- Investigation of mechanical properties and abrasive assisted electrochemical machining parameters on Al6061-10%TiB2-3%Gr hybrid ceramic composite

P. Satishkumara,* and N. Natarajanb

aAssistant Professor, Department of Mechanical Engineering, Study World College of Engineering, Coimbatore - 641105

bProfessor, Department of Mechanical Engineering, Muthayammal EngineeringThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

This research paper investigates mechanical, morphological behavior of Al6061-3%Gr, Al6061-10%TiB2, Al6061-10%TiB2-3%Gr and optimizes input machining parameters in abrasive assisted and straight electro chemical machining. The Hybrid ceramic composite (HCC) are reinforced with TiB2 and Graphite. The composites are fabricated by stir casting method to achieved good mechanical property and wear resistance. This hybrid composite are highly suitable material for automobile and aerospace components. ECM is an excellent way to produce micro components with special features and this fabrication method is used for biomedical applications. Machining of HCC is very serious problems due to its hardness. The ECM is a very complex process in practice. The quality of production mainly depends on the input machining parameters. The economical and high quality of micro drill on HCC is achieved by controlling machining parameters like current, voltage, electrolyte concentration, feed rate, gap between the tool and work. Performance of abrasive assisted ECMM and straight ECMM process in terms of maximum material removal rate and minimum overcut were analysed. The maximum material removal rate is acquired through abrasive assisted ECMM process

Keywords: Al6061-10%TiB2-3%Gr, Stir Casting, Electrochemical Machining, Over Cut, Material Removal Rate

The Hybrid ceramic composite fabrication through liquid stir casting routine is much admired technique because of its exclusive advantages [1-2]. Al-TiB2 com- posite is one of the outstanding composite in mechanical sectors where light weight, superior mechanical properties and better wear resistance are major deliberation especially in automobile, aeronautical applications [3]. Micro slots and holes produced in micro products with complex features in ECMM technology have been effectively adapted. Wide- range of desirable research work is required in the region of machining parameter and tool design [4]. The micro machining in HCC is very complicated process because of the hard reinforcement particles present in the matrix. Due to hard particles present in the main matrix the micro drilling HCC is a difficult task for production engineers. The majority of recent literatures deals in terms of tool life, quality of drilled hole, and surface roughness during micro drilling in HCC [5]. The micro ECM is extremely difficult, so it is not easy to desire the most favorable machining parameters for improving the production superiority. The optimization of process parameters is necessary for the understanding of a higher productivity with desired quality, which is the primary endurance in today’s forceful market circumstances. Most favorable quality of micro hole in ECM is able to generate through combinational control of different process parameters [6]. Graphite reinforcement particles have excellent lubricates property used in an extensive range of applications in aluminium composite materials. So this reinforcement composite material is used to construct components in definite mechanical and morphological behaviors, and enormous wear resistance property such as engine cylinder liner pistons and piston rings and bearing [7-8].

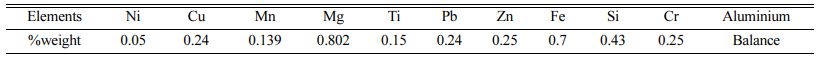

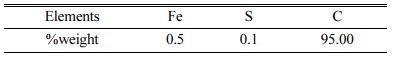

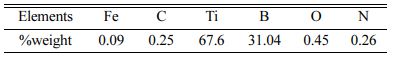

Many of literatures authenticate that there is no clear work is carried out on Al6061+TiB2+Gr composite material fabricated in liquid phase route. In this research Al6061+10%TiB2+3%Gr composite material is fabricated by and analysis of the mechanical and morphological behaviors of that hybrid composite is done. The chemical composition of Al6061, Gr and TiB2 are shown in Table 1-3 respectively. This research work is generally focuses on mechanical and morphological behavior of Al6061-10%TiB2-3%Gr hybrid composite. The investigation of the ECMM machining parameters are analysed for producing the high quality micro drill on Al6061-10%TiB2-3%Gr hybrid composite. Table 2

By using stir casting method Al6061-3%Gr, Al6061- 10%TiB2 and Al6061-10%TiB2-3%Gr aluminium hybrid composites are fabricated [9-10]. The mechanical and morphological behaviors of obtained hybrid composite were compared with Al6061 [11]. These composites are investigated for its machining parameters using ECMM for producing the high quality micro drill on Al6061-10%TiB2-3%Gr hybrid composite.

Al6061+10Wt%TiB2+3Wt% Gr composite materials fabricated by liquid phase route (stir casting method). Initially Al6061 material was melted for 60 minutes in a muffle furnace at 700 oC. The reinforcement particles TiB2 and Graphite (Gr) particles are primarily preheated at 850 oC for 60 minutes for oxidation progression. The Gr reinforcement particles are added into the molten metal (25-30 um) and the furnace temperature is maintained at 750 oC. The TiB2 particles are fed into the molten liquid at 0.01Kg/min while maintaining the stirring rate at 400 rpm in the whole time process. The Al6061+10Wt%TiB2 and Al6061+3Wt% Gr composites are produced in same approach [12-14].

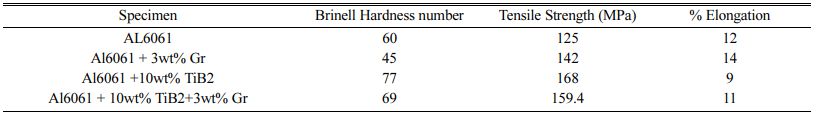

The potential strength of tensile, yield, ultimate and ductility were measured as per ASTM E8M standard for every composite. Brinell hardness test was carried out in every sample with 250 kg load with 5 mm diameter steel ball intender as per ASTM E10 standard for every composite. From the above test results normal value has been taken and graph was plotted as per the average value. Microstructure studies carried out in every specimen in polishing and etched route [15].

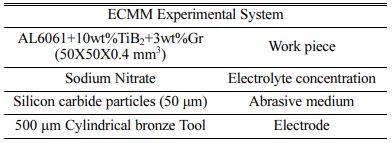

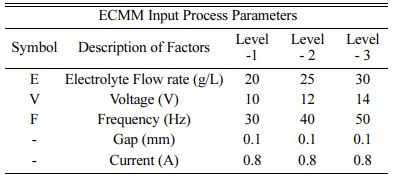

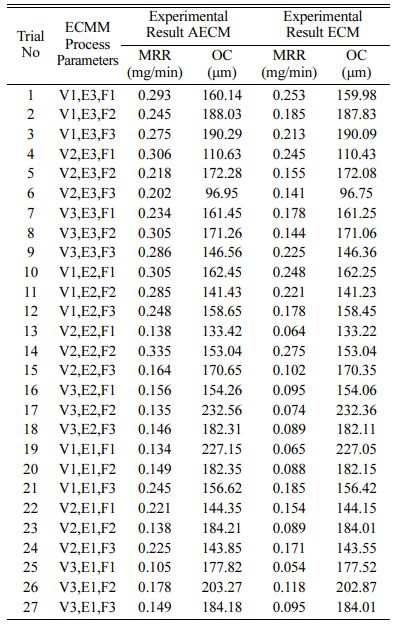

Formation of high quality micro holes in micro products is complex nature. Electro chemical machining is excellent way to produce the micro holes. It was very difficult to achieve good surface finish with high precision of dimension [3, 16]. Abrasive assisted electro chemical micro machining is excellent way to achieve maximum MRR, good surface finish with high precision of dimension. Based on the beginning experimental trial results the levels are recognized. The dimensions of work material 50´50´0.4 mm obtained through wire cut EDM. The experimental setup used in this research work is shown in Fig. 1. The experimental system used for electrochemical machining process is presented in Table 4. The input process parameter and its levels used in this research work are presented in Table 5. Based on the previous literatures the process parameters are selected. This is also analysed with the industrialists working in this area and the levels of the process parameters are selected. Micro drilling of HCC is performed in ECM and abrasive assisted ECM. The responses selected are material removal rate and overcut. Design of experiment is used to conduct the experiments and L27 orthogonal array is performed and the composition of the process parameters for conducting each run is designed using Minitab software. The experimental data comprising the 27 experiments and measured responses are recorded in Table 6.

|

Fig. 1 Experimental setup. |

Mechanical properties

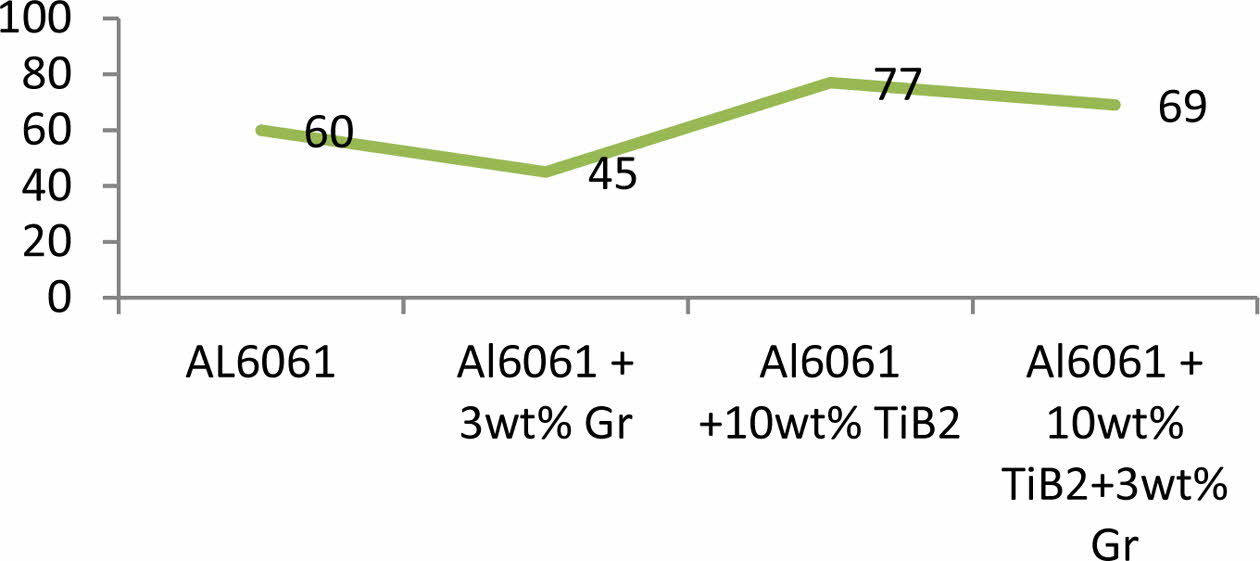

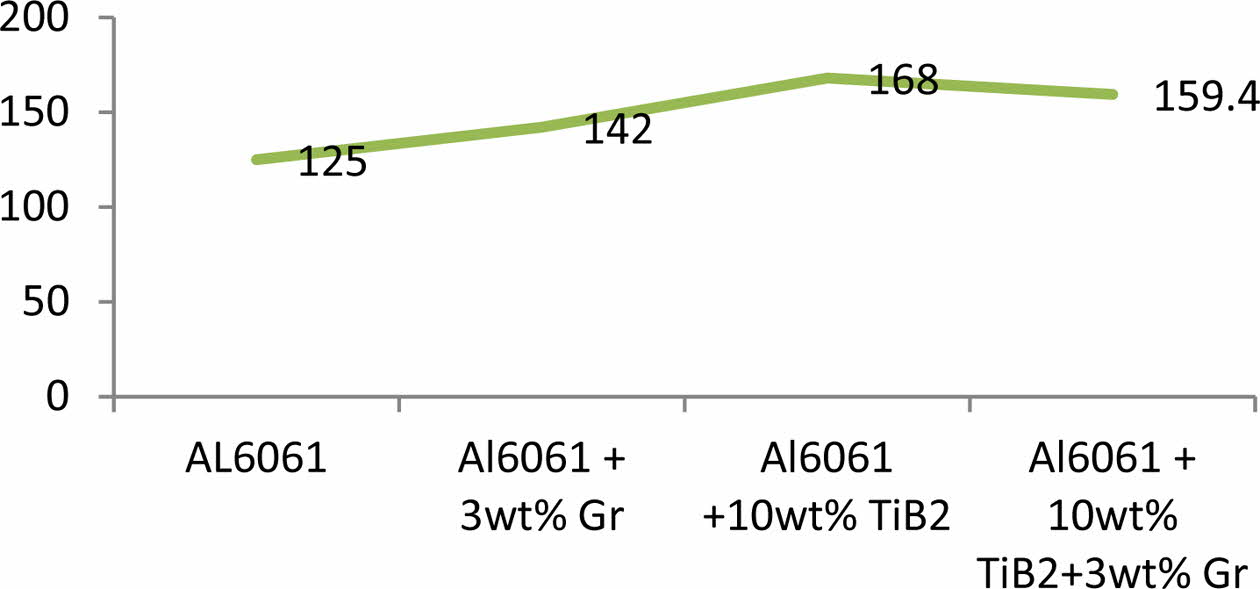

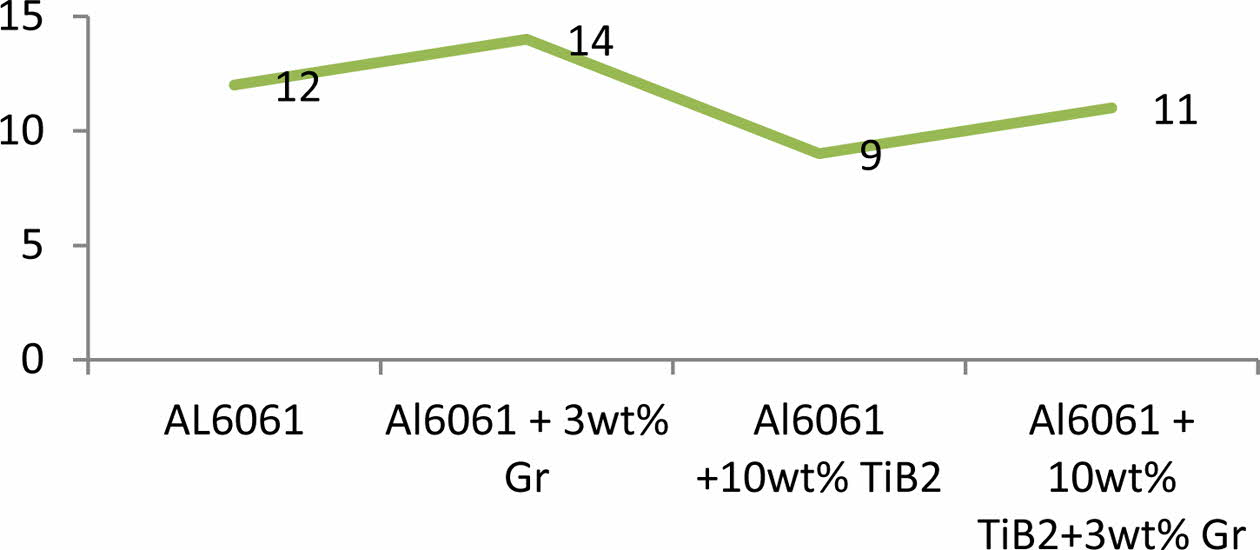

The hardness of Al6061 and its hybrid composites containing 3 wt% Gr, 10 wt% TiB2 are evaluated using Brinell hardness tester. From Fig. 2, it is observed that adding the Gr particles into the Al6061 the hardness nature is decreased. Adding TiB2 particles into the AL6061 hardness value is 17% increased compare with AL6061. From Fig. 3, it is observed that the addition of TiB2, Gr reinforcement particles into the main matrix increases the ultimate tensile strength gradually. From Fig. 4, it is noted that the % elongation and the ductile behavior was increased by the addition of Gr particles into AL6061. The addition of Gr particles composite material becomes soft, ductile and increasing lubricating behavior. The TiB2 reinforcement particles added into the AL6061 which resists course dislocations causes decreased ductile behavior. The mechanical properties for various HCC compositions are presented in Table 7.

Fractography

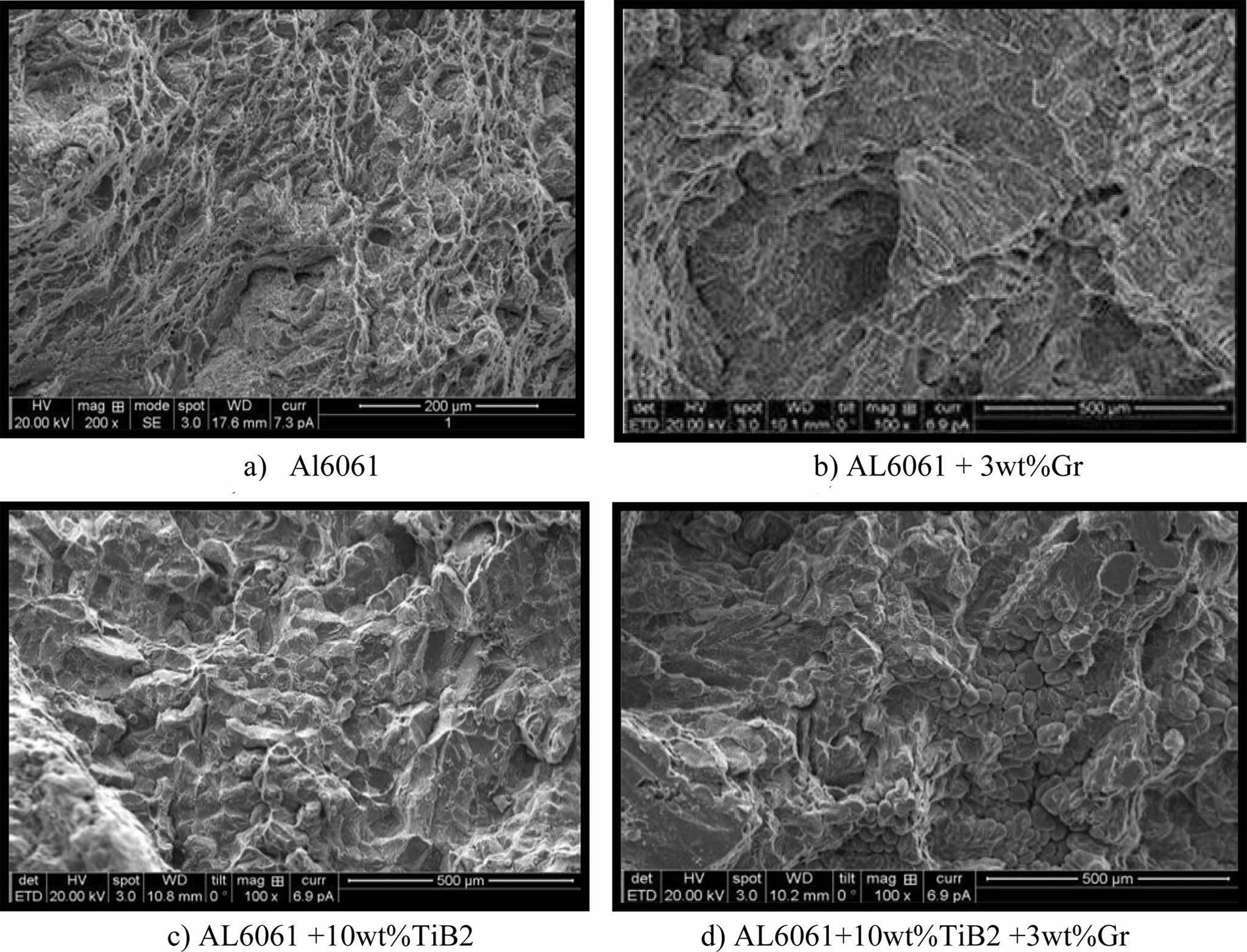

The reinforcement particles circulation is homogeneous and there is no porosity, cracks formed. Figs. 5(a) to (d) represents the scanning electron microscopic images of the HCC specimen used in this research work. Fig. 5(a) represents the image of Al6061. The reinforcement particles circulation is homogeneous and there is no porosity, cracks formed. The wt%TiB2, wt%Gr particles is clearly exposed in the microphotographs. Fig. 5(b) represents the image of HCC of Al6061-3%Gr. It is observed that the Graphite is distributed evenly and provides good lubrication effects for the specimen. Fig. 5(c) represents the image of HCC of AL6061-3%Gr-10%TiB2, which describes the distribution of the reinforcing elements – Graphite, TiB2 in the metal matrix and is observed that the reinforcing elements are distributed evenly and provides higher strength. Fig. 5(d) represents the image of AL6061-3%Gr-10%TiB2 and composition of all the elements present in the HCC is shown and they are distributed evenly. This image also reveals that the cracked surfaces defines the ductile fracture including of frequent dimples over whole surfaces of base metal. When addition of Gr reinforced into the base metal shows hairline fracture with less amounts of dimples on the surface. The addition of TiB2 into the base metal shows the ductile and brittle fracture nature.

Taguchi Technique on Micro drilling process on Al6061-10%TiB2 - 3%Gr hybrid composite

The quality micro holes is produced by electro chemical micro machining setup and as well as abrasive assisted electro chemical micro machining setup through controlling of initial machining parameters. The drilling process is carried out twice in each process parameter setup. Machining time, overcut and material removal rate is obtained in each and every experiment level. The responses of each process parameters are obtained by Taguchi method. L27 OA is used to conduct 27 experiments and the responses are recorded and analysed.

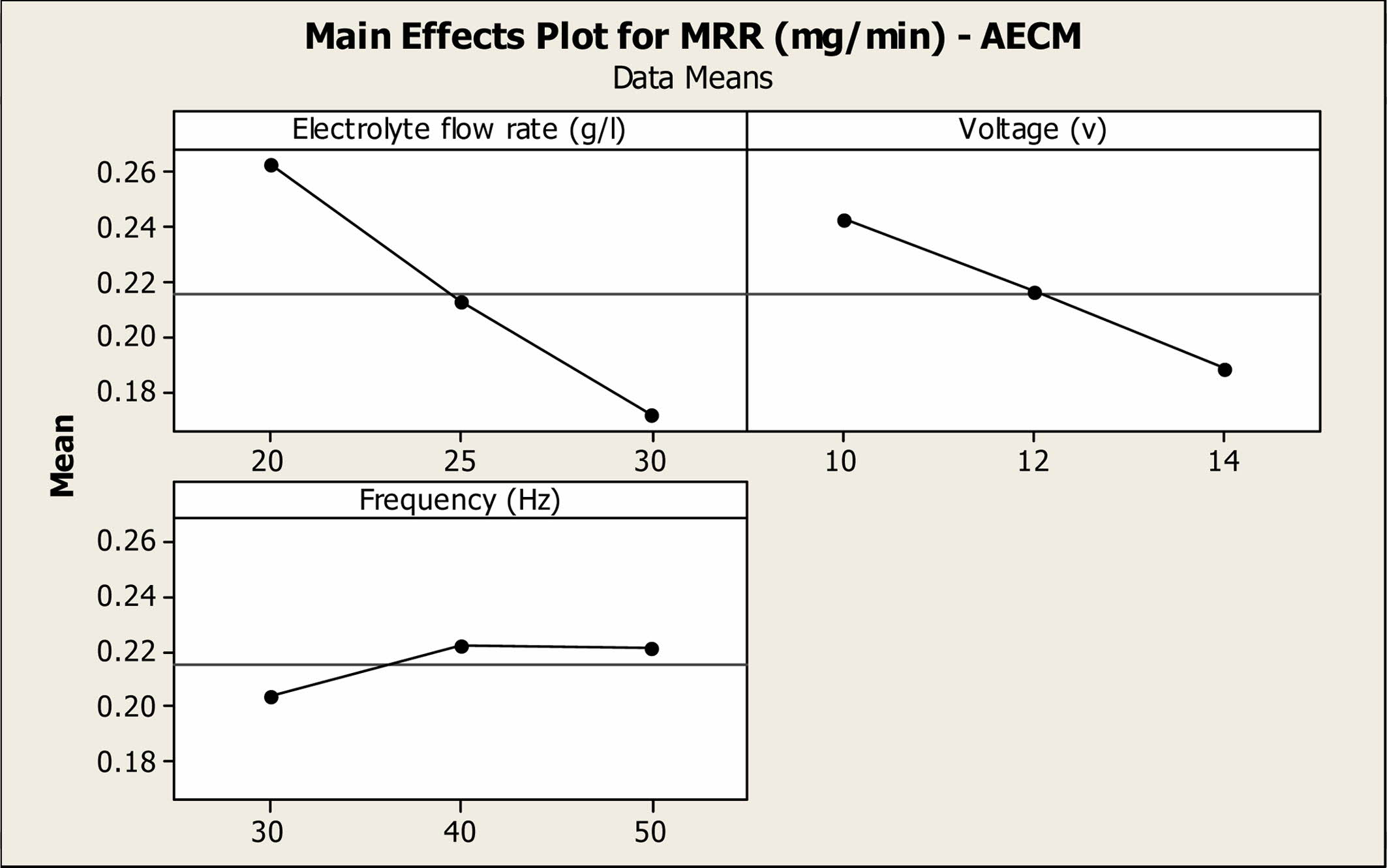

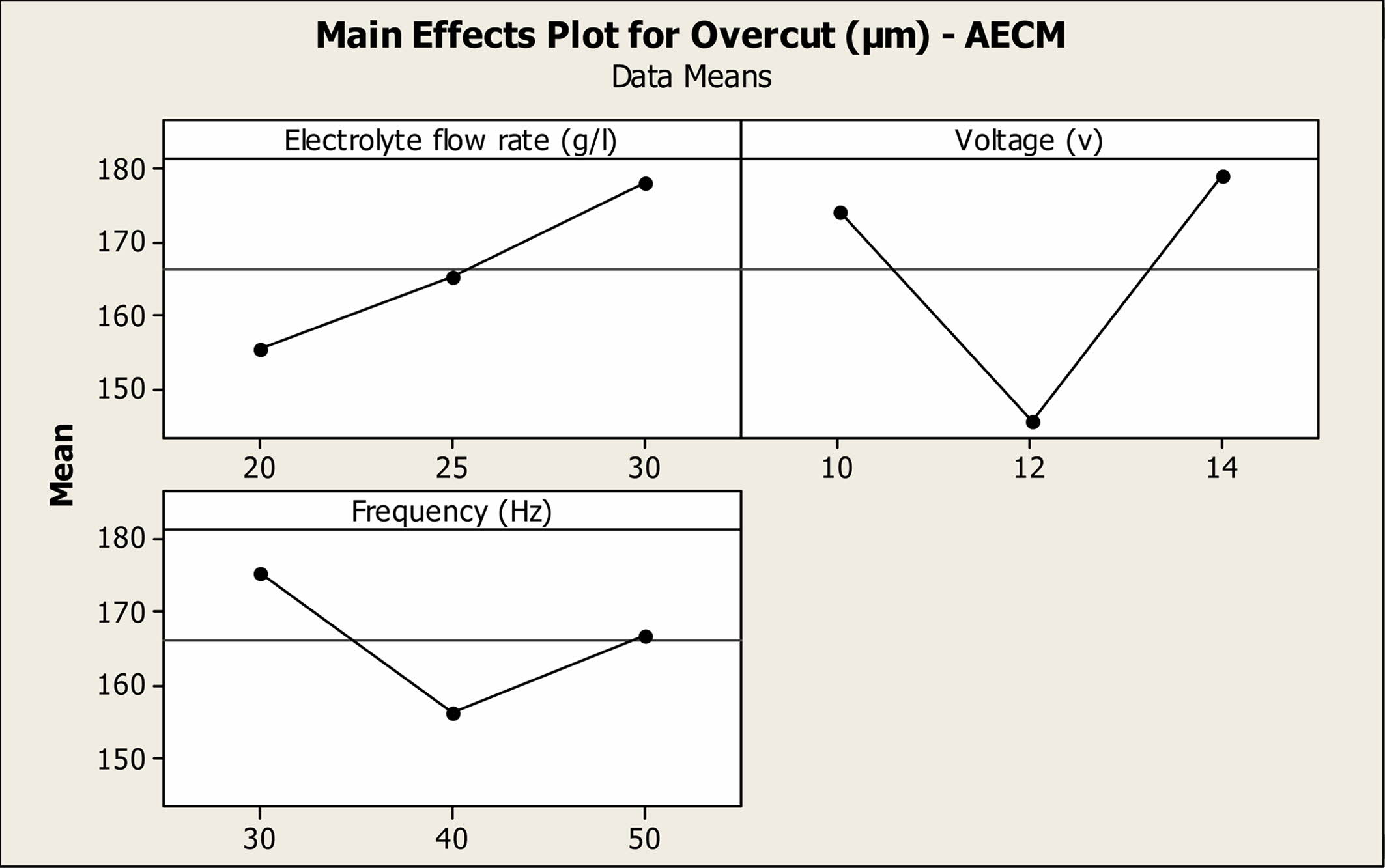

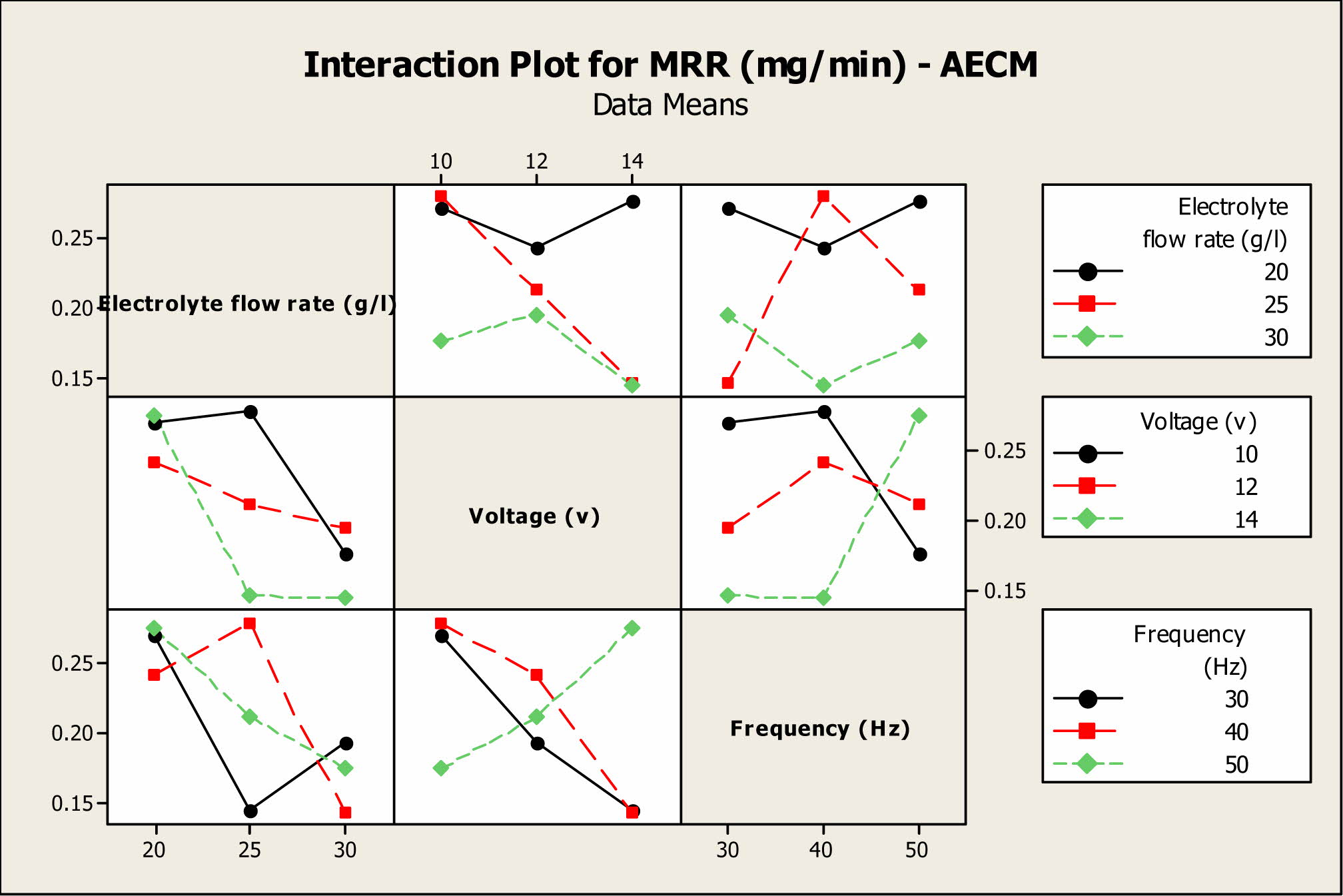

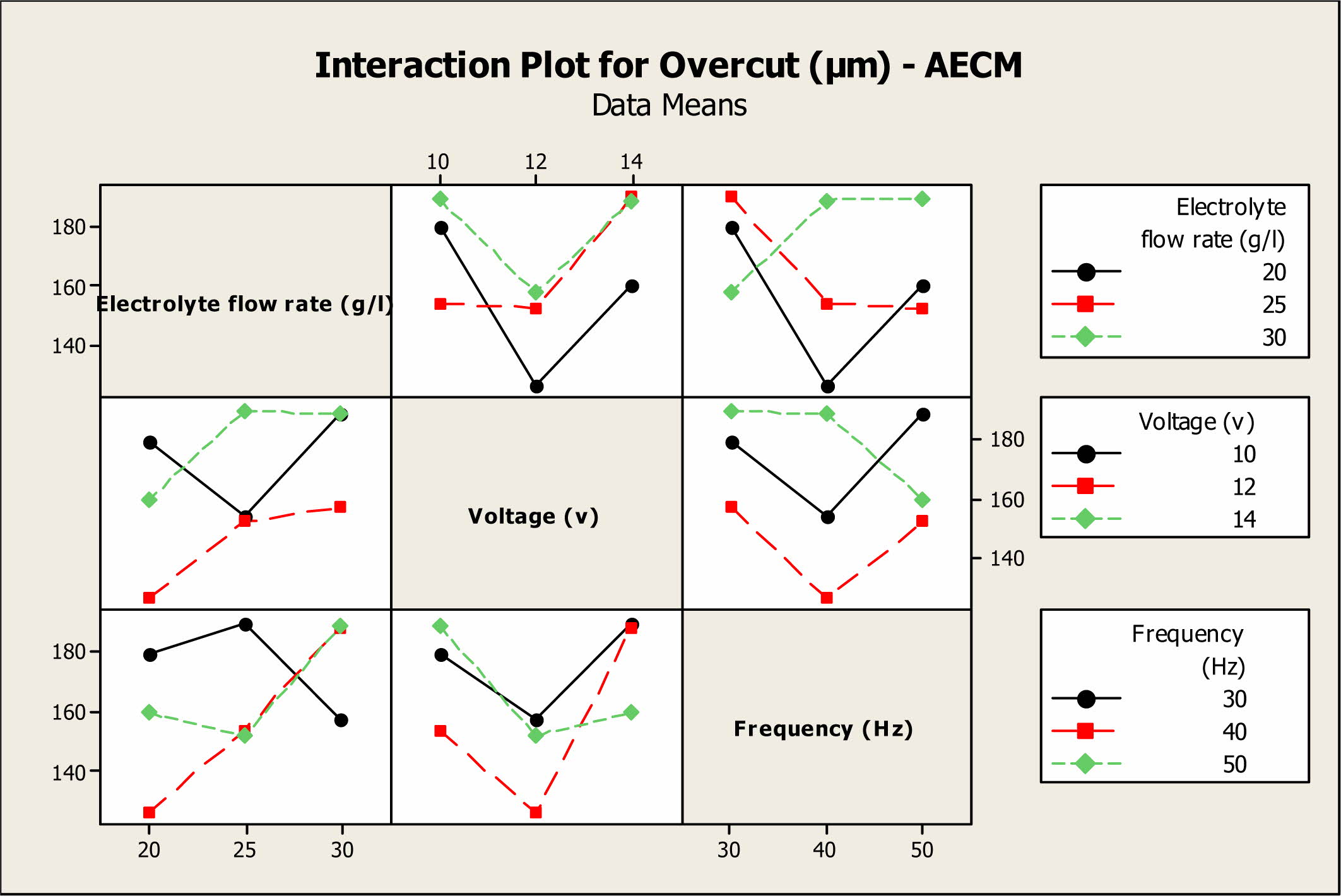

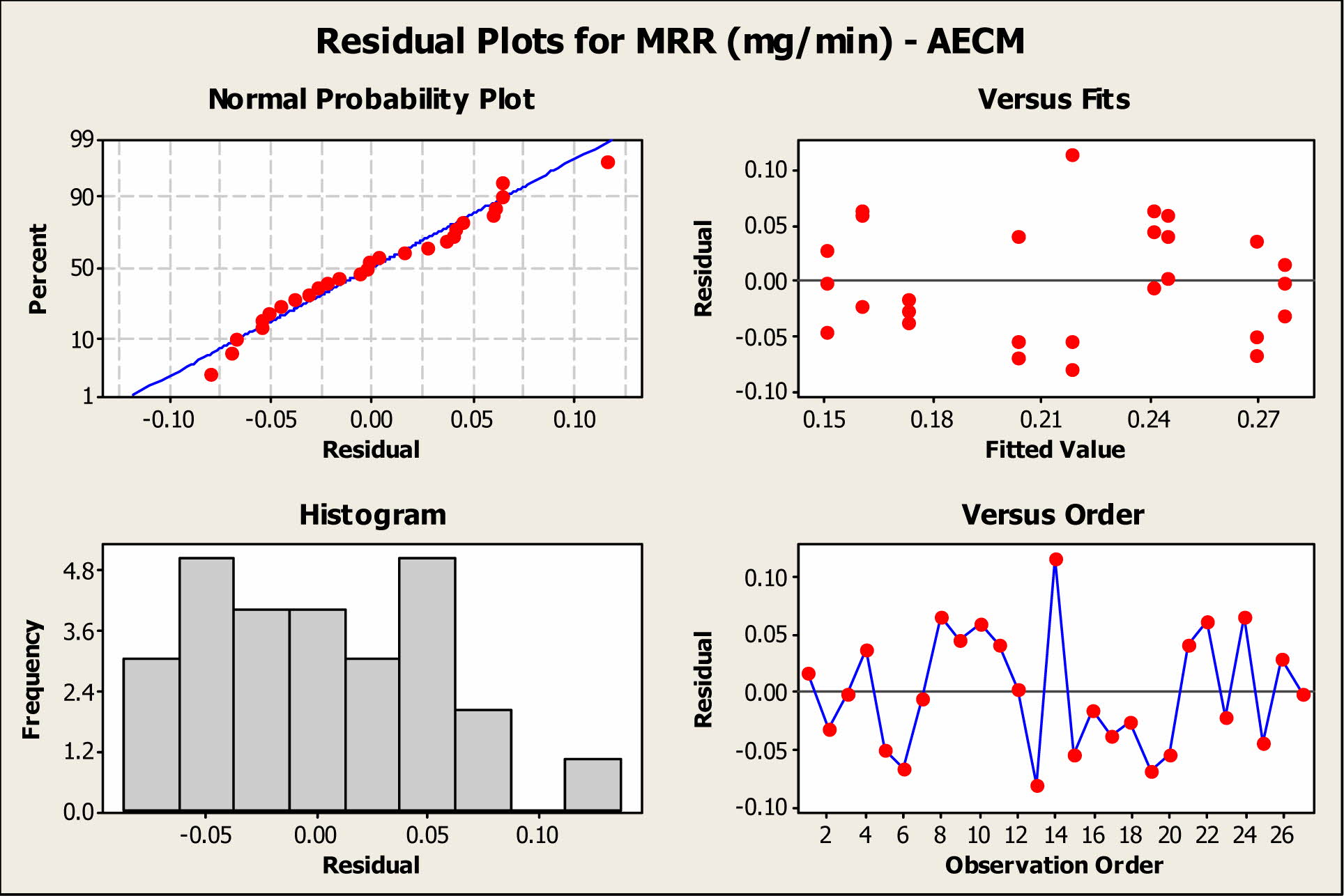

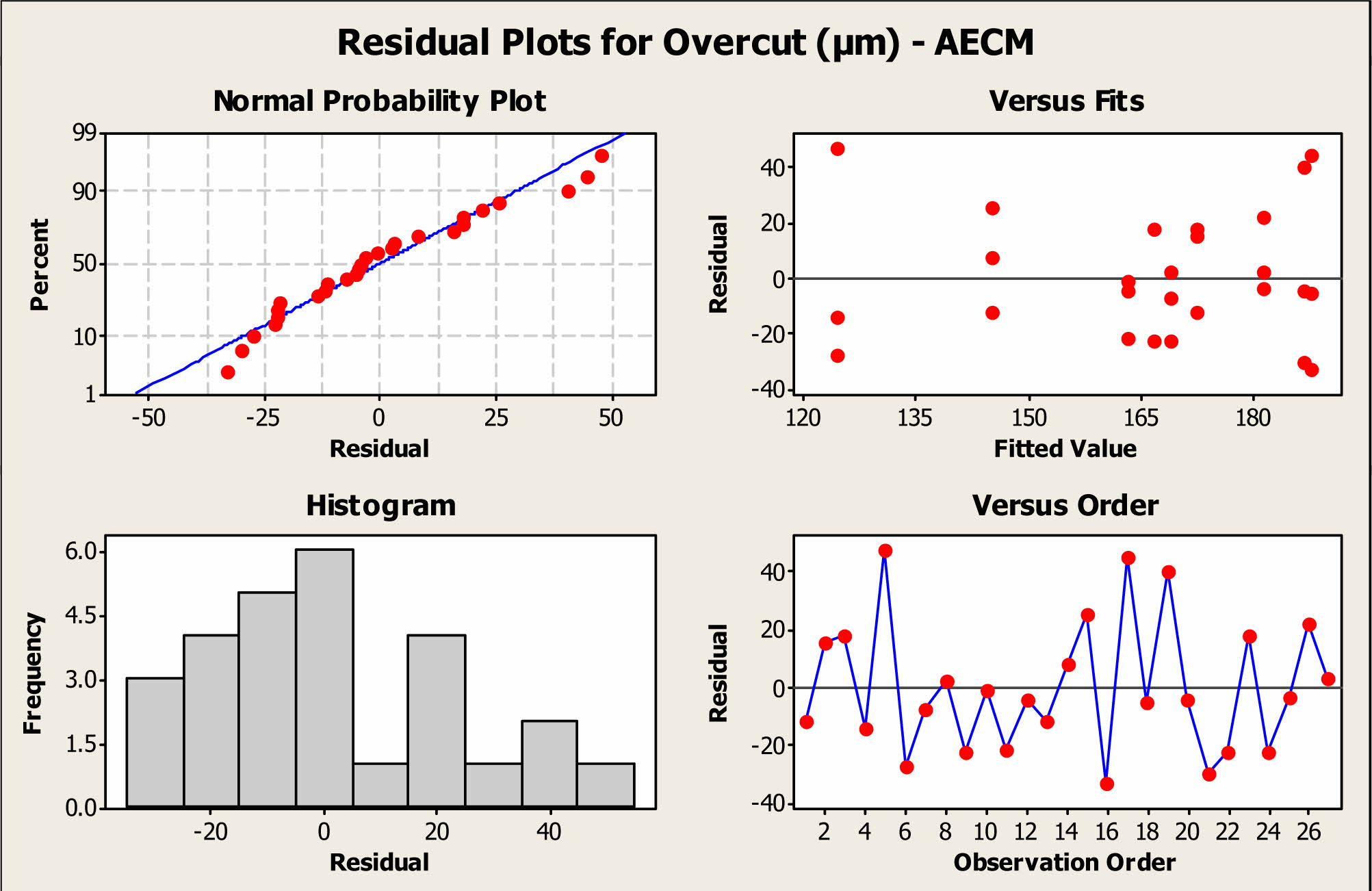

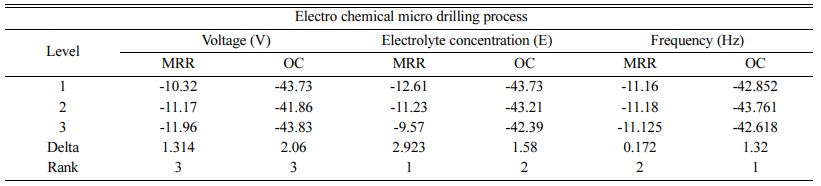

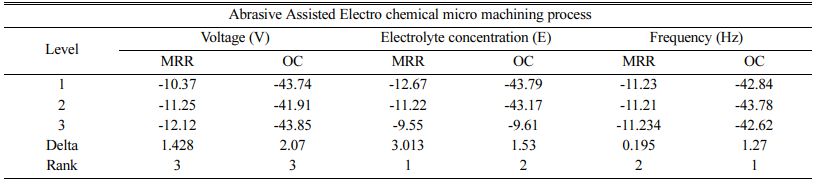

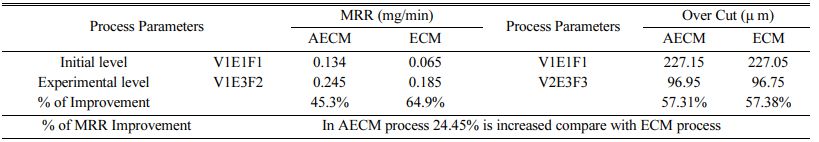

Table 8 and Table 9 represents the response table Response table for micro drilling process on Al6061-10%TiB2 - 3%Gr hybrid composite in ECM and AECM respectively. Fig. 6 and Fig. 7 represents the main effects plots for the SN ratios for material removal rate and overcut respectively. Fig. 8 and Fig. 9 represents the interaction effect of the process parameters over the responses for material removal rate and overcut respectively. It is observed that the material removal rate shows a very little change with frequency, where as when the voltage increases there is a decrease in material removal rate and it is vice versa with respect to the electrolyte concentration. From the main effects plots and the interactions plot, it is observed that the electrolyte concentration is the most influencing parameter and it is followed by frequency and voltage. Similarly in the overcut, it is observed that the frequency is the most influencing parameter and it is followed by electrolyte concentration and voltage. Similarly, it is observed that overcut increases with increase in electrolyte concentration whereas the voltage and frequency finds a rapid change. The maximum material removal rate is identified at 40 Hz, 30 g/L, 10 V and the smallest amount of overcut is identified at 50 Hz, 30 g/L, 12 V. Interaction plots explains MRR and OC interactions on each level of the process parameters. The most favorable level of MRR is identified at categorization of medium frequency, higher electrolyte concentration and minimum voltage, and least amount of Over Cut is found at combination sequence of maximum frequency, minimum electrolyte concentration and medium voltage. The residual plots for material removal rate and overcut are shown in Fig. 10 and Fig. 11 respectively. In residual graphs, all the points lies very close to the central median line and in between the upper median line and lower median line. This infers that the mathematical equation are satisfactory and the results are within the acceptable limit. Validation is conducted for material removal rate and overcut for HCC drilled in ECM and AECM and it is observed the material removal rate is increased to 45.3% in AECM and 64.9% in ECM, similarly the overcut is increased to 57.31% in AECM and 57.38% in ECM. Comparatively it is observed that there is an increase of 24.45% in AECM process when compared to ECM process. The validation results are given in Table 10.

|

Fig. 2 Brinell Hardness. |

|

Fig. 3 Tensile strength. |

|

Fig. 4 % Elongation. |

|

Fig. 5 SEM Images |

|

Fig. 6 Main Effects plot for SN ratios of MRR. |

|

Fig. 7 Main Effects plot for SN ratios of Overcut. |

|

Fig. 8 Interaction effect for SN ratios of MRR. |

|

Fig. 9 Interaction effect for SN ratios of Overcut. |

|

Fig. 10 Residual plots for MRR. |

|

Fig. 11 Residual plots for Overcut. |

|

Table 8 Response table for micro drilling process on Al6061-10%TiB2 - 3%Gr hybrid composite in ECM |

|

Table 9 Response table for micro drilling process on Al6061-10%TiB2 - 3%Gr hybrid composite in AECM |

In this work, Al6061+3Wt%Gr, Al6061+10Wt%TiB2 and Al6061+10Wt%TiB2+3Wt%Gr composites through liquid metallurgy route was prepared. Micro structure shows the reinforcement particles was homogeneously distributed in the composite. In addition of graphite particles into the Al6061 matrix ultimate strength ofthe composite material is increased. Introducing 10Wt%TiB2 particles into the Al6061 base material increases the value of hardness and the UTS of composite. Introducing 10Wt%TiB2 and 3Wt%Gr particles into the Al6061 base material, it increases the value of UTS compared with Al6061-10Wt%TiB2 and Al6061-3Wt%Gr com- posites. The ductility value of hybrid composites Al6061+10Wt%TiB2+3Wt%Gr was higher than Al6061 +10Wt%TiB2 composites but less when compared to Al6061+3Wt%Gr composites. The hardness value of Al6061+10Wt%TiB2+3Wt%Gr hybrid composites was more than Al6061+3Wt%Gr composites but the hardness value is very near compared to Al6061+10Wt%TiB2 composites. In ECM micro drilling process the rate of MRR is improved upto 64.9% and OC is recovered upto 57.38% compared to initial levels of machining parameters. The Maximum MRR was achieved at 30 g/L electrolyte concentration, 40 Hz frequency, 10 V machining voltage and minimum overcut obtained at 30 g/L electrolyte concentration, 50 Hz frequency, 12 V machining voltage. The MRR is pretentious as a result of machining voltage and frequency and Over cut is is pretentious as a result of the electrolyte concentration and Frequency. Based on validation result the material removal rate of abrasive electrochemical machining process is improved upto 24.45% compared with straight ECM process, this is because in AECM process MRR is produced by combination effect of anodic dissolution and mechanical abrasion. Al6061+10Wt%TiB2+3Wt%Gr crossbreed composites were one of the encouraged commercial materials in the engineering aspects of composites.

- 1. J. Hashim, L. Looney, and M.S.J. Hashmi, J. Mater. Process. Technol. 92 (1999) 1-7.

-

- 2. J. Hashim, L. Looney, and M.S.J. Hashmi, J. Mater. Process. Technol. 123[2] (2002) 258-263.

-

- 3. Q. Cai, Y. Liu, Z. Ma, L. Yu, J. Xiong, and H. Li, J. Alloys Compd. 586 (2014) 78-84.

-

- 4. P. Satishkumar, N. Natarajan, S. Dharmalingam, and P. Pitchandi, Int. J. Heavy Veh. Syst. 25[3-4] (2018) 430-441.

-

- 5. M.M.K. Reddy, Int. J. Mech. Eng. Appl. 1[4] (2013) 78-86.

-

- 6. A. RiazAhamed, P. Asokan, S. Aravindan, and M.K. Prakash, Int. J. Adv. Manuf. Technol. 49[9-12] (2010) 871-877.

-

- 7. M. Roy, B. Venkatataraman, V. Bhanuprasad, Y.R. Mahajan, and G. Sundararajan, Metall. Trans. A 23[10] (1992) 2833-2847.

-

- 8. R. Thirumalai, J. Senthilkumaar, P. Selvarani, R.M. Arunachalam, and K.M. Senthilkumaar, Aust. J. Mech. Eng. 10[2] (2012) 157-168.

-

- 9. N. Natarajan and R.M. Arunachalam, NISCAIR Online Periodicals Repository 70[07] (2011) 500-505.

- 10. Y. Pazhouhanfar and B. Eghbali, Mater. Sci. Eng. A 710 (2018) 172-180.

-

- 11. S. Suresh, N.S.V. Moorthi, S.C. Vettivel, and N. Selvakumar, Mater. Design 59 (2014) 383-396.

-

- 12. S. Murugan, T. Senthil, and P.D. Rajan, J. Metall. Mater. Sci. 60[2] (2018) 73-78.

- 13. D. Dey, A. Bhowmik, and A. Biswas, J. Comp. Mater. 55[14] (2021) 1979-1991.

-

- 14. M. Paidpilli, G.K. Gupta, and A. Upadhyaya, J. Comp. Mater. 53[9] (2019) 1181-1195.

-

- 15. H. R. Ezatpour, S. A. Sajjadi, M. H. Sabzevar, and Y. Huang, Mater. Design 55 (2014) 921-928.

-

- 16. Bhandare, Rajeshkumar, Gangaram, Parshuram, and M. Sonawane, Int. J. Eng. Adv. Technol. 3[3] (2013) 61-65.

This Article

This Article

-

2022; 23(3): 383-390

Published on Jun 30, 2022

- 10.36410/jcpr.2022.23.3.383

- Received on Dec 30, 2021

- Revised on Feb 9, 2022

- Accepted on Feb 24, 2022

Services

Services

Shared

Correspondence to

Correspondence to

- P. Satishkumar

-

Assistant Professor, Department of Mechanical Engineering, Study World College of Engineering, Coimbatore - 641105

Tel : +9791927002 - E-mail: sp.sathishkumar10@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.