- Effect of CBN surface coating on properties of abrasive and vitrified CBN composites

Xuezhi Wanga,b,*, Minghai Wanga,b,*, Jingqiang Zhanga, Wenbo Fanc and Tianbiao Yud

aSchool of Mechatronics Engineering, Shenyang Aerospace University, Shenyang 110136, People’s Republic of China

bKey Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process of Shenyang Aerospace University, Shenyang 110136, People’s Republic of China

cArmy Artillery and Air Defense Forces Academy Shenyang 110867, People’s Republic of China

dSchool of Mechanical Engineering & Automation, Northeastern University, Shenyang 110819, People’s Republic of ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The advantages of CBN abrasive and vitrified bonds allow the wide use of vitrified CBN grinding tools. However, their properties can be affected by various factors such as vitrification itself and binding between vitrified bond and abrasive grains. In view of this, the current work aims to improve the binding characteristics of vitrified bond and abrasive grains by elucidating the effect of CBN surface coating. In particular, the thermal properties of typical nickel and titanium coated abrasive grains were compared with those of ordinary abrasive grains. Furthermore, the strength, microstructure and phase composition of vitrified CBN composites were studied as well. According to the results, the thermal stability of abrasive grains decreased after coating processing. However, applying the vitrified CBN composite material and sintering, if appropriable, was shown to ensure protection of the abrasive grains. Moreover, as an intermediate transition layer, the bonding properties of vitrified bond and abrasive grains can be improved to some extent. Finally, the vitrified Ti-coated CBN composite was found to possess the best performance

Keywords: CBN, Coating, Vitrified bond, Strength, Microstructure

In recent years, vitrified bond grinding wheels have become a new trend of the new-generation grinding wheels [1]. Unlike resin and metal bond wheels, vitrified wheels are the most promising ultra-precision grinding wheels because of their outstanding properties such as controlled porosity, good self-dressing capability, high machining efficiency and surface precision [2-5]. The convenient low-frequency dressing of vitrified bond grinding wheels allows one to improve their machining accuracy [6]. In addition, the advantages of vitrified bond grinding wheels include large elastic modulus, stable chemical properties, small thermal expansion coefficient, non-deformable grinding tool, and high precision grinding workpiece [7, 8]. Since such types of grinding wheels are produced at a high temperature, complex chemical reactions occur during the firing process, and new compounds are generated between the substances, which is beneficial for enhancing the strength of the wheel [9]. Therefore the vitrified bond grinding wheels increasingly find application in industrial production [10].

Furthermore, to a certain extent, the development and utilization of abrasive tools can reflect the national machining level. In particular, the introduction of CBN abrasive tools provided a breakthrough in the field of production and processing technology [11, 12], ensuring obvious economic benefits. However, the current state of ultra-high speed abrasives is still relatively backward and their quality remains low, strongly limiting the large-scale application of these materials. In this respect, the strength characteristics of vitrified bond CBN grinding wheels, mainly determined by the vitrified bond itself and the binding properties between the vitrified bond and the abrasive grains, are insufficiently good because of the low surface free energy of smooth CBN abrasive grains [13].

The bond strength of the abrasive grains can be increased by coating them with a material that possesses high affinity to both the abrasive composite and the vitrified bond [14]. In particular, abrasive grains surface metallization using strong carbide-forming elements (Ti [15-17], Mo [18], W [19], Cr [20], etc.) is considered a promising way for improving the interfacial bonding between abrasive grains and copper [21]. In another work [14], WC coated diamond grains have been proposed for this purpose.

The second route is coating layer reacts with the abrasive surface by formation of metal matrix alloy. For example, the brazing of CBN to WC-Co was successfully performed in Ref. [19] via microwave hybrid heating utilizing Ag-Cu-In-Ti (APA7) braze alloy. In that study, Ti atoms diffused towards CBN to produce the TiB2, TiB, and TiN reaction layers with CBN. Furthermore, it was found [17] that Ti coating could enhance the bond strength between the diamond and the metal matrix for TiC species forming between the diamond and the outer Ti layer.

There are also other coating methods to improve their oxidation resistance. The experiments had proven that oxide coatings, such as SiO2 [22], TiO2, Al2O3 [23], and ZnO [24], contributed to the initial oxidation temperature of the abrasives and their ability to be wetted by the vitrified bonds during high-temperature sintering [13]. Yan et al. [3] reported a PVP-aided method to enhance the oxidation resistance of ultrafine diamonds by encapsulating UFDs into silica shells, leading to the formation of core/shell structures.

Ordinary abrasive grains are known by their poor wettability and average bonding quality, which is dis- advantageous to the processing efficiency and service life of the abrasive. In order to improve the binding force of abrasive and vitrified bond, the surface of the abrasive grains must be properly treated. This ensures that the damage of the grinding wheel is reduced and the overall performance of the abrasive tool is improved. In this paper, the effect of CBN surface coatings on the properties of vitrified bond CBN composites was studied. The typical nickel and titanium coated abrasive grains were compared with ordinary abrasive grains with respect to their thermal characteristics as well as strength, microstructure, and phase composition of vitrified CBN composite materials.

Abrasive coating process

Abrasive coating treatment plays a very important role in the control of abrasive grains by vitrified bond. On the one hand, it allows one to improve the wettability between vitrified bond and CBN abrasive grains to some extent, thereby increasing the bend strength of vitrified CBN composites along with the service life of abrasive tools. On the other hand, the coating layer will act as a protective film for the CBN abrasive grains, which can reduce their damage caused by excessive temperatures in the grinding process, exerting a positive effect on the overall performance of the abrasive tool.

Now, the common processing means are electroless plating, vacuum physical vapor deposition, vacuum chemical vapor deposition, powder cover sintering, atomic layer plating, and chemical etching. And the coating materials are ceramics, metals, oxides, and so on.

Morphology and energy dispersive spectrum analysis of coated abrasive grains

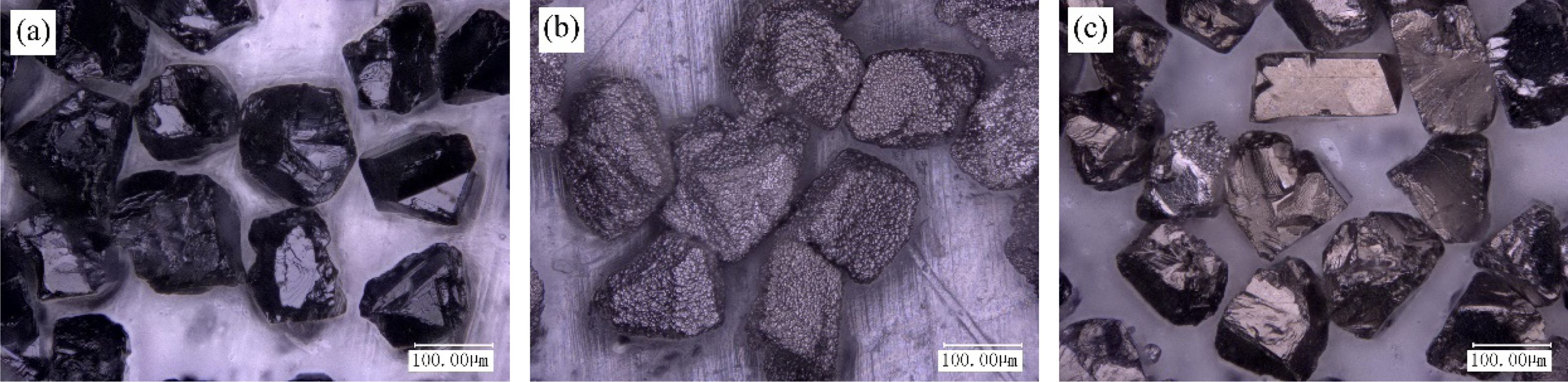

Fig. 1 displays the uncoated CBN grains and the nickel- and titanium-plated CBN grains. The morphological features and characteristics of the three kinds of abrasive grains were obviously different. Compared with untreated abrasive grains, the titanium coating was thinner, and there was no obvious difference in surface topography. The edges of the titanium-plated CBN abrasive grains were rough and appeared to be damaged, perhaps due to the high temperature exposure during the titanium plating process. Ni-coated CBN abrasive grains’ surface is rough, and a layer of metal nickel is attached. Among them, the Ni-plated CBN was prepared by chemical plating process and its brand was CN56, while the Ti-coated CBN abrasive was prepared by evaporation plating process and its brand was Ti-850.

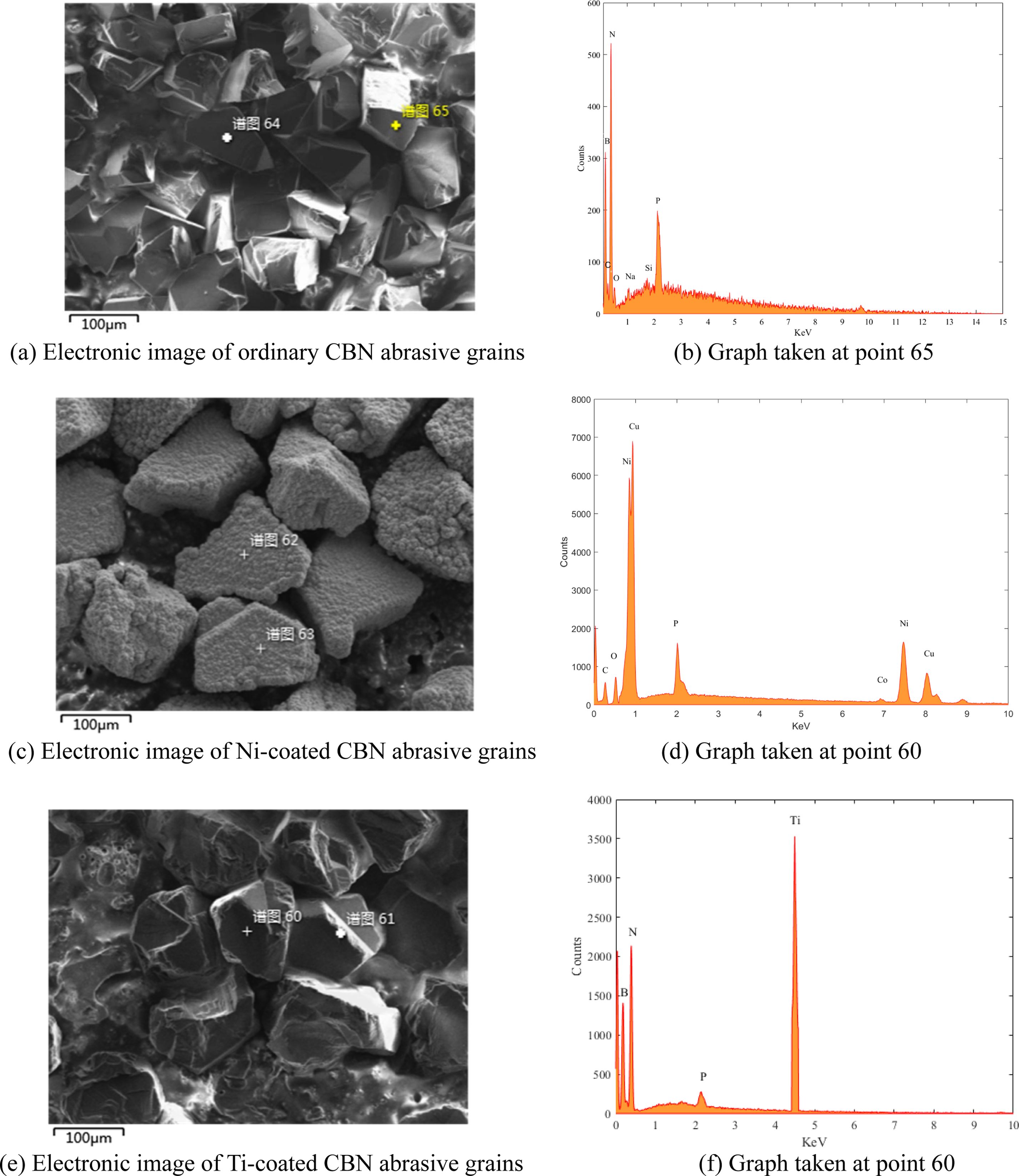

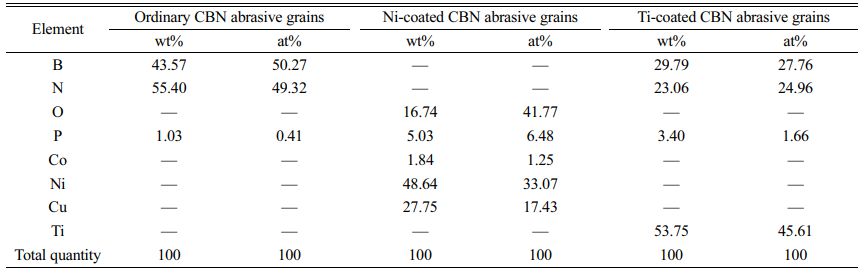

In order to further analyze the surface composition of CBN abrasive grains, energy-dispersive X-ray spectro- scopy (EDX) was used to study the element distribution on the surface of CBN abrasive grains before and after treatment, and the results are shown in Fig. 2. And, the energy-dispersive X-ray spectroscopy data of the three kinds of CBN abrasive grains was shown in Table 1.

According to the EDX results, the surfaces of all three kinds of abrasive grains contained phosphorus, which was related to a CBN preparation process. CBN is synthesized by HBN under static high pressure and high temperature catalyst method. Boric acid and tricalcium phosphate are used in the preparation of HBN, which makes the prepared CBN contain phosphorus element. Besides, the surface of Ti-coated CBN abrasive grains exhibited a certain amount of Ti and a small quantity of oxygen. In addition, the surface of nickel-plated CBN abrasive grains revealed the presence of not only Ni, but also Cu elements in the same proportion as Ni, as well as a low Co content.

Thermal analysis of coated abrasive grains

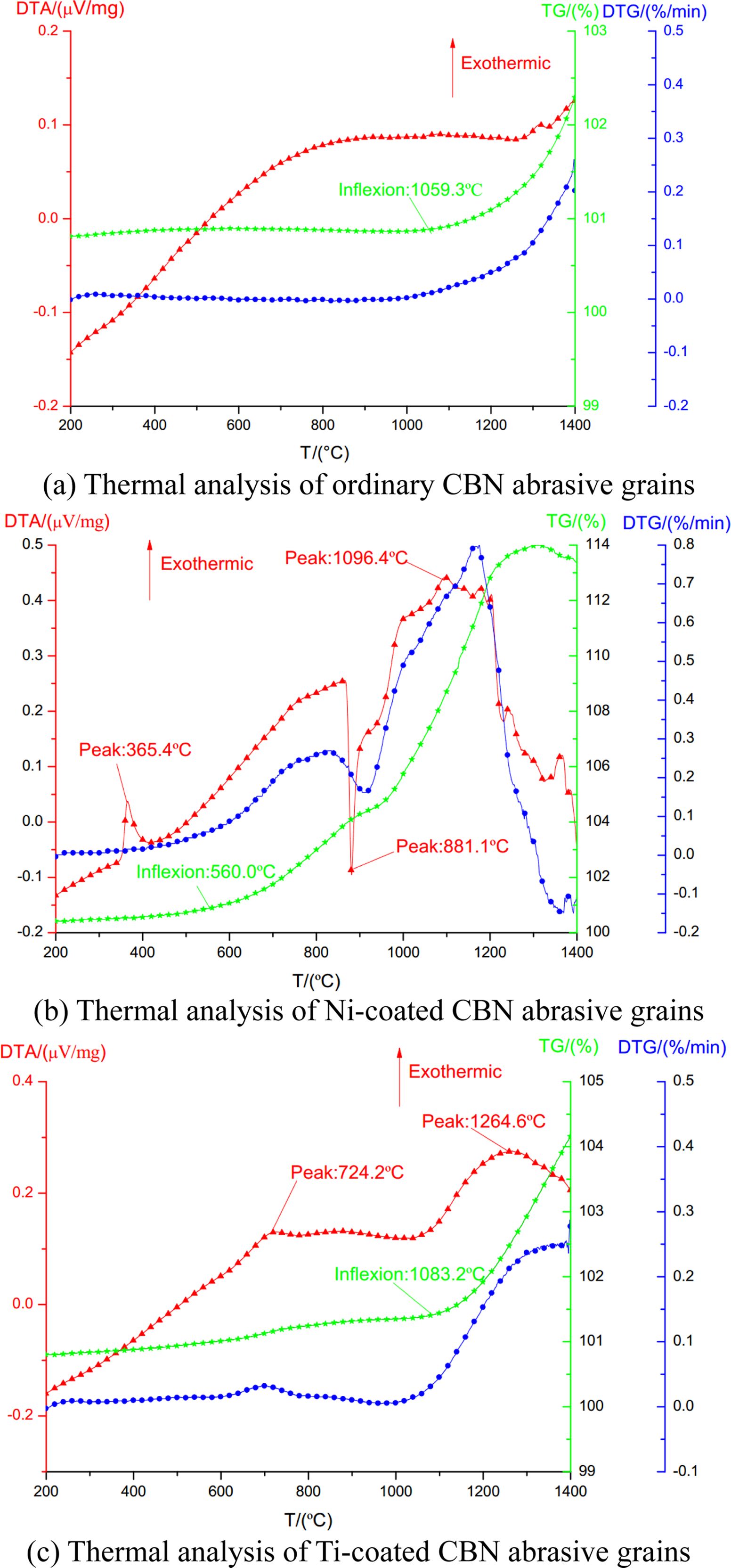

To assess the thermal stability of different abrasive grains, a synchronous TG-DSC thermal analyzer (STA 449 F3) was used to conduct the differential thermal analysis of the three kinds of CBN abrasive grains. The corresponding data are plotted in Fig. 3. The measurements were done at the heating rate of 20 ℃/min within a temperature range from room temperature (20 ℃) to 1400 ℃.

According to Fig. 3(a), the ordinary CBN abrasive grains began to be oxidized at 1059.3 ℃, and the oxidation increased with increasing heating temperature. A weight gain of 2.25% was achieved during the whole reaction from room temperature to 1400 ℃. The DTA images of Ni-coated CBN abrasive grains are relatively complex. In Fig. 3(b), the exothermic and endothermic peaks are observed at 365.4 ℃, 881.1 ℃, and 1096.4. Besides, multiple exothermic and endothermic peaks appeared above 1100 ℃. Since the surface of Ni-coated CBN abrasive grains contained a small amount of Cu and Co, the exothermic peak at 365.4 ℃ seemed to be attributed to the oxidation temperatures of these elements. At the same time, the EDX results of Ni-coated CBN abrasive grains showed that the contents of Cu and Ni elements on the surface of the abrasive grains were equivalent, which may correspond to the melting point of copper alloy of 881.1 ℃. In turn, the peak at 1096.4 ℃ is likely the initial oxidation temperature of CBN abrasive grains. Furthermore, at about 560 ℃, a dramatic increase in the TG values of Ni-coated CBN abrasive grains indicates that Ni has begun to oxidize at this temperature. In spite of a slight difference, the curves in Fig. 4(c) follow the same trend as those in Fig. 3(c). In particular, a noticeable exothermic peak appeared at 724.2 ℃, which could signify the oxidation of titanium at this temperature. Due to the small content of Ti, there was only a thin layer on the surface of CBN abrasive grains. Even though the weight gain of CBN abrasive grains was insignificant, it could be clearly seen in the DTG plots as a peak at the temperature above 724.2 ℃. With a further increase in the temperature, the weight gain of CBN abrasive grains became greater at 1083.2 ℃, indicating the onset of oxidation in them. The emergence of an intense exothermic peak at 1264.6 ℃ could mean the acceleration of reaction. To summarize, the thermal stability of ordinary abrasive grains was found to be the best, followed by that of Ti-coated abrasive grains. At the same time, the coating could effectively protect the abrasive grains and increase their oxidation temperature.

|

Fig. 1 Morphological features of (a) ordinary, (b) Ni-coated, and (c) Ti-coated CBN abrasive grains |

|

Fig. 2 Energy-dispersive X-ray spectroscopic analysis of three kinds of CBN abrasive grains. |

|

Fig. 3 Thermal analysis of CBN abrasive grains |

|

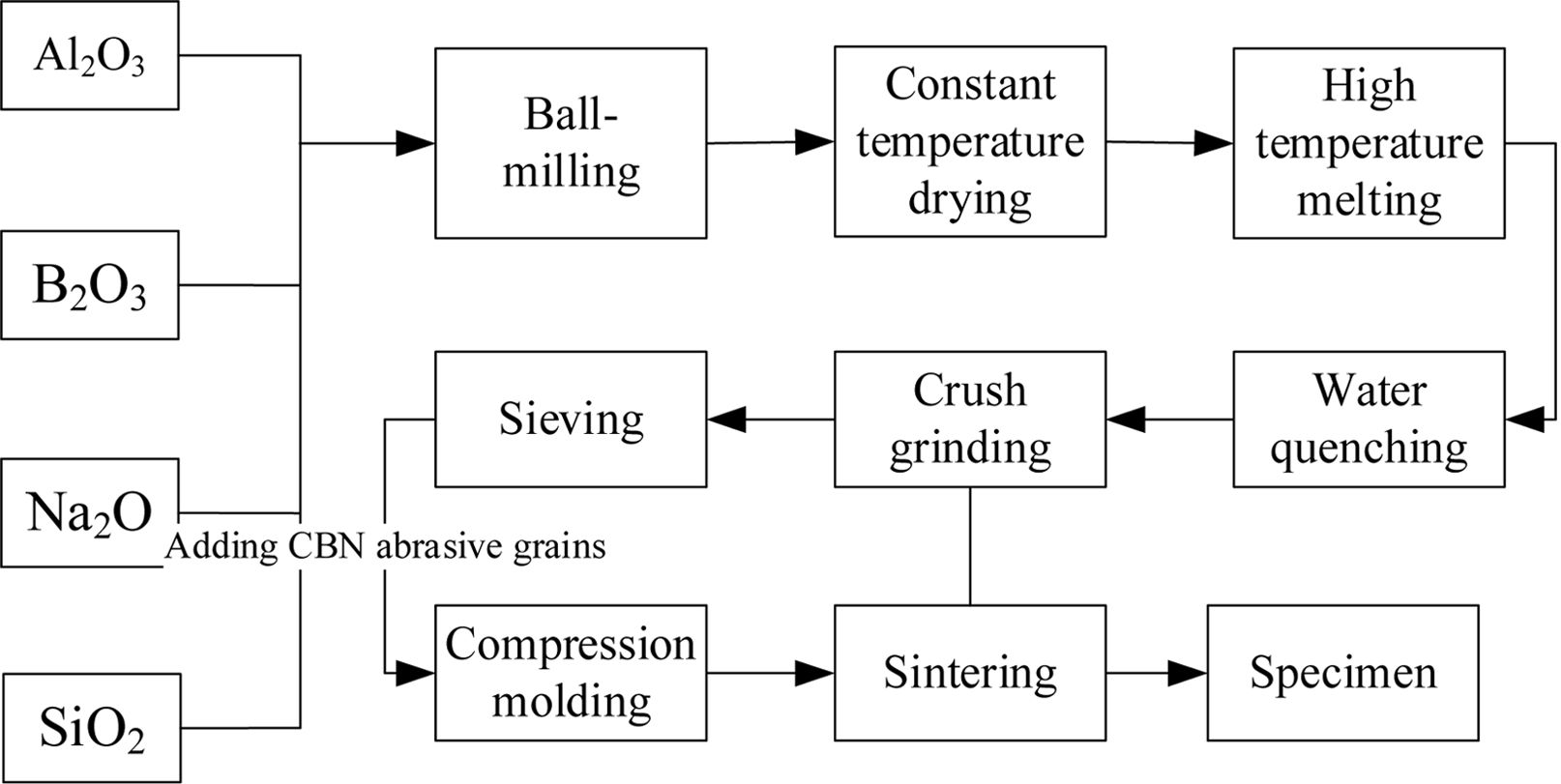

Fig. 4 Preparation process of vitrified CBN composites. |

Specimen preparation

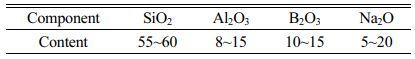

A basic vitrified bond was based on a SiO2-B2O3-Al2O3-Li2O-Na2O glass system [25], in which the constituents were introduced in the form of silica, boron trioxide, alumina, lithium carbonate, and sodium carbonate, respectively. The formulation of the vitrified bond is shown in Table 2. The raw materials were weighed accurately, milled together for 6 h in a ball mill with a ball: powder ratio of 2:1, and sieved through a 200# mesh. Then the mixture was melted at 1200 °C for 2 h in an electric furnace and quenched in deionized water. After that the blend was dried, crushed, and milled for 24 h in a ball mill. The powdered vitrified bond was afterwards sifted through the 200# mesh. The vitrified CBN composites were obtained by mixing the vitrified bond and CBN grains, and the average CBN grain size was 120/140# (Henan Funaike Ultrahard Material Co. Ltd., China NO.880). The samples were molded into rectangular bars (37 mm×6 mm×6 mm) under a pressure of 200 MPa. The details of the preparation process are available in Fig. 4.

In order to explore the effect of abrasive coating on the vitrified CBN composite, a series of sintering experiments was carried out. During the preparation of vitrified CBN composites, it was necessary to control the heating rate [26] and prolong the holding time, both of which would affect the compactness of composite materials [27]. In the sintering process, the heating rate was 150 ℃/h from 20 ℃ to 730 ℃, and the holding time was 20 min at 100 ℃ and 573 ℃, respectively. Whereafter the furnace was heated up to 730 ℃ and kept warming for 2 h. Finally, as the furnace cooled to room temperature, the sample was sintered.

Specimen characterization

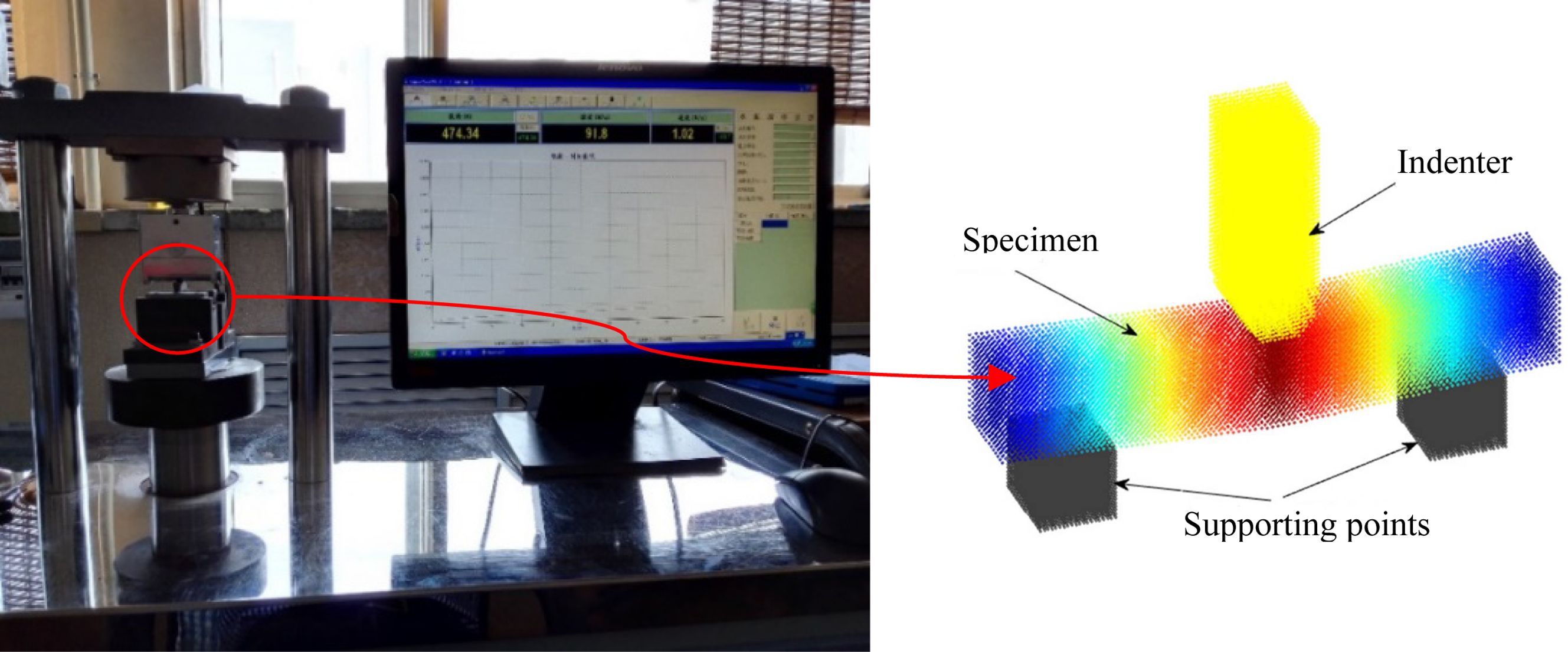

The bend strength of samples was measured via a three-point method using a DYE-300B testing machine at a cross-head speed of 0.5 mm/min. Prior to trials, the samples were ground to the same dimensions of 37 × 6 × 6 mm3. The bend strength was calculated as follows [28].

where F is the fracture load of the sample (N), L is the length between the two supporting points (L=20 mm), b and h are the width and thickness of the fracture of the specimen (mm). Each kind of samples was tested five times and the results were averaged. The testing process is shown in Fig. 5.

The microstructure of the fracture surfaces of sintered composites was examined via scanning electron microscopy (SEM, Zeiss Ultra Plus). The crystalline phases of the specimens were analyzed using an X-ray diffractometer (X’Pert Pro MRD, Panalytical, Netherlands) in CuKα1 radiation at a scan rate of 10°/min (λ = 1.5406 Å).

|

Fig. 5 Bend strength measurements |

Effect of coating on strength of vitrified CBN composites

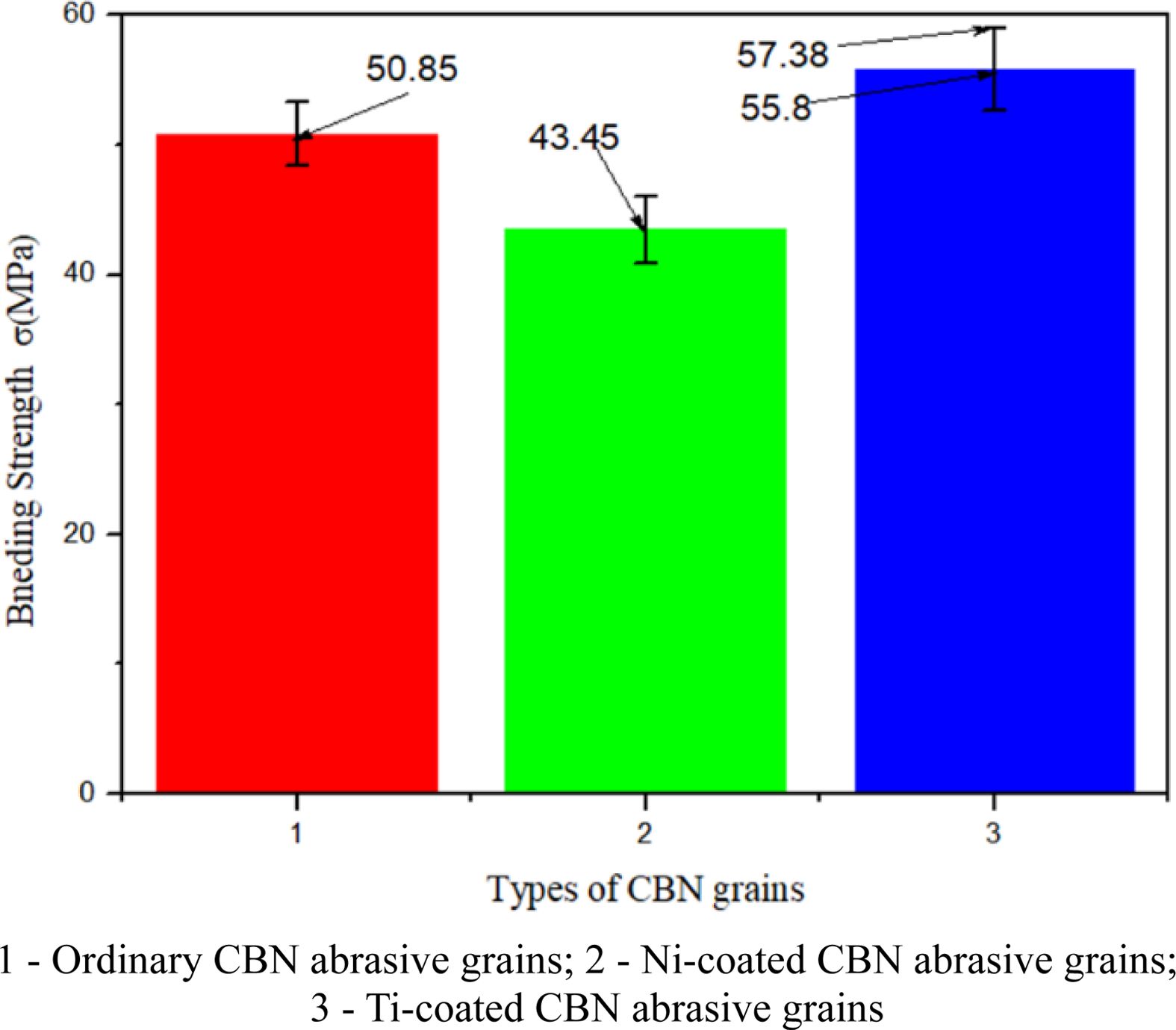

Only when the abrasive grains and the vitrified bond are prepared into the grinding wheels and participate in the grinding process, the effect of the abrasive grains can be played. The strength of vitrified CBN composite materials is the basic condition for ensuring the safety and long service life of grinding tools [29]. The strength of vitrified CBN composites depends on the strength of vitrified bond itself, but also on the bond strength between vitrified bond and CBN abrasive grains. To further elucidate the effect of coated CBN abrasive grains, vitrified CBN composites with different coatings were prepared, and the strength graph for each type of composites is given in Fig. 6.

The plots in Fig. 6 reveal the slight variations in the strength of ordinary and coated vitrified CBN composites. The highest strength is attributed to Ti-coated CBN abrasive grains, whereas the lowest one is found for a Ni-coated CBN composite. The maximum bending strength of the vitrified CBN composites with Ti-coated CBN abrasive particles is 57.38 MPa, and the average flexural strength of the ceramic CBN composites with titanium coated CBN abrasive particles is 9.7% and 28.4% higher than that of the ceramic CBN composites with ordinary CBN abrasive grains and Ni-coated CBN abrasive grains, respectively.

To study the internal structure characteristics of vitrified CBN composites and the bonding state between CBN abrasive grains and vitrified bond, the fracture morphologies and phases of vitrified CBN composites based on the ordinary, Ti-coated and Ni-coated CBN abrasive grains were probed respectively.

Effect of coating on the microstructure of vitrified CBN composites

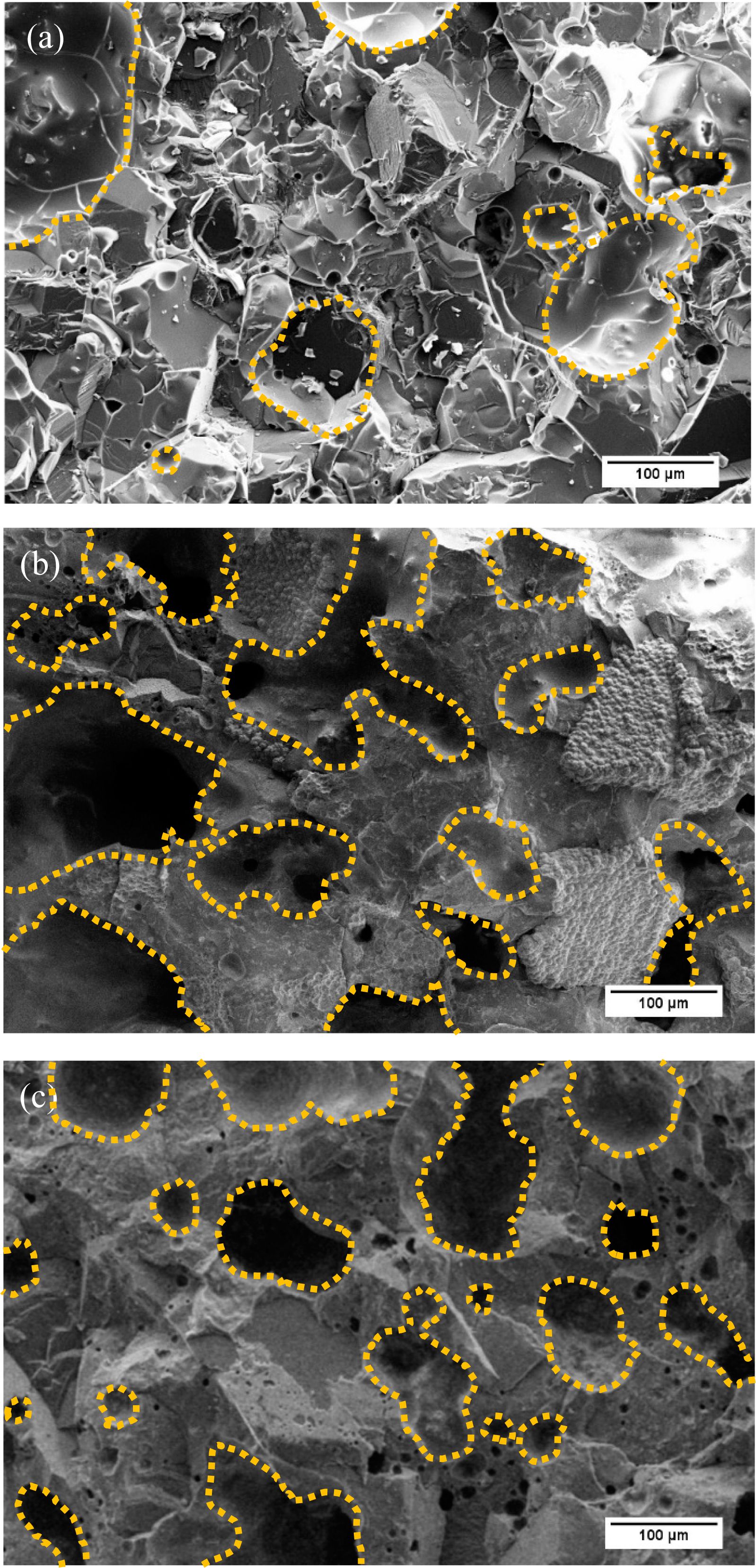

When the surface of CBN abrasive grains is coated with different metal, it can result in various thermal reactions. Moreover, the characteristics of sintered vitrified CBN composites, i.e., the bonding state between the coated CBN abrasive grains and the vitrified bond, will also be different, which will exert a certain influence on the microstructure of vitrified CBN composites. Fig. 7 shows the fracture morphologies of the vitrified CBN composites with ordinary abrasive additives, as well as the coatings with titanium- and nickel-plated CBN abrasions under the same sintering environment.

It is seen that using various CBN abrasive coatings drastically changes the microstructure of vitrified CBN composites. The porosity of vitrified CBN composites with coated CBN abrasive grains was obviously higher than that of the ordinary vitrified CBN composite. At the same time, the porosity of vitrified CBN composite with Ni-coated CBN abrasive grains was particularly prominent, and the pores with large diameters were clearly observed in Fig. 7(b) and (c). Combined with thermal stability results for CBN abrasive grains, it can be concluded that multiple pores could be due to the gradual surface layer oxidation of coated CBN abrasive grains under the action of high temperature, leading to a release of a certain quantity of heat. Since the heat arises from the interior of the vitrified CBN composite, it induces the local expansion of the material and, consequently, the emergence of numerous coarse pores. Moreover, the larger thickness of the nickel-plated CBN abrasive coating is conducive to an increase in the quantity of oxidized nickel, resulting in the better performance of Ni-coated CBN abrasive.

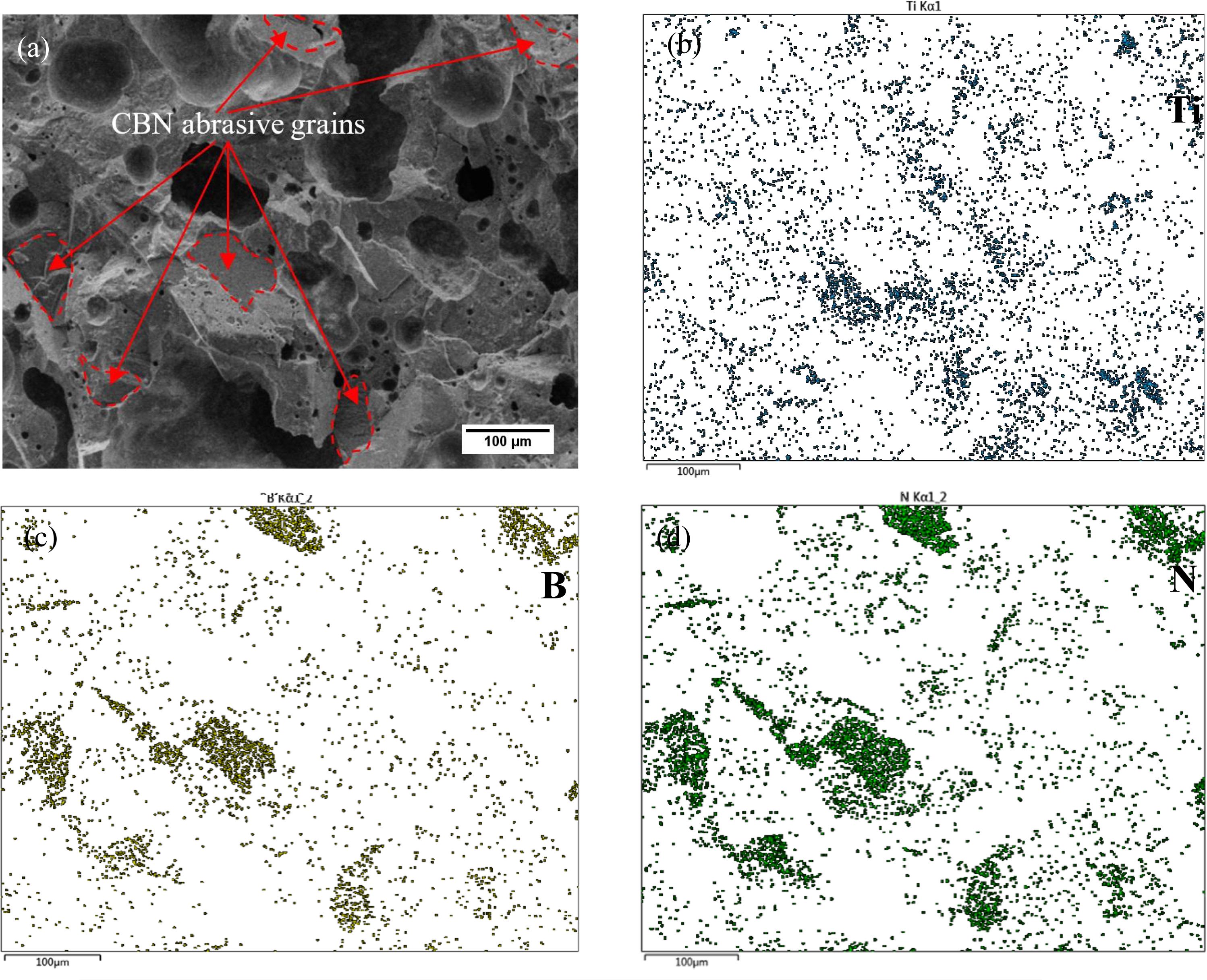

In order to further study the internal causes of the strength change for vitrified CBN composites, the ports of vitrified bond Ti-coated CBN composites were analyzed via scanning electron microscopy. Fig. 8 displays the corresponding SEM optical micrograph and the element distribution (EDS) diagram.

Fig. 8(a) depicts the spline section of a Ti-coated CBN composite, selected for surface scanning. Fig. 8(b)-(d) illustrate the Ti, B, and N element distributions within the selected zone from Fig. 8(a). According to Fig. 8(c) and 8(d), the B and N elements were detected at the same areas, indicating that these locations corresponded to CBN abrasive grains. As seen in Fig. 8(b), the Ti elements were mainly settled around some CBN abrasive grains, but their low content could mean that the CBN surface was coated with a thin titanium layer. In addition, titanium in the titanium-plated layer not only existed on the surface of CBN abrasive grains, but also diffused into the vitrified bond.

Effect of coating on the phase composition of vitrified CBN composite material

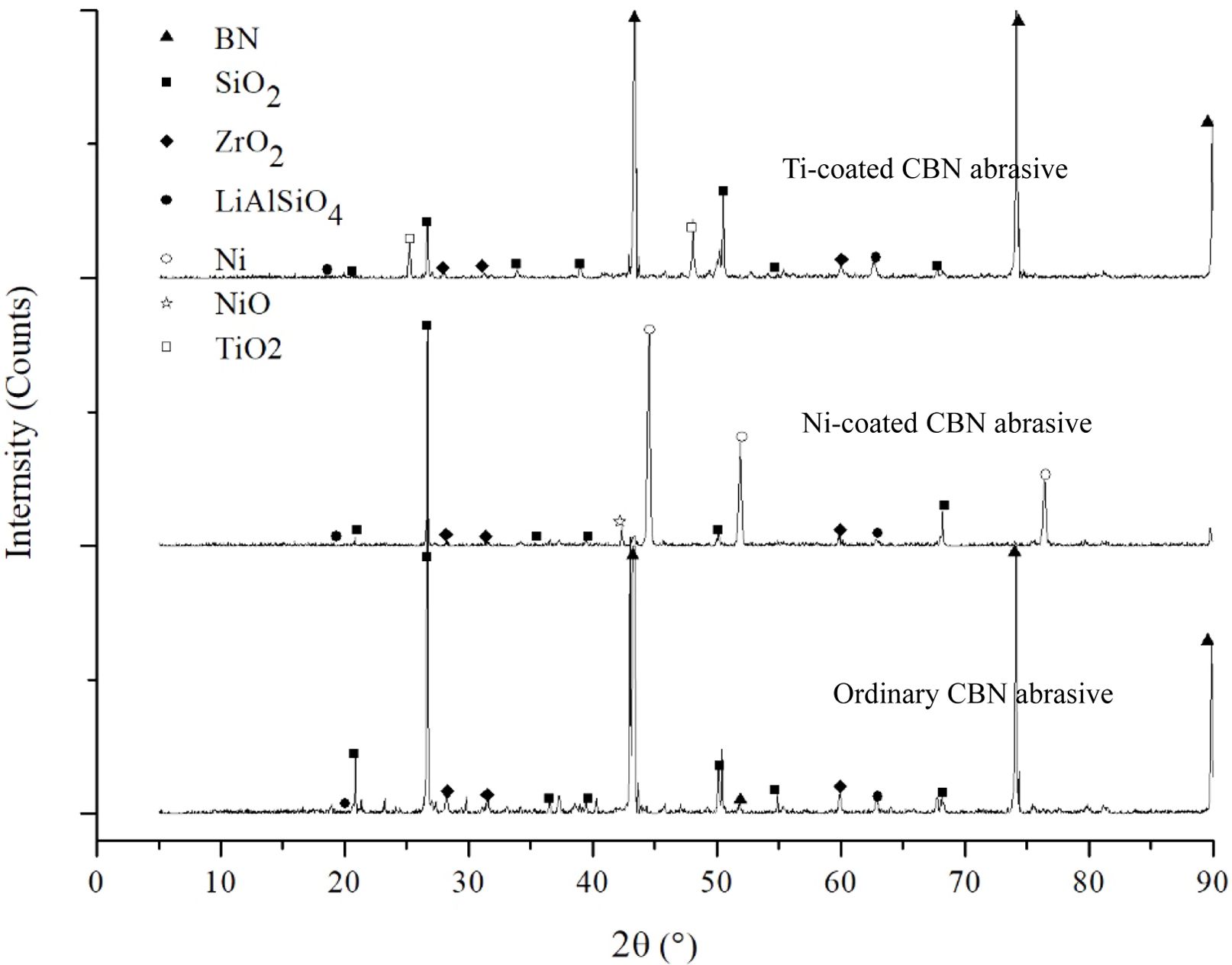

To investigate the effect of coated CBN abrasive grains on the properties of vitrified CBN composites, the phase composition of the latter was analyzed by X-ray diffraction, and the results are shown in Fig. 9.

The main phases of vitrified CBN composites with three kinds of abrasive grains were found to be basically the same; the only difference was that the new Ni, NiO and TiO2 phases appeared in the composites. The results confirmed that the oxidation of Ni and Ti occurred during the sintering of vitrified CBN composites. Besides, no BN phase was detected in the composite material with Ni-coating abrasive grains. This was due to the fact that the abrasive was well coated with a nickel layer. Moreover, Ti has spread through the vitrified bond, leading to the emergence of a new TiO2 phase, which enabled one to improve the performance of vitrified bond as well as the bond strength between the abrasive grains and the vitrified bond.

|

Fig. 6 Effect of different CBN abrasive grains on the strength of vitrified composites |

|

Fig. 7 Fracture morphologies of vitrified CBN composites with different CBN abrasive grains: (a) ordinary, (b) Ni-coated, and (c) Ti-coated CBN abrasive grains. |

|

Fig. 8 Fracture morphology and surface scanning results of titanium- plated CBN vitrified bond composites. |

|

Fig. 9 Phase composition of vitrified CBN composites with different CBN abrasive grains. |

The coating of CBN abrasive grains can change their surface characteristics to a certain extent, which exerts a noticeable effect on the structure of related vitrified CBN composite materials as well as the binding state of vitrified bond and abrasive grains. In this respect, a comprehensive study of CBN abrasive grains coated with different metals and the corresponding vitrified CBN composites allowed one to draw the following conclusions.

(1) The porosity of vitrified CBN composites with Ti- and Ni- coated CBN abrasive grains was obviously higher than that of ordinary CBN abrasive grains. The best bonding state was found between Ti -coated CBN abrasive grains and vitrified bond. This was due to the oxidation and diffusion of a metal Ti layer toward the vitrified bond, thus improving the interfacial bond strength. However, applying the Ti coating reduced the strength and toughness of CBN abrasives.

(2) For Ni-coated CBN abrasive grains, the Ni layer was shown to protect the grains and improve their thermal stability. However, the vitrified CBN composite materials could be easily oxidized, which caused their local expansion. This led to the generation of a large amount of pores and reduced the strength of the composites.

This research is supported by Natural science Foundation of Liaoning Province (No. 2021-MS-263), Open Fund of Key Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manu- facturing Process of Shenyang Aerospace University (SHSYS-202101), Foundation of Liaoning Province Education Administration (NO. JYT 2020132) and Independent Innovation Special Fund Project of AECC (ZZCX-2019-019).

- 1. X. Wang, T. Yu, X. Sun, Z. Wang, and W. Wang, J. Ceram. Process. Res. 17[9] (2016) 969-973.

-

- 2. N. Yan, D.P. Zhao, L. Wang, Q. Zou, Y.Y. Xi, X.P. Guo, B. Wang, Z.L. Wang, L.P. Wang, W.J. Dai, M.Z. Wang, and Y.C. Zhao, Int. J. Refract. Metal. Hard Mater. 43 (2014) 212-215.

-

- 3. X. Yang, J. Bai, W. Jing, B. Wang, and J. Yang, Ceram. Int. 42[7] (2016) 9283-9286.

-

- 4. J. Shi, F. He, J. Xie, H. Yang, Z. Guo, and X. Liu, Ceram. Int. 45[12] (2019) 15358-15365.

-

- 5. K.H. Lin, Y.T. Tsai, and K.L. Wang, J. Ceram. Process. Res. 21[1] (2020) 103-112.

-

- 6. T.-K. Chuang, Y.-T. Tsai, and K.-H. Lin, Int. J. Refract. Metal. Hard Mater. 74 (2018) 107-113.

-

- 7. J.C. Lopes, L. De Martini Fernandes, B.B. Domingues, R.C. Canarim, M. Da Penha Cindra Fonseca, L.E. De Angelo Sanchez, R.F.M. De Oliveira, H.J. De Mello, P.R. Aguiar, and E.C. Bianchi, Int. J. Adv. Manuf. Technol. 103[1-4] (2019) 1567-1577.

-

- 8. X. Wang, X. Sun, Z. Ma, T. Yu, and W. Wang, Ceram. Int. 44[18] (2018) 22301-22307.

-

- 9. W.J. Zhang, Y.M. Chong, I. Bello, and S.T. Lee, J. Phys. D Appl. Phys. 40[20] (2007) 6159-6174.

-

- 10. Y. Liang, Z. Li, and Y. Zhu, Mater. Chem. Phys. 236 (2019) 121810.

-

- 11. D. Herman and S. Węgrzyk, Ceram. Int. 45[10] (2019) 12773-12779.

-

- 12. T. Yu, A.F. Bastawros, and A. Chandra, Int. J. Mach. Tools Manuf. 121 (2017) 70-80.

-

- 13. J. Shi, F. He, J. Xie, X. Liu, and H. Yang, Ceram. Int. 45[16] (2019) 19704-19709.

-

- 14. T. Okada, K. Fukuoka, Y. Arata, S. Yonezawa, H. Kiyokawa, and M. Takashima, Diam. Relat. Mater. 52 (2015) 11-17.

-

- 15. R. Chang, J. Zang, Y. Wang, Y. Yu, J. Lu, and X. Xu, Diam. Relat. Mater. 77 (2017) 72-78.

-

- 16. R. Chang, Y. Wang, J. Zang, Y. Yu, J. Lu, and X. Xu, Adv. Powder Technol. 28[9] (2017) 2281-2287.

-

- 17. Q. Gu, J. Peng, L. Xu, C. Srinivasakannan, L. Zhang, Y. Xia, Q. Wu, and H. Xia, Appl. Surf. Sci. 390 (2016) 909-916.

-

- 18. Q. Kang, X. He, S. Ren, L. Zhang, M. Wu, T. Liu, Q. Liu, C. Guo, and X. Qu, J. Mater. Sci. 48[18] (2013) 6133-6140.

-

- 19. S. Tamang and S. Aravindan, Mater. Lett. 254 (2019) 145-148.

-

- 20. Y. Zhu, L. Wang, W. Yao, and L. Cao, Appl. Surf. Sci. 171[1-2] (2001) 143-150.

-

- 21. Z. Tan, Z. Li, G. Fan, Q. Guo, X. Kai, G. Ji, L. Zhang, and D. Zhang, Mater. Design. 47 (2013) 160-166.

-

- 22. D. Zhao, Z. Wang, Y. Xi, Q. Zou, X. Li, B. Wang, X. Guo, M. Liang, W. Li, M. Wang, and Y. C. Zhao, Mater. Lett. 113 (2013) 134-137.

-

- 23. X. Yan, X. Li, X. Wang, and H. Yan, Diam. Relat. Mater. 77(2017) 79-83.

-

- 24. Y. Wang, Y. Yuan, X. Cheng, X. Li, J. Zang, J. Lu, Y. Yu, and X. Xu, Mater. Sci. Eng. C Mater. Biol. Appl. 53 (2015) 23-8.

-

- 25. R.-C. Zhou, X.-P. Liu, L. Wan, P.-Z. Gao, M.-Y. Liao, and Y.-L. Zhu, J. Europ. Ceram. Soc. 41[1] (2021) 300-309.

-

- 26. S.-M. Yong, J. Ceram. Process. Res. 20[1] (2019) 59-62.

-

- 27. C.H. Ting, S. Ramesh, C.Y. Tan, N.I.Z. Abidin, W.D. Teng, I. Urriésd, and L.T. Bang, J. Ceram. Process. Res. 18[8] (2017) 569-574.

- 28. K.K. Kandi, G. Punugupati, M. Pagidi, and C.S.P. Rao, Silicon (2022).

-

- 29. D. Shan, Z. Li, Y. Zhu, H. Ye, K. Gao, and Y. Yu, Ceram. Int. 38[6] (2012) 4573-4578.

-

This Article

This Article

-

2023; 24(1): 8-16

Published on Feb 28, 2023

- 10.36410/jcpr.2023.24.1.8

- Received on May 14, 2022

- Revised on Jul 1, 2022

- Accepted on Aug 12, 2022

Services

Services

- Abstract

introduction

abrasive surface treatment of cbn

preparation and characterization of vitrified cbn composites

effect of abrasive coating on the properties of composites

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Xuezhi Wang, Minghai Wang

-

aSchool of Mechatronics Engineering, Shenyang Aerospace University, Shenyang 110136, People’s Republic of China

bKey Laboratory of Fundamental Science for National Defense of Aeronautical Digital Manufacturing Process of Shenyang Aerospace University, Shenyang 110136, People’s Republic of China

Tel : +86-24-89728447 Fax: +86-24-89728909 - E-mail: wangxuezhineu@126.com, wangminghai2008@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.