- Optimization of fiber length and filler content for improving the mechanical behaviour of musa acuminate fiber-reinforced epoxy composite using response surface methodology

S. Sathiyamurthya, S. Saravanakumara,*, N. Ananthib and P. Devic

aDepartment of Automobile Engineering, Easwari Engineering College, Chennai-89

bDepartment of Information Technology, Easwari Engineering College, Chennai-89

cB.S. Abdur Rahman Crescent Institute of Science & Technology, ChennaiThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

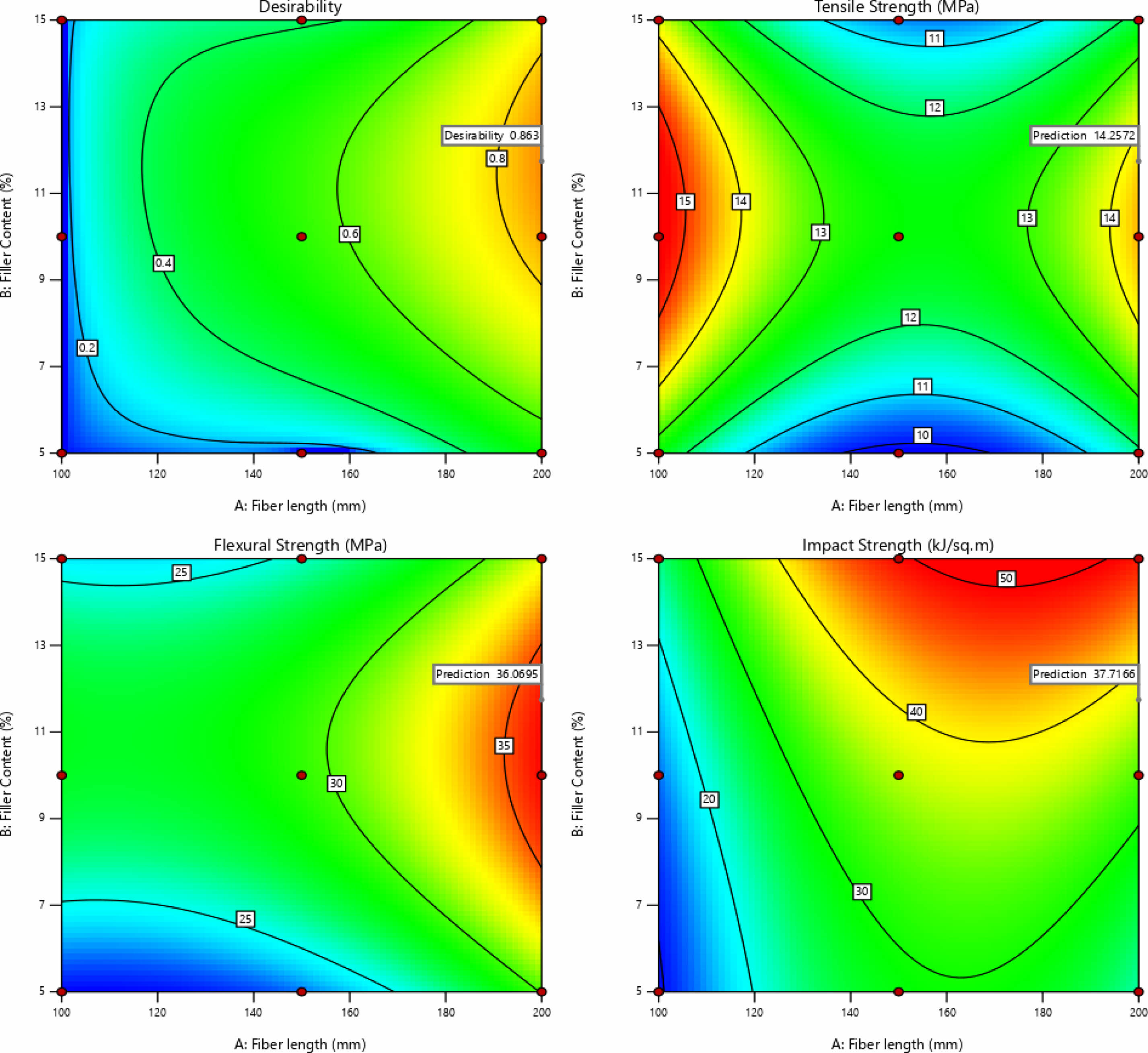

In recent years, it is crucial to describe and enhance the natural fiber’s strength qualities as well as look for new opportunities to use them in composite materials. The technical characteristics of a novel series of Al2O3 and Boiled eggshell fillers added polymer composite using Banana fiber as a strengthening material in an Epoxy polymer matrix have been studied in this current experiment. Composites were created and evaluated for varying fiber lengths (100, 150, and 200 mm) and weight percentages of fillers (5, 10, and 15%). 9 samples were prepared and the tensile (TES), flexural (FLS), and impact strength (IMS) of the composites were measured. The numerical formulas were developed for the tensile strength, flexural strength, and impact strength with the investigated process factors using the Design Expert 13 statistical software output coefficients. Optimization was carried out using response surface methodology and the ultimate ideal parameters for maximum tensile strength, impact strength, and flexural strength were discovered as a fiber length of 200 mm and filler content of 11.74%. Final optimum values were found the tensile strength of 14.25 MPa, the impact strength of 37.71 kJm-2, and the flexural strength of 36.069 MPa. It is observed that the impact of Al2O3 and boiled eggshell filling materials in the improvement of mechanical properties are very enormous

Keywords: Banana fiber, Al2O3, Boiled eggshell, Mechanical characteristics, Response surface methodology

The superior tensile strength and low carbon imprint on the environment [1, 2] are the main reason natural fiber composites participate in prominent functions in a variety of applications [3]. To address some specific demands, there is an increasing demand for novel composite materials with improved characteristics [4, 5]. Furthermore, when epoxy resins go through the solidification process, they become brittle [6]. Brittleness is an indication of a serious problem that may be mitigated by using a filler or natural fiber reinforcement [7]. Furthermore, these constant polymer laminates with fiber reinforced have various disadvantages, such as delamination, which may be avoided by using fillers instead of long fibers [8, 9].

Mohamad Zaki Hassan et al. [10] conducted a study on the tensile behavior of banana fiber-reinforced epoxy composites, investigating the effects of varying fiber length and fiber content. The researchers found that the composites were highly dependent on the span of fibers, percentage of fiber loading, and surface modification. The researchers identified the optimal parameters for maximizing the technical characteristics of the composite as a fiber span of 3.25 mm and a fiber content of 29% by weight. KR Sumesh et al. [11], examine the weight percentage of banana and coir fiber influencing the mechanical characteristics using the Taguchi design method and concluded that 15% banana and 10% coir, and 8% NaOH treatment have maximum tensile strength. Hossain, Md Sahadat et al. [12] focused on characterizing banana fiber polyester composites and discovered that incorporating banana fiber can lead to reduced costs while improving the technical properties of the composites. A Stalin et al. [13], examine the strength of vetiver/banana fiber-strengthening vinyl ester polymer composites and determined that composites with a fiber orientation of 90 degrees exhibited the uppermost flexural strength compared to other orientations. Ibrahim Iliyasu et al. [14], Using the Central Composite Design (CCD) as the foundation, the researchers used Response Surface Methodology (RSM) to perform a study to examine the physical and mechanical behavior of composites. They focused on examining the impacts of variations in fiber weight composition (between 30 and 35% by weight) and fiber length (between 1 and 5 mm) on a number of properties, including tensile strength, flexural strength, impact strength, water absorption behavior, and others. According to the study's findings, the optimal Epoxy-Deleb fiber composite comprised fibers with a length of 3 mm and a fiber weight composition of 38.3%. This composite had excellent properties such as a high tensile modulus, tensile strength, flexural strength, impact energy, and little water absorption. These findings imply that the particular blend of fiber weight composition and length had a substantial impact on the composite material's general characteristics. Adeniyi, A.G. et al. [15] discuss the finite element analysis (FEA) of the effective elastic properties of banana fiber-reinforced polystyrene composites. It compares the numerical results obtained from FEA with existing analytical models and evaluates properties such as longitudinal modulus, transverse modulus, in-plane Poisson ratio, and in-plane shear modulus. The study finds that the elastic properties increase with increasing fiber volume fraction and that the FEA results are in good agreement with the analytical models. Muralikrishna, M.V.V, et al. [16] focuses on the development of mechanical properties in banana fiber composites. The study investigates the reinforcement of polymer plastics with different proportions of banana and glass fiber composites. The results show that the glass/banana composition has better mechanical properties. The study also found that the fracture toughness of the composites increases with an increase in the volume fraction of banana fibers.

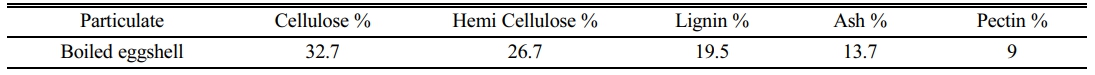

Following a thorough study of the available literature, it was discovered that a number of studies had been carried out to investigate the effects of fiber length on the mechanical properties of natural fiber polymer composites. The combined effects of fiber length and filler content on the mechanical behavior of natural fibers have not yet been investigated in a single study, nevertheless. The goal of this study is to ascertain how the mechanical properties of epoxy composites reinforced with banana fibers are affected by the length of the fiber and the amount of filler. The utilization of banana fibers in composite manufacturing offers a compelling combination of sustainability, mechanical strength, lightweight properties, and versatility, making them an attractive choice for developing high-value composite products banana fibers are considered emerging materials for composite manufacturing due to their high conversion rate from agro-waste to valuable products [17-20]. One of the key advantages of banana fibers is their widespread availability throughout the year and across various regions worldwide [21, 22]. This characteristic enhances their economic value and makes them highly desirable for composite production [23, 24]. Boiled eggshells are utilized as fillers in this study because it offers benefits such as waste utilization to reduce its environmental impact and promote sustainability, cost-effectiveness due to large quantities of egg production worldwide, enhanced mechanical properties due to high calcium carbonate content, lightweight nature, biodegradability, thermal insulation, and improved flame retardancy [25-27].

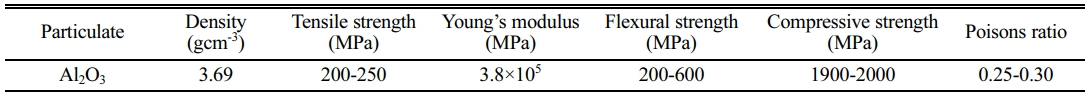

Particle fillers have the ability to significantly improve the performance of polymers and their composites [28] in a variety of structural and industrial applications. This most recent development has received a lot of interest in the industry [29]. Aluminum oxide (Al2O3), also known as alumina, is a widely used and economically feasible material in engineering ceramics. It can serve as a filler in different polymer matrices [30, 31]. Due to its low cost and ease of availability, Al2O3 is one of the most widely used ballistic ceramics [32]. Even against tungsten core bullets, it has outstanding ballistic efficiency, and it can successfully withstand small-caliber mild steel ammunition [33-36]. It can be found easily in purities ranging from 90% to 100%.

This research proposal aims to investigate and determine the optimal process parameters, namely fiber length and filler weight percentage, to enhance the material characteristics of banana fiber-polymer composites. The proposed fillers for the composites include Aluminum oxide and boiled eggshell [37, 38]. The best input parameters to enhance material characteristics of Al2O3/Eggshell filler added banana fiber composites were identified using the optimization technique of Response surface methodology (RSM) [39-42]. The two key criteria employed to optimize the mechanical strengths of epoxy-based composites were fiber length and filler wt% during the hand lay-up process.

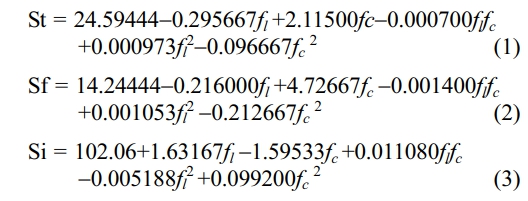

Banana fibers are recovered using fiber extractor equipment from agricultural sources. A cleaned part of the banana stem is placed on the machine's fixed platform, and the ends are secured with jaws to prevent movement or the fibers from being broken too soon (Fig. 1a). The fibers are then cleaned and dried outdoors after being removed. Following the same process as with any other material, the fibers can be woven using looms once they have been collected (Fig. 1b).

The recovered banana fibers were dressed and rinsed with clean, running water to get rid of the dirt, and they were then dried under UV light for 72 hours to get rid of any remaining moisture. Small sections of the banana fibers - 100 mm, 150 mm, and 200 mm were cut off.

Typically, polymers serve as effective reinforcing binders and load transfer agents for the entire laminate system. For the matrix, the unsaturated epoxy resin was chosen due to its accessibility, affordability, and high compatibility. Cobalt octoate was utilized as an accelerator and MEKP (Methyl Ethyl Ketone Peroxide) as a catalyst throughout the entire process.

Aluminum oxide (Al2O3) and boiled eggshells are used as fillers. Chennai, Tamil Nadu-based Go Green Products acquired aluminum oxide. The farmers gathered the boiled eggshells. When fillers are added to composites, many benefits become apparent, including void avoidance, abrasion resistance, heat resistance, stability, viscosity, and fabrication mobility.

Table 1 represents the mechanical properties of alumina particulate and the chemical composition of an eggshell is presented in Table 2.

Composite Fabrication

The manufacturing process of aluminum oxide and boiled eggshell-impregnated banana fiber-epoxy composites involved a simple hand lay-up method. Prior to the fabrication process, the surfaces of the mold were coated with a releasing agent made of polyvinyl acetate. This releasing agent helps prevent the composite materials from sticking to the mold surfaces, facilitating the demolding process. The resin was combined with the powdered Al2O3 and boiled eggshell in proportions of 5 to 10 percent. The resin coating was put on top of the releasing agent by brush. The resin coating was covered with randomly oriented banana fibers, which were then compressed firmly (at 1000 N) for one hour.

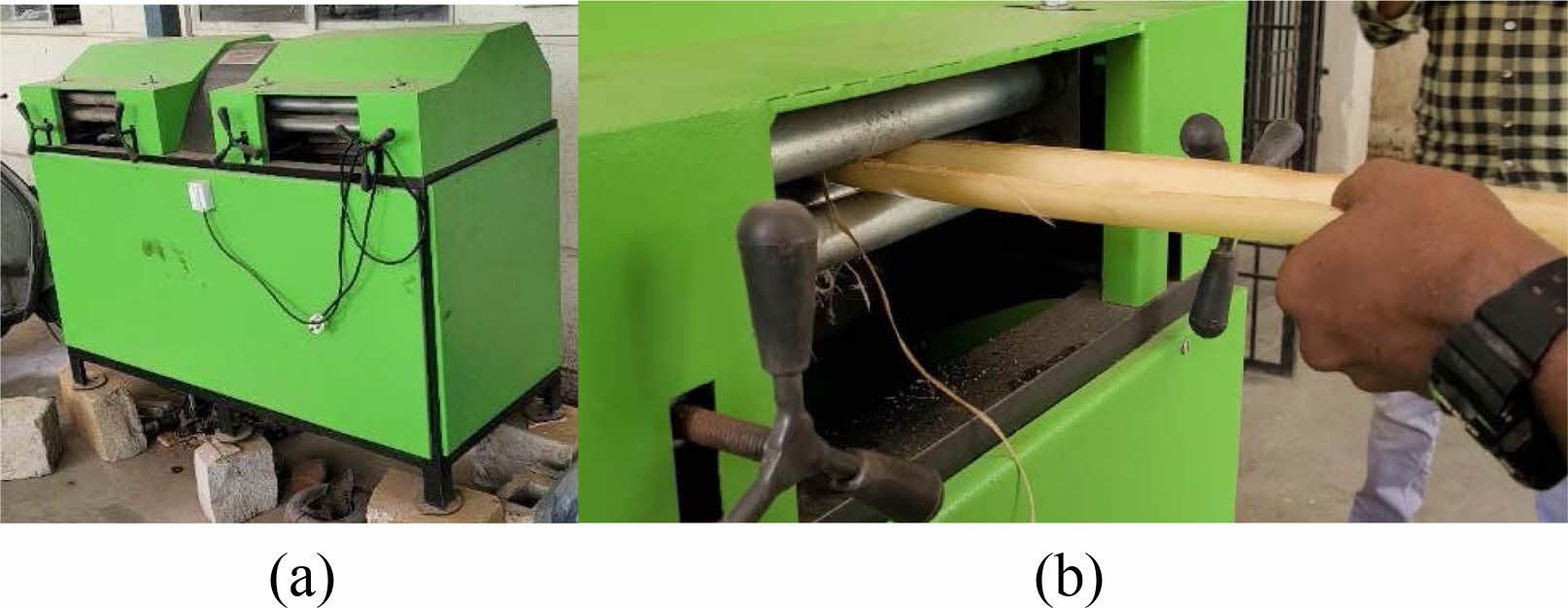

The composite was separated from the mould surface after one hour and then kept at ambient temperature (29 °C) for curing purposes. The whole factorial design matrix was utilized to construct many types of Epoxy composites using the same procedure. Fig. 2 displays a snapshot of a few of the manufactured composites. The composite plates were made to be 3 mm thick, and airlock inclusions during the hand lay-up process were prevented by evenly putting weight on the composite's surface after the resin mixture had flowed freely. The fiber content is 30% and the matrix content is 70% in weight based taken for the fabrication of the composite.

Testing

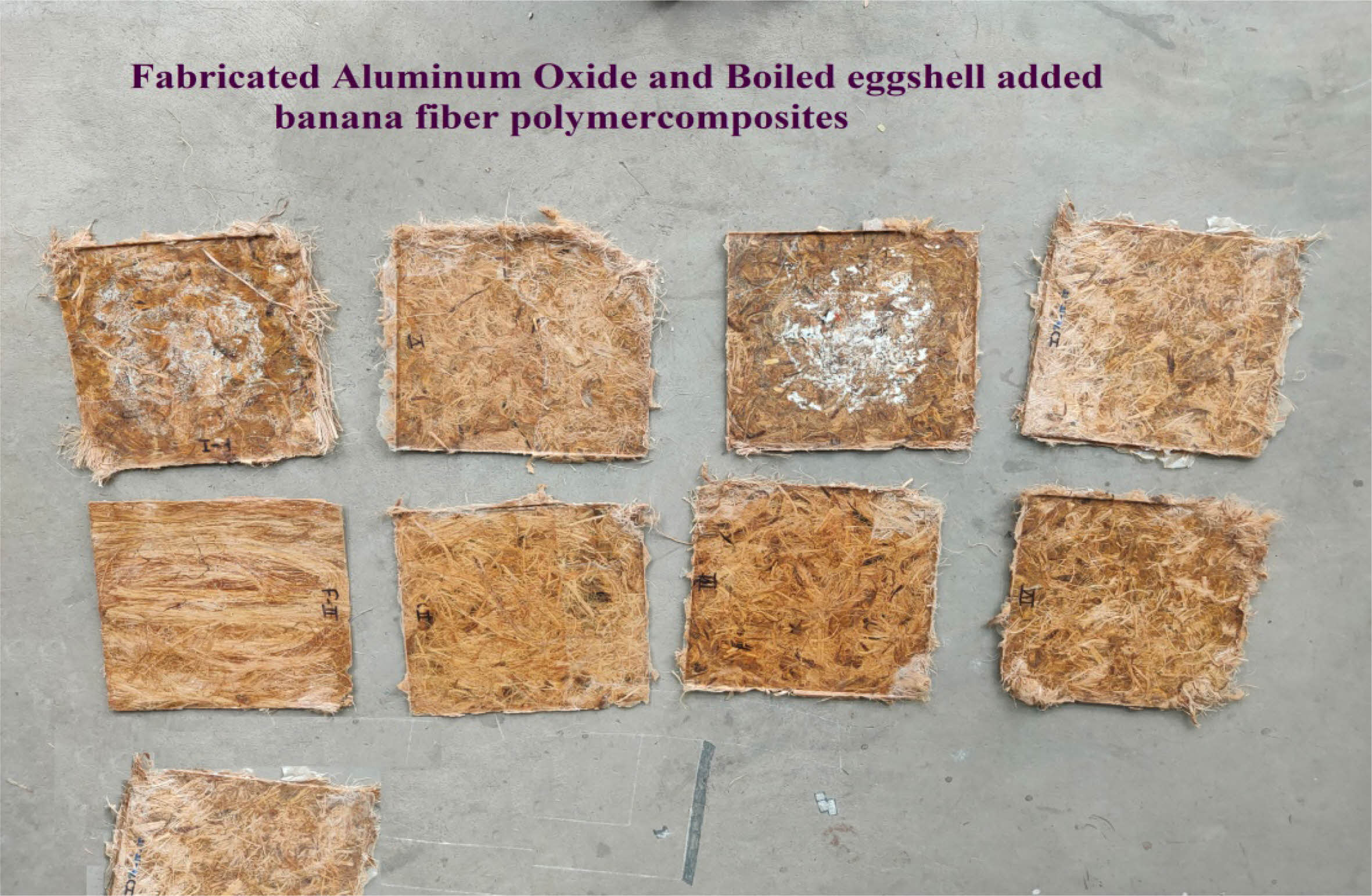

Using a UNITEK type universal testing apparatus, the tensile stability of composite materials with Al2O3, boiled eggshell, and banana fiber added to epoxy was evaluated. The acceptable dimensions of the specimens, which were created in accordance with ASTM standard D638-10, were 165×25×3. Each composition's three identical samples were tested, and the average result was noted. A gauge length of 100 mm and a constant cross-head speed of 5 mm/min were kept throughout the testing process. Testing four identical specimens yielded the average tensile strength value (Fig. 3a).

The produced composites were cut into rectangular test pieces measuring 127 mm×12.7 mm×3 mm for the bending test. The specimen has been built as a beam, and the weight was put at the center. The three-point bending test was performed by ASTM D790-07 using an Instron machine (Model: 3382) with a 10 kN load cell at 2.8 mm per min rate loading. The average flexural strength of composites was determined by testing four identical specimens. Fig. 3b depicts a photographic representation of the cracked lines formed during the bending test.

The impact strength test was conducted by ASTM D256- 06 requirements employing a Tinius Olsen impact tester. The manufactured composite was cut into specimens with approximate lengths, widths, and thicknesses of 65, 65, and 3mm, respectively. A single swing of a pendulum shattered the sample specimen, which was fixed at the bottom. The pendulum hits the face of each four samples and the average amount of absorbed energy taken. Fig. 4 depicts a photographic view of impact test specimens following a fracture. The tests were conducted at the Central Institute of Plastic Engineering and Technology, Guindy, Chennai, Tamilnadu, India.

Design of Experiments

A thoughtfully designed experiment may provide valuable information regarding the effects of one or more variables on a response variable. To establish diverse circumstances of mechanical properties along the range, the input parameters fiber length (L) and filler weight percentage (wt%) were combined in this experiment.

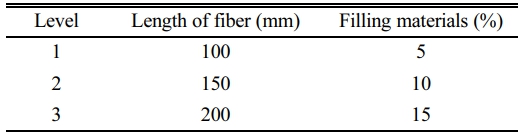

Table 3 lists the fiber parameters and their levels. Following a full factorial design in which each parameter had three levels and two parameters, 9 composites were created.

The results of each test for 9 composites are listed in the below Table 4.

Mathematical analysis of mechanical properties

The Design Expert 13 statistical software output coefficients were used to generate the numerical formulas for the tensile, flexural, and impact strength using the examined process parameters. The statistical significance of the models and the proximity of corrected and expected R2 values are taken into consideration while selecting the quadratic models for tensile strength, flexural strength, and impact strength.

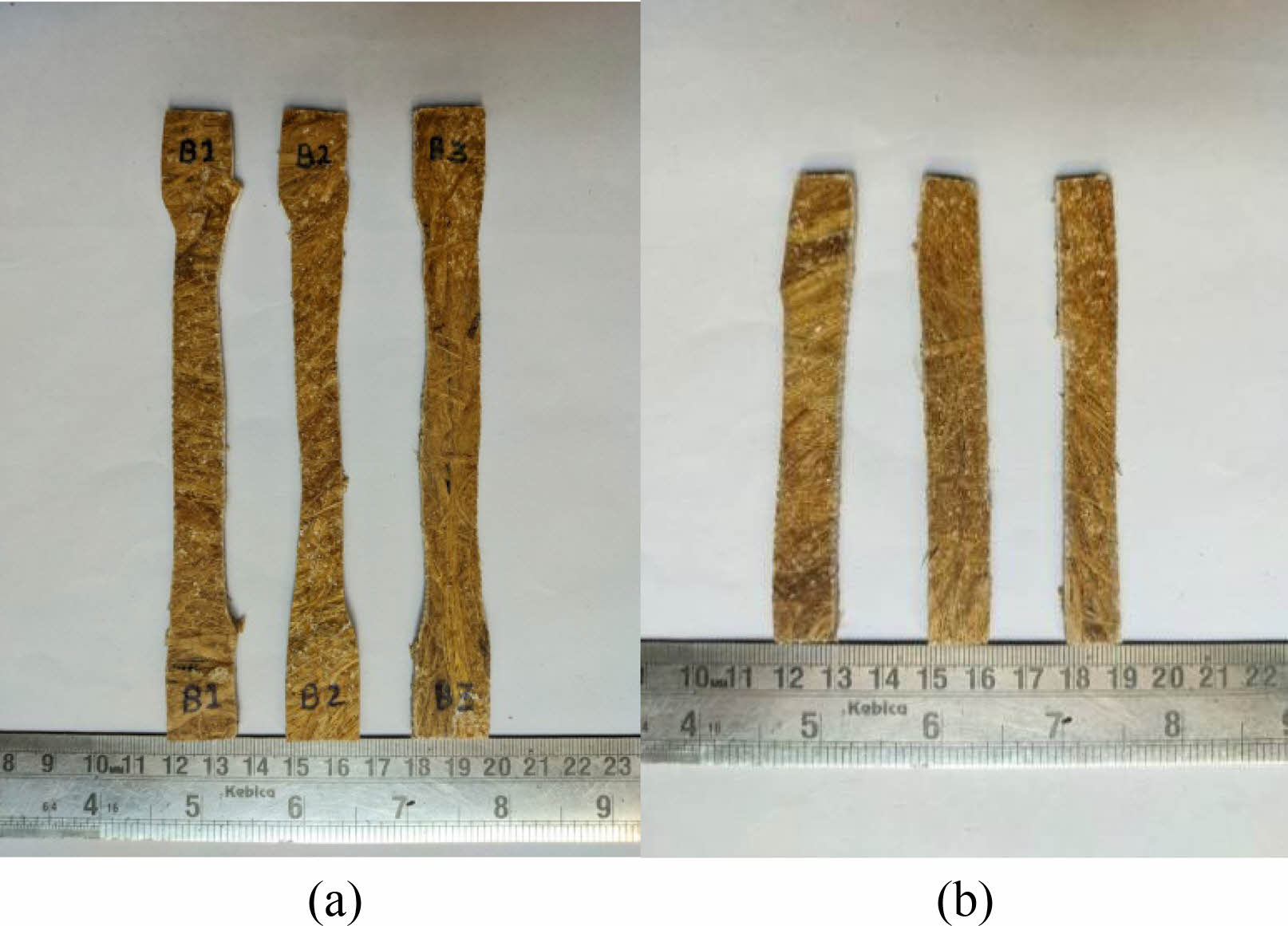

Equations (1), (2), and (3) show the regression equations for the tensile strength (St), flexural strength (Sf), and impact strength (Si) in Al2O3 and boiling eggshell powder added banana fiber reinforced epoxy composites. How well the model is predicted to predict future outcomes is determined by the coefficient of correlation (R2).

Where fiber length is fl and filling materials contribution percentage is fc.

The term fl represents fiber length whereas fc represents filler content in weight percentage.

ANOVA for mechanical properties

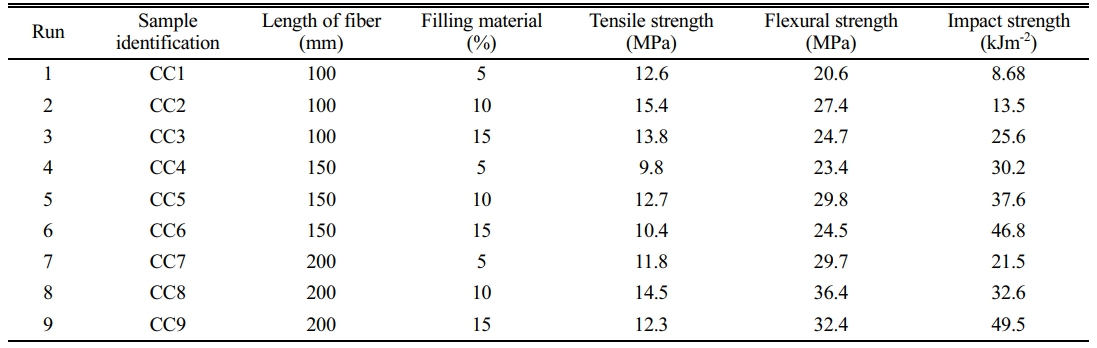

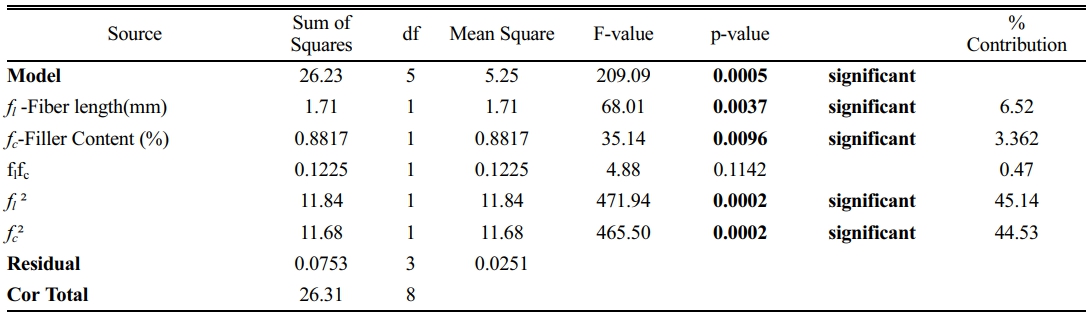

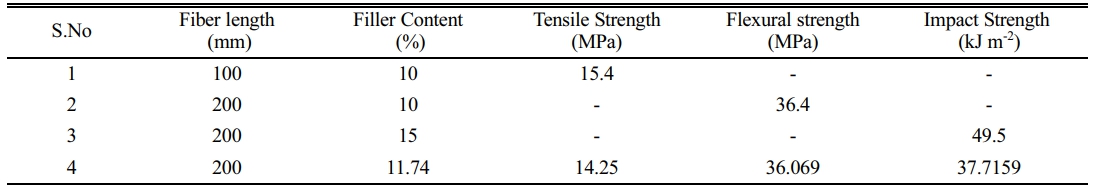

The results of the tensile strength ANOVA are summarized in Table 5. The obtained F-value of 209.09 suggests that the model is statistically significant. A probability value below 0.05 is considered significant, indicating that the variables fl, fc, fl2, and fc2 have a significant impact on the model.

It was observed that the fiber length (fl), and filler content (fc) affect the tensile strength with a contribution of 6.52% for fiber length (fl) and 3.362% for filler content (fc). Also, it is noticed that fl2& fc2occupy a major role in maximizing the tensile strength.

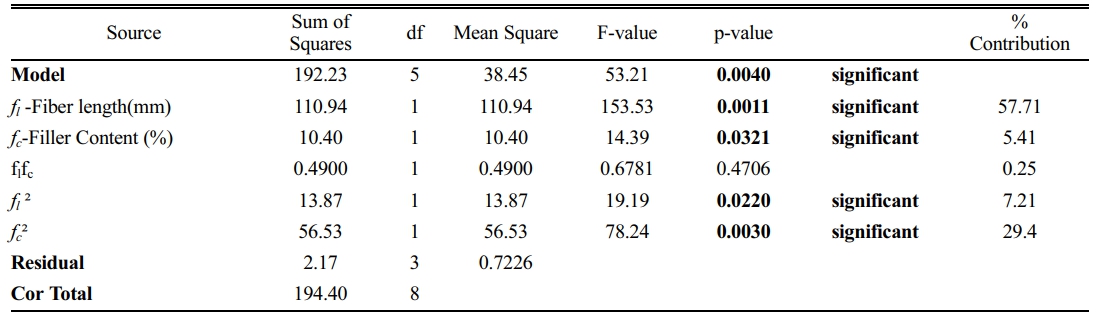

Based on the results from Table 6, the flexural strength model is deemed significant, as indicated by the high F-value of 53.21. In this case, the variables fl (fiber length), fc (fiber content), fl2 (squared fiber length), and fc2 (squared fiber content) are identified as important factors affecting flexural strength. Conversely, the model terms with p-values larger than 0.1000 are considered insignificant. Furthermore, the interaction between fl and fc is found to be insignificant concerning flexural strength. It is noteworthy that fiber length (fl) has a predominant influence on flexural strength, contributing approximately 57.71% to the variation observed. Additionally, the variable fc2 (squared fiber content) plays a significant role in maximizing flexural strength. These findings highlight the importance of fiber length and squared fiber content in determining the flexural strength of the composite material under investigation.

From Table 7, the impact model is significant because of the F-value of 64.97. In this scenario, the model variables fl, fc, & fl 2 are significant model terms. If a signal-to-noise ratio is larger than 4 then the model is significant. In this situation, a signal-to-noise ratio of 22.583. This paradigm is useful for navigating the design space. It was observed that the fiber length ( fl ) and filler content ( fc) predominantly affect the impact strength with a contribution of 33.95% of fiber length and 41.24% of filler content. Also, it is noticed that filler content plays a major role in maximizing impact strength.

|

Fig. 1 (a) Banana fiber extraction machine. (b) Banana fiber being extracted. |

|

Fig. 2 Fabricated composites |

|

Fig. 3 Test specimens after fracture, (a) Tensile, (b) Flexural strength. |

|

Fig. 4 Impact test specimens after fracture. |

Analysis of Variance of fiber parameters

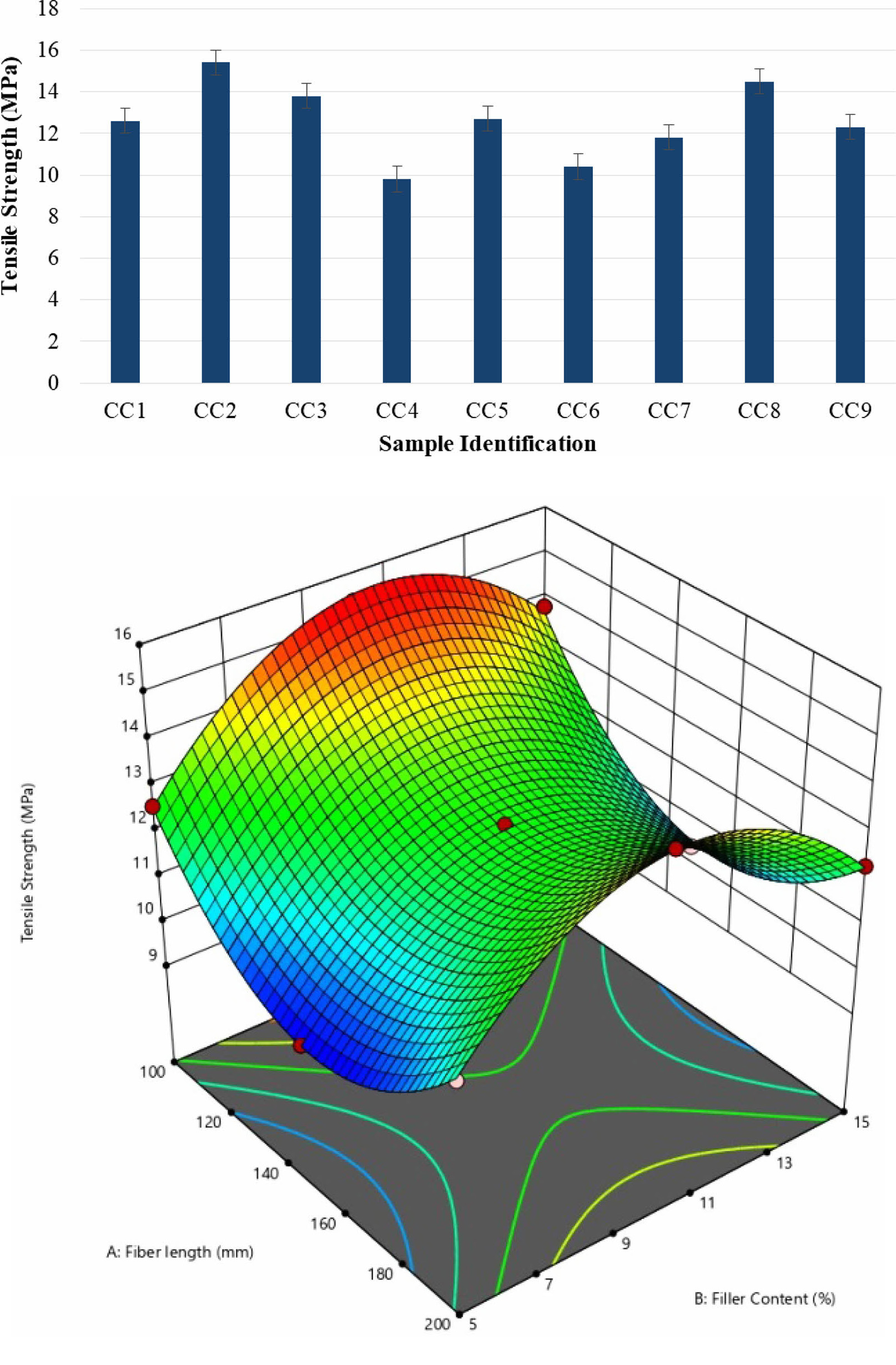

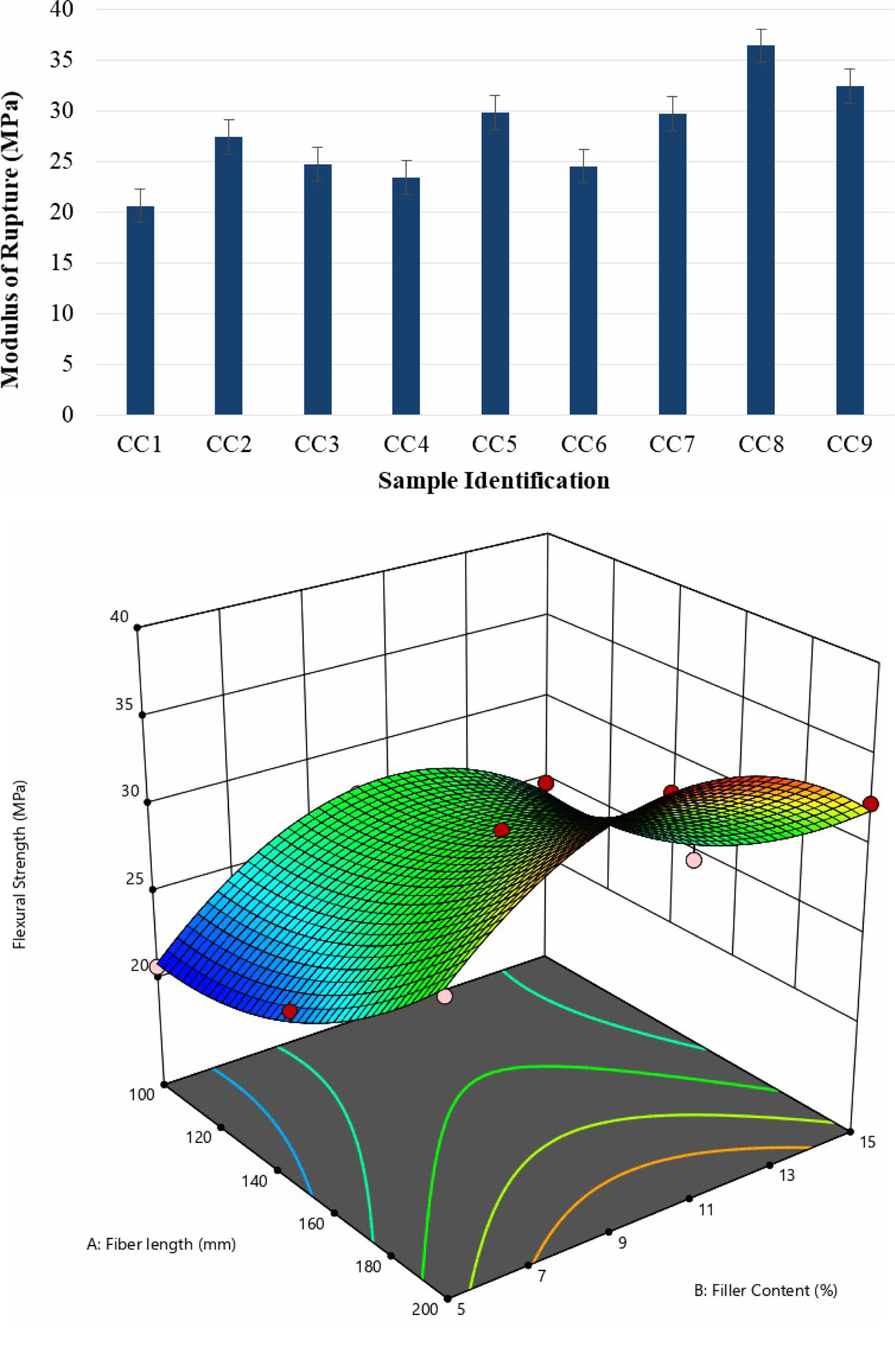

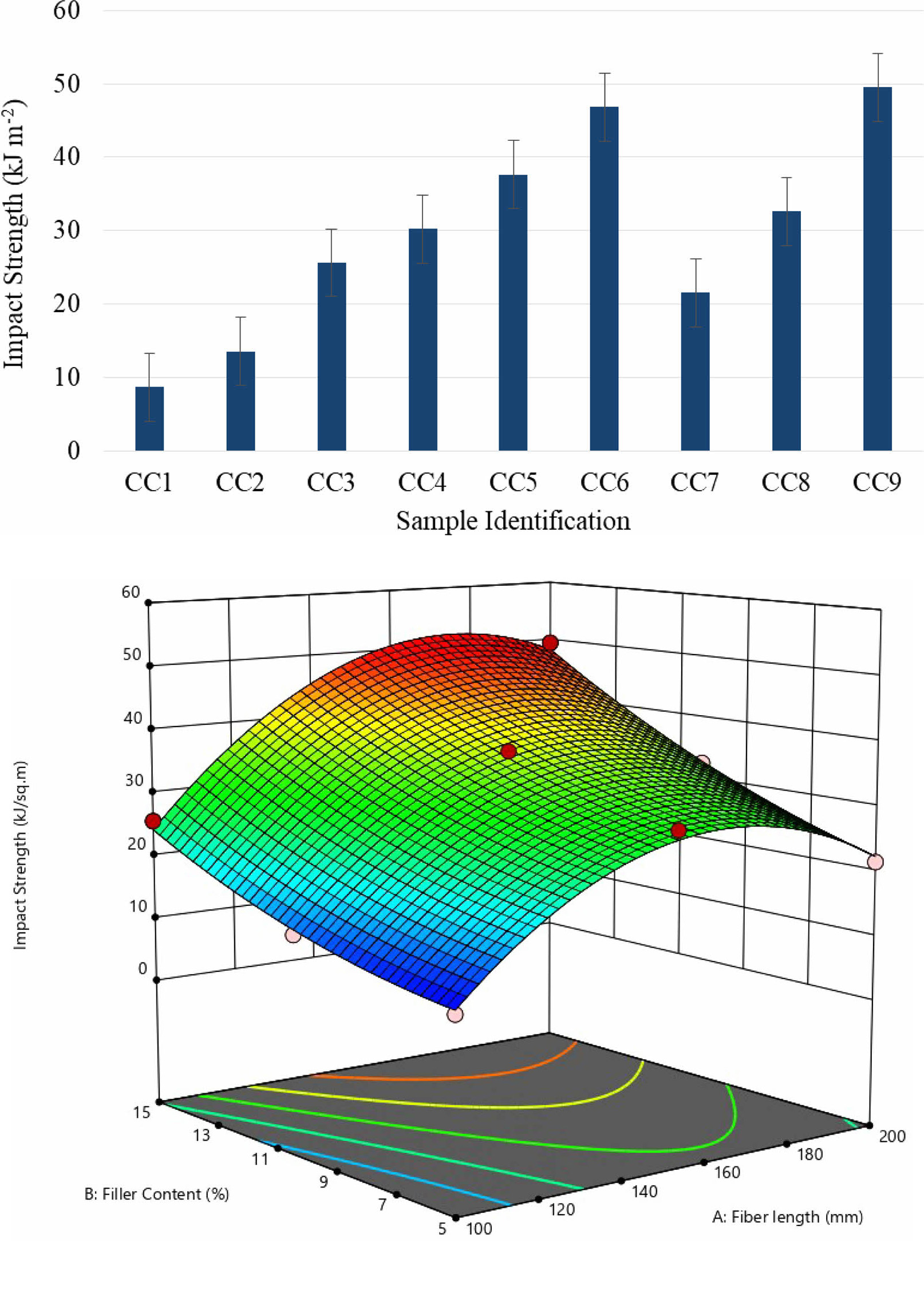

The comparison graph of tensile, flexural, and impact strength for the sample composites are shown in Figs. 5, 6, and 7 respectively.

From Fig. 5b, the tensile strength improved by adding the filling materials by 5% to 10%, and then it decreases by enhancing the filling materials by 10% to 15%. To enhance tensile strength, filling materials play a vital role. Also, it was noted that the tensile strength decreases by increasing the fiber length. The greatest tensile strength has been achieved by the fiber length of 100 mm because randomly oriented short Banana fibers carry the maximum tensile load.

As with tensile strength, the flexural strength also increases by adding the filling materials by 5% to 10%, and then it is reduced by increasing the filling materials by 10% to 15% because plastic deformation is much higher than the elastic properties. But the maximum flexural strength attained in fiber length is 200 mm and filler content 10%. From Fig. 6b, there was an improvement in flexural strength by increasing the length of the fiber.

From Fig. 7b, it was observed that there is an improvement in impact strength when filling materials are increased. Also, fiber length plays a major role in impact strength. In the fiber length of 200 mm with 15% filler content, the impact strength is maximum.

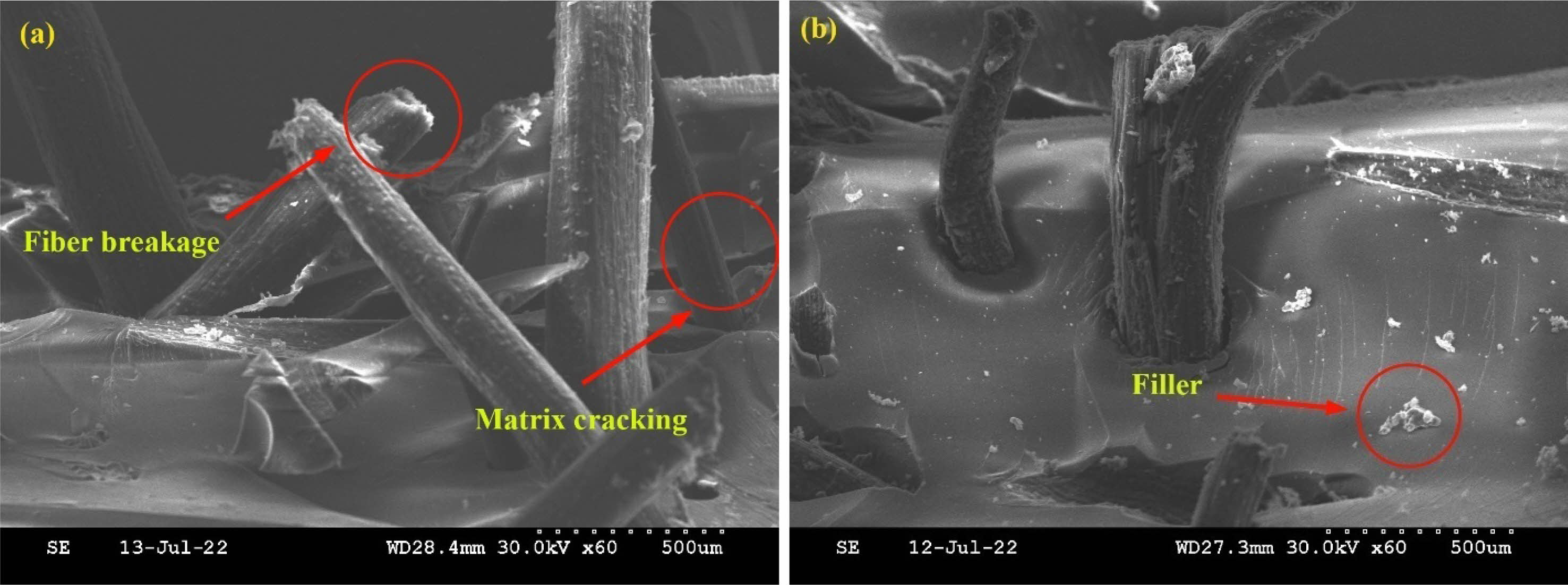

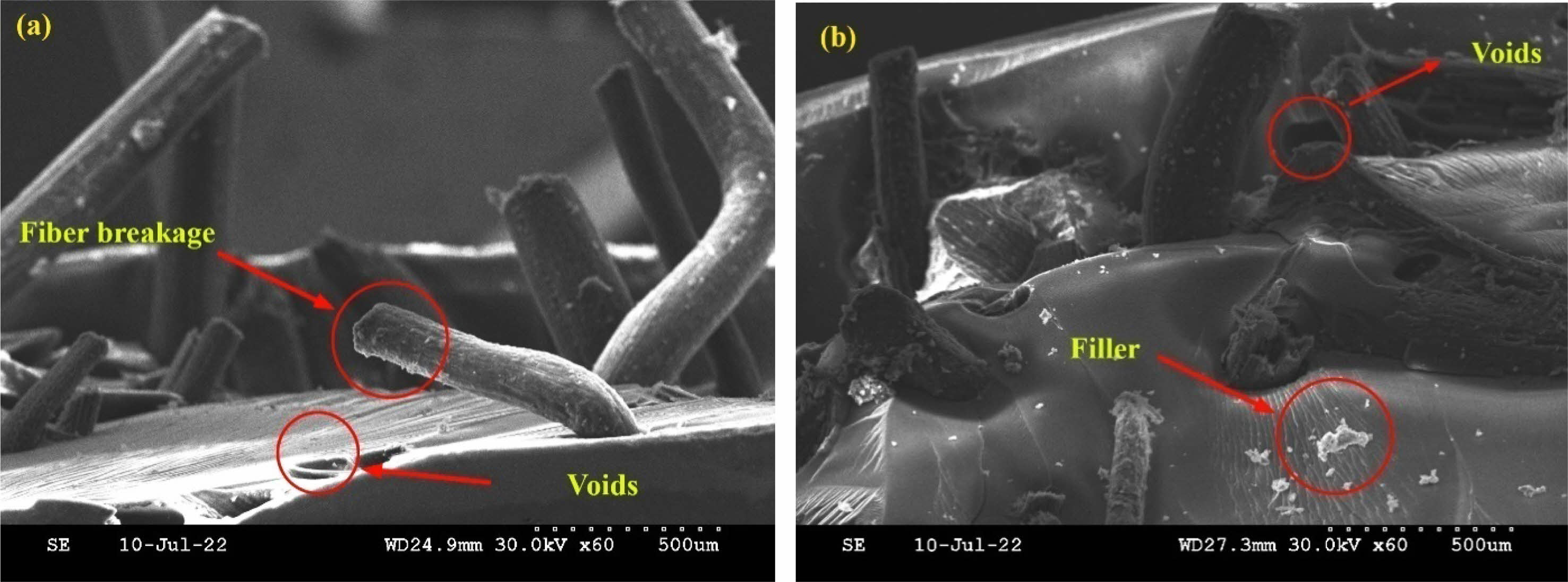

SEM Analysis for fractured surfaces

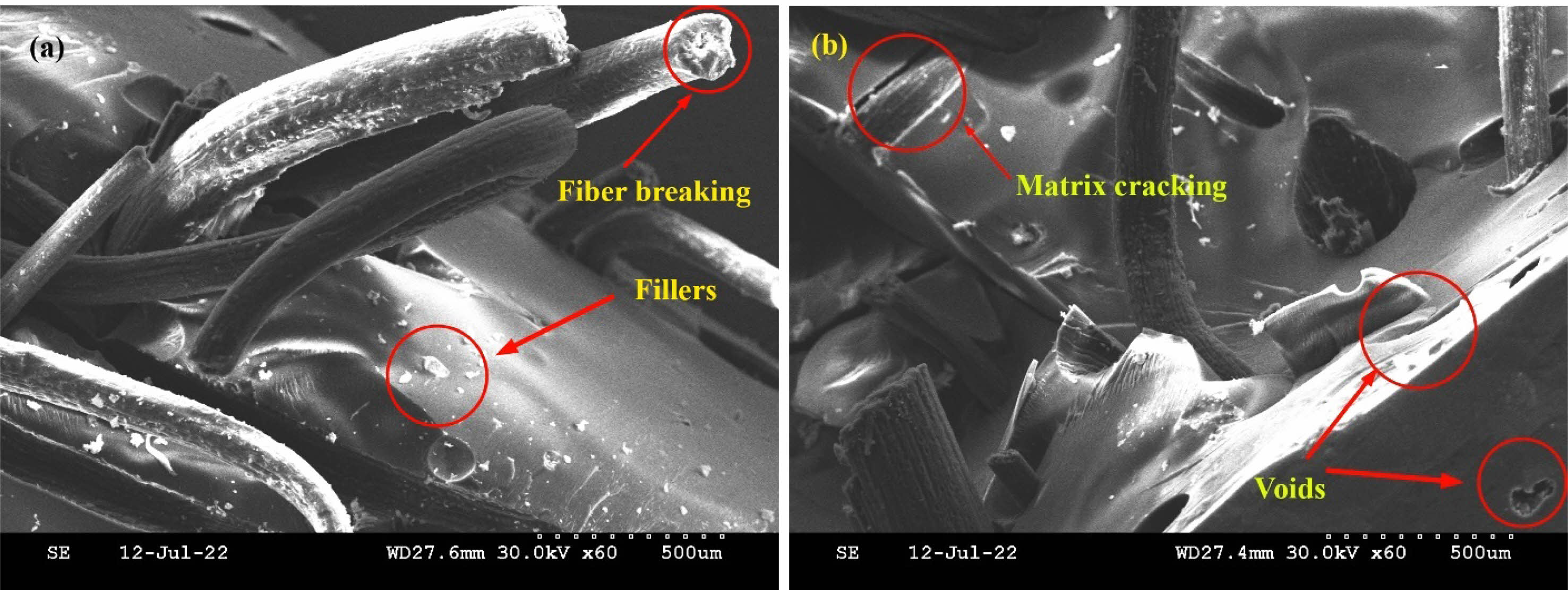

Figs. 8, 9, and 10 demonstrate the scanning electron microscopy (SEM) analytical findings of broken surfaces following tensile, flexural strength, and impact strength respectively. SEM images were used to investigate the presence and distribution of aluminum oxide and boiled eggshell filling materials in the bonding material and surface of the fiber.

Observation of fractured specimens revealed that failure in Aluminum oxide and boiled eggshell filler added to the banana-epoxy specimen was little pull out of Banana fibers and larger extension of the banana fibers might occur soon, resulting in fiber pull out and matrix collapse.

The mechanical properties were improved in Aluminum oxide and boiled eggshell filler added banana-epoxy composites by reducing the presence of poor inter-laminar bonds, a laceration on the fiber surface, and voids formation due to fiber breakage. The fractography of fracture surfaces revealed a consistent distribution of aluminum oxide and boiled eggshell particles in an epoxy resin system. The fiber pull-out was observed because some fibers were not fully engaged in stress transmission. There was an aggregation of fibers due to the random dispersion of fibers, which resulted in the development of bundles. Because these bundles operated as stress transfer barriers, the interface was weak. The fiber breakage was identified in the high adhesion between fiber and matrix components because of the high brittleness of matrix materials

In mechanical testing, matrix cracking began along the fracture lines, and voids developed which causes fiber pull-out. The resin component has a small impact on a composite structure's tensile load-carrying capacity. The fiber had split at various levels, indicating that some energy had been absorbed during the draw out of the strands. Due to impact damage, matrix debris was discovered in all of the cracked fractography.

Optimization of input parameters

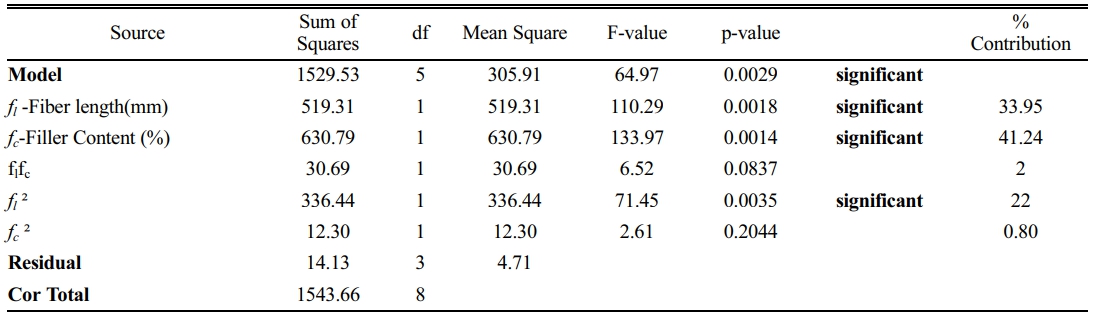

Non-linear regression modeling and response surface design were employed to optimize the tensile strength, flexural strength, and impact strength. In this study, the statistical software tool Design Expert 13 was carried out. Table 8 shows the ideal settings for obtaining higher mechanical strength levels.

From Fig. 11, it was discovered that the 100 mm length banana fiber with 10% filling materials gives the maximum tensile strength, and the flexural strength was enhanced at 200 mm fiber length and 10% filling materials, and the impact strength also increased at 200 mm length and 15% filling materials.

The ultimate ideal parameters for maximum tensile strength, impact strength, and flexural strength were discovered by multi-objective optimization as fiber length of 200 mm and filler content of 11.74%.

|

Fig. 5 a. Effect of input parameters on tensile strength |

|

Fig. 6 a. Effect of fiber parameters on the flexural strength. |

|

Fig. 7 a. Effect of input parameters on impact strength. |

|

Fig. 8 SEM analysis of tensile strength. |

|

Fig. 9 SEM analysis of flexural strength. |

|

Fig. 10 SEM analysis of impact strength. |

|

Fig. 11 Optimization result of the input parameter to maximize the output parameter |

The utilization of various spans of banana fiber in polymer composite applications was discussed in this investigation. The Al2O3 and boiled eggshell-impregnated banana fiber-reinforced epoxy composites were equipped and tested to evaluate their mechanical properties. From this work, the following observations were made.

The greatest tensile strength has been achieved by the fiber length of 100 mm and 10% of filler content because randomly oriented short Banana fibers carry the maximum tensile load. The maximum flexural strength attained in fiber length is 200 mm and filler content is 10%. In the fiber length of 200 mm with 15% filler content, the impact strength is maximum.

The tensile strength, impact strength, and flexural strength values of the short and irregularly oriented banana fiber-reinforced epoxy composites were improved by adding the filling materials (Al2O3 and boiled eggshell). Final optimum values were found that the tensile strength of 14.25 MPa, impact strength of 37.71 kJ m-2, and flexural strength of 36.069 MPa.

The mechanical properties were improved when the weight percentage of filling materials content is increased from 5 percent to 10 percent and decreased with increases in filling materials content from 10 percent to 15 percent. It is observed there was an enormous influence of filling materials in the betterment of mechanical properties.

When the banana fiber length is maximum the flexural strength and impact strength were improved because of longer banana fibers tend to provide increased reinforcement and resistance against bending forces and better energy absorption and dissipation upon impact. The banana fibers are discontinuous in nature. So composites reinforced with non-woven Banana fibers were created to increase mechanical characteristics. The potential uses of banana fiber composites are proposed for manufacturing vehicle and industrial components.

- 1. A. Gholampour and T. Ozbakkaloglu,J. Mater. Sci. 55[3] (2020) 829-892.

-

- 2. K.R. Sumesh and K. Kanthavel, J. Ind. Text.51[4] (2022) 6705S-6727S.

-

- 3. N. Venkateshwaran and A.E. Perumal, J. Reinf. Plast. Compos. 29[15] (2010) 2387-2396.

-

- 4. S.S. Kumar, S.S. Murthy, N. Ananthi, and P. Devi, Biomass. Conv. Bioref. (2023).

-

- 5. S.S. Murthy, S.A. Thaheer, and S. Jayabal, Proc. Inst. Mech. Eng. Pt. L J. Mater. Des. Appl. 226[1] (2012) 52-60.

-

- 6. V.V. Rajan, M. Shanmugam, V. Santhanam, and S.R. Kumar, IOP Conf. Ser. Mater. Sci. Eng. 988[1] (2020) 012046.

-

- 7. G. Ramesh, K. Subramanian, S.S. Murthy, and S. Jayabal, Polym. Compos. 41[11] (2020) 4899-4906.

-

- 8. L. Naidu and Kona. S, Int. J. En. 31[4] (2018) 659-665.

- 9. S.A. Kumar, K. Arumugam, V.R. Mutyala, K.K. Ram, and T.S.K. Kumar, Mater. Today. Proc.45[1] (2021) 6149-6153.

-

- 10. M.Z. Hassan, S.M. Sapuan, S.A. Roslan, and S. Sarip, J. Mater. Res. Technol. 8[4] (2019) 3517-3528.

-

- 11. K.R. Sumesh and K. Kanthavel, J. Ind. Text. 51[3] (2022) 4441S-4459S.

-

- 12. M.S. Hossain, M.B. Mobarak, F.K. Rony, S. Sultana, M. Mahmud, and S. Ahmed, Nano. Hybrid. Compos 29[1] (2020) 84-92.

-

- 13. A. Stalin, S. Mothilal, V. Vignesh, M.R. Sanjay, and S. Siengchin, J. Ind. Text. 51[4] (2022) 5869S-5886S.

-

- 14. I. Iliyasu, J.B. Bello, A.N. Oyedeji, K.A. Salami, and E.O. Oyedeji, Sci. Afr. 16 (2022) e01269.

-

- 15. A.G. Adeniyi, A.S. Adeoye, J.O. Ighalo, and D.V. Onifade, Mech. Adv. Mater. Struct. 28[18] (2021) 869-1877.

-

- 16. M.V.V. Muralikrishna, T.S. Kumari, R. Gopi, and G.B. Loganathan, Mater. Today. Proc. 22[1] (2020) 541-545.

-

- 17. S. Kumar, S. Shamprasad, Y.S. Varadarajan, and M.A. Sangamesha, Mater Today. Proc. 46 (2021) 2471-2476.

-

- 18. R. Kumar, A. Ganguly, and R. Purohit, Int. J. Interact. Des. Manuf, (2023).

-

- 19. V.S. Jagadale and S.N. Padhi, Int. J. Eng. Innov. Technol. 8 (2019) 3006-3011.

-

- 20. K. Begum, M.A. Islam, and M.M. Huque, J. Sci. Res. 7[3] (2015) 97-111.

-

- 21. Krishnudu, D. Mohana, D. Sreeramulu, and P.V. Reddy, AIP. Conf. Proc. 1952[1] (2018) 020058.

-

- 22. V. Vinoth, S.S. Murthy, N. Ananthi, and U. Elaiyarasan, Int. J. Mater. Eng. Innov.13[3] (2022) 208-221.

-

- 23. S. Jayabal, R.R. Prasth, R.R. Rajan, S.S. Murthy, and K. Christal, Cellulose 28[35] (2016) 31-33.

- 24. M. Sutharsan, K.G. Balamurugan, M. Rajarajan, and S.S. Kumar, In. Rect. Adv. in. Mater. Mod. Manuf, (2022) 533-542.

-

- 25. V.S.S. Sundaram, S.S. Kumar, V. Balambica, D.S. Kumar, M.C. Sekaran, R. Muraliraja, and Y. Asres, J. Nanomater, (2022).

-

- 26. S.S. Murthy, A.S.A. Thaheer, and S. Jayabal, Ind. J. Fiber. Text. Res. 38[1] (2013) 81-86.

- 27. S.R. Muneeswaran, S.J. Vairamuthu, S. Nagarajan, B. Stalin, and S. Jayabal, Mater Today. Proc.33[1] (2020) 4790-4792.

-

- 28. H.V. Pham and M. Nanko, J. Ceram. Process. Res. 16[5] (2015) 468-471.

-

- 29. R. Srinivasana, S. Prabu, S. Ramesh, and R. Viswanathan, J. Ceram. Process. Res. 23[6] (2022) 783-793.

-

- 30. S.S. Kumar, S. Selvarasu, T. Babu, R.K. Kumar, and V. D. Kumar, Int. J. Veh. Struct. 14[3] (2020).

- 31. K.N. Fatema, H.M. Lim, J.S. Hong, K.S. Lee, and I. Kim, J. Ceram. Process. Res. 24[1] (2023) 197-204.

-

- 32. M. Shanmugam, S.S. Murthy, G.R. Kumar, S.S. Kumar, T. Prabakaran, and V.S.S. Sundaram, Mater. Today. Proc. 37[1] (2021) 1943-1956.

-

- 33. M. Shahida, R.A. Malika, H. Alrobeib, J. Kimc, M. Latifc, A. Hussaina, M.U. Iqbala, and A. Hafizb, J. Ceram. Process. Res. 22[2] (2021) 149-157.

-

- 34. S.S. Kumar, N.K.C. Mohan, S.T. Prabakaran, M. Muniyappan, M. Shanmugam, and V.S.S. Sundaram, Mater. Today. Proc. 37[1] (2021) 1963-1972.

-

- 35. H.W. Choi, S.J. Kim, H. Yang, Y.S. Yang, Y.H. Rim, and C.R. Cho, J. Ceram. Process. Res. 20[1] (2019) 63-68.

-

- 36. P.G. Krishnan, B.S. Babu, and K. Siva, J. Ceram. Process. Res, 21[2] (2020) 157-163.

-

- 37. Sultana, Sazia, M.M. Rahman, Z. Yeasmin, S. Ahmed, and F.K. Rony, J. Ceram. Process. Res. 21[3] (2020) 285-295.

-

- 38. V.D. Kumar, K.M. Mrityunjayaswamy, M. Chinnapandian, V.B. Hemadri, and S.S. Kumar, In. Rect. Adv. in. Mater. Mod. Manuf. (2022) 379-388.

-

- 39. M. Abolfazli and M.H. Paydar, J. Ceram. Process. Res. 23[2] (2022) 188-198.

-

- 40. D. Lee, H.S. Hong, H. Jeong, and S.-S. Ryu, J. Ceram. Process. Res. 23[2] (2022) 149-153.

-

- 41. S. Sridhar, S.N. Kumar, M. Nallusamy, and R. Maguteeswaran, J. Ceram. Process. Res. 23[4] (2022) 498-502.

-

- 42. K.M.S. Kumar, N. Kathiravan, L. Girisha, and M.S. Perumal, J. Ceram. Process. Res. 23[4] (2022) 541-545.

-

This Article

This Article

-

2023; 24(4): 683-692

Published on Aug 31, 2023

- 10.36410/jcpr.2023.24.4.683

- Received on Apr 24, 2023

- Revised on Jun 29, 2023

- Accepted on Jul 6, 2023

Services

Services

Shared

Correspondence to

Correspondence to

- S. Saravanakumar

-

Department of Automobile Engineering, Easwari Engineering College, Chennai-89

Tel : +91 9941255088 - E-mail: sskmechanical@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.