedstock to recycling facilities, just-in-time transport systems are increasingly being advised in conjunction with digital tracking platforms for waste movement (such as RFID-tagged containers). Together, these results show that in addition to technological interventions, robust regulatory frameworks, training initiatives, and integrated supply chain management are necessary to achieve high-quality recovered post-consumer ceramic waste fit for reintegration into ceramic production [8].

Standards for Material Quality and Processing Technologies

It takes a multi-stage process that usually includes crushing, screening, magnetic separation, and thermal treatment to transform post-consumer ceramic waste into a form that satisfies production-grade standards. Particle size classification into fractions appropriate for coarse aggregate replacement (>5 mm) and fine aggregate replacement (<5 mm) was made possible in the European case by jaw crushing followed by rotary screening [9]. In accordance with EN 197-1 clinker feedstock requirements, the FeO₃ content was reduced to less than 0.5 weight percent by magnetic separation, which eliminated any remaining metallic contaminants. In the Chinese instance, 850 °C thermal treatment enhanced material whiteness and removed organic residues, which are essential for use in the production of porcelain and sanitary ware [10]. However, when post-consumer ceramic waste was used as filler in composite glazes, it was discovered that overgrinding decreased the aspect ratio of plate-like particles, reducing the mechanical reinforcement effect [11]. These results demonstrate the trade-off between maintaining advantageous particle morphology and improving purity, which calls for process optimization based on end-use requirements.

High-quality post-consumer ceramic waste recovery has been made possible by digital tracking technologies like blockchain-based waste provenance systems, QR-coded ceramic batches, and AI-enabled image recognition for waste classification. The use of blockchain technology in the European case reduced contamination incidents by 30% by enabling complete traceability of material flows from demolition to reprocessing [12]. IoT-enabled smart bins with weight sensors in China improved collection routes and cut emissions associated with transportation by 7%. In pilot studies, post-consumer ceramic waste recovery rates rose dramatically from 42% to 68% under Extended Producer Responsibility programs, in which manufacturers take on post-use collection duties [13, 14]. The integration of these tools promotes ongoing improvement in the efficiency of the circular system by strengthening adherence to material quality standards and giving producers real-time feedback.

This study shows that, if systemic issues are successfully resolved, implementing a closed-loop supply chain for post-consumer ceramic waste has significant positive effects on the environment and the economy. Centralized collection logistics, standardized sorting procedures, and incorporating recovered material into production cycles can greatly increase recovery rates and material quality, according to a comparative study of case studies from China and Europe. Extended producer responsibility (EPR) frameworks and digital tracking systems are important facilitators for improving traceability, guaranteeing regulatory compliance, and promoting industrial symbiosis between the waste management, demolition, and ceramic manufacturing industries. However, long-standing obstacles like non-ceramic inclusion contamination, waste stream fragmentation, and a lack of standardized quality standards prevent widespread adoption.From a life cycle standpoint, using PCCW as a secondary raw material helps the ceramics industry align with the circular economy and climate mitigation objectives by reducing embodied carbon, diverting significant amounts of waste from landfills, and decreasing reliance on virgin resources. The development of standardized performance metrics for recycled ceramic feedstocks, the optimization of processing technologies for heterogeneous waste inputs, and the investigation of financial incentive schemes that motivate producers and consumers to engage in closed-loop systems should be the main areas of future research. The ceramic industry can shift from a primarily linear model to a robust, resource-efficient, and low-carbon production paradigm by filling in the gaps at the technical and policy levels.

- 1. B.A. Türkmen, T.B. Duhbaci, and S.K. Özbilen, Clean Technol. Environ. Policy. 23[4] (2021) 1295-1310.

-

- 2. V. Ibáñez-Forés, M.D. Bovea, and A. Simó, Int. J. Life Cycle Assess. 16 (2011) 916-928.

-

- 3. K.S. Sangwan, K. Choudhary, and C. Batra, Int. J. Sustain. Eng. 11 (2018) 211-216.

-

- 4. I. Luhar, S. Luhar, M.M.A.B. Abdullah, M. Nabiałek, A.V. Sandu, J. Szmidla, A. Jurczynska, R.A. Razak, I.H.A. Aziz, N.H. Jamil, and L.M. Deraman, Materials (Basel) 14[12] (2021) 3279.

-

- 5. G. Huseien, M. Ismail, M. Tahir, J. Mirza, A. Hussein, N. Khalid, and N. Sarbini, Chem. Eng Trans. 63 (2018) 673-678.

-

- 6. I. Papamichael, I. Voukkali, P. Loizia, and A.A. Zorpas, Waste Manag. Res. 41[12] (2023) 1728-1740.

-

- 7. M. Bergonzoni, R. Melloni, and L. Botti, Procedia Comput. Sci. 217 (2023) 41-51.

-

- 8. S.O. Bamaga, M.A. Ismail, Z.A. Majid, M. Ismail, and M.W. Hussin, Arab. J. Sci. Eng. 38 (2013) 2293-2301.

-

- 9. P. Chindaprasirt, S. Homwuttiwong, and C. Jaturapitakkul, Constr. Build. Mater. 21 (2007) 1492-1499.

-

- 10. P. Quinn, Y. Yang, Y. Xia, X. Li, S. Ma, S. Zhang, and D. Wilke, Archaeometry 63 (2021) 40-52.

-

- 11. S. Yeni, G. Femiana, H. Gunawan, and P.V. Putri, J. Distrib. Sci. 20[6] (2022) 87-97.

-

- 12. L. Cui and S. Hertz, Ind. Mark. Manag. 40[6] (2011) 1004-1011.

-

- 13. C. Karrapan, M. Sishange, E. Swanepoel, and P.J. Kilbourn, J. Transp. Supply Chain Manag. 11 (2017) 1-10.

-

- 14. L. Zheng and Z. Yihua, J. Ceram. Process. Res. 26[2] (2025) 257-260.

-

This Article

This Article

-

2025; 26(4): 694-697

Published on Aug 31, 2025

- 10.36410/jcpr.2025.26.4.694

- Received on Jun 9, 2025

- Revised on Aug 14, 2025

- Accepted on Aug 18, 2025

Services

Services

- Abstract

introduction

materials and methods

waste composition and recovery potential

conclusion

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Huiyi Liu

-

Department of Business and Trade, Dongguan Polytechnic, Dongguan, Guangdong 523800, China

Tel : +86 15818461861 - E-mail: hy159357852@126.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.