- Evaluating ceramic powder flow and shrinkage for binder jetting in heritage artifact fabrication

Qi Chen Yua and Qiang Liub,*

aJungwon University 85 Munmu-ro, Goesan-eup, Goesan-gun, Chungcheongbuk-do, 28024, Korea

bDepartment of Basic Studies, Shandong Xiehe University, Jinan 250000, ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The integration of digital manufacturing and ceramic engineering presents transformative opportunities for tailoring ceramic properties through process optimization. This study investigates the influence of powder morphology and process parameters on the printability and performance of alumina (Al2O3) components fabricated via binder jetting. Alumina powders with varied particle shapes and size distributions were characterized for shape factor, flow rate, and bulk properties to assess their suitability for layer-wise deposition. Print accuracy and resolution were evaluated by fabricating geometrically standardized specimens, followed by dimensional analysis using 3D scanning. Experimental results reveal a direct correlation between flow rate and dimensional fidelity, while powders with higher shape factors (closer to spherical) exhibit improved flowability and uniform spreading. Post-sintering analysis was conducted to examine density, shrinkage, porosity, and mechanical strength. Graphical data are presented to illustrate relationships such as shape factor vs. angle of repose, flow rate vs. print accuracy, and sintering temperature vs. final part density. The findings provide a comprehensive understanding of how powder characteristics and digital process control can be leveraged to enhance the precision and quality of 3D-printed alumina ceramics.

Keywords: Angle of repose, shape factor, shrinkage

Ceramics have traditionally occupied a key role in human cultural expression, with their existence ranging from functional tools and household items to spiritual symbols, artistic sculptures, and structural components [1]. These artifacts, firmly established in the technological and aesthetic customs of their era, offer significant understanding of the social, spiritual, and material aspects of past societies. In modern society, museums and exhibitions act as guardians of this ceramic heritage, not just protecting these items but also crafting stories that connect the past with the present [2]. Museums are progressively transforming from static collections into dynamic, research-oriented venues that integrate digital technologies to improve preservation, accessibility, and public involvement.

Leading this transformation is the increasing fusion of digital fabrication technologies with ceramic materials, providing novel methods for production, reproduction, and presentation. This convergence holds important consequences for curatorial practice: fragile or damaged items can now be digitally reconstructed or reimagined with remarkable precision, allowing artists and designers to partner with technologists to create innovative works that expand the limits of form, material, and interpretation [3]. Among the different additive manufacturing methods, binder jetting has become a notably promising technique for digitally shaping ceramics. Its capacity to generate intricate shapes without requiring support structures, along with its compatibility with fine ceramic materials like alumina, renders it particularly well-suited for museum purposes where both aesthetic accuracy and structural stability are essential [4].

Binder jetting functions by selectively applying a liquid binder onto a thin layer of ceramic powder, creating objects one layer at a time. This method provides exact management of internal structure, surface finish, and size precision, which is essential for the faithful reproduction of complex objects or the creation of creatively influenced installations [5]. The effective implementation of binder jetting for alumina ceramics relies on a comprehensive understanding of powder flowability, particle morphology, and sintering characteristics, which directly influence print precision, surface quality, and mechanical strength [6]. This research explores these issues by methodically examining how the shape factor of powder and flow rate influence the printability and overall quality of binder-jetted alumina parts, particularly regarding their use in museum and exhibition settings. The research seeks to create practical guidelines for the digital reproduction and fabrication of ceramic objects suitable for curatorial display, tactile replicas for public interaction, and interpretive installations that merge heritage with innovation by establishing experimentally supported links among flow behavior, dimensional accuracy, and sintered properties. In this work, we aim to add to an expanding collection of interdisciplinary insights that facilitate the digital evolution of cultural heritage, framing ceramics not merely as historical objects but as dynamic participants in the conversation between tradition and technology.

This research utilized commercially available Al2O3 powder with a nominal particle size range of 20-60 μm (3M, Alumina) as the primary ceramic material for additive manufacturing. The powder was utilized in its original state without any alterations. A water-soluble polymeric binder PVA: Polyvinyl alcohol, suitable for ceramic binder jetting systems, was chosen to deliver sufficient adhesion between powder layers during printing and to guarantee the strength of the green part. Characterization of the powder was performed through readily available and non-instrumental techniques to evaluate flow properties. The flowability was assessed using the Hall flowmeter technique as per ASTM B213 specifications. In this experiment, 50 grams of powder were permitted to pass through a Hall funnel, and the duration taken was noted with a digital stopwatch. To guarantee consistency, three measurements were collected and averaged. Furthermore, the angle of repose technique was employed to assess the cohesiveness of the powder. The powder was funnelled onto a flat surface, creating a conical mound. The ruler was used to measure both the height and diameter of the heap, and the tangent formula was applied to calculate the angle of repose. These straightforward yet insightful tests offered information on the powder's appropriateness for binder jetting, particularly concerning spreading behavior and packing density.

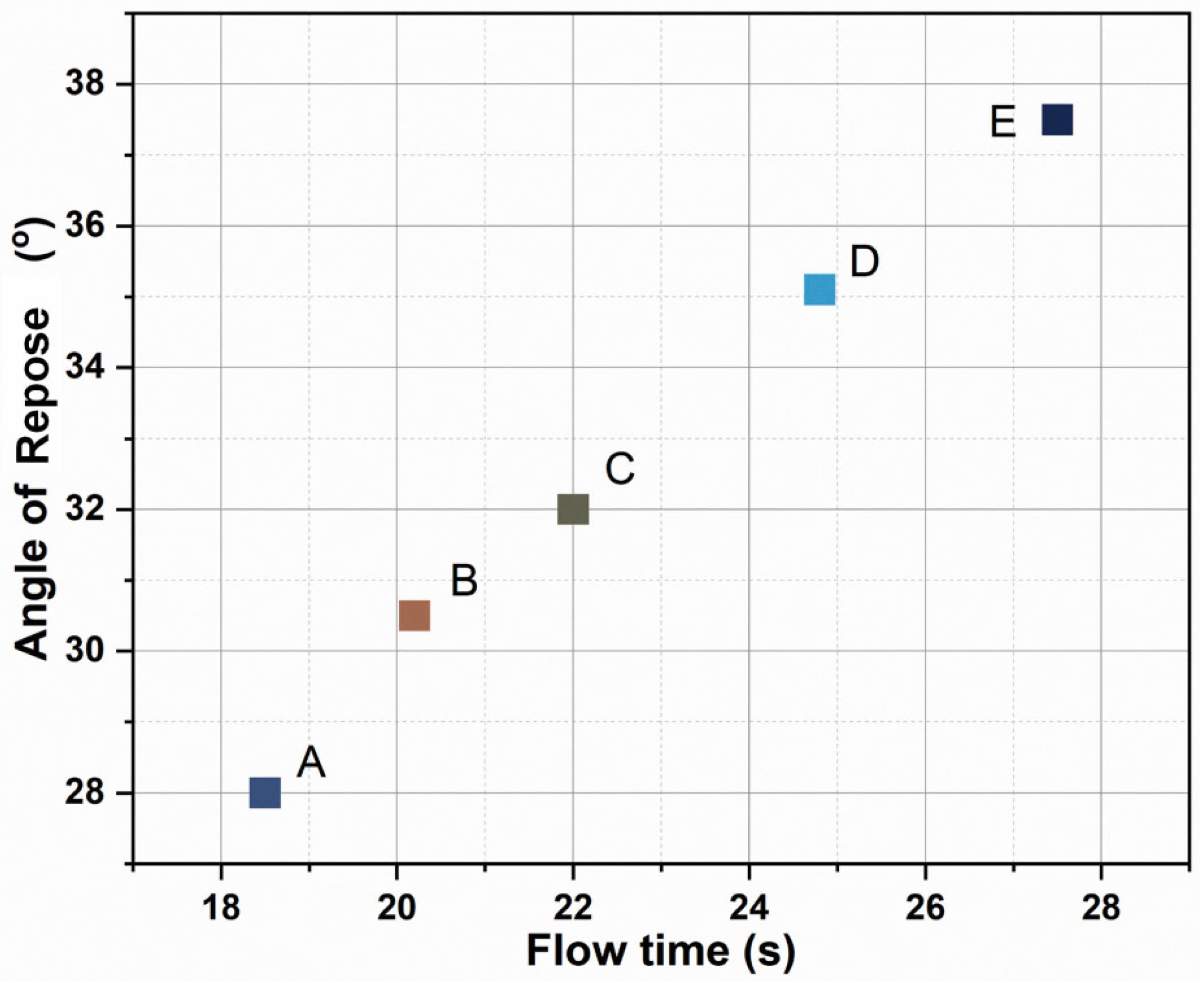

The flow characteristics were evaluated through a mix of physical characterization and dimensional accuracy assessment. Of these, the angle of repose test acted as a key measure of powder flow characteristics. In binder jetting, powder flowability is a vital factor, as it directly affects the consistency and uniformity of every deposited layer both of which are crucial for achieving high-resolution, defect-free prints. The angle of repose was determined by enabling the ceramic powder to pour from a funnel onto a level surface, creating a conical pile. The angle formed between the heaps incline and the horizontal surface indicates the friction and cohesion properties of the particles in the powder [7]. The Angle of Repose vs. Flow Time graph (Fig. 1) demonstrates a strong positive correlation, suggesting that powders with longer flow times displayed steeper repose angles. The angle of repose notably rose from 28° to 37.5° as the duration of flow lengthened from 18.5 to 27.5 seconds. This implies that powders exhibiting lower flow rates tend to have more robust interparticle interactions, probably because of irregular particle shapes, rough surfaces, or a broad particle size distribution. These characteristics obstruct steady flow and aid in the creation of larger conical piles. In a binder jetting setup, such powders may result in inadequate layer spreading, resulting in uneven layer thickness, the creation of voids, or irregular binder penetration [8].

Additionally, elevated angles of repose frequently correlate with a propensity for the powder to bridge or block the recoater blade or hopper during layer deposition, creating practical difficulties in process stability. This impaired flowability directly results in flaws in green components, including surface roughness, dimensional inaccuracies, or weak inter-layer adhesion. In contrast, powders exhibiting a lesser angle of repose and quicker flow rates generally distribute more evenly, facilitating smoother layers and more consistent interactions with the binder. These advantageous traits are essential for the effective manufacturing of intricate ceramic parts, particularly in uses demanding high geometric precision, like digitally produced reproductions for museum collections or cultural artifacts [9]. Therefore, comprehending the connection between repose angle and flow duration enables better selection or preparation of ceramic powders before additive manufacturing. Adjusting these parameters can greatly improve print quality, decrease material waste, and lessen the necessity for post-processing steps, rendering binder jetting a more effective and dependable method for ceramic applications in digital restoration and cultural preservation.

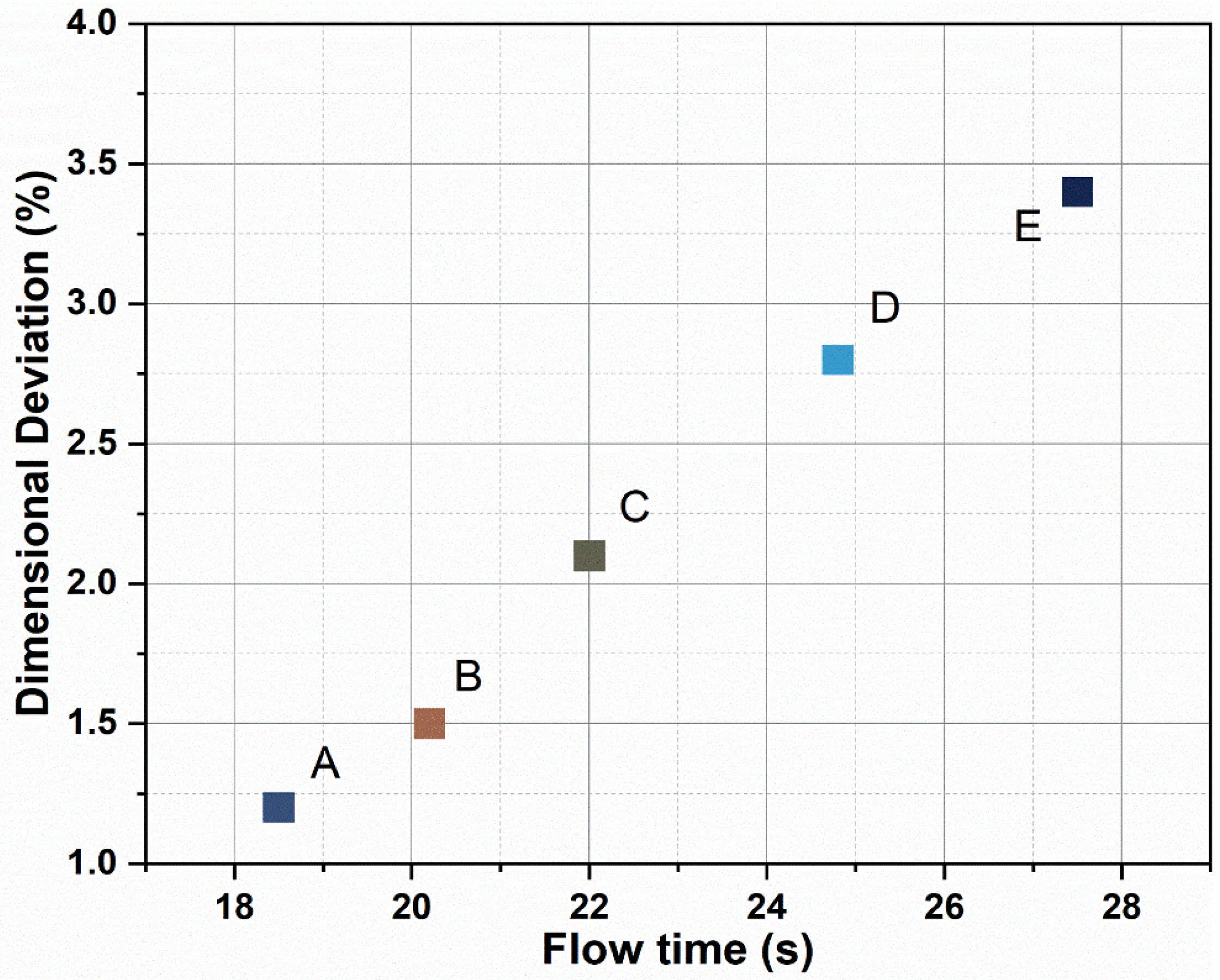

The relationship between powder flow behavior and the dimensional accuracy of printed parts was further examined through the Flow Time vs Dimensional Accuracy analysis (Fig. 2). This is especially critical in applications such as heritage object reproduction or museum-quality ceramic fabrication, where fidelity to original dimensions is essential for authenticity and functional integration into existing collections. The flow time, defined as the time taken for a fixed mass of powder to pass through a standard funnel, serves as a practical indicator of the powder's dynamic behavior under gravity-driven flow conditions. In this study, a clear inverse relationship was observed between flow time and dimensional accuracy. As the flow time increased from 18.5 seconds to 27.5 seconds, the percentage dimensional deviation also increased, ranging from 1.2% to 3.4%. This trend reflects the detrimental impact of poor flowability on layer homogeneity and binder-powder interaction during the printing process. Powders with shorter flow times exhibited better flowability, enabling more uniform layer deposition and consistent powder packing density [10]. This uniformity leads to more predictable and repeatable dimensional outcomes, as the printed part’s geometry closely adheres to the slicing data. In contrast, powders with longer flow times are more prone to inconsistent layer formation, which introduces variability in layer thickness, local density gradients, and binder distribution. These inconsistencies result in geometrical distortions, dimensional swelling or shrinkage during drying and sintering, and in severe cases, print failure or delamination.

In binder jetting, dimensional discrepancies are typically cumulative throughout the print height, indicating that even small variations in initial layers can extend and intensify as the printing advances. Thus, choosing or designing powders with enhanced flow properties is essential not just for obtaining precise prints but also for minimizing post-processing needs like machining or support adjustments [11]. The noted correlation highlights the significance of powder flow characteristics as a critical factor in process design, particularly for ceramic materials that are more reactive to volumetric variations during thermal processing than polymers or metals. This discovery endorses the incorporation of flow testing as a preliminary qualification phase in digital ceramic manufacturing processes. In digital restoration and museum exhibits, where replicas need to visually and dimensionally resemble rare or ancient originals, achieving dimensional accuracy through powder flow optimization is essential [12]. These findings provide additional confirmation of the significance of material-process interaction in influencing the effectiveness and dependability of binder jetting for advanced ceramic applications

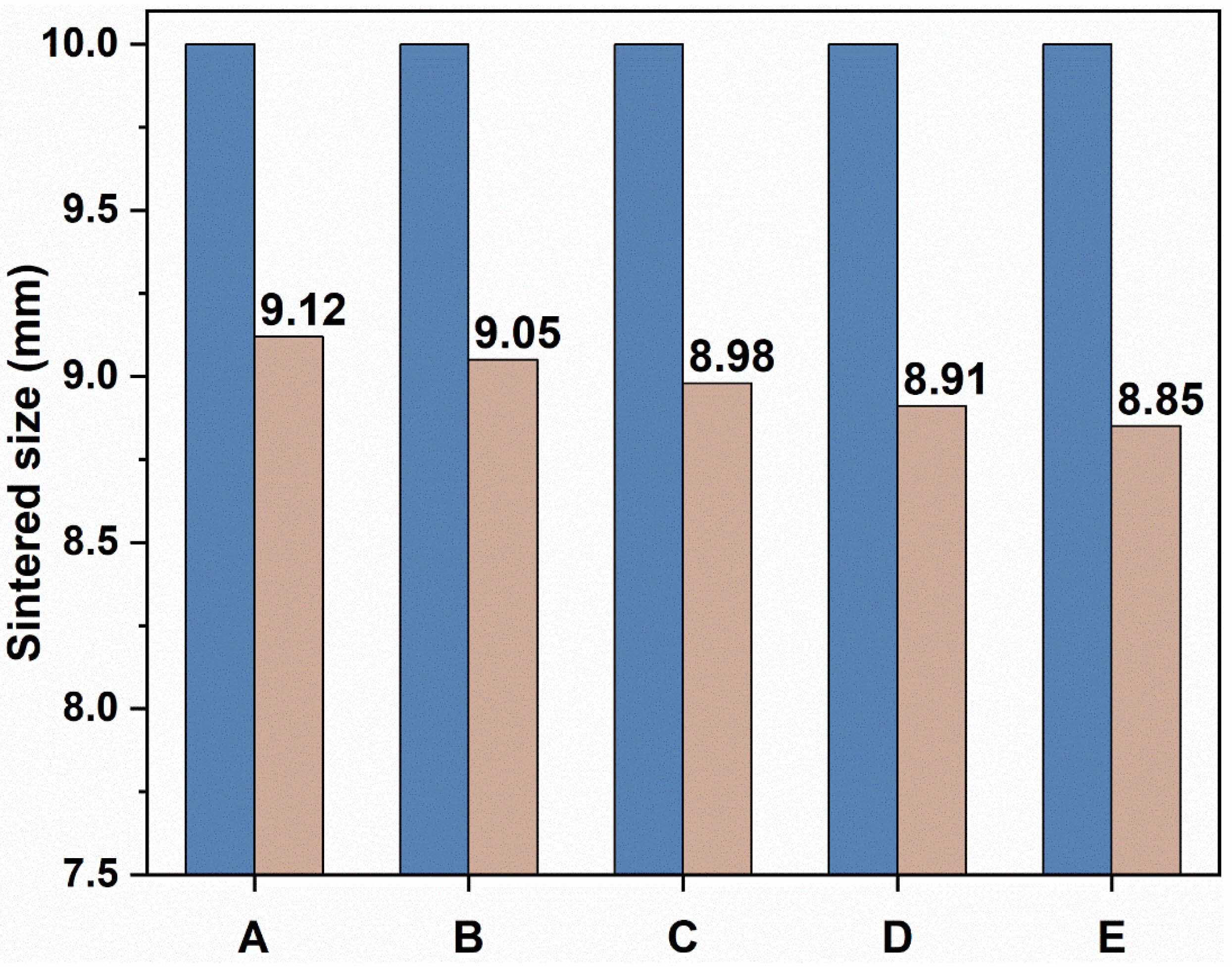

The analysis of Green Part Size vs. Sintered Part Size (Fig. 3) was conducted to assess the dimensional alterations caused by shrinkage induced by sintering, an important factor in the binder jetting process of ceramics. The shift from the green (as-printed) phase to the sintered (final) phase entails considerable microstructural changes, encompassing binder removal, particle reorganization, neck formation, and increased density [13]. These processes consistently result in volumetric shrinkage, which, if not considered, can jeopardize dimensional accuracy, especially in scenarios like the digital reconstruction of archaeological ceramics, where maintaining size and shape is crucial. In the present research, every printed ceramic sample showed a quantifiable decrease in linear measurements following sintering. The shrinkage percentages, determined relative to the initial size of the green part, varied from about 8.8% to 11.5%, showing minor differences throughout the sample group [14]. The graph comparing Green and Sintered Size exhibited a nearly linear trend, reflecting uniform shrinkage patterns among various specimens. This consistency indicates effective management of the initial powder packing density and binder saturation, both of which are recognized to affect sintering results.

The observed shrinkage falls within the expected range for oxide-based ceramic systems fabricated via binder jetting. It is primarily attributed to the removal of the organic binder phase during the debinding step and the subsequent densification of ceramic particles during high-temperature sintering. While some variation in shrinkage was observed among samples, these differences may stem from local heterogeneities in green density or minor inconsistencies in thermal exposure during sintering. In practical terms, this dimensional contraction necessitates the use of shrinkage compensation strategies in the digital design phase. By incorporating empirically derived shrinkage factors into CAD models, it becomes possible to produce printed parts that sinter down to their intended final dimensions with minimal deviation.

|

Fig. 1 Correlation between angle of repose and powder flow time. |

|

Fig. 2 Impact of powder flow time on dimensional accuracy of printed parts. |

|

Fig. 3 Linear shrinkage from green to sintered state in binder jetted ceramics. |

This research examined the combination of digital fabrication methods with ceramic processing, emphasizing the binder jetting technique for possible applications in cultural heritage restoration and museums. The flow characteristics of the ceramic powder were quantitatively evaluated using angle of repose and flow time measurements, demonstrating a significant positive correlation that directly influenced the print quality and dimensional precision of the produced components. Powders exhibiting enhanced flow properties showed greater dimensional accuracy, highlighting the necessity for pre-processing flowability evaluation in digital ceramic production processes. Dimensional analysis conducted prior to and following sintering revealed consistent linear shrinkage between 8.8% and 11.5%, emphasizing the necessity of integrating shrinkage compensation in the digital design phase to guarantee precision of the final part. The uniformity in shrinkage characteristics among samples reinforces the dependability of binder jetting for creating geometrically accurate ceramic parts. These findings confirm the practicality of binder jetting as a digital production method for creating high-quality ceramic pieces, especially in settings like museums and exhibitions where precision in reproduction and artistic fidelity are crucial. The results add to the expanding area of digitally facilitated cultural preservation and establish the foundation for upcoming studies that include more intricate geometries, surface treatments, and advanced material systems.

- 1. W. Du, X. Ren, Z. Pei, and C. Ma, J. Manuf. Sci. Eng. 142[4] (2020) 040801.

-

- 2. E. Sachs, M. Cima, J. Cornie, D. Brancazio, J. Bredt, A. Curodeau, T. Fan, S. Khanuja, A. Lauder, J. Lee, and S. Michaels, CIRP Ann. 42[1] (1993) 257-260.

-

- 3. N. Travitzky, A. Bonet, B. Dermeik, T. Fey, I. Filbert-Demut, L. Schlier, T. Schlordt, and P. Greil, Adv. Eng. Mater. 16[6] (2014) 729-754.

-

- 4. B.Y. Tay, J.R.G. Evans, and M.J. Edirisinghe, Int. Mater. Rev. 48[6] (2003) 341-370.

-

- 5. D. Yao, C.M. Gomes, Y.P. Zeng, D. Jiang, J. Gunster, and J.G. Heinrich, Mater. Lett. 147 (2015) 116-118.

-

- 6. E. Salahi and J.G. Heinrich, Br. Ceram. Trans. 103[3] (2004) 115-120.

-

- 7. R. Hamano and T. Ikoma, MRS Adv. 3[18] (2018) 969-975.

-

- 8. M. Hotta, A. Shimamura, N. Kondo, T. and Ohji, J. Ceram. Soc. Japan 124[6] (2016) 750-752.

-

- 9. A. Budding and T.H.J. Vaneker, Procedia CIRP, 6 (2013) 527-532.

-

- 10. M. Vaezi and C.K. Chua, Int. J. Adv. Manuf. Technol. 53[1-4] (2011) 275-284.

-

- 11. D. Dimitrov, W.V. Wijck, K. Schreve, and N. de Beer, Rapid Prototyping J. 12 (2006) 42-52.

-

- 12. K. Lu and W. T. Reynolds, Powder Technol. 187 (2008) 11-18.

-

- 13. C.X.F. Lam, X.M. Mo, S.H. Teoh, and D.W. Hutmacher, Mater. Sci. Eng. C 20 (2002) 49-56.

-

- 14. N. Ramakrishnan, P.K. Rajesh, P. Ponnambalam, and K. Prakasan, J. Mater. Process Technol. 169 (2005) 372-381.

-

This Article

This Article

-

2025; 26(4): 690-693

Published on Aug 31, 2025

- 10.36410/jcpr.2025.26.4.690

- Received on Jun 4, 2025

- Revised on Jun 24, 2025

- Accepted on Jul 22, 2025

Services

Services

Shared

Correspondence to

Correspondence to

- Qiang Liu

-

Department of Basic Studies, Shandong Xiehe University, Jinan 250000, China

Tel : +86 13093733120 - E-mail: 13093733120@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.