- Electromagnetic shielding effectiveness of Ba(Zn1/3Nb2/3)O3: chopped strands composites for wide frequency applications

Ethem İlhan Şahin*

Advanced Technology Research and Application Center, Adana Alparslan Türkeş Science and Technology University, Adana 01250, Turkey

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

In this work, the conventional mixed oxide process was used to form Ba(Zn1/3Nb2/3)O3-chopped strands composites. The single phase compound with the chemical equation Ba(Zn1/3Nb2/3)O3 was generated after sintering at 1250 °C for 4 h. Varied amounts of Ba(Zn1/3Nb2/3)O3-chopped strands were fabricated for the structural examination. X-ray diffraction (XRD), energy-dispersive X-ray spectroscopy (EDS) and scanning electron microscopy (SEM) were carried out for the structural analysis, and the results showed that the second phase did not form in Ba(Zn1/3Nb2/3)O3. In addition to, the Ba(Zn1/3Nb2/3)O3-strands composites were created by hot pressing using the compositions of Ba(Zn1/3Nb2/3)O3-chopped strands in various rates and epoxy. The Ba(Zn1/3Nb2/3)O3-chopped strands compound created in varied weights, and epoxy powder were utilized to manufacture microwave shielding effect composites. Using a two-port vector network analyser (VNA) device, the microwave shielding effect of Ba(Zn1/3Nb2/3)O3-chopped strands composites was examined in a range of 0-8 GHz. A minimal of -44.75 dB shielding effectiveness value was reached at 6.24 GHz and 1.4 mm in thick. The Ba(Zn1/3Nb2/3)O3-chopped strands were fabricated as composite and their properties were defined characterized for shielding effectiveness. To modify microwave shielding effectiveness, the content of components in the specimens may be adjusted for the wider and required frequency ranges

Keywords: Ba(Zn1/3Nb2/3)O3 (BZN), Matrix composites, Microwave shielding, Mixed oxide

The demand for high frequency applications has increased due to the widespread use of movable devices, 5G or upcoming 6G, 7G wireless communication technology, and electronic equipment, as well as the satellite

communication and mobile communication sectors. As a result, electromagnetic radiation (EMR) and electromagnetic interference (EMI) are inevitably seen as a serious threat [1].

Additionally, as the usage of mobile and wearable devices depending on varied wireless technologies, such as GPS, Wi-Fi, Bluetooth and near field communication rises, so does the amount and frequency of the human body’s exposure to EMI [2]. In addition to harming human health, electromagnetic radiation also can be interfere with the electrical power system's effectiveness and exit. Even greater detrimental impacts on human health may result from extended exposure to EMR, according to recent studies. Numerous studies have shown that electromagnetic variables may contribute to a variety of neuropsychiatric conditions, such as depression, attention deficit disorder, and hyperactivity in young people [3, 4].

Signal radiations generated by EMI can greatly damage electronic applications. This can cause digital machines to malfunction at high exposure. Electromagnetic interference, particularly in aviation [5], can harm the communication command and control system and result in risk and accidents, in this context, new and improved EMI shielding materials have drawn a lot of attention [6-8]. There are several uses for composite electromagnetic shielding textiles in the areas of apparel and composite materials. In addition, EMI radiation shielding concrete materials are widely used in nuclear medicine facilities and nuclear research facilities [9, 10]. As a result, the study and creation of electromagnetic shielding materials has become crucial. EMI shielding materials that be able to be seamlessly incorporated with wireless technologies that are robust and wearable are required.

One effective method for addressing the aforementioned issues is the use of EMI shielding materials [11]. The shielding effect of electromagnetic waves lessens interference by converting electromagnetic energy into heat energy by reflexion or absorbance of radiation power [12, 13]. The only way to stop dangerous radiation and safeguard electronic equipment is to provide a barrier that filters out interference. There is a lot of interest in strong and lightweight protective materials [14, 15]. Shielding effect, which may be used in a variety of ways, is an effective way to limit electromagnetic emissions. Examples include sheets, tapes, foams, and screens made of textiles, wire mesh, solid metal, and sheets. The term “shielding effectiveness is a phrase used to define the shielding performance (SE) [16].

Shielding effect materials can be made thinner by including dielectric grains, which will boost their effectiveness. Another method for electromagnetic interference shielding is the absorption and reflectiveness of radiation by specific polymeric or metallic shielding substances that are put near to the emitting components [17, 18].

By obstructing fields, shielding effectiveness substances are utilized as barriers to reduce the electromagnetic area in space [19]. Ba(Zn1/3Nb2/3)O3 (BZN) ceramic is one of the microwave dielectric material that has a great potential application in communication sector. High dielectric materials known as Ba(Zn1/3Nb2/3)O3 (BZN) ceramic materials are utilized in electronics as micro/radio-wave filters and/or microwave resonators [20]. For multifunctional activities, they are reportedly promising materials [21]. The smart dielectric qualities that exhibit high quality factor (Qxf values) identify this class of ceramics as dielectric resonators and microwave band filters [22]. Recent research confirmed that perovskite ceramic systems with single or multiphase phases might be controlled to have extensive tunability when used as resonators due to their high Q-factor and thermal stability. It has been established that magnetic fields have the ability to govern composite resonators made of ferrite-dielectric phases.

They may be employed in several tunable microwave devices as a result of this characteristic. The doping of different cations into the structure of BZN ceramic materials is seen to improve their dielectric characteristics, making them more suitable as multifunctional devices. BaCO3, ZnO, and Nb2O5 are often utilized as starting materials for producing BZN ceramic, and the reactant powders are then calcined at 1000-1200 °C before being sintered at 1200-1400 °C [23].

Glass fibers (chopped strands or glass fiber roving) are among the most significant reinforcement in the high performance composite manufacturing industry and have exceptional mechanical properties [24]. Chopped strands are a elastic and inexpensive reinforcing for composite materials. It resists corrosion and is lightweight. The interface connection between the fiberglass and the matrices resins controls the composite’s qualities [25, 26].

Due to its excellent strength, moisture resistance, and electrical and fire insulation compared to other composites, matter of chopped fibers, e-glass/epoxy composites are also emerging as a potential material for marine applications. The chopped fibers are chopped from continuous glass fibers. Clipped fibers are designed to resist the rigors of splicing.

Due to its superior physical and chemical characteristics, it is mostly utilized in the manufacturing of technical textiles, including those for the automobile, athletic, aviation, wind turbine, and reinforced concrete industries [27].

The most efficient ways to improve its various qualities are thought to be by strengthening BZN ceramic with a secondary phase in various forms, such as fibers or particles. This accessible material, which is obtained from relatively cheap raw materials, can be used in many areas in the desired frequency ranges with these remarkable properties.

In previous research, colemanite/PANI/SiO2 composites’s maximum electromagnetic shielding effect performance was demonstrated to be -41.1 dB at 16.09 GHz and 1.5 mm thick [28]. For another example, the produced Wollastonite/PANI/Colemanite were shown to have a shielding effect value of -41.65 at 6.26 GHz at the thick of 1.5 mm [29]. Furthermore, 0.25% MWCNT composites had a highest electromagnetic shielding effect value of -39 dB at 1.6 GHz [30]. Besides, radiation shielding effectiveness (SE) of concrete containing oxidizing slag aggregate from electric arc furnaces was examined as another instance in the research [34]. As another example, EMP shielding protection of mortar mixed with SiC and graphite was measured [35]. As another work, it has been understood that a materiel with shielding efficiency was designed as a frequency selective surface (FSS), a desirable -20 dB attenuation in transmission characteristics at all frequencies of the GSM system [33].

Shielding effectiveness or insertion loss is related to how far the electromagnetic wave coming to the material passes across. The incoming electromagnetic wave is reported to be reduced by 90% and to travel 10% to the opposite side with a shielding effect worth of -10 dB [31, 32].

Ba(Zn1/3Nb2/3)O3-chopped strands were created as a composite in this experiment using the best possible parameters, and for the first time, their attributes for shielding effectiveness were determined. Ba(Zn1/3Nb2/3)O3-chopped strands into varying ratios, new composites were created using in diverse amounts with epoxy by hot pressing at thick of 1.4 mm. These composites were characterized and determined using XRD (Bruker /Alpha -T). Using a two port VNA (R & S FSH-K 42) device at a wideband frequency (0-8 GHz), including L, S and C radar frequency bands, the microwave shielding effectiveness values of composites made of BZN-chopped strands were determined.

Preparation of Ba(Zn1/3Nb2/3)O3

BZN powder was created by the mixed oxide technic. In this method, BaCO3, ZnO and Nb2O5 were mingled as starting materials in a stoichiometric ratio. ZnO (99.9%) was obtained from merc powders, whereas Nb2O5 (Sigma-Aldrich : 99%) and BaCO3 (Sigma-Aldrich : % 99) were obtained from sigma-aldrich powders. For 15 hours, powders were mixed in a ball mill; after that, zirconia balls were utilized to increase the mixture even more. The slurries were first left to dry for 24 hours at 100 °C, and then they would be calcined for 4 hours at 1100 °C in an airtight crucible composed of alumina to minimise evaporation losses, which were calculated by weighting the specimens before and after calcination. The calcined powders were first ground in an agate mortar before being made into pellets of 1-2 mm thick and 10 mm diameter using a uniaxial press at 2 MPa pressure. After burying the pellets in the BZN powder, to prevent the loss of volatile species, the patterns were sintered between 1100 °C and 1300 °C for 4 hours at a heating and cooling rate of 250 °C/h [40, 42].

After calcining at 1100 °C, the single phase Ba(Zn1/3Nb2/3)O3 powders were sintered at 1250 °C.

The phases in the doped sintering specimens were measured using XRD and CuK radiation (λ = 1.5406 Å) inside this range 2θ: 10-70° at a scanning speed of 1/min. Following sputter coating with an Au/Pd alloy, the specimens' fracture surfaces were studied in the scanning electron microscope (JEOL 5910LV) at 20 kV. SEM was used to identify the phases and examine the morphology. The energy dispersive spectrometry (EDS, Oxford-Inca-7274) was employed to do the chemical analyses. The microwave shielding effect of composite materials constructed of BZN:chopped strands were measured in the frequency range of 0-8 GHz using only a two-port vector network analyser device.

Preparation of chopped strands/Ba(Zn1/3Nb2/3)O3 composites

After being broken up in a agate mortar, the chopped strands were stoichiometrically mixture with sintered BZN powders. In accordance with the compositions of chopped strands-sintered BZN in ethanol medium, powders were mingled with ethanol for 20 h at 80-20 wt.% and 20-80 wt.%, respectively. For 20 hours, zirconia balls were used to stir particles in an ethanol medium within a plastic container using a ball mill. This increased the mixture even more. The slurries were dried under vacuum for 24 hours at 60 oC before being pressed. The slurries were dried for 20 hours at 100 oC, and filtering and washing the resultant mix with ethanol and deionized water were generated the composites.

The features of EMI shielding effectiveness of composites with different molar ratios were examined. To determine how the strands ingredient influenced the electromagnetic shielding effect, chopped strands/BZN composites in varied ratios [chopped strands-Ba(Zn1/3Nb2/3)O3 (at 80-20 wt.%), chopped strands-Ba(Zn1/3Nb2/3)O3 (at 20-80 wt.%)] were created. The composites were made using BZN with chopped strands. Hot pressing was used to create composite materials made of chopped strands and BZN in a variety of ratios.

Preparation of epoxy-(chopped strands/Ba(Zn1/3Nb2/3)O3) composites

The composites were created by molding and curing powdered BZN/chopped strands composition and epoxy. The specimen powders were mixed with epoxy in a 5:1 weight ratio. In a hydraulic press, molding was completed for 1 hour at 150 °C and 5 MPa pressure. To measure the shielding effectiveness, they were formed into 20 mm-diameter pellets with a 1.4 mm thickness. Composites were fabricated using epoxy in certain ratios of chopped strands/BZN to provide a broadband microwave shielding effect. To achieve a broadband microwave shielding effect, composite materials were created utilizing epoxy and certain ratios of chopped strands/Ba(Zn1/3Nb2/3)O3.

XRD analyzed of chopped strands/Ba(Zn1/3Nb2/3)O3

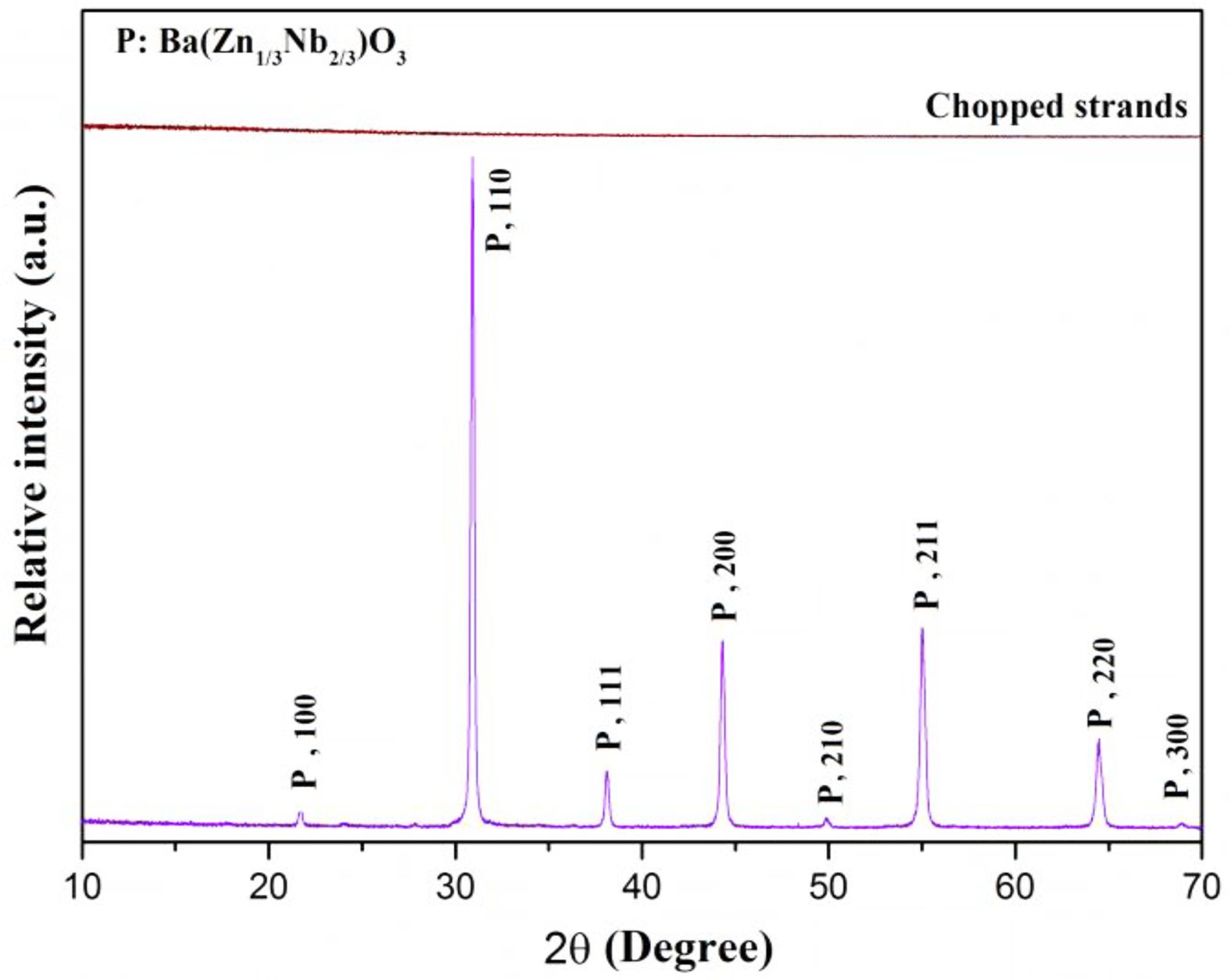

To describe the characterization of BZN and chopped strands, the XRD diffracted its X-ray pattern. BZN was annealed at 1250 °C for 4 hours, and the XRD analysis revealed the creation of a single phase structure and chopped strands (Fig. 1). Principal phases are designated as BZN as can be observed in the detection of Ba(Zn1/3Nb2/3)O3 (PDF Card No:00-039-1474). By applying a mixed oxide technique with an appropriate calcination temperature and the removal of any possible intermediary phases, the powders’ single phase structure was obtained. All of the specimens were sintered for 4 hours at 1250 °C [41].

XRD examination indicated that the BZN powders lacked a secondary phase. The samples' phase structures maintained single phase BZN-pure chopped strands phase and their diffraction peaks were consistent with BZN, chopped strands, and the samples themselves. BZN is mostly temperature sensitive during synthesis, and high temps are occasionally employed to create single phases.

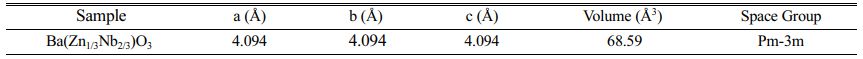

BZN has a cubic crystal structure as centrosymmetric. Using Full Prof, the experimental lattice parameters and unit cell volume were calculated in Table 1, and the XRD pattern was matched to the XRD pattern of BZN [36, 37].

SEM Analysis of Ba(Zn1/3Nb2/3)O3

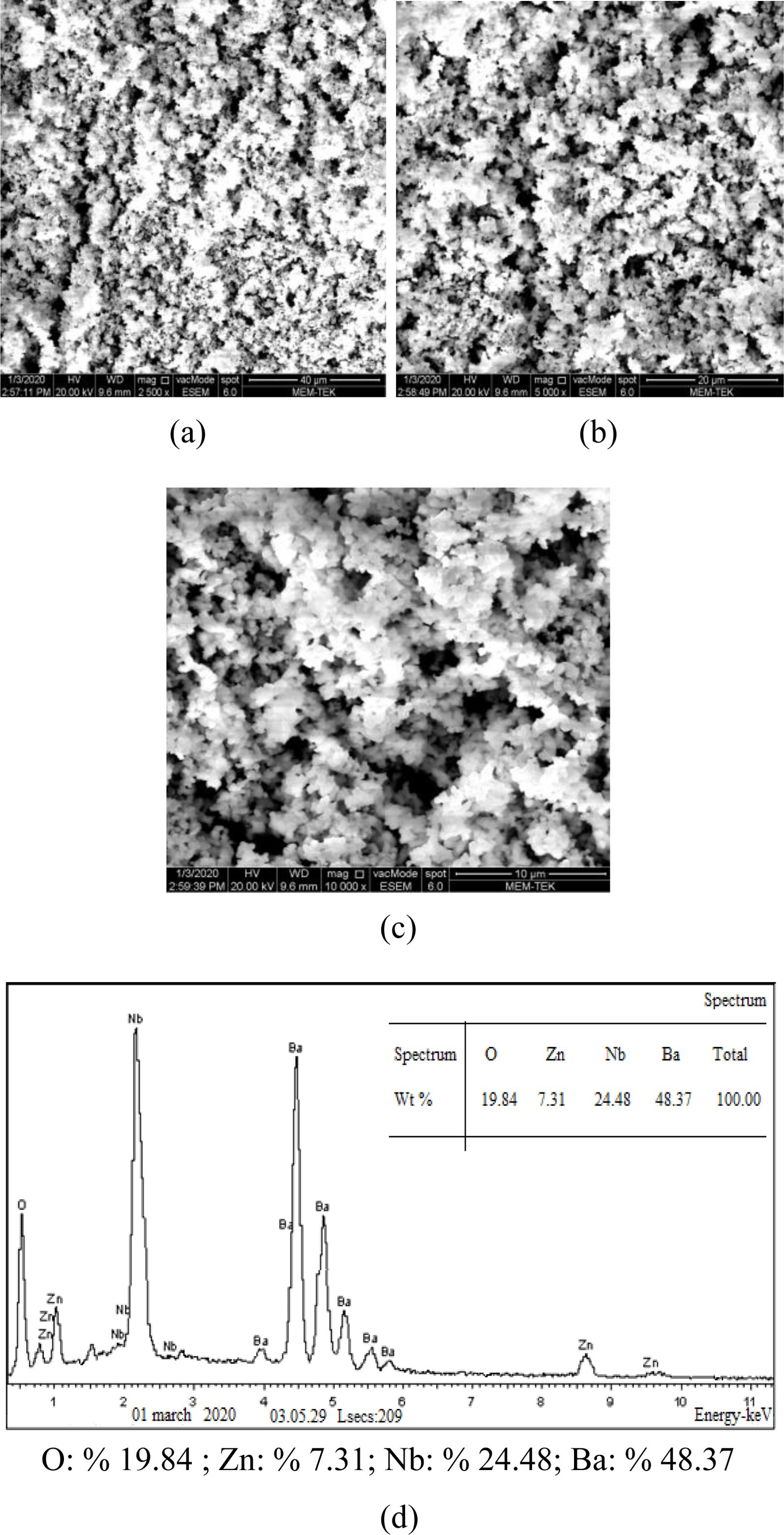

SEM was used to examine the specimens that were heat treated at 1250 °C for 4 h.

As in the XRD analysis, SEM examination revealed that only BZN single-phase structure was created in all samples, and no secondary phases or microstructural impurities were found (Figs. 2(a), (b) and (c)). The majority of grains had a cubic structure form as centosymmetric, and no discernible compositional variation was found in the EDS analysis across grains with various morphologies.

EDS analysis applied to BZN grains showed that the composition of the grains was close to the theoretical composition of the BZN compound. The Ba(Zn1/3Nb2/3)O3 grains' EDS examination yielded values that were extremely similar to the material's theoretical composition (19.84% O, 7.31% Zn, 24.48% Nb, 48.37% Ba). It is determined that the grain size is compatible when particle size is assessed at various magnifications (Fig. 2(d)).

Densities Measurement of Ba(Zn1/3Nb2/3)O3

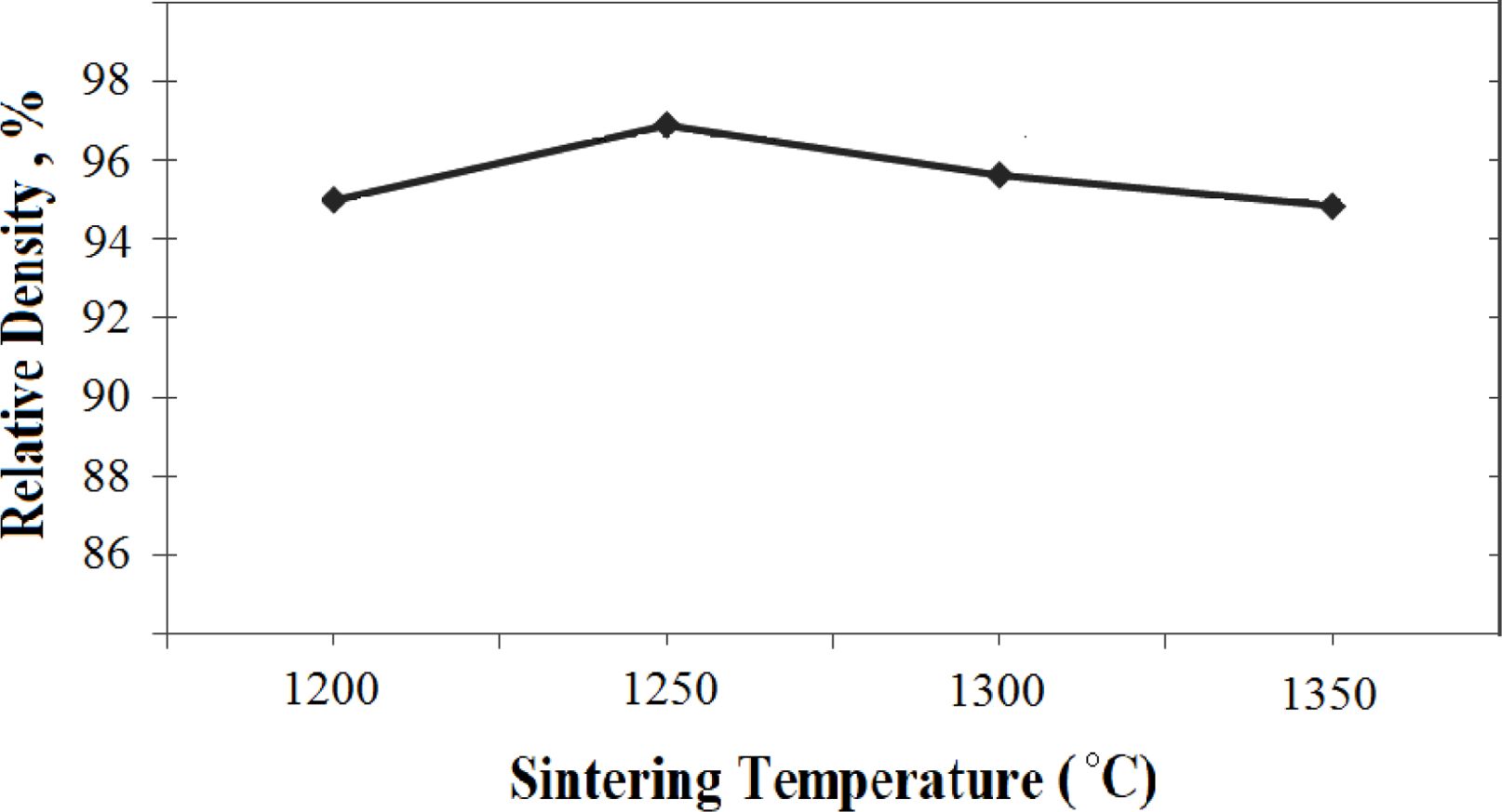

Densities of BZN pellets obtained after sintering were measured using the Archimedes method.

While BZN ceramics had a relative density of approximately % 95 at 1200 °C, the density value reached % 97 at 1250 °C and then a gradual decrease was experienced in the density value. The decrease in density after 1300 °C is probably due to ZnO losses (Fig. 3).

EMI Shielding Measurements of Chopped Strands/ Ba(Zn1/3Nb2/3)O3 Compositions

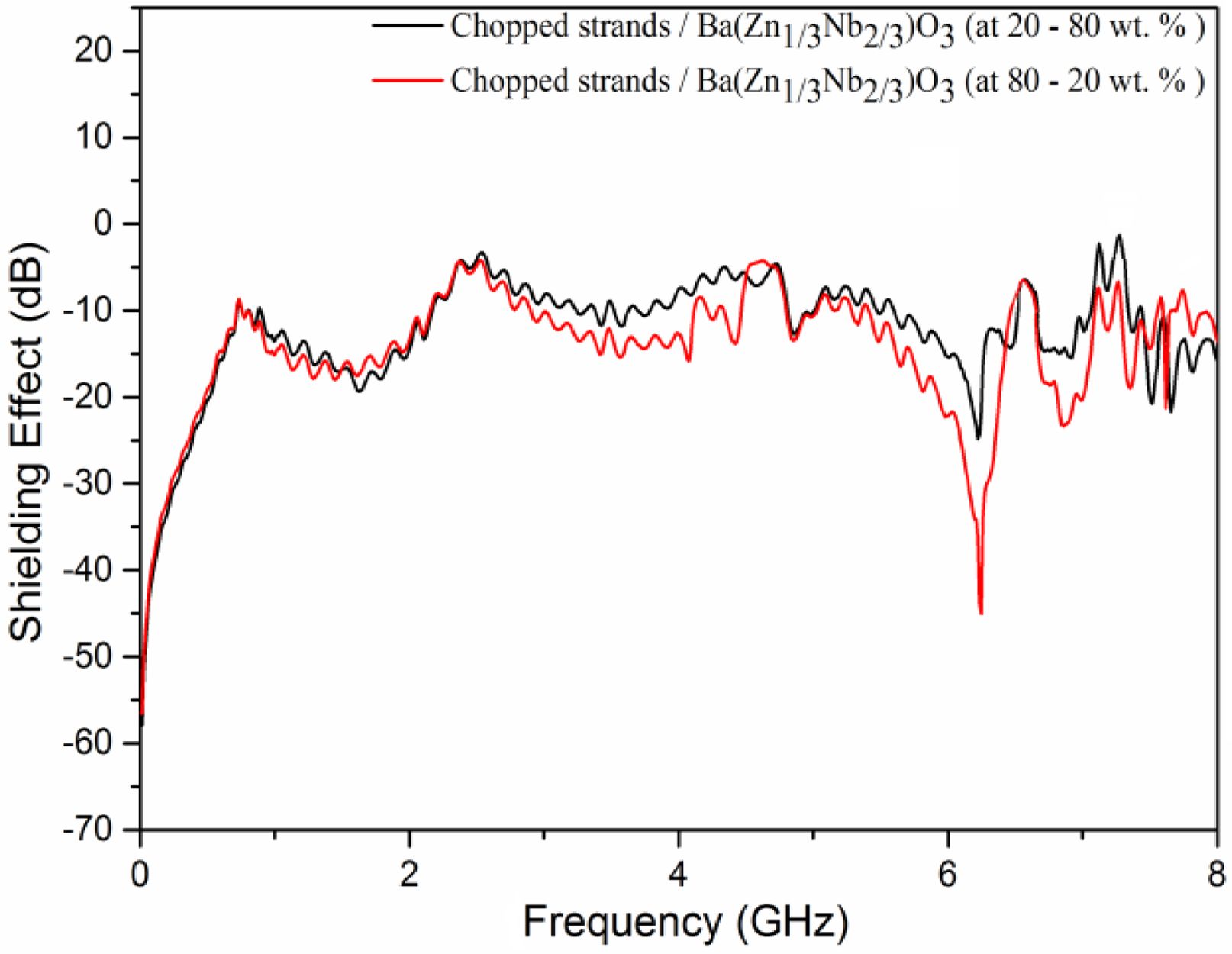

The frequency dependent of the shielding efficacy performance of the epoxy-(chopped strands/BZN) composites in the frequency range of 0-8 GHz is shown in Fig. 4.

Two port VNA (R & S FSH-K 42) device was used for shielding effect measurements. To perform the SE test, coaxial holders of sufficient diameter maintaining 50-ohm impedance at the input and output ports were used. Basically, a sample-free value was calculated first. The samples were then placed sequentially in the instrument, always compacted evenly at three different locations to maintain consistent pressure throughout the sample.

The device sends the output values to the computer where the SE was determined. The difference between the presence and absence of samples was displayed on the computer as shielding efficiency values The measurement of the device was checked by measuring the smooth round, 1.4 mm thick samples repeatedly. Sample thickness is a critical dimension and thin is ideal. For best reproducibility of SE measurements, reference sample area and load sample were the same in thickness, measured SE values of composites were related to geometry and orientation [38, 39]. The shielding effect value depends on how far the incoming electromagnetic wave passes through the composite material. When the EMI does not pass, it will either be reflected back or absorbed by the material. That is, the material that gives EMI protection feature has either back reflection or absorbance, for this, separate measurements are required with this device.

In the Ba(Zn0.33Nb0.67)O3/chopped strands composites, the microwave shielding effectiveness of chopped strands-BZN (at 80-20 wt.%) were obviously superior than those of chopped strands-BZN (at 20-80 wt.%). One band at 6.24 GHz with -44.75 dB in chopped strands/Ba(Zn1/3Nb2/3)O3 compositions (at 80-20 wt.%) was all that was present. This composite material arrived -23.48 dB and -21.34 dB, at 6.86 GHz and 7.61 GHz, respectively. Further, in the frequency regions of 0 and 0.71 GHz, 0.77 and 2.15 GHz, 2.91 and 4.11 GHz, 4.78 and 5.01 GHz, 5.41 and 6.45 GHz, 6.64 and 7.09 GHz, 7.28 and 7.58 GHz, it accomplished shielding effectiveness value under -10 dB. In addition, the compositions had a shielding effectiveness below -20 dB in the range of frequency between of 0 GHz and 0.48 GHz, 5.93 GHz and 6.38 GHz, 6.81 GHz and 6.96 GHz.

When the quantity of Ba(Zn0.33Nb0.67)O3 powder increased and chopped strands content decreased, the chopped strands/Ba(Zn1/3Nb2/3)O3 compositions (at 20-80 wt.%) reached to -19.65, -12.83, -24.96, -15.81, -20.92 and -21.79 dB, at 1.62, 4.85, 6.22, 6.92, 7.51 and 7.65 GHz, respectively. In the frequency ranges between 0 and 0.49 GHz, 6.15 and 6.24 GHz, this composite also demonstrated shielding effect performance under -20 dB. In contrast, it reached a shielding effectiveness under -10 dB in the frequency ranges of 0 and 0.73 GHz, 0.89 and 2.16 GHz, 4.81 and 4.91 GHz, 5.6 and 6.49 GHz, 6.65 and 7.05 GHz, 7.44 and 8 GHz.

The greatest wideband shielding performance was provided by the chopped strands/Ba(Zn1/3Nb2/3)O3 (at 80-20 wt.%), with a value under -20 dB in the frequency range of 5.93 and 6.38 GHz.

As assessed in the particular radar bands, like wlan frequency and wide frequency range, chopped strands/ BZN are intriguing. They provide strong shielding effect as fine durable distinct sample materials.

For EMI shielding, multiple reflections brought on by internal reflections in the shielding material are crucial. This phenomena is more evident if the material has a lot of large surface areas or interfacial regions.

This porous composite materials most likely have a huge internal number of grain boundaries and big specific surface area. These characteristics enhance the wave shielding effect, and lightness is an advantage for materials with porous structures.

The multiinterfaces between Ba(Zn0.33Nb0.67)O3 and chopped strands play a critic role in the electromagnetic shielding materials. The value of microwave shielding effect also related to the matching (coherence) of the impedance of the irradiation on the surface of the composite material. The matching impedance on transmissions between the components of the composites is improved by chopped strands. In fact, the sharp shielding effect peaks occur, because of the resonance effect of reflection and holder geometry.

The shielding effect (SE) test’s goal is to figure out how much insertion loss results from placing a substance between the source and the signal analyser.

EMI shielding is affected by reflection loss and absorption loss. The other effect is multiple reflection effect, which describes internal reflections within the shielding material. When there are many big surface or interfacial areas, this impact generally becomes apparent. This creation is influenced by the shape, microstructure, and geometric composition of the composite, as well as many electromagnetic wave reflections and refractions. There are possibly multiple internal grain boundaries and a sizable specific surface area in sintered Ba(Zn1/3Nb2/3)O3 with porous features. These characteristics improve the shielding effect, and the material’s lightweight is another advantageous characteristic.

Chopped strands improve the transmission impedance between composites’s parts. Because interfacial polarization exists, the many interfaces between BZN and chopped strands encourage an increased electro- magnetic shielding effectiveness. When Ba(Zn1/3Nb2/3)O3 crystallite’s size decreases and its asymmetrical regions increase, there are more collisions in the surface spins. Increases in the distribution of the observed particle size in the crystal structure may also be interpreted as a rise in the shielding effect peak widths.

In this technique, microwave shielding action of composites may be modified by adjusting chopped strands and Ba(Zn1/3Nb2/3)O3 concentration. Chopped strands based Ba(Zn1/3Nb2/3)O3 composites have a significant shielding efficacy rate for electromagnetic waves in a wide band region. Studies show that the composite structure is affected by the concentration of chopped strands.

Chopped strands have an impact on the material's transmission, increasing the effectiveness of the shielding.

|

Fig. 1 XRD patterns of single phase Ba(Zn1/3Nb2/3)O3 sintered for 4 h at 1250 ° C. |

|

Fig. 2 SEM pictures of single-phase Ba(Zn1/3Nb2/3)O3 heat treated

for 4 h at 1250 °C (a) at 2500, (b) at 5000, (c) at ×10000 (d) EDS

examination of BZNat 5000 |

|

Fig. 3 Variation of relative densities of Ba(Zn1/3Nb2/3)O3 with sintering temperature. |

|

Fig. 4 Shielding effect of the epoxy-(chopped strands/Ba(Zn1/3Nb2/3)O3) composites: chopped strands /Ba(Zn1/3Nb2/3)O3 (at 20- 80 wt.%) compositions, chopped strands/Ba(Zn1/3Nb2/3)O3 (at 80- 20 wt.%) compositions. |

|

Table 1 Calculated lattice parameters of Ba(Zn0.33Nb0.67)O3 sample (heat treated 4 h at 1250 °C) by using Full Prof |

Herein, shielding effectiveness properties of chopped strands/Ba(Zn1/3Nb2/3)O3 composites are investigated.

Ba(Zn1/3Nb2/3)O3-chopped strands (at 20-80 wt.% and 80-20 wt.%) composites were manufactured using mixed oxide process and this is the first research of epoxy based chopped strands/Ba(Zn1/3Nb2/3)O3 composites measured in the between 0-8 GHz frequency.

By adjusting the chopped strands and Ba(Zn1/3Nb2/3)O3 powder control, shielding effect performance of material can be varied for the required frequency bands.

Chopped strands based Ba(Zn1/3Nb2/3)O3 composites have a bright future as microwave shielding effectiveness, on account of their straightforward and affordable arrangement methods. Chopped strands of Ba(Zn1/3Nb2/3)O3 were used to increase the microwave shielding effectiveness.

Chopped strands-Ba(Zn1/3Nb2/3)O3 (at 80-20 wt.%) compositions-epoxy with a minimal SE of -44.75 dB at 6.24 GHz and 1.4 mm thickness showed the best shielding effectiveness.

The SEM analysis confirmed the XRD result, as single phase Ba(Zn1/3Nb2/3)O3 in the composite.

Depending on quantity of chopped strands, the microwave shielding properties of BZN-chopped strands composites vary.

The composition of epoxy-chopped strands/ Ba(Zn1/3Nb2/3)O3 (at 80-20 wt.%) gives a high shielding effect value of under -20 dB at frequencies between 0 and 0.48 GHz, 5.93 and 6.38 GHz, 6.81 and 6.96 GHz. Between 0 and 0.71 GHz, 0.77 and 2.15 GHz, 2.91 and 4.11 GHz, 4.78 and 5.01 GHz, 5.41 and 6.45 GHz, 6.64 and 7.09 GHz, 7.28 and 7.58 GHz, This composition has a shielding effect of less than -10 dB.

The shielding efficacy characteristics are significantly influenced by the quantity of chopped strands. This composite was developed for the first time especially for this purpose.

Chopped strands based Ba(Zn1/3Nb2/3)O3 composites have a strong shielding effectiveness proportion for electromagnetic waves in a wide band region at thick of 1.4 mm.

Analyses in the microwave frequency range have demonstrated the appeal of these composites for application in 3G/4G mobile technologies.

Microwave shielding abilities of chopped strands based Ba(Zn1/3Nb2/3)O3 composites can be studied in further detail with other additions and ratios.

In order to increase the microwave shielding, Ba(Zn1/3Nb2/3)O3-chopped strands composites are being employed.

The shielding effectiveness and reflection loss of this composite with another dopant materials might be investigated in radar bands and higher frequency ranges.

In honor of Prof. Dr. Ayhan Mergen, who passed away in 2017, Mr. Salim Şahin (died in 2014) and Ms. Emsal Şahin this work was made.

For their assistance, we also acknowledge the Advanced Techology and Application Center at Adana Alparslan Türkes Science and Technology University.

Prof. Mesut Kartal and Prof. Selçuk Paker Prof. Sedef Kent Pınar from İstanbul Technical University.

- 1. X.Y. Wu, B.Y. Han, H.B. Zhang, X. Xie, T.X. Tu, Y. Zhang, Y. Dai, R. Yang, and Z.Z. Yu, Chem. Eng. J. 381 (2020) 122622-122630.

-

- 2. A.H. Frey, Environ. Health Perspect. 106[3] (1998) 101- 103.

-

- 3. C.W. Lou, Chin-Mei Lin, Wen-Hao Hsing, A.-P. Chen, and J-H. Lin, Text. Res. J. 81[13] (2011) 1331-1343.

-

- 4. M. Shi, M. Shen, X. Guo, X. Jin, Y. Cao, Y. Yang, W. Wang, and J. Wang, ACS Nano 15[7] (2021) 11396-11405.

-

- 5. S. Karch, L. Jäger, E. Karamatskos, C. Graz, A. Stammel, W. Flatz, J. Lutz, B. Holtschmidt-Täschner, J. Genius, G. Leicht, O. Pogarell, C. Born, H.-J. Möller, U. Hegerl, M. Reiser, M. Soyka, and C. Mulert, J. Psychiatr. Res. 42[9] (2007) 734-745.

-

- 6. E.İ. Şahin and M. Emek, Avrupa Bilim ve Teknoloji Dergisi 41 (2022) 240-245.

-

- 7. J. Avloni, M. Ouyang, L. Florio, A.R. Henn, and A. Sparavigna, J. Thermoplast. Compos. Mater. 20[3] (2007) 241-254.

-

- 8. L. Zhang, N.T. Alvarez, M. Zhang, M. R. Haase, R. Malik, D. Mast, V. Shanov, Carbon 82 (2015) 353-359.

-

- 9. X.C. Wang, and Z. Liu, Prog. Electromagn. Res. Lett. 33 (2012) 177-186.

-

- 10. O. Gencel, Fire Mater. 36[3] (2012) 217-230.

-

- 11. A.M. El-Khayatt, Ann. Nucl. Energy 37[7] (2010) 991-995.

-

- 12. B. Yao, W. Hong, T. Chen, Z. Han, X. Xu, R. Hu, J. Hao, C. Li, H. Li, S.E. Perini, M.T. Lanagan, S. Zhang, Q. Wang, and H. Wang, Adv. Mater. 32[14] (2020) 1907499.

-

- 13. X. Zhang, Y. Rao, J. Guo, and G. Qin, Carbon 96 (2016) 972- 979.

-

- 14. A.F. Qasrawi and A.A. Hamarsheh, J. Electron. Mater. 51 (2022) 3693-3704.

-

- 15. Y. Yuan, L. Liyang, M. Yang, T. Zhang, F. Xu, Z. Lin, Y. Ding, C. Wang, J. Li, W. Yin, Q. Peng, X. He, and Y. Li, Carbon 123 (2017) 223-232.

-

- 16. K. Sankaran, M. Deshmukh, M.B. Ahamed, and S.K.K. Pasha, Composites Part A 114 (2018) 49-71.

-

- 17. H.B. Zhang, Q. Yan, W.G. Zheng, Z. He, and Z.Z. Yu, ACS Appl. Mater. Interfaces 3[3] (2011) 918-924.

-

- 18. B.P Singh, V. Choudhary, P. Saini, and R.B. Mathur, AIP Adv. 2[022151] (2012) 1-7.

-

- 19. G.G. Tibbetts, M.L. Lake, K.L. Strong, and B.P. Rice, Compos. Sci. Technol. 67 (2007) 1709-1718.

-

- 20. S. Kamba, H. Hughes, D. Noujni, S. Surendran, R.C. Pullar, P. Samoukhina, J. Petzelt, R. Freer, N.M. Alford , and D.M. Iddles, J. Phys. D: Appl. Phys. 37[14] (2004) 1980-1986.

-

- 21. M. Huang, X. Yang, and F. Jiang, Mater. Res. Express 5[6] (2018) 066301.

-

- 22. X. Cui, L. Liu, H. Li, F. Liu, C. Lijing, and S. Liu, Mater. Res. Express 7[1] (2020) 016306.

-

- 23. A.F. Qasrawi, E.İ. Sahin, M. Emek, M. Kartal, and S. Kargin, Mater. Res. Express 6 (2019) 095095.

-

- 24. M.A. Shayed, C. Cherif, R.D. Hund, T. Cheng, and F. Osterod, Text. Res. J. 80[11] (2011) 1118-1128.

-

- 25. F.M. Zhao and N. Takeda, Composites Part A 31[11] (2000) 1203-1214.

-

- 26. I. Topcu, M. Ceylan, and E.B. Yilmaz, J. Ceram. Process. Res. 21[5] (2020) 596-601.

-

- 27. N. Gupta, T. C. Lin, and M. Shapiro, JOM 59 (2007) 61-65.

-

- 28. E.I. Şahi̇n and M. Emek, Avrupa Bilim ve Teknoloji Dergisi 21 (2021) 83-89.

-

- 29. E.I. Şahin, M. Emek, B. Ertug, and M. Kartal, Beykent Üniversitesi Fen ve Mühendislik Bilimleri Dergisi 13 (2020) 34-42.

-

- 30. F. Tariq, M. Shifa, M. Tariq, S.K. Hasan, and R.A. Baloch, Adv. Mater. Res. 1101 (2015) 46-50.

-

- 31. D.D.L. Chung, J. Mater. Eng. Perform. 9 (2000) 350-354.

-

- 32. T.H. Ting, R.P. Yu, and Y.N. Jau, Mater. Chem. Phys. 126[1] (2011) 364-368.

-

- 33. J.J. Golezani, M. Kartal, B. Döken, and S. Paker, IETE J. Res. 68[2] (2022) 1406-1410.

-

- 34. H.S. Lim, H.S. Lee, and S.J. Kwon, J. Ceram. Process. Res. 20[4] (2019) 363-371.

-

- 35. O-S. Park and H-K. Cho, J. Ceram. Process. Res. 23[2] (2022) 165-170.

-

- 36. F.Galasso and J.J. Pyle, J. Phys. Chem. 67[7] (1963) 1561-1562.

-

- 37. W. Hui and P. Daviesy, J. Am. Ceram. Soc. 89[4] (2006) 2239-2249.

-

- 38. S. Yang, K. Lozano, A. Lomeli, and H.D. Foltz, Composites Part A 36[5] (2005) 691-697.

-

- 39. E.İ. Şahin, Lith. J. Pyhs. 62[3] (2022) 161-170.

-

- 40. W.K. Jung, J-W. Hong, and D.H. Choi, J. Ceram. Process. Res. 22[1] (2021) 86-90.

-

- 41. B. Jin, X. Wang, L.-S. Yang, and C.-J. Wan, J. Ceram. Process. Res. 17[7] (2016) 712-716.

-

- 42. C.J. Peia, G.G. Yaoa, and Z.Y. Renb, J. Ceram. Process. Res. 17[7] (2016) 681-684.

-

This Article

This Article

-

2023; 24(1): 190-196

Published on Feb 28, 2023

- 10.36410/jcpr.2023.24.1.190

- Received on Sep 15, 2022

- Revised on Oct 12, 2022

- Accepted on Dec 8, 2022

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Ethem İlhan Şahin

-

Advanced Technology Research and Application Center, Adana Alparslan Türkeş Science and Technology University, Adana 01250, Turkey

Tel : +90 322 455 00 00 Fax: +90 322 455 00 02 - E-mail: shnethem@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.