- Study on engineering strength properties of ceramic waste powder stabilized expansive soil using machine learning algorithms

D. Sivabalaselvamania,*, P. Kulanthaivelb, J. Yogapriyac and Inderjit Singh Dhanoad

aAssociate Professor, Department of Computer Applications, Kongu Engineering College, Perundurai, Tamilnadu, India

bAssistant Professor, Department of Civil Engineering, Kongu Engineering College, Perundurai, Tamilnadu, India

cProfessor, Department of Computer Science and Engineering, Kongunadu College of Engineering and Technology, Thottiam, Tamilnadu, India

dAssistant Professor, Department of Computer Science and Engineering, Guru Nanak Dev Engineering College, Ludhiana, Punjab, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

In recent years, geotechnical engineers prefer environmentally friendly and sustainable techniques in order to improve the engineering characteristics of Expansive soil. The major objective of this paper is to study the engineering properties of Expansive soil with Ceramic Waste Powder (CWP). A series of laboratory tests such as pH and electrical conductivity tests, Unconfined Compression test, Splitting Tensile test, Free swell Index test, Swelling Pressure test, California – Bearing Ratio test, and Atterberg’s limit test were carried out in order to evaluate the engineering behavior of expansive soil with CWP. The experimental test results showed that the CWP significantly improved the engineering characteristics of the soil. CWP inclusion in expansive soil was tested at 0%, 5%, 10%, 15%, 20% and 25%. The maximum compressive strength and tensile strength were achieved at a 20% inclusion of CWP in the expansive soil. The maximum compressive strength and tensile strength at optimum CWP content of 20% were 641 kPa and 78 kPa respectively. The reduction of free swell index percentage from 2.7% to 0.5% indicated the replacement of swelling particles of expansive soil by non – swelling particles with respect to the inclusion of CWP. Using the Simple Regression Algorithm, Lasso Algorithm, Ridge Algorithm, and Support Vector Machine (SVM) Algorithm, multiple models for predicting CBR of an expanding soil stabilized with Ceramic Waste Powder have been proposed in this article. Hence, the CWP can be utilized as a soil stabilizing material in field applications

Keywords: Expansive soil, Ceramic waste powder, Strength properties, Support vector machine

Soil plays a vital role in the environment as it is also responsible for life on earth. It is formed from the disintegration of the major types of rocks, viz., Igneous, Metamorphic and Sedimentary Rocks. Hence, the disintegrated parts have different engineering, physical and chemical characteristics [3]. Soil is typically a non-homogeneous, porous, earthen material whose engineering behavior is influenced by alteration in moisture content and density. In the geotechnical fields, clay is considered a problematic soil that needs modifications for better construction applications. Expansive soil, a high clayey soil, is highly compressible and possesses low shear strength. It is found in almost any parts of Maharashtra, Gujarat, Madhya Pradesh, Andhra Pradesh, and a few parts of Tamil Nadu. It occupies almost 18% of the total area of India. Predominantly, it is found deep on the top banks of rivers Godavari and Krishna. The sensitivity is greater in the case of changes in moisture content [15]. Construction on this type of soil is difficult because of its instability and volume change. Owing to the capillary action in soils, the water permeates into the top surface and bottom layers [14].

The movements will influence the lightly loaded structures such as foundations, pavements, canal beds, linings, and residential buildings and hence, may cause severe damage [9]. Soil stabilization is essential for enhancing the engineering properties of the soil so as to improve the bearing capacity of the soil and control settlements and the swell–shrink behavior of the soil.

Approximately 8 percent of the total Carbon dioxide emission worldwide is produced during the manufacture of cement [23]. Finding an alternative to cement and lowering the carbon emissions brought on by cement manufacturing are essential needs [22]. A variety of ground improvement techniques are advised viz. preloading, compaction, column techniques, soil replacement, soil nailing, grouting, etc. In the present scenario, the researchers are in search of new innovative and sustainable technology that suits well in all aspects [5]. Refractory wastes are produced in significant quantities during the manufacture of high-temperature industrial kilns used to make steel, ceramics, and cement [27]. Environmental issues had already arisen as a result of both the depletion of natural resources and the manufacturing waste that comes from production [21].

Quarry Dust [2], marble dust [16], baryte powder [16], pyroclastic dust [16], and brick powder [16] are some of the prominent dust/powders like waste materials that successfully utilized for the stabilization of expansive soil. It is generally acknowledged that ceramics do have great endurance for accepting various components because of the heterogeneous nature of natural ceramic raw materials. However, using waste in construction projects has a significant potential [26]. The CWP can be utilized to stabilize the expansive soil. On account of the unavailability of good quality construction material within the desired location, the cost eventually rises [17]. The waste from ceramics is both harmful and hefty [25]. About 32% of the everyday production in industries is neglected as a waste of which about 40% is occupied by ceramic waste. The problematic factors such as intrinsic swell–shrink behavior, settlements, shear strength, and permeability in expansive soil can be solved with the inclusion of CWP. CWP helps in improving soil strength and controlling swell potential. The prevention of disposal of harmful substances to the environment, the protection of biodiversity all over the world, increment in strength and other engineering properties of soil, and permeability reduction and penetration are the added advantages of utilizing industrial wastes in an efficient way [17]. It was observed that the stability period increased with an increase in CWP in soil [20]. Minimizing environmental contamination is greatly beneficial by using discarded marble dust as a sustainable material for subgrade stabilization [24].

The present study focuses on the engineering performance of CWP with Expansive soil in different percentage inclusion of CWP and provided with different curing periods. The specimens to be tested for the experiments were untreated Expansive soil and Expansive soil with 5%, 10%, 15%, 20%, and 25% of CWP inclusion. The treated expansive soil is tested by conducting pH and Electrical Conductivity tests, Unconfined Compression test, Splitting Tensile test, Free swell Index test, Swelling Pressure test, California – Bearing test, and Atterberg’s limit test. The microanalysis was also conducted in which the ceramic waste content inclusion resulted in variation in gradation, presence of chemical and mineralogical composition, and cohesion and interlocking among particles.

California Bearing Ratio test for stabilized soil is not only time-consuming but also expensive. Soft computing approaches, such as the Simple Regression Algorithm, Lasso Algorithm, Ridge Algorithm, and SVM Algorithm, can be used to construct models that predict CBR of stabilized expanding soil.

Using Ceramic Waste Powder (percent) as an input variable, the model was used to predict the CBR of a non-expansive clayey soil stabilized with Ceramic Waste Powder, and the accuracy of the model was compared to that of a multiple regression analysis (MRA) model constructed with the same inputs. In this study, we analyze the effective prediction of several Regression algorithms models created to estimate the CBR of expanding soil stabilized using Ceramic Waste Powder. The sustainability of the stabilization is also achieved with respect to the CWP inclusion. The effective utilization of waste materials obtained from crushing and quarrying has become possible with the application in the Geotechnical field.

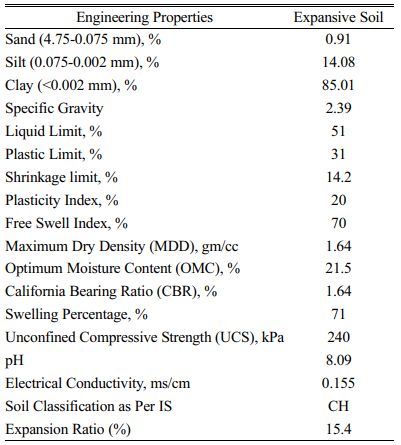

Expansive Soil

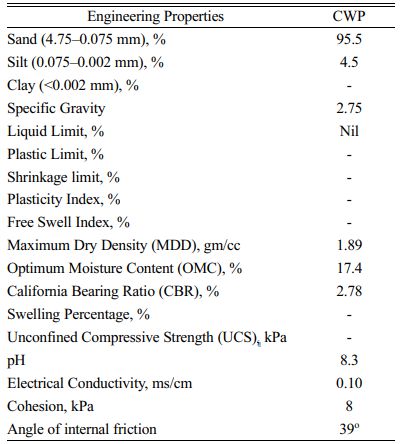

The soil was collected from Semmancheri, Chennai, India at a depth of 1.5m below the ground level. The soil characteristics are shown in Table 1. A higher percentage of clay was found in the soil. Based on the index property test results the soil was classified as High Compressible Clay (HCC) as per Indian Standard (IS).

Ceramic Waste Powder

The Ceramic Waste Powder was collected from SIPCOT, Perundurai. The basic properties are elucidated in Table 2. CWP is the residue that is improperly disposed into the environment. The ineffective disposal of CWP results in huge environmental impacts. Hence, efficient utilization of CWP in soil holds a greater advantage in stabilizing the highly problematic clay soils and also can be implemented in a variety of applications. Ceramic waste is strong, durable, and resistant to all kinds of declining powers and these properties allow it to be a substitute for replacements [1]. The chemical composition of expansive soil and CWP obtained from X-Ray Fluorescence Spectroscopy was tabulated in Table 3.

pH and Electrical Conductivity Test

pH tests were conducted to verify the pozzolanic reactivity between the soil specimen and the CWP added to it. The pH meter was calibrated to 4.0, 7.0, and 9.20 as standard reference values for buffer solutions. At an interval of about 1.5 hours, the pH value of slurries was noted. The procedure followed was based on IS 2720 – 26 (1987).

Electrical Conductivity tests were performed so as to determine the electrical resistivity of the materials. Sample preparation and procedure were similar to that of pH tests. Therefore, the values were determined after the samples were obtained from the unconfined compression test. The procedure was followed based on IS 14767 (2000).

Unconfined Compression Tests

The soil was oven-dried at 105 oC for 24 hours for obtaining dry soil for sample preparation. The specimen of 76 mm height and 38 mm in diameter and cylindrical in shape was prepared by static compaction to perform the test. The specimens were prepared with respect to the Optimum Moisture Content (OMC) and Maximum Dry Density (MDD) values were obtained. A constant strain rate of about 1.2 mm/min was maintained. The curing period of 28 days was maintained. It was covered with polyethylene bags as the air-controlling desiccators. It was left for curing till the desired curing time. The samples were denied in case of a change in weight of higher than 0.5%. The procedure was repeated for three specimens at the same percentage for each sample. The mean value obtained from the tests conducted provided the Unconfined Compressive Strength of the sample. Here, the experiment was performed according to IS 2720 (Part 10) (1973).

Splitting Tensile Tests

The Splitting Tensile Tests were performed to observe the curve that explains tensile strength variation in each sample. The soil mixture was filled in a steel ring of 31.50 mm thick and a diameter of 71.5 mm. In case of to the slurry state, there was no compaction provided. The specimens were covered with plastic or aluminum foils so as to undergo curing. Later, the specimens with varying water contents were exposed to airdrying at a temperature of 23 oC and 45% relative humidity. The specimens were wrapped again at constant moisture content under similar laboratory conditions followed. Before testing the specimens, it is essential to note the weight and required dimensions. It was tested in the uniaxial testing machine as per ASTM D3967-16 standards. According to the standards, the specimen failure occurred between one to ten minutes, and a strain rate of about 0.5% per minute was observed.

Swelling Pressure

Swell pressure of the soil is the resistance offered by the soil against swelling. In this test, the volume change was arrested. The swelling pressure depends on the amount of clay, Moisture content, nature of pore fluid, and alternate wetting and drying cycles. The initial reading of the proving ring was marked before starting the experiment. The specimen was maintained at a constant volume. The exact reading shown by the dial gauge was noted. The volume deviation with respect to the swelling was noted from the strain gauge. The soil specimen was then taken out for the determination of water content. The procedure was followed according to IS 2720(Part 41):1977.

Prediction of CBR in Stabilized Expansive Soils using Regression Models

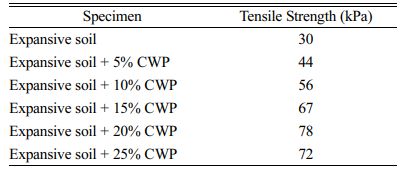

Different experiments on expanding soil- Ceramic Waste Powder samples/mixes were used to create data for the creation of Simple Regression Algorithm, Lasso Algorithm, Ridge Algorithm, and SVM Algorithm models. Various regression approaches were used to create soil - Ceramic Waste Powder samples for the suggested models. The soil was combined with Ceramic Waste Powder from 0% to 25% in 5% increments, and Ceramic Waste Powder was added to the soil from 0% to 5% in 1% increments. CBR tests were performed on samples that were produced within their respective ranges.

Visualization

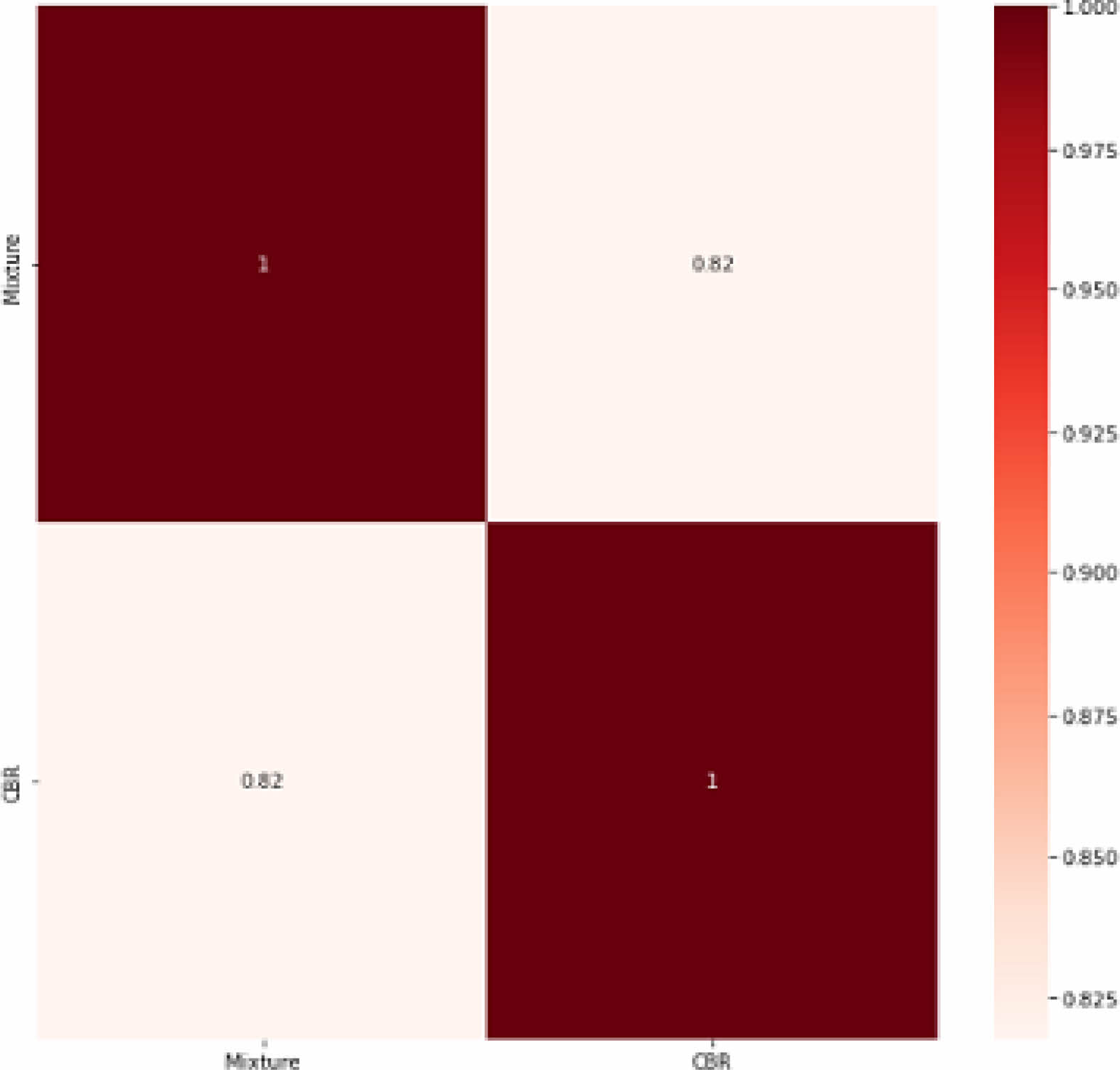

To establish a relationship between CBR and soil mixture, linear regression analysis was developed by using Google CoLab to predict the CBR value. Correlation quantifies the degree to which dependent and independent variables are related.

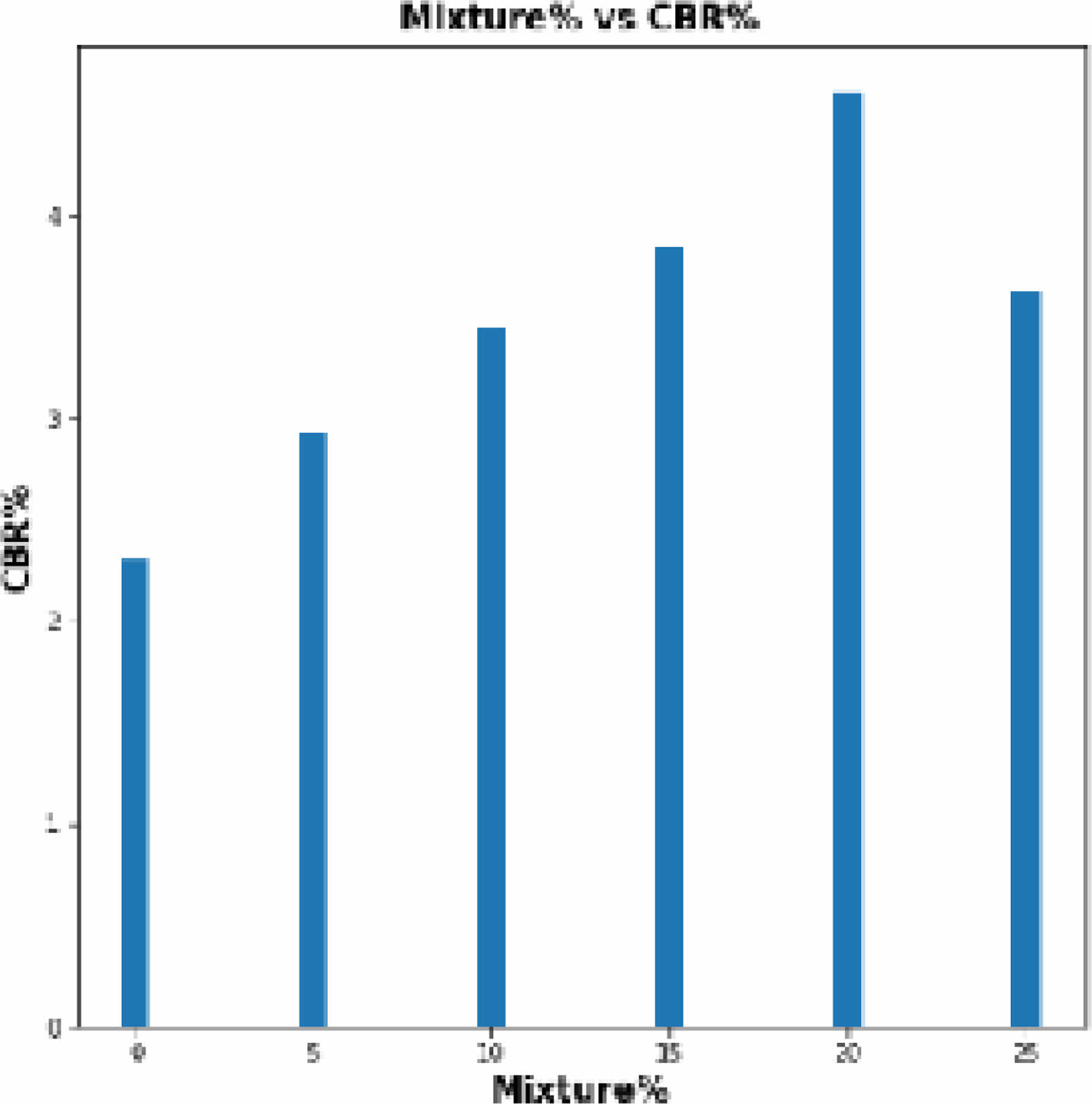

From the above CBR vs. Soil Mixture, it can be said that there is a proportional relationship between CBR and mixture. The CBR values are increasing with the increase of mixture to some extent. The correction is calculated like Mixture-Mixture = 1, CBR-CBR = 0.82, and Mixture-CBR will be calculated using different algorithms. Therefore, it can be observed that there is comparatively good relationship between CBR and Mixture for the expanded soil.

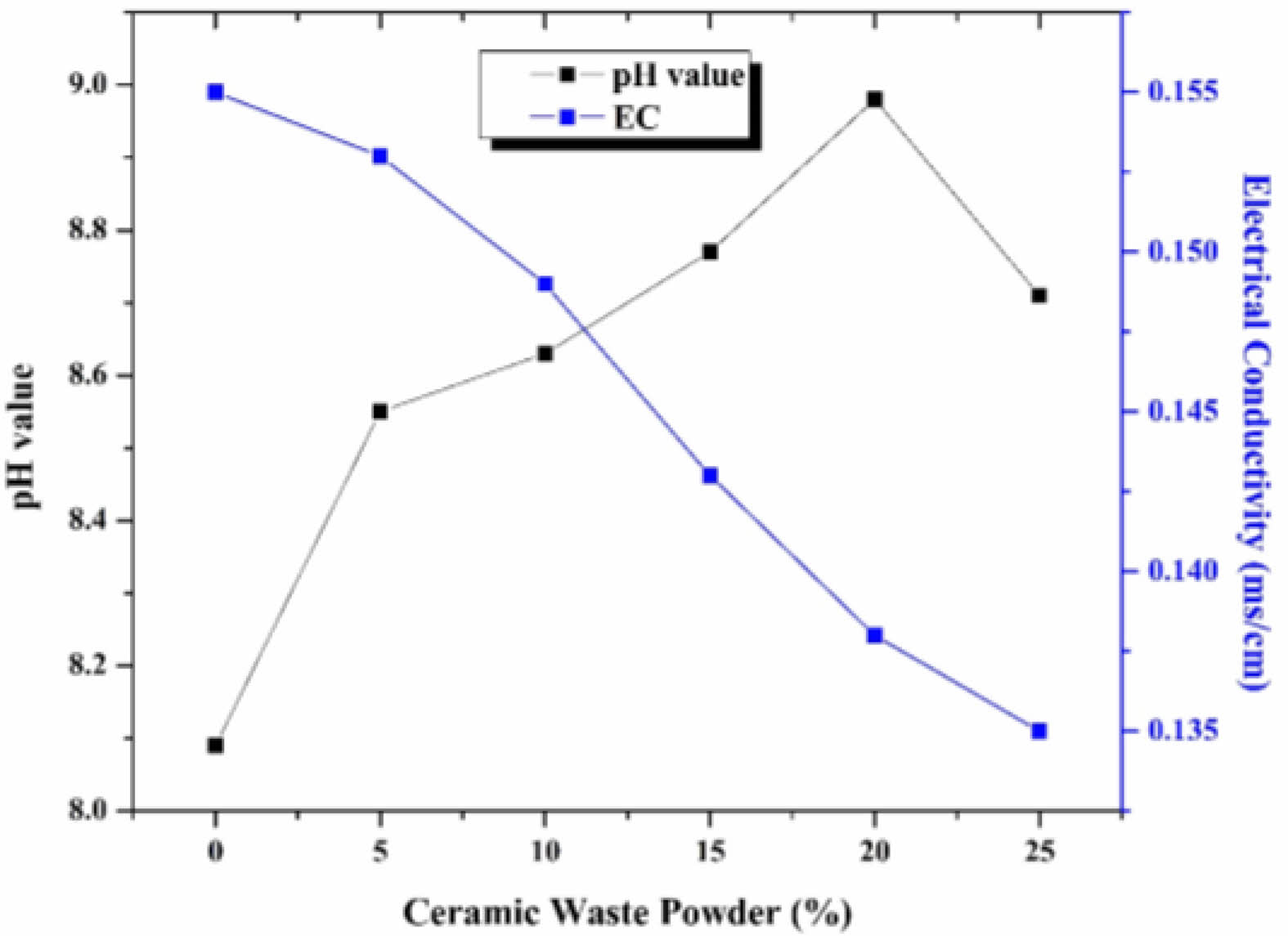

Physico – Chemical Analyses on Soil – CWP Mixes Fig. 1 Fig. 2

The influence of CWP on the unconfined compressive strength is shown in Fig. 3. Based on the Fig. 3, pH of the soil increases till 20% inclusion of CWP content into the soil. This is due to the increase in the calcite ions due to the inclusion of CWP which eventually increases the ionic strength of the soil. This leads to an increase in pH. Further inclusion of CWP resulted in the reduction of pH due to the addition of coarse particles into the soil. There may be an increment in the pH value in case the soil regains pH with an increase in nutrient content. This was observed due to the reduction of toxic elements with respective increments in CWP inclusion into the soil. The pH value at an optimum percentage of 20% inclusion of CWP was found to be 8.98 which was higher than the results obtained from Expansive soil with cement kiln dust additive with a pH of 7.72 [10]. The pH value attained for a chemical admixture as 9.85 [13] and mineral additives as 8.12 [11] in expansive soil was found to be consistent with the present study values.

The electrical conductivity obtained from the result was notably decreasing with respect to the increase in the CWP inclusion in soil. This increment was observed due to an increase in bulk density of the soil – CWP matrix. The bulk density of CWP was observed to be higher than the bulk density of clay soil. Hence, the pH value increased, and electrical conductivity decreased with respect to an increase in CWP inclusion in soil. The EC value obtained was quite low in comparison with other admixtures since the bulk density was found to be higher for Expansive soils. This was achieved when compared with mineral admixtures included in expansive soil 0.45 [11]. The results obtained were comparatively better than the result obtained from the Marble Dust [4].

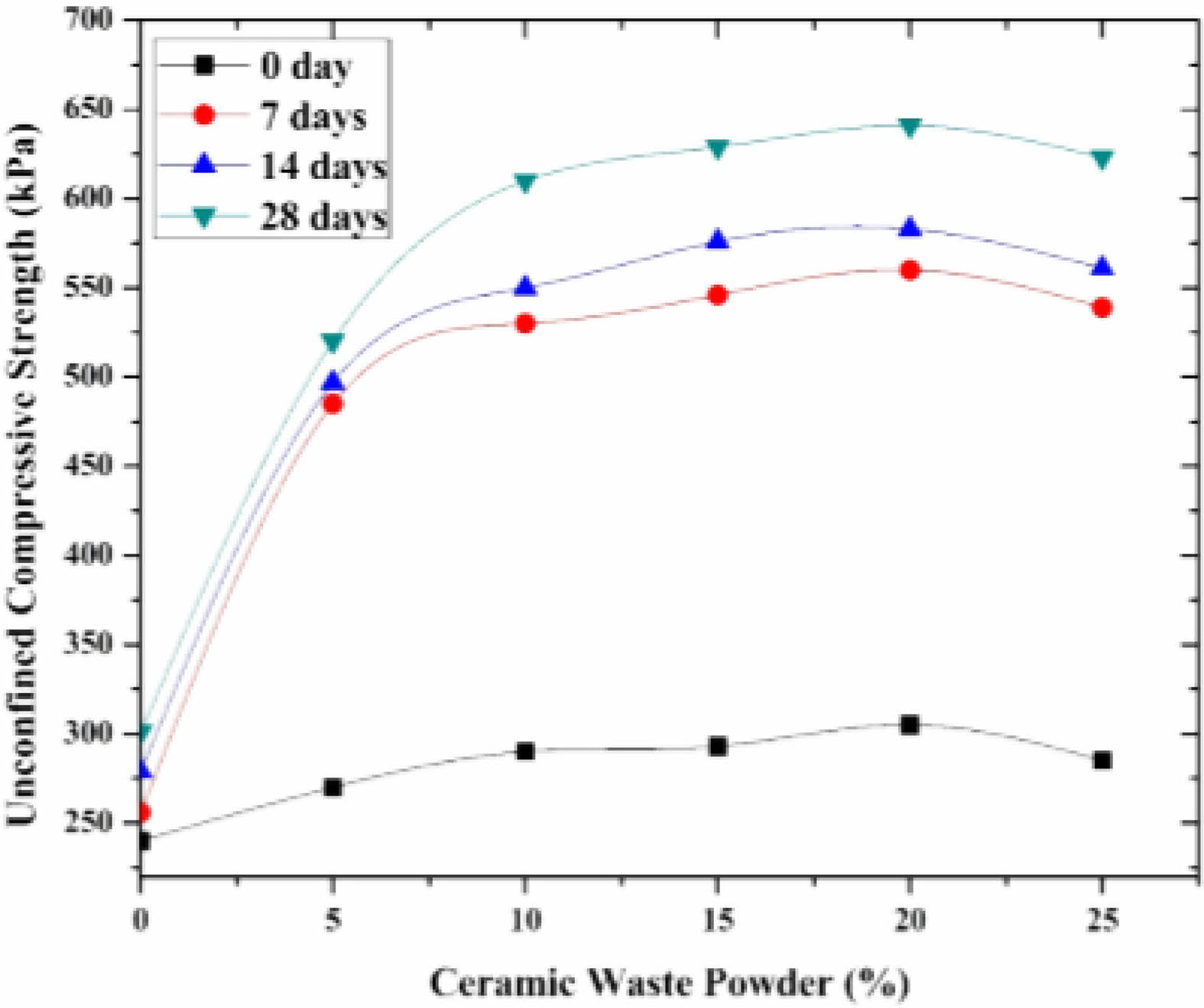

Influence of CWP on Unconfined Compressive Strength of the Expansive Soil

The influence of CWP on the unconfined compressive strength of soil is shown in Fig. 4. From the Fig. 4, the CWP percentages were taken as 0%, 5%, 10%, 15%, 20% and 25%. The UCS values obtained at 0 days of curing at 0%, 5%, 10%, 15%, 20% and 25% of CWP were 240 kPa, 270 kPa, 290 kPa, 293 kPa, 305 kPa and 285 kPa respectively. The strength variation noted after 7 days of curing shows a drastic variation such that for 0%, 5%, 10%, 15%, 20% and 25% of CWP, the obtained UCS values were 240 kPa, 270 kPa, 290 kPa, 293 kPa, 305 kPa and 285 kPa respectively. A sluggish variation was observed for the specimens treated and cured for 14 days and 28 days.The UCS values obtained were 279 kPa, 497 kPa, 550 kPa, 576 kPa, 561 kPa and 301 kPa, 520 kPa, 610 kPa, 629 kPa, 641 kPa, 623 kPa for 14 and 28 days of curing respectively. The strength was found to be increased with respect to an increase in the percentage of CWP content to 20% and the strength gradually decreased after the addition. It was noted that an increase in curing time enhanced the strength of the soil irrespective of CWP content. Hence, the optimum UCS value was obtained by the addition of 20% of CWP. The strength improvement at 20% of CWP at 0, 7, 14, and 28 days of curing were 1.27, 2.19, 2.08, and 2.13 folds respectively in comparison to the untreated soil sample. The pozzolanic reaction with lime held for a long period helped in improving the strength of the soil. From the acquired results, strength was improved notably in shorter curing periods. Hence, this study that the utilization of CWP in lime-stabilized soil showed a greater enhancement in strength in a shorter curing period. The optimum compressive strength obtained at 20% in the current study was 641 kPa. It was quite higher than the compressive strength attained from the 20% inclusion of marble dust which is 630 kPa [4] after 28 days of curing. At 7 days of curing, the soil showed an immense increase in compressive strength.

In the present study, the expansive soil with CWP inclusion provided better results in comparison to the previous studies conducted. The strength of expansive soil included with CWP was lower when compared to the 1.5 MPa obtained from expansive soil with volcanic ash as studied [11]. The variation was due to different kinds of CWP and the amount of dosage in it. The present study showed efficient results in comparison with the studies conducted using various admixtures at 43 kPa as studied in earlier works [12]. The unconfined compressive strength attained from the study conducted [7] was consistent with the strength obtained in the present study. The variation was due to the type of admixture used and the amount of dosage. Therefore, utilizing CWP in soil has many beneficial effects as it has a higher compressive strength.

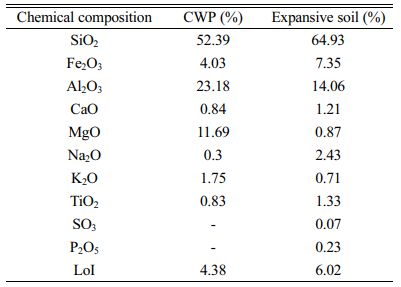

Influence of CWP on Tensile Strength of Expansive Soil

The influence of CWP on the tensile strength of expansive soil was shown in Table 4. As observed from the table, the tensile strength value calculated from the splitting tensile test after 30 days of curing was shown in Table 3 with respect to the inclusion of CWP at 0%, 5%, 10%, 15%, 20%, and 25%.

From the table, it was observed that the tensile strength increased. The curing time and concentration of CWP inclusion were found to be responsible factors for the tensile strength improvement. From the experiment, it can be concluded that the tensile strength increased with a higher curing period. Here, an optimum tensile strength was achieved at 20% as 78 kPa. An increase in tensile strength was observed with respect to CWP inclusion and increased curing periods. The result was observed to be consistent with earlier studies [19].

Influence of CWP on Swelling Behaviour of Expansive Soil

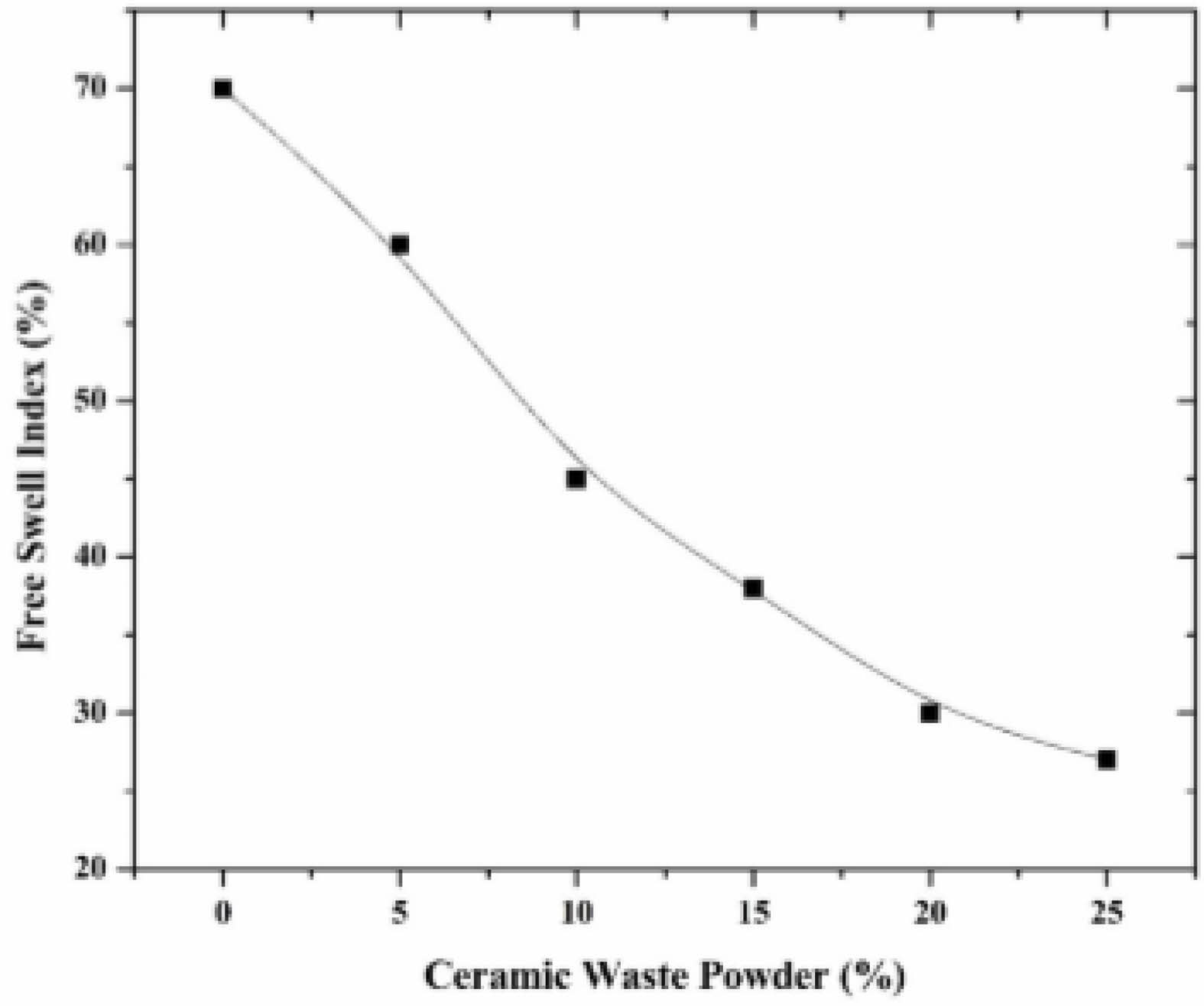

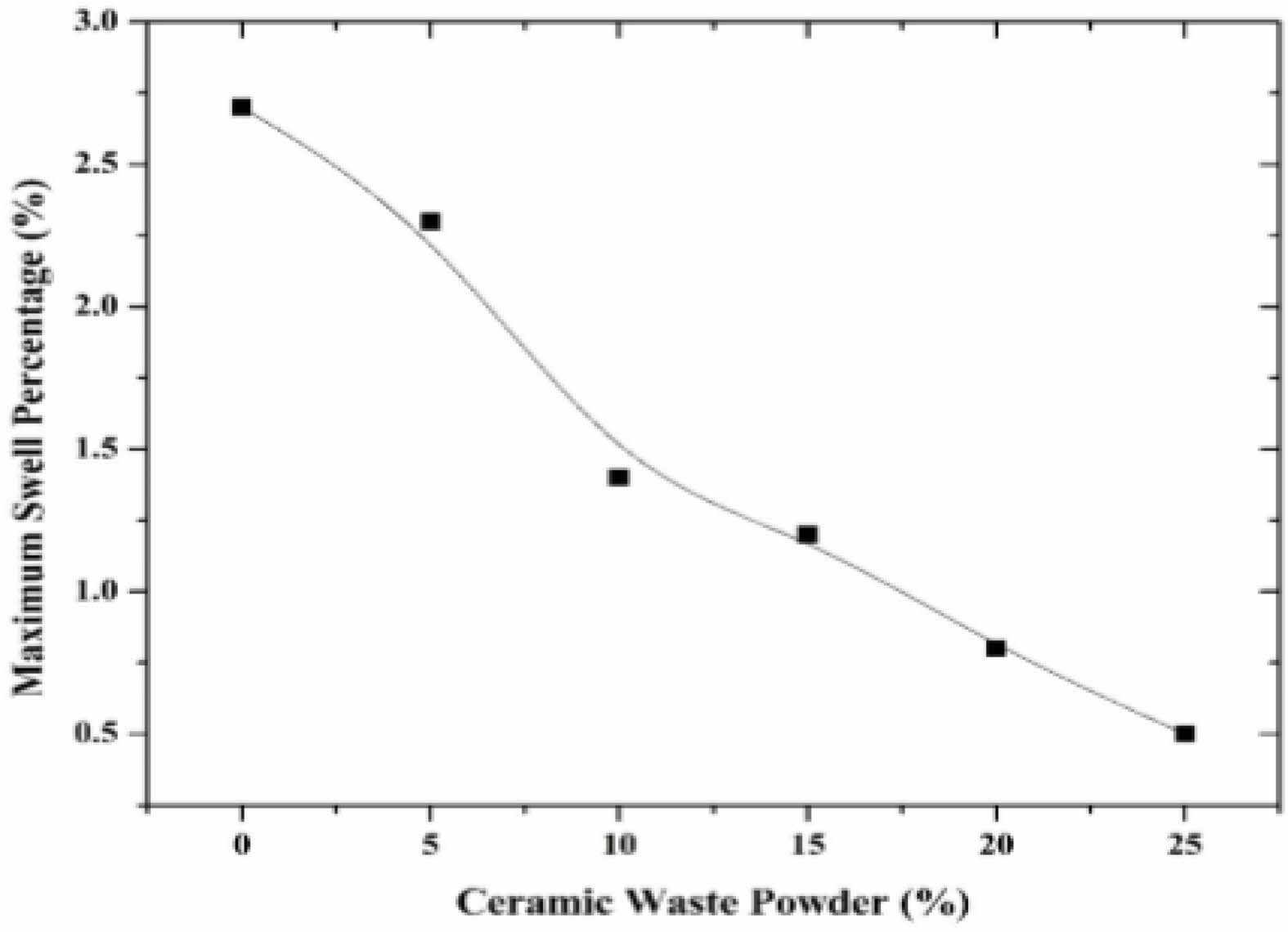

The influence of CWP on the free swell index was shown in Fig. 5. The FSI values obtained for 0%, 5%, 10%, 15%, 20% and 25%inclusion of CWP were 70%, 60%, 45%, 38%, 30% and 27% respectively. Hence, a decrease in the swelling percentage was observed with respect to increases in the percentage of CWP. This phenomenon was observed due to the presence of a higher amount of sand and silt particles that eventually enhanced the non–expansive nature of CWP. The porosity of expansive soil decreased with an increase in CWP content with respect to the electrical conductivity of the soil – CWP mixes. From Fig. 6, it was observed that after the amendment of CWP in soil, the decrease in percentage of Free Swell Index in accordance to the addition of 5%, 10%, 15%, 20% and 25% of CWP were 2.7%, 2.63%, 1.4%, 1.2%, 0.8% and 0.5% respectively. It was clearly shown in Fig. 2. The decrease in percentage occurs because the swelling particles of soil were replaced with non–swelling particles of CWP [4]. Hence the effective usage of CWP can control the swell behavior of soil efficiently. In this present study, it was observed that the FSI value decreased with an increase in CWP content.

The decreasing percentage of CWP with respect to addition of 0%, 5%, 10%, 15%, 20% and 25% of marble dust were 2.26, 1.42, 1.00, 0.80, 0.47, and 0.13 respectively. The free swell index percentage as observed with the inclusion of 0%, 30%, 40%, and 50% of Marble powder was 50.50% and no further decrease respectively. The results were consistent with Marble dust inclusion in Expansive soil [4]. There was a 61% reduction in free swell index value with CWP inclusion but 86% was observed with respect to the addition of Fly ash [18]. A greater reduction in the free swell index was observed with respect to CWP inclusion in soil compared to other industrial wastes at 28 % [8]. However, the present study showed a higher percentage compared to the other studies conducted on expansive soil.

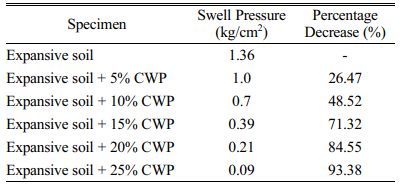

Influence of CWP on Swell Pressure of Expansive Soil

The influence of CWP on swell pressure was provided in Table 5. From the table, the swelling pressure of expansive soil was found to be 1.36 kg/cm2. The values obtained with respect to the inclusion of CWP at 5%, 10%, 15%, 20%, and 25% were provided in Table 5. The swell pressure varied for different percentages of CWP inclusion. A decrease in swell pressure was observed. The reduction of pressure was observed as the inclusion of CWP increased, substantially the surface area occupied by CWP in the soil also increases. This eventually results in lesser interaction between clay particles and particles in the soil. Hence, it was observed that swell pressure decreased with an increment in a decreased percentage of CWP. The decrease in percentage of swell pressure with respect to CWP inclusion of 0%, 5%, 10%, 15%, 20% and 25% were 26.47%, 48.52%, 71.32%, 84.55% and 93.38%.

The result obtained was consistent with the results obtained from the earlier studies of Gautam et al., 2018 in the case of soil – marble dust matrix and soil with marble dust and coil fiber with a reduction of 92.02%. The swell pressure variation in the soil – CWP matrix was higher in comparison with the results obtained from the previous studies using industrial wastes at 24% [2].

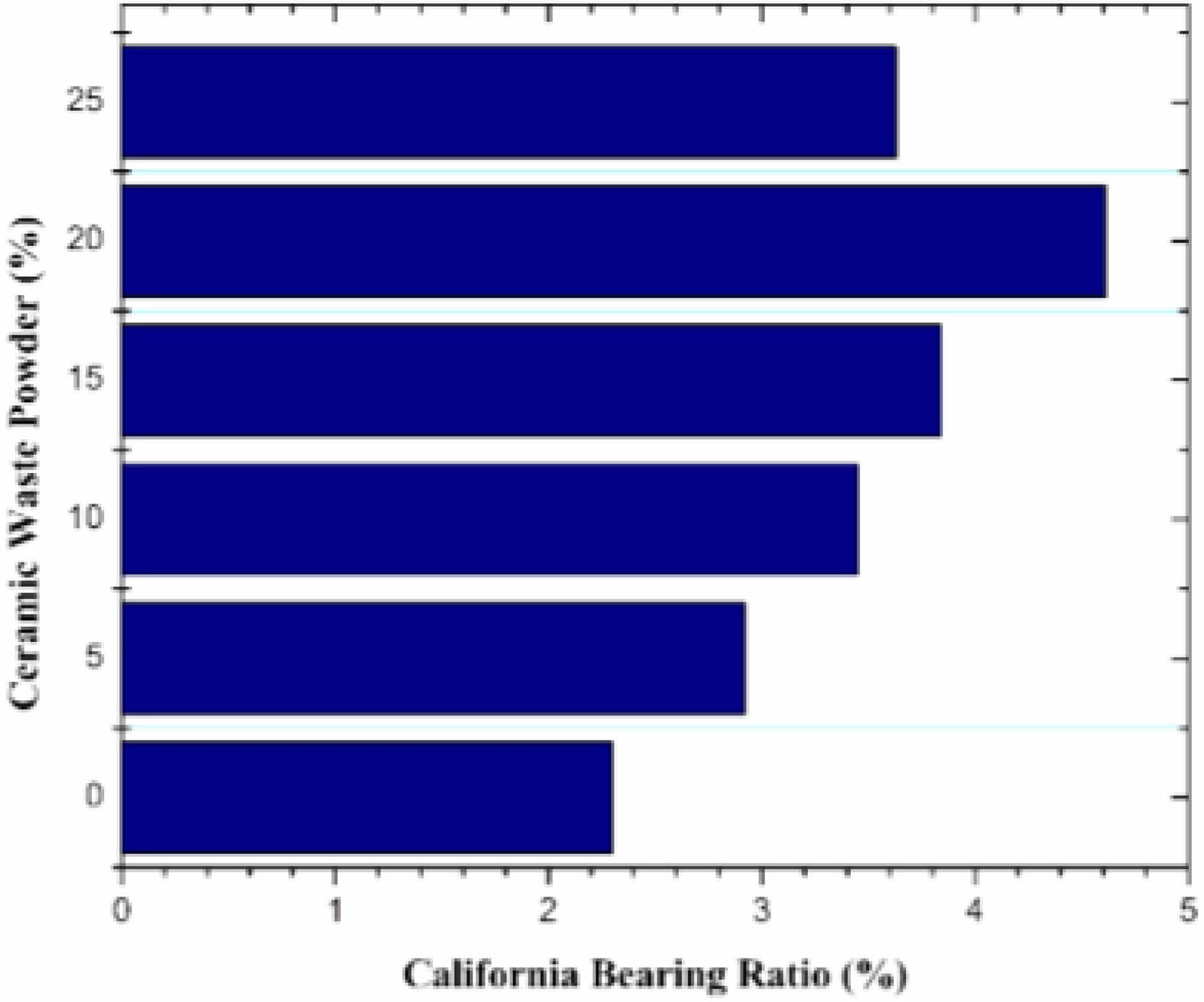

Influence of CWP on California Bearing Ratio of Expansive Soil

The influence of CWP on the California – Bearing Ratio values as obtained from the test is shown in Fig. 7. From the result obtained, it was clear that there was an increase in CBR percentage with respect to increasing CWP content in Expansive soil. The CBR values increased with respect to the increase in CWP content till it reached the optimum value of 15% and a decrease in the values was observed for further addition of CWP into the soil. The values obtained with respect to increase in CWP inclusion at 0%, 5%, 10%, 15%, 20% and 25% were 26.95%, 68.26%, 136.08%, 80% and 41.3% respectively. Hence, an optimum value was achieved at 15% CWP inclusion as 5.43%.

The influence of CWP on the California – Bearing Ratio values as obtained from the test was shown in Fig. 7. From the result obtained, it can be observed that there was an increase in CBR percentage with respect to the increase CWP content in expansive soil. The CBR values increased with respect to the increase in CWP content till it reached the optimum value of 15% and a decrease in the values was noted for the further addition of CWP into the soil. The CBR values attained with respect to increase in CWP inclusion at 0%, 5%, 10%, 15%, 20% and 25% are 26.95%, 68.26%, 136.08%, 80% and 41.3%. Hence, an optimum value was achieved at 15% CWP inclusion as 5.43%.

The CBR value obtained for a previous study conducted on CWP resulted in 4% which was less according to the present study as lime was also included [2]. And also, a higher CBR value was obtained in soil – CBR mix than obtained from other industrial wastes [8]. The results were consistent in the case of soil – Marble Dust mix [4]. Hence the CWP inclusion shows greater efficiency than other industrial wastes.

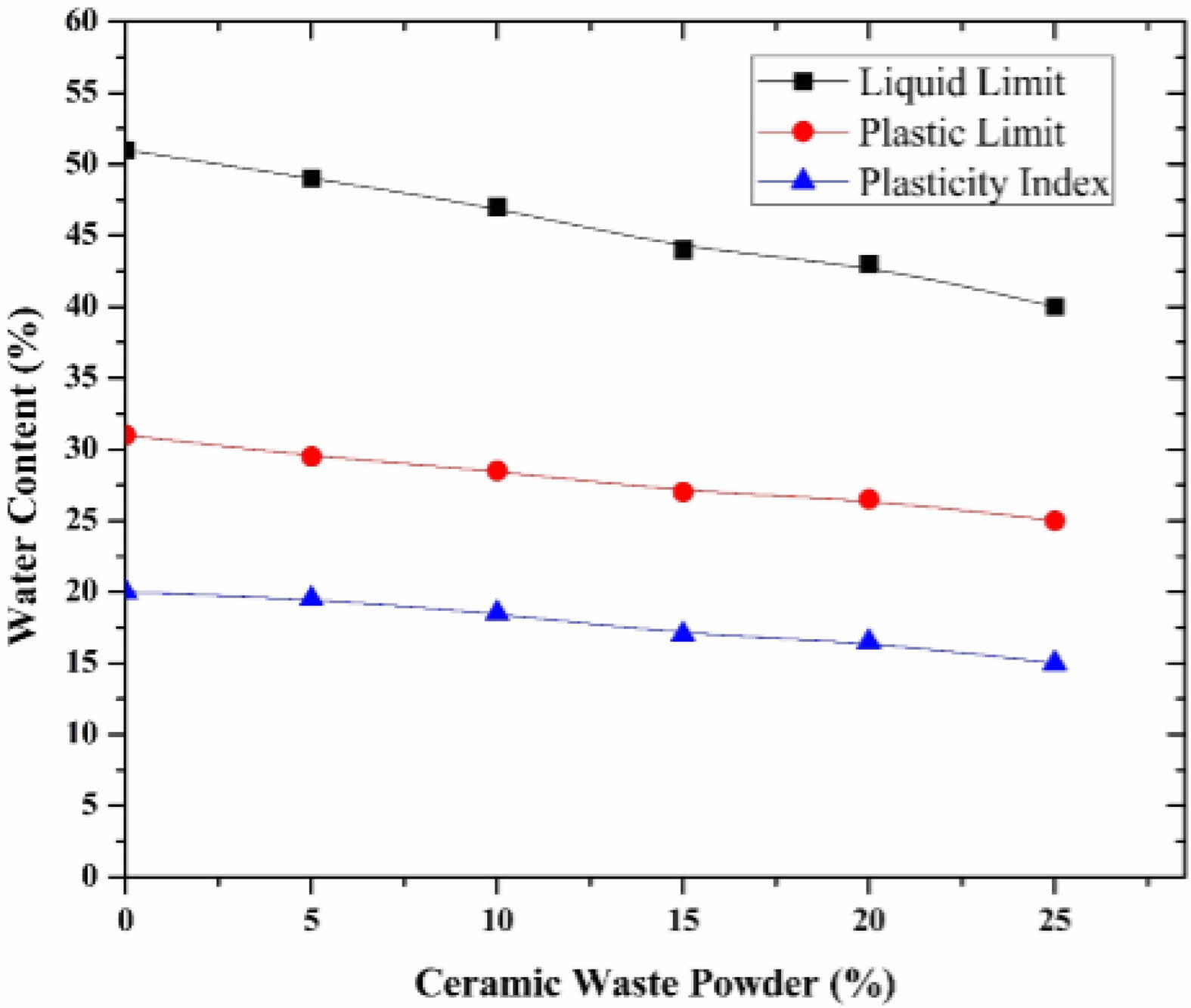

Influence of CWP on Index Properties of Expansive Soil

The influence of CWP on the index properties of expansive soil was provided in Fig. 8. The values of liquid limit, plastic limit, and plasticity index for different percentages of CWP were shown in Fig. 8. From the figure, it can be observed that the Liquid limit values obtained with respect to the addition of 0%, 5%, 10%, 15%, 20% and 25% of CWP were 51%, 49%, 47%, 44%, 43% and 40%. Plastic limit values obtained with respect to the addition of 0%, 5%, 10%, 15%, 20% and 25% of CWP were 31%, 29.5%, 28.5%, 27%, 26.5% and 25% respectively. In this case, the plastic limit and liquid limit values decreased with an increase in CWP concentration. The plastic index is the difference between the liquid limit and the plastic limit. It also decreased with an increase in CWP content. Due to the increasing nature of granular soil with respect to the increase in CWP content that eventually ended in aggregation, the liquid limit does not attain a linear reduction. It can also be due to the fast reactivity between the expansive soil and CWP.

The liquid limit and plasticity index obtained at an optimum percentage of 20% is 43% and 16.5% respectively. The results revealed the better performance of the soil – CWP mix in comparison with the earlier studies conducted on Expansive soil – Lime Matrix [14] and soil – Marble Dust matrix [4]. A better result in the present study was observed when compared with the inorganic chemical additives [13]. Variations in results were due to the type of admixture used and the dosage amount included in the soil.

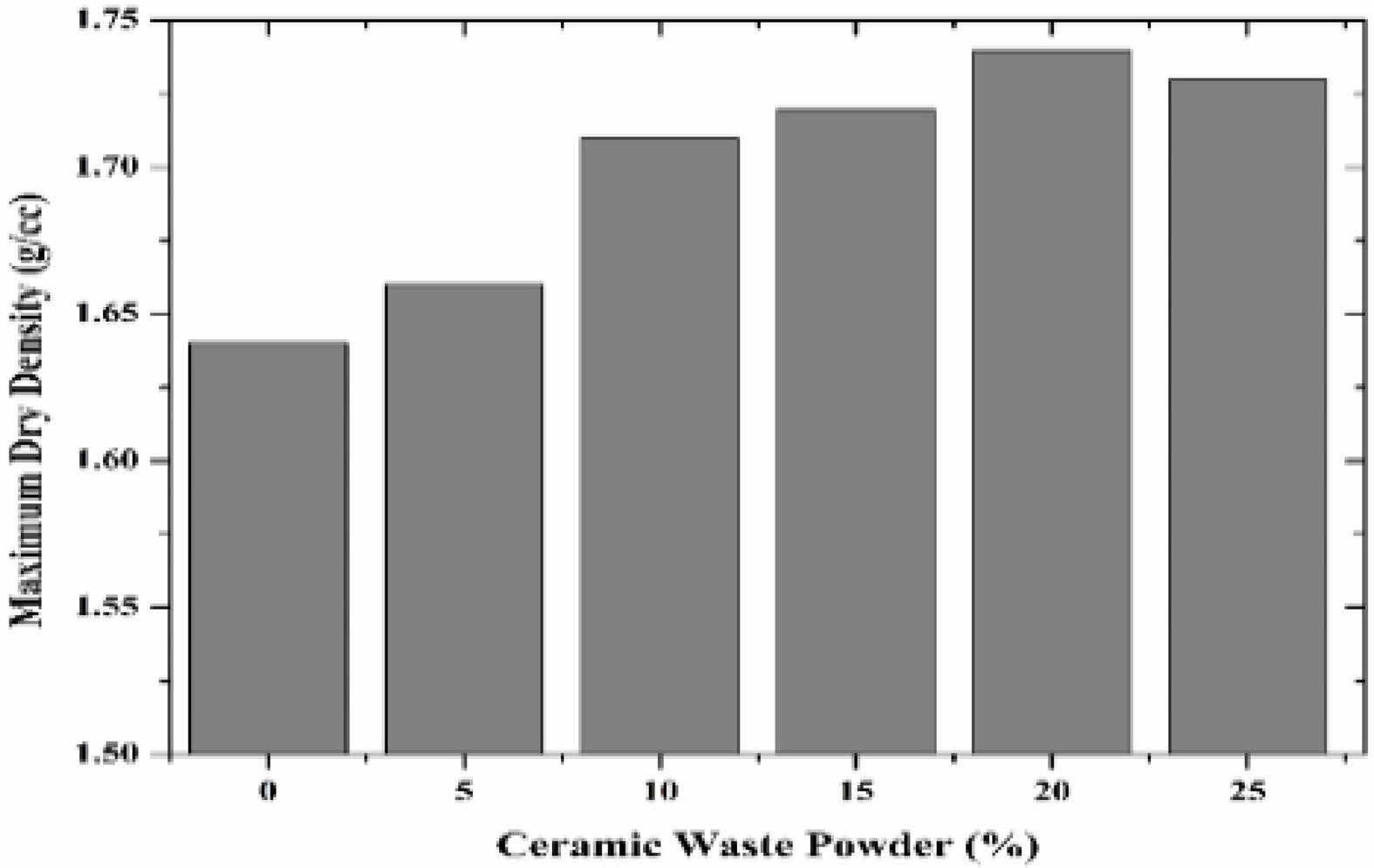

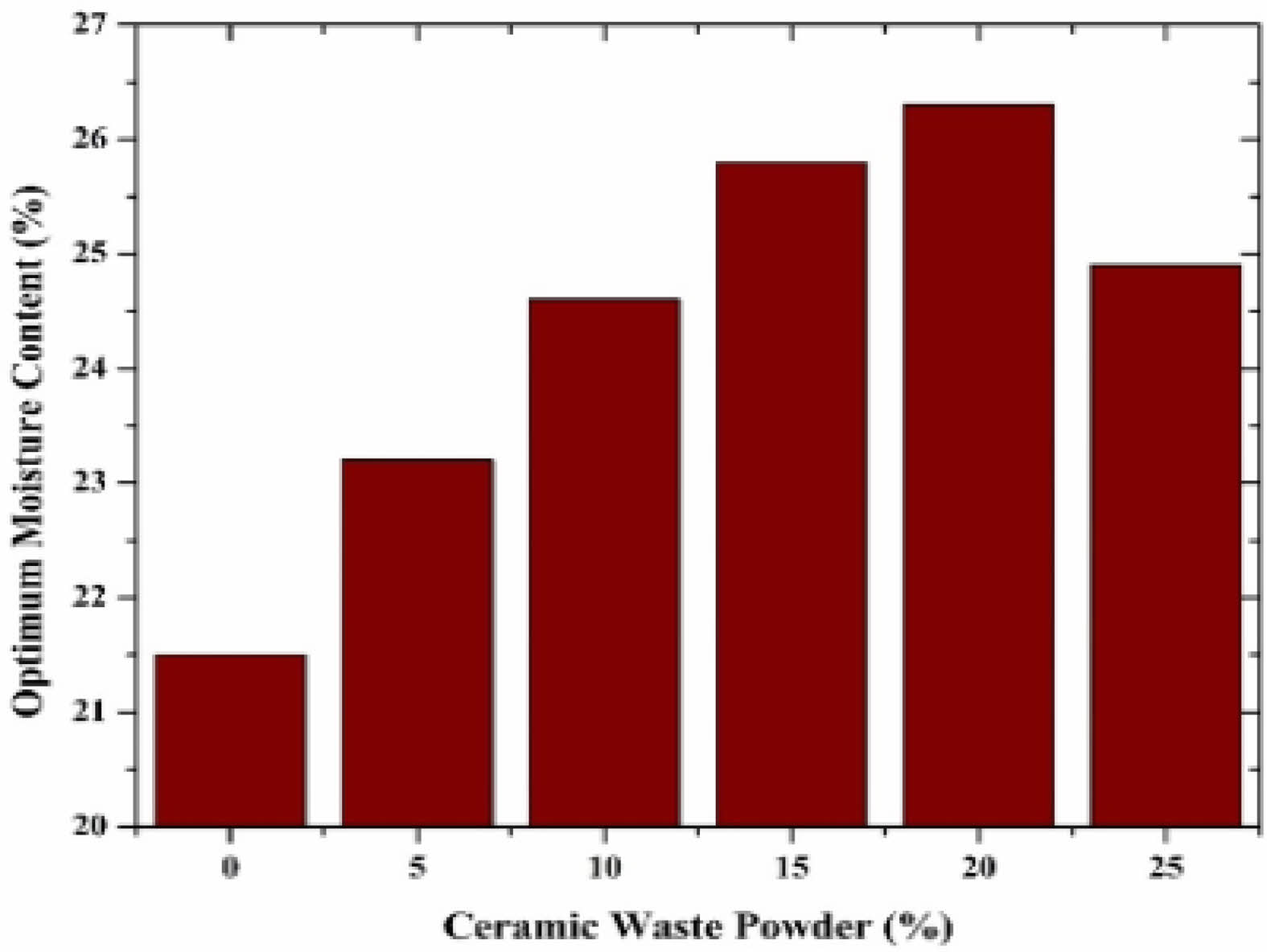

Influence of CWP on compaction Characteristics of Expansive Soil

The influence of CWP on compaction characteristics of expansive soil is shown in Figs. 9 and 10. From the figure, it was certain that the values of Maximum Dry Density (MDD) (Fig. 9) and Optimum Moisture Content (OMC) (Fig. 10) increased with the increase in the percentage of CWP. The increase in MDD was due to gradation enhancement to attain a well-graded mixture with the gradual inclusion of CWP. The electrolyte concentration increased with the release of Ca2+ ions into the pore fluid thereby decreasing the voids present. This led to an increase in the Maximum Dry Density of the soil specimens. The increment in OMC was observed because the pores were available to hold the water which eventually increased the water holding capacity. The increase in OMC was observed because of the requirement of water to form Ca (OH)2 and to dissociate into Ca2+ and OH- ions. Hence, in this present study, a notable increase in both MDD and OMC occurred with respect to an increase in the percentage of CWP in soil.

The Maximum Dry Density and Optimum Moisture Content increased gradually with the addition

of CWP to the expansive soil. The MDD and OMC obtained at an optimum of 20% were 1.74 g/cc and 26.3%. In comparison with the earlier studies conducted on Expansive soil [4], the values obtained in the present one showed a better variation so as to meet the required results. The MDD and OMC at optimum obtained from the current study are higher than the results obtained in previous studies with mineral admixtures [12]. So, the usage of CWP in soil enabled the function of the soil matrix in an efficient way.

Performance of Various Regression Algorithms in Machine Learning

In this study, total data of soil-Ceramic Waste Powder mixtures in various proportions were acquired. Some data were utilized for training, while others for testing. The parameters used in the Simple Regression Algorithm, Lasso Algorithm, Ridge Algorithm, and SVM Algorithm models were listed in the table with their maximum, minimum, average, and standard deviation values.

For the construction of the Simple Regression Algorithm, Lasso Algorithm, Ridge Algorithm, SVM, Algorithm models and differential regression algorithms were utilized in training procedures. The number of neurons in the hidden layer was found to be four, while the number of hidden layers was one. For the models, the activation function for the input layer, hidden layer, and output layer was clearly a hyperbolic tangent sigmoid.

The effective use of SVM models was dependent on the selection of appropriate parameters, such as the kind of kernel function, which were determined by trial and error. Different kernel functions, such as polynomial, radial, and spline kernel functions, were used to create SVM models. Google CoLabwas used to do the necessary computations for model development. Table 6

|

Fig. 1 Mixture vs CBR. |

|

Fig. 2 Correlation between Mixture and CBR |

|

Fig. 3 Variation of pH with respect to CWP inclusion into soil. |

|

Fig. 4 Unconfined Compressive Strength with varying CWP. |

|

Fig. 5 Free swell index with varying inclusion of CWP percentage. |

|

Fig. 6 Maximum swell percentage with varying inclusions of CWP percentages. |

|

Fig. 7 Effect of CWP inclusion on CBR of the expansive soil. |

|

Fig. 8 Liquid limit, plastic limit and plasticity index with respect to variation IN CWP percentages. |

|

Fig. 9 Maximum dry density with respect to variation in CWP percentage. |

|

Fig. 10 Optimum moisture content of the specimens with respect to varying CWP. |

|

Table 5 Swell pressure observed for the specimens with varying CWP percentages. |

The geotechnical behavior and interaction mechanisms were understood by performing a series of experiments. The importance of utilization of CWP as an admixture in expansive soil was clearly defined from the results obtained. The conclusions drawn from the present study were as follows.

(1) The pH value increased with an increase in CWP inclusion in the soil till the optimum value was attained. The optimum value obtained is 8.98. The increase was due to the increase in the ionic strength of the soil as CWP content is included in the soil.

(2) Electrical conductivity decreased with respect to an increase in the CWP content of the soil. The reduction was due to an increase in the bulk density of the clay soil. The bulk density of the CWP was higher compared to the Expansive soil.

(3) The strength attained from the unconfined compression test increased till it obtained an optimum value of 20% with an increase in CWP inclusion in expansive soil. This represented maximum stiffness at 20% CWP inclusion. Furthermore, the optimum compressive strength value was found to be 641 kPa after 28 days of curing. From the results, it was observed that the strength of the soil was affected by the curing period also.

(4) From the splitting tensile test, it was observed that the tensile strength increased with an increase in CWP inclusion. The strength improved till an optimum value of 78 kPa is attained at 20% CWP inclusion. The curing period was also considered to be an important factor in determining the strength of the soil. The optimum strength was reached after 30 days of curing. However, the optimum percentage may be varied with respect to the engineering properties of soil.

(5) The free swell index test results revealed that the soil changed from high swelling to low swelling characteristics with respect to increasing CWP content in the soil. The differential free swell percentage decreased from 70% to 27%. This tendency of reduction in swelling added merit to the CWP inclusion in soil.

(6) Swell Pressure decreased substantially with an increase in CWP content in expansive soil. The decrement in pressure percentage was observed from 26 % to 57 %. Hence, a considerable reduction in swell pressure was noted in the soil – CWP matrix. This helped in controlling the swelling characteristics that lead to improvement in soil stabilization.

(7) California Bearing Ratio increased to 15% of CWP inclusion. It reached 5.43% from 2.3%. A further decrease in the percentage represented that an optimum was reached at 15% inclusion of CWP content as 5.43%. The percentage increment with respect to the 15% inclusion of CWP content into the soil was 136.08%.

(8) From the particle size analysis, it was observed that the plasticity index of the soil decreased from 20% to 15%. This reduction was due to the replacement of plastic particles of the expansive soil to non–plastic CWP particles accordingly.

(9) The Maximum Dry Density and Optimum Moisture Content increased with respect to the addition of CWP. The increment in the result was due to the improvement in gradation of the soil – CWP matrix. The void reduction may also influence the increment in MDD and OMC values.

Hence, utilization of CWP in Expansive soils provided greater efficiency than other industrial wastes. The effective usage of CWP in the soil can improve soil stability with sustainable and environmentally – friendly means.

- 1. A. Iravanian, S.A. Saber, Earth. Environ. Sci. 614[1] (2020) 012081.

-

- 2. A.K. Sabat, Electron. J. Geotech. Eng. 17(Z) (2012) 3915-3926.

- 3. S. Selvakumar, P. Kulanthaivel, and B. Soundara, Nanotechnol. Environ. Eng. 6 (2021) 1-10.

-

- 4. A.K. Jain, and A.K. Jha, Soils Found. 60[4] (2020) 737-751.

-

- 5. P. Kulanthaivel, B. Soundara, and A. Das, KSCE J. Civ. Eng. 24[9] (2020) 2631-2642.

-

- 6. S. Mohanty, D.R. Pradhan, S.S. Das, and S.K. Pradhan, Int. J. Appl. Artif. Intell. Eng. Syst. 3[2] (2018) 555606.

- 7. P. Kulanthaivel, B. Soundara, S. Selvakumar, and A. Das, Environ. Sci. Pollut. Res. 29 (2022) 66450-66461.

-

- 8. R. Garg, T. Biswas, MD D. Alam, A. Kumar, A. Siddharth, and D.R. Singh, J. Phys.: Conf. Ser. 2070 (2021) 012238.

-

- 9. P.S. Singh, and R.K. Yadav. Int. J. Eng. Res. Sci. Tech. 3 (2014) 158-63.

- 10. S.D. Prathap Kumar, Int. J. Eng. Res. Technol. (2016) 104-107.

- 11. Y. Cheng, and X. Huang, Appl. Sci. 30[9] (2019).

-

- 12. S. Pachaiappan, V. Murugaiyan, R. Prethiv Kumar, T.M. Dhavud, and R. Muralidharan, Int. J. Sci. Eng. Res. 10[8] (2017) 2229-5518.

-

- 13. J. Nayak, and T. Singh, Int. J. Eng. Sci. Res. Technol. 12[6] (2017) 12-16.

- 14. K.S. Mehta, R.J. Sonecha, P.D. Daxini, P.B. Ratanpara, and K.S. Gaikwad, Int. J. Eng. Res. Appl. 4[5] (2014) 25-32.

- 15. P.R. Modak, P.B. Nangare, S.D. Nagarle, R.D. Nalawade, and V.S. Chavhan, Int. J. Eng. Technol. Innov. 1[5] (2012) 2277-3754.

- 16. A.K. Sabat, and R.P. Nanda, Int. J. Civ. Struct. Eng. 1[4] (2011) 939-948.

- 17. S.N. Bhavsar, H.B. Joshi, P.K. Shrof, and P.J. Ankit, Int. J. Sci. Res. Engineering Dev. 2[2] (2014) 2321-0613.

- 18. S.K. Mohanty, P.K. Pradhan, and C.R. Mohanty, Geotech. Geol. Eng. 34 (2016) 1435-1451.

-

- 19. A. Soldo, M. Miletić, and M.L. Auad, Sci. Rep. 10 (2020) 267.

-

- 20. C.A.U. Okeke, Bull. Eng. Geol. Environ. 79 (2020) 2169-2185.

-

- 21. A. Shayesteh, M.Y. Fard, and M. Vafaeian, Constr. Build. Mater. 341 (2022) 127826.

-

- 22. X. Ouyang, L. Yu, L. Wang, S. Xu, Y. Ma, and J. Fu, J. Build. Eng. 61 (2022) 105253.

-

- 23. X. Chen, D. Zhang, S. Cheng, X. Xu, C. Zhao, X. Wang, and X. Bai, J. Build. Eng. 52 (2022) 104418.

-

- 24. N.W. Jassim, H.A. Hassan, H.A. Mohammed, and M.Y. Fattah, Results Eng. (2022) 100436.

-

- 25. B. Balegh, H. Sellaf, and A. Hadjmostefa, Case Stud. Constr. Mater. 13 (2020) e00368.

- 26. A.M. Hamzah, S.K. Zakaria, S.Z. Salleh, A.H. Yusoff, A. Ali, M. Mohamad, M.N. Masri, S.A. Sobri, M.A.A. Taib, F. Budiman, and P.T. Teo, J. Ceram. Process. Res. 22[2] (2021) 200-207.

- 27. J. Song, X. Yang, P. Chen, R. Liu, D. Luo, L. Li, and J. Liu, J. Ceram. Process. Res. 22[4] (2021) 394-400.

This Article

This Article

-

2022; 23(6): 902-911

Published on Dec 31, 2022

- 10.36410/jcpr.2022.23.6.902

- Received on Jun 29, 2022

- Revised on Sep 27, 2022

- Accepted on Oct 26, 2022

Services

Services

Shared

Correspondence to

Correspondence to

- D. Sivabalaselvamani

-

Associate Professor, Department of Computer Applications, Kongu Engineering College, Perundurai, Tamilnadu, India

Tel : +919940049001 - E-mail: sivabalaselvamani@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.