- Development of high-strength pervious concrete with an emphasis on durability properties

Mycherla Chaitanyaa,* and G. Ramakrishnab

aResearch Scholar, Puducherry Technological University, Civil Engineering, Puducherry, India

bProfessor, Puducherry Technological University, Civil Engineering, Puducherry, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The problem of ground water recharge because of impervious pavement surfaces can be mitigated to some extent with the construction of pervious or porous concrete pavements. Pervious concrete pavement allows water infiltration due to its porous nature. However, the major concern with pervious concrete is their low compression strength. Many researchers have made efforts in enhancing the pervious concrete mechanical properties but very few have investigated the durability aspects of pervious concrete. In the present work, studies were conducted to develop a high-strength and durable pervious concrete. The effect of M-sand, silicafume and polypropylene fibers on porous concrete's hydrological and mechanical properties was examined. The optimum dosage of M-sand is also found out. The study revealed that the compression strength of porous concrete enhanced with an addition of 10% M-sand. The optimum dosage of silicafume and fibers are found to be 15% and 1%. The maximum compression strength achieved was 31 Mpa with a permeability of 2.38 mm/s. The experimental study also revealed that the durability of porous concrete has improved significantly with the inclusion of silicafume, M-sand and polypropylene fibers. The resistance offered by pervious concrete to abrasion and impact improved to 8% from 27% and the pervious concrete mix composed of silicafume has offered high resistance to acid attack. The addition of silicafume has decreased the percentage change in compressive strength to 22% from 46%.

Keywords: Pervious concrete, Durability, Silicafume, Permeability, M-Sand, Abrasion, Acid attack

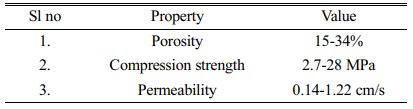

Porous concrete is an amalgam of cementitious material, coarse aggregate (CA) with no or little fine aggregate (FA) and water. The typical pervious concrete prepared in the present study is shown in Fig. 1. The pervious concrete (PC) pavement is intended to withstand the vehicular load and also the passage of water through it. Therefore, the structural and hydrological aspects are crucial during the service life of the pavement. The key properties of pervious concrete are shown in Table 1.

Pervious concrete is used as a pavement material and effectively controls storm water pollution, reduces noise between tires and pavement, road surfaces glare, etc. However, the low compression strength of pervious concrete has limited its usage in parking lots [1, 2]. The strength aspects of porous concrete can be enhanced with desired permeability. The aggregate-binder ratio is more crucial than the water-binder ratio in improving the strength of pervious concrete. Supplementary cementitious substances can escalate the compression strength of porous concrete up to the threshold limit. The size and type of aggregate also profoundly affect the strength of pervious concrete [3]. The interfacial transition zone present between aggregate and binder paste plays a predominant role in the strength characteristics of pervious concrete. The usage of rice husk ash and coal waste ash also increased the tensile and compression strength of the porous concrete [4]. The silica content present in rice hush ash makes it one of the best alternatives for cement replacement [5].

The incorporation of silica fume (SF) can improve concrete's compression and tensile strength. The addition of granulated blast furnace slag, silica fume, and zeolite was also found to increase the strength [6-8]. Out of various cementitious materials available, SF is found to be one of the best replacements for cement because of its higher SiO2 content. The reactivity of SF in concrete depends largely on the SiO2 content. The addition of SF not only enhances the compression strength, it also improves the durability of concrete significantly. The optimum dosage of SF is found to be 5-20% [9, 10]. The use of sustainable, environmental friendly and waste materials has increased rapidly in the construction industry [11, 12]. The aggregate size can also affect the hydrological properties. The mix composed of well-graded aggregate possesses higher compressive strength, and the addition of fine aggregate was also found to raise the compression strength [13]. The hydrological properties can also be affected by the aggregate size [14]. The workability of porous concrete can be improved using super plasticizers (SP) and admixtures. The addition of a cohesive agent was also effective in improving the strength aspects of porous concrete. The inclusion of a super plasticizer and thickening agents improves the bond present between cement paste and aggregate [15]. The right proportion of SF and super plasticizer can produce a high strength pervious concrete [16].

Failure by crack is one of the concern for concrete [17]. The lack of durability can lead to cracking of concrete [18]. The addition of fibers (F) in appropriate quantities can improve the pervious concrete mechanical and durability properties. For example, reinforcing PC with polypropylene fibers increased the tensile strength of porous concrete. The polypropylene fibers in combination of nylon fibers have also found to reduce the weight loss of concrete in fire [19]. Fibers and Fine aggregate can meliorate the raveling resistance of pervious concrete [20, 21]. Furthermore, the resistance of PC to abrasion and the freeze-thaw durability were significantly improved by macro synthetic fibers [22]. The resistance of PC to abrasion was reduced with the raise in size of aggregate and aggregate-binder ratio [23]. The addition of carbon fibers improved pervious concrete's physical and mechanical properties. Carbon fibers were also found to enhance the workability of porous concrete [24]. The other fibers like steel, glass and polyphenylene sulfide fibers were also effective in enhancing the durability of porous concrete [25]. The addition of steel fibers to concrete is found to produce a high performance concrete [26]. The characteristics of porous concrete can get better with the compaction energy. The compaction of the pervious concrete mix should be adequate. Heavy compaction leads to reduced hydraulic features, and low compaction will produce a weak pervious concrete mix [27]. Compaction and finishing are vital in producing a durable PC [28].

Many researchers have explored the resistance of PC to abrasion and the widely adopted method was cantabro loss. The abrasion resistance can also be found out using Asphalt Pavement Analyzer (APA), wheel test apparatus, Los Angeles Abrasion Machine, Abrasion by underwater method etc [29, 30]. The acid resistance of PC can be improved by using SF as cementitious material and also by increasing the water-binder ratio [31, 32]. The valuable inputs from the literature include the addition of silicafume and fly ash improved the strength of pervious concrete. the abrasion and impact resistance can be improved with the addition of fibers.

The present study improves the pervious concrete strength with varying proportions of M-sand and SF. The effect of M-sand and polypropylene fibers on porous concrete's hydrological and mechanical properties was examined. In addition, the resistance to impact of pervious concrete was also determined. The effect of M-sand, SF and fibers on the impact resistance of porous concrete is examined.

|

Fig. 1 Pervious concrete specimen. |

The main intention of this work is to develop a high strength PC that can withstand the moderate to high traffic without compromising its permeability and durability. The combined effect of FA, SF and fibers on PC specimens mechanical and durability properties is evaluated. The usage of M-sand and its effect on PC properties is summarized. This research also signifies the resistance offered by pervious concrete with different mix compositions to chemical attacks. The critical observations of the author regarding the durability aspects of PC were presented subsequently.

Materials

Cementitious materials

The53 grade ordinary Portland cement was used. Silicafume was used as supplementary cementitious material. The cement specific gravity was found to be 3.15. The composition of SF is presented in Table 2.

Aggregate

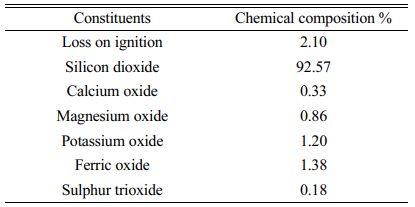

Natural graniteis used as coarse aggregate, and the size was 10-4.75 mm. The fine aggregate used in the present investigation is M-sand, and the specific gravity was found to be 2.60. The properties of coarse aggregate are presented in Table 3.

Fibers

Polypropylene fibers of length 12 mm and aspect ratio 500 is used in the present study as shown in Fig. 2.

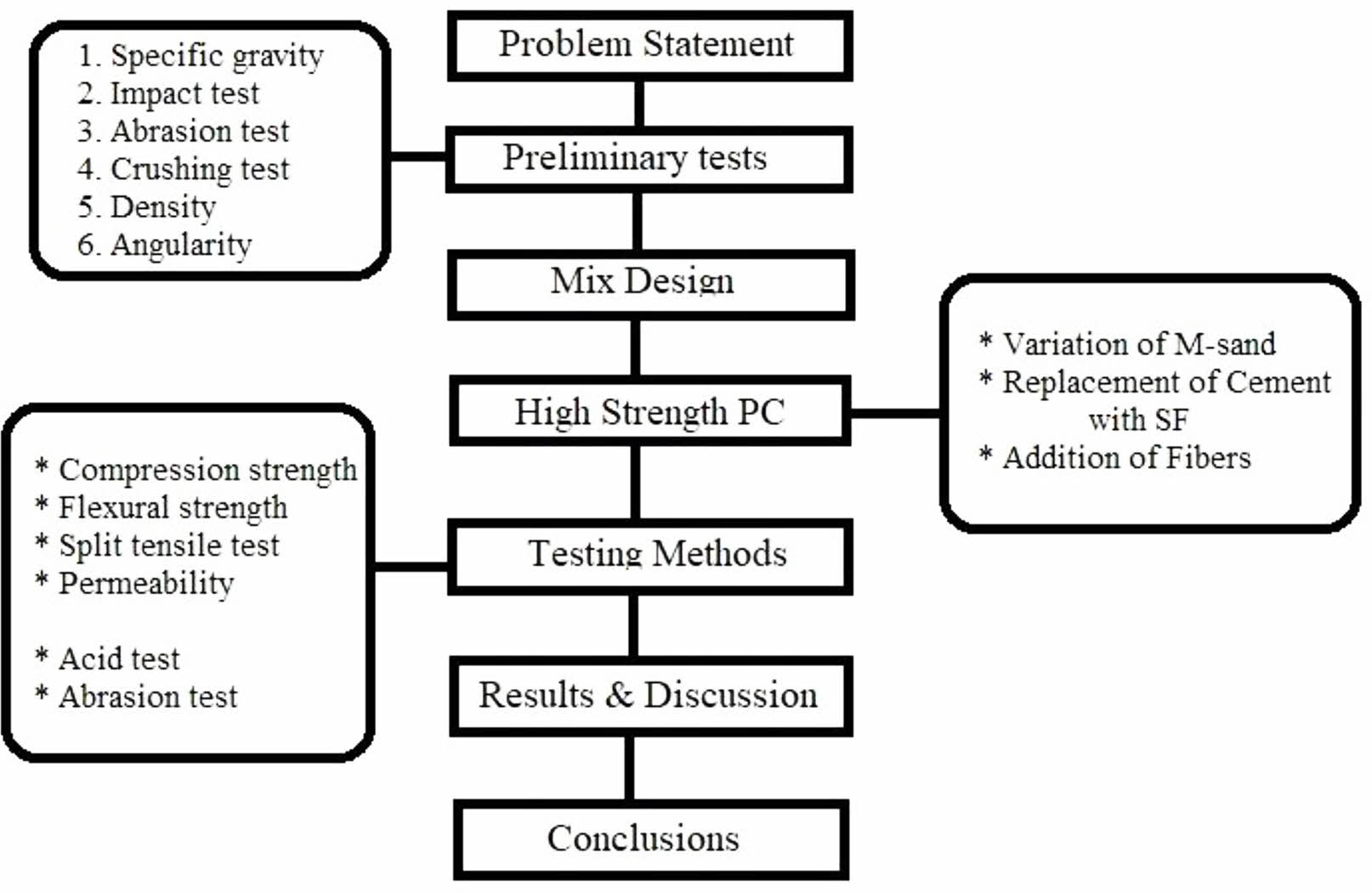

Methodology

The adopted methodology in the present work is shown in Fig. 3. This section explains themix design of pervious concrete, tests conducted relevant to mechanical and durability aspects and their interpretation.

Mix Design

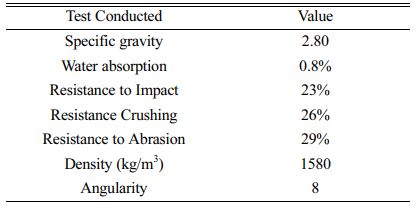

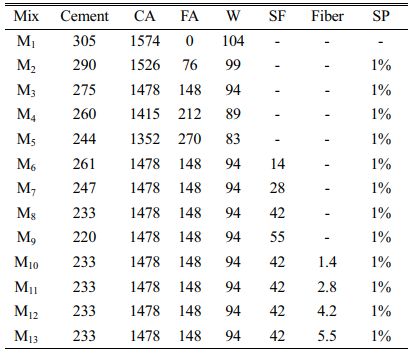

The mix design of porous concrete was carried out to find the optimum proportions according to the procedure mentioned in ACI 522R-2010, as shown in Table 4. The aimed void content was 15%. The optimum proportions of M-sand, SF, and polypropylene fibers that result in maximum strength were found out. The PC specimens for compression, flexural, and tensile strength were tested following IS 516. A thorough mixing of ingredients was carried out as shown in Fig. 4 and then filled in moulds by compacting each layer and cured for 28 days.

Test Methods

Strength Tests

The compression strength was performed on cubes of 100×100×100 mm. The cubes were cast and kept in water for seven and 28 days to estimate the compression strength at respective ages. The flexural strength was performed on prisms of size 500×100×100 mm after curing the specimen for 28 days and the tensilestrength of PC specimens was determined on cylindrical specimens of 150×300 mm as shown in Fig. 5 after curing for 28 days in accordance with IS 516 [33].

Hydrological Properties

The falling head permeability coefficient test was carried out on specimens of size 100 mm×100 mm after curing for 28 days according to ASTM D 5856-95 [34]. The porosity of freshly mixed and hardened PC of all the mixes was also determined. The porosity of freshly mixed PC was determined as per the procedure described in ASTM C 1688 [35] and the porosity of hardened pervious concrete was determined according to ASTM C 1754 [36].

Durability

The durability aspects of PC are studied through the resistance to impact and abrasion test, and acid attack. The resistance against impact and abrasion is conducted on 100×100 mm cylinders as per ASTM C1747 [37]. The specimens will be subjected to both abrasive and impact forces in the Los Angeles abrasion machine. Three PC specimens were prepared for each mix and the mean value is found out.The mass of three specimens were noted and placed in Los Angeles machine and rotated at 30 to 33 rotations per minute for 500 revolutions. After 500 revolutions, the material is discharged and sieved using 25 mm sieve. The weight of material retained on 25 mm sieve is recorded. The resistance of PC to acid attack was found out on 50×100 mm specimens as per ASTM C267 [38]. The specimens were immersed in diluted 5% HCL solution and tested for compression strength after 1, 7, 14 and 28 days of immersion.

|

Fig. 2 Polypropylene fibers. |

|

Fig. 3 Methodology of Work. |

|

Fig. 4 Mixing of Ingredients. |

|

Fig. 5 Split tensile test on specimewn. |

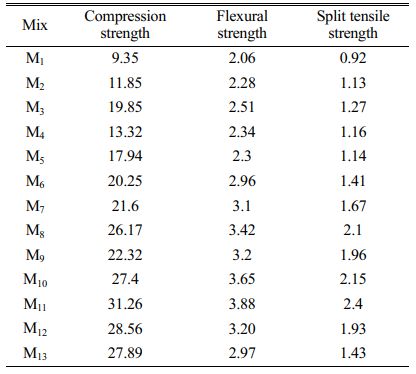

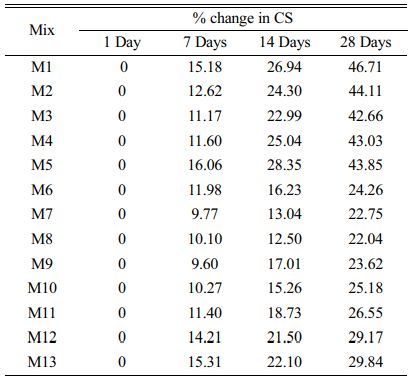

Compression and Flexural strength

The compression, flexural and tensile strength of different mixes is presented in Table 5. The addition of 10% M-sand as fine aggregate improved the compression strength with a permeability of 3.76 mm/s. The addition of SF has also improved the strength and the optimum proportion of SF was found to be 15% which is in coincidence with the existing literature [9]. The addition of fibers has improved the strength by 20%. The maximum flexural strength was obtained for the mix M11. The tested prism for flexural strength is shown in Fig. 6.

Hydrological Properties

Permeability

The pervious concrete specimens used to conduct the permeability test were shown in Fig. 7. The total numbers of specimens prepared were 39. The average permeability coefficient corresponding to mix is found by casting three specimens.

Each specimen was sealed properly to avoid leakages before conducting the permeability test. The permeability of all the mixes is shown in table6. It was observed that the addition of SF have decreased the permeability because of its very fine nature that will minimize the voids present in the pervious concrete. However, the permeability values of M11 are within the range as prescribed in ACI 522R 2010.

Durability

Impact Resistance of Pervious concrete

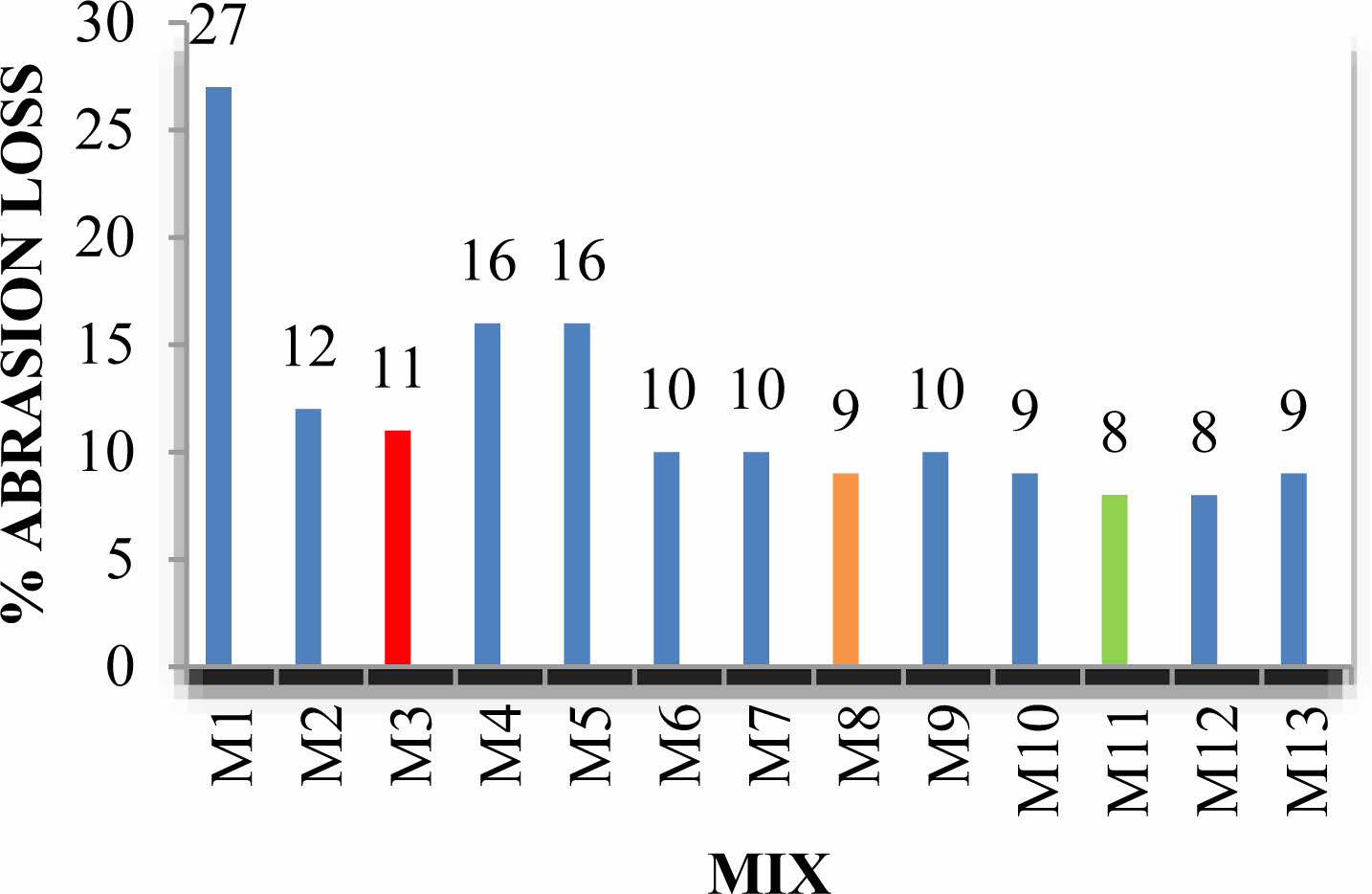

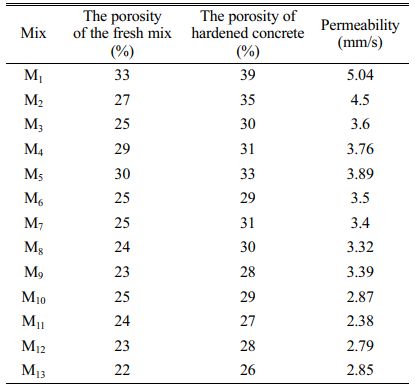

The calculated mass loss for all the mixes is shown in Table 7. It was observed that the inclusion of M-sand and SF improved the abrasion resistance of PC significantly which is in coincidence with the existing literature [9].

The mass loss of the initial M1 was very high and the impact resistance improved for the other mixes with the inclusion of M-Sand, SF and fibers. The strength of mix is directly proportional to the resistance offered by PC to abrasion and impact. The abrasion and impact resistance was found to be high for the mixes M3, M8 and M11. The comparison of abrasion and impact resistance offered by all the mixes is shown in Fig. 8.

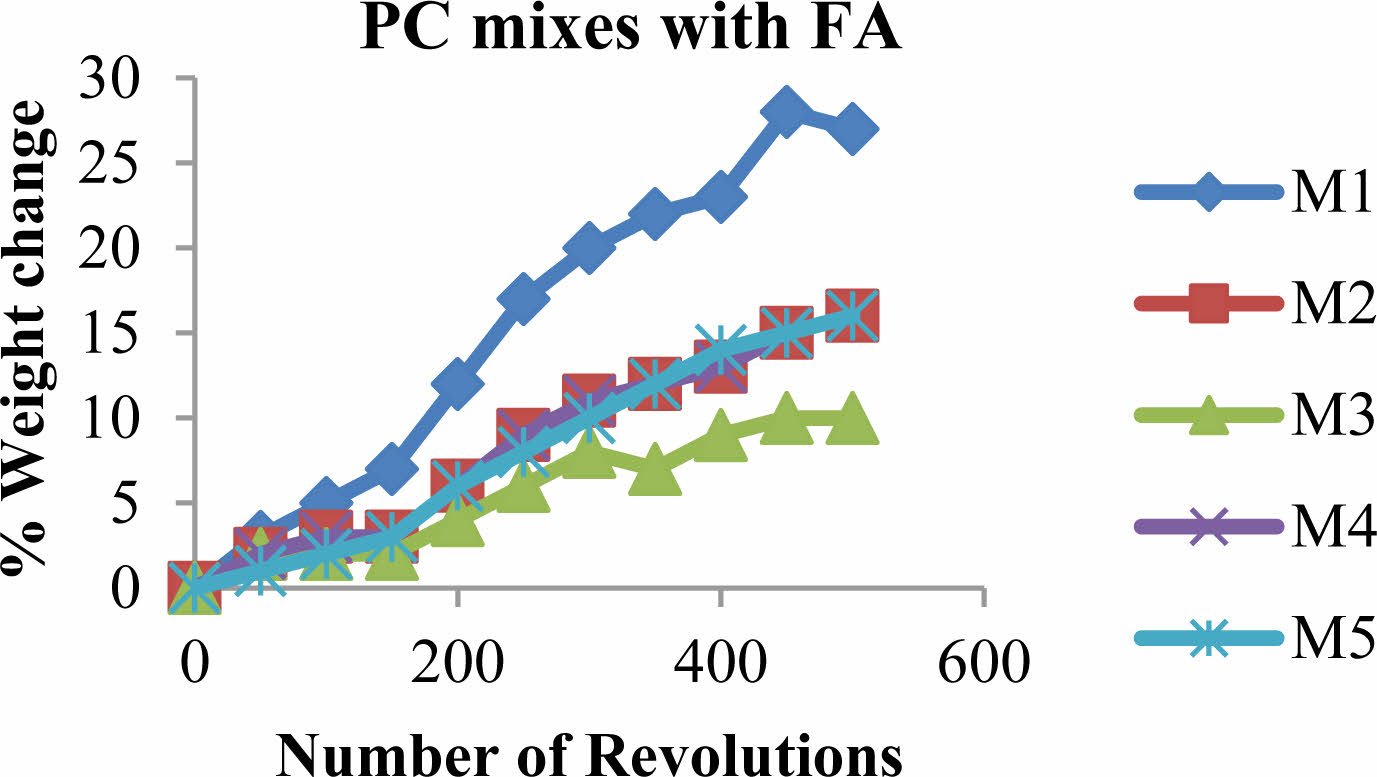

Effect of FA

The mass loss or weight change of specimens for every 50 revolutions up to 500 revolutions was determined. It was observed that the mass loss increased with the number of revolutions and decreased significantly with fine aggregate inclusion as shown in Fig. 9.

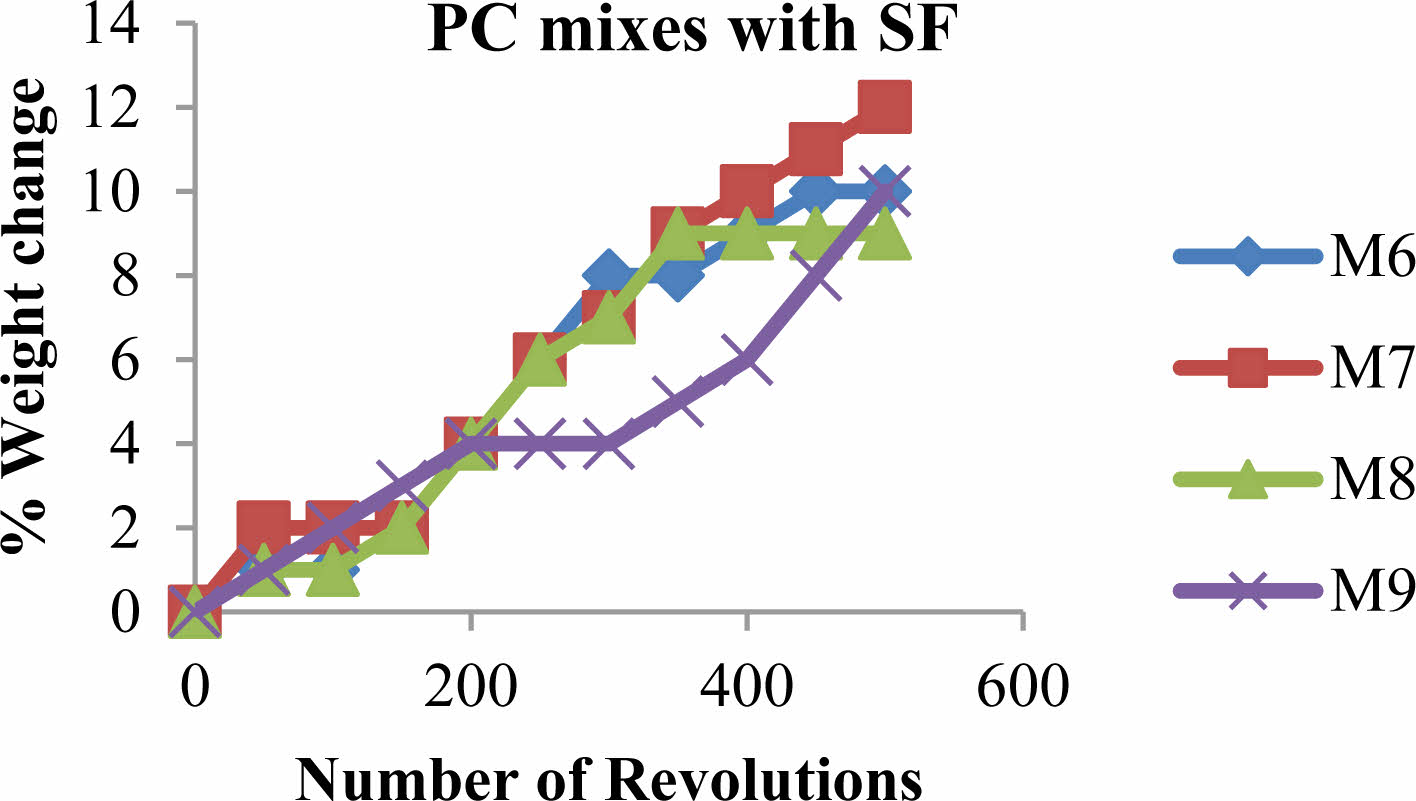

Effect of SF

The porous concrete mix with 10% FA replaced the cement content with silica fume from 5-20% proportions. As a result, the weight loss was reduced with the addition of silica fume, as shown in Fig. 10.

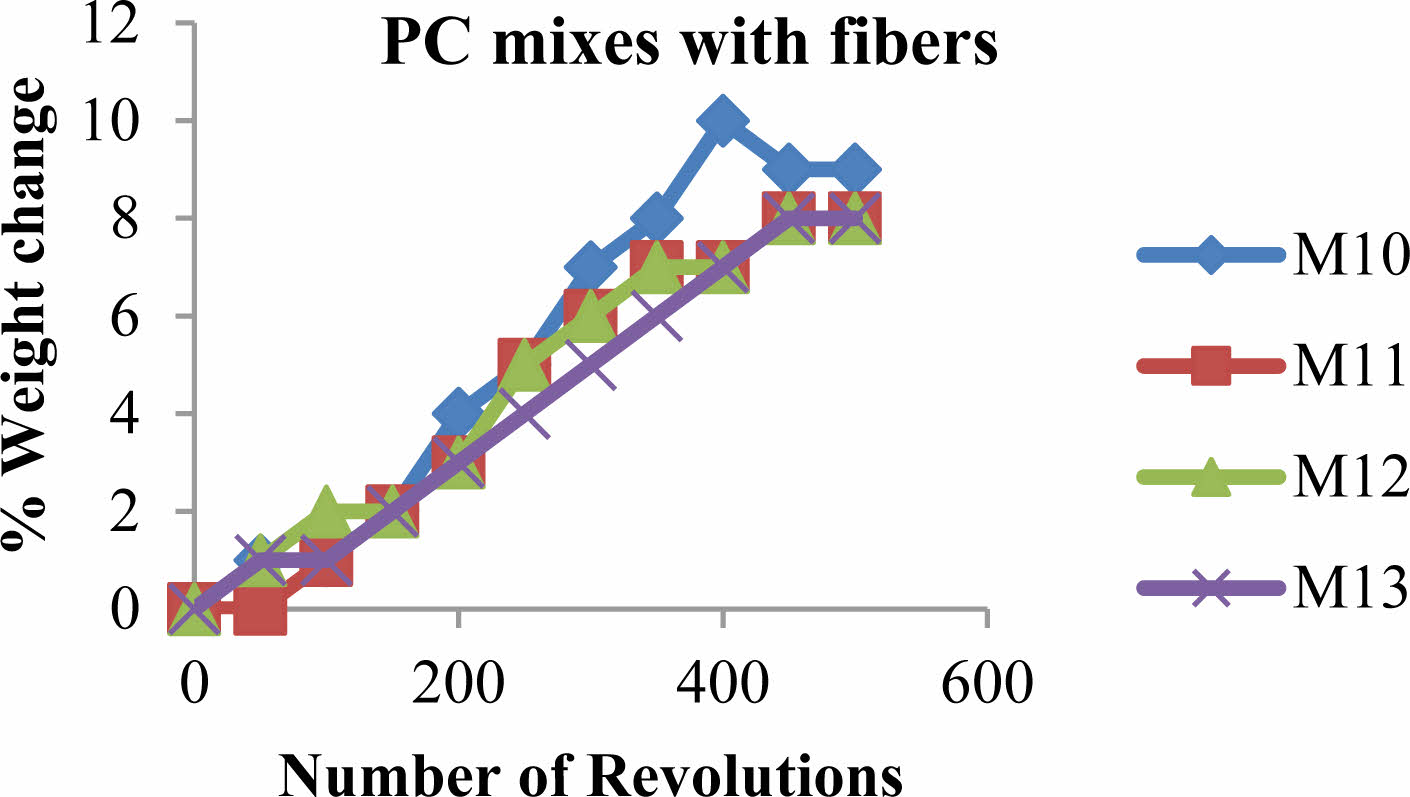

Effect of Polypropylene Fibers

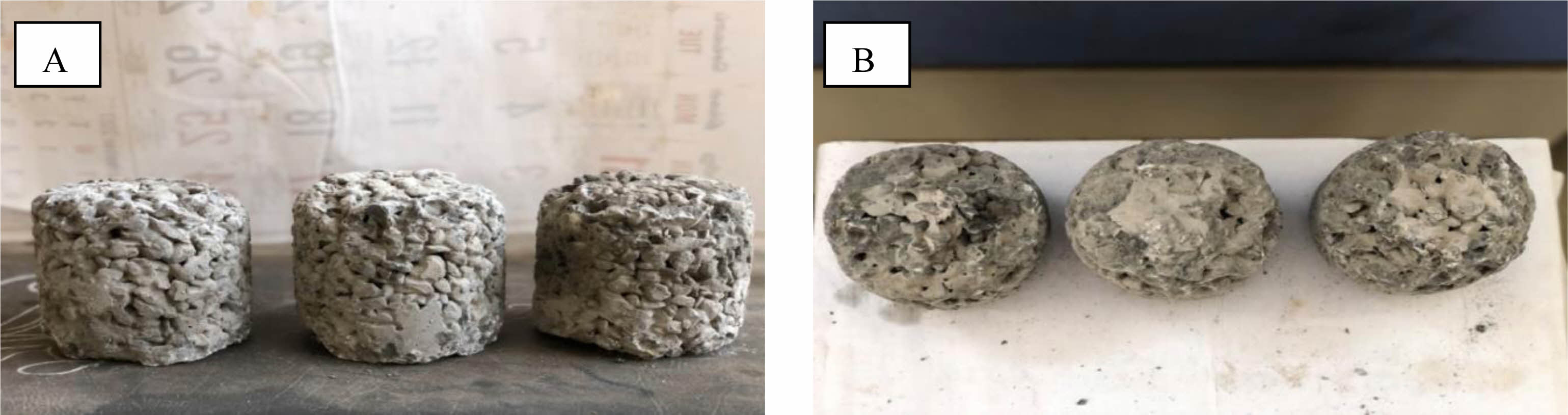

The pervious concrete mix with 10% fine aggregate and 15% SF was used to develop the mixes with polypropylene fibers varying from 0.5-2.0% proportions. The addition of fibers also reduced the weight loss as shown in Fig. 11. The specimens after subjected to impact test were shown in Fig. 12.

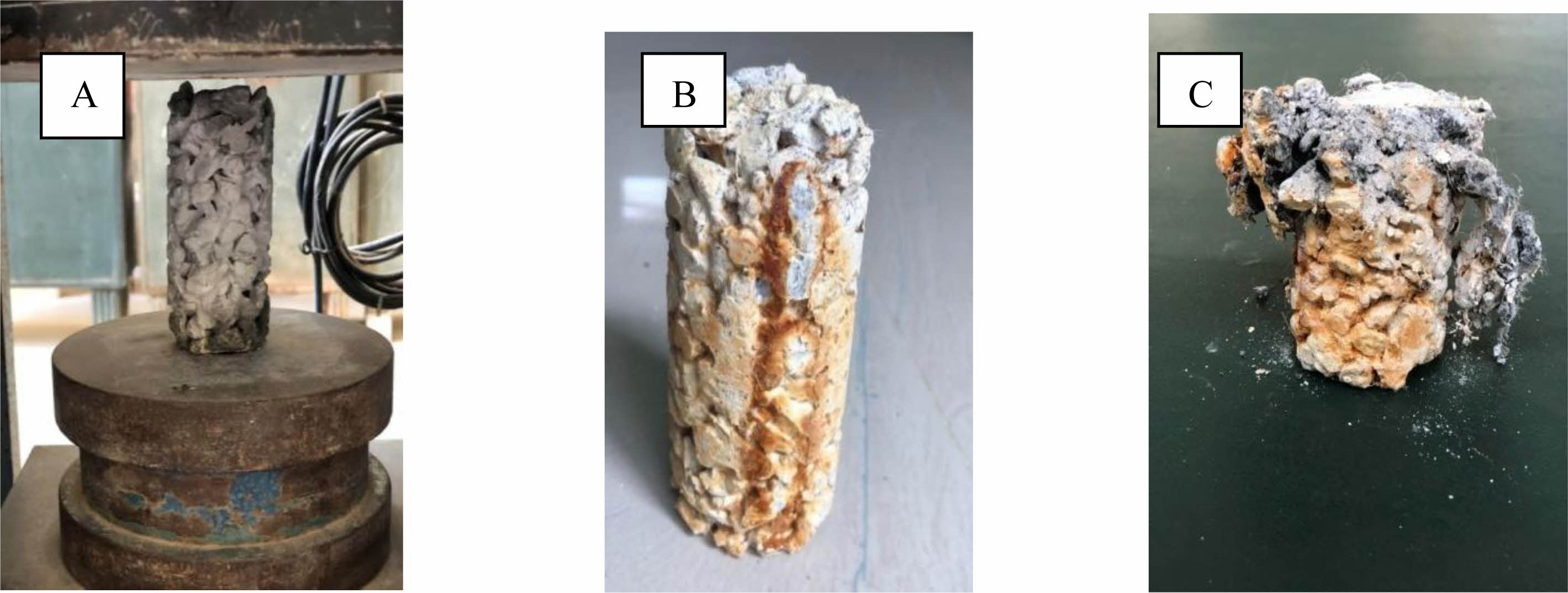

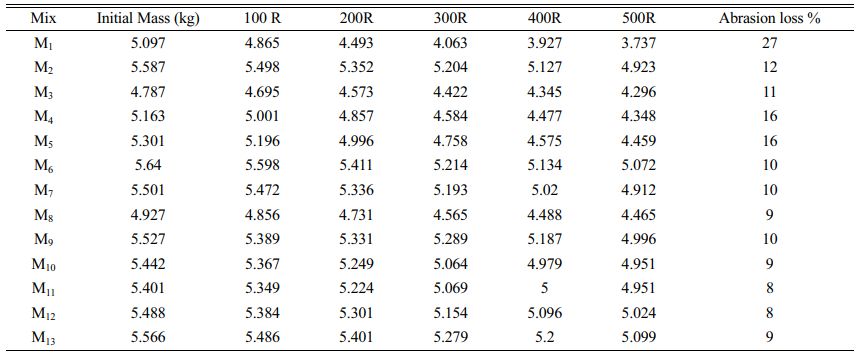

Acid Attack

The pervious concrete specimens were immersed in diluted 5% acidic solution and the percentage weight change and % change in compressive strength were calculated after one, seven, 14 and 28 days of immersion. The acid first formed a white layer after reacting with the surface of pervious concrete and then it penetrates into the specimen [39]. The PC specimens before and after the immersion periods were shown in Fig. 13. The calculated change in compression strength for each mix is presented in Table 8. The % change in compression strength is found to increase with immersion period. However, the mixes with high strength offered good resistance to acid attack and specimens with SF offered better resistance which makes them durable. The acid resistance of pervious concrete specimens composed of SF has improved significantly which is as per the existing literature.

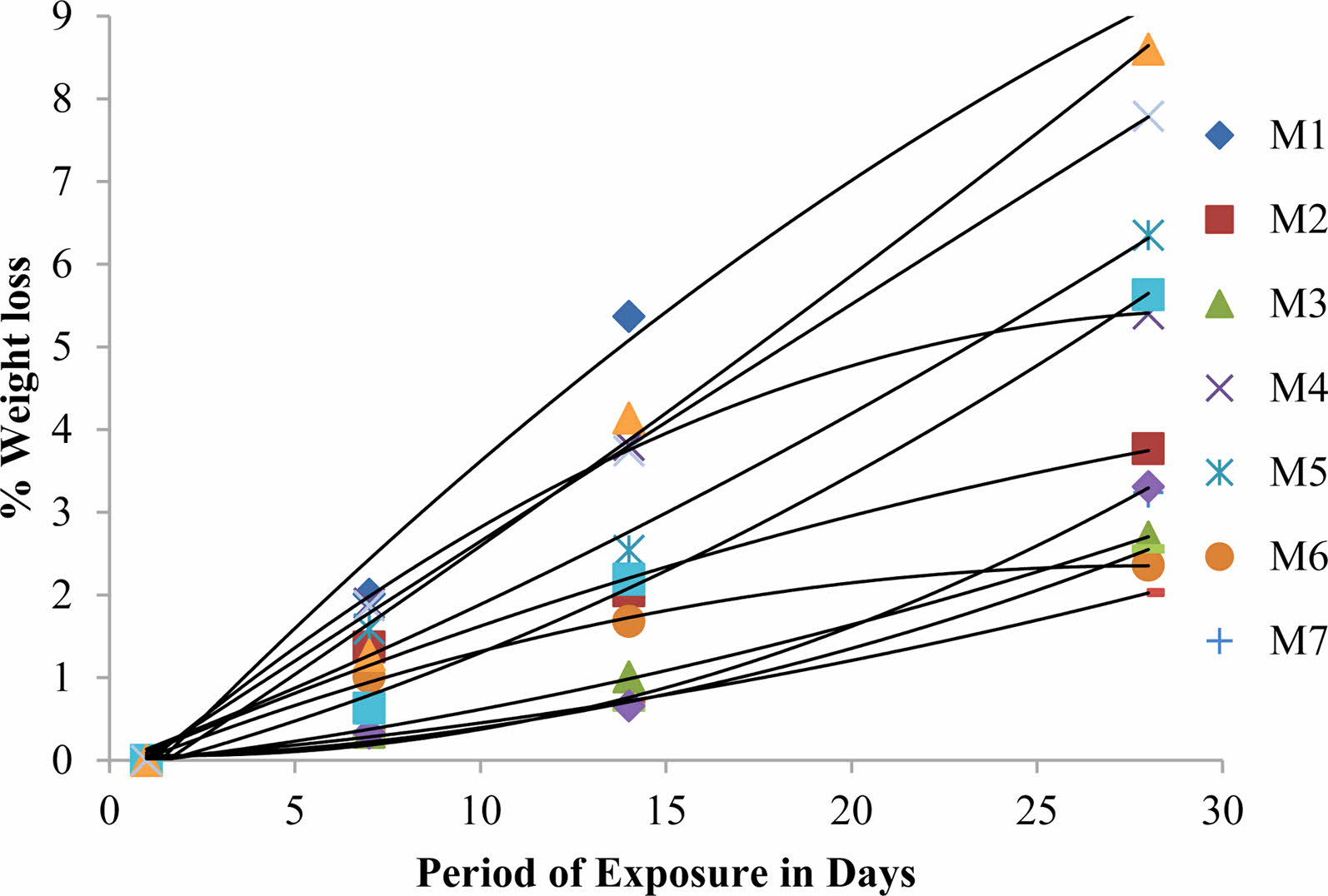

The percentage weight change of specimens after the immersion period is calculated and a plot was made between period of exposure and % weight loss as shown in Fig. 14. It was observed that the percentage weight loss was high for the mix M1 and then M4 and M5. The high percentage weight loss is because of relatively low strength of the mix.

|

Fig. 6 Flexure test on PC |

|

Fig. 7 Cured permeability cylinders. |

|

Fig. 8 % Abrasion loss of mixes |

|

Fig. 9 % weight change of PC mixes with FA. |

|

Fig. 10 % weight change of PC mixes with SF |

|

Fig. 11 % weight change of PC mixes with Fibers. |

|

Fig. 12 Pervious concrete specimens (A) before impact test; (B) after impact test. |

|

Fig. 13 Pervious concrete specimens (A) before acid attack; (B) after acid attack; (C) after testing for compression. |

|

Fig. 14 %weight loss vs. Period of Exposure |

The strength of PC can be enhanced with right combination of SF, FA and poly propylene fibers. However, utmost care has to be taken while working with PC as unlike conventional concrete, the workability of pervious concrete is very low. The compaction should be adequate as author has observed the permeability reduction of few specimens because of heavy compaction. The addition of SF strengthens the transition zone and also the very fine nature of SF reduces the voids and thereby enhances the strength of PC mix. The addition of M-sand as fine aggregate in 5-15% improves not only the strength but also the durability aspects of pervious concrete. It is also observed that the polypropylene fibers showed good resistance to abrasion and acid attack. The toughness of pervious concrete is enhanced and inclusion of fibers has resisted the failure of pervious concrete specimen as it holds the material together without segregation.

In the present study, the durability tests are limited to abrasion and acid attack. However, the researchers can further examine the developed pervious concrete mix for freeze-thaw resistance. The effect of flyash in combination with silicafume on the abrasion resistance of pervious concrete can be further studied.

The carried experimental investigation has resulted in below conclusions,

• The pervious concrete compression strength is enhanced by 112% with the 10% fine aggregate addition.

• The silica fume replacement has increased the compression strength by 32% and flexural strength by 36%.

• The maximum compression strength developed was 31.26 MPa with a permeability of 2.38 mm/s with 1% polypropylene fibers. The addition of polypropylene fibers beyond 1% has decreased the mechanical characteristics of porous concrete.

• The abrasion and impact resistance of pervious concrete increased significantly with the addition of M-sand. The abrasion and impact resistance improved from 27% to 8% for the final mix M11.

• The addition of SF to the PC has improved the acid resistance and also resistance to impact and abrasion.

• The percentage change in compressive strength has reduced significantly from 46% to 22% with the addition of silicafume.

AcknowledgementsThe authors would like to thank the AICTE for the support under Research Promotion Scheme (NDF-RPS) grant number: 8 -17 / RIFD /RPS-PDF /Policy-1 /2018-19 dated March 13, 2019.

Not applicable as research does not involve human or animal subjects.

Not applicable as research does not involve human or animal subjects.

Not applicable

- 1. ACI 522 R, in “Report on pervious concrete” (2010).

- 2. W. Goede and L. Haselbach, J. Transp. Eng. 138[1] (2012) 98-104.

-

- 3. A.K. Chandrappa and K.P. Biligiri, Constr. Build. Mater. 111 (2016) 262-274.

-

- 4. G. Shafabakhsh and S. Ahmadi, Int. J. Eng. Trans. B: Appl. 29[2] (2016) 192-201.

- 5. A.A.M. Fazli, S.K. Zakariaa, N.I.N.A. Rahmana, S.Z. Salleha, A.H. Yusoffa, N.A. Sallehb, M.A.A. Taibc, F. Budimand, A. Alia, and P.T. Teo, J. Ceram. Process. Res. 21[6] (2020) 667-682.

-

- 6. G. Pachideh, M. Gholhaki, and A. Moshatgh, Int. J. Eng. Trans. C: Appl. 32[9] (2019) 1277-1283.

- 7. M. Chaitanya and G. Ramakrishna, in proceedings of Mater. Today. 46 (2021) 634-637.

-

- 8. G. Adil, J.T. Kevern, and D. Mann, Constr. Build. Mater. 247 (2020) 118453.

-

- 9. P. Fidjestol and A.N. Kojundic, in “Guide for the use of silica fume in concrete” (2006).

- 10. M.J. Shannag, Cem. Concr. Compos. 22 (2000) 399-406.

-

- 11. J. Song, X. Yang, P. Chen, H. Xu, D. Luo, R. Liu, and Z. Lai, J. Ceram. Process. Res. 23[4] (2022) 409-414.

-

- 12. S. Sridhar, S. Nandhakumar, M. Nallusamy, and R. Maguteeswaran, J. Ceram. Process. Res. 23[4] (2022) 498-502.

-

- 13. M. Chaitanya and G. Ramakrishna, Rec. Adv. in Civ. Eng. Lect. Notes Civ. Eng. 172 (2022).

- 14. A. Ibrahim, E. Mahmoud, M. Yamin, and V.C. Patibandla, Constr. Build. Mater. 50 (2014) 524-529.

-

- 15. M.A.R. Bhutta, K. Tsuruta, and J. Mirza, Constr. Build. Mater. 31 (2012) 67-73.

-

- 16. J. Yang and G. Jiang, Cem. Concr. Res. 33 (2003) 381-386.

-

- 17. T.H. Ahn and T. Kishi, J. Ceram. Process. Res. 16[1] (2015) 117-123.

-

- 18. J.H. Kim, J.S. Ryou, H.G. Kim, T.H. Ahn, Y.S. Lee, and A. Qudoos,, J. Ceram. Process. Res. 20[1] (2019) 70-76.

-

- 19. Y. Heo and K. Kim, J. Ceram. Process. Res. 16 [1] (2015) 28-32.

-

- 20. A. Bonicelli, G.M. Arguelles, and L.G.F. Pumarejo, Procedia. Eng. 161 (2016) 1568-1573.

-

- 21. G. Xu, W. Shen, X. Huo, Z. Yang, J. Wang, W. Zhang, and X. Ji, Constr. Build. Mater. 158 (2018) 141-148.

-

- 22. J.T. Kevern, D. Biddle, and Q. Cao, J. Mater. Civ. Eng. 27[9] 2015.

-

- 23. J. Leon Raj and T. Chockalingam, Road Mater. Pavement Des. (2019) 1468-0629.

-

- 24. M. Rangelov, S. Nassiri, L. Haselbach, and K. Englund, Constr. Build. Mater. 126 (2016) 875-885.

-

- 25. S. Hesami, S. Ahmadi, and M. Nematzadeh, Constr. Build. Mater. 53 (2014) 680-691.

-

- 26. D. Han, K.M. Kim, G.C. Lee, J.G. Choi, and G.T. Koh, J. Ceram. Process. Res. 16[1] (2015) 56-62.

-

- 27. Kevern, K. Wang, and M. Suleiman, in “Pervious Concrete Construction: Methods and Quality Control” (2006).

- 28. M. Adamu, K.O. Ayeni, S.I. Haruna, Y.H.I. Mansour, and S. Haruna, Case Stud. Constr. Mater. 14 (2021).

-

- 29. M. Gesoglu, E. Guneyisi, G.J. Khoshnaw, and S. Ipek, Constr. Build. Mater. 73 (2014) 19-24.

-

- 30. H. Wu, B. Huang, X. Shu, and Q. Dong, J. Mater. Civ. Eng. ASCE, 23 (2011) 697-702.

-

- 31. H. Guo, Z.G. Song, and S.Y. Yang, Key. Eng. Mater. 517 (2012) 352-356.

-

- 32. L. Gao, Y. Lai, M.R.I. Pramanic, and W. Zhang, Mater. 14[10] (2021) 2670.

- 33. IS 516, in “Method of Tests for Strength of Concrete” (2012).

- 34. ASTM D 5856-95, in “Standard Test Method for Measurement of Hydraulic Conductivity of Porous Material Using a Rigid-Wall, Compaction-Mold Permeameter” (1995).

- 35. ASTM C 1688, in “Standard test method for Density and Void content of Freshly Mixed Pervious concrete” (2009).

- 36. ASTM C 1754, in “Standard test method for Density and Void content of Hardened Pervious concrete” (2012).

- 37. ASTM C 1747, in “Standard test method for Determining Potential Resistance to Degradation of Pervious concrete by Impact and Abrasion” (2013).

- 38. ASTM C 267, in “Standard Test Methods for Chemical Resistance of Mortars, Grouts, and Monolithic Surfacings and Polymer Concretes” (2020).

- 39. Z. Ge, S. Li, Y. Wu, Y. Sha, J. Sun, and J. Tian, J. Ceram. Process. Res. 23[5] (2022) 685-693.

-

This Article

This Article

-

2023; 24(2): 257-265

Published on Apr 30, 2023

- 10.36410/jcpr.2023.24.2.257

- Received on Sep 17, 2022

- Revised on Dec 27, 2022

- Accepted on Jan 27, 2023

Services

Services

- Abstract

introduction

research significance

materials and methodology

results and discussion

critical observation

future scope

conclusions

- Acknowledgements

- Ethical approval

- Consent to participate

- Consent to publish

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Mycherla Chaitanya

-

Research Scholar, Puducherry Technological University, Civil Engineering, Puducherry, India

Tel : +919000457245 - E-mail: mycherlac@pec.edu

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.