- Effect of nanoclay and nano rice bran powder in clay soil

M.R. Abishaa and J. Prakash Arul Joseb,*

aResearch Scholar, Department of Civil Engineering, Noorul Islam Centre for Higher Education, Thuckalay, Kanyakumari, India

bResearch Supervisor, Department of Civil Engineering, Noorul Islam Centre for Higher Education

Thuckalay, Kanyakumari, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This research article intends to put forward the analysis report on effect of using Nano clay and Nano Rice Bran powder in clay soil. The virgin (or) parent soil is tested for knowing their assets and then based on the optimum moisture content about 0.2%, 0.4%, 0.6%, 0.8%, 1%, 1.2%. of Nano Clay and Nano Rice Bran powder added. First all the required engineering property of the clay soil is determined followed by them Atterbergs limit, Standard proctor compaction test, California Bearing Ratio test for soil with different additives were determined. The significant improvement while using nano additives were noted. The Liquid Limit of virgin soil is 44% and while adding Nano Clay and Nano Rice Bran powder 0.2% on each trial the Liquid Limit decreases to 37% and 39%. Likewise the plastic limit, shrinkage limit also decreases on increasing additive content. Optimum Moisture Content (OMC) decreases on Nano material addition. For Nano Rice Bran and Nano Clay the optimum value for OMC is 0.6% and 0.8%. The CBR value is determined for analysing the sugrade strength. Maximum value obtained at 1% of Nano Clay and Nano Rice Bran powder addition. On evaluating the overall outcomes, it is clearly known 1% of Nanomaterial is enough for achieving good stabilized soil

Keywords: Nano clay, Nano rice bran powder, CBR value, Clay soil

Earth is covered by soil layer is known as pedosphere. These soil layers are not in uniform condition in all places. It is mention the word hidden cancer for expansive soil [1]. The reason behind this is expansive soil will create foundation settlement, subsidence of subgrade, cracks found on surface of road and in channel wall and leakage in dam. In order to avoid such problem created by expansive soil, replacement of soil, controlling humidity, adopting special layer foundation, modifying soil by chemicals were carried out. The history of road stabilization says effective stabilization mechanism can be done through compaction [2].

In engineering term we can say stabilization is a way to bring poor quality soil to useable one. Stabilization imply that changing (or) improve any one (or) more of selected soil sample properties [3] For changing (or) improving its properties various additives were used and many numbers of research is also conducted. Other than this the undesirable behaviour can also be avoided by providing reinforcement, ground water lowering, by compacting and by providing drainage [4].

Some of the traditional binding materials used in geotechnical engineering are lime and cement [5, 6] and in some situation combination of both also adopted. The traditional method of using cement as binding agent is very much encouraged and used throughout the world. This was not accepted in [7]. He said used of cement make hazardous environment, the carbon dioxide emission in cement make ozone layer to deplete and cause harmful life for human and animal. The disadvantages of using traditional methods are carbon dioxide emission, high amount of energy consumption, high expense [8, 9].

Some of the well-known dust/powder-like waste materials that effectively used for the stabilization of expansive soil include quarry dust, marble dust, baryte powder, pyroclastic dust, and brick powder [10]. Because natural ceramic raw materials are heterogeneous, it is widely accepted that ceramics do have tremendous endurance for accepting different components. However, there is a large potential for using waste in construction projects [11]. The expansive earth can be stabilized by using the CWP. Costs ultimately increase as a result of the lack of high-quality construction materials in the desired location [12].

Other than this material more additives were used and their behaviour analysed by various researchers, some of the additives are kaolin clay [13], carpet waste, geo grid [14], chemicals, electricity, geotextile, fabrics [15], quick lime [16], periwinkle shells ash [17, 18]. It make a vast review about fibre type stabilizing material, the materials in the article are coir, coir pith, palm, jute, flax, sisal and barley straw fiber. These fibers are the natural fiber, apart from this some synthetic fibers are also used, they are carpet waste, polypropylene, rubber waste, glass, polyester, polyethylene, poly vinyl alcohol [19]. In his review clearly give an details about which type of soil , bitumen were used and there outcomes.

Solid wastes like flyash, blast furnace slag, cement kiln dust, rice husk ash, cement, sugar cane bagasse, cow dung [20], choir etc were used commonly. Now in advancement to stabilization plastics, nanomaterials, geopolymers [21] are used. Electric porcelain waste (Fe2O3 and TiO2) is used to make bricks, and this research looks at how varied nano material ratios affect the permeability coefficient, apparent porosity, compressive strength, volume shrinkage rate, and microstructure features of these materials [22].

The implement of nano technology concept in geotechnical engineering gives better outcomes. The nano sized material which we are using in civil engineering purpose are not cementitious material, but it has a tendency to fill the spacing once it is added and make tight bonding and good strength more than cementitious materials [23]. This study examined the particle size, alkaline activator concentration, and solid-liquid ratio of IGCC fused slag in order to assess its potential as a high-strength geopolymer. According to the findings, the geopolymer's compressive strength was predicted to exhibit strong bonding in the slag form [24] Nano- materials size ranges from 1 to 111 nm will have high surface area, they have high reactive property and it also change physical, chemical and mechanical behaviour of soil [25].

Generally nano clay and nano silica are used for soil stabilization [26]. Some of the other additives which we are using now a days are nano copper, nano alumina, nano magnesium oxide and carbon nano tube, nano titanium dioxide, nano silicone dioxide [27], nano calcium carbonate. For subgrade improvement [28] suggest nano zinc oxide for avoiding payment failiure. In order to have a greater ebility to enhance the degraded soil into potential one carbon based nano particles used, they are carbon nano fibers and carbon nano tubes [29].

With its high specific surface area, fine and mono- disperse particle size, and steady crystal structure, nanoporous carbon (NPC) obtained from the pyrolysis of zeolitic imidazolate frameworks (ZIFs) is an attractive material [30].

While adding nanosilica nanomaterials, the soil property changed and the capacity of holding water content increases [31]. For improving the behaviour of asphalt cement nano clay and nano zinc oxide used [32].

Traditional method and modern method of stabilization can be combined together for better strength [33]. Has conducted research on combination of lime and zinc oxide nanomaterial. Here zinc oxide nanomaterial act as a secondary stabilizing agent. The required strength is not meet by lime. So in addition to lime, zinc oxide nanomaterial is added. Research conducted by [34] contain 5 binders flyash, GGBS, rice husk ash, precipated silica, calcium chloride) and these binders added in varying proportion. Cement GGBS, pulverised flyash and roadcem are used as binder [35]. By separating two binders in different proportion also stabilization takes place in experiment use 4:1 ratio of rice husk ash and lime and 65:35 ratio of rice husk and calcium carbide residue.

From the above research on focus of the nano rice bran powder with the use of nano clay has not been studied. The proposed work is focussed on the readily available nano clay and nano powder is prepared from nano laboratory by ball milling technique (Nano Rice Bran Powder). Likewise nano rice bran powder other nano powders can also be prepared for example egg shell, soil, coconut shell, human hair, waste plastic etc. These materials can convert into nanosize and then used as an additive. The raw rice husk is used in stabilization and their result shown that the silica content in the rice husk improves the soil property and while using along with cement its pozzolanic reaction increases [36].

The focus of this research is to report the effect of nano additive which is readily available in market (nano clay) and nano powder which is prepared in laboratory from waste product nano rice bran powder), in weak clay soil [37]. The change in behaviour of soil is noted and optimum dosage of nano material required is also determined.

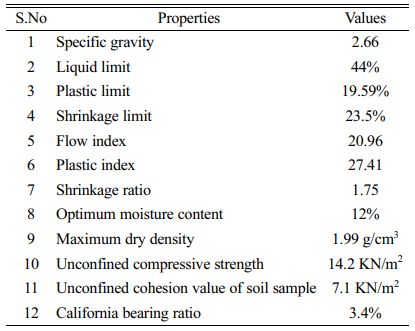

Soil sample collection

In order to determine the efficiency of nanomaterial addition in weak soil, the soil sample is collected from Chunkankadai, local area at a depth of 1 meter below the earth surface. The sample collected is in a disturbed manner. Fig. 1 shows the pictorical view of collected sample then Table 1 contain the assests of the sample. The overall engineering property of soil says the sample is expansive in nature and it is a clay soil.

From the soil properties with reference to [38] the liquid limit with (WL) corresponding to plastic index (IP) its clearly known the collected sample is clay soil with medium plasticity. It has 2.66 specific gravity and 12% optimum moisture content.

Additives

Nano clay

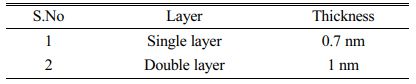

Montmorillonite clay which obtained from volcanic ash is treated for reducing there size, final product obtained is nanoclay [39, 40] utter the nanoclay powder are acting as a potential stabilizer. The nano additive used first is nanoclay powder. The nano clay particles are the fine particle of mineral silicates. The thickness of these additive [41] are given in the Table 2, from this we can conclude single layer nanclay size will be less than 0.7 nm and for double layer between 0.7 nm to 1 nm. The nanoclay Fig. 2 powder is white in colour with high surface area.

In order to enhance the swelling and plasticity characteristics this additive is added in 0.2%, 0.4%, 0.6%, 0.8%, 1%, 1.2% and the improvements are recorded. The fine pores in the soil are filled by these nano sized powder and create a change in the sample. The nanoclay has the tendency to absorb the water, but that depends on availability of cations in the soil layer.

Nano Rice Bran powder (NRB)

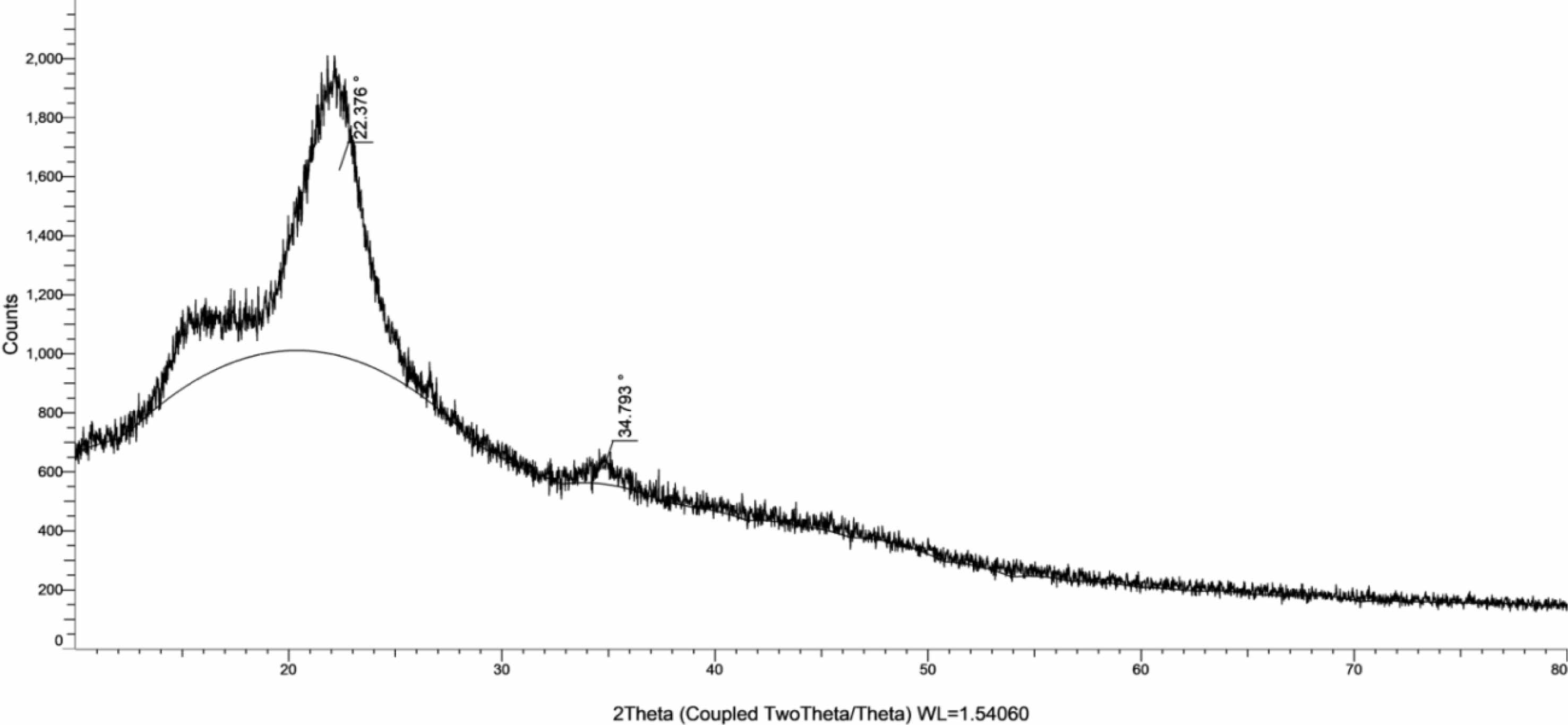

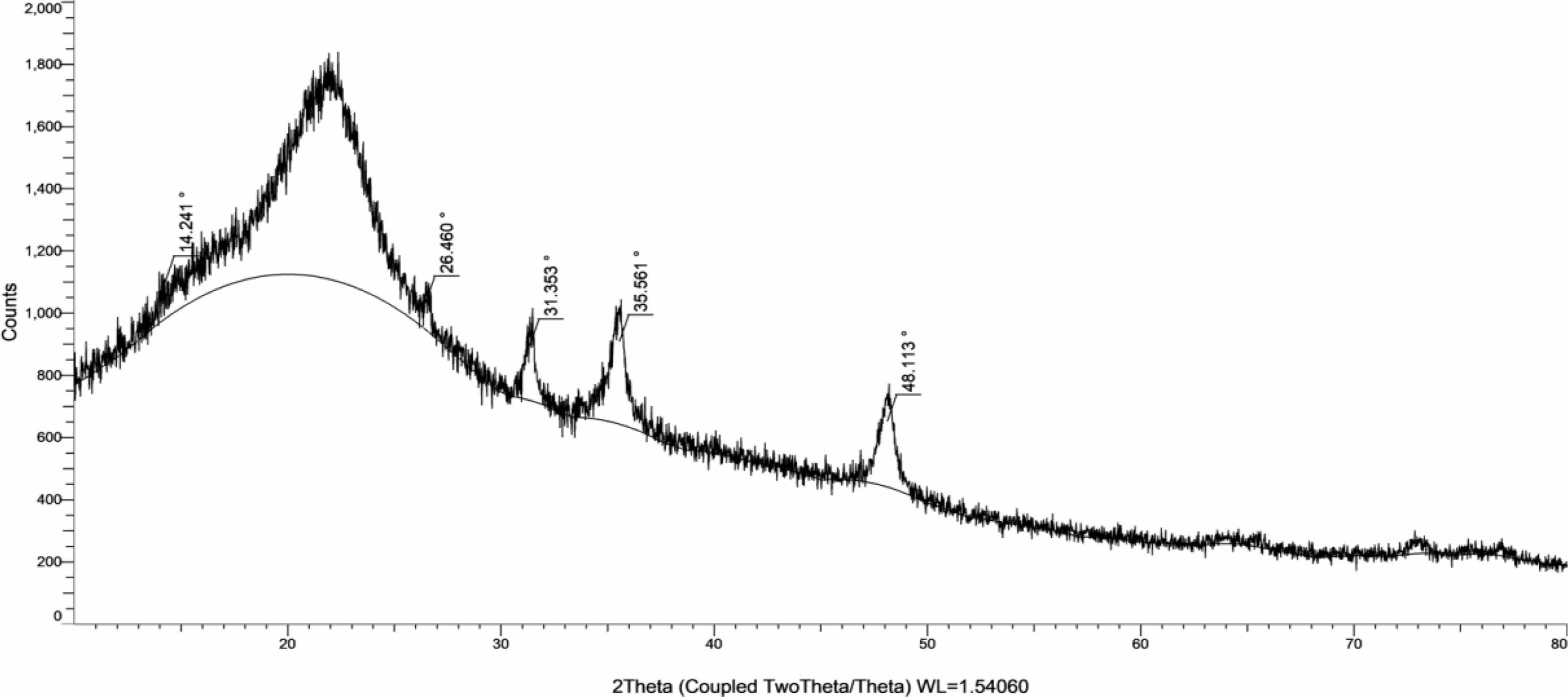

Secondly used nano additive is nano rice bran powder. These nano sized rice bran powder is prepared by collecting raw rice bran powder from the mill and by using ball milling technique. One of the component of raw rice is rice bran. In rice milling process while removing starchy endosperm, the end by product rice bran will be produced [42]. The raw rice bran is converted into nano rice bran powder for getting high surface area material, so only the fine pores in clay soil get filled and reduce shrinkage. If raw rice bran used means due to low surface of material the voids can’t be filled. Under ball milling technique each run 12 gram sample used @ 300 rpm for 10 hours. Fig. 3 and Fig. 4 shows the raw rice bran powder and nano rice bran powder. The colour changes from golden yellow to grey after ball milling. The obtain nano rice bran powder is added in varying percentage such as 0.2%, 0.4%, 0.6%, 0.8%, 1%, 1.2% and the obtained datas are recorded. Fig. 5 Fig. 6 shows the XRD diffraction of raw rice bran powder, in Fig. 7 the diffraction pattern of nano rice bran powder is shown. From the figure its came to know the raw rice bran converted to nano rice bran. The multiple peak formed that means amphorous is coverted to nano material in Fig. 7 clearly defined the formation nano rice bran powder, extra peak found in low crystalline state. The by product of rice will contain silica content in amorphous state that is shown in Fig. 6. About 87.7% of silica present in rice by product.

|

Fig. 1 Virgin Soil |

|

Fig. 2 Nanoclay |

|

Fig. 3 Nano rice bran powder |

|

Fig. 4 Rice bran powder. |

|

Fig. 5 Ball milling cylinder and balls. |

|

Fig. 6 XRD of Rice bran powder. |

|

Fig. 7 XRD of Nano Rice Bran Powder |

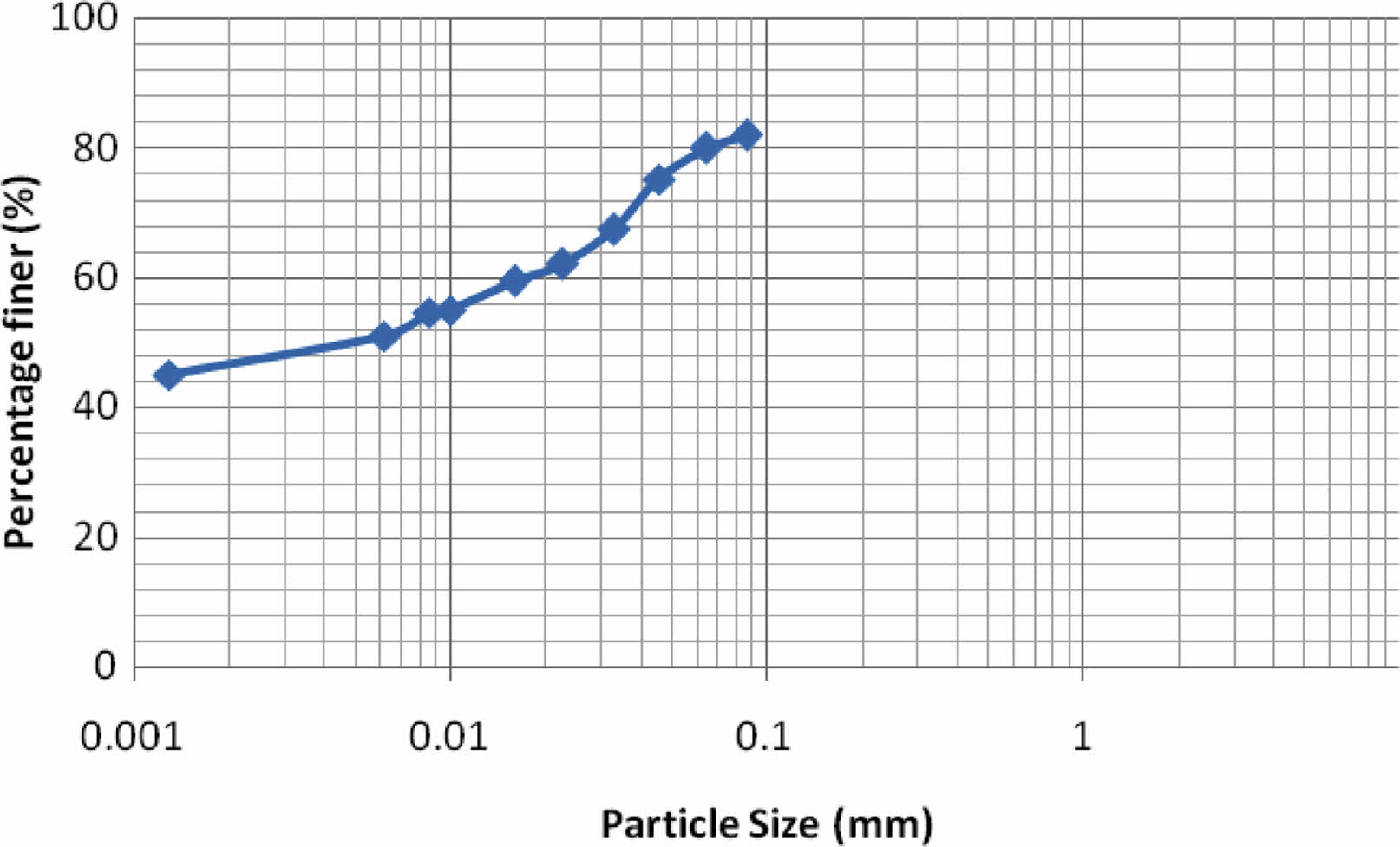

Hydrometer analysis

The equipment hydrometer is to determine the relative density of liquid. Hydrometer is calibrated to give relative density values of any liquid relative to density of water. For analyzing fine grained soil. Particle size, hydrometer is used. Soil size which is smaller than 75 micron can be analyzed by sedimentation analysis. Sedimentation analysis is done by pipette method and hydrometer method. Here for our purpose hydrometer analysis method is used. From the graph its clearly known the collected sample is clay soil with silt content. In Fig. 8 the soil size is between 0.001 to 0.1 so the collected soil is clay type soil. Hydrometer analysis graph shows relation between percentage finer (%) and particle size (mm). Furthermore, calcination (dehydroxylation) at a specific temperature can boost the nano-pozzolanic clay's activity [43], which is more useful for enhancing the mechanical properties of cement-based materials.

Atterbergs limit

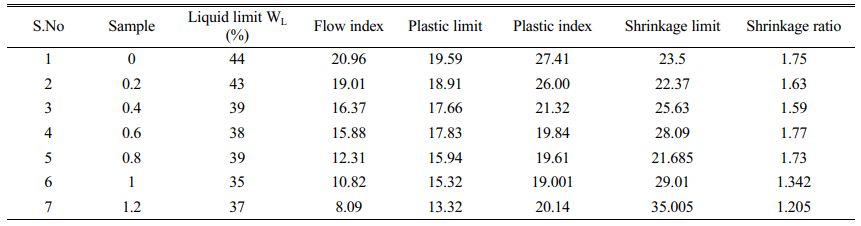

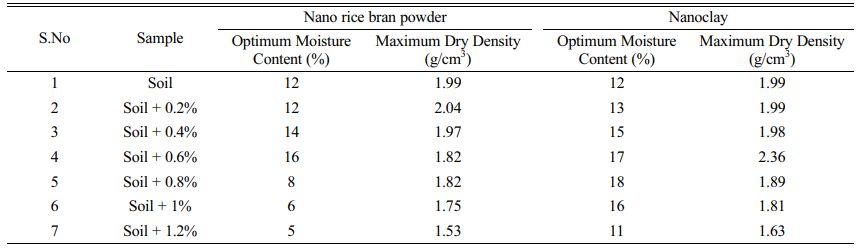

Atterbergs limit means the method of measuring the availability of water content in fine grained soil. The water content is measured by liquid limit, plastic limit and shrinkage limit. The outcome of Atterberg limit shows whether the sample is in solid(or) semi solid(or) plastic (or) liquid state. Atterbergs limit are mostly used to find out the tendency of clay as well as silty soil [44]. The Table 3, 4 shows the liquid limit, flow index, plastic limit, plastic index, shrinkage limit, shrinkage ratio of soil and soil with different % of nanoclay powder and nano rice bran powder.

The result shows that soil with nanoclay addition of 1%reduces the liquid limit to 35%, then again when 0.2% extra added to liquid limit change from 35% to 37%. Hence the drop of liquid limit from 44% to 35% can be seen in addition of 1% of nanoclay. The flow index decreases when admixture addition increases, same as that plastic limit, plastic index decreases whereas shrinkage limit increases on increasing admixture.

While checking the outcomes of soil sample with nano rice bran powder optimum value obtained at 0.6% addition of nano rice bran powder. Hence liquid limit drops from 44% to 37%. After that the addition of each 0.2% leads to increase the liquid limit from 37% to 38%, 43%, 39%. Increasing amount of admixture leads to decrease plastic limit, flow index, plastic index and shrinkage ratio. Whereas shrinkage limit increases.

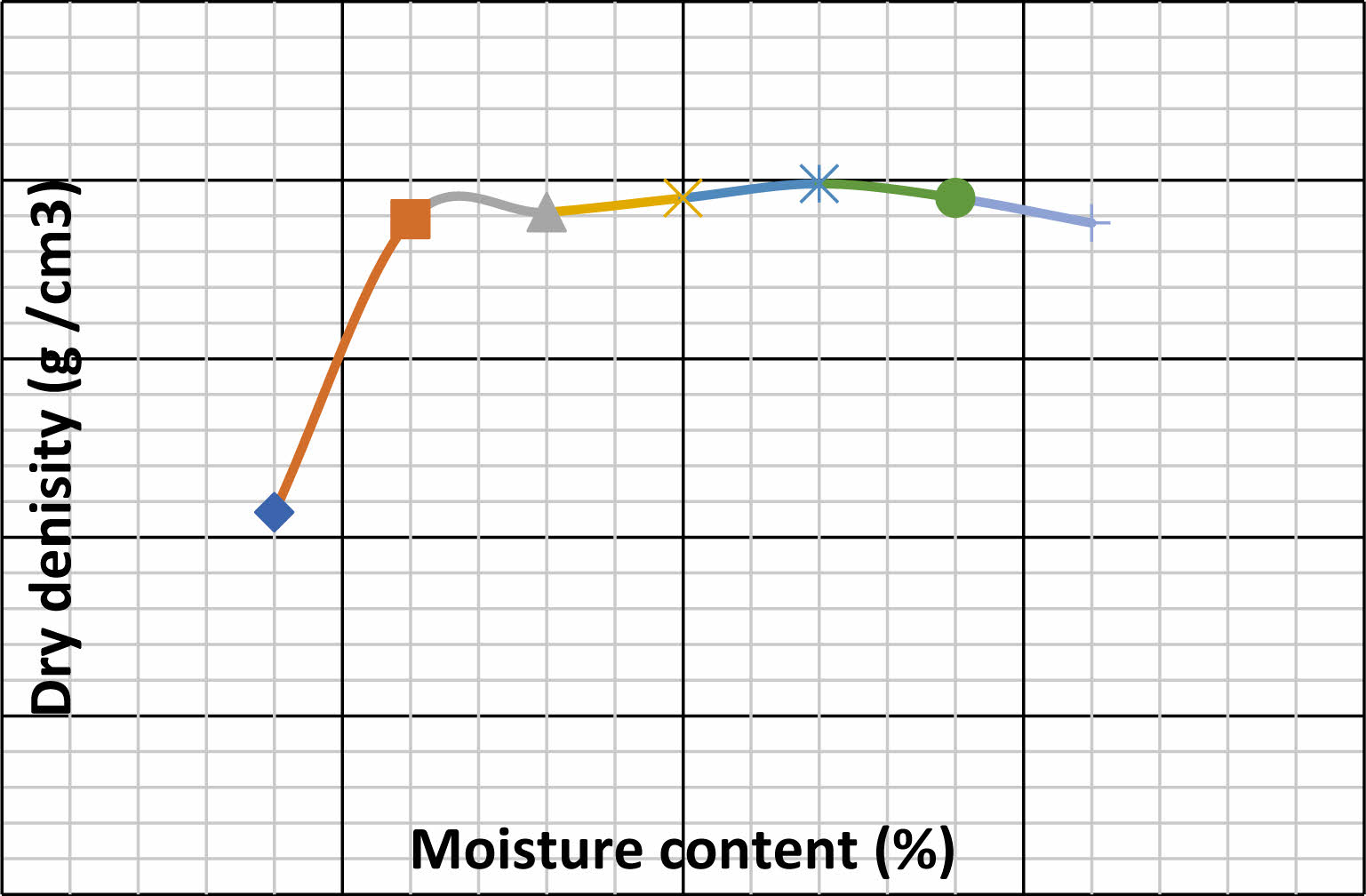

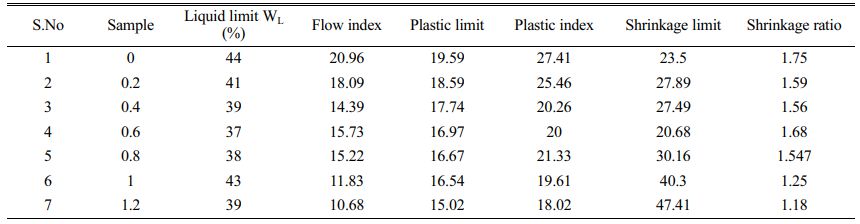

Standard proctor compaction test

For determining maximum limit of dry density and the exact optimum moisture content, standard proctor compaction test conducted as per Indian Standard code IS :2720 (Part 7). The measuring of maximum level dry density and optimum water content is termed as compaction analysis [45]. About 2.5 kg of sample was taken and overdried then required amount of water added. The mould is cleaned and wet soil is placed in the mould by 3 layers, each layer is tamped by 25 number of blows, excessive soil trimed off and weight is taken. The experiment repeated by increasing the water content until the weight of soil with mould decreases. The Fig. 9 shows the relation between moisture content and dry density. The standard proctor compaction test is done for collected original soil and soil with nano additives with different percentage (0.2, 0.4, 0.6, 0.8, 1, 1.2%). The maximum dry density value and optimum moisture content of soil and different percentage of nano additives are listed in the Table 5.

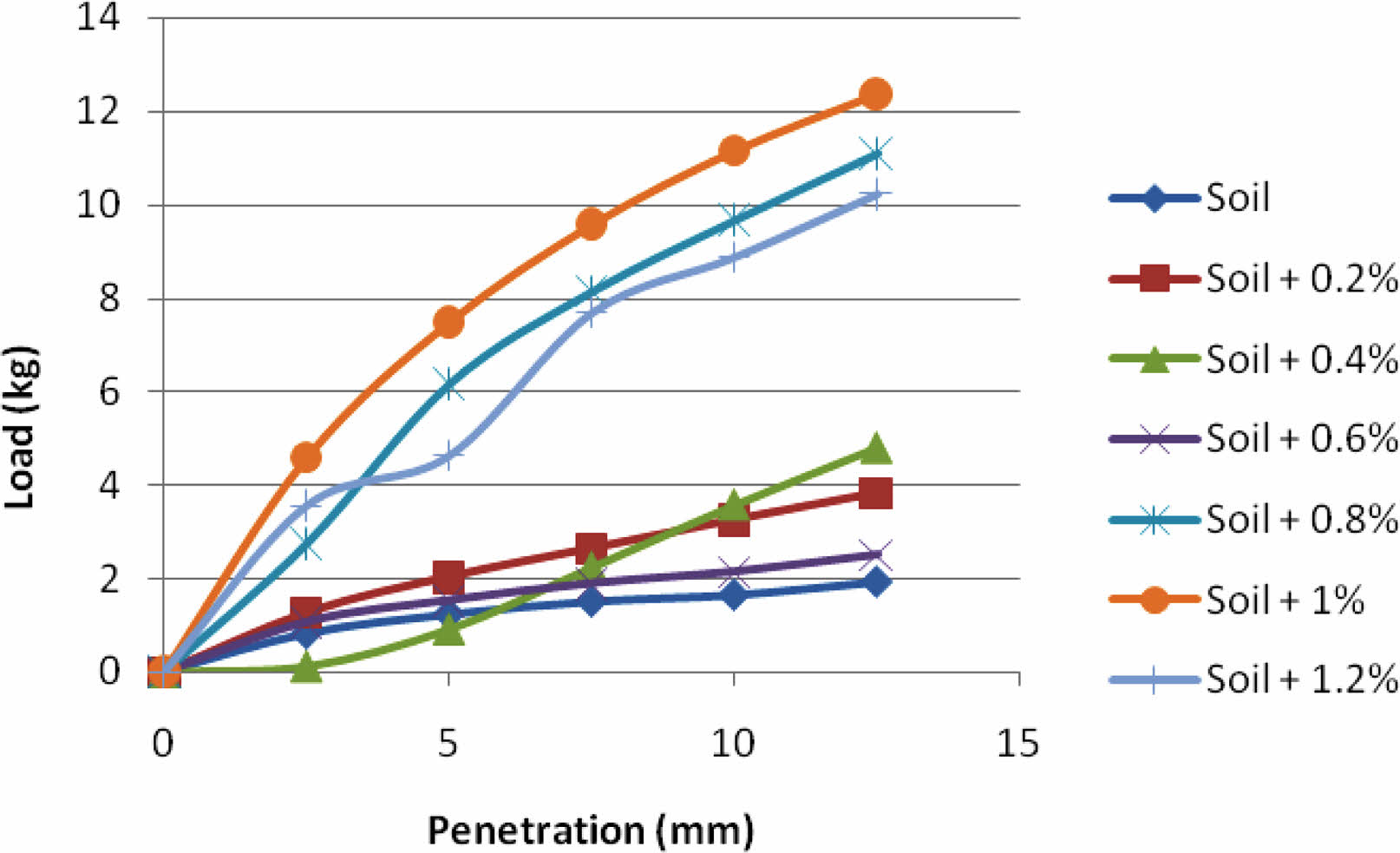

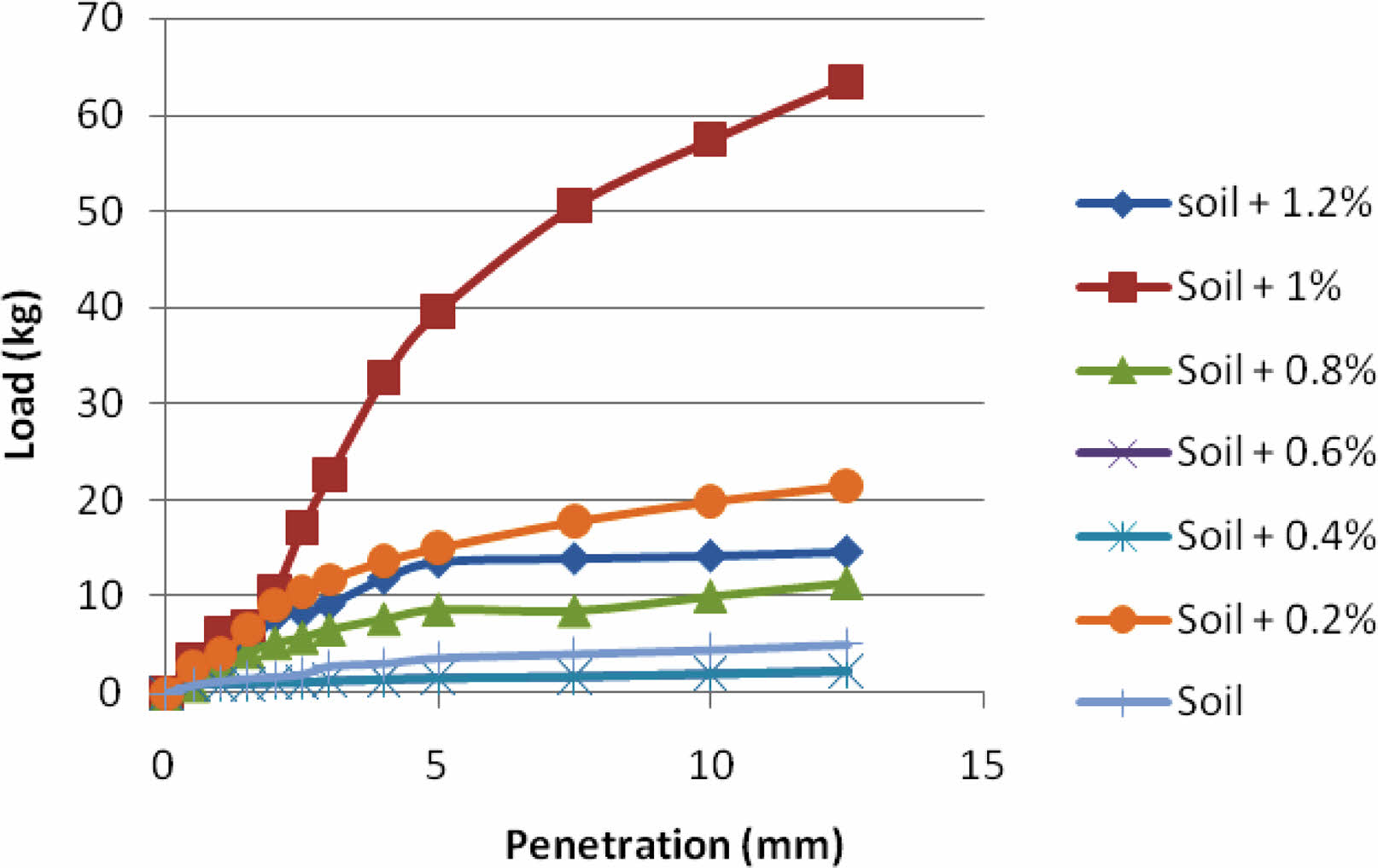

California bearing ratio

The highway department of California state (USA) established California bearing ratio test, which is also named as CBR Test.

The paved area (or) subgrade strength is determined by using CBR. For laboratory investigation 5 kg of sample is taken. The samples are placed in the mould by 3 layers with proper compaction. Then the load is applied and corresponding readings are noted. The CBR test is carried out for virgin sample then with additives. The comparison graph is in Fig. 10 and Fig. 11.

From the Fig. 10 the graph represent maximum load penetration relation at 1% addition of nanoclay. Further addition of 0.2% nanoclay along with 1% nanoclay leads to lower the relation between load and penetration. CBR value also lower when more than 1% of nanoclay powder additive is added. The relation between load (kg) and penetration (mm) gives the CBR value. It has been found that nano-clay is more effective than other additives at boosting cement-based materials' mechanical characteristics and resistance to chloride ion penetration [46].

In Fig. 11 the graph shows that maximum CBR values reached when % of nano rice bran powder is added, again then there is fall in CBR value by excessive addition of nano rice bran powder is approximately same value obtained that means the load penetration relationship is nearly same. Maximum value can seen in 1% addition, so for CBR improvement 1% consider as optimum.

|

Fig. 8 Hydrometer analysis of soil |

|

Fig. 9 Collected Soil Sample Moisture content and Dry density relation graph. |

|

Fig. 10 load and penetration details of soil with nanoclay |

|

Fig. 11 load and penetration details of soil with nano rice bran powder. |

The experimental study is conducted by adding varying amount (0.2%, 0.4%, 0.6%, 0.8%, 1%, 1.2%) of nanoclay and nano rice bran Powder in virgin soil. The optimum dosage of 1% of nanomaterial is considered as an optimum amount which is enough for achieving good strength. Both the nanomaterial are good in their properties. But by using nano rice bran powder the waste rice bran powder is utilized in best way. The CBR Value of soil is also improved which is very much helpful for subgrade to withstand the maximum load. The nanomaterial has high filling ability that means it has high surface area which lock the water and improve the bearing capacity. From this experiment it is clear that beyond the optimum dosage of nano admixture create agglomeration in soil that leads to failure. Overall nano additives produce best outcome and it is recommended to use in further civil applications.

- 1. Y. Liu, Y. Su, A. Namdar, G. Zhou, Y. She, and Q. Yang, Adv. Civ. Eng. 2019.

-

- 2. F.E. Jalal, Y. Xu, B. Jamhiri, and S.A. Memon, Adv. Mater. Sci. & Eng. 2020.

-

- 3. V. Subramani, and S. Sridevi, Int. J. Res. Appl. Sci. Eng. Tech. 4 (2016) 641-645.

- 4. A.J. Choobbasti, M.A. Samakoosh, and S.S. Kutanaei, Const. & Bldg. Mat. 211 (2019) 1094-1104.

-

- 5. R. Zhang, M. Long, and J. Zheng, Adv. Civ. Eng. (2019).

- 6. Y. Liu, C.W. Chang, A. Namdar, Y. She, C.H. Lin, X. Yuan, and Q. Yang, Const. Build. Mats. 221 (2019) 1-11.

-

- 7. K.C. Onyelowe, T. Amhadi, C. Ezugwu, H. Ugwuanyi, U. Iro, I. Jideofor, E. Amanamba, D.B. Van, A.B. Salahudeen, F. Sosa, and J. Aririguzo, Int. J. Low-C. Tech. 14[3] (2019) 410-416.

-

- 8. J. Rosales, F. Agrela, J.R. Marcobal, J.L. Diaz-López, G.M. Cuenca-Moyano, Á. Caballero, and M. Cabrera, Mats. 13[14] (2020) 3058.

-

- 9. P.M. Zhan, Z.H. He, Z.M. Ma, C.F. Liang, X.X. Zhang, and A.A. Abreham, J. Bldg. Environ. 30 (2020) 101-259.

-

- 10. A.K. Sabat, and R.P. Nanda, Int. J. Civ. Struct. Eng. 1[4] (2011) 939-948.

- 11. A.M. Hamzah, S.K. Zakaria, S.Z. Salleh, A.H. Yusoff, A. Ali, M. Mohamad, M.N. Masri, S.A. Sobri, M.A.A. Taib, F. Budiman, and P.T. Teo, J. Ceram. Proc. Res. 22[2] (2021) 200-207.

-

- 12. S.N. Bhavsar, H.B. Joshi, P.K. Shrof, and P.J. Ankit, Int. J. Sci. Res. Eng. Dev. 2[2] (2014) 2321-0613.

- 13. K.C. Onyelowe, T. Amhadi, C. Ezugwu, H. Ugwuanyi, U. Iro, I. Jideofor, E. Amanamba, D.B. Van, A.B. Salahudeen, F. Sosa, and J. Aririguzo, Int. J. Low-Carbon. Tech. 14[3] (2019) 410-416.

-

- 14. Z.J. Taher, J.I.V. Scalia, and C.A. Bareither, Trans. Geotech. 24 (2020) 100387.

-

- 15. J. Krishnan, and S. Shukla, Arab. J. Geosci. 12[14] (2019) 1-25.

-

- 16. J. Khazaei, and H. Moayedi, Arab. J. Sci. & Eng. 44[10] (2019) 8337-8346.

-

- 17. R.K. Etim, D.U. Ekpo, G.E. Udofia, and I.C. Attah, Innov. Infra. Sol. 7[1] (2022) 1-17.

-

- 18. C.C. Ikeagwuani, and D.C. Nwonu, J. Rock Mech. & Geotech. Eng. 11[2] (2019) 423-440.

-

- 19. S. Andavan, and B.M. Kumar, Mat. Tod.: Proc. 22 (2020) 1200-1202.

-

- 20. A.K. Yadav, K. Gaurav, R. Kishor, and S.K. Suman, Int. J. Pvmt. Res. & Tech. 10[3] (2017) 254-261.

-

- 21. E. Adeyanju, C.A. Okeke, I. Akinwumi, and A. Busari, Case Stud. Const. Mat. 13 (2020) e00388.

-

- 22. S. Jieguang, Y. Xueqing, C. Ping, X. Hao, L. Deping, L. Rongjin, and L. Zhijun, J. Cer. Proc. Res. 23[4] (2022) 409-414.

-

- 23. P. Kulanthaivel, B. Soundara, S. Velmurugan, and V. Naveenraj, Mat. Today.: Proc. 45 (2021) 507-511.

-

- 24. Y. Kim, K. Seong-yeol, and T. sung. J. Ceram. Proc. Res. 18[3] (2017) 214-219.

-

- 25. A. Kalhor, M. Ghazavi, M. Roustaei, and S.M. Mirhosseini, Cold Reg. Sci. & Tech. 161 (2019) 129-136.

-

- 26. F. Changizi, H. Ghasemzadeh, and S. Ahmadi, Road Mat. & Pvmt. Des. (2021) 1-18.

-

- 27. S.S. Shahin, P. Laila, and A.E. Fayed, In Seventh Int. Conf. on Nano Tech. Const. 1[1] (2015) 1-5.

- 28. P.P. Kulkarni, and J.N. Mandal, Int. J. Geosyn. & Grnd. Eng. 8[1] (2022) 1-17.

-

- 29. J.E. Sani, P. Yohanna, and I.A. Chukwujama, J. King Saud Univ.-Eng. Sci. 32[1] (2020) 11-18.

-

- 30. T.R. Pilladi, K. Ananthansivan, and S. Anthonysamy, Powder Tech. 246 (2013) 247-251.

-

- 31. A.H. AlSaeedi, J. King Saud Univ.-Eng. Sci. (2022) 101926.

-

- 32. A. Al-Omari, M. Taamneh, and R. Imam, J. King Saud Univ.Eng. Sci. (2021) 1-6.

-

- 33. M. Khodaparast, A.M. Rajabi, and M. Mohammadi, Const. & Bldg. Mat. 281 (2021) 122548.

-

- 34. R. Gobinath, G. Raja, E. Prasath, G. Shyamala, A. Viloria, and N. Varela, Mat. Today: Proc. 27 (2020) 657-663.

-

- 35. E.U. Eyo, S. Ng'ambi, and S.J. Abbey, J. Rock Mech. & Geotech. Eng. 12[5] (2020) 1056-1069.

-

- 36. A. Siddika, M.A. Al Mamun, R. Alyousef, and H. Mohammad Hosseini, J. King Saud Univ. Eng. Sci. 33[5] (2021) 294-307.

-

- 37. F. Alharbi, M. Almoshaogeh, M. Shafiquzzaman, H. Haider, M. Rafiquzzaman, A. Alragi, S. ElKholy, E.A. Bayoumi, and Y. El-Ghoul, Sustain. 13[3] (2021) 1443.

- 38. F. Bergaya, and G. Lagaly, Hdbk. clay Sci. Newnes (2013).

- 39. N. AlMasoud, M.A. Habila, Z.A. Alothman, T.S. Alomar, N. Alraqibah, M. Sheikh, A.A. Ghfar, and M. Soylak, Anal. Methodol. 12[41] (2020) 4949-4955.

-

- 40. A. Johari, H. Golkarfard, F. Davoudi, and A. Fazeli, Iran Bldg. Eng. Geo. & Environ. 80[9] (2021) 6725-6748.

-

- 41. A. Kausar, In Clay Nanopar. (2020) 169-184.

-

- 42. S. Bhosale, and D. Vijayalakshmi, Curr. Res. Nutr. & Food Sci. J. 3[1] (2015) 74-80.

-

- 43. A.E. AL-Salami, M.S. Morsy, S. Taha, and H. Shoukry, Const. Bldg. Mat. 47 (2013) 138-145.

-

- 44. T. Christian John, Ency. Phy. Sci. & Tech. (Third edition) (2003) 63-76.

-

- 45. A. AlObaid, K.U. Rehman, S. Andleeb, K.O. Erinle, and A. Mahmood, J. King Saud Univ. Sci. 34[1] (2022) 101716.

-

- 46. A.M. Rashad. Mat. & Des. 52 (2013) 143-157.

-

This Article

This Article

-

2023; 24(2): 242-249

Published on Apr 30, 2023

- 10.36410/jcpr.2023.24.2.242

- Received on Jul 26, 2022

- Revised on Sep 26, 2022

- Accepted on Nov 3, 2022

Services

Services

Shared

Correspondence to

Correspondence to

- Arul Jose

-

Research Supervisor, Department of Civil Engineering, Noorul Islam Centre for Higher Education

Thuckalay, Kanyakumari, India

Tel : 8056238075 - E-mail: prakasharuljosej@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.