- Simulation testing of performance of cement-based high ductility nano-earthquake resistant materials and its application in housing structure

Sicong Du, Zhenhua Fu* and Hongyan Gu

Department of Building Engineering, Hebei Vocational University of Industry and Technology, Shijiazhuang Hebei, 050091, China

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Modernist ideology has been on the rise recently, questioning life’s patterns and treating structures as living organisms that can change over time while being environmentally friendly. Yet, a wide variety of innovative materials have had an impact on the future of science and technology in the building industry. The development of economically innovative nanotechnology also results from cement-based high ductility materials that are earthquake resistant. Although it has been suggested that cement-based high ductility nano-earthquake resistant materials. Thus, the goal of addressing the work is to observe the construction of cement-based high ductility nano-earthquake resistant materials and it influence on the proposal work of house constructions. It uses fundamental concept, a sort of gained research which considers infrastructure effects, usage patterns, to provide a thorough evaluation of cement-based high ductility nano-earthquake resistant materials

Keywords: Nanotechnology, Nano materials, High ductility, Resistant materials, Housing structure.

In concrete science field, innovative cement knowledge are being modified at the nanoscale to produce concrete with novel qualities and a novel appropriate structure cement-based high ductility materials has risen to the top in the past decades despite the fact that there are a lot of other decent types. These materials are drawing attention since they might lengthen the lifespan of concrete and reduce the expense and necessity of managing lengthy building undertakings. The relationship between architecture and nanotechnology is made possible by the latter’s introduction of novel materials [1].

A new interpretation of and need for a more intelligent design of the living aspects is brought. Identifying adaptable homes for housing that may, prior to occupation, adapt to the users’ demands in various design layouts while still being able to accommodate a person and their needs at the time [2, 3]. Additionally, it must to be capable of changing its course in response to emerging technology, demographic shifts, and occasionally even a change in house design. The adaptable dwelling allows the residents to take on tasks both after they move in and even during the design phase.

Moreover, adaptable homes eventually depended on user plan methods. Flexible homes would incur environmental costs if high ductility, Nano-earthquake resistant cement-based materials were used. Modern architecture can be used with carefully chosen materials to promote comfort and efficiency while also minimising the life cycle’s negative environmental effects. The issue that this article attempts to solve is how to lessen costs and the impact of utilising this material in the construction of flexible homes, which is a concept of green design, while improving the current issues with cement-based high ductility nano-earthquake resistant materials.

In a nutshell, how to lessen the difficulties associated with using cement-based materials that are nano-earthquake resistant of building while incorporating design.In order to achieve this, We effort to protect the decreased complications of using the products for homes using grounded theory, and finally, we measure a relationship between two variables using a correlational research design [4].

Objective

Environmental expenses would be involved with the usage of cement-based, highly ductile, nano-earthquake resistant compounds in concrete. Thorough research, the collection of resources and by what means to mix with present manner can substantially increase wellbeing and efficiency, as well as greatly minimise the environmental impact of the life cycle.

Research Question

How to lessen the difficulties associated with employing cement-based high ductility nano-earthquake resistant materials concrete in conventional building while including green design.

Research Methods

Beginning with the description method, a qualitative methodology, which will be used to explain cement-based high ductility materials and describe its qualities, conservation effects, sustainability, and methods of use, grounded theory will then be used to defend the material’s reduced challenge, and finally, by using causal comparison.

Nano Cement materials

The parts, stage, and scale of concrete are just a few of its many characteristics. Water, numerous additional mineral additives, and various mixes are examples of ingredients. These substances can vary in size, quantity, and other factors depending on the projects and circumstances [5, 6].

The materials in Nano concrete degrade from Nano to micro to macro in a method that every ingredient gains qualities from lesser gauge size. The diverse scales of the micro and Nano metre scale crystals combine and attach by water.

Cement-based high ductility nano-earthquake resistant materials

Buildings, structures, and building materials must be ductile in order to be designed to withstand earthquakes. There is discussion of ductility and its significance in design. Knowing what ductility is crucial to comprehending the significance of ductility in affecting building performance. The general definition of ductility in the field of material engineering research. In a broader sense, we must consider ductility as a structure’s capacity to withstand greater deformations without collapsing. According to specific guidelines outlined in regulations, ductility detailing—also known as ductile detailing—is the process of giving a structure additional ductility beyond that provided by the ductility of its constituent parts. Dynamic forces, which are regarded as seismic demands, cause a structure to become less elastic, which leads to deterioration in the following stage [7]. It may experience a plastic stage, fracture, or damage when stiffness noticeably declines and deformations sharply rise even under light loads. An engineer must be prepared for these scenarios, and we must make sure that our design can withstand these loads without experiencing more significant deformations or collapsing. We need to incorporate or improve the building’s ductility in order to meet this goal.

Throughout the past 40 years, concrete has also been employed extensively in construction. The makeup, as we are known about is cement, aggregates, and water. Here, different sizes of aggregates—both fine and coarse—are combined with the right amount of water. Yet, cement is once more strong in compression and fragile in tension. Compared to masonry, concrete has a higher compressive strength, but is weaker when subjected to stress. Even though the water proportions determine the cement strength, high or low water levels would have an impact on the cement mortar and strength [8]. Therefore undesirable for sustainable and ecologically friendly development, and a steady decrease in their use is required. Several researchers have looked on substitutes for cement and steel, however none of these materials can totally replace cement and steel.Only partially supplement cement, and adding ductility to concrete can only partially minimise the usage of steel [9].

In this world of concrete, the cement-based high ductility nano-earthquake resistant materialsconcrete has garnered attention among many other cutting-edge innovations. The ability of concrete mixes to develop strength through a process called carbonation is another advantageous feature. Water with carbon dioxide in it may react with anhydrite cement particles, causing secondary hydration.

Pros & Cons of cement-based high ductility nano-earthquake resistant materials

Pros

The major advantage of cement based high ductility nano earthquake resistant material is that it has an estimated 200-year lifespan but might continue for decades or even centuries. So, it may be stated that by replacing such materials in historic buildings, its sustainability can be improved and these national values can be further safeguarded.

On a typical surface, it’s crucial to fill and seal cracks to stop them from enlarging. It must not be disregarded or taken for granted, freeing up time for other activities [10, 11].

Cons

It is expensive. However, replacing those new materials with older ones will be more expensive and time-consuming. The fact that not many contractors are familiar with using self-healing concrete is its second drawback. It is still relatively new, and not all businesses utilise it that way, nor are all contractors required to. It can be challenging to find a builder in your area who is experienced and employs this material [12].

Sustainability in Nanotechnology

Sustainability has emerged as one of the most important challenges in today’s world, and architecture is no exception. Improving human health and safeguarding the environment are two of sustainability’s key objectives. [13]. Due to its unique and beneficial behaviours that can lessen or even eliminate the difficulties now present in the construction industry, as well as their potential to alter how projects are managed and demand, nanotechnology has received a lot of attention.

Presence of cement-based high ductility nano-earthquake resistant materials

Individuals frequently alter the design of their homes as a response to numerous inevitable circumstances, including self-identification, way of life, advancements in technology, As a result, it goes without saying that housing needs to be adaptable in order to handle change. Flexibility is stated to treat the rigidity of the structure, extending its lifespan and maximising its use of resources and embodied energy. Early in the 20th century, structures initially appeared in canada due to the severe housing crisis that followed World War Following years of study and development, many academics now claim that flexibility has a significant impact on building materials and designs [14].

The function of a building and its lifespan are largely determined by its size and shape. In this regard, small-scale structures used for residential purposes are typically located in suburban and outlying areas of cities, and concrete is a common building material. However, due to the size of residential structures, concrete is primarily used.It should go without saying that architects should alter and enhance their design standards and tactics in order to extend the lifespan of constructions [15]. Also, the building should continue to work quite well in the new setting as the suburb develops in the future, thus the design should be adaptable enough to take these changes into account.

Performance

Nano silica and grapheme oxide

When nanosilica is added to cement, the higher compressive and flexural strengths are caused by the increased amount. The greatest mechanical performance of concrete with 5 weight percent nanosilica showed compressive, tensile, and flexural strengths that were 1.8, 2.4, and 1.8 times higher after 30 days, respectively, than control specimens. The flaws produced by insufficient dispersion are the main reason why mechanical characteristics start to decline at 7 weight percent addition of nanosilica compared to the ideal dosage of 4 weight percent. The quantity of nanosilica is greater than what is necessary to mix with Liberated CH leaks out to partially replenish the cement. The compressive strength is also greatly influenced by the size of the filler. Agglomerated nanosilica (25-35 nm) performed half as well as smaller nanosilica (10-15 nm).Comparing the utilisation of finer nanosilica to that of agglomerated nanosilica, more filler and fewer weak zones are provided.

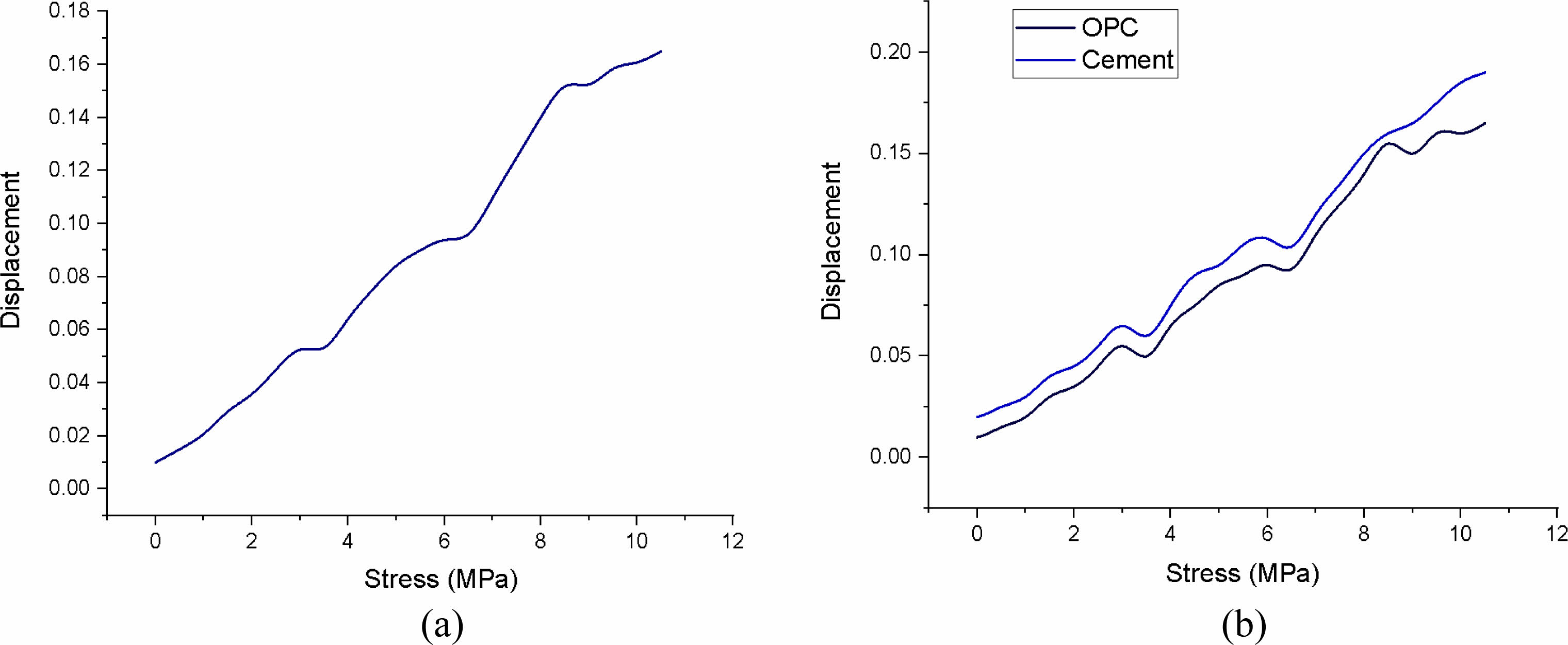

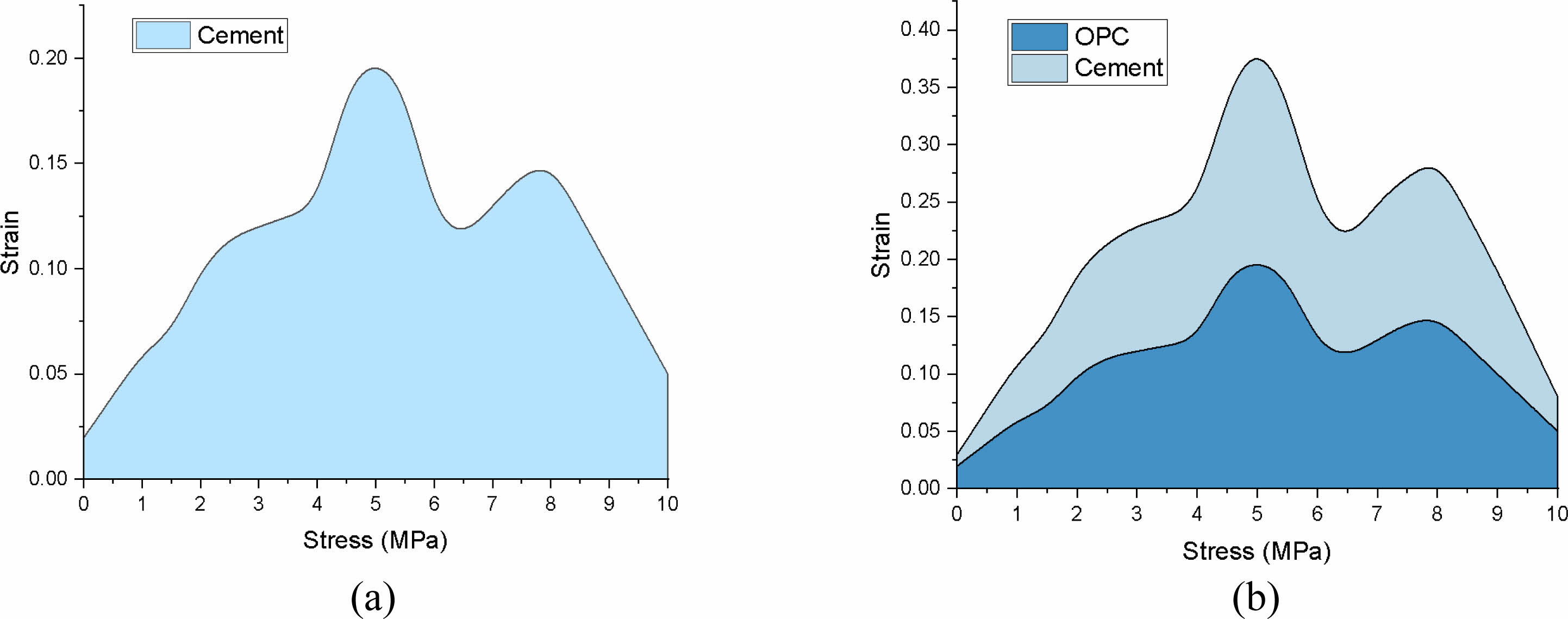

According to preliminary analyses of displays ductile behaviour. GO’s functional groups’ interfacial adhesion is analogous to that of functionalized CNTs [16]. GO is a promising material to improve the cement matrix because of the strong covalent interaction between the hydration products deposited on the sheet and the GO interface. According to the stress-strain curve in Fig. 2, the elastic modulus has somewhat increased to 3.7 MPa from 3.48 MPa as shown below. The delayed microcrack initiation can be used to explain the improved strain capacity. Further research on the impact of 0.03 weight percent of GO showed that the compressive strength rose by 46.2% along with the failure stress and strain [17]. When compared to cement with CNT reinforcement, GO exhibits a superior increase in compressive strength at a lower concentration. The gain can be attributed to GO’s excellent reinforcement. Fig. 1(a, b) represents the cement in stress versus displacement and cement is better in displacement compare OPC

|

Fig. 1 Cement in Stress Vs. Displacement & Cement is better in displacement compare to OPC |

|

Fig. 2 Stress-strain curve of Cement & Stress-strain curve of OPC and cement. |

The durability of the building would be increased by eliminating the need for material repairs or replacements thanks to the use of self-healing concrete, which has a 25% efficiency rate for repairing cracks and damage to the original strength [18, 19].

According to the studies, self-healing concrete with the capacity to repair cracks will boost this durability by 25% while still providing 80% of the needs of occupants in modern buildings. These materials will thus sustain all of the spaces and structures of the building in addition to offering a secure environment for users to dwell in. Even though every effort made during construction fully satisfies the requirements of every layer, the presence of self-healing concrete will increase the building’s longevity by doubling all other efforts [20-23].

The distribution of resources, the application of crucial building design criteria, particularly in developing nations, and the ideology of modernism today have altered the way that life is designed and brought it closer to the building technology and industry, architects have turned to flexible design to address this new outlook and the changes required. For instance, homes that, over time, are receptive to all users and their needs. This kind of design adds additional dimensions to building design (especially support), thus opening up the possibility of changing the demand axis arrangement at a low cost.

But, without the connection between architecture, technology, and materials, this would not be possible. The creation of concrete composites based on the enhancement of the mechanical characteristics of concrete is a result of the tremendous potential of nanotechnology to enhance the performance of construction materials, particularly concrete, which has the largest consumption. One of the most astounding Nanoproducts in concrete is self-healing concrete, which exhibits many desirable qualities including low pollution, affordable pricing, environmental friendliness, and good durability performance in challenging conditions.

Hence, the incorporation of flexible design and cement-based high ductility nano-earthquake resistant materials can significantly improve human life by reducing the need to utilise the environment for building materials, repairing them, or replacing them through the use of high-strength and durable cement composites. This involves reducing the amount of energy and labour used during construction, which prevents environmental pollution. On the other hand, because of these materials’ strong mechanical strength, structures will last longer, which influences architects’ sensitivity to more principled design and precisely designed architectural spaces based on various human demands.

- 1. C. Manivel and L.Savadamuthu, Dg. J. Nanomater. Biostructures 15[3] (2020) 787-798.

-

- 2. M. Ceylan and I. Topcu, J. Ceram. Process. Res. 21[5] (2020) 539-546.

-

- 3. M. Mia, M.K. Gupta, J.A. Lozano, D. Carou, D.Y. Pimenov, G. Krolczyk, A.M. Khan, and N.R. Dhar, J Cleaner Prod. 210 (2019) 121-133.

-

- 4. S. Pradhan, S. Singh, C. Prakash, G. Królczyk, A. Pramanik, and C.I. Pruncu, J. Mater. Res. Technol. 8[5] (2019) 4849-4862.

-

- 5. M.A. Sofuoglu, Sadhana J. 46[2] (2021) 1-9.

-

- 6. V. Singh, A.K. Sharma, R.K. Sahu, and J.K. Katiyar, J. Manuf. Process. 62 (2021) 378-387.

-

- 7. A. Thakur, A. Manna, and S. Samir, Silicon 12[1] (2020) 71-85.

-

- 8. M. Shahid, R.A. Malik, H. Alrobeib, J. Kimc, M. Latif, A. Hussain, M.U. Iqbal, and A. Hafiz, J. Ceram. Process. Res. 22[2] (2021) 149-157.

-

- 9. T. Nithyanandhan, and R. Ramamoor, J. Ceram. Process. Res. 22[4] (2021) 369-376.

-

- 10. R.K. Singh, A.K. Sharma, A.R. Dixit, A.K. Tiwari, A. Pramanik, and A.Mandal, J. Clean. Prod. 162 (2017) 830-845.

-

- 11. D. Setti, M.K. Sinha, S. Ghosh, and P.V. Rao, Int. J. Machine Tools and Manuf. 88 (2015) 237-248.

-

- 12. M.K. Sinha, R. Madarkar, S. Ghosh, and P.V Rao, J. Clean. Prod. 141 (2017) 1359-1375.

-

- 13. B. Li, C. Li, Y. Zhang, Y. Wang, D. Jia, M. Yang, N. Zhang, Q. Wu, Z. Han, and K. Sun, J. Clean. Prod. 154 (2017) 1-11.

-

- 14. M.A.H.M. Shariff, Y.A. Rahim, A.N.M. Khalil, A.M. Ali, A.I. Azmi, and H.M. Salleh, In Intelligent Manufacturing and Mechatronics 18 (2021) 365-372.

-

- 15. Y. Touggui, A. Uysal, U. Emiroglu, S. Belhadi, and M. Temmar, Int. J. Adv. Manuf. Technol. 115 (2021) 3983-3997.

-

- 16. R. Anand, A. Raina, M. Irfan Ul Haq, M.J. Mir, O. Gulzar, and M.F Wani, Tribology Transactions 64[2] (2021) 350-366.

-

- 17. D.R. Joshua and A. Jegan, J. Ceram. Process. Res. 23[1] (2022) 69-78.

-

- 18. C. Chanakyan and S. Sivasankar, J. Ceram. Process. Res. 21[6] (2020) 647-655.

-

- 19. N. Zeelanbasha, V. Senthil, and G. Mahesh, Int. J. Operat. Res. 38[2] (2020) 221-254.

-

- 20. Z. Zeelanbasha, V. Senthil, and B.R. Senthil Kumar, Transactions of FAMENA 42[3] (2018) 115-128.

-

- 21. N. Li, Y.J. Chen, and D.D. Kong, Adv. Manuf. 7[2] (2019) 142-154.

-

- 22. M. Linus, N. Schaal, and K.Wegener, Procedia Cirp 58 (2017) 163-168.

-

- 23. K.M. Senthilkumar, A. Sivakumar, R.M. Shivaji, S.K. Tamang, and M. Giriraj Journal of Ceramic Processing Research 23[2] (2022) 233-236.

-

This Article

This Article

-

2023; 24(6): 921-925

Published on Dec 31, 2023

- 10.36410/jcpr.2023.24.6.921

- Received on Apr 9, 2023

- Revised on Aug 20, 2023

- Accepted on Aug 26, 2023

Services

Services

Shared

Correspondence to

Correspondence to

- Sicong Du, Zhenhua Fu

-

Department of Building Engineering, Hebei Vocational University of Industry and Technology, Shijiazhuang Hebei, 050091, China

Tel : 0311-85239777 Fax: 0311-85239777 - E-mail: ZhenhuaFu6@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.