- The influence of firing temperatures on the phase formation, microstructure and mechanical properties of alumina zirconia composite ceramics

Aurawan Rittidecha,* and Aekkasit Suthapintub

aDepartment of Physics, Faculty of Science Mahasarakham University, Mahasarakham, Thailand, 44150

bFaculty of Science and Technology, Rajabhat Mahasarakham University, Mahasarakham, Thailand, 44000This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This research prepared composite ceramics between Al2O3 (6 mol% MgO); AM and ZrO2 (4 mol% Y2O3); ZY with 50:50 ratio. The samples were sintered under two-step method with four different sintering temperature conditions. It was found that the densities and shrinkage values tended to slightly increase with the lower T2 temperature for the length of holding times. XRD patterns showed a combination main phase between Al2O3 and ZrO2. Rietveld refinement was used to calculate the percentage of phase composition. All of samples were reveled weight percentage of main composition as m-ZrO2 c-ZrO2 t-ZrO2 and r-Al2O3 in different sintering conditions. Rietveld analysis of data revealed a high ratio of t-ZrO2, c-ZrO2 phases from the two stage sintering condition with T1 temperature at 1600 °C for 60 min and T2 temperature at 1450 °C for 10 h, and T1 temperature at 1600 °C for 60 min and T2 temperature at 1500 °C for 5 h. SEM micrographs revealed grain shape and size of grains. The average grain size of AM as 0.863-1.156 µm and ZY was 0.622-0.902 µm:, the size of grain tended to increase with high T2 temperature for the length of holding time. EDX identified large grains corresponding to the Al2O3 phase and small round oval shapes corresponding with the ZrO2 phase. The mechanical properties were measured by Vicker and Knoop hardness calculate the fracture toughness value. It was found that the optimum mechanical properties were obtained from composite ceramic with sintering conditions temperatures of T1 temperature at 1600 °C for 60 min and T2 temperature at 1450 °C for 10 h; this resulted in the highest of fracture toughness value of about 0.32 GPa∙m1/2. The optimal two stage sintering conditions were obtained from a high ratio of t-ZrO2 and c-ZrO2 phases with fine grain size.

Keywords: ZrO2, Al2O3, Mechanical properties, Two stage sintering, Rietveld method.

In order to improve the fracture toughness of Al2O3 ceramics, a second phase is usually introduced into them, so that the second phase is filled at the grain boundary of alumina, which is conducive to preventing the extension of fracture lines and improving the fracture toughness of alumina ceramics [1, 2]. The fracture toughness of Al2O3 ceramics has been improved by adding ZrO2 as the second phase and sintering to form intergranular or intragranular structure. Alumina-zirconia composite is a common second-phase toughened ceramic material. As an important engineering material, it is widely used in structural ceramics applications because of its unique mechanical and chemical properties [3, 4]. It is well known that the properties of sintered ceramics are mainly dependent on the initial powder properties. Work by Jilin Huet al. [5] confirmed that high-quality composite powder can be used to prepare high-performance multi phase ceramics. Among dopants used in Al2O3, magnesium oxide (MgO) has an important effect on mechanical properties since it can reduce the sintering temperature and grain size [6, 7]. Other work [8] has revealed that small amounts of magnesia (≤0.70 wt.%), when added to zirconia-toughened alumina, enable it to become a promising material for machining applications. Zirconia in the tetragonal form at room temperature which has the best mechanical properties among all forms and provides toughening mechanisms associated with the phase transformation from t-ZrO2 to m-ZrO2 under stress [9, 10]. Many reports have reported attempts to synthesize a metastable tetragonal phase formation in zirconia at low temperature [11-13]. Zirconia stabilized with Y2O3 has the best properties for mechanical device applications. Stabilizing oxides (e.g., Y2O3) are used to stabilize cubic and tetragonal zirconia forms at room temperature. The mechanical properties of ZrO2 ceramics with 4 mol% Y2O3 addition depend strongly on the microstructure as well as composition as reported by Rittidech et al.[14]. The mechanism of t-ZrO2 to m-ZrO2 transition is typical of partially stabilized zirconia and frequently supported by many studies of the transformation strength process, which has been widely, discussed [15, 16]. The alumina-zirconia system (AZx with 15-50 mol% ZrO2) is interesting to study [17, 18]. The ceramic composite between AM and ZY at a ratio of 50:50 was therefor selected for investigation due to its good properties and reduced production costs. The process of heat treatment is important in preparation of ceramics. The microstructure of Al2O3-ZrO2 composite ceramics can be controlled by two ways i.e., either by using additives to prohibit the grain growth, used for obtaining highly dense ceramics, or it can be controlled by using novel processing techniques to modify the microstructure. Two-stage sintering process is one of the ways of eliminating grain growth in the final stage of sintering reported by Chen and Wang [19]. Two stage sintering methodologies involve sintering with thermal pretreatment at a high sintering temperature for short holding times, followed by a second stage at lower temperature for long holding times. The first-stage high temperature sintering step helps eliminate supercritical pores while the second-stage low temperature sintering step suppresses grain growth [19]. However, different Al2O3 and ZrO2 contents of composite ceramics will be suitable for two stage sintering using different conditions. The 0.50AM-0.50ZY composite ceramics sample were investigated to find optimal two stage sintering conditions, which are revealed producing appropriate composite ceramics.

Recently, composite ceramics between Al2O3 using addition of 6 mol%MgO and ZrO2 addition of 4 mol%Y2O3 with 50:50 ratio under four different firing conditions (TS-1) T1 temperature at 1650 °C for 60 min and T2 temperature at 1500 °C for 5 h, (TS-2) T1 temperature at 1650 oC for 60 min and T2 temperature at 1500 °C for 10 h, (TS-3) T1 temperature at 1600 °C for 60 min and T2 temperature at 1450 oC for 10 h, and (TS-4) T1 temperature at 1600 °C for 60 min and T2 temperature at 1500 °C for 5 h were prepared by solid state reaction using two stage sintering method. The influence of firing conditions on bulk densification, percentage of shrinkage, phase formation, crystal structure calculated by Rietveld refinement, microstructure and microhardness is also studied.

The composite ceramic alumina zirconia was used as matrix powders to which Al2O3 was added MgO 6.0 mol% to form AM and ZrO2 was added Y2O3, 4.0 mol% to form ZY. The powder of AM : ZY at 50:50 ratio was mixed in varying proportions and then wet ball milled for 24 h. After ball-milling, drying in electronic furnaces and sieving with 120 mesh, the resulting powders were annealed at 1200 °C, with dwell times of 120 min and heating/cooling rates of 10 °C/min. The composite powders were then pressed at 3 MPa to form pellets having 1.5 cm diameter using a hydraulic press and sintered in an alumina crucible under two stage sintering with 4 different conditions. These conditions were (TS-1) (1) T1 temperature at 1650 °C for 60 min and T2 temperature at 1500 °C for 10 h, (TS-2) (2) T1 temperature at 1650 °C for 60 min and T2 temperature at 1500 °C for 5 h, (TS-3) (3) T1 temperature at 1600 °C for 60 min and T2 temperature at 1450 °C for 10 h, and (TS-4) (4) T1 temperature at 1600 °C for 60 min and T2 temperature at 1500 °C for 5 h. The sintering experiments were carried out in an electrical furnace (Nabertherm, Germany). The bulk densities of sintered sample were calculated using Archimedes’ method. Phase identification was then performed using an X-ray diffractometer (XRD; Bruker model D8 advance). Subsequently, Rietveld refinement of the XRD patterns of all samples was performed using TOPAS software. Microstructural analysis was performed by using Scanning Electron Microscopy (SEM) (JEOL JSM-840A) of sintered samples on a polished surface. The microhardness of the bulk ceramics was measured using a micro scan from Vickers and Knoop (FM-700e type D, Future Tech., Japan).

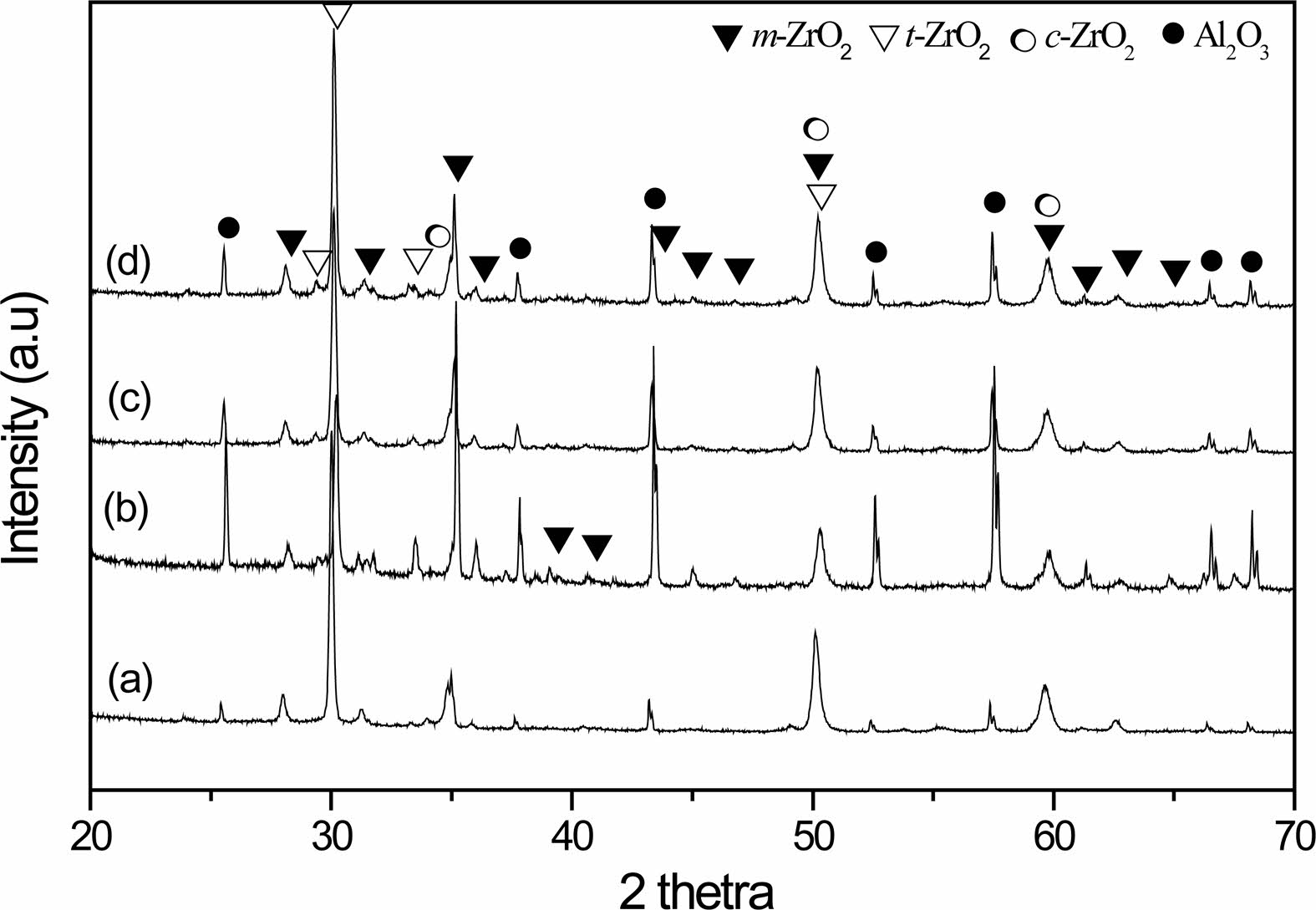

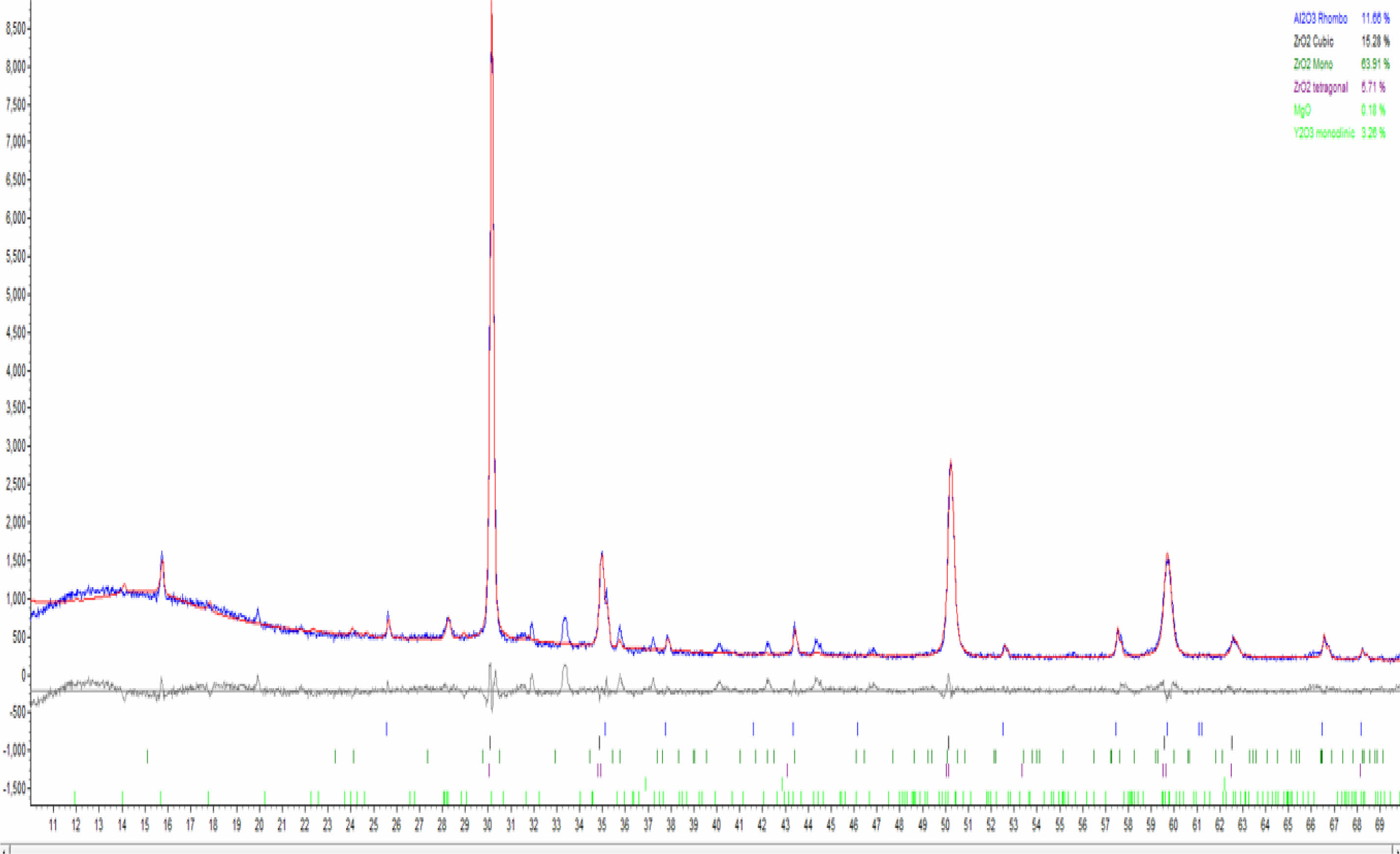

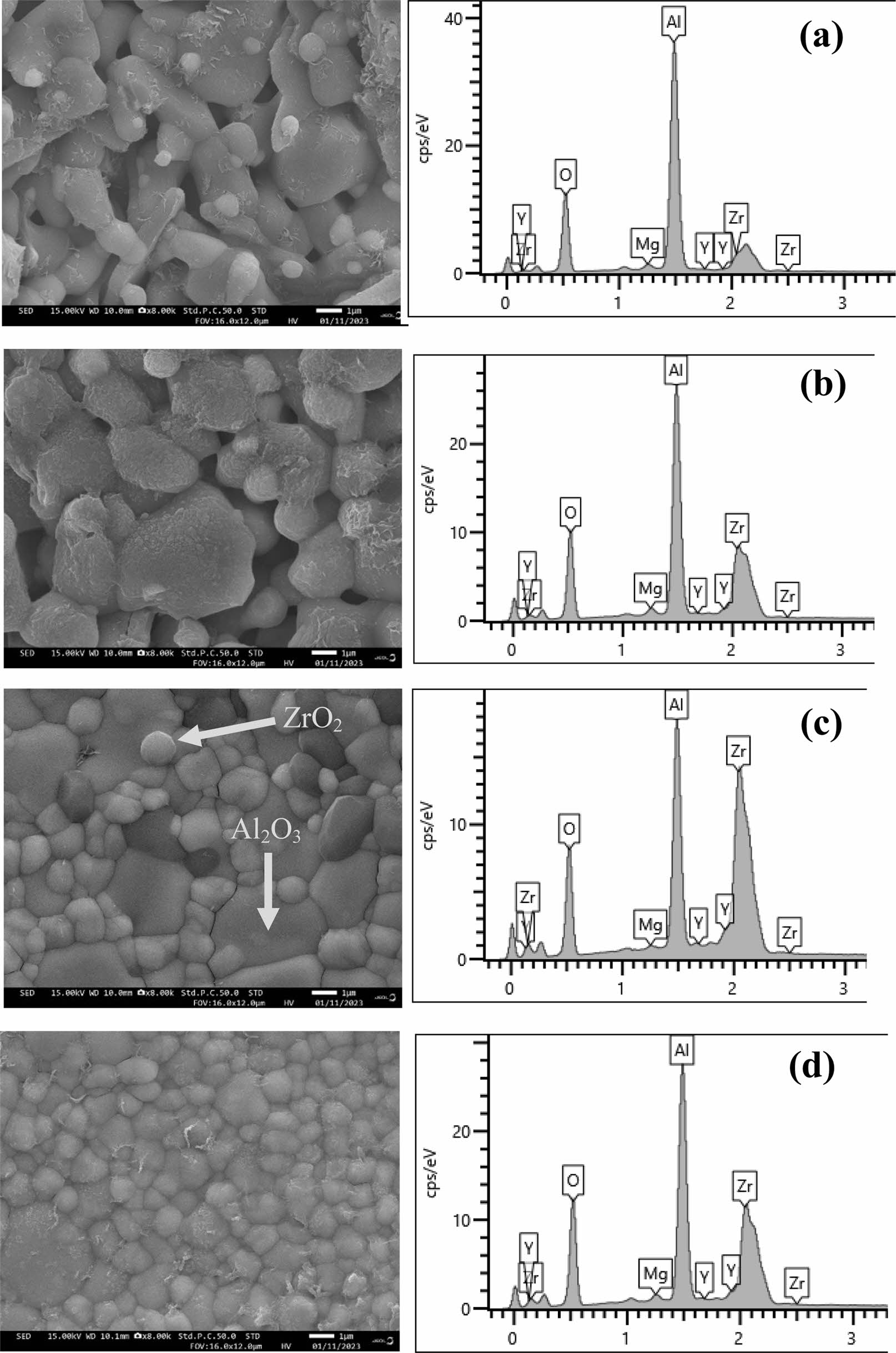

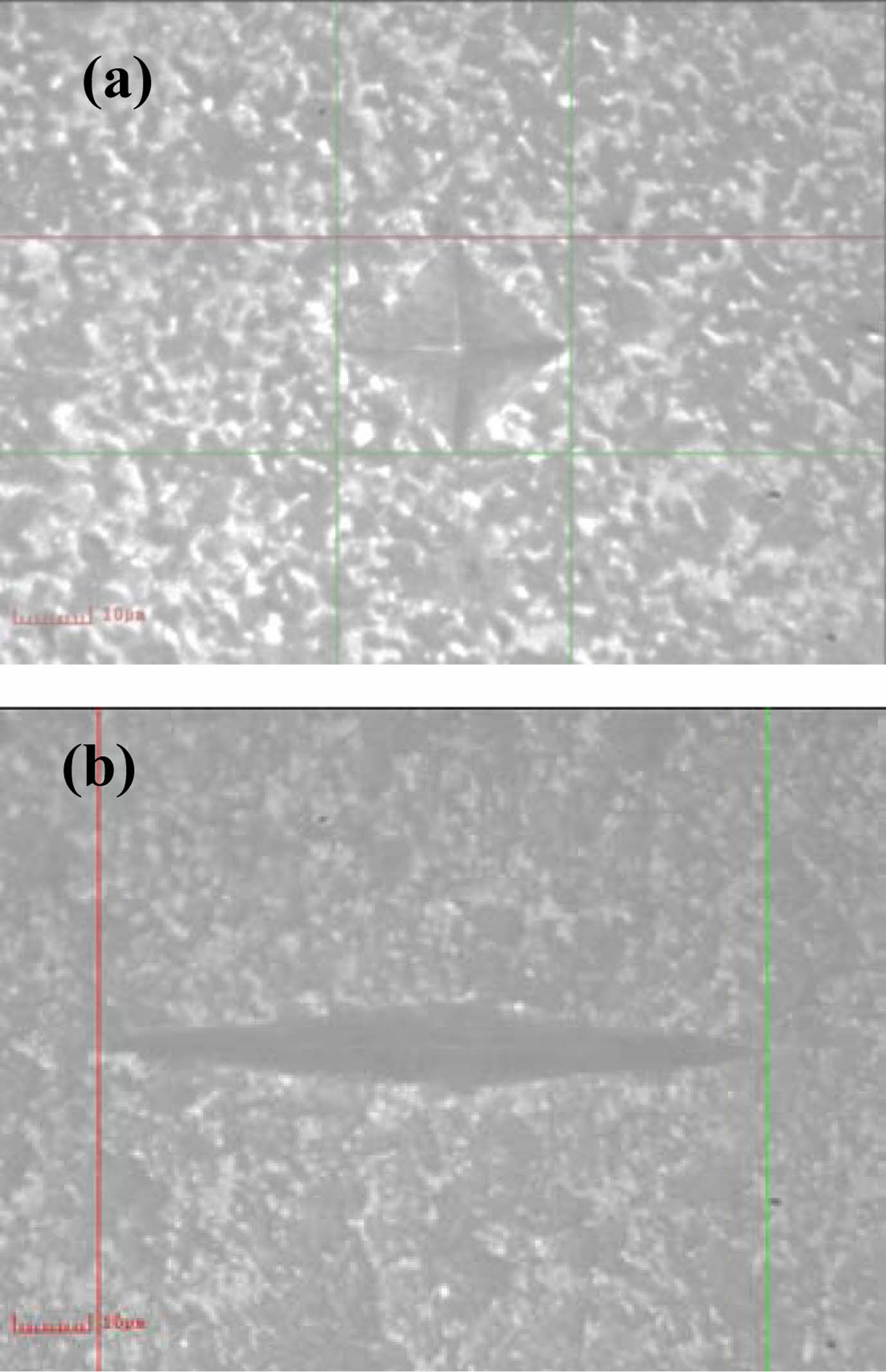

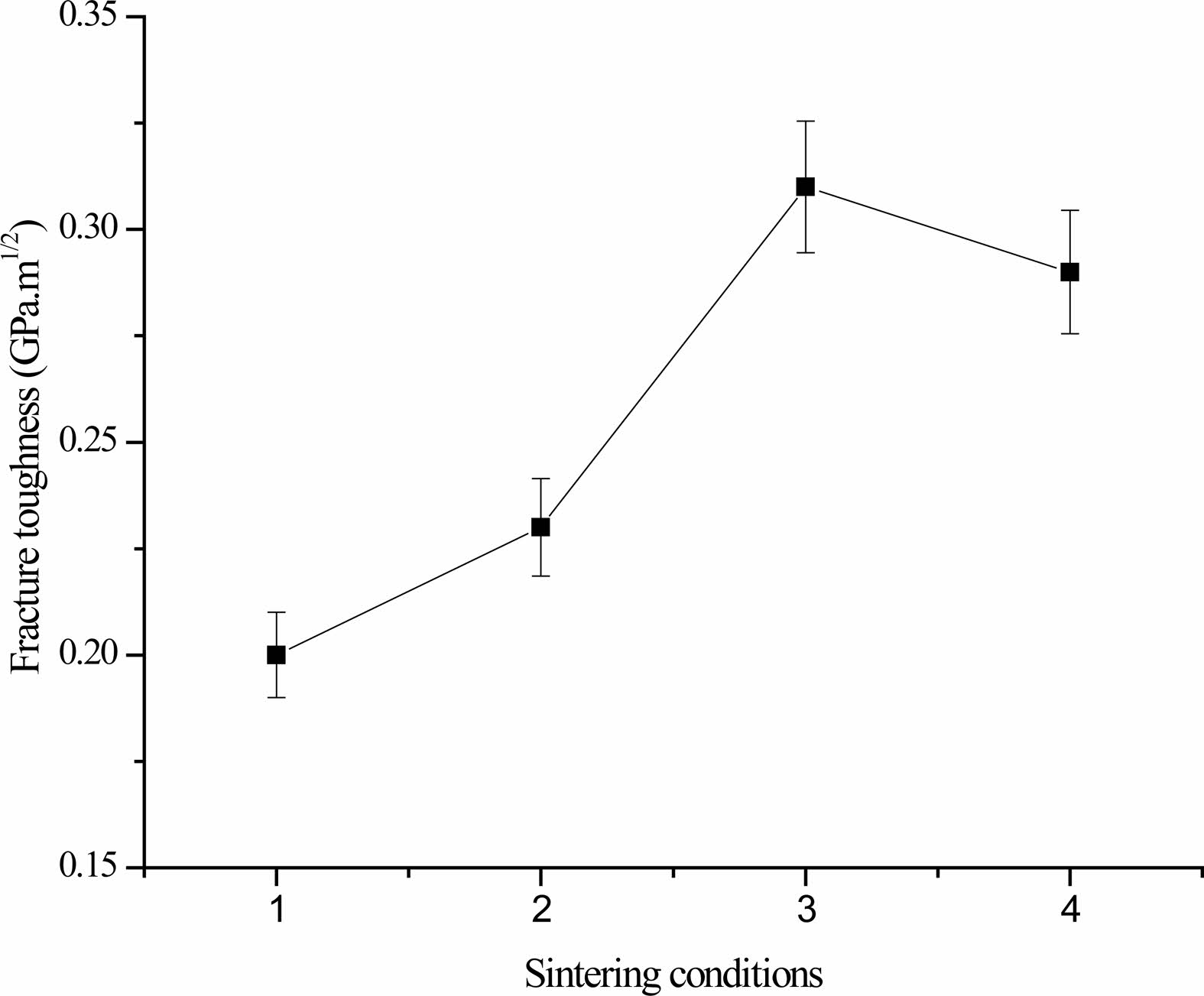

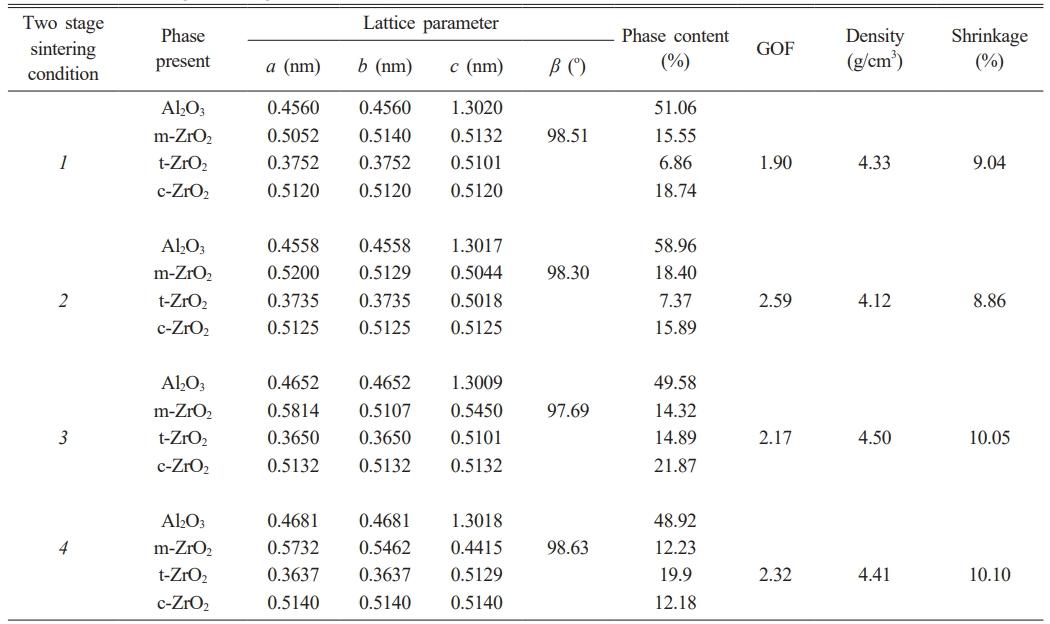

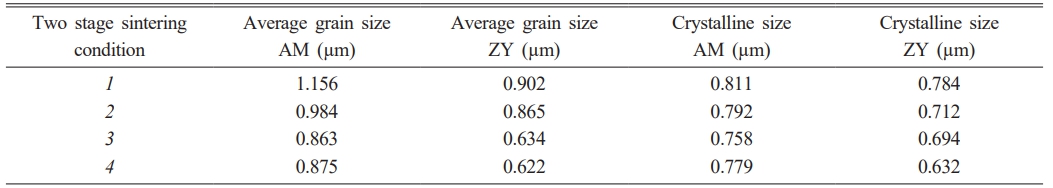

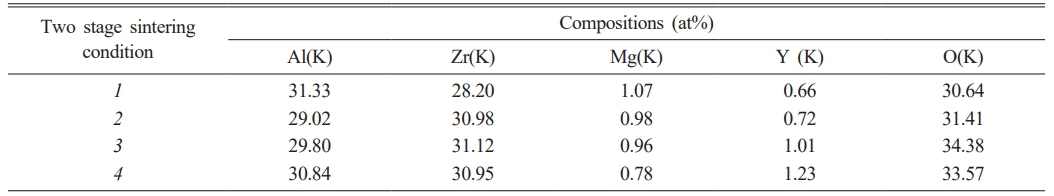

The x-ray diffraction patterns (XRD) of 0.50AM-0.50ZY composite ceramics with two stage sintering different conditions are given in Fig. 1. XRD patterns consist of two main phases of alumina and zirconia. Apart from the alpha (α)-Al2O3 and monoclinic (m), tetragonal (t), cubic (c) zirconia were found. The main reflections in the pattern form around 2θ=25, 30, 35, 43, 50, 57 and 59° that closely match the characteristic reflections of Al2O3-ZrO2 [20-22]. The XRD patterns of sintering condition of TS-3 and TS-4 clearly revealed the tetragonal phase and cubic phase of ZrO2 by the presence of 2θ as 30o and the splitting of peaks around 2θ as 35 and 50o. Full pattern matching refinement of XRD patterns was performed using the TOPAS program based on the Rietveld method. This obtained more detailed information on crystallographic spectra of 0.50AM-0.50ZY composite ceramics with different sintering condition and selected samples with sintering condition of the TS-3 as shown in the XRD refinement pattern in Fig. 2. The fitted patterns were in good agreement with the respective experiment data, denoted by GOF factors listed in Table 1. The lattice parameter of the AM is showed to be in the range of 0.4558-1.3020 nm, while the ZY phase consists of three different crystallographic system; m-ZrO2, t-ZrO2 c-ZrO2. It was found that two stage sintering condition by the lower T2 temperature for the length of holding times were obtained the high percentage of phases content of t-ZrO2, c-ZrO2. Table 1 shows the relationships between the crystallographic and physical properties of 0.50AM-0.50ZY with different two stage sintering conditions. Densities of sintered sample were determined using the Archimedes principle. Table 1 contains data about the densities, percentage of shrinkage of 0.50AM-0.50ZY composite ceramics with different two stage sintering condition. It was observed that the density was between 4.12-4.50 g/cm3. The optimal density was obtained in the sample with the two stage sintering condition of TS-3 (T1 temperature at 1600 oC for 60 min and T2 temperature at 1450 oC for 10 h) and TS-4 (T1 temperature at 1600 oC for 60 min and T2 temperature at 1500 oC for 5 h). The promotion of densification by the addition of yttria in zirconia and magnesia in alumina under two stage sintering is reflected by the lower temperature required to achieve a high final density than when using undoped and conventional sintering. The crystalline sizes of AM and ZY phases calculated from the XRD patterns are summarized in Table 2. The crystalline sizes of AM were in the range 0.863-1.156 µm and for ZY they were in the range 0.622-0.902 µm. Fig. 3(a)-(d) shows the SEM/EDX micrographs of as-received 0.5AM-0.5ZY composite ceramics with different two stage sintering condition. The microstructure of the sintered 0.5AM-0.5ZY composite ceramics with different two stage sintering condition is showed in Fig. 3, where the ZY phase has a smaller spherical grain shape, while the AM phase is larger and darker grains agreement with the other research [20, 23, 24]. The presence of AM and ZY grain in the specimens was confirmed by EDX analysis (as shown by arrows in Fig. 3(c)). Microstructural characteristics in Fig. 3(c)-(d) were observed, i.e., uniform sized grains with well-packed and continuous grain structure while, the samples in Fig. 3(a)-(b) had a large grain size with low well-packed consistent with bulk density results. SEM results confirmed the small grain size from two stage sintering conditions of TS-3 and TS-4 as revealed by high fraction contents of t-ZrO2 and c-ZrO2 by Rietveld results. Almost no abnormal grain growth appeared. This supported previous research, in which the composite ceramics between alumina and zirconia restrained abnormal grain growth in alumina-based materials [21]. By applying the linear intercept method [25] the grain sizes in SEM micrographs were estimated for these samples as shown in Table 2. It can be seen that 0.5AM-0.5ZY composite ceramics with different two stage sintering condition showed average grain sizes for AM in the range 0.863-1.156 µm, while the average grain sizes of ZY was 0.622-0.902 µm. After display a comparison of the grain sizes in Al2O3-ZrO2 (Y2O3) composite ceramics after conventional sintering [26], Al2O3-ZrO2 (Y2O3) composite ceramics without MgO addition after two stage sintering [20] and 0.5AM-0.5ZY composite ceramics with different two stage sintering condition, it was found that the sizes of grains in 0.5AM-0.5ZY composite ceramics with different two stage sintering condition was smaller than in ceramics from the other two cases. The main reason for the application of two stage sintering is inhibition of grain growth in the final stage sintering by the application of the second, low temperature, heating step. Moreover, MgO addition in alumina is also an important factor in controlling grain size as reported in the other works [7, 14]. The EDX analysis and chemical compositions for 0.5AM-0.5ZY composite ceramics with different two stage sintering conditions are shown in Table 3. The mechanical properties of 0.5AM-0.5ZY composite ceramics with two sintering different conditions were investigated by measuring microhardness by Knoop and Vickers techniques and then calculating the fracture toughness values. The selected samples with two sintering conditions of TS-3 are shown as indentation of Vickers and Knoop hardness micrographs in Fig. 4(a-b). Figure 5 shows the relationship between fracture toughness values and the two different sintering conditions. It was found that the fracture toughness values increased with lower T2 temperature during holding times. The sample of 0.5AM-0.5ZY composite ceramics with two sintering conditions of TS-3 had a high fraction of t-ZrO2, c-ZrO2 phases. These results confirm that increases in hardness were due to the small grain size and lower value of the crystalline size, corresponding to densities and phase analysis. The fracture toughness values of all compositions was higher than that of the Al2O3-ZrO2 with only doped Y2O3. The highest value for fracture toughness was demonstrated by 0.5AM-0.5ZY composite ceramics with two sintering conditions of TS-3, which corresponds to the highest percentage fraction in the tetragonal phase and cubic phase by XRD. It had high densification and optimal microstructure revealed by SEM.

|

Fig. 1 XRD patterns of 0.5AM-0.5ZY composite ceramics with different two stage sintering conditions (a) TS-1 (b) TS-2 (c) TS-3 (d) TS-4. |

|

Fig. 2 Rietveld refinement of 0.5AM-0.5ZY composite ceramics with two stage sintering of TS-3 condition |

|

Fig. 3 SEM/EDX micrographs of 0.5AM-0.5ZY composite ceramics with different two stage sintering conditions (a) TS-1 (b) TS-2 (c) TS-3 (d) TS-4 |

|

Fig. 4 Indentation of microhardness of 0.5AM-0.5ZY composite ceramics with two stage sintering of TS-3 condition (a) Vickers (b) Knoop. |

|

Fig. 5 The relationship between fracture and different two stage sintering conditions 0.5AM-0.5ZY composite ceramics. |

|

Table 1 Parameters obtained from Rietveld analysis and densities, percentage of shrinkage of 0.5AM-0.5ZY composite ceramics with different two stage sintering conditions. |

|

Table 2 Average grain sizes and crystalline size of 0.5AM-0.5ZY composite ceramics with different two stage sintering conditions. |

|

Table 3 Chemical compositions of 0.5AM-0.5ZY composite ceramics with different two stage sintering conditions. |

The 0.5AM-0.5ZY composite ceramics with four different two sintering conditions were successfully prepared. The influence of heat treatment was investigated by characterization of densification, phase analysis and mechanical properties. The key parameters that controlled the phase formation, microstructure, mechanical properties was various four sintering conditions. It was found that the lower T2 temperatures (holding times) resulted in optimal characterization of samples. The 0.5AM-0.5ZY composite ceramics with two sintering conditions of TS-3:T1 temperature at 1600 °C for 60 min and T2 temperature at 1450 °C for 10 h had optimal densification, the highest microhardness and fracture toughness. These samples had a high percentage fraction of t-ZrO, c-ZrO2 phase composition, and they showed a fine grain size and small crystallize size of the AM phase and ZY phases.

This research project was financially supported by Thailand Science Research and Innovation (TSRI) and Mahasarakham University, Thailand.

- 1. Y. Shi, A. Neubrand, and D. Koch, Adv. Eng. Mater. 21 (2019) 1800-1806.

-

- 2. M. Samadi, G.F. Huseien, H. Mohammadhosseini, H.S., Lee, N.H Abdul Shukor Lim, M.M. Tahir, and R. Alyousef, J. Clean. Prod. 266 (2020) 1218-1225.

-

- 3. K. Cui, X. Shen, Y. Zhang, H. Wang, H. Mao, and J. Zhu, J. of Mater. Res. and Tech. 25 (2023) 5520-5537.

-

- 4. H.L. Calambas Pugalin and M.P. Albuno, Ceram. Inter. 40 (2014) 5289-5298.

-

- 5. J. Hu, X. Tian, C. Hu, Y. Luo, H. Peng, and J. Luo, J. Ceram. Process. Res. 17[11] (2016) 1181-1187.

-

- 6. K. Matsunaga, A. Nakamura, T. Yamamoto, and Y. Ikuhara, Solid State Ionics 172 (2004) 155-158.

-

- 7. A. Rittidech, L. Portia, and T. Bongkarn, Mater. Sci. and Eng. A 438-440 (2006) 395-398.

-

- 8. A.Z.A. Azhar, H. Mohamad, M.M. Ratnam, and Z.A. Ahmad, J. Alloys Comp. 497 (2010) 316-320.

-

- 9. M. Ruehle, Adv. Mater. 9 (1997) 195-198.

- 10. A.G. Evans, N. Burlingame, M. Drory, and W.M. Kriven, Acta Metallurgica 29 (1981) 447-456.

-

- 11. M.G. Shahri, A. Shafyei, A. Saidi, and K. Abtahi, Ceram. Inter. 40 (2014) 13217-13221.

-

- 12. O. Gorban, S. Synyakina, G. Volkova, S. Gorban, T. Konstanyiova, and S. Lyubchik, J. Sol. Stat. Chem. 232 (2015) 249-255.

-

- 13. A. Akkus and T. Boyraz, J. Ceram. Process. Res. 19[3] (2018) 249-252.

-

- 14. A. Rittidech, S. Wantrong, and S. Chommi, J. Ceram. Process. Res. 22[2] (2021) 1-5.

-

- 15. B. Basu, Int. Mater. Rev. 50 (2005) 239-256.

-

- 16. J. Chevalier, L. Gremillardw, A.V. Virka, and D.R. Clarke, J. Am. Ceram. Soc. 92 (2009) 1901-1920.

-

- 17. J.S. Hong, S.D. De la Torre, K. Miyamoto, and L. Gao, Mater. Lett. 37 (1998) 6-9.

-

- 18. P.G. Rao, M. Iwasa, J. Wu, J. Ye, and Y. Wang, Ceram. Inter. 30 (2004) 923-926.

-

- 19. I.W. Chen and X.H. Wang, Nature 404 (2000) 168-171.

-

- 20. A. Rittidech and N. Suekwamsue, Ceram. Inter. 41 (2015) s123-s126.

-

- 21. C.J. Wang, C.Y. Huang, and Y.C. Wu, Ceram. Int. 35 (2009) 1467-1472.

-

- 22. N.A. Rejab, A.Z.A. Azhar, K.S. Kian, M.M. Ratnam, and Z.A. Ahmad, Mater. Sci. Eng. A 59 (2014) 518-524.

-

- 23. M. Weimin, W. Lei, G. Renguo, S. Xudong, and L. Xikun, Mater. Sci. Eng. A 447 (2008) 100-106.

- 24. J. Zygmuntowicz, J. Tomaszewska, J. Jelen, P. Piotrkiewicz, M. Wachowski, J. Torzewski, and R.Z. Urowski, Chem. Eng. Sci. 263 (2022) 1180-1186.

-

- 25. W.E. Lee and W.M. Rainforth, “Ceramics Microstructure Property Control by Processing” (Chapman & Hall, London, 1994).

- 26. A. Rittidech, R. Somrit, and T. Tunkasiri, Ceramics. Ceram. Int. 39 (2013) s433-s436.

-

This Article

This Article

-

2024; 25(1): 22-27

Published on Feb 29, 2024

- 10.36410/jcpr.2024.25.1.22

- Received on Sep 12, 2023

- Revised on Dec 4, 2023

- Accepted on Dec 5, 2023

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Aurawan Rittidech

-

Department of Physics, Faculty of Science Mahasarakham University, Mahasarakham, Thailand, 44150

Tel : +66-43-754379 Fax: +66-43-754379 - E-mail: aurawan.r@msu.ac.th

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.