- Eco-Efficient Concrete: A sustainable reutilization of Ceramic Tile Waste Powder (CTWP) as a partial replacement for cementitious material in a recycled fine aggregate concrete

S. Janania, G.S. Rampradheepb, P. Kulanthaivelc and P.C. Murugand

a,b,cDepartment of Civil Engineering, Kongu Engineering College, Perundurai, India

dDepartment of Automobile Engineering, Kongu Engineering College, Perundurai, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The waste generated from the construction will not only leads to environmental crisis but also project overrun. The environmental problems results in increase of pollution that leads society to unfit for living organisms. Many investigations have been carried out on the area of Construction Waste (CW). At the end of 2025, the volume of CW generated will nearly double to 2.2 billion tons worldwide. Construction waste contributing 40% depletes earth’s environment. The research comprised of two phases. Phase one focuses on the reduction of material waste generated from the construction that can be reutilized as fine aggregate in concrete of different proportions 25%, 50%, 75% and 100%. Phase two aims to decrease the amount of CO2 emission from the cement and that can be achieved by utilization of CW material - Ceramic Tile Waste Powder (CTWP) as a substitute for cement in varying proportions 0%, 10%, 20%, 30% and 40%. The research showed the performance of Eco-Efficient Concrete with different proportions of CTWP and Recycled Fine Aggregate (RCFA) through measured properties. The use 30% CTWP & 100% RCFA replacement level adequate for compressive strength improvement at 28 days is 24.8 N/mm2. The simultaneous use of increased percentage of CTWP & RCFA at different replacement levels enhances the durability Properties

Keywords: Construction waste, Ceramic tile waste powder, Recycled fine aggregate, Eco-friendly, Sustainable development

Globally, everyone aware of that earth becoming unfit for organism’s survival not only due to natural calamities but also mainly due to human activities. The rapid development of infrastructure projects in a country is a major source of national income. Concrete plays a major role [1]. Concrete – a main ingredients include cement & water - binding materials, coarse aggregate and fine aggregate -filler materials. Cement is the largest manufactured material globally. Buildings include bridges, dams, reservoirs, sky scrapers, archi- tectural building and so on could not be possible without cement-based materials. On the positive impact side, it is good in compression, cost, energy efficient, more suitable and easier to use and another side it was an extreme one, which causes serious of environmental problems includes carbon dioxide emissions at a higher rate and major utilization of resources [2]. The Green- house Gases (GHG) generated from the cement was contributed around 8% annually. The cement kiln dust used as a substitute material for concrete keeping remaining materials constant [3]. Moreover, recycled concrete provide response to the problems encountered with grubbing of natural aggregates and the waste disposal from the buildings or demolished wastes. 90% of waste being dumped into the landfill. Many substitutions have been made for cement which includes e-waste, glass, plastics and demolished concretes. Recycling is required to avoid mass dumping [4]. The waste generated must be reused other it causes negative impact to the environment causes pollution and also economy loss [5]. In order to eliminate this negative impact from cement an alternative replacement of cementitious material is needed to decreases the discharge of CO2 into the atmosphere throughout its life cycle from the production to after construction that can happen during any stages of point of process [6, 7]. Ceramic Tile Waste Powder serves a favourable cementitious supplementary material for cement [8]. India and China accounts around 55% of tiles production annually. Production increases waste generated also gets increased [9]. Plastic waste and ceramic waste powder serves a good interlocking bond and also exhibits innovative, environmentally friendly and cost-effective material when used in the construction sector [10]. Ceramic waste powder contributes to more than 22 billion of tons annually during the polishing process of tile and mineral contribution by silica and alumina was around 80% [11]. The properties of cement and CTWP were compared and finalised that it had a potential to use as a replacement material but its investigation further needed. The replacement of CTWP made with different proportions includes 0% to 60% by mass. The result concluded that 20% of ceramic replacement gives good results in compression. After 20 percentage of inclusion there was a decrease in compression found [12]. Eco-friendly concretes have been developed by replacing Ordinary Portland Cement with Ceramic waste powder of different percentage in the range of 0% to 50% in difference of 10% by weight of M20 Grade of concrete and the effective replacement was 30% with greater Compressive strength when compared to other mix ratios [13]. In addition to cement replacement one of the most demanded materials was sand. The research focuses on replacement of fine aggregate in concrete with RCFA. RCFA reduce the usage of natural materials and that contribute towards country ecological status [14]. In order to reduce the consumption of natural fine aggregate, the waste from the construction named as construction debris effectively utilised in the concrete [15]. The utilisation of construction debris in the concrete in form of fine aggregate implies new solution to the infrastructure environment but the properties not as much as good when compared to the sand because of its interface zone and higher water absorption rate [16]. The research made on with different proportions of RCFA in concrete as a replacement material for fine aggregate says 0%, 25%, 50%, 75% and 100% and CTWP in concrete as a replacement material for cement says 0%, 10%, 20%, 30% and 40%. But the combination of these CTWP and RCFA in a concrete was not addressed. So, the research aims with the combination of replacement made on concrete for cement and sand were analysed with hardened and durability Properties. The economic feasibility of recycled fine aggregate with ceramic tile waste powder and its long-term performance will analysed in the future [17].

Cement

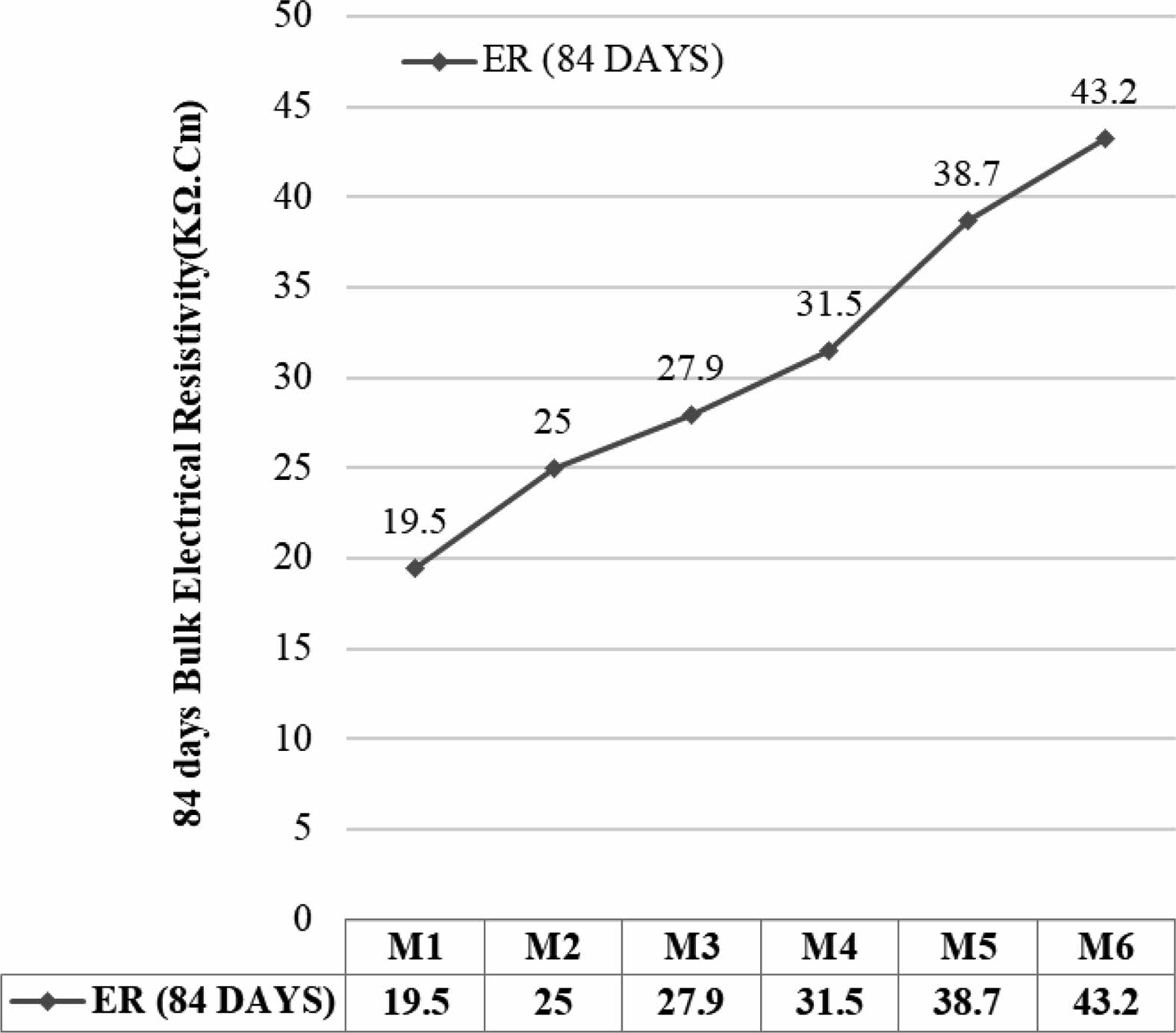

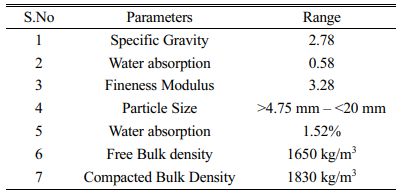

In this research, Ordinary Portland Cement (OPC) of grade 53 was used, produced by Chettinad cement corporation Ltd., and the physical properties were listed in Table 1.

Ceramic Tile Waste Powder (CTWP)

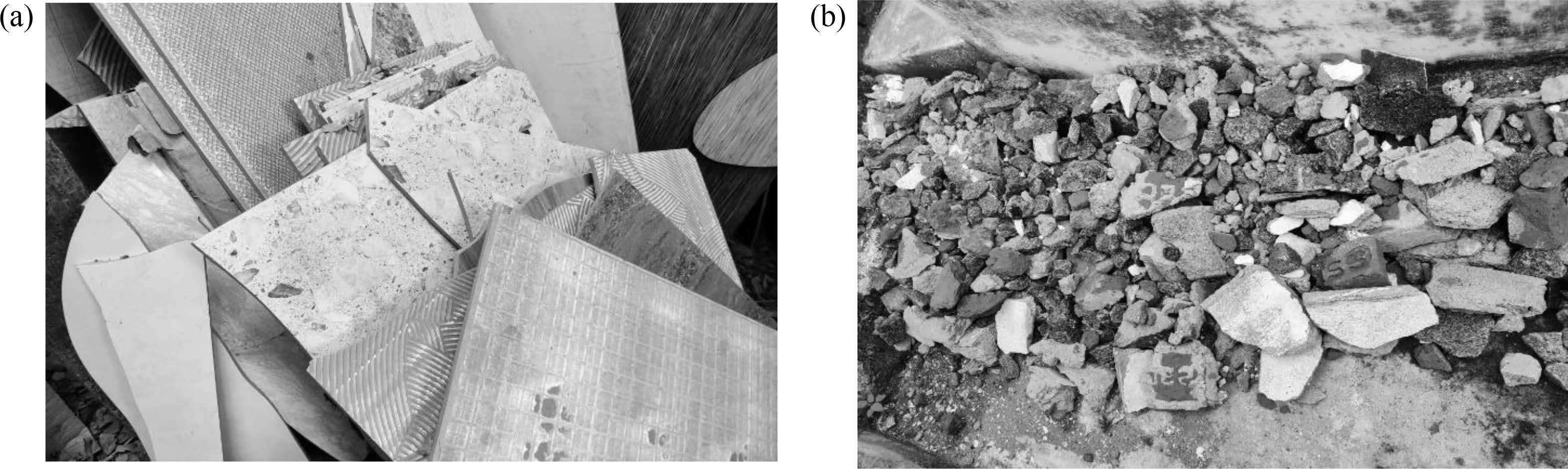

The construction wastes were collected from Parryware Roca Private Ltd., Perundurai. It was categorised to ceramic waste shown in Fig. 1(a) and other construction waste namely concrete and brick Fig. 1(b). Ceramic Tile raw materials includes silica sand, clay, feldspar.

Initially ceramic waste was converted to CTWP in three step process.

• Step 1: Breaking – Ceramic tiles were broken manually using hammer

• Step 2: Crushing – Jaw crusher to get 0.005 – 0.01 m ceramic particles

• Step 3: Grinding – Using cement test mill for a period of 60Minutes

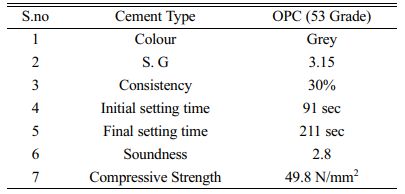

The chemical composition of cement and CTWP were presented in Table 2.

Recycled Fine Aggregate (RCFA)

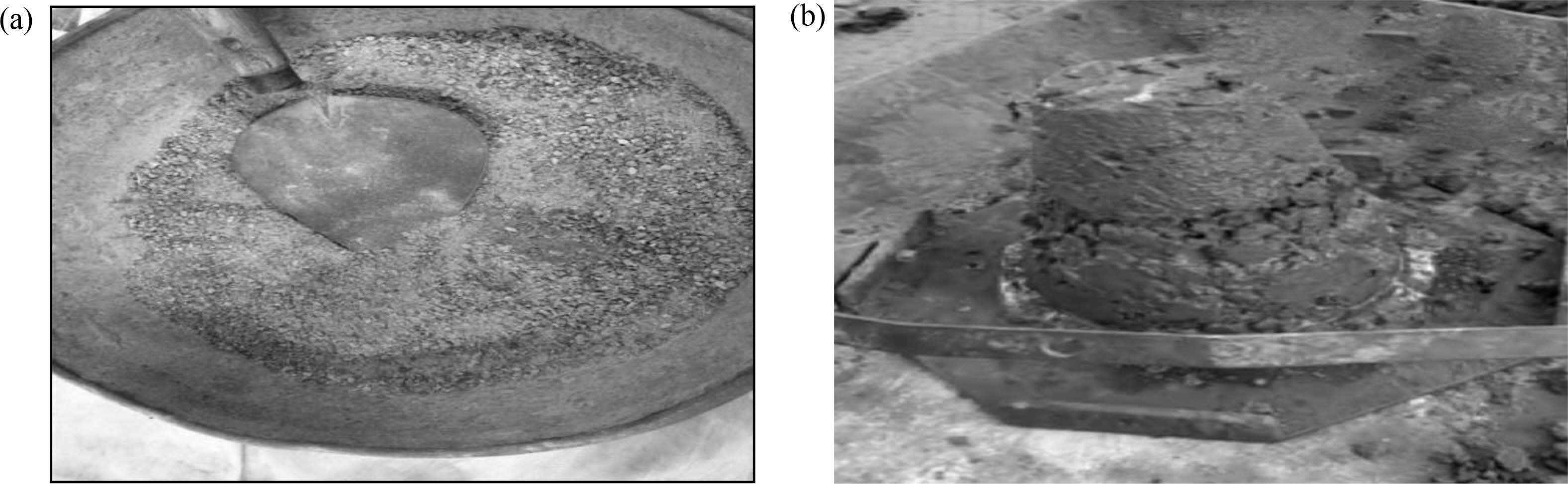

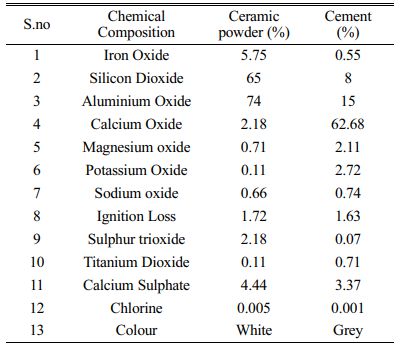

The Concrete and Brick Waste was collected from the demolished 32-year age building near Chennimalai. The recycled aggregate was crushed using jaw-type crusher and used as fine aggregate in the project with different trails named as RCFA 1 – RCFA 5 Shown in Table 3.

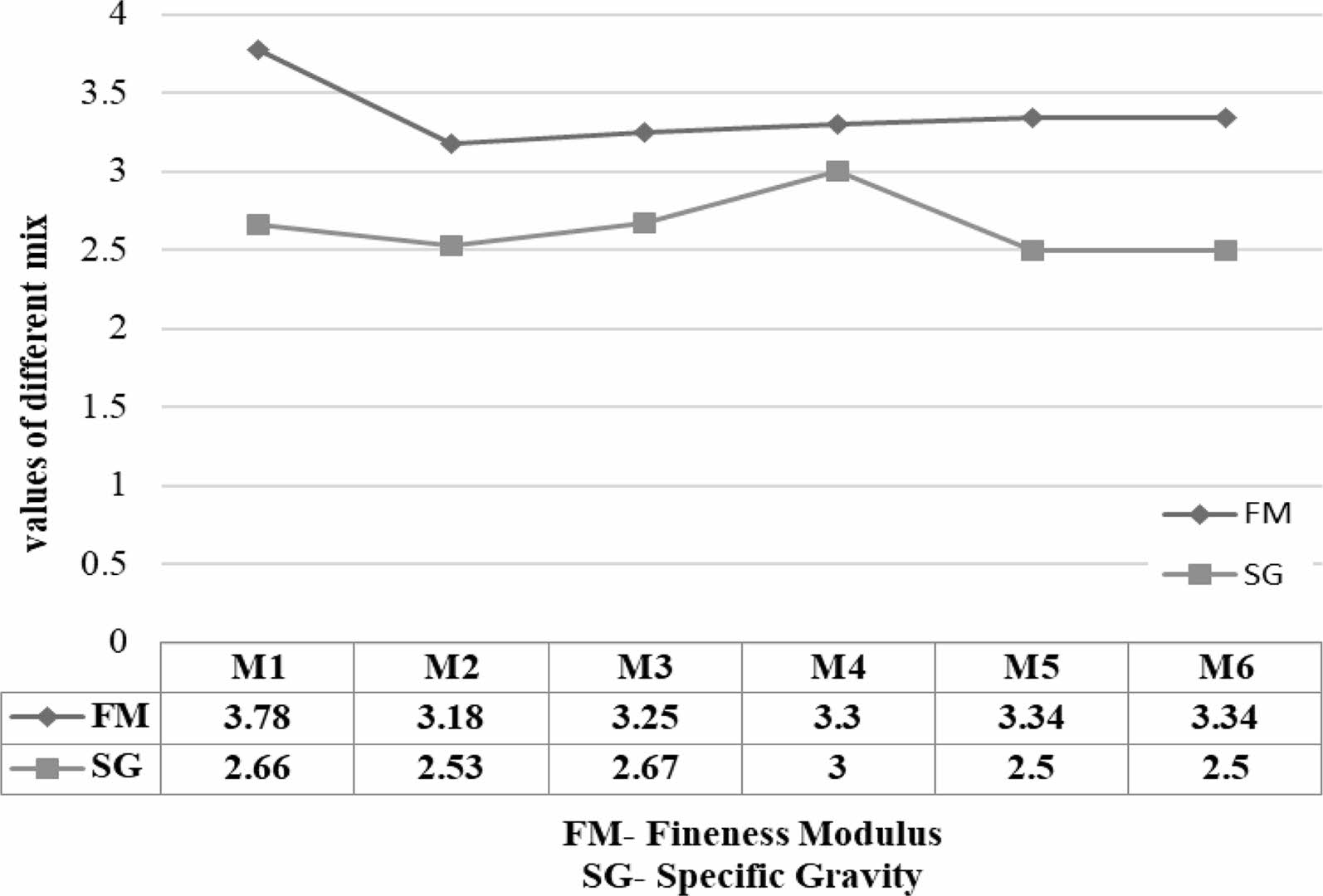

Recycled Fine Aggregate (RCFA) in the study shown in Fig. 2(a) & (b). Fig. 3

Coarse Aggregate

An important parameter which occupies major portion in concrete. The coarse aggregate was obtained from local quarry. The coarse aggregate used in this research was a natural aggregate conforming to the quality parameter requirements of IS 383:1970. The index properties of coarse aggregate shown in Table 4.

Water

Chemical reaction with cement takes place only when sufficient amount of water added to the concrete. The influencing parameter for the bond between the aggregate and cement was water. Water to cement ratio used in the concrete was 0.45.

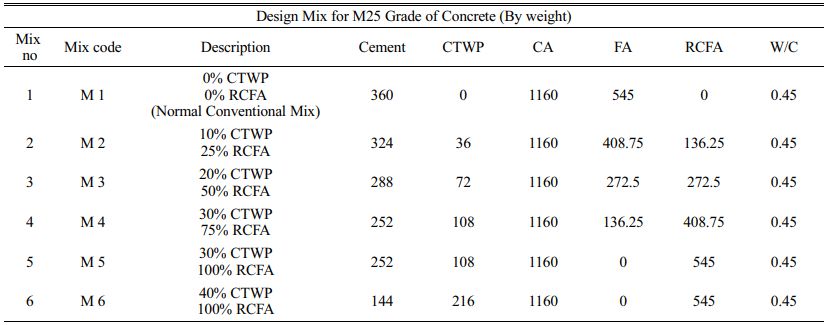

Mix Proportions

In order to determine the mix design for Eco-efficient concrete, the proportions for each material shown in Table 5. The table clearly shows the replacement proportions of CTWP with cement of 0%, 10%, 20%, 30%, 40% and RCFA with natural fine aggregate of trail 25%, 50%, 75% and 100% is used.

Specimen Preparation

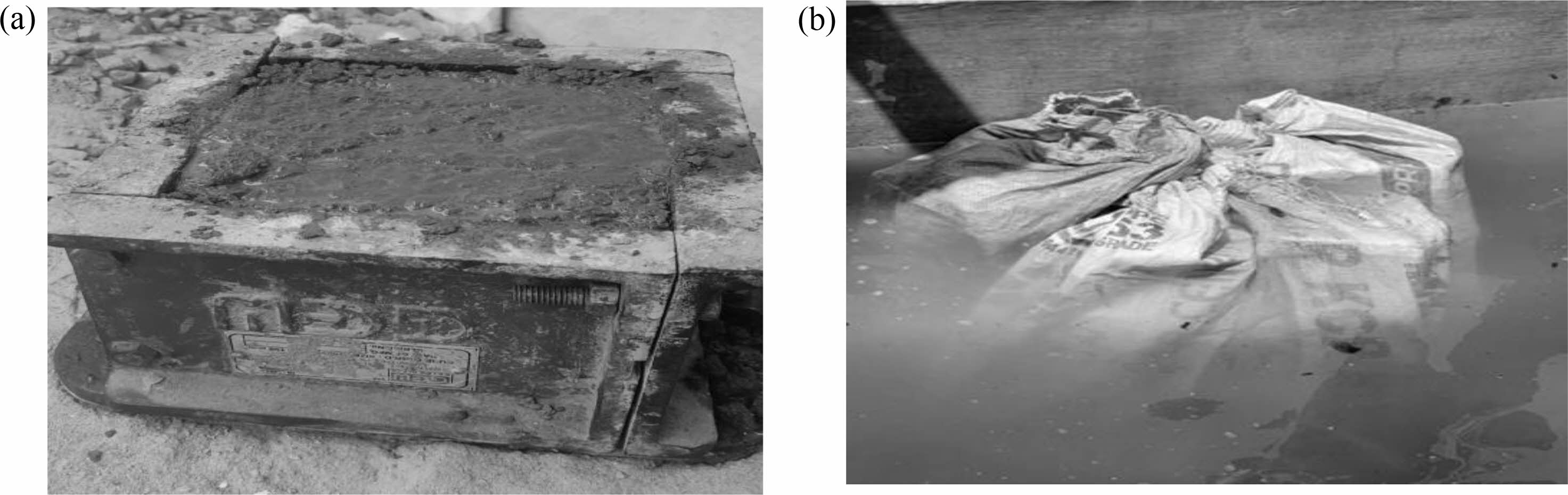

The Mould is prepared as per mix proportion in the Table 5 to determine the hardened properties of Eco-efficient concrete which includes compressive of cube size 150 mm×150 mm×150 mm and split tensile cylinder size 300 mm×150 mm and flexural prism of 100 mm×100 mm×500 mm. After moulding specimen will be cured for 7 days, 14 days and 28 days as shown in Fig. 4(a) & 4(b). Once demoulded the mechanical properties will be evaluated.

Specimen Testing

Compressive Strength Test

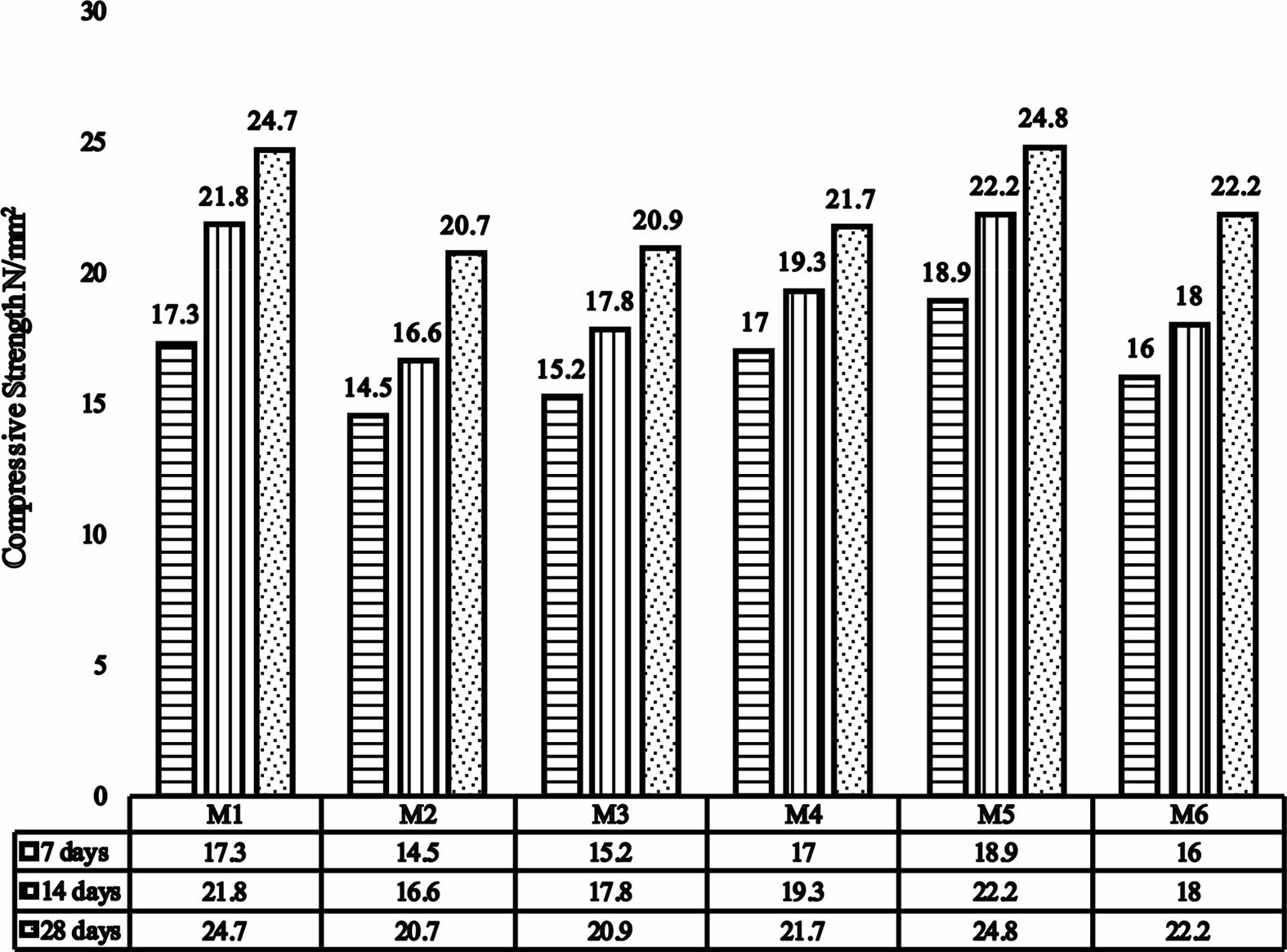

As per IS Code 516 – 1959, the compressive strength of concrete cubes was carried out. after the specified curing days, the concrete cubes specimens were taken from the water and left to surface dry condition until further process. Three cubes for each mix ratio were casted and tested after curing age of 7 days, 14 days and 28 days and results were show in Fig. 5.

Split Tensile Strength Test

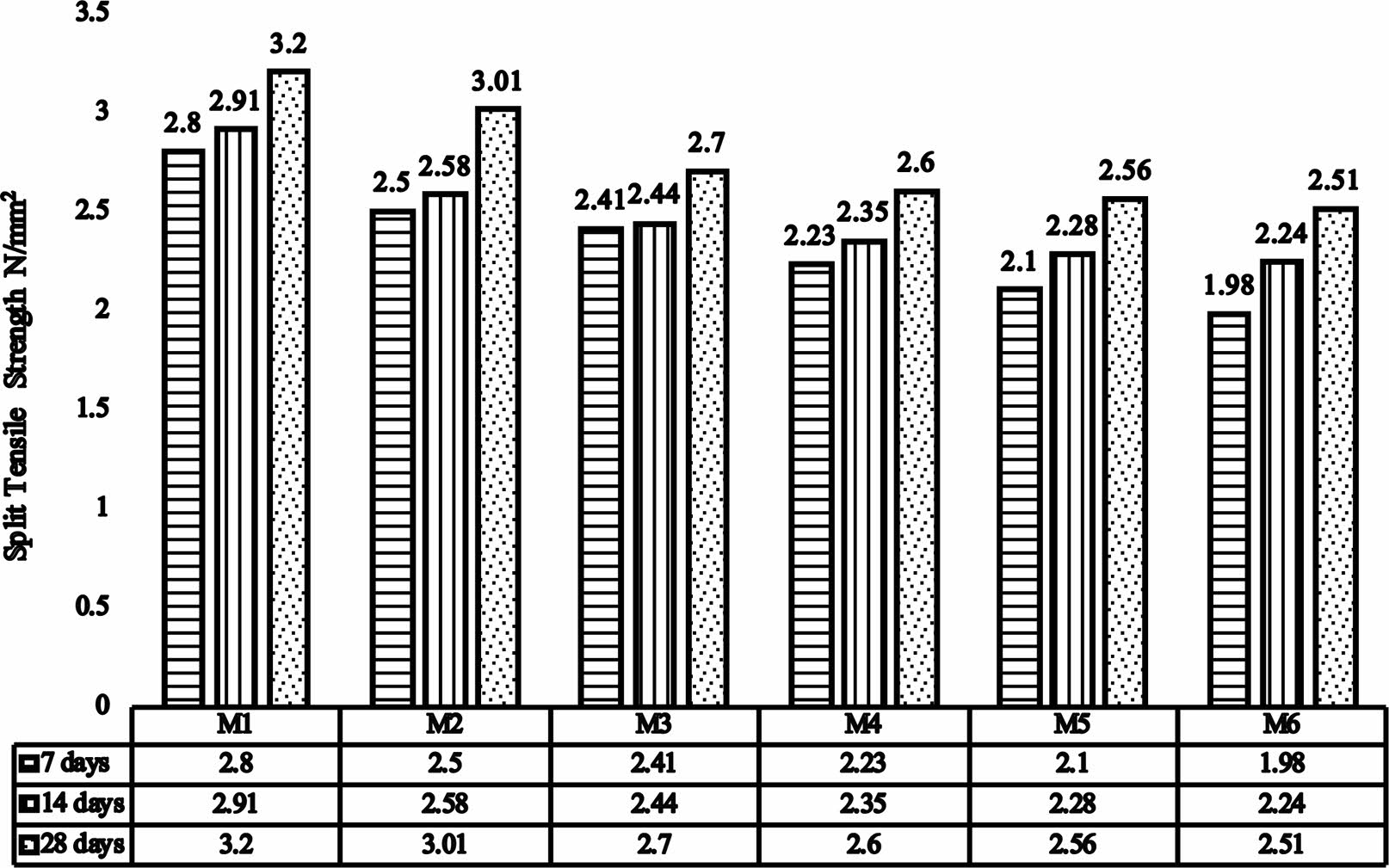

As per IS: 5816:1999, the split tensile strength of concrete cylinders was carried out at 7, 14 and 28 days respectively. This method of test was conducted to determine the performance of concrete mix indirectly. The strength of the mix was determined on a compression testing machine by placing cylinders horizontally. The results were shown in Fig. 6.

Flexural Strength Test

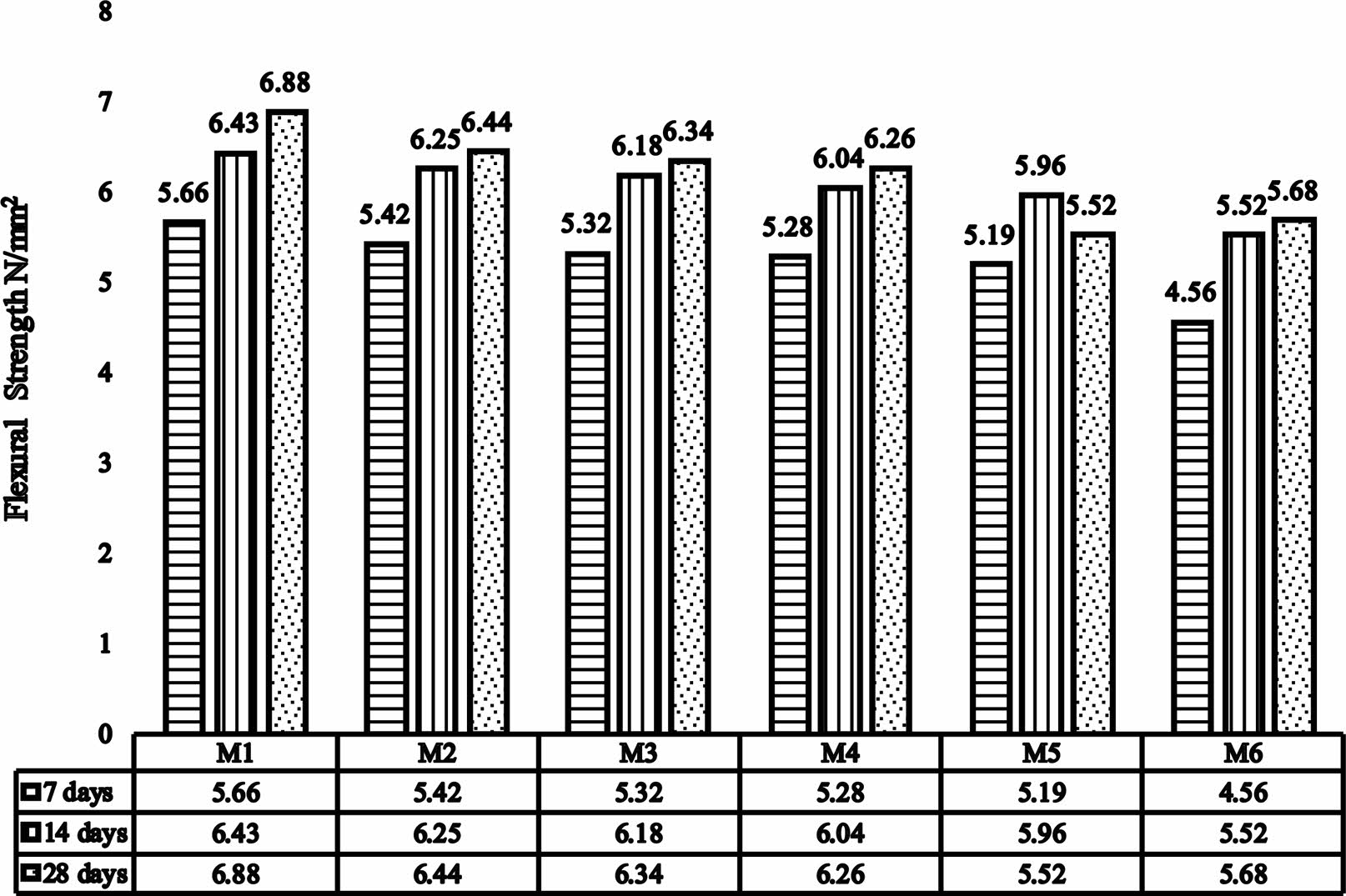

As per IS 516:1959, the flexural Strength of concrete prism was carried out. This method is to determine the bending properties of a concrete mix. The strength of mix for each prism from each mix was determined. The prism was moulded and cured at 7, 14 and 28 days respectively. The results were shown in Fig. 7.

Water Absorption Test

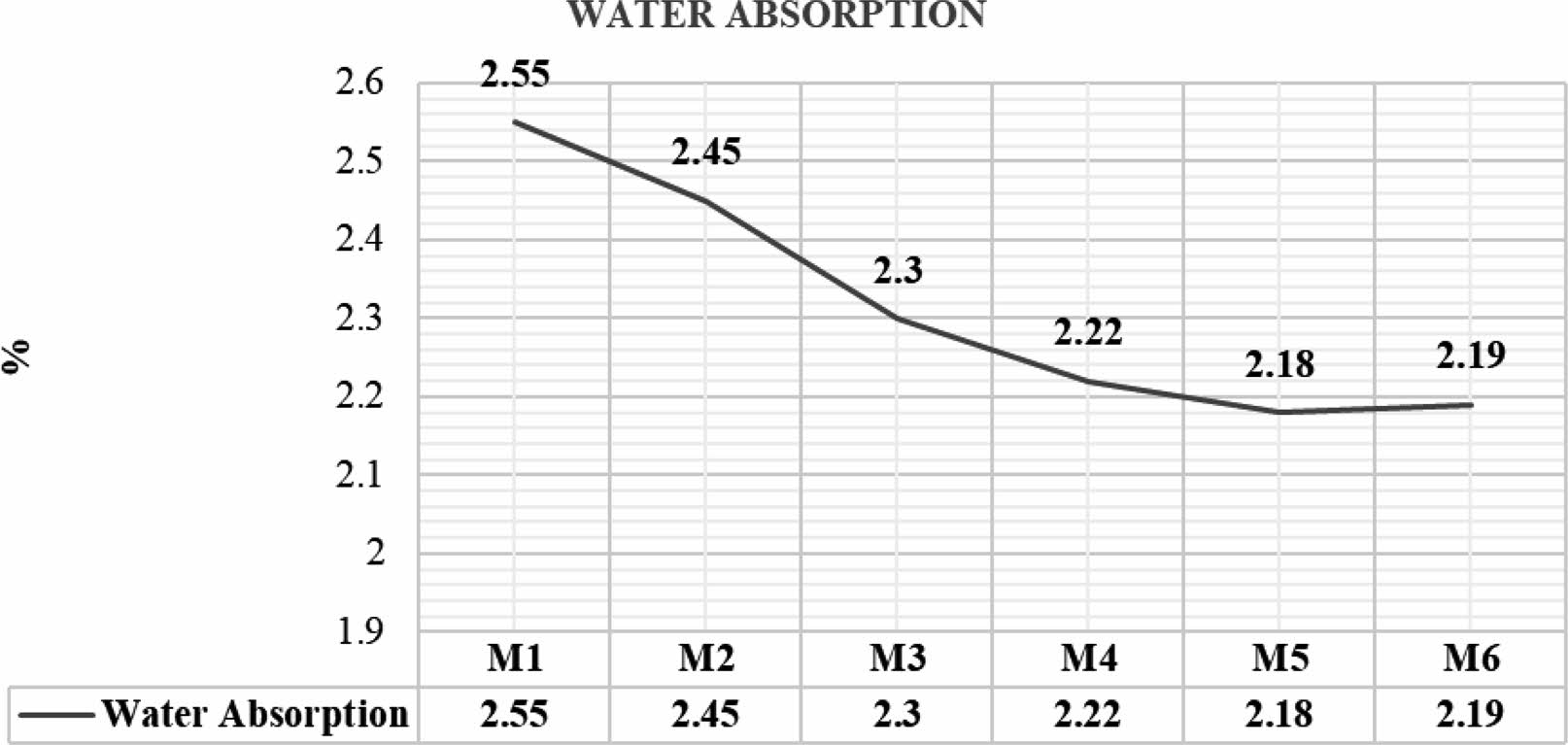

The test was carried out as per the IS 2815:2005 Part 01. The cubical concrete blocks from each mix ratio were immersed in water for 24 hours at a normal room temperature. After 24 hours of curing, the specimen is placed outside for surface dry and weighing were taken W1. Then the specimen is placed in oven at temperature of 110 oC for not less than 1000 minutes and weighed W2. The specimen test results shown in Fig. 8.

Chloride Ion Penetration Test

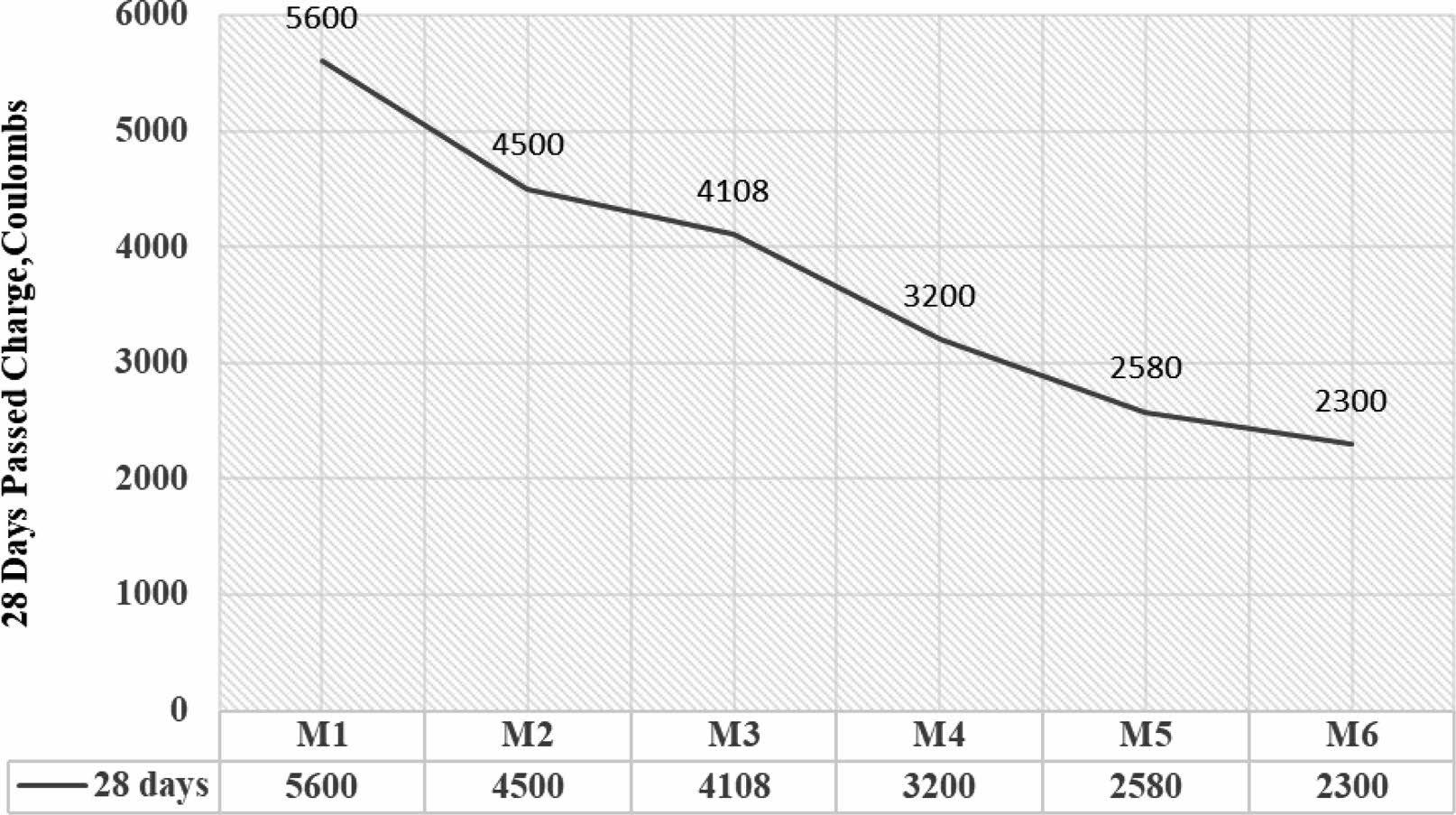

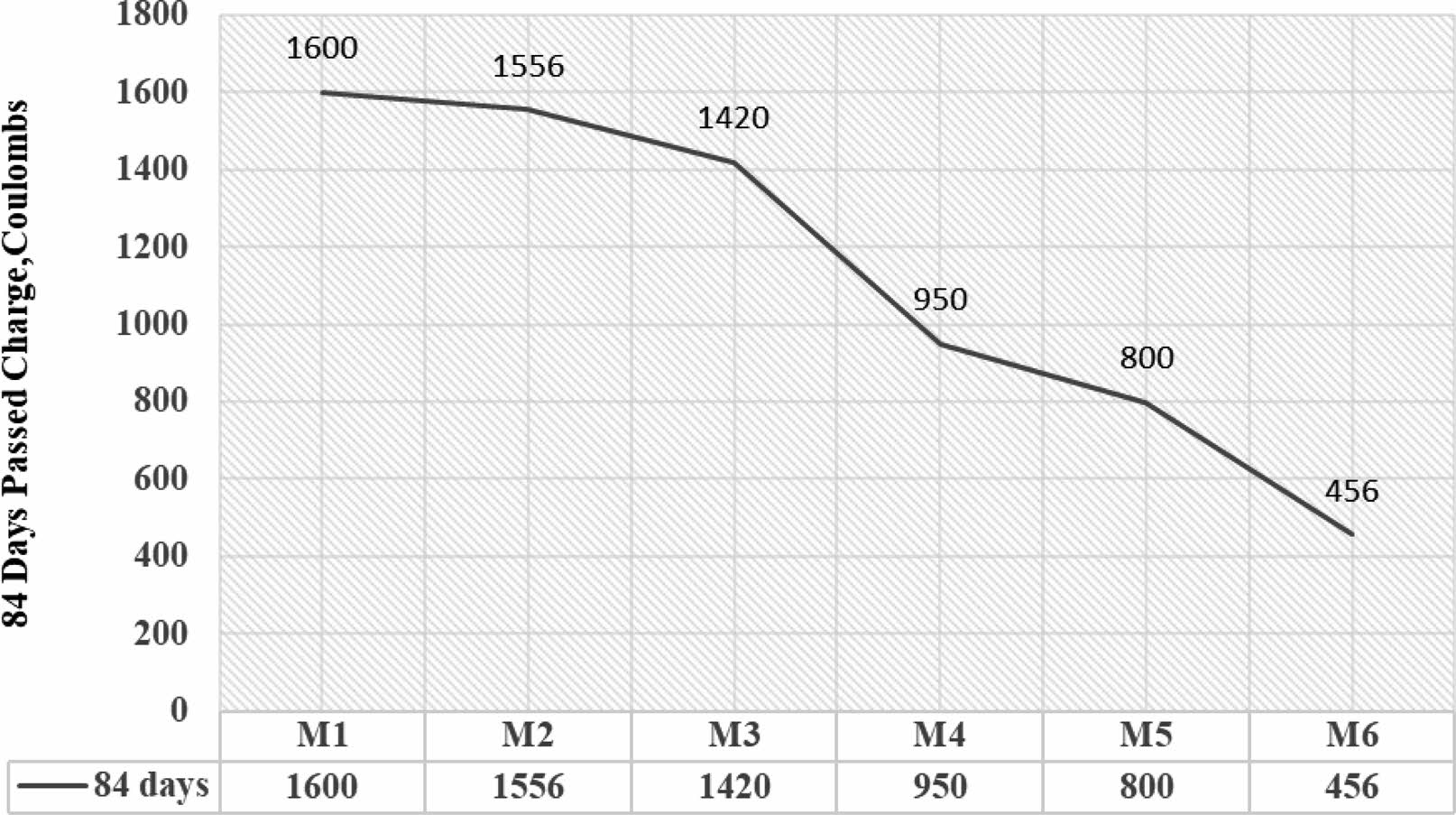

The important parameter in determining the durability properties was chloride ion penetration which clearly indicates the anti-chloride permeability of concrete. Fig. 9 and Fig. 10 shows the chloride ion penetration of concrete mix at 28 days and 84 days as per RCPT-ASTM C 1202.

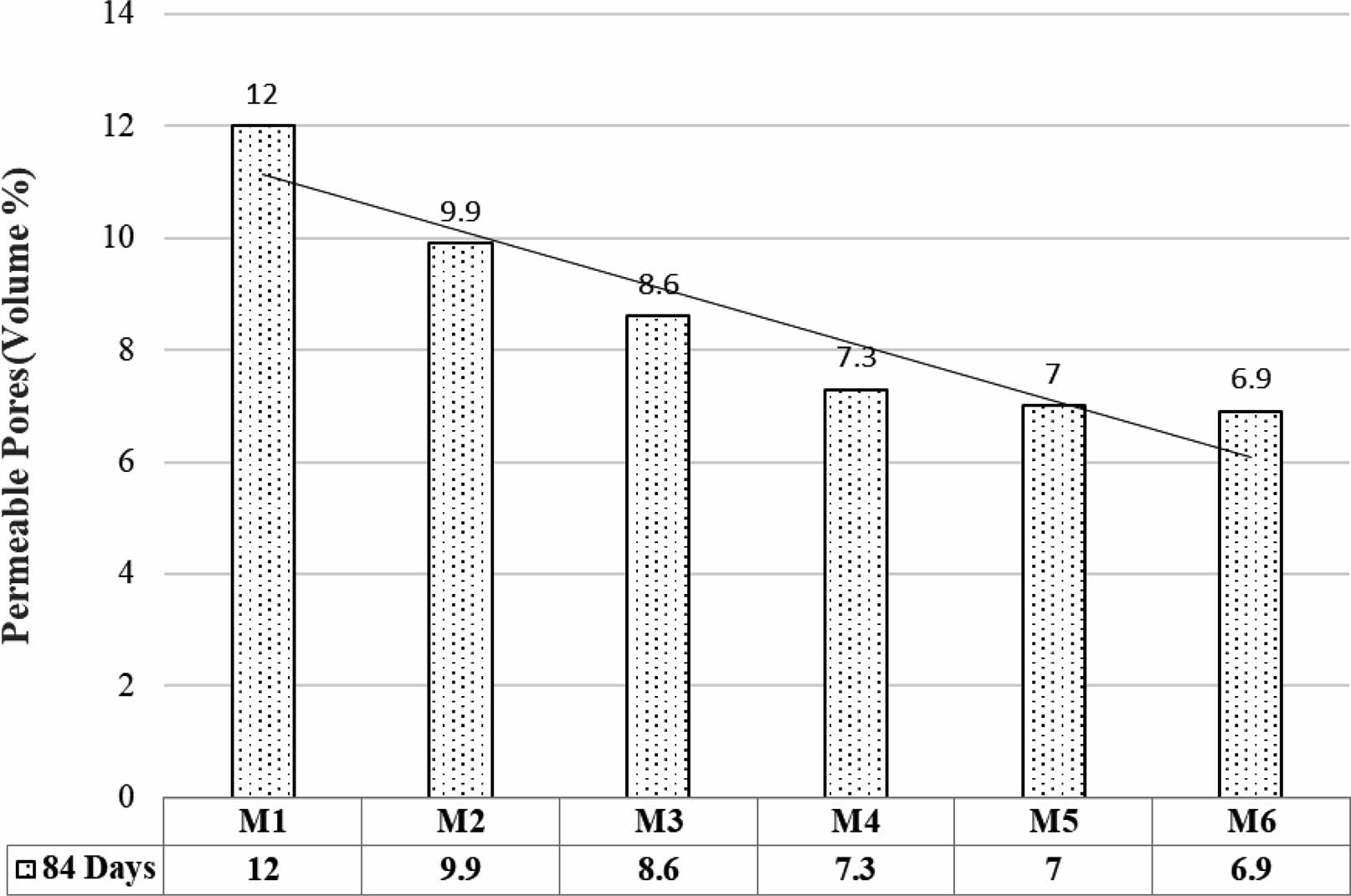

Permeability Pores Test

The microstructure development can be assessed by the measuring pores in the concrete mix as per IS 3085-1965. The pores in the concrete enroots for the water percolation in the concrete that increases the water absorption rate in the concrete. Fig. 11 shows the microstructure analysis of pores in the concrete mix at 84 days.

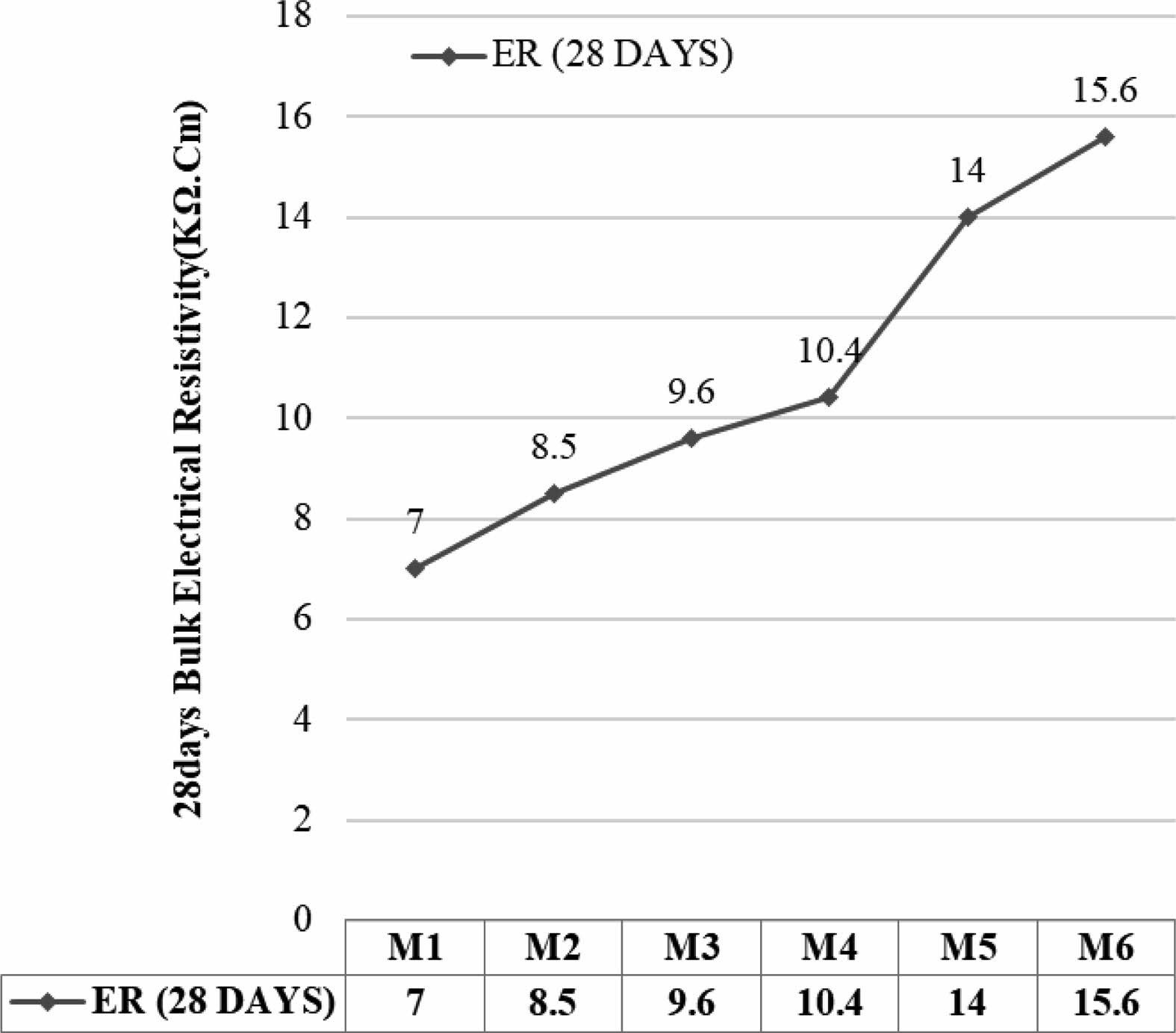

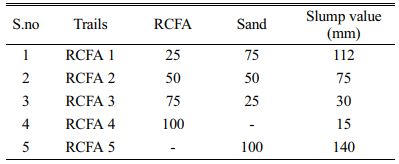

Bulk Electrical resistivity Test

In order to determine the corrosion protection of the concrete mix electrical resistivity were analysed as per ASTM C1876-19. The pore size and porosity play a major role that affect the electrical resistivity of a concrete. The through electrical resistivity microstructure development assessed. The pores discontinuity reduces the mobility thereby increase the corrosion protection and concrete resistivity. The results were shown in Fig. 12 & 13.

|

Fig. 1 Photographic View of Construction Waste (1a. CTWP & 1b. Concrete & Brick waste). |

|

Fig. 2 (a) & (b) Photographic View of RCFA and Slump Test |

|

Fig. 3 Fineness and Specific Gravity of RCFA & Sand Mix |

|

Fig. 4 (a) & (b). Photographic view of Casting and Curing |

|

Fig. 5 Effect of CTWP & RCFA on Compressive Strength. |

|

Fig. 6 Effect of CTWP & RCFA on Split Tensile Strength. |

|

Fig. 7 Effect of CTWP & RCFA on Flexural Strength. |

|

Fig. 8 Effect of Water Absorbed on concrete mix |

|

Fig. 9 Effect of Chloride ion Penetration on concrete mix for 28 days. |

|

Fig. 10 Effect of Chloride ion Penetration on concrete mix for 84 days. |

|

Fig. 11 Effect of Permeability Pores in Concrete Mix |

|

Fig. 12 Effect of Bulk Electrical Resistivity at 28 days. |

|

Fig. 13 Effect of Bulk Electrical Resistivity at 84 days. |

Effect of CTWP & RCFA on compressive strength

Compressive strength determined after curing age of 7, 14 & 28 days and results were recorded. The test result comparisons made with normal conventional concrete M1 and Eco-efficient concrete M2 to M6 shown in Fig. 5. The average value of compressive strength was recorded from three samples of each mix ratio. Initially the inclusion of wastes in two phases does not show any significant improvements during 7 days mainly due to the lack of hydraulic reaction. After 14 days it shows good improvement in compressive strength. From the experimental results, it was observed that the mix ratio M1 and M5 are much similar. And also, compressive strength increased from M2 to M5, after M5 it starts decreasing. The increased compressive strength mainly due to the existence 30% of silica oxide in ceramic waste. It was concluded that compressive strength increased up to 30% of CTWP & 100% of RCFA. After 30% of CTWP it starts decreasing and hence more research was preferred on that field [18]. The 28 days strength for M1 and M5 was much similar having 0.1% difference found. M5 mix shows maximum result of 24.8 N/mm2 at 28 days strength.

Effect of CTWP & RCFA on Split Tensile Strength

From the determination of split tensile strength implies that normal conventional mix M1 gives the higher values compared to all the mix proportions M2 to M6 as shown in Fig. 6. And moreover, the strength decreases slightly from M2 to M5. M4 and M5 exhibit much similar results. The result of split tensile strength was not synonymous with other research findings [19]. For normal conventional concrete mix M1 the strength was developed at early age of 7 days and in other concrete mix M2 to M6, the strength was developed between 14 days to 28 days. The key findings from this result values are that normal conventional concrete mix ratio M1 gives very good split tensile strength of 3.2 N/mm2. Mix M1 Strength was around 3 N/mm2 very close to the mix M1. The previous researchers concluded that, when RCFA added in normal concrete mix, the reduction in split tensile strength was found [20]. When ceramic replacement for cement carried out on normal conventional mix, it exhibits reduction in strength when ceramic content added to the mix [21]. The graph concluded that CTWP & Ceramic replacement on concrete shows very poor results on split tensile strength in comparison with normal conventional mix.

Effect of CTWP & RCFA on Flexural Strength

From the test observed Fig. 7. the normal conventional concrete mix M1 shows higher strength values when compared with other mix ratios M2 to M6. the added proportion of substitute material does not indicate much effect on strength results but have smaller variations found with M1. The 7 days strength was found to be much close in all the mix ratios but in later ages it was varying. The flexural strength for normal conventional concrete exhibits higher test results with 6.88 N/mm2 at 28 days. The added content of CTWP & RCFA in mix ratio causes strength to decrease similar to split tensile strength.

Effect of CTWP and RCFA mixed concrete on Water Absorption

From the test results shown in the Fig. 8. It was observed that the normal conventional concrete M1 absorbs more water compared to all other mixes M2 to M6. Initially M1 and M2 results were so close 0.10 that shows that addition of difference CTWP does not indicate any negative effect on concrete mix. Secondly, due to the addition of RCFA& CTWP in the mix, M3 to M6 decreases. The main reason for the decreased absorption of water was recycled aggregate were non porous in nature and absorbs less water [22] According to the results the substitute M5 (CTWP 30% & RCFA 100%) mix gives better replacement when compared to all other mix ratios with the value of 2.18%.

Effect of CTWP and RCFA mixed concrete on Chloride ion Penetration

From the test results observed for chloride ion penetration, the curing age of 28days for M25 grade of mix including CTWP & RCFA were 5600, 4500, 4108, 3200, 2580 and 2300 coulombs for 0% & 0%, 10% & 25%, 20% & 50%, 30% & 75%, 30% & 100%, 40% & 100% replacement levels accordingly in Fig. 9. The curing age of 84days for M25 grade of mix including CTWP & RCFA were 1600, 1556, 1420, 950, 800 and 456 coulombs for 0% & 0%, 10% & 25%, 20% & 50%, 30% & 75%, 30% & 100%, 40% & 100% replacement levels accordingly in Fig. 10. Mix with M2 to M6 were awarded as “lower” for chloride ion Penetration for 28 days curing period. Mix with M2 to M6 were awarded as “very lower Penetration for 84 days curing period [23]. The causes for this would be pore structure provided by the RCFA in addition to the Pozzolanic effect of CTWP [24].

Effect of CTWP and RCFA mixed concrete on Permeability Pores

The measuring of pores in a concrete mix was a microstructure analysis. The results of permeable pores at 84 days are shown in Fig. 11. For all mix ratios M2 to M6, increased percentage of CTWP & RCFA, the pore percentage decreases. From M2 to M6 the substitute level of CTWP & RCFA increased, the percentage of permeable pores decreases when compared with other mix. The normal conventional concrete mix shows higher permeable pores percentage with 12 [25]. The permeable Pores value is directly proportional with chloride ion Penetration. This graph clearly shows that when substitute happen with material used in normal mix the pore percentage decreases. The permeable pore decreased was caused by the effect of micro filling ability of CTWP and the RCFA creates better interlocking zone between the particles. This helps in the reduction of induce of water into the particles which directly shows the effect on chloride ion penetration. The graph clearly shows that durability parameters of concrete with age.

Effect of CTWP and RCFA mixed concrete on Bulk Electrical Resistivity

At 28 days of age, the resistivity results shown in Fig. 12 and for 84 days of age, the resistivity results shown in Fig. 13. The resistivity results from the above Fig. 12 and Fig. 13 for all mix M1 to M6 were high compared to normal conventional concrete mix. The improvement in the electrical resistivity for the above mix mainly due to micro filling and pozzolans effect of ceramic powder which leads to denser microstructure and reduced pore connectivity and also concluded that lower permeability when ceramic powder added on concrete mix [26].

This research aimed to analyse the utilisation of waste generated from the construction industry and usage of ceramic tiles waste in concrete as leads to more negative impact to the environment and also to the living beings. The research merely focuses on how theses waste can be utilised fully in the construction sector. The performance analysis of different characteristics of ceramic and construction waste mix of M25 grade was carried out. The green concrete was evaluated for workability and hardened concrete measured the compressive strength, split tensile strength and flexural strength. The durability characteristics also measured by chloride ion penetration, permeability, water absorption and electrical resistivity. The below conclusion is obtained from the rest results.

1. In terms of compressive strength, the CWTP was an effective replacement for cement up to 30% and RCFA give good results up to 100%. The combination of CWTP 30% & RCFA 100% can be used as substitute material for cement and fine aggregates in concrete.

2. For both split tensile strength & flexural strength, the crack resistance was good for normal conventional mix and other mix ratios shows very low strength and water absorption does not show good results as the RCFA presence in more amount leads to more capillary pores.

3. The durability properties show very good results when increased amount of substitute material added to mix. The inclusion of CTWP & RCFA showed excessive resistance to chloride penetration and high electrical resistivity.

4. The microstructure analysis of pores in concrete decreased with increase in substitute material. This test results directly proportional with water absorption and chloride penetration.

CWTP can be act as a promising alternative for cement because of its less CO2 Emission. RCFA can be act as replacement material to some extent but cannot be effectively used as a substitute because of its porous nature. The combination of CWTP & RCFA gives good results on compression.

- 1. A.M. Neville, Properties of concrete. 4 (1995).

- 2. X. Chen, D. Zhang, S. Cheng, X. Xu, C. Zhao, X. Wang, Q. Wu, X. Bai, J. Build. Eng. 52 (2022) 104418.

-

- 3. K.B. Najim, I. Al-Jumaily, and M. Abdukhaliq, Atea. Constr. Build. Mater. 103 (2016) 123-129.

-

- 4. M. Batayneh, M. Iqbal, A. Ibrahim, Waste Management 27[12] (2007) 1870-1876.

-

- 5. M. Bravo, J. Brito, J. Pontes, L. Evangelista, J. Clean. Product. 99 (2015) 59-74.

-

- 6. A. Adessina, A. Ben, J.-F. Barthélémy, C. Chateau, D. Garnier, Cement Concr. Res. 126 (2019) 105900.

-

- 7. A. Juan, C. Medina, M.I. Guerra, J.M. Moran, P.J. Aguado, M.I.S. de Rojas, M. Frias, O. Rodriguez, Ceram. Mater. (2010) 197-214.

- 8. Y.-H. Cheng, F. Huang, R. Liu, J.-I. Hou, G.-I. Li, Mater. Struct. 49[3] (2016) 729-738.

-

- 9. R.V. Meena, J.K. Jain, H.S. Chouhan, A.S. Beniwal, Clean. Mater. (2022) 100085.

-

- 10. Z. Ma, M. Liu, Z. Duan, C. Liang, H. Wu, J. Clean. Product. 257 (2020) 120518.

-

- 11. A.S. El-Dieb, M.K. Dima, Sustain. Mater. Technol. 17 (2018) e00063.

-

- 12. E. Vejmelková, M. Keppert, P. Rovnaníková, M. Ondráček, Z. Keršner, R. Černý, Cement Concr. Comp. 34[1] (2012) 55-61.

-

- 13. A.D. Raval, D.I.N. Patel, and P.J. Pitroda, Int. J. Eng. Tren. Technol. 4[6] (2013) 2324-2329.

- 14. S.C. Bostanci, M. Limbachiya, and K. Hsein, J. Clean. Product. 189 (2018) 176-196.

-

- 15. P. Plaza, I.F. Sáez del Bosque, M. Frías, M.I. Sánchez de Rojas, C. Medina, Constr. Build. Mater. 285 (2021) 122926.

-

- 16. R.V. Silva, J.D. Brito, and R.K. Dhir, Constr. Build. Mater. 178 (2018) 19-31.

-

- 17. M. Joseph, L. Boehme, Z. Sierens, L. Vandewalle, Magaz. Concr. Res. 67[11] (2015) 592-597.

-

- 18. T. Umar, Springer. Cham. (2021) 157-162.

- 19. P.O. Awoyera, J.M. Ndambuki, J.O. Akinmusuru, D.O. Omole, HBRC J. 14.3 (2018) 282-287.

-

- 20. M.S. Ahmed, H.S. Vidyadhara, Int. J. Eng. Res. Technol. 2 (2013) 76-82.

- 21. V.K. Atkuri, G.V. Rama Rao, IOP Conference Series: Mater. Sci. Eng. 1025[1] (2021).

-

- 22. F. Théréné, E. Keita, J. Naël-Redolfi, P. Boustingorry, L. Bonafous, N. RousselCement Concr. Res. 137 (2020) 106196.R

-

- 23. F. Pacheco-Torgal, J. Said, Retraction 44 (2021) 155.

-

- 24. F. Bektas, Iowa State University, 2007.

- 25. A. Juan-D. Rodríguez-Robles, J. García-González, M.I.S. de Rojas Gómez, M.I. Guerra-Romero, N. De Belie, J.M. Morán-del Pozo, Constr. Build. Mater. 270 (2021) 121455.

-

- 26. M.C. Bignozzi, B. Stefano, Cement Concr. Res. 41[9] (2011) 947-954.

-

This Article

This Article

-

2022; 23(6): 884-891

Published on Dec 31, 2022

- 10.36410/jcpr.2022.23.6.884

- Received on Jun 28, 2022

- Revised on Oct 1, 2022

- Accepted on Oct 26, 2022

Services

Services

Shared

Correspondence to

Correspondence to

- S. Janani

-

Department of Civil Engineering, Kongu Engineering College, Perundurai, India

Tel : + 919688551995 - E-mail: janani.civil@kongu.edu

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.