- Interior hardcover material and processing technology based on art beauty principle

Lijuan Zhang*

Zhengzhou University of Light Industry, 450002, Zhengzhou, Henan, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

In recent years, interior decoration has gained popularity in China, making the optimization of the process for interior hardcover materials and processing technology based on the principles of artistic beauty a significant task. This paper introduces a process design method using the linear discriminant analysis algorithm and explores the application of artistic beauty principles in the processing technology of indoor hardbound materials. The research begins with a summary of the current research status, followed by an investigation of various aspects of processing technology. It identifies five factors influencing the efficiency of processing indoor hardbound materials and optimizes the traditional process method accordingly. The proposed scientific machining model for hard mounting materials is then presented. Finally, a design experiment is conducted to verify the feasibility of the machining model. The research findings indicate that the processing optimization model based on the linear discriminant analysis algorithm effectively enhances the processing quality and efficiency of indoor hard decoration materials.

Keywords: Linear discriminant analysis, Interior hardcover materials, Processing technology, Artistic beauty rules, Efficiency evaluation.

Currently, research on the processing technology of indoor hard decoration materials in China mostly relies on traditional distributed and independent research strategies, with some multi-objective collaborative research (Nico dissmeyer et al., 2018) [1]. Over the past 30 years, the rapid advancement of information technologies in China has led to the evolution of processing methods for indoor hard decoration materials. Modern approaches like intelligent processing, enhanced efficiency, and improved data quality offer opportunities for large-scale research in optimizing processing technology for indoor hard decoration materials. Intellectualization has become a prominent characteristic in this field (fengna Chen et al., 2020) [2]. Currently, existing indoor hard mounting material processing systems offer various optimization methods. However, it remains challenging for indoor hard mounting companies to differentially process materials based on their characteristics, apply targeted material processing methods, and achieve optimal processing quality (Dong Yu et al., 2019) [3]. Therefore, it becomes increasingly practical to develop an evaluation model for interior hardcover materials and processing technology based on linear discriminant analysis and artistic beauty principles.

This research makes the most of each type of indoor hardbound materials and their distinctive processing technologies. By analyzing the characteristics of processed materials and dynamically tracking them in real-time, a comprehensive simulation approach is achieved. Quantitative indicators, using the local method Correlation factors, are employed to measure the similarity between indoor hard decoration materials, processing efficiency, and conformity with expected standards. This enables an effective variable weight analysis of the factors impacting the processing technology of indoor hard decoration materials. Divided into three parts, the paper explores interior hardcover materials and processing technology based on the art beauty principle. The first part presents the current domestic and foreign research status on influencing factors related to interior hardcover materials and processing technology. The second part constructs an optimization model for material processing technology using linear discriminant analysis and establishes an evaluation index system for indoor hard decoration materials and processing technology based on linear discriminant analysis and Gauss matrix evaluation strategy. The third part designs relevant experiments to test the optimization model of material processing technology and draws conclusions based on the results.

In recent times, there has been a significant focus on research areas pertaining to the processing techniques of indoor hard decoration materials. Researchers at Stanford University in the United States have observed that conventional approaches are still predominant in the utilization of interior hardcover materials and their processing methodologies. These conventional strategies, however, tend to overlook the influence of distinct characteristics among various interior hardcover materials on the principles governing artistic aesthetics. Consequently, this oversight hampers the optimization process of interior hardcover materials and their processing techniques, thereby limiting the potential for substantial enhancements in scientific efficiency (GERD Bramerdorfer et al., 2019) [4]. Scholars from the University of Tokyo in Japan have introduced an adaptive optimization model for interior material processing technology, utilizing a self-strategy approach. By dissecting the components of diverse interior decoration materials, the processing methodologies for distinct types of interior hard decoration materials have been refined to facilitate layered processing of these materials [5]. Concurrently, researchers from Harvard University in the United States have experimentally validated the effectiveness of a processing technique rooted in a closed-loop control system. This method proves to be instrumental in optimization efforts, significantly enhancing the efficiency of indoor materials during the processing stages. The assessment of indoor hard mounting materials and processing technology's efficacy is achieved through the utilization of multiple performance indicators (Gottlieb Söhrlein et al., 2018) [6]. Drawing upon fundamental methods and practical insights related to indoor material processing technology, experts from the National University of Singapore have identified the prevalent inefficiencies in current processing methodologies. To address this, they propose a monitoring approach centered around machine vision algorithms. Through comprehensive oversight of diverse indoor materials throughout the processing stages, this strategy enables the attainment of three optimized states during processing (Fatemeh Ahangaran et al., 2019) [7]. Furthermore, researchers from Zhejiang University in China have realized real-time monitoring and data analysis of indoor hard mounting materials by conducting continuous, comprehensive data collection throughout the processing procedures. Empirical experiments subsequently demonstrate the potency of these processing techniques in elevating efficiency. The resulting benefits include enhanced processing efficiency, elevated quality reliability, and an accessible approach (Manuel Felix et al., 2019) [8]. In summation, the existing body of domestic and international research concerning indoor hard decoration materials and processing technology has yet to incorporate the material processing optimization technique grounded in linear discriminant analysis. While there exists a considerable foundation of basic research in the domain of interior hardcover materials and processing technology, the outcomes concerning specific quantitative dynamic evaluation systems and efficiency enhancements remain somewhat limited.

The application of linear discriminant analysis method in the model of indoor hardbound material processing

Linear Discriminant Analysis (LDA) constitutes an extension of Fisher's linear discriminant techniques. This methodology employs statistical, pattern recognition, and machine learning approaches to identify a linear amalgamation of attributes characterizing distinct object types or occurrences, enabling effective differentiation between them. The outcome of this amalgamation can be harnessed to formulate a linear classifier or, more commonly, to condense dimensions for subsequent categorization tasks [1]. The Linear Discriminant Analysis algorithm stands as a classical linear learning technique, garnering substantial attention in various domains both domestically and internationally. Its primary objective revolves around reclassifying established datasets based on predefined principles. These classification rules entail the procedure of reassigning diverse data categories according to their relevancy as stipulated by established guidelines [10]. In the context of scrutinizing the processing methodology for diverse indoor hard decoration materials, the Linear Discriminant Analysis approach aims to optimize the process through the clustering of distinct processing methods applicable to various indoor materials. The method finds broader utility in tasks such as identifying associations and correlations in informational contexts related to target entities or in performing fuzzy searches and filters for uncharted targets. Effectively harnessing this approach for data mining and efficiency evaluation necessitates the translation of target data into machine-interpretable language through pattern recognition. Conventionally, experts utilize the vector space model to process characteristic data within the target group. Consequently, when constructing the processing model for indoor hard materials, it becomes imperative to achieve distributed computations for unknown data through Linear Discriminant Analysis. Conversely, the clusters integrated within Linear Discriminant Analysis share similarities with groups, embodying an abstract set concept. Variations in cluster cohesion arise from the choice of distinct clustering methodologies, engendering diverse degrees of member similarity. Hence, during the formulation of the indoor hard decoration materials processing model, this paper adopts a Linear Discriminant Analysis algorithm grounded in the data envelopment factor. This approach selects three pertinent parameters associated with the processing quality of indoor hard decoration materials and introduces an efficiency evaluation framework founded on Linear Discriminant Analysis principles.

Once the processing model of indoor hard mounting materials is determined, it becomes imperative to delve into the process of optimizing their processing technology. Consequently, drawing from the theory of collaborative multi-factor relationships, this investigation employs a novel optimization approach for indoor hardcover material processing technology. This method is rooted in a multi-relationship recommendation algorithm, which examines the interconnectedness of various procedures in conventional indoor hardcover material processing techniques. Through this, a multi-factor coupling analysis model is formulated. This model facilitates a comprehensive evaluation encompassing aspects such as processing method selection, classification of processing efficiency, and the quality and quantity of processing. This evaluation culminates in the experimental refinement of processing for distinct indoor hardcover materials. Research findings indicate that the accuracy of evaluating processing technology is enhanced using the process efficiency evaluation model for indoor hardcover materials, incorporating the multi-relationship recommendation algorithm and linear discriminant analysis strategy, as opposed to conventional process analysis methods (Joo young Kim et al., 2018) [11]. As a result, this study concentrates on typical material categories encountered in indoor hard decoration processes. A thorough analysis of diverse aspects of common indoor hard decoration materials is conducted, followed by data clustering. Ultimately, the processing efficiency and quality of the subject under investigation are assessed (Shiyu Jia et al., 2018) [12]. This process delineates the optimization procedure for indoor hardbound material processing technology in the following steps: The initial phase entails optimizing the processing methods for distinct indoor hard mounting materials. The pertinent indoor hard mounting material analysis system extracts feature information from the data and converts it into binary code, commonly utilized in computer systems. This enables computerized storage and comparison with existing information in the indoor hard mounting materials database. Through this information gathering procedure, diverse hard mounting material processing techniques are scrutinized, generating secondary experimental analysis data. These data are then input into the established computer data processing network. The computer database information, along with a pre-set automatic judgment program, collaboratively execute adaptive analysis (Sharpless Katherine e et al., 2019) [13]. Concurrently, to enhance the stability of processing efficiency evaluation for indoor hard mounting materials and mitigate overall errors, this study employs a layered optimization control method founded on material analysis and process control theory. This involves restoring material performance based on specific data information, thus achieving logarithmic actualization.

In the subsequent phase of enhancing the processing technology for indoor hard decoration materials, the focus lies on quantifying the impact of optimization. This quantification is achieved by employing vectors as a specialized means of data representation. The objective is to transform the informational data into vector format, allowing for its storage. The degree of optimization effect is determined by quantifying values, wherein a higher value corresponds to a more favorable optimization outcome (Salam et al., 2018) [14]. As an illustration, when categorizing data of similar nature pertaining to different types of indoor hard mounting materials, a comparison can be made based on these vectors possessing unique data recording capabilities. When the level of concurrence meets the pre-defined criteria, it becomes feasible to conduct data processing, judgment, and classification for the targeted data, thus realizing an optimized quantification framework for hard mounting material processing technology, as elucidated by Levy. To assess and recognize the similarity of machining processes, an innovative linear judgment analysis approach is employed. The original machining process undergoes random optimization via the utilization of chaotic sequences post-deformation.

Step 3: after the above steps are completed, it is necessary to optimize the processing process of indoor hard decoration materials, and set different aesthetic feeling degrees of art hair exhibition. We set the value as X, then the expression form of aesthetic feeling degree corresponding to different types of indoor hard decoration materials is , represents the corresponding vector, then the expression of is:

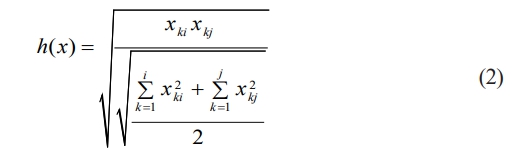

When the artistic aesthetics of different types of indoor hard decoration materials are inconsistent, quantitative expression is needed to realize the quantitative expression of different types of artistic aesthetics. The expression with the value H is:

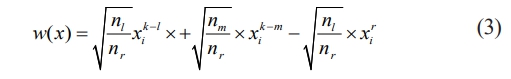

The correction coefficient for different types of indoor hard decoration materials is w, which is expressed as follows:

The experimental design process of interior hardcover material and processing technology based on art beauty principle

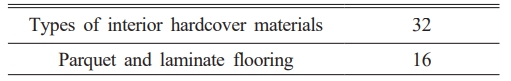

Before the formal experiment, it is necessary to design the standard reference value for the common types of indoor hard decoration materials. Considering the difference of aesthetic sense of different types of indoor hard decoration materials and the difference of correlation between different processing methods, this study uses the common indoor hard decoration materials in the current market (solid wood floor and composite floor with known basic information, floor tile and The basic information data of natural stone is the control group, and the same type of indoor hardbound materials with unknown information is the experimental group (solid wood floor and composite floor with unknown basic information, floor tile and natural stone, etc.) for practical test. In the process of this experiment, we provided 32 sets of different types of indoor hard decoration materials (including 32 sets in the control group and 64 sets in the experimental group) through the support of an interior decoration company. The distribution of types and quantities of indoor hardbound materials is shown in Table 1.

During the experimental procedures involving both the experimental group and the control group, this study employs an enhanced linear discriminant analysis method alongside a nonlinear multi-dimensional evaluation approach for assessment. This nonlinear evaluation model comprises eight preset numerical parameters, which categorize the parameter information of the experimental group and the known data from the control group into eight distinct evaluation outcomes based on varying parameter configurations [15-18]. The comparative analysis of data transformation into space vectors considers the number, distance, and angle, ensuring a robust degree of data information similarity and matching within each vector cluster. This approach facilitates the objective evaluation of the experimental process and unfolds as follows: Initial Experiment Stage: While examining diverse data related to distinct indoor hard decoration materials, multiple target data points are irregularly chosen as the anchors for the initial linear judgment analysis. By comparing these anchors with secondary target vectors that require evaluation, the distance between the eigenvectors is compared, leading to the determination of parameter information intrinsic to varying indoor hard decoration materials. Subsequent Experiment Phase: The sample centers of each indoor hardbound material model are re-evaluated using the linear judgment analysis algorithm. Spatial vectors for different indoor hardbound material data sources are established, and the parameter information comparison across various hardbound material types determines the similarity arrangement between different clusters. This process forms cluster groups with logical structures and yields secondary evaluation outcomes. Final Experiment Stage: The processing methods for distinct indoor hard mounting materials are analyzed with respect to their processing quality [19-21]. For this study's experimental process, known indoor hard mounting materials and processing methods are used to aggregate foundational data for similar indoor hard mounting materials. This summarized and classified data information is then grouped to mitigate the impact of input sequence variation for different indoor hard mounting material samples on the selection of the initial linear judgment analysis method. Consequently, the overall non-linear evaluation model benefits from enhanced objective evaluation and variable weight analysis.

Results and Analysis of the Experiment

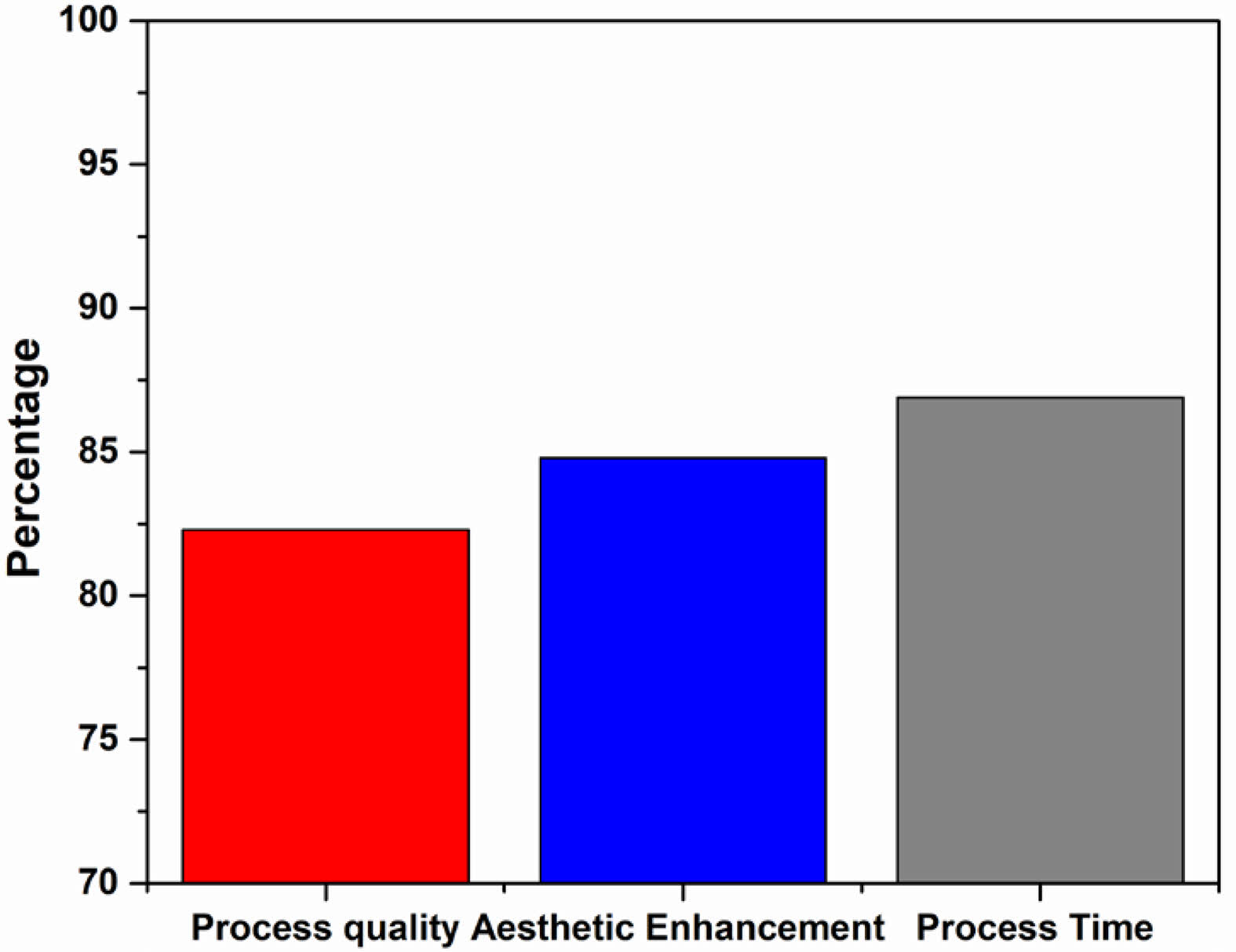

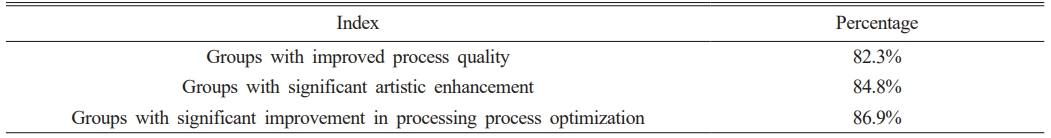

The data analysis method applied in this experiment is the linear judgment analysis method. The subjects under investigation are categorized into the control group and the experimental group. The control group encompasses indoor hardbound materials with known foundational information (e.g., solid wood floor, composite floor, floor tiles, natural stone), while the experimental group comprises the same indoor hardbound materials but with unspecified information (e.g., solid wood floor, composite floor, combined floor, floor tiles, natural stone). Different data analysis methods are employed for various types of indoor hard decoration materials, covering aspects such as material composition, artistic appeal, processing methods, processing technology quality, and processing technology efficiency. Through the integration of linear discriminant analysis and non-linear comprehensive evaluation, this experiment reveals that the overall processing quality of different indoor hardbound materials is notably high. This underscores the effectiveness of indoor hardbound materials rooted in the principle of artistic beauty. Specifically, 82.3% of the total indoor hardbound materials showcase improved processing technology quality. Among these, 43.1% pertain to floor materials and 39.2% to floor tiles. Furthermore, within the group with enhanced processing technology quality, a significant 84.8% exhibit heightened artistic aesthetic enhancement, comprising 50.1% floor materials and 44.7% floor tiles. The effectiveness of specific processing strategies such as optimization of processing time and cost is notable as well, with 86.9% of groups demonstrating significant improvements. This underscores the substantial positive impact of the indoor hard decoration materials and processing technology model based on artistic beauty principles on the efficiency of conventional indoor hard decoration materials and processing techniques. The detailed experimental outcomes, as well as the improvement in processing quality of indoor hardbound materials, are presented in Table 2. The evaluation results regarding indoor hardbound materials and the quality of processing technology based on the linear judgment analysis algorithm model are illustrated in Fig. 1.

|

Fig. 1 Evaluation of the quality of material processing technology |

As scientific and technological advancements continue, conventional processing techniques for indoor hard decoration materials fall short of meeting current developmental requirements. This study introduces a process design approach grounded in the linear discriminant analysis algorithm and investigates the integration of artistic beauty principles into the processing technology of indoor hardbound materials. To begin, an overview of the present research landscape is provided. Subsequently, traditional processing methods for indoor hardbound materials are examined, considering five factors influencing processing efficiency. The approach is optimized, culminating in the proposal of a more scientifically refined machining model for hard mounting materials. The practicality of this model is then confirmed through a design experiment. The findings indicate that the processing optimization model based on the linear discriminant analysis algorithm substantially enhances the processing quality and efficiency of indoor hard decoration materials. Nevertheless, it is worth noting that the scope of this study is primarily confined to assessing interior hard decoration materials and processing efficiency. The study does not extensively address how to amplify aesthetic enhancements within the broader context of interior decoration procedures. Thus, prior to implementing this model, interior decoration companies are advised to conduct thorough investigations into holistic aesthetic design throughout the interior hard decoration process.

The study was supported by the paper of “Jun Porcelain Glaze Technology Design and Simulation Based on artificial Intelligence” (No. 202102311008), which is the key R & D and promotion special project of Henan Province in 2021.

- 1. M.R. Abisha and J.P.A. Jose, J. Ceram. Process. Res. 24[2] (2023) 242-249.

-

- 2. F. Chen, H. Zhang, X. Chen, and J. Ren, Build. Simul. 13 (2020) 637-646.

-

- 3. D. Yu, X. Huang, X. Zhang, J. Zhang, Q. Lu, and Y. Fang, IEEE Trans. Appl. Supercond. 29[2] (2019) 1-5.

-

- 4. G. Bramerdorfer, IEEE Trans. Magn. 55[8] (2019) 1-9.

-

- 5. H. Yildizay, J. Ceram. Process. Res. 24[2] (2023) 237-241.

-

- 6. G. S. Oehrlein and S. Hamaguchi, Plasma Sources Sci. Technol. 27[2] (2018) 023001

-

- 7. F. Ahangaran, A.H. Navarchian, and F. Picchioni, J. Appl. Polym. Sci. 136 (2019) 48039.

-

- 8. M. Felix, V.P. Puyana, A. Paul, and R. Sepulveda, J. Appl. Polym. Sci. 136 (2019) 47953.

-

- 9. J.H. Lee, J.C. Park, B.S. Park, and H.K. Park, J. Ceram. Process. Res. 24[2] (2023) 216-221.

-

- 10. C. Burkhardt, N. Dauphas, U. Hans, B. Bourdon, and T. Kleine, Geochim. Cosmochim. Acta 261 (2019) 145-170.

-

- 11. J.Y. Kim, J.W. Kim, E.K. Lee, J.I. Park, B.L. Lee, Y. N. Kwon, S. Byun, M.S. Jung, and J.J. Kim, J. Mater. Chem. C 6[48] (2018) 13359.

-

- 12. S. Jia, R. Zhang, G. Lin, R. Peng, P. Gao, Y. Han, Y. Fu, J. Ding, Q. Wu, K. Zhang, J. Xie, and J. Li, J. Clin. Lab. Anal. 32 (2018) 22391.

-

- 13. K.E. Sharpless and L.M. Lisa, J. Aoac Int. 83[2] (2019) 413.

-

- 14. H. Salam, Y. Dong, I.J. Davies, A. J. Appl. Polym. Sci. 135[5] (2018) 45769.

-

- 15. P. Modak, W. Hammond, M. Jaffe, M. Nadig, and R. Russo, Reproducible, biocompatible medical materials from biologically derived polysaccharides: Processing and Characterization. J. Appl. Polym. Sci. 137 (2020) 48454.

-

- 16. M. Alrwashdeh and S.A. Alameri, Energies 15[10] (2022) 3772.

-

- 17. M. Alrwashdeh, S.A. Alameri, and A.K. Alkaabi, Nucl. Sci. Eng. 194[2] 2020 163-167.

-

- 18. A. Alraisi, Y. Yi, S. Lee, S.A. Alameri, M. Qasem, C.Y. Paik, and C. Jang, Ann. Nucl. Energy 165 (2022) 108784.

-

- 19. M. Harikaran, P. Kulanthaivel, A.R. Krishnaraja, and P.C. Murugan, J. Ceram. Process. Res. 24[2] (2023) 266-273.

-

- 20. M. Alrwashdeh and S.A. Alameri, Energies 15[21] (2022) 8008.

-

- 21. L. Wanqiang, J. Chunmeng, and L. Shuangxi, J. Ceram. Process. Res. 24[2] (2023) 329-335.

-

This Article

This Article

-

2024; 25(1): 28-33

Published on Feb 29, 2024

- 10.36410/jcpr.2024.25.1.28

- Received on Sep 17, 2023

- Revised on Oct 30, 2023

- Accepted on Oct 30, 2023

Services

Services

Shared

Correspondence to

Correspondence to

- Lijuan Zhang

-

Zhengzhou University of Light Industry, 450002, Zhengzhou, Henan, China

Tel : +86 18537894698 Fax: +86 0371-23658698 - E-mail: zhanglijuan2009030@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.