- Comparative study between hot isostatic pressing and pressure less sintering for self-lubricating CuO/ZTA composites

K. Rajaa,*, M. Dhanabalb, Bipin Kumar Singhc and P. Ganeshanc

aDepartment of Mechanical Engineering, Anna University Regional Campus Coimbatore, Coimbatore- 641046, Tamil Nadu, India

bDepartment of Mechanical Engineering V.S.B. Engineering College, Karur – 639111, Tamil Nadu, India

cCenter for Augmented Intelligence and Design, Department of Mechanical Engineering, Sri Eshwar College of Engineering, Coimbatore - 641202, Tamil Nadu, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Self-lubricating composite, comprises of CuO/ZTA is developed for its application as cutting inserts. The powders of zirconia toughened alumina (ZTA) is prepared through co-precipitation process, further mixed with MgO particles (act as sintering aid) and CuO (provide self-lubrication) using mechanical assistance. After mixing the homogeneous composites are used to fabricate the Inserts obeying powder metallurgy process sintered through Hot isostatic pressing (HIP) and cold press technique. The sintered samples are cut to size using diamond wheel on tool grinder machine. The geometry of inserts are maintained according the international (ISO) standard SNUN 120408. The mechanical characterizations of developed inserts are carried out on mirror polished samples. Crack bridging and crack deflection are the influential phenomenon on the fracture toughness, whereas impurity phases of CuO at grain boundary result in little decrement in hardness. After mechanical characterization the inserts are used to machine AISI 4340 steel on conventional N-26 lathe. Flank wear after 5 min of machining for all inserts are calculated at fixed set of machining parameters to explore the performance of indigenously developed inserts. The self-lubrication phenomenon showed its effect on tool life i.e. thin layer (Patchy layer) formation increases the life of novel inserts.

Keywords: CuO/ ZTA, Self-lubrication, Machining, Flank wear.

High precision at minimum machining costs always attract attention of industries due to critical link with profit and quality of manufactured component. To achieve high precision of components, cutting inserts plays vital role as it is responsible for conversion of raw material to finish product through chipping technology. The recent paradigm of Industry 4.0 indeed require prolong useful tool life at minimum cost, to omit the auxiliary cost of machining incurred by coolants, grinding of tool, grinding worker, and handling time to replace the tool at regular interval. Therefore, to short out the auxiliary costs ceramic cutting tools are highly acknowledged [1-3] that showed huge potential to sustain in harsh environment with prolong tool life. The high hardness, high mechanical properties, resistance to wear, fracture and chipping along with high hot hardness are some ideal properties that all govern by ceramic tool [3-5]. Furthermore, the application of ceramic tool to achieve mass production in manufacturing industries is also possible. The advent of ceramic as cutting tool for machining of grey cast iron probably takes place in 1930s but lack of knowledge on fabrication technologies on ceramics, its commercial application was limited till 1970s [6]. Thanks to the invention of advanced ceramic composite that explored numerous of fabrication process that open the application of ceramic in every sector most important as cutting inserts. The first commercial ceramic tool was made up of HP aluminium oxide reinforced with titanium carbide showed an excellent result over traditional tools [7]. Further development in properties of ceramic by reinforcing some additives made these tool capable to machine the 60-63 Rc with superior surface finish [8]. Furthermore, the improvements in strength imparted through dispersion techniques of additives lead to multifarious application in every industry. Later Claussen, 1976 [9] and Gravie [10] explored the concept of toughening phenomenon by dispersion of ZrO2 in alumina matrix acted as revolutionary mechanism in the application of alumina ceramic as cutting tool. The developed composites is known as zirconia toughed alumina (ZTA) that have peculiar volume expansion properties responded with critical shear strain value. The mechanism illustrated that during transformation of tetragonal crystal structure (t) to monoclinic crystal structure (m) phase dispersed zirconia particles expand their volume by ~3-4 percent [11] result in exception high fracture toughness value. Recent inventions of hot pressing (HP), spark plasma sintering, and microwave sintering technologies provide high mechanical properties in-situ with simpler fabrication process, bring the ceramic components for real world application [12]. Increase in the demand of ceramic materials shouted another challenge of inferior tribological properties, also applicable with the ceramic cutting tool. So, at start the said challenges are encountered by providing coating to the ceramic tools, but these coating are effective only upto the film exist. It was observed that after few minutes of machining the problem again reached to initial state. To encounter such problem scientific community invented novel concept i.e. reinforcing third phase material inside the matrix that act as lubricant. The concepts have well worth and acted as a pioneer concept towards development of self lubricating composites. After postulation of such concepts numerous of researches were dedicated to develop self lubricating materials by doping the hard matrix of ceramic with soft additives like CuO, Graphene, SiCp, CaF2, h-BN, MoS2 etc. [13-16]. In this regard, Dey et al. [17] reinforced several metal oxides of Cu, Ti, Mg, Zn, Mn inside the zirconia toughened alumina (ZTA) composites to improve the tribological properties. All developed composites showed improvement in tribological properties but highest improvement was noticed for Cu doped ZTA due to formation of CuO that result in formation of soft thin layer (patchy layer) at interface responsible for improvement in tribological properties. Xing et al. [18] developed self-lubricating composite by coating with Ni-MoS2-Al2O3 particles using laser powder-bed fusion (additive manufacturing technique)on high-speed steel cutting tools (HSS). The novel tool showed an improvement of 8.8-11.7% in co-efficient of friction (COF) whereas, reduction in cutting force and power by 17.6-29.6% and 17.3-22.0% respectively, compared with conventional HSS tool. Gupta et al. [19] explored the concept of textured tool that efficiently improved the useful tool life and minimizes the cutting force by incorporating self lubricating phenomenon. Parihar et al. [20] used spark plasma sintering technique to develop self-lubricating cutting tool made up of functionally graded cemented tungsten carbide with solid lubricant. The developed insert showed huge potential for dry machining suited for manufacturing industries for mass production. Fangyuan et al. [21] used laser cladding technique to fabricate the cutting inserts of (TiBw +TiCp)/Ti composite for application as cutting inserts. Tremendous improvement in plastic deformation was observed with cladding technique consequences in high useful tool life. Recently, Singh et al. [22, 23] successfully developed CuO/MgO/ZTA self-lubricating inserts to demonstrate its machining performance and fracture mechanism for AISI 4340 steel. A huge potential of such compsites is found in manufacturing sector. The application of ceramics is also showed by various researchers [24-26] that have huge potential to replace conventional systems in manufacturing sector.

Hence, the study from above literature suggested huge potential of self-lubricating composites towards its application as cutting inserts. Furthermore, the uniform microstructure maintained in the ceramic always play significant role in strength, or fracture toughness, dependent on sintering mechanism. The efficient sintering process for CuO/MgO/ZTA is still inconclusive and direly require through investigation for its effective application as cutting tool. Therefore, in this study two sintering process are carried out i.e. pressure less sintering and hot isostatic pressing (HIP) to densify the composites for its application as cutting inserts. The studies also reveal the machining performance of developed inserts for machining of AISI 4340 steel. The predominant physics that lies to improve and degrade the properties are also thoroughly discussed.

In ceramics preparation procedures play a vital effect on the end properties. Hence in this investigation all the standards have been strictly followed in order to develop the self-lubricating CuO/ZTA composite. In the aforementioned composite, copper oxide (CuO) act as a lubricant, and zirconia toughened alumina (ZTA) as parent matrix. The requisite amounts of compounds i.e. 1.5 wt% CuO, remaining ZTA were selected from earlier optimization work carried out by the Co-authors [27]. In aforementioned research work the quantity of CuO was varied from 0.5 wt.% to 5 wt.% inside ZTA matrix. The functional as well as mechanical properties for each sample were carried out. The research showed 1.5 wt.% CuO doped ZTA had minimum CoF as value of 0.24 also poses highest fracture toughness and flexural strength with a little compromise in hardness. Furthermore, the composition of ZTA comprises alumina and yttria stabilized zirconia in the ratio of 90 : 10 were maintained in all composites. In this investigation, at first ZTA was prepared using co-precipitation route considering all nitrate salts of high purity more than 99%. The requisite amounts of salts were properly mixed in distilled water using magnetic stirrer followed by drop wise mixing of 0.1 mol% ammonium nitrate through a burette. The mixing was continued till the pH of solution not reached to 9 maintaining the temperature of 70 ˚C. The selection of nitrate salts for preparation of ZTA composites is based on easy dissolving nature of nitrate ions in warm water that can remove out easily during filtration. Furthermore, the pH plays a vital role for complete formation of precipitate that decides the properties of developed composites. It is found that the complete formation of precipitates generally occurs at pH 9. So, in this experiment the composites were prepared by maintaining the pH 9. Furthermore, the agglomeration of particles during precipitation is avoided by maintaining a temperature around 70 ˚C. The formed precipitate was decant from water and pour into a filter unit where, warm water are mixed to remove the nitrate ions present in the precipitate. After complete removal of nitrate ions, the jelly cakes of ZTA composites were kept in an oven for 12 h. The dried mass were crushed manually and kept at 800 ˚C for calcination. The calcined ZTA powders were further used to mixed CuO and MgO using powder metallurgy route. The powders of 1.5 wt.% CuO were thoroughly dispersed in alcoholic medium using probe sonicator. The dispersed powders were kept in zirconia jar with requisite amount of ZTA powder under alcoholic medium. The alumina balls of different sizes (diameter 8, 10, 12 mm) were also placed inside the zirconia jar to obtain better attrition effect during milling. The jar was fully tightened and fixed on a planetary ball mill. The powders were milled for next 12 h under a rotational speed of 360 rpm. The perfectly milled powders were dried and calcined at 800 ˚C to remove all impurities. The calcined powders were mixed with PVA solution for granulation. After granulation the powders were sintered using two processes the first one is pressure less sintering and second one is hot isostatic pressing (HIP) technique. In cold pressed technique the requisite amount of powders were pressed at pressure of 500 MPa on a hydraulic press. The pressed samples were slowly removed from the die and kept in a ceramic crucible. The samples were fully covered with alumina powders for uniform distribution of heat and kept in a HT furnace at a temperature of 1500 ˚C for half hour as soaking time. In another process the developed CuO/ ZTA composites powders were pour into the graphite die for compaction and sintering at a pressure of 500 MPa and temperature of 1500 ˚C using HIP technique. In this case also the heating time was maintained as half an hour. After sintering the samples were used for morphological characterization. After morphological characterization the samples were thoroughly polished using silicon powder and diamond paste. After polishing the samples were cut to size maintaining ISO SNUN 120408 to develop the cutting insert for machining of AISI 4340 steel. After imparting the shape and size the edges of inserts were beveled to impart strength. The well finished inserts were again decomposed at 800 ˚C to reveal the stress developed during polishing and imparting the shape. The heated inserts were used to machine AISI 4340 steel.

In this investigation three samples named as Z1 for ZTA, Z2 for CuO/ZTA prepared through pressure less sintering, and Z3 for CuO/ZTA prepared through HIP technique. For every characterization the same process were opted for better comparison and clear understanding behind the physics of sintering process.

Process opted for Morphological investigation

The fully densified samples were selected for morphological study using FESEM images. The images were taken at same magnification for better comparison of grains formed after sintering. The phases present inside the matrix were evaluated through XRD technique in the angle (2θ) lies between 20° and 70°.

Process opted for Mechanical properties investigation

After phase evaluation the bulk density of polished samples were evaluate through Archimedes principal. The relative density i.e. ratio of bulk density to theoretical density were calculated for better understanding of densification. Furthermore, the mechanical properties i.e. hardness and fracture toughness were evaluated on Vickers testing machine. An average of ten reading for hardness and five readings for the fracture toughness were consider to cite the value of hardness and fracture toughness.

Process opted for Machinability investigation

The perfectly shaped inserts as per SNUN 120408 were selected to evaluate the machining performance in terms of flank wear during machining of AISI 4340 steel on the conventional lathe. The tool signature maintain on tool holder (made: NTK) as -6o, -6o, 6o, 6o, 15o, 15o, and 0.8 mm. Piezoelectric dynamometer (make: Kistler, model: 9272) fitted at tool post just below the tool holder was used to measure the cutting force. After every pass of machining the surface roughness of machined surface was measured thorough SURTRONIC 25. Averages of ten readings were used to cite the surface roughness. At last the flank wear after 5 min of machining was measured on the Tool Makers’ Microscope. The parameter selected for machinability evaluation were cutting speed as 300 m/min, depth of cut as 1 mm and feed rate as 0.18 mm/sec based on earlier investigation carried out by Singh et al. [28].

Analysis of Physical Properties

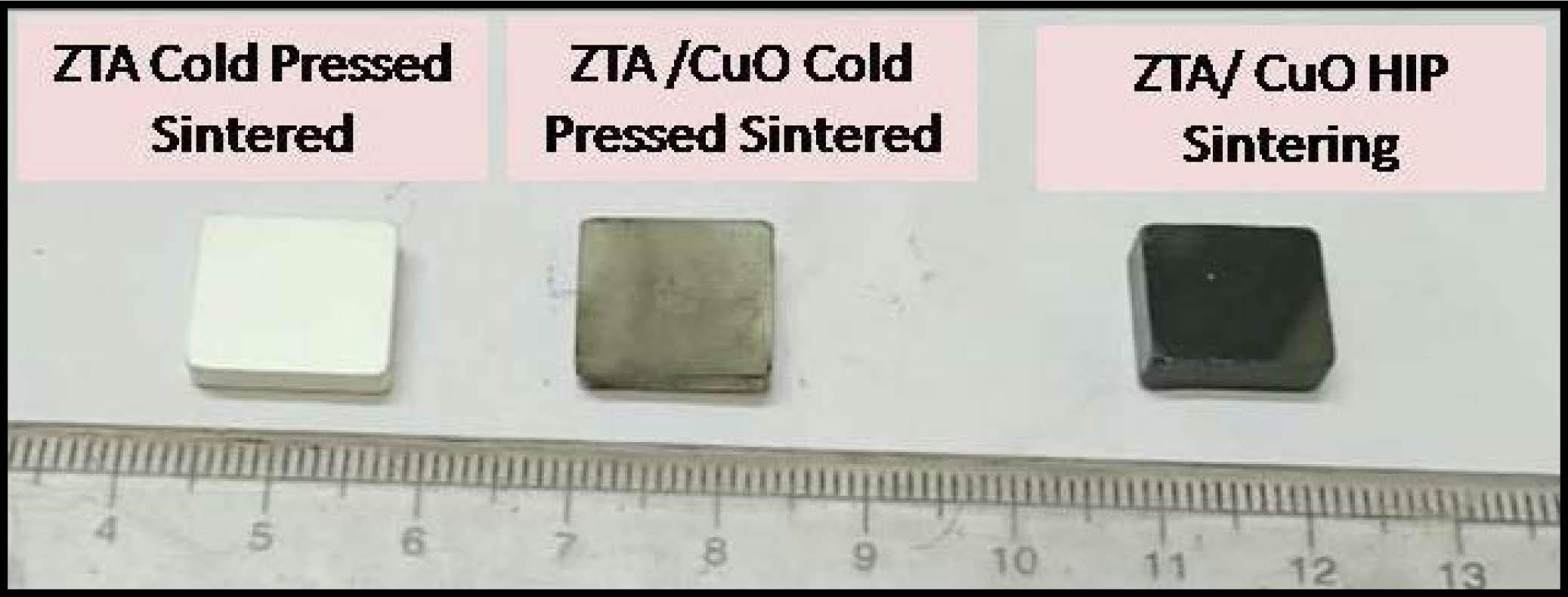

The composites of ZTA/CuO are classified as self-lubricating ceramics that have all necessary properties for prolong life. The composites fabricated through powder metallurgy route in which earlier researchers [29] revealed that CuO grain undergone liquid phase during sintering operation. Furthermore, the research carried out by Ran et al. [30] clearly demonstrated that the viscosity flow of metal oxide was very low when reinforced inside the YSZ or ZTA matrix. The flow restriction maintained the homogeneous distribution of CuO inside the matrix after sintering, but restructuring of CuO grains could be possible. Hence, a comparative study between pressureless sintering (conventional sintering) and hot pressing technique during densification was investigated. The images of all three samples Z1, Z2 and Z3 after sintering are shown in Fig. 1. From images it can be observed that the homogeneously structure with uniform distribution of CuO grains is observed in case of Z3.

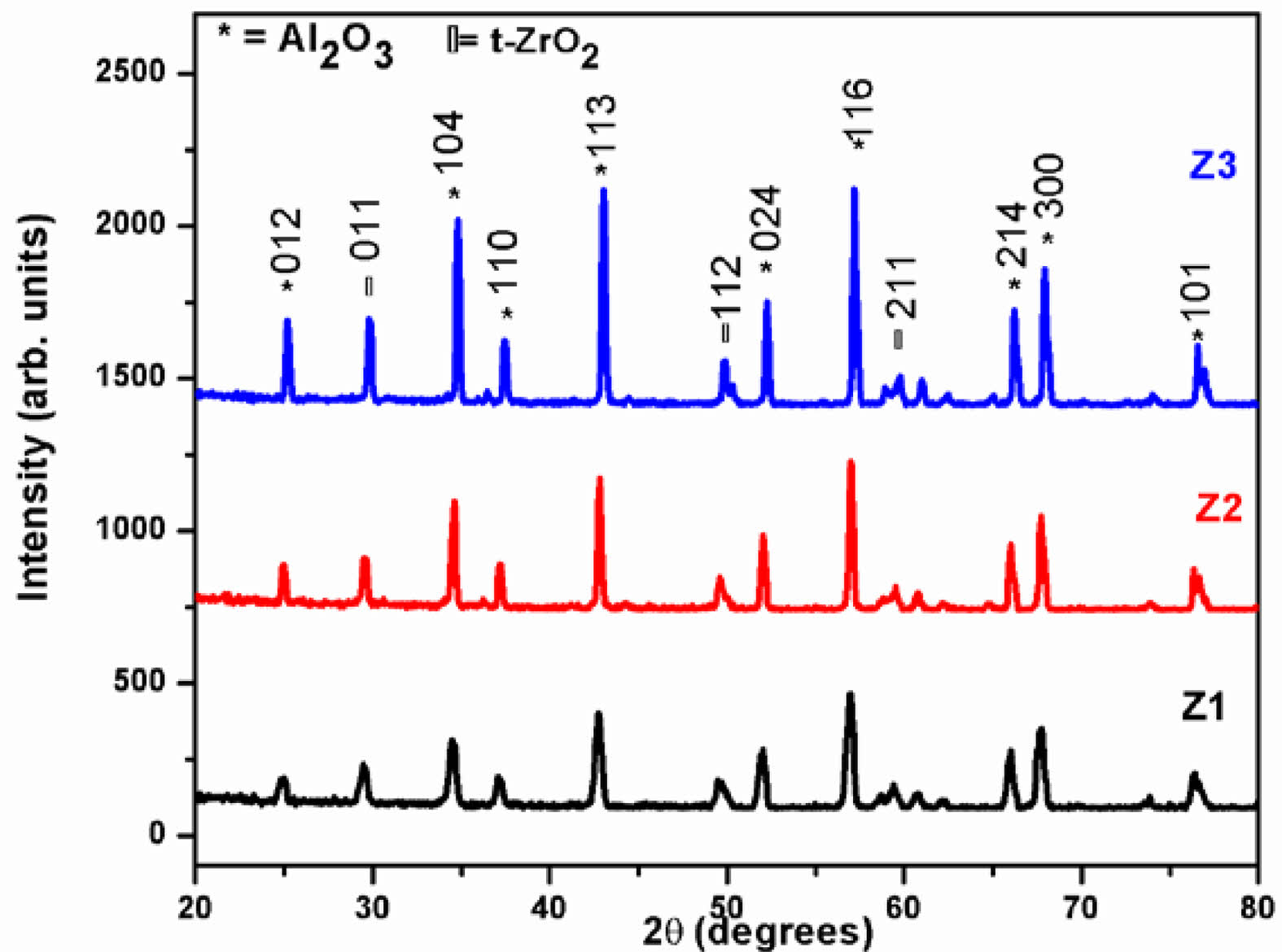

The XRD plot of Z1, Z2 and Z3 samples are shown in Fig. 2. The homogeneous mixing of CuO inside the matrix alongside low amount of CuO (beyond the detection limit of XRD) make difficult to identify the phases through XRD phase analysis.

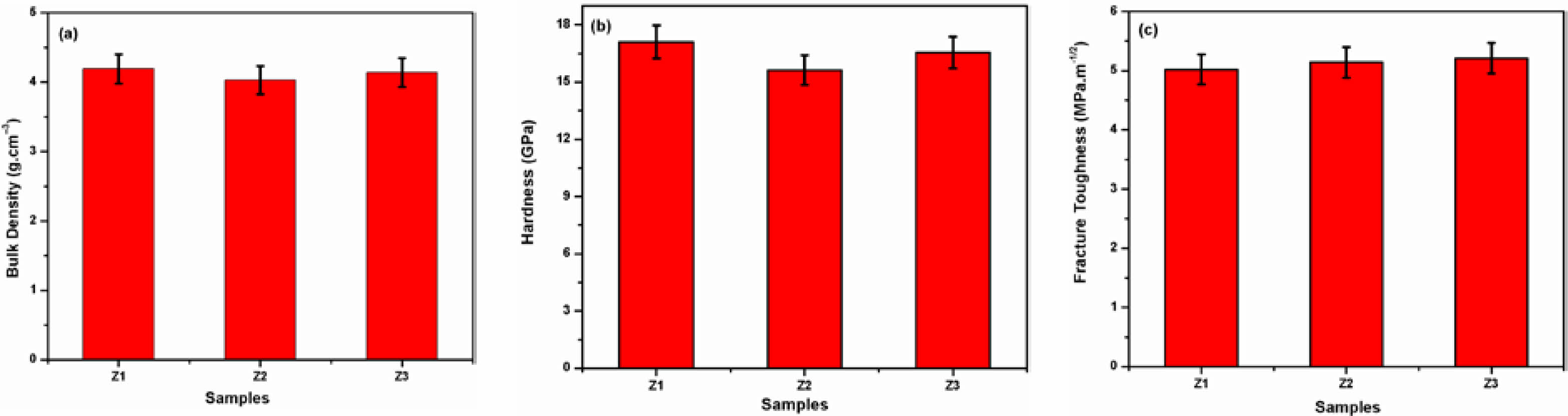

The evaluated values of bulk density, hardness and fracture toughness are shown in Fig. 3(a), (b) and (c). From figure it can be observed that the bulk density of Z2 samples i.e. pressure less sintering have lowest density than Z2 and Z3 samples. Whereas, approximately similar value of bulk density is observed for the Z2 and Z3 samples. The result is attributed to the uniform grain sizes present inside the cluster which is high for Z3 samples. This may happen due to controlled pore mobility rate that have huge impact on the grain growth predominant in case of HIP sintering. The simultaneous action of pressure and temperature restrict the pores consequences in the uniform grain size. Whereas, in case of Z1 and Z2 samples abnormal grain growth is noticed due to uncontrolled capability of temperature (i.e. temperature didn’t affect the pore mobility rate) to restrain pore mobility rate. The results are in agreement with earlier research carried out by Pratap et al. [31].

The investigation on hardness shown in Fig. 2(b) also replicate the same results as observed for density, but the value of hardness for Z2 and Z3 is lower than Z1 sample. This result observed due to creation of impurity phases at the grain boundary by presence of CuO particles. The earlier researchers illustrate that the presence of CuO particle inside the cluster make Cu-enrich phases at the grain boundary. The Cu-rich region crates a weaker section in the cluster and can be easily deformed. The presence of such region exaggerated the propagation of crack or larger deformation result in lower value of hardness in the both Z2 and Z3 samples.

Interesting results are observed for Z2 and Z3 samples in which high fracture toughness is higher than parent matrix Z1. This result may be due to predominant behavior of crack bridging and crack deflection phenomenon inside the cluster exaggerated by presence of Cu-grains. The results are in agreement with the Oh et al. [32] who demonstrated that the ductility of second phase grain inside hard matrix act as barrier for propagation of crack or shock the stress need to propagate the crack through plastic dissipation. Furthermore, the dissipation of acoustic waves act as relief of stress required higher amount of energy for crack propagation ultimately result in high value of fracture toughness.

Analysis of machining performance

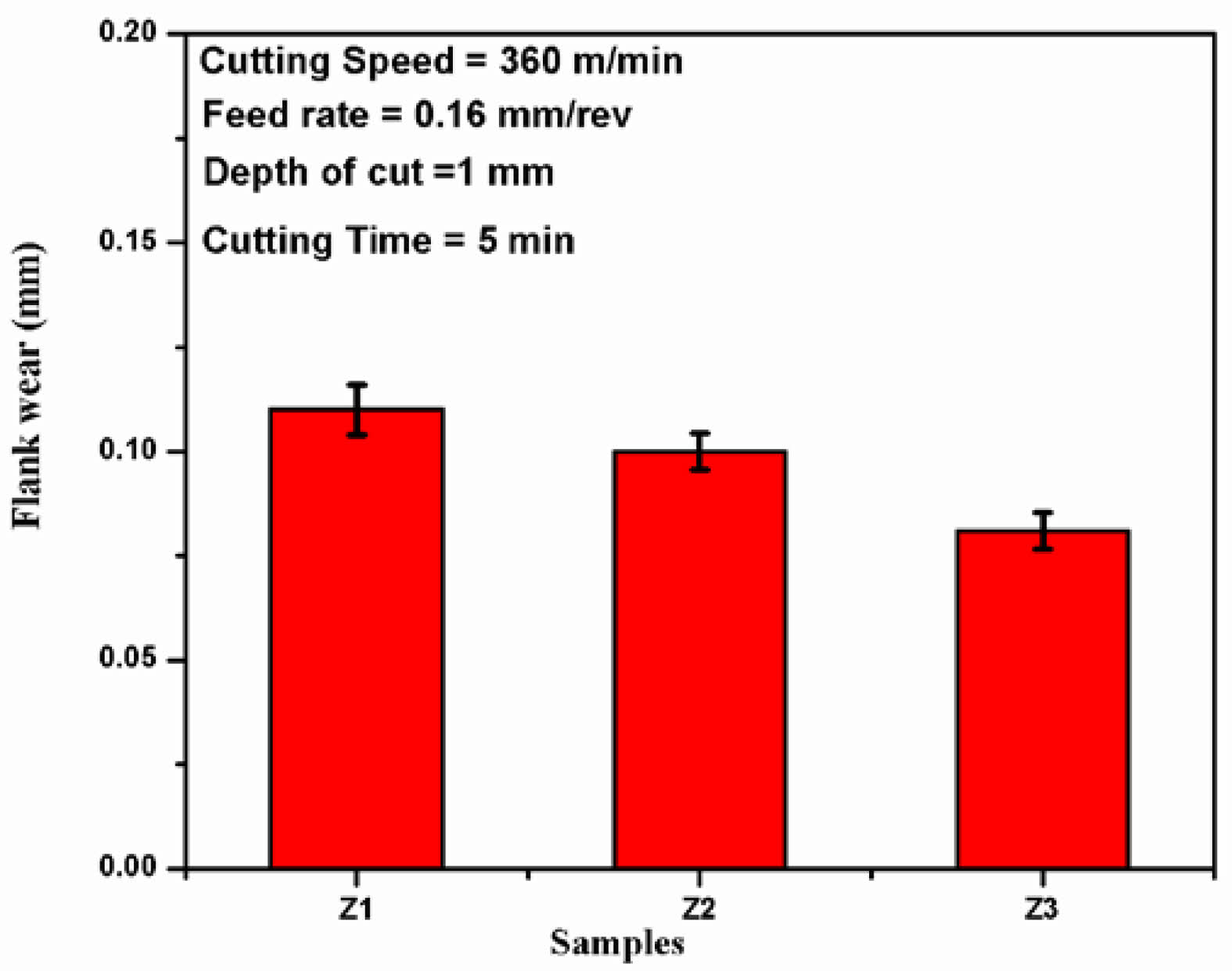

The performance of any cutting inserts is entirely dependent on the tool life which is changing with materials properties. In this investigation, Z1, Z2 and Z3 composites are selected to fabricate the three cutting inserts. These inserts are tested on conventional lathe maintaining the ISO Standard 3685 for calculating tool life illustrated by Kumar et al. [33]. Researchers demonstrated that when the average flank wear exceed 0.3 micron the tool is considered to be rejected. So, an optimized condition i.e. cutting speed of 300 m/min, feed rate of 0.16 mm/min and depth of cut as 1 mm based on the earlier research of Singh et al. [34] are selected to evaluate the machining performance. The tool run time kept as 5 min for all three insert for better comparative analysis. The results are shown in Fig. 4. From Fig. 4 it can easily observed that the flank wear after 5 min of machining lies below 0.3 mm for all the three inserts. The interesting phenomenon is noticed for Z3 samples where the minimum flank wear is achieved. The earlier investigations for ceramic inserts illustrated that the flank wear are highly influenced by adhesive wear and plastic deformation of grains during machining. The minimum flank wear observed for Z3 sample is attributed to uniform presence of copper oxide particles inside the cluster that ultimately form a stable thin film at the interface of tool and workpiece. The formations of films at the interface during machining consequences in the restriction of adhesive wear, that also controls the flank wear.

|

Fig. 1 Final shapes and sizes of Cutting Inserts after Sintering. |

|

Fig. 2 XRD plot of Z1, Z2 and Z3. |

|

Fig. 3 Mechanical properties i.e. bulk density, hardness and fracture toughness of Z1, Z2 and Z3 samples. |

|

Fig. 4 Comparative result of flank wear after 5 min of machining. |

Investigation successfully showed comparative study between pressure less sintering and hot static pressing to develop homogeneous CuO/ZTA composites. The result shows slight decrement in mechanical properties with incorporation of CuO particles inside the ZTA matrix. A beneficial effect on the fracture toughness is observed with the incorporation of CuO particles. The machining result shows that inserts prepared through HIP technique have high longer life compared to other inserts. The uniform distribution of CuO particle formed a thin layer at the interface responsible for increase in the tool life.

The author like to thanks Principal and Director of Sri Eshwar college of engineering for their supports. Also, the authors thanks to the staff member of Department of Mechanical Engineering staff (DST-Fist Sponsored Department) for continuous support to carried out this work.

Fund received by DST-INDIA-FIST Program-2022 [TPN-83971] (SR/FST/College-/ 2022/ 1300).

No conflict between the authors.

Availability of data and material

All data are presented in the manuscript

K Raja: Formal analysis, Methodology, Supervision, Dhanabal M: Validation, Visualization, Bipin Kumar Singh: Experimentation, Validation, Visualization, P. Ganeshan: Write-up, Visualization

- 1. B. Bitterlich, S. Bitsch, and K. Friederich, J. Eur. Ceram. Soc. 28[5] (2008) 989-994.

-

- 2. N. Canikoglu, J. Ceram. Processing Res. 22[3] (2021) 258-263.

-

- 3. B.K. Singh, A.A. Yaduvanshi, and A.K. Mishra, in "Tailored Functional Materials" Springer Proceedings in Materials 15 (Springer, 2022) Singapore.

-

- 4. P. Kumar, A. Pratap, N. Mandal, and B.K. Singh, Mater. Today: Proc. 44 (2021) 1806-1810.

-

- 5. N. Mandal, B. Doloi, B. Mondal, and B.K. Singh, Proc. Inst. Mech. Eng. B J. Eng. Manuf. 231[8] (2015) 1396-1408.

-

- 6. E.D. Whitney, in “Ceramic cutting tools: materials, development and performance” (Materials Science and Process Technology Series, 1994).

- 7. T. Kitagawa, A. Kubo, and K. Maekawa, Wear 202[2] (1997) 142-148.

-

- 8. W. Grzesik and J. Małecka, CIRP Annals 60[1] (2011) 121-124.

-

- 9. N.J. Claussen, Am. Ceram. Soc. 59[1‐2] (1976) 49-51.

-

- 10. R.C. Garvie, R.H. Hannink, and R.T. Pascoe, Nature 258[5537] (1975) 703.

-

- 11. K. Raja, P. Ganeshan, B.K. Singh, R.K. Upadhyay, P. Ramshankar, and V. Mohanavel, Sādhanā 48[2] (2023) 72-78.

-

- 12. Y. Le Godec and S. Le Floch, Materials 16[3] (2023) 997.

-

- 13. S. Mazumder, A. Kumar, B.K. Singh, H. Roy, and N. Mandal, Mater. Res. Express 6[8] (2019) 085086.

-

- 14. D. Jianxin, C. Tongkun, Y. Xuefeng, and L. Jianhua, Int. J. Mach. Tools Manuf. 46[9] (2006) 957-963.

-

- 15. B.K. Singh, D. Ghosh, N. Mandal, and H. Roy, J. Inst. Eng. (India): D 100[2] (2019) 263-273.

-

- 16. W. Guangyong, X. Chonghai, Z. Yonglian, and Y. Mingdong, Appl. Mech. Mater. 66-68 (2011) 1598-1604.

-

- 17. A.K. Dey, S. Chatterjee, and K. Biswas, J. Mater. Eng. Perform. 26[12] (2017) 6107-6116.

-

- 18. Y. Xing, C. Luo, M. Zhu, Y. Zhao, K. Ehmann, Z. Wu, and L. Liu, J. Mater. Process. Technol. 318 (2023) 118010.

-

- 19. M.K. Gupta, Q. Song, Z. Liu, R. Singh, M. Sarikaya, and N. Khanna, Tribol. Int. 155 (2021) 106775.

-

- 20. R.S. Parihar, R.K. Sahu, and S.G. Setti, Int. J. Refract. Hard. Met. 104 (2022) 105788.

-

- 21. Z. Fangyuan, L. Zhian, Q. Hui, Z. Xinyu, and Z.J. Taiji, J. Mater. Process. Technol. 318 (2023) 118035.

-

- 22. B.K. Singh, S. Goswami, K. Ghosh, H. Roy, and N. Mandal, Int. J. Refract. Hard. Met. 98 (2021) 105551.

-

- 23. B.K. Singh, Trans. Indian Ceram. Soc. 82[1] (2023) 1-13.

-

- 24. S. Pazarlioğlu and S. Salman, J. Ceram. Processing Res. 20[1] (2019) 99-112.

-

- 25. B. Kim, S. Jeon, C.J.V. Tyne, H. Park, and H. Lee, J. Ceram. Processing Res. 17[5] (2016) 459-463.

-

- 26. P. Ganeshana, Y. Sravani, K. Raja, and Bipin Kumar Singh, J. Ceram. Processing Res. 25[5] (2023) 781-787.

-

- 27. B.K. Singh, S. Samanta, S.S. Roy, R.R. Sahoo, H. Roy, and N. Mandal, Mater. Res. Express. 6[12] (2020) 125208-20.

-

- 28. G. Gokilakrishnan, B.K. Singh, and M. Vigneshkumar, J. Ceram. Processing Res. 24[4] (2023) 655-661.

-

- 29. J.R. Seidensticker and M.J. Mayo, Scr. Met. Mater. 31 (1994) 1749-1754.

-

- 30. S. Ran, L. Winnubst, D.H.A. Blank, H.R. Pasaribu, J.W. Sloetjes, and D.J. Schipper, J. Am. Ceram. Soc. 90 (2007) 2747-2752.

-

- 31. A. Pratap, P. Kumar, G.P. Singh, N. Mandal, and B.K. Singh, Mater. Today: Proc. 26 (2020) 2442-2446.

-

- 32. S.T. Oh and S.I. Lee, J. Nanosci. Nanotechnol. 10[1] (2010) 366-369.

-

- 33. A.S. Kumar, A.R. Durai, and T. Sornakumar, J. Mater. Process. Technol. 173[2] (2006) 151-156.

-

- 34. B.K. Singh, H. Roy, B. Mondal, S.S. Roy, and N. Mandal, Mach. Sci. Technol. 22[6] (2018) 899-913.

-

This Article

This Article

-

2024; 25(1): 79-84

Published on Feb 29, 2024

- 10.36410/jcpr.2024.25.1.79

- Received on Nov 7, 2023

- Revised on Dec 8, 2023

- Accepted on Dec 11, 2023

Services

Services

- Abstract

introduction

process opted to manufacture self-lubricating inserts

experimental investigation

discussion on the observed results

conclusion

- Acknowledgements

- Funding

- Conflict of Interest

- Author Contributions

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- K. Raja

-

Department of Mechanical Engineering, Anna University Regional Campus Coimbatore, Coimbatore- 641046, Tamil Nadu, India

Tel : +91 8110057539 - E-mail: rajagce@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.