- Suitability of clays from Maroua (Far North Cameroon) and physical properties of their adobe bricks reinforced with staff waste powder for eco-friendly construction

Bertin Pagna Kagonbéa,*, Klamadji Moussa Ngarenab, Özgür Cengizc,d,*, Djoulaiyatou Djalloe, Soureiyatou Fadil-Djenabouf, Viviane Djaoyang Bakaïnéa,g, Etienne Yannég, Fréderic Pagoré Djodag and Débonnaire Bandeyah

aLocal Materials Authority Promotion (MIPROMALO), P.O. Box 2396, Yaoundé, Cameroon

bDepartment of Mining and Geological Engineering, Faculty of Life and Earth Sciences, University of Pala, P.O. Box 20, Pala, Chad

cDepartment of Metallurgy and Materials Engineering, Faculty of Technology, Afyon Kocatepe University, 03200, Afyonkarahisar, Türkiye

dDepartment of Ceramic, Fine Arts Faculty, Afyon Kocatepe University, 03200, Afyonkarahisar, Türkiye

eNational Advanced School of Mines and Petroleum Industries, University of Maroua, P.O. Box 46, Cameroon

fDepartment of Life and Earth Sciences, Higher Teachers’ Training College, University of Maroua, P.O. Box 55, Maroua, Cameroon

gDepartment of Civil Engineering and Architecture, National Advanced School of Engineering of Maroua, University of Maroua, P.O. Box 58, Maroua, Cameroon

hDepartment of Materials Engineering, School of Chemical Engineering and Minerals Industries, University of Ngaoundéré, P.O. Box. 454, Ngaoundéré, CameroonThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

From a perspective of sustainable development in Cameroon in general and in the far north in particular, the development of an ecological material is a major issue. This article deals with the evaluation of clay soil used in the production of adobe bricks and the influence of staff waste powder on the physical and mechanical properties of bricks made from this material. Geotechnical tests consisted of granulometry and Atterberg limits. The physic-mechanical properties, notably linear shrinkage, water absorption, and compressive strength tests of the adobe brick specimens, were performed according to modern material standards. The granulometric analysis reveals dominant proportions of clay fractions ranging from 30.15 to 42.5%. The plasticity test shows that the studied soils are almost essentially low (M1) and medium (M2, M3) plasticity clays, depending on the case. The clay soil samples are made up of quartz, smectite, kaolinite, and illite, according to the mineralogical analyses carried out. The most abundant oxides in the three samples are SiO2 (57.51-60.53%), Al2O3 (11.93-23.49%), and Fe2O3 (6.87-7.51%), while K2O, MgO, TiO2, P2O5, Na2O, and MnO are in small amounts. The measurement of mechanical properties such as water absorption, linear shrinkage, and compressive strength showed an improvement in resistance when increasing staff waste powder in clay soil is observed. Based on the test results, the studied clay soils were suitable for adobe brick production.

Keywords: Clayey soil, Adobe bricks, Staff waste powder, Stabilization, Cameroon.

The use of Adobe bricks in building technology, using clay and/or clay-based raw materials is not a new technology, and in fact, it extends back thousands of years [1-3]. Their accessibility as a starting material, their widespread use as the main building material was justified by their low energy consumption and ease of production. Even today, constructions using this material are frequently seen as second-class building materials for low-income earners and are associated with subpar housing in many parts of the world [4-6]. However, the earth continues to be one of the noblest building element. It is an ecological, simple, and local technique [7, 8]. In addition, there are several reasons for valorizing crude earth technology, among which the main argument is energy saving: production of 1 m3 of concrete consumes 1.0-1.8 MJ, however the same amount of raw earth for construction consumes only 1% of this quantity of energy [9]. Thus, during the last three decades, in Africa, for instance, cement-based housing was preferred. The recent popularity of concrete can be attributed to both its perceived modernity and prosperity as well as its good mechanical properties, durability, and standardized implementation techniques [10]. However, building shelters using concrete is not cost effective way of construction in developing countries, and this generates important environmental impacts [11-14].

On the other hand, the growing pressure from both a housing shortage and environmental concerns has triggered a renewed interest in earth bricks, chiefly because of their low environmental impact [14]. Compared with concrete, it is known that raw earth bricks or buildings made from simple earth materials have poor physical and mechanical properties. In general, the manufacturing and construction methods used for adobe brick production are based on empirical knowledge that, with world development and industrialization, tend to disappear. Adobe is an earthen brick made from a simple mixture of sand, clay, organic material, and water, molded and then dried in the sun [15]. Embodies the multiple advantages of earthen construction. These include a positive environmental impact, excellent thermal performance, low cost, fire resistance, and the ability to absorb pollutants [16-19]. Further benefits of valorizing crude earth are the availability of raw materials, the minimal amount of waste and CO2 emissions, and waste generation, and the diversity of original traditional building methods, and architecture [2].

In sub-Saharan African countries and particularly in Cameroon, there are five types of earth house construction methods that are primarily utilized rural communities: adobe, rammed earth, cob, wattle, daub, and compacted soil blocks [20]. Nevertheless, such a structure has various deficiencies, including mechanical strength, water resistance, and durability [21]. To address these issues, plant debris, fly ash, small amounts of cement or lime, and a significant quantity of construction waste are commonly added [22].

Nowadays, in the Far North region of Cameroon, massive quantities of waste are produced during the construction of new infrastructure or the demolition of old buildings and more populations that are affluent employ traditional materials like concrete. Unfortunately, this bulky waste is not recycled or reused, so it pollutes the environment. In rural areas, most individual homes are built with adobes made with natural clayey soil composed mainly of vertisol; this can be attributed to the rural population's low-income level. Then, adobe bricks made from this vertisol have low mechanical strength due to their physical complexity [6, 16]. During the rainy season, we can observe that when exposed to water, they quickly deteriorate, seriously damaging buildings and shortening their lifespans. Kagonbé et al. [12] and Yaboki et al. [19] observed that the termites persistently damage earth-based structures in such locations, requiring regular maintenance. They stated that in order to address their housing issue, rural residents chose to use burnt earthen bricks, which use a lot of energy and cause desertification in this ecologically vulnerable region of the nation.

It appears that the adobe bricks made with vertisol are difficult to stabilize in a context of predominantly artisanal construction. Composed mainly of incompressible clay, these raw materials do not mix well with cement like the one brick made from laterite. Hence, there is a need to find a way to improve its properties for an exploitation purpose given its enormous quantity. In the past decade a lot of research have been focused on development of adobe bricks reinforced with industrial, agro-by-product binders, lime, additionally, fibers have demonstrated that adding these mixes increases durability and decreases the formation of cracks while drying [5, 6, 17, 18, 22-26]. The purpose of this work is to study the effect of staff powder waste on the mechanical properties and water stability of adobe bricks made with vertisol from Maroua, and as a result, alternative solutions for sustainable brick production in this area are suggested.

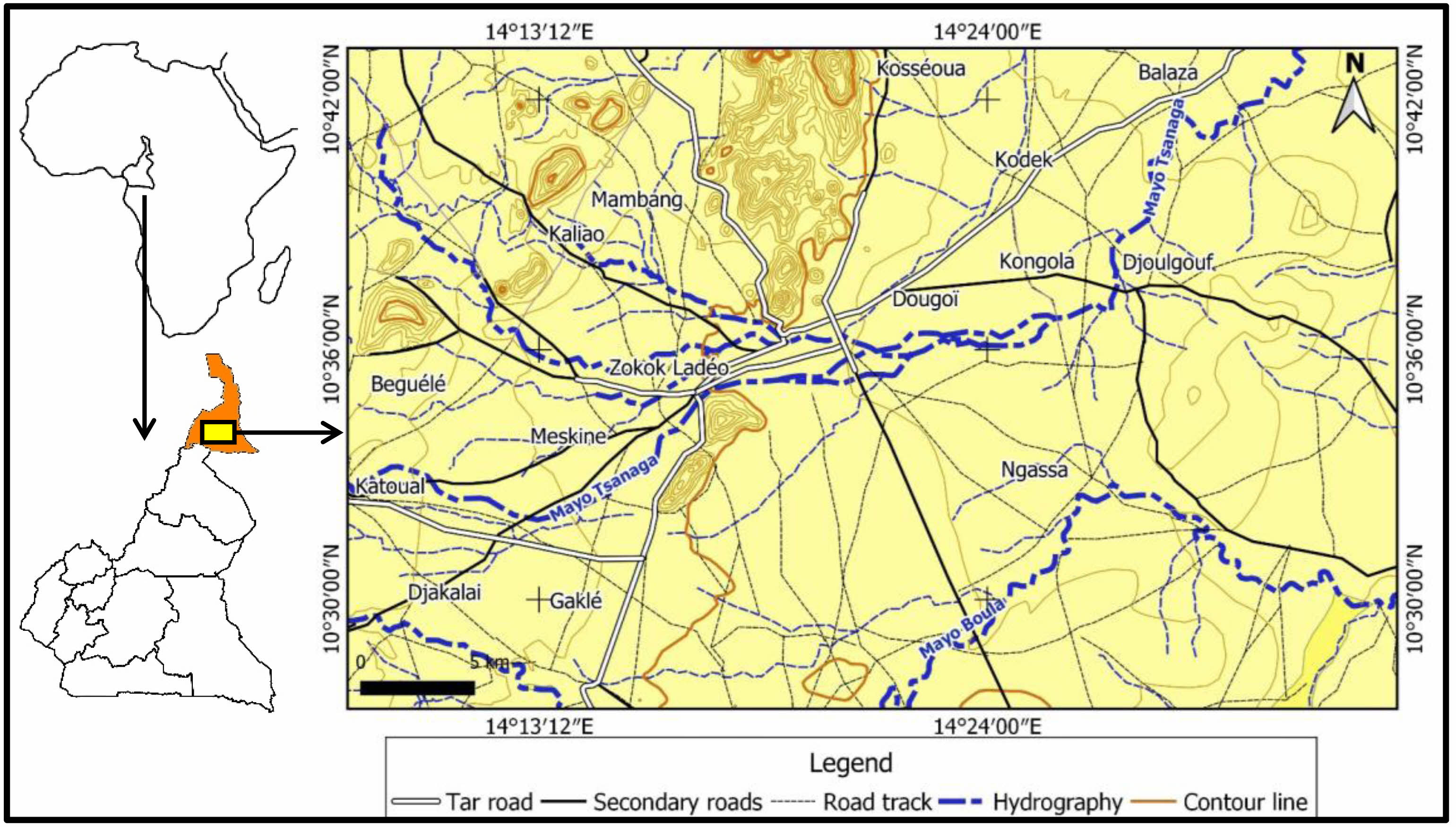

The research area is situated in the Diamaré Division in Cameroon Far North (Fig. 1). The Sudan-Sahelian climate of the area is characterized by two seasons that are unevenly distributed: a brief rainy season that lasts four months, from May to early October, and an extended dry period that lasts around eight months, from late October to early May [27]. The hydrography of the area shows a dendritic network characterized by the existence of seasonal rivers. It consists of two sub-basins: Mayo Kaliao and Mayo Tsanaga, which are tributaries of the larger Lake Chad basin.

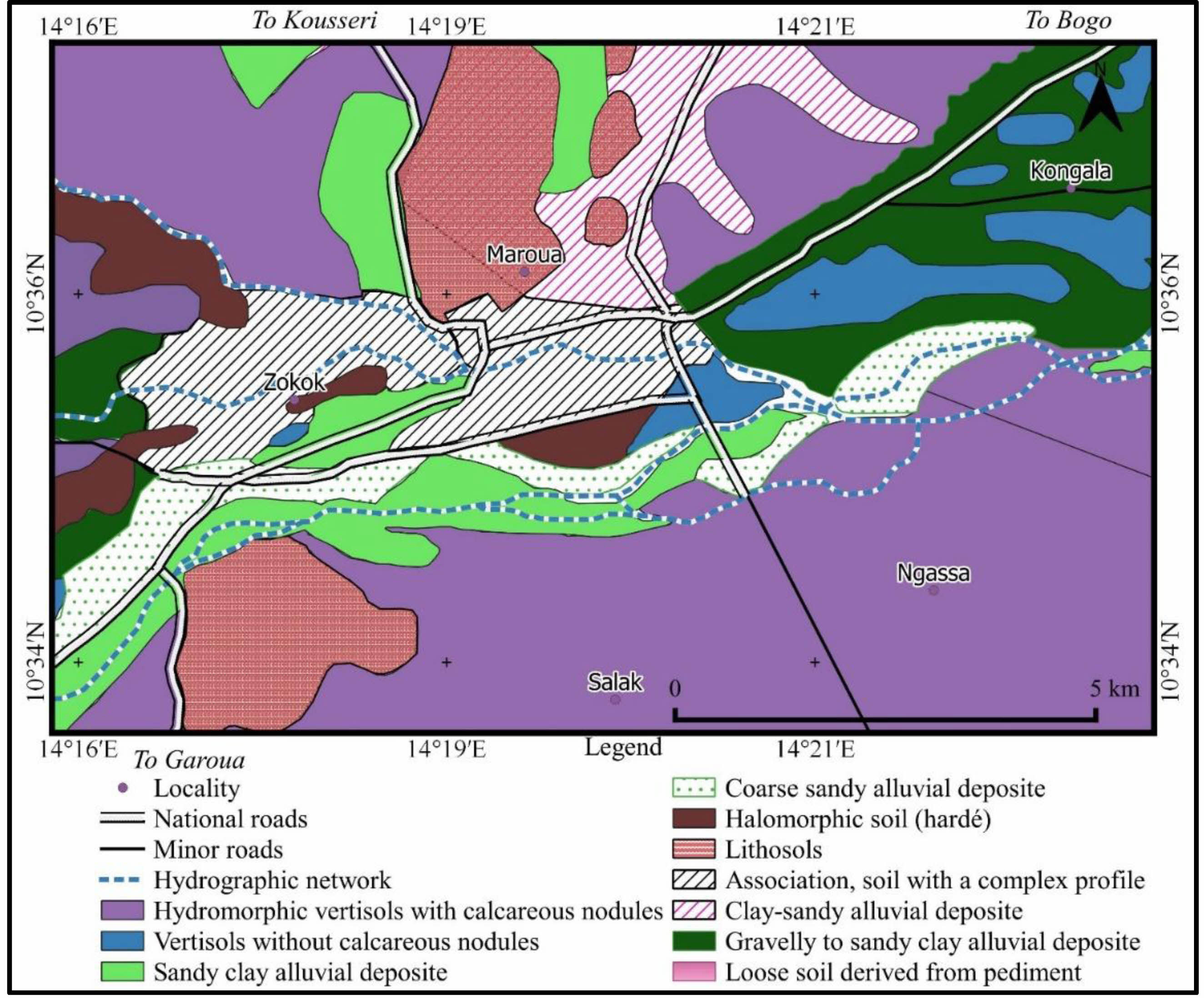

The grassy steppe and arboreal savannah covered the vegetation. According to Tsozué et al. [28], this region is identified by a sharp distinction between the flat and high-relief mountainous areas. The highlands are either isolated inselbergs or mountains. In this context, the pedogenesis process is reduced due to intense erosion and the plains with generally low slopes and sometimes flooding [28]. The majority of the soils that are encountered are hydromorphic vertisols, which are divided into two categories: hydromorphic vertisols that have calcareous nodules and vertisols that do not [9] (Fig. 2). These vertisol soils are associated with little-weathered soils, poorly developed soils, ferruginous soils, and fersiallitic soils [27, 28]. Moreover, holomorphic soils, lithosoils, tropical ferruginous soils, and alluvial deposits are present as well (Fig. 2). Geologically, the basement rocks found are volcanic, plutonic, and metamorphic rocks. This region mostly consists of gabbros and lacks volcanic rocks. Volcanic rocks are not present in this area, but it mainly consists of gabbros [29]. Gneisses and massive garnet-rich rocks, respectively [29], represent metamorphic and plutonic rocks.

|

Fig. 1 Location map of the study area. |

|

Fig. 2 Soil Map of the Study Area, extracted from North Cameroon Soil Map at 1:100000, Yaounde, ORSTOM. |

Fieldwork and raw material collection

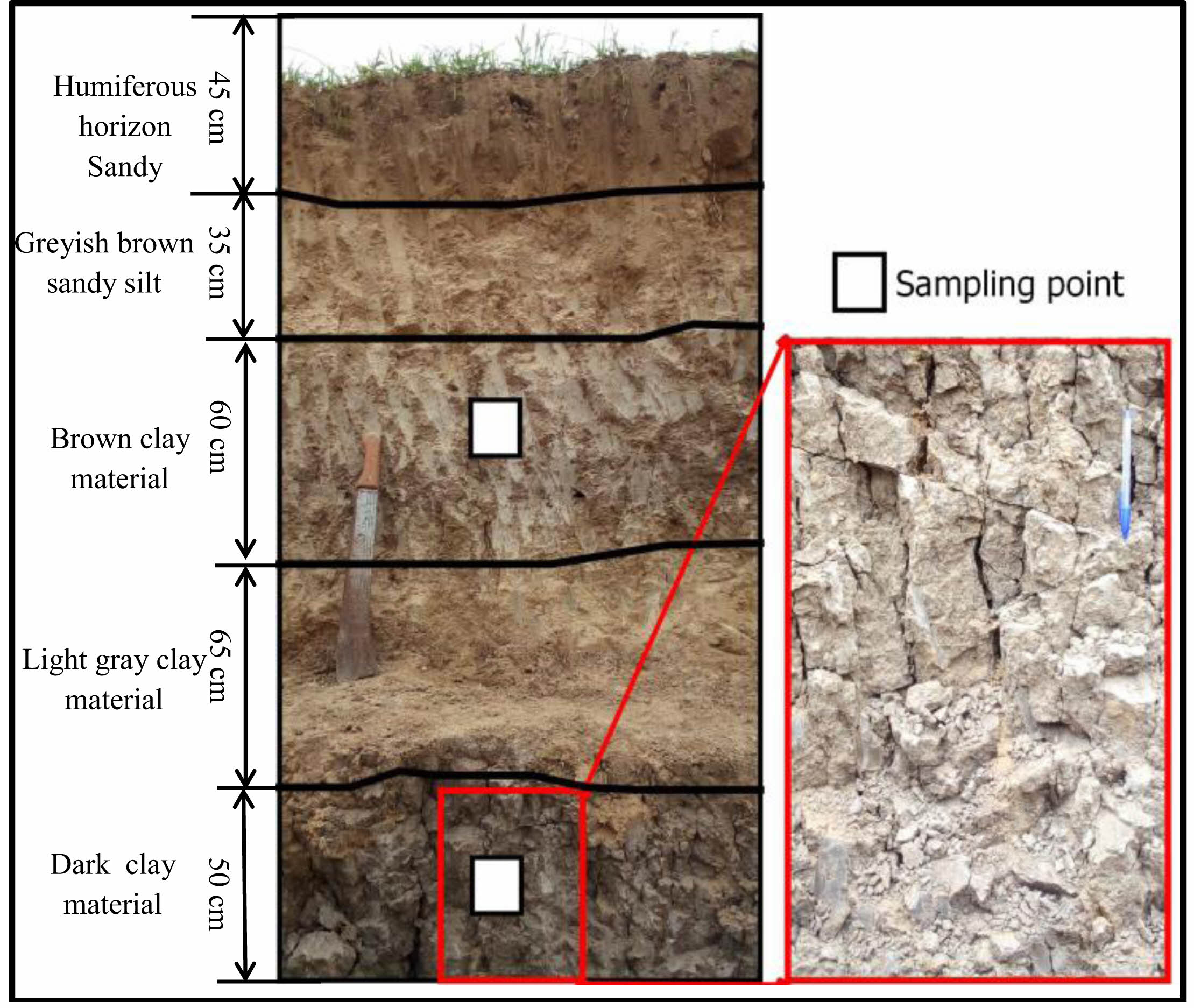

In the present study, clay soil was used as a raw material for the manufacturing of adobe bricks with the addition of staff powder waste. The field survey was carried out in the dry season. After field prospecting works, the used clay soil sample was obtained from a production site in the Maroua I district and Far North region of Cameroon. This clay soil was chosen because of its abundant use by farmers to produce adobe bricks for their houses. Color, texture, consistency, structure, porosity, and transition between several horizons are the features taken into account in the description of the three profiles (M1, M2, and M3) that were dug. Each profile yielded one sample, which was then labeled and carried to laboratories for various analyses and adobe brick manufacturing processes.

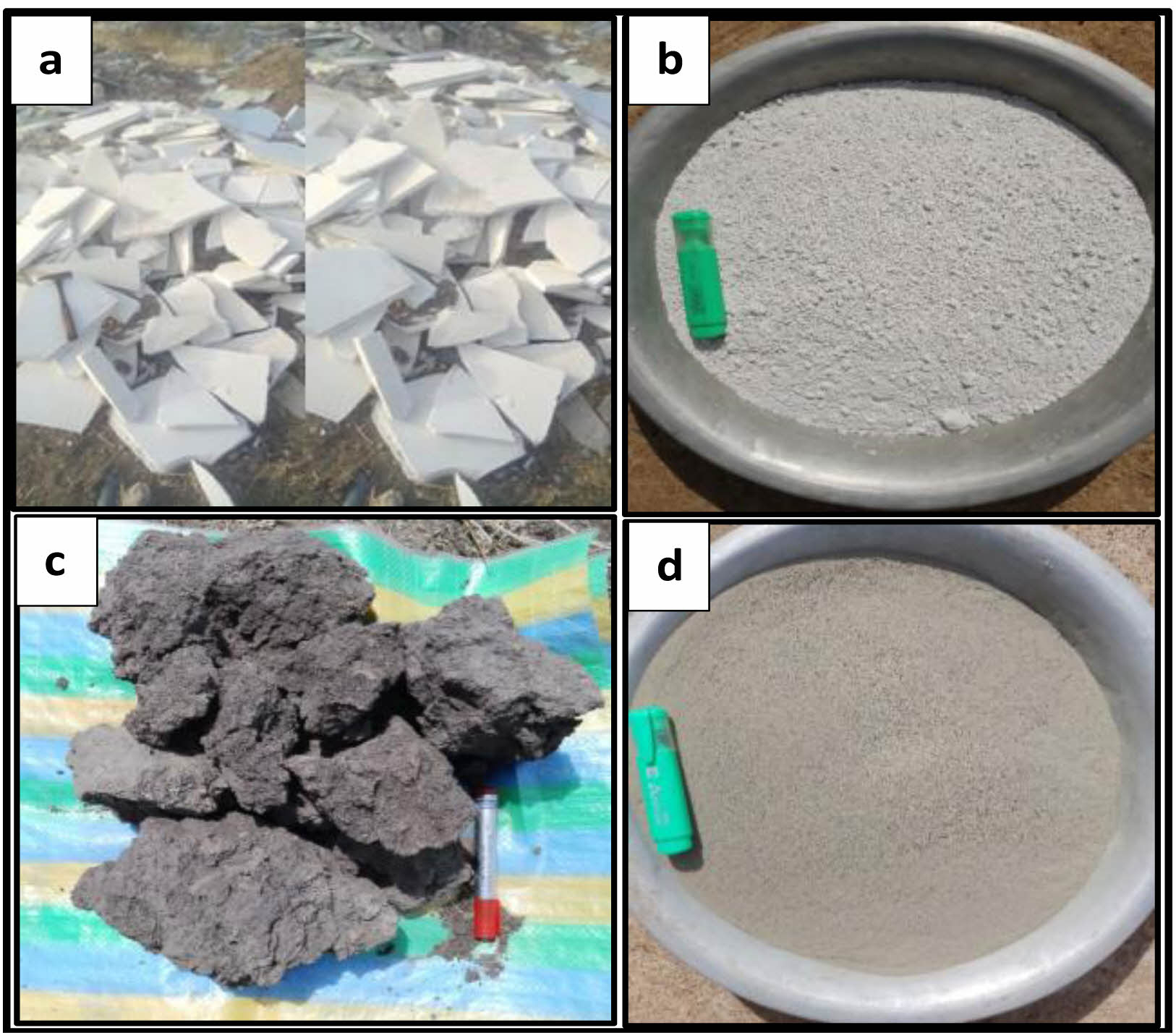

Staff is a rigid material made from modeling plaster reinforced with sisal, jute, or silicone. It is obtained from gypsum, also known as "plaster stone." However, its chemical composition can vary depending on the brand and type of product. In general, it is composed of gypsum (calcium sulfate), water, starch, polymers, and other additives. The demolition of buildings in major cities generates huge amounts of waste, including the large quantities of staff originally used for decoration. This waste (Fig. 3a, and 3b) can be recycled by using it in the manufacture of building materials such as adobe bricks.

Laboratory work

Geotechnical, geochemical, and mineralogical characterization of clay soil sample

The geotechnical characteristics measured on the raw clayey material were grain size distribution and Atterberg limits. After drying in an oven at 105 °C for 24 h and crushing (Fig. 3c, and 3d), the particle size analysis was analyzed using two complementary methods: Dry sieving was used for the coarser fraction (≥80 μm), while gravity sedimentation was applied to the finer fraction (≤80 μm) following the ASTM D-422 standard [30]. The liquid limit (WL) was determined using the Casagrande apparatus [31], while the plastic limit (WP) was carried out on the rods of 15 mm in length and about 3 mm in thickness according to the ASTM D-4318-00 [32] specification. According to that specification, the plasticity index (IP) is given by equation (1):

Where IP is the plasticity index, WL is the liquid limit, and WP represents the plastic limit (Eq. 1).

The raw materials chemical composition was determined by X-Ray fluorescence (XRF) (Bruker S8 Tiger 4 kW spectrometer, Cimencam, Cameroon). X-Ray diffraction was used to determine the mineralogical composition of the raw sample powders, which included both disoriented powders. A Bruker Advance D8 diffractometer (copper Kα1 radiations, λ = 1.5418 Å, V = 40 kV, and I = 30 mA) was used according to the methodology of Moore and Reynolds [33].

Elaboration and physical test on adobe specimens

The manufacture of the specimens consisted of grinding and mixing the material with the stabilizer (staff waste powder), molding, and drying the stabilized adobe bricks. Each stage was therefore crucial to obtaining the best results. The clayey material and staff waste used as stabilizer was ground into particles smaller than <5 mm in a grinding machine (Fig. 3). Following this process, it was mixed with water manually to create a homogenous slurry (clay soil + staff waste powder).

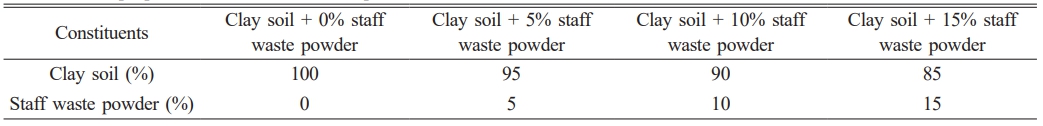

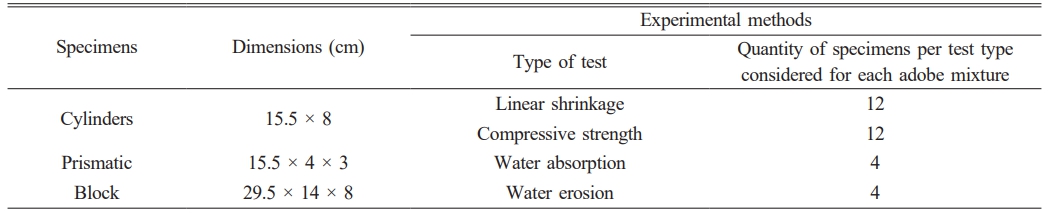

Based on either existing research in the field of soil stabilization, four recommended combinations (5, 10, and 15%) were created for the study in order to examine how the stabilizer employed affected the physical characteristics of the adobe brick specimens (Table 1). The adobe mixtures were used to prepare three different series of specimens, as detailed in Table 2, and Fig. 4. As recommended by the prior study, the stabilized adobe brick specimens were placed in plastic bags and allowed to cure at constant production moisture for around 28 days at room temperature in a laboratory (30 ± 5 °C) [18, 19, 24]. Cured adobe bricks were dried at 40 ± 2 °C until the change of mass was less than 0.1% between 24 h, before testing their properties.

To assess the physical properties of adobe specimens, the prepared specimens were tested for linear shrinkage, water absorption, water erosion test, and compressive strength at the end of curing periods. Linear shrinkage is the decrease in the length of the specimen dimensions to several drying phases. It is measured using a graduated laboratory ruler, and the lengths of samples are determined after molding (R1), and after final drying (R2). Linear shrinkage at different drying phases is calculated by the following relationships:

where R1 and R2 are expressed in mm (Eq. 2).

The water absorption is defined as the ratio of the mass increase induced by imbibition in water to the sample's dry mass. It was calculated by the weight difference between the samples after immersion in water and the dry samples using the equation (Eq. 3). The test is carried out according to NF EN 14617-1 [34].

Where m2 is the wet mass (g) and m1 is the dry mass (g), (Eq. 3).

Uniaxial compression testing was carried out on the prepared samples to determine their compressive strength. A hydraulic press with a load cell capacity of 200 kN was employed for the test. In accordance with AFNOR NF P 15-451, the tests were conducted at a displacement rate of 0.5 mm/min [35]. It was calculated with the following equation:

where Rc (N/mm2) is the compressive strength, Fc (N) is the maximum breaking force, and S (mm2) is the surface of the plates used in the test (1600 mm2) (Eq. 4).

The resistance to water erosion of the adobe bricks was measured according to the protocol suggested by Mbumbia et al. [36], which is a variant of the drip test on considering four adobe brick specimens. For these tests, four prismatic adobe specimens of each formulation (0, 5, 10, and 15%) are used to replicate the effects of rain on erosion for 15 and 30 minutes at a flow rate of 1.5 liters per second. The samples are angled toward the horizontal by 63 degrees. Each sample was left under the jet flow during 15 and 30 min. The spray is situated around 1.5 meters above the sample.

|

Fig. 3 Raw materials used: (a) Staff waste; (b) Staff powder waste; (c) Clay sample; (d) Crushed clay. |

|

Fig. 4 Preparation of adobes for the different tests: (a) Molds of cylindrical samples (b) Superior view of the cylindrical adobe samples (15.5 × 8 cm); (c) Molded cylindrical samples; (d) Prismatic molds; (e) Superior view of the prismatic adobe bricks (15.5 × 4 × 3 cm3 ); (f) Molded prismatic samples; (g) Manuel press for compressed earth bricks; (h) Superior view of the adobe bricks made using manual press (29.5 × 14 × 8 cm3 ). |

Physical properties of the studied material

Features of the studied materials on the field

The morphological features of the studied materials profiles (Profile M1) are illustrated in Fig. 5. Globally, these materials are dark in color (2.5Y- 4/1), brown (10YR 5/8), and light gray (2.5YR-7/1) in dry conditions, with desiccation cracks at the surface. The presence of these features is related to vertical movements with changing moisture conditions [37]. According to the same authors, the dark color could be related to the strong impregnation of profile by organic matter during pedogenesis or to prolonged waterlogging. The structure is generally angular and blocky, and textural classes range from clayey to clayey sandy. These features are associated with the parent rock type, location, environment, and the origin of clay components, which might be hydrothermal, residual, or alluvial [19]. Besides, carbonate nodules and mycelium were also recognized in the Ngassa site due to the calcification process. Overall, these characteristics are similar to those obtained by Basga et al. [37] in Logon Valley; Azinwi et al. [38, 39] and Kagonbé et al. [40, 41] in Benue Valley.

Particle size distribution and Atterberg limits

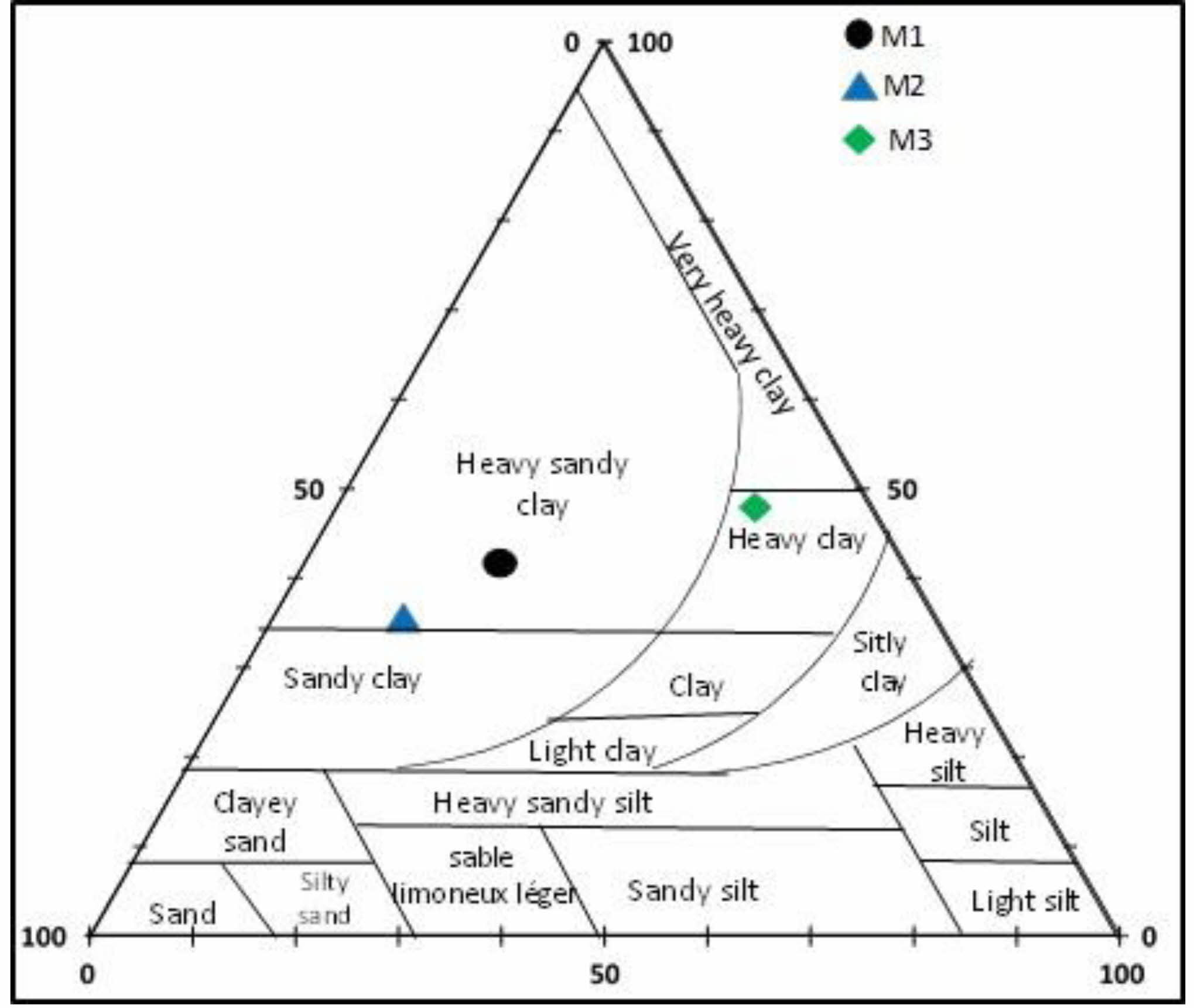

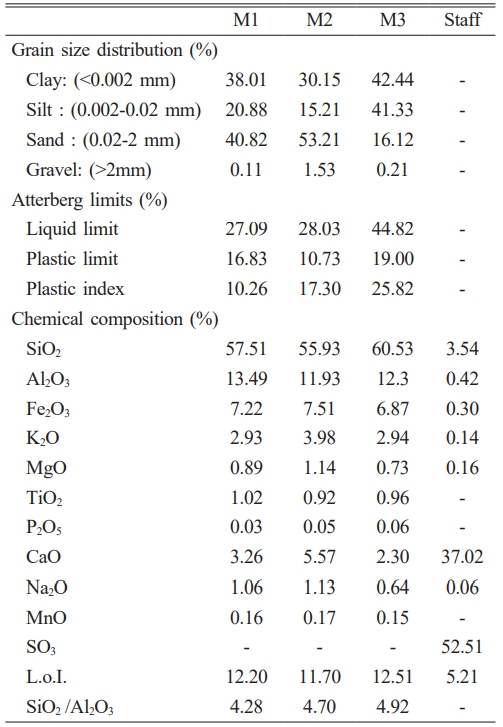

The suitability of clay soil for brick production is based principally on its particle size distribution and plasticity [42, 43]; it influences the final technical properties of products [44, 45]. The values of the geotechnical parameters (particle size distribution and Atterberg limits) measured on the studied soils are given in Table 3. From these results, the particle size distribution shows that these clay soils are globally poor in gravel fraction (0.11-1.53%), while the clay (30.01-42.44%) and sand fractions (16.12-53.21%) are relatively abundant, respectively. Except for the M3 sample, which contains the largest amounts of silt fraction of 41.33%, the M2 and M1 samples are below 20.88%. These results are similar to those obtained by Tsozué et al. [28], Yanné et al. [46], and Iyammi et al. [48] on some local clay soil in the Soudano-Sahelian area. Plotted in the ternary diagram (Fig. 6) [49], M1 and M2 clayey materials are mostly within the heavy sandy clay zone; however, the M3 sample has a heavy texture. Compared to the clay materials from Benue Valley (North, Cameroon) [40, 41], they facilitate pre-treatments for engineering reasons since they are less sandy and more clayey. According to some reports, the optimal soil grain size distribution for producing high-quality earth bricks is about 20-40% sand, 25-45% silt, and 20-35% clay-sized particles [50]. Based on this work, the clay raw materials are appropriate for making adobe bricks. According to Hendry and Noll [51], a desirable material for manufacturing clay bricks should have roughly 30% sand-size particles since this minimizes shrinkage, which typically happens when soft clayey material dries.

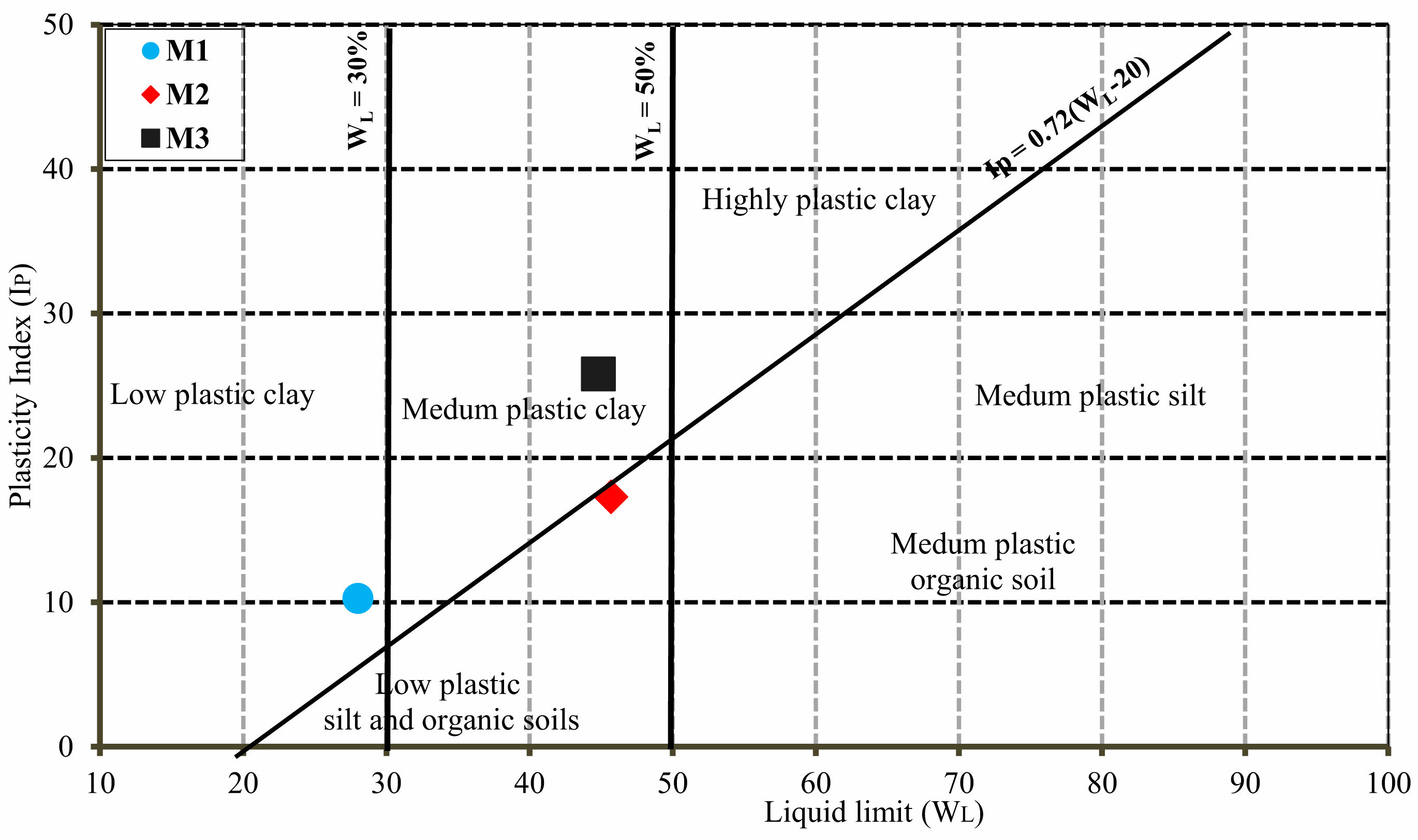

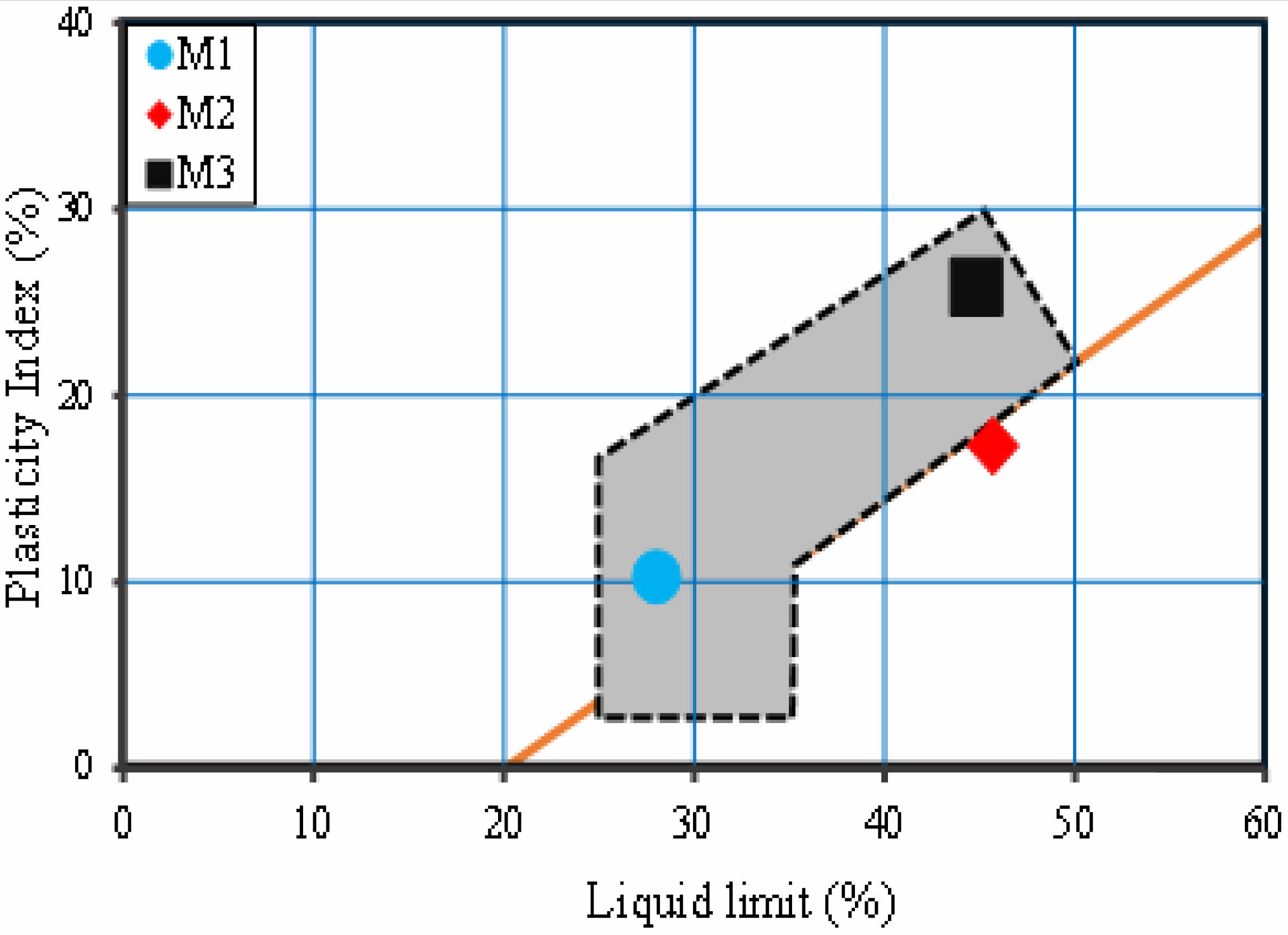

Clay plasticity defines the properties of soil to undergo deformation without cracking and is one of the most important properties for the choice of clay raw material for solicitation [37, 40, 43, 52, 53]. It facilitates the shaping during a manipulation, which ensures cohesion in the raw state [41]. The data of Atterberg’s limits characteristics of the studied clay raw material are presented in Table 3. Observation of these values shows that the plasticity limits in the samples varied from 10.73 to 19%. M3 samples have higher plasticity limit values than M1 and M2. Plasticity limit values are lower than those obtained on Maroua clay soil (22-30%) from northern Cameroon [28]. The limits of liquidity ranged from 27.09 to 44.82%, while the plasticity index of all the sampled clay varies between 10.26 and 25.82%. The position of the studied samples on the Casagrande Chart (Fig. 7) indicates M1 sample is low plastic clay, while M2 and M3 are medium plastic clay. These variations can be related to the quantity of organic matter, mineralogy composition, and particle size distribution [40]. According to CRATerre-EAG’s classification diagram (Fig. 8), the soils studied are suitable for the manufacture of raw earth bricks.

Geochemical and mineralogical characteristics

The results obtained from the three samples are summarized in Table 3. The geochemical composition results of major elements indicate that studied clay soil has high SiO2 contents between 57.51 to 60.53% with an average value of 57.99% (Table 3). The alumina content was also slightly higher, ranging from 11.93 to 13.49%, followed by Fe2O3 (6.87-7.51%), and K2O (2.93-3.98%). The higher content of Al2O3 within clay soils depends on the degree of hydrolysis. and, therefore, a higher Al2O3 content results from increased hydrolysis which also produces more kaolin minerals [49, 50]. Nonetheless, the K2O enrichment observed in the investigated samples is most likely the result of the potassium content being released by feldspar dissolution and indicates the existence of mica. The other major oxides have relatively low contents: MgO (0.73-1.14%), TiO2 (0.92-1.02%), P2O5 (0.03-0.06%), Na2O (0.64-1.13%), and MnO (0.15-0.17%). Na2O presents small variations from one site to another. The significant leaching of calc-alkaline elements is reflected in the low MgO and Na2O values [50]. This is probably due to their high mobility during the kaolinization process [54, 55]. The proportion of CaO was significant (2.30-5.57%), and the M2 sample had a higher value (5.57%). The SiO2/Al2O3 ratio was ranged from 4.28 to 4.92, which was higher. According to Nguetnkam et al. [57], this suggests the presence of 2:1 phyllosilicate of smectite type and an indicator of the abundance of quartz. Higher loss on ignition (LoI) is the result of the swelling minerals' structure releasing water, as compared to non-swelling clays like kaolinite. This may explain the significant LoI values (11.70-12.51%) observed for these three samples (Table 3).

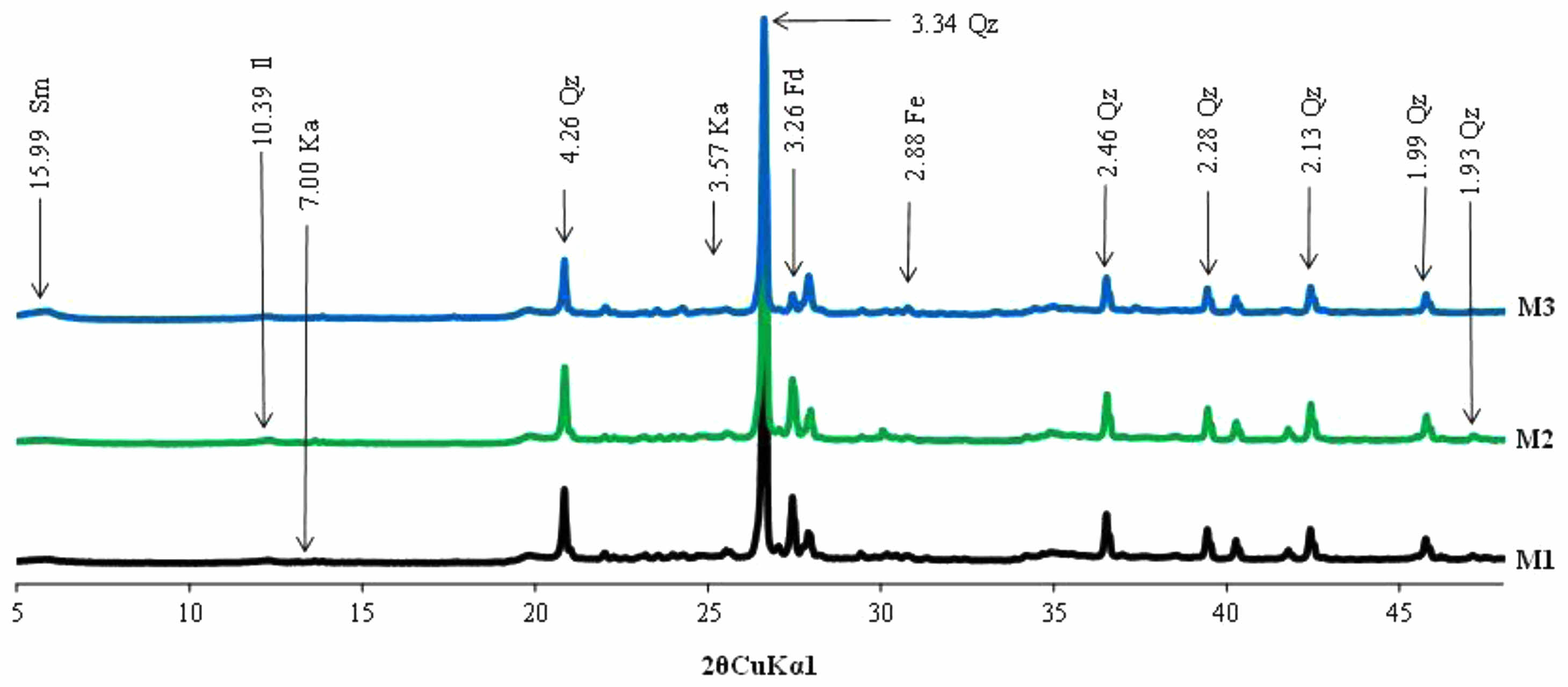

The determined mineralogical composition of the samples of the three studied clays (M1, M2 and M3) are presented in Fig. 9, which shows polymineralized materials. The X-Ray diffraction results indicate that the clay sample is composed of primary minerals such as quartz (4.26 Å, 3.34 Å, 2.46 Å, 2.28 Å, 2.13 Å, 1.99 Å, and 1.93 Å) and feldspars (3.26 Å). The secondary minerals are smectites (15.99 Å), illite (10.39 Å), kaolinite (7.00 Å), and iron (2.88 Å). Overall, the mineralogical composition of the materials varies very slightly from one site to another. The mineralogical composition has not varied widely from previous work in the dry tropical zone of Cameroon [40, 41, 57, 58]. Furthermore, these mineral phases are regularly found in this area and it is similar to the work of Tsozué et al. [28], Yanné et al. [46] on Maroua clays, and Onwona-Agyeman et al. [47] on Ghanaian clay, which showed that the clays in these areas are consisting mainly of quartz. Moreover, the presence of non-clay minerals suggests similar provenance from the parent material [6]. According to Kagonbé et al. [40, 41]; Tchedélé et al. [58], and Iyammi et al. [48], the different degrees of plasticity index and higher value of LoI observed in these clay soils are significantly enhanced by the presence of illite and smectite. On the other hand, Kagonbé et al. [16] and Wanga et al. [53] observed that a reasonably high proportion of quartz could improve the geotechnical characteristics of the brick, such as compaction parameters and dry density. In conventional adobe bricks, the presence of clay minerals such as illite could improve the quality of product stability because of its structural stability [53]. Furthermore, smectite minerals are known to affect the swelling and shrinking behavior of the material when wet and dry. Overall, the mineralogical composition of clay soils supports its application in adobe bricks, particularly due to its favorable properties for manufacturing processes.

Physico-mechanical properties of adobe specimens reinforced with staff waste powder

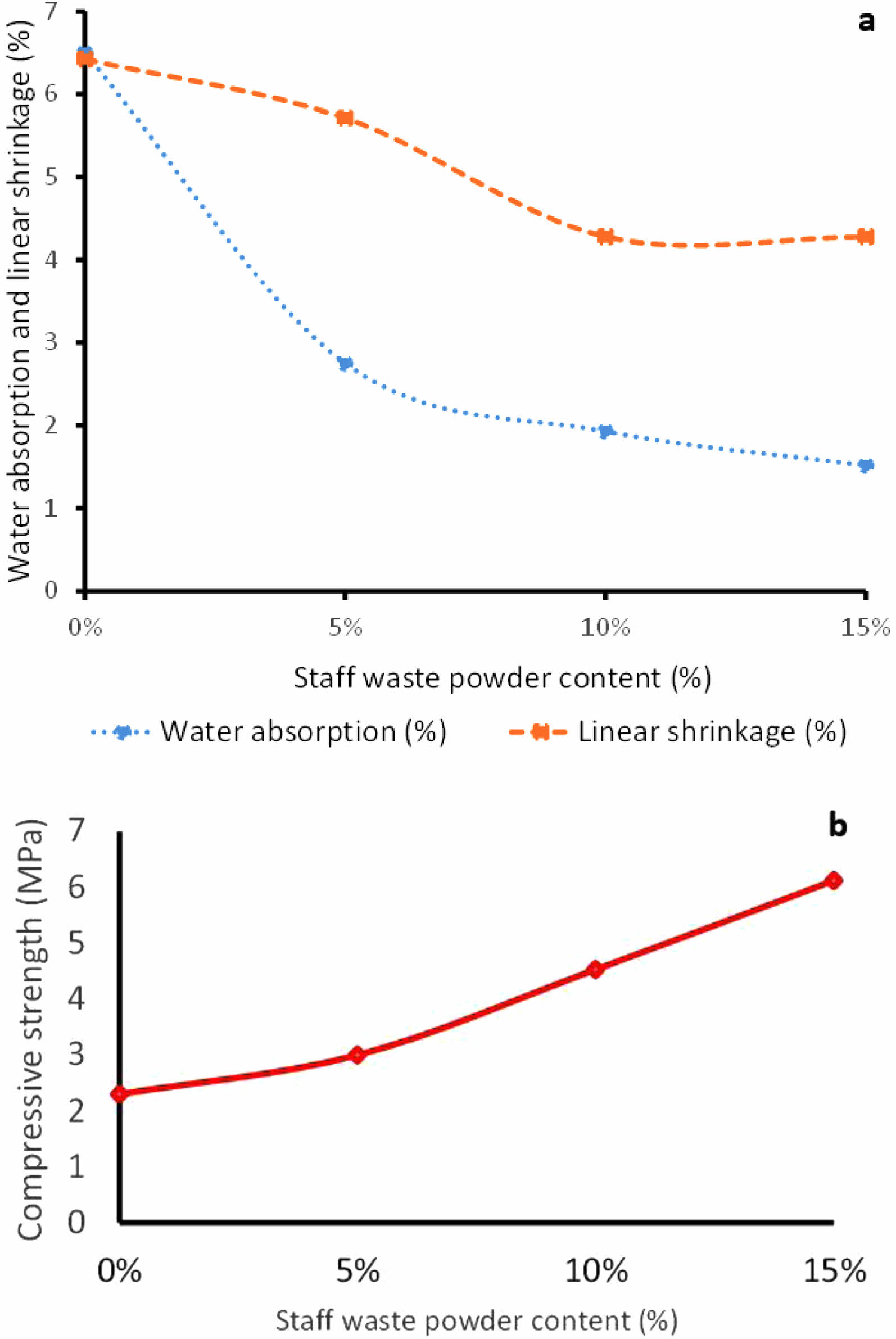

The relationship between water absorption, linear shrinkage, water erosion, and compressive strength between clay mixture and staff waste powder are illustrated in Fig. 10, and Fig. 11. As in Fig. 10a, and Fig. 10b, respectively, it is can be seen that with the increase of staff waste powder content, the water absorption and linear shrinkage slightly decrease from 6.50 to 1.52%, and 6.42 to 4.28%, respectively. It should be observed, however, that the presence of staff waste powder in adobe bricks limits water absorption. According to the literature [54, 55], water absorption and linear shrinkage are important parameters in the choice of clay raw material for the manufacture of adobe bricks. These parameters give an idea of the stability of finished products. It should be noticed that the gradual addition of staff waste powder would modify the structure of the clay raw material. Adobe can lessen water absorption thanks to this mixing behavior, which is propitious for construction materials. This progressive reduction of water absorption as a function of the increase in the quantity of staff waste powder would be mainly due to the occupation of the voids between the particles, which contributed to reducing the total porosity. The comparable results of using reinforced waste plant fiber to enhance the durability of adobe samples have been documented [56-60]. According to the previous studies, the porous soil structure and waste powder distribution are responsible for the water absorption capacity.

In terms of compressive strength (Fig. 10b), the results obtained show that the non-reinforced adobe bricks have the compressive strength at 2.30 MPa. On the other hand, adobes bricks stabilized at 5, 10 and 15% have compressive strengths of 3.00, 4.53, and 6.12 MPa, respectively. Globally, the highest value of compressive strength is 6.12 MPa and corresponds to the composition mixed with the 15% of staff waste powder. Adobes non-stabilized with staff waste powder have a lower compressive strength. Based on these results, it can be observed that the compressive strength of the studied material increases when the percentage of staff waste powder also increases in the mixture. This compressive strength value is lower than that required by the Earthen Building Materials Cameroonian standard, which is 2.82 MPa [61]. Concisely, clayey soil mixtures and staff waste powder significantly affect the mechanical properties of adobe bricks. The dissolution of weak chemical links between stable ingredients is the cause of this [25, 26]. This number is comparable to the compressive strength obtained by Meukam et al. [62], Malkanthi and Perera [60] Souaibou et al. [63], and Touolak et al. [64]. The same observed in their works that the compressive strength of brick depends on the soil type, amount of stabilizer, and the compaction energy used to form the bricks.

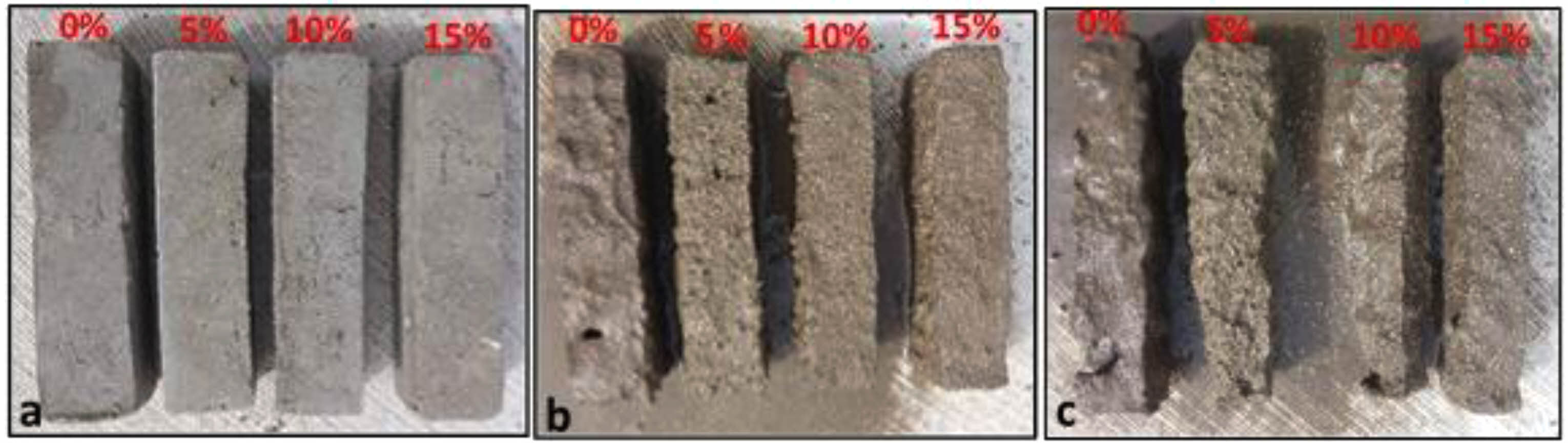

Concerning the water erosion tests, Fig. 11 shows representative results of each adobe mixture. Besides, it can be seen how the incorporation of staff waste powder does not reduce significantly the erosion generated by water. This low resistance to water erosion could be linked to the chemical and mineralogical composition of the clay soil used [65, 66]. Furthermore, chemically, it can also be observed that the crushed staff waste no longer acts actively after a second reuse for the manufacture of adobe bricks. Consequently, direct exposure of these adobe bricks in zones that get a lot of rain should be avoided.

|

Fig. 5 Vertical sections and view of desiccation cracks of the studied vertisols. |

|

Fig. 6 Position of clay soil studied in Belgian triangular diagram for textures [46]. |

|

Fig. 7 Casagrande’s plasticity Chart [31] showing the position of clay material samples; M1, M2, M3. |

|

Fig. 8 Position of the studied samples (M1, M2, M3) in CRATerre-EAG diagram. |

|

Fig. 9 X-Ray diffraction pattern of the raw material; Sm: Smectite; Ka: Kaolinite; Il: Illite; Qz: Quartz; Fd: Feldspar; Fe: Ironoxide. |

|

Fig. 10 Variation of some physical test with the reinforcement of the adobe brick: (a) Water absorption and linear shrinkage; (b) Compressive strength made with the press of 6 MPa. |

|

Fig. 11 Water erosion performance of each adobe mixture: (a) before spray test; (b) spray test after 15 min; (c) spray test after 30 min. |

|

Table 3 Physical properties and chemical compositions of the clay soil studied and the average chemical composition of staff used. |

The use of clay soil in adobe brick production requires the mastery of its geotechnical, mineralogical, geochemical, and mechanical characteristics. The main purpose of the experiment was to evaluate the effect of staff waste powder on the clay soil from Maroua (Far North, Cameroon) for adobe bricks used as sustainable building material. Staff powder is a waste of industrial processing. Used in considerable quantities and abandoned on building sites after demolition, it can be used as an additive in the mixture of adobe bricks. Clay soil used for adobe brick formulation presents good geotechnical, mineralogical, and chemical characteristics. Globally, the addition of staff waste powder to clay soils studied had a positive effect on compressive strength, linear shrinkage, and water absorption. Besides, the compressive strength of adobe bricks made with 5, 10 and 15% of staff waste powder is above ≥ 3 MPa according to the mechanical tests. The Cameroonian standard indicates that it is within acceptable limits. However, during erosion test, it was observed that the experimental briquettes were slightly eroded after simulation of an intense rainfall of 1.5 l/s for a period of 15 to 30 minutes. The empirical workability chart reveals that the investigated clay soils are suitable for rammed earth and adobe masonry construction. Consequently, it can now viable to prove the possibility for repurposing staff waste powder in adobe bricks as a result to this exploratory investigation. Nonetheless, more research is necessary to fully comprehend how the mineral phases interact.

The authors have not disclosed any funding.

Available on request.

The authors declare that they have no conflict of interest.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

- 1. S. Ahmada and Y. Iqbalb, J. Ceram. Process. Res. 17[4] (2016) 373-379.

-

- 2. S.F. Djenabou, F.C. Gentry, and P.D. Ndjigui, J. Ceram. Process. Res. 23[2] (2022) 113-120.

-

- 3. D.Y. Shin and K.N. Kim, J. Ceram. Process. Res 10[6] (2009) 739-743.

-

- 4. Y. Kulshreshtha, N.J.A. Mota, K.S. Jagadish, J. Bredenoord, P.J. Vardon, M.C.M. Loosdrecht, and H.H. Jonkers, Constr. Build. Mater. 247 (2020) 118615.

-

- 5. D.E. Montgomery, Dynamically-compacted cement stabilised soil blocks for low-cost walling, University of Warwick, Warwick (2002).

- 6. J.P. Temga, A. Mazzù, J.P. Nguetnkam, D. Palazzini, R. Ndjouenkeu, and F.Vitali, Inter. J. Sust. Engi. 7 (2014) 222-234.

-

- 7. C. Babé, D.K. Kidmo, A. Tom, R.R.N. Mvondo, R.B.E. Boum, and N. Djongyang, Case Stud. Constr. Mater. 13 (2020) e00422.

-

- 8. B.P. Kagonbé, B. Souleymanou, V.D. Bakaïné, R.E.B. Belinga, B.T.Aziwo, A.N. Hamdja, and L. Boubakar, Open J. Appl. Sci. 13 (2023) 874-887.

-

- 9. G. Gerneke, J. South African Institute of Architects (1992) 28-31.

- 10. B. Emad, Z. Gholamreza, S. Ezzatollah, and B. Alireza, J. Clean. Prod. 51 (2013) 142-161.

-

- 11. B. Wei and L. Yang, Microchemical J. 94 (2010) 99-107.

-

- 12. B.P. Kagonbé, G. Guidana, Y. Djepaze, A.L. Pahimi, E. Yaboki, N.A. Hamdja, and P.S. Alioum, J. Mater. Environ. Sci. 14[5] (2023) 548-559.

- 13. E. Piaia, B. Turillazzi, R. Di Giulio, and R. Sebastian, Sustainability 16 (2024) 3687.

-

- 14. M.C.J. Delgado and I.C. Guerrero, Constr. Build. Mater. 20[9] (2006) 679-690.

-

- 15. S. Maini, Auroville Build. Center-India (2005).

-

- 16. B.P. Kagonbé, D. Tsozué, A.N. Nzeukou, S.D. Basga, R.E. Belinga, B. Likiby, and S. Ngos, J. Mater. Environ. Sci. 11 (2020) 658-669.

- 17. M. Ouedraogo, K. Dao, Y. Millogo, J.E. Aubert, A. Messan, M. Seynou, L. Zerbo, and M. Gomina, J. Build. Eng. 23 (2019) 250-258.

-

- 18. C. Babé, E. Yanné, M. Souaibou, L. Bakaiyang, B. Kola, G. Assoualaye, L. Tawé, R. Danwé, D.K. Kaoga, and N. Djongyang, AMPC 14 (2024) 146-164.

-

- 19. E. Yaboki, J.P. Temga, A.M. Balo, S.J. Basga, B. Atougour, and J.P. Nguetnkam, J. Mater. Environ. Sci. 12 (2021) 353-372.

- 20. F. Hadji, N. Ihaddadene, R. Ihaddadene, A. Betga, A. Charick, and P.O. Logerais, J. Build. Eng. 32 (2020) 101823.

-

- 21. I. Alam, A. Naseer, and A.A. Shah, Constr. Build. Mater. 77 (2015) 154-159.

-

- 22. J.P. Temga, A.B. Madi, S.B. Djakba, P.Z. Zame, M.A. Angue, J.R. Mache, J.P. Nguetnkam, and L.D. Bitom, J. Build. Eng. 19 (2018) 472-479.

-

- 23. J. Concha-Riedel, G. Araya-Letelier, F.C. Antico, U. Reidel, and A. Glade, Springer Singapore, (2019).

-

- 24. G. Araya-Letelier, J. Concha-Riedel, F.C. Antico, and C. Sandoval, Constr. Build. Mater. 198 (2019) 762-776.

-

- 25. G. Araya-Letelier, H. Gonzalez-Calderon, S. Kunze, C. Burbano-Garcia, U. Reidel, C. Sandoval, and F. Bas, J. Clean. Prod. 273 (2020) 122806.

-

- 26. S. Sandwidi, A. Compaore, K. Haro, T. Dabilgou, S. Sinon, O. Sanogo, J. Koulidiati, and A. Bere, Open J. Appl. Sci. 13 (2023) 60-75.

-

- 27. C. Seignobos and O. Iyébi-Mandjek, IRD Editions, Marseille 171 (2005).

-

- 28. D. Tsozué, A.N. Nzeugang, J.R. Mache, S. Loweh, and N. Fagel, J. Build. Eng. 11 (2017) 17-24.

-

- 29. D.M. Gountié, D. Tsozué A. Kpoumié, and N.A. Nzeukou, Acta Geochimica 42 (2022) 1-24.

-

- 30. ASTM D-422-63, ASTM Stand. Guid. (2002) 1-8.

- 31. A. Casagrande, Transactions of the American Society of Civil Engineers 113 (1948) 901-930.

-

- 32. ASTM D-4318-00, Annual Book of ASTM Standards 4 (2000) 1-14.

- 33. D.M. Moore and R.C. Robert, Oxford University Press (1989).

- 34. NF EN 14617-1, AFNOR: Paris, France (2005).

- 35. NF P 15-451, AFNOR: Paris, France (1963).

- 36. L. Mbumbia, A. Mertens de Wilmars, and J. Tirlocq, Constr. Build. Mater 14[3] (2000) 121-131.

-

- 37. S.D. Basga, D. Tsozué, J.P. Temga, J. Balna, and J.P. Nguetnkam, ISWCR 6 (2018) 237-244.

-

- 38. P.A. Tamfuh, E.D. Woumfo, D. Bitom, and D. Njopwouo, The Open Geology J. 5 (2011) 33-55.

- 39. P.A. Tamfuh, E.D. Woumfo, F.O. Tabi, A. Boukong, A.D. Mvondo Ze, D. Bitom, and V.B. Kamgang Kabeyene, Geo. Env. Earth Sci. Int. 6 (2016) 1-15.

-

- 40. B.P. Kagonbé, D. Tsozué, A.N. Nzeukou, and S. Ngos III, GEP J. 9 (2021) 86-99.

-

- 41. B.P. Kagonbé, D. Tsozué, A.N. Nzeukou, and S. Ngos III, Heliyon 7 (2021) e07608.

-

- 42. P. Kasinikota and D.D. Tripura, Constr. Build. Mater. 280 (2021) 122520.

-

- 43. M. Demirel and B. Aksakal, J. Ceram. Process. Res. 19[1] (2018) 5-10.

-

- 44. C. Turco, A. Paula, E. Teixeira, and R. Mateus, Constr. Build. Mater. 325 (2022) 126888.

-

- 45. F.O. Aramide and A.P. Popoola J. Ceram. Process. Res. 19[2] (2018) 87-94.

-

- 46. E. Yanné, A.A. Oumarou, B.D. Nde, and R. Danwé, AMPC 8 (2018) 378-386.

-

- 47. B. Onwona-Agyeman, N. Lyczko, D.P. Minh A. Nzihou, and A.J. Yaya J. Ceram. Process. Res. 21[1] (2020) 35-41.

-

- 48. I.B. Moctar, T.L. Yannick, A.S.-T. Albertine, J.R. Mache, and N. Mominou, JMST Advances J. 5 (2023) 13-26.

-

- 49. A. Richer de Forges, C. Feller, M. Jamagne, and D. Arrouays, Etude de Gestion des Sols 15 (2008) 97-111.

- 50. C. Chan and Z. Shahri, ARPN J. Eng. Appl. Sci. 11 (2006) 7193-7197.

- 51. A. Hendry and F. Noll, Khalaf India. Soc. Ecol. Work. Paper 1 (2015) 4.

- 52. R.F.D. Ntouala, V.L. Onana, V. Kamgang, and G.E. Ekodeck, J. Build. Eng. 5 (2016) 50-56.

-

- 53. Q. Wang, S. Li, H. Yu, F. Li, H. Xu, H. Qiao, J. Liu, and Q. Du, J. Ceram. Process. Res. 18[8] (2017) 594-598.

-

- 54. G. Yanık, Clay Minerals 46 (2011) 397-410.

-

- 55. A. Nzeukou Nzeugang, D. Tsozué, B. Kagonbé Pagna, A. Balo Madi, A. Fankam Deumeni, A. Ngos, C. Nkoumbou, and N. Fagel, SN App. Sci. 3 (2021) 551.

-

- 56. H.G. Dill, H.R. Bosse, K.H. Henning, A. Fricke, and H. Ahrendt, Miner. Deposita 32 (1997) 149-163.

-

- 57. J.P. Nguetnkam, R. Kamga, F. Villiers, G.E. Ekodeck, and J. Yvon, Comptes Rendus Geosci 340 (2008) 451-461.

-

- 58. T.L. Yannick, T.G.G. Molay, T.D. Japhet, S.M.A. Donald, A. Therèse, N.M. Soualiou, and M.N.L. Leroy, JMST Advances 4 (2022) 25-44.

-

- 59. R. Begum, A. Habib, and H.A. Begum, IJESE 2 (2014) 36-38.

- 60. S.N. Malkanthi and A. Perera, IOP Mater. Sci. Eng. 431 (2018) 604-611.

-

- 61. Modjonda, Souaibou, Y. Etienne, and D. Raidandi, AMPC 13 (2023) 177-196.

-

- 62. P. Meukam, Y. Jannot, A. Noumowe, and T.C. Kofane, Constr. Build. Mater. 18 (2004) 437-443.

-

- 63. NC 102-114, Blocs de Terre Comprimée, MINDIC, Yaoundé-Cameroun (2002-2006).

- 64. B.T. Touolak, F.T. Nya, E.N. Haulin, E. Yanne, and J.M. Ndjaka, AMPC 5 (2015) 191-204.

-

- 65. C.S Costa, F. Rocha, and A.L. Velosa, Geol. Soc. Spec. Publ. 416 (2016) 91-100.

-

- 66. S.Y.R. López and J.S. Rodríguez, J. Ceram. Process. Res 16[1] (2015) 162-168.

-

This Article

This Article

-

2025; 26(4): 547-558

Published on Aug 31, 2025

- 10.36410/jcpr.2025.26.4.547

- Received on Mar 17, 2025

- Revised on Jul 27, 2025

- Accepted on Aug 7, 2025

Services

Services

- Abstract

introduction

geographical and geological setting

materials and methods

results and discussion

conclusion

- Funding

- Data availability statement

- Conflict of Interest

- Declaration of Interest

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Bertin Pagna Kagonbé a, Özgür Cengiz c,d

-

aLocal Materials Authority Promotion (MIPROMALO), P.O. Box 2396, Yaoundé, Cameroon

cDepartment of Metallurgy and Materials Engineering, Faculty of Technology, Afyon Kocatepe University, 03200, Afyonkarahisar, Türkiye

dDepartment of Ceramic, Fine Arts Faculty, Afyon Kocatepe University, 03200, Afyonkarahisar, Türkiye

Tel : (+237) 672803795; (+90) 2722282538 Fax: (+90) 2722281417 - E-mail: kagonbebertin@gmail.com, ocengiz@aku.edu.tr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.