- Application of VR interactive technology in graphic design of ceramic materials

Shiqiu Gu and Xiaogang Xing*

Art School of Sanjiang, University, Nanjing, Jiangsu 210012

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Design has changed in a way that has been closely tied to the growth of human culture and civilization. A society's growth affects every aspect of human productivity and daily living. A type of ceramic product known as "alive ceramics" has both utilitarian and decorative appeal. Even though living ceramics are recognized as an ancient and traditional art form in our nation, user demands and preferences must come first in their design. Human-centered design has become a mature and thoroughly researched subject in our day. Designing ceramic objects requires careful consideration of humanization. Virtual reality (VR) testing and evaluation of ceramic products is now possible because of advancements in VR technology. Through a computer-generated virtual model, this lets designers and buyers experience and evaluate the benefits and drawbacks of a product prior to its construction. A recent study has shown that the human-centered design method can be considerably enhanced by incorporating virtual reality (VR) technology into the design process for living ceramics. Using VR, designers can mimic real-world environments and gather essential user feedback to enhance the overall design of the product. Additionally, the use of VR technology enables more effective and economical design iterations. In this project, we'll look into how human-centered design and virtual reality (VR) technology may be used to research living ceramic design

Keywords: Living ceramics, VR, Simulation, Design process

Because China has a long history and strong cultural roots, its ceramic culture is thriving. Ceramic production may be traced back to the Neolithic period as a way for people to create functional and aesthetically pleasing objects for daily use. Living ceramics are a popular type of pottery that blends aesthetic appeal with practicality. In China, living ceramics are regarded as an ancient and traditional art form [1].

The maturation of aesthetic awareness and the capacity to appreciate beauty occurs throughout time. The design of living ceramics must prioritize the needs and preferences of the end-users and adopt a human-centered design philosophy. The term "artistic living" refers to a current movement characterized by an increased interest in interior design and a desire to create unique and individualized living situations. Humanized design takes into account not just aesthetic principles and functional requirements but also human tradition, religious culture, living realities, moral standards, and the humanistic spirit [2].

During the design process for living ceramics, one must keep both material and spiritual issues in mind. The aim of its design is to create an enjoyable and comfortable experience for the user as opposed to simply being functional. As a result of the rapid expansion of modern technology, digital technology is becoming more pervasive in a variety of facets of daily life, having a significant impact on current design practices.

Virtual reality-based technologies have the potential to significantly alter the manufacturing of living ceramics (VR). Virtual reality (VR) is a technology that enables immersion, interaction, and conceptualization through the use of computer-based human-machine interfaces [3, 4]. This is accomplished through the use of computer graphics, simulation technology, multimedia technology, artificial intelligence technology, computer network technology, parallel processing technology, and multisensory technology. This allows it to simulate human senses such as sight, hearing, and touch. This feature allows users to completely immerse themselves in a computer-generated, artificial environment. Designers can simulate ceramic models using virtual reality (VR) technology, and customers have network access to 3D diagrams of package design models. This has the potential to significantly improve the user experience, overall design, and human-centered design approach for living ceramics. This essay will examine how virtual reality (VR) technology can be applied to the process of designing living ceramics and how human-centered design can be used to produce living ceramic products [5].

The literature review on humanized design in living ceramics and the use of virtual reality technology in the design process would look at academic journals, books, and research papers, among other sources.

It would be essential to investigate the origins and cultural importance of Chinese pottery. This would involve researching the beginnings of ceramic production in ancient China, the evolution of ceramic technology and design, and the relevance of ceramics in Chinese culture and art [6]. The concept of "humanized design" and how it connects to the evolution of "living ceramics" would also be an interesting subject of research. To do this, research would need to be conducted on the principles and methods of human-centered design, the relationship between design and user experience, and the influence of cultural and socioeconomic factors on design decisions. In addition to these fields, there would be a substantial amount of literature on the application of VR technology in the design process. This would require studies into virtual reality's technological components, such as the usage of computer graphics, simulation technologies, and artificial intelligence, as well as studies on how successfully VR can enhance the design process and user experience [7]. In order to provide a comprehensive grasp of the topic at hand, the literature study would frequently include academic and industrial research. The course would include subjects such as humanized design, the use of VR technology in the design process, and the cultural and historical significance of ceramics in China.

The literature review would look at the current state of the Chinese ceramic industry as well as market trends and customer preferences for living ceramics. Also discussed would be the conception and production procedures for living ceramics, as well as the environmental implications of ceramic manufacture. The evaluation of case studies and examples of effective humanized design in living ceramics, as well as the use of VR technology in the design process, would also be essential components of the literature review [8]. Future research and design projects may utilize these case studies as a resource since they provide valuable information about the industry's challenges and prospects. The literature review would also investigate the potential for VR training and instruction in ceramics. To achieve this, it would be necessary to investigate the use of virtual reality in ceramic design courses and the potential benefits of VR technology in ceramic design and manufacturing education. The literature review would also include studies on the limitations and drawbacks of virtual reality (VR) technology in the production of living ceramics, as well as suggestions for future research avenues to advance this topic. The literature study would provide a comprehensive evaluation of the present status of research on humanized design in living ceramics and the use of VR technology in the design process [9]. It would include a variety of scholarly publication sources.

Developing a VR Display Platform for Ceramics

Using virtual reality technology to establish a platform for displaying ceramic wares is an exciting idea. The concept is to provide an interactive e-commerce platform that allows consumers to modify the shape and color of ceramic objects [10]. This allows users to customize their ceramic products from the comfort of their own homes.

The appearance of ceramics is crucial to their attractiveness. Modeling and ornamentation are essential for giving ceramic objects a distinctive and personalized appearance. Engineers must measure the surface data of the ceramic models from numerous angles in order to do this. However, when measuring various regions, the local coordinate system can be inconsistent, leading to measurement overlap. To address this issue, engineers must standardize the local coordinate systems and remove overlap. In the virtual reality design phase, every link must be examined in relation to the ceramic product's final fabrication [11]. In determining the service and mechanical qualities of ceramic materials, the composition, microstructure, and sintering process are crucial considerations. Engineers must take these elements into account in order to design and manufacture ceramic goods that meet particular specifications. In addition, when measuring data, there might be a great deal of noise and outliers that can have an impact on the subsequent surface reconstruction. In order to achieve appropriate results, the data must be de-noised and streamlined [12].

In today's economy, the design of virtual ceramics must take into account the unique preferences and experiences of each consumer. When virtual reality technology is used in ceramics, information can be sent in real time, giving a 360-degree view of the product. This is possible at any time or place, and it can be a good way to get people's attention. The distinctive artistic attractiveness of technology using virtual reality can aid in exhibiting scientifically enabled technical advancements. Creating a virtual reality platform for ceramic products could enable consumers to modify the shape and color of their products via an e-commerce website, resulting in a more engaging and personalized experience [13]. The design and decoration of ceramics can have a significant impact on their desirability, and the use of virtual reality can facilitate the creation of unique and individualized designs. Data must be collected from different angles and orientations in order to precisely measure and generate a virtual model of a ceramic product. The data must then be integrated, and duplicates must be deleted in order to establish a unified model. The virtual reality design procedure must also evaluate the viability of the ceramic manufacturing procedure. Ceramic materials' composition, microstructure, and sintering technique have a significant impact on the qualities and performance of the finished product. The ceramic model can be simulated and seen from various angles by removing outliers and utilizing the dopant mass fraction as an input. However, there could be a lot of noise and outliers when collecting data from measuring equipment, which could lower the surface reconstruction's accuracy. In order to fight this, the data must be de-noised and simplified before reconstruction [14, 15].

Using VR reverse Technology

The design of domestic ceramic products must take into account both functionality and user convenience. As competition in the marketplace increases, consumers demand more personalized products, and this includes craft gifts. Using solid design, it is possible to make a three-dimensional model of a ceramic product, which can then be output in different ways. Further modifications and adjustments can be made to the background and viewpoint nodes to improve simulation results. Then, the model can be put into CAD software to design effects and make a 3D image of the ceramic product [16].

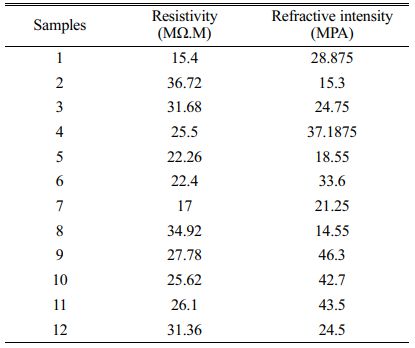

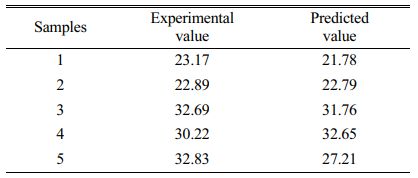

The positions of the ceramic models can be changed from where they start by moving them or turning them. The model was optimized with the help of a network with a hidden layer of 5 neurons. After 5255 training iterations, the overall error was 0.4%. The network was then evaluated using data from five doping methods that weren't used during training. Interpolation points and time sensors are often used to better route changes in time to different nodes in the ceramic kiln. The positions of the ceramic models are established using displacement and rotation angle [17]. One advantage of using virtual reality technology to create homemade gifts is the simplicity with which the materials of the model can be changed to make it appear more realistic. Materials may be allocated to a single component, a group of objects, or both.

In the field of designing and making ceramics, the above equations are used to describe and calculate things like predicting and evaluating network performance using experimental data, the routing process for simulation, and figuring out displacement and rotation angles for ceramic models. But without more information about how and why these equations are used, it may be hard to fully understand what they mean and how important they are [18].

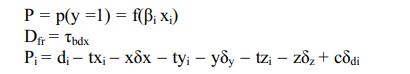

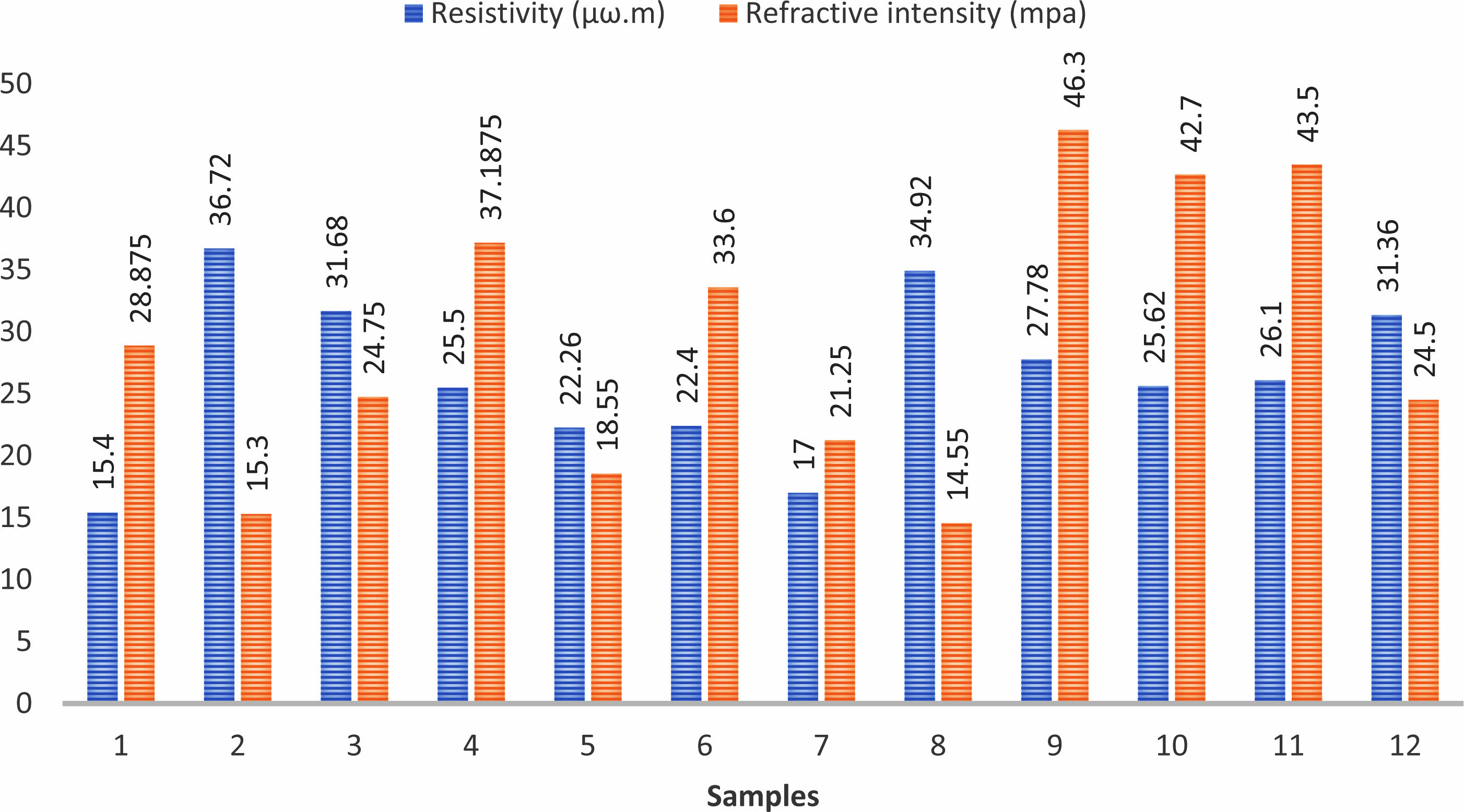

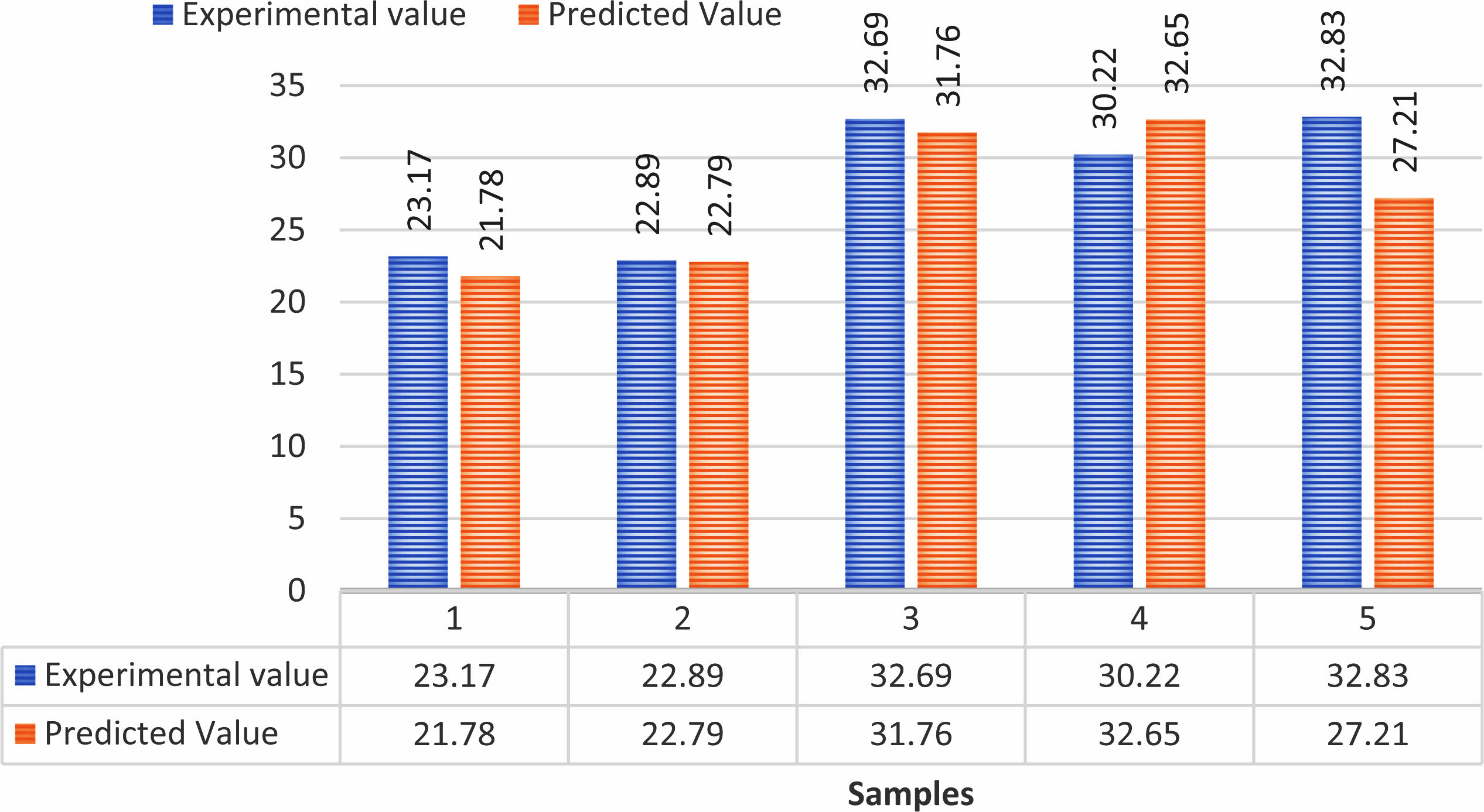

Fig. 1 Fig. 2 Table 1 Table 2

|

Fig. 1 Visualization of Resistivity vs Refractive intensity. |

|

Fig. 2 Visualization of Experimental Value vs Predicated Value. |

Providing people with innovative products and ideas that they can utilize in their day-to-day lives as well as making contemporary ceramic art more accessible to the general public should be the key goals. Humanization has emerged as an essential component in the design of ceramics intended for day-to-day usage; it is the factor that, in the end, determines whether a product is successful or not. The designers of these ceramics have to take the customers' needs and tastes into consideration in order to make the ceramics comfortable for the users, aesthetically stunning, and personalizable. Buyers are able to have a more engaging and dynamic experience while browsing things thanks to virtual reality technology, which is a cutting-edge design tool. This gives customers the ability to fully comprehend the benefits of the product. The digital component of ceramic product design can be improved by making virtual reality models of the ceramic things being designed. Designers and customers are now able to more quickly analyze the benefits and drawbacks of a product by using virtual representations on computers. They are also able to give suggestions for its development and eliminate wasteful trial production processes. This not only saves time and money, but it also leads to increased satisfaction among customers. Ceramic designers need to conduct research on Chinese culture, incorporate its essence, stay current with design concepts, and be innovative by employing virtual reality technology and fusing humanized and aesthetic design in order to create ceramic works that are distinctive and possess Chinese characteristics.

- 1. K.S. Kupaysinovna, Turk. J. Comp. Math. Edu. (TURCOMAT) 12[7] (2021) 939-946.

-

- 2. H.S. Nogay, T.C. Akinci, and M. Yilmaz, Neural. Comput. Appl. 34[2] (2022) 1423-1432.

-

- 3. M. Aliqué,, C.D. Simão, G. Murillo, and A. Moya, Adv. Mater. Technol. 6[3] (2021) 2001020.

-

- 4. E. Sowade, M. Polomoshnov, A. Willert, and R.R. Baumann, Adv. Eng. Mater. 21[10] (2019) 1900568.

-

- 5. T.H. Yang, J.R. Kim, H. Jin, H. Gil, J.H. Koo, and H.J. Kim, Adv. Func. Mater. 31[39] (2021) 2008831.

-

- 6. K.H.W. Seah, M. Rahman, and K.H. Yong, Proc. Inst. Mech. Eng., Part B: J. Eng. Manuf. 217[1] (2003) 29-43.

-

- 7. P. Svec, Z. Gabrisova, and A. Brusilova, J. Ceram. Process. Res. 20[1] (2019) 113-120.

-

- 8. L. Wang, “Second EAI International Conference, Big IoT-EDU 2022”, July 29-31, 2022, Proc., Part II (pp. 591-601).

-

- 9. C.L. Cramer, E. Ionescu, M. Graczyk-Zajac, A.T. Nelson, Y. Katoh, J.J. Haslam, L. Wondraczek, T.G. Aguirre, S. LeBlanc, H. Wang, and M. Masoudi, J. Eur. Ceram. Soc. (2022).

-

- 10. T. Jiang, H.-Y. Jin, Z.-H. An, J.F. Yang, and G.-J. Qiao, J. Ceram. Process. Res. 10[1] (2009) 113-116.

-

- 11. K. Parida, H. Bark, and P.S. Lee, Adv. Funct. Mater. 31[39] (2021) 2007952.

-

- 12. Q. Wang, L. Velasco, B. Breitung, and V. Presser, Adv. Energy Mater. 11[47] (2021) 2102355.

-

- 13. B.M. Randjelović, V.V. Mitić, S. Ribar, C.A. Lu, I. Radovic, A. Stajcic, I. Novakovic, and B. Vlahovic, Mod. Phys. Lett. B 34[34] (2020) 2150159.

-

- 14. Z. Zhao, Ceram. Int. 47[4] (2021) 4389-4397.

-

- 15. N. Shahrubudin, T.C. Lee, and R.J.P.M. Ramlan, Procedia Manuf. 35 (2019) 1286-1296.

-

- 16. R. Yadav, A. Meena, and A. Patnaik, Polym. Adv. Technol. 33[6] (2022) 1762-1781.

-

- 17. Y. Lakhdar, C. Tuck, J. Binner, A. Terry, and R. Goodridge, Prog. Mater. Sci. 116 (2021) 100736.

-

- 18. H. Yang, S. Xu, D.E. Chitwood, and Y. Wang, Front. Environ. Sci. Eng. 14 (2020) 1-10.

-

This Article

This Article

-

2023; 24(3): 507-511

Published on Jun 30, 2023

- 10.36410/jcpr.2023.24.3.507

- Received on Jan 30, 2023

- Revised on Mar 24, 2023

- Accepted on Mar 27, 2023

Services

Services

Shared

Correspondence to

Correspondence to

- Xiaogang Xing

-

Art School of Sanjiang, University, Nanjing, Jiangsu 210012

Tel : 02552897064 Fax: 02552897066 - E-mail: XiaogangXing6@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.