- Optimization of stir casting process parameter using response surface methodology

Senthilkumar KMa,*, Sivakumar Ab, Rohokale Milind Shivajic, S.K. Tamangd and Giriraj Me

aFaculty of Mechanical Engineering, Kumaraguru College of Technology, Coimbatore, India

bFaculty of Mechanical Engineering, Kongu Engineering College Perundurai, India

cFaculty of Mechanical Engineering, SKN Sinhgad Institute of Technology & Science, Lonavala, India

dFaculty of Mechanical Engineering, North Eastern Regional Institute of Science and Technology, Nirjuli, India

eFaculty of Design and Automation, Vellore Institute of Technology, Vellore, IndiaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Response surface methodology is used to optimize the stir casting process parameters for the aluminium metal matrix composite reinforced with boron carbide with several weight percentages. The stir casting process parameters used in this work are the weight percentage of the reinforcing element, stir casting mixing time and particle size of the reinforcing element used in the fabrication of the metal matrix composite. The levels are chosen and central composite design is implemented to optimize the tensile strength of the metal matrix composite. The analysis of variance is calculated and the estimated regression coefficients for the tensile strength are obtained. Also the residual plots and the contour plots are plotted and discussed here

Keywords: Stir casting, Al7075, Boron carbide, Response surface methodology, Optimization

Matrix is considered to be an important phase in the formation of composite structure. Functions of the matrix are to give rigidity and shape of the structure are provided by the matrix material and good surface finish is obtained by the presence of matrix material and near net shape parts. The reinforcement in composite materials increases the tensile strength, stiffness, elongation etc. The reinforcing elements helps to carry the load effectively, provide good stiffness, give high electrical conductivity and excellent strength. The mechanical properties of the fibre should be appreciable and Good orientation of the fibres in the composite should be observed in the fabrication of the composite material. The constituent elements in a composite retain their identities. The materials used in the composite do not dissolve or completely merge into one another. The term composite material refers to all solid materials which compose of more than one component. These components are mostly in separate phases. Short fibre reinforced composite are further classified into two types namely, aligned and randomly ordered fibre composites. Glass, aramid and carbon fibres are generally used for composite materials. Optimization of surface roughness is carried out using RSM. It is inferred that the percentage of increase in the weight percentage of the reinforcing elements will increase the tensile strength of the metal matrix composite [1].

Stir casting process is developed to prepare a titanium oxide reinforce Al7075 composite with varying weigh proportions and investigated the mechanical properties of the composite [2]. Better material characteristics is obtained in hybrid reinforcement and effective optimization is also done [3, 4]. The multifunctional aspects of the aluminium alloy metal matrix composite are finding several applications in solar panel, aerospace technology, antenna reflectors etc. [5-8]. The optimization techniques are employed in the analysis investigations of the fibre reinforced composite materials [9]. Several studies on the reinforcement of silicon carbide in the fabrication of the metal matrix composite with aluminium alloy is investigated [10-13], however there are very limited reviews are studied in the reinforcement of boron carbide in the metal matrix composite. The natural fibre composites possess high mechanical properties and electrical properties. Also these fibres finds several applications in automobile industries due to its excellent tensile strength and hardness [14-16]. Optimization of process parameters in machinng of GFRP composites are analysed. Desirability based approach response surface methodology are used and mathematical models for the responses are developed and validated [17, 18]. Drilling of natural fibre reinforce composites are demonstrated and mathematical models are developed and validated. The grey relational analysis is used to rank the optimum machining parameters for the composite materials [19, 20]. The investigation of epoxy based composites are carried out and optimization of the parameters are done [21, 22].

Al7075 metal matrix is considered as the matrix and the boron carbide particles are considered as the reinforcing element in this work. Aluminium alloy Al 7075 possesses high strength, toughness, fatigue resistance, improved ductility and consist of zinc as the primary alloying element. Al 7075 alloys find several industrial applications in bicycle equipments, sports equipments, aircraft com- ponents and so on. The stir casting process is used to fabricate the composite and it is tested for its tensile strength using the UTM. Stir casting is liquid state method, in which the molten metal is stirred continuously and the reinforcing element, he dispersed phase is added to the molten metal to have a uniform composition of the composite material. In this way the metal matrix composites are prepared thereby getting the advantage of the mechanical properties of both the matrix phase and the dispersed phase in the finally fabricated composite material. The percentage of boron carbide is varied from 3 percentage to 9 percentage with the Al7075 alloy. Stir casting is useful in preparation of composite material because of its mass production and economic aspects. Stir casting employs stirring of the metal matrix and the reinforcement material in high temperature, thereby the mixing of the metal matrix and the reinforcing material will take place effectively. This will improve the mechanical properties of the composite material.

The experimental setup comprises of an electric furnace and a stirrer. The current supplied to the furnace is in the range of 230V AC and 50 Hz. The aluminium alloy in the form of scraps is placed in the furnace and heated to a temperature above 650 degree Celsius. This is followed by adding the preheated reinforcing elements, boron carbide in several weight percentages. The metal matrix composites are fabricated and the specimens are tested for the tensile strength, which are prepared as per the ASTM standards. Universal tensile testing machine is employed and the three readings are recorded for each run and average of the three values is recorded here.

The design of experiments is used to optimize the process parameters for stir casting process to obtain maximum tensile strength for the metal matrix composite specimen. The tensile strength is useful in determination of the breaking force required for any material to break and also it estimates how the material elongates when the force is employed to the material. Since determination of a breaking point of a material, tensile strength is the primary and most important characteristics, in this work tensile strength is considered.

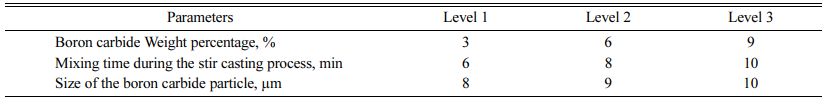

The process parameters used in this work are percentage of weight composition of the reinforcing element, boron carbide, mixing time of the reinforcing element to the metal matrix, Al7075 alloy and size of the particle of the reinforcing element. The levels of the process parameters are presented in Table 1.

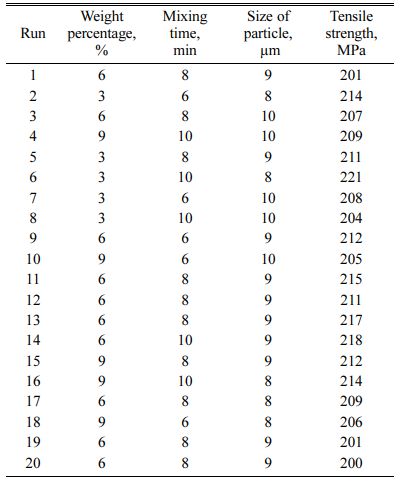

This work focuses on selection of process parameter employed for stir casting such as weight percentage of the reinforcing elements, mixing time and size of the reinforcing elements. These levels are recommended by the industrialists practicing fabrication of the metal matrix composites employed for several industrial applications and it is also suggested by the previous researchers in their work. Response surface methodology is useful in determining the mathematical relationship between the process parameters and responses. This is statistical technique which is used to optimize the parameters and to find the importance of interaction effects of the parameters on the response variables used in the optimization process. Central composite design is used for conducting the experiments and the tensile strength is recorded and the experimental data are presented in Table 2.

Twenty 20 specimens are made in this work. Response surface methodology is incorporated and central composite design is used to conduct twenty experiments as suggested by the design expert software. The set of the experiment are given by the design expert software and for each experiment, the metal matrix composites are prepared by varying the mixing time, weight percentage of the reinforcing element and size of the reinforcing particle. The specimens once prepared are tested for tensile test in the UTM and the values are recorded.

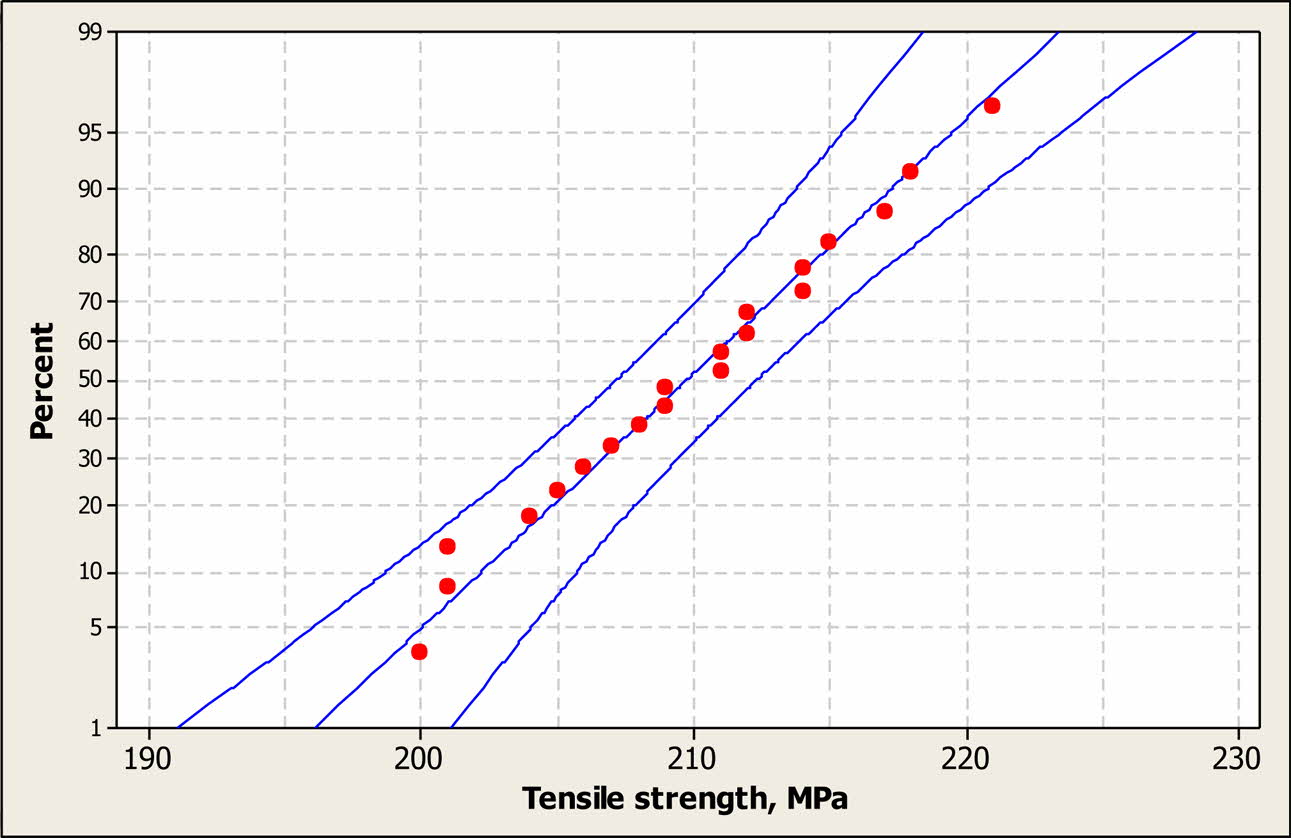

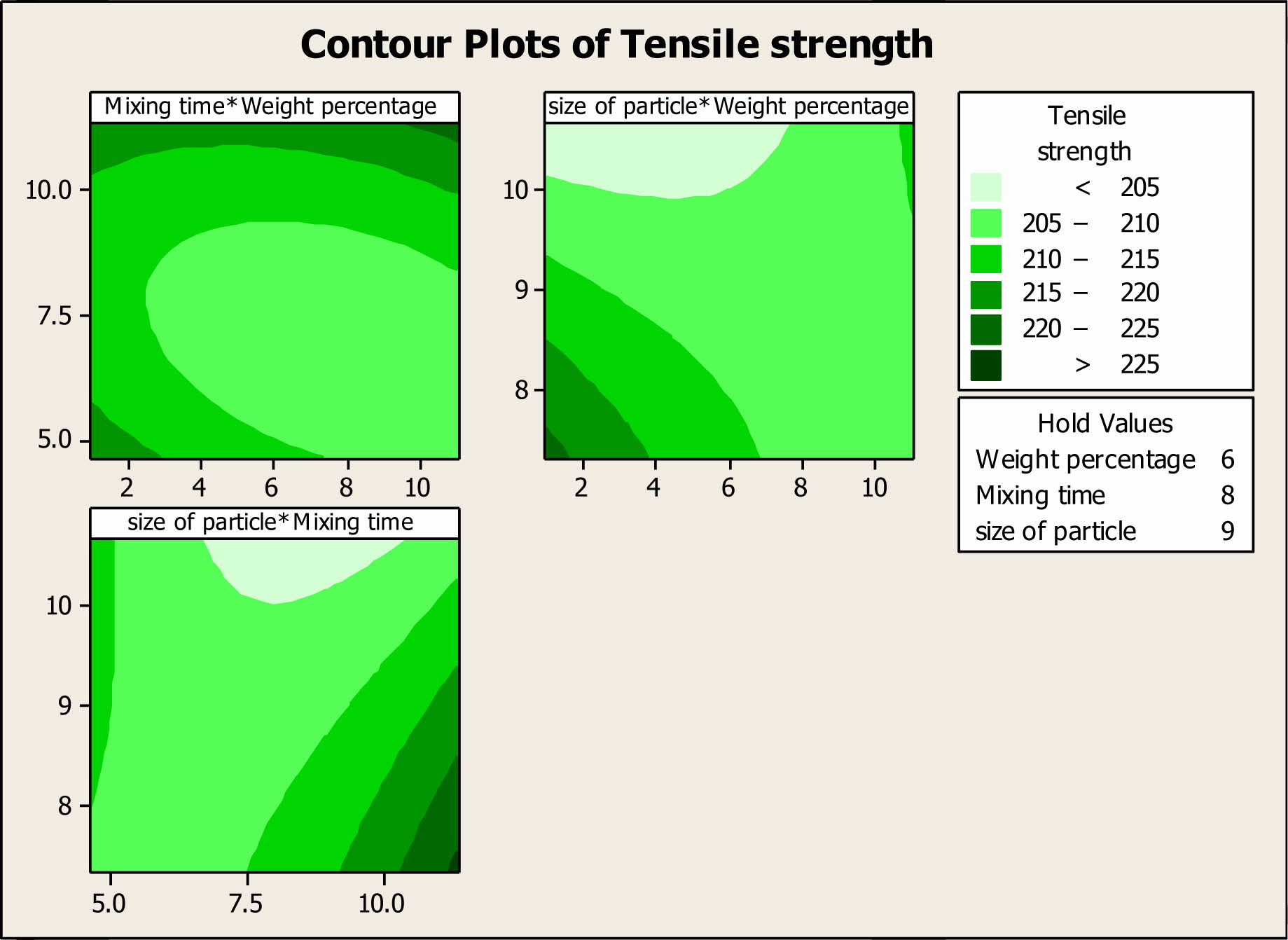

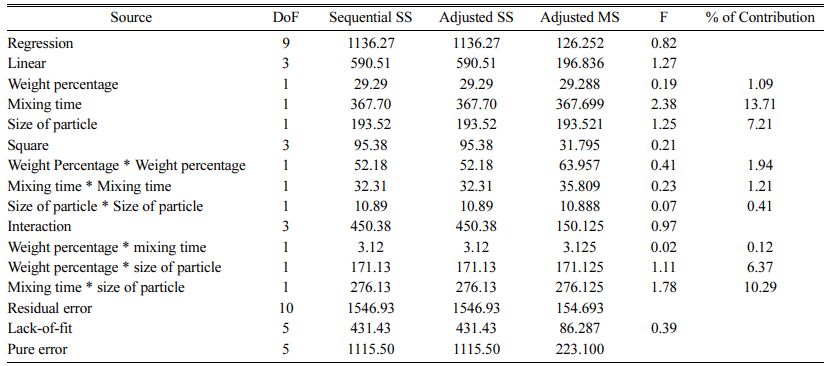

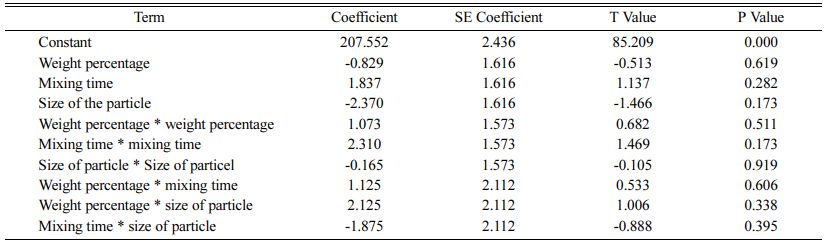

The Analysis of variance for the tensile strength is determined and presented in Table 3. It is observed that the most influencing parameter is size of the particle which is used as the reinforcing element in the metal matrix composite. The estimated regression coefficient for the tensile strength is presented in Table 4 and the regression equation for tensile strength is obtained. The normal probability plot for the tensile strength is shown in Fig. 1 and it is inferred that all the recorded values falls near to the median line and the results are found to be satisfactory. The contour plots are plotted for the tensile strength and it is shown in Fig. 2. The contour plots for tensile strength are plotted and it is concluded that the optimal values of the stir casting process parameter for obtaining maximum tensile strength is weight percentage of boron carbide is 6%, mixing time in the stir casting process is 6 min and size of the reinforcing elements of the boron carbide is 9.

|

Fig. 1 Normal probability Plots for Tensile strength. |

|

Fig. 2 Contour Plots for Tensile strength |

The Al7075 aluminium alloy is reinforced with boron carbide for fabricating the metal matrix composite using stir casting process. The stir casting process parameters employed in this work is mixing time, percentage of the reinforcing element and size the boron carbide particle. The optimization of the tensile strength of the metal matrix composite is done using response surface methodology with central composite design. The analysis of variance is performed and the contour plots are plotted and investigated. Validation results are conducted and it is noted that the tensile strength of the composite material at the optimum results are found to 221 MPa and very close to the predicted results.

- 1. S.A. Kumar, A.P. Kumar, B.B. Naik, and B. Ravi, Mater. Today Proc. 5[9] (2018) 17924-17929.

-

- 2. S.V. Alagarsamy, and M. Ravichandran, Mater. Res. Express. 6 (2019) 086519.

-

- 3. K. Mandal, S. Sarkar, S. Mitra, and D.Bose, Mater. Today Proc. 26 (2020) 660-664.

-

- 4. T.B. Rao, Adv. Manuf. 4[3] (2016) 202-216.

-

- 5. I. Kerti, F. Toptan, Mater. Lett. 62 (2008) 1215- 1218.

-

- 6. F. Toptan, A. Kilicarslan, A. Karaaslan, M. Cigdem, and I. Kerti, Mater. Des. 31 (2010) S87-S91.

-

- 7. Y.C. Feng, L. Geng, P.Q. Zheng, Z.Z. Zheng, and G.S. Wang, Mater. Des. 29 (2008) 2023-2026

-

- 8. R.M. Mohanty, K. Balasubramanian, and S.K. Seshadri, Mater. Sci. Eng. A 498 (2008) 42-52.

-

- 9. K. Murugan, S. Venkatesh, R. Thirumalai, and S. Nandhakumar. Mater. Today Proc. 37 (2020) 110-114.

-

- 10. K.M. Shorowordi, T. Laoui, A.S.M.A. Haseeb, J.P. Celis, and L. Froyen, J. Mater. Process Technol. 142 (2003) 738-743.

-

- 11. M. Kok, J. Mater. Process Technol. 161(2005) 381-387.

-

- 12. Y.C. Feng, L. Geng, G.H. Fan, A.B. Li, and Z.Z. Zheng, Mater. Des. 30 (2009) 3632-3635.

-

- 13. E. Mohammad Sharifi, F. Karimzadeh, and M.H. Enayati, Mater. Des. 32 (2011) 3263- 3271

-

- 14. G.S. Krishnan, L.G. Babu, R. Pradhan and S. Kumar, Mater. Res. Express. 7[1] (2019) 015102.

-

- 15. K. Palanikumar, S. Prakash and K. Shanmugam, Mater. Manuf. Process. 23[8] (2008) 858-864.

-

- 16. O. Osita, O. Ignatius, U. Henry, Int. J. Eng. Technol. 7 (2016) 68-77.

- 17. Y.M. Kin, J.H. Kwon, S.H. Kang, J.H. Jung, P.J. Kim, and K.J. Lim, J. Ceram. Process. Res. 13[S2] (2012) S211-S214.

- 18. M. Srinivasan, S. Ramesh, S. Sundaram and R. Viswanathan, J. Ceram. Process. Res. 22[3] (2021) 345-355.

-

- 19. R. Vinayagamoorthy, I.V. Manoj, G. Narendra Kumar, I. Sai Chand, G.V. Sai Charan Kumar and K. Suneel Kumar, J. Mech. Sci. Technol. 32[5] (2018) 2011-2020.

-

- 20. M.P. Jenarthanan and R. Jeyapaul, Int. J. Eng. Sci. Technol. 5[4] (2013) 22-36.

-

- 21. R. Thirumalai, R. Prakash, R. Ragunath, and K.M. Senthilkumar, Mater. Res. Express. 6 (2019) 1-8.

- 22. KM. Senthilkumar, R. Thirumalai, M. Seenivasan, and T. Venugopal, J. Ceram. Process. Res. 22[6] (2021) 731-738.

This Article

This Article

-

2022; 23(2): 233-236

Published on Apr 30, 2022

- 10.36410/jcpr.2022.23.2.233

- Received on Jan 31, 2022

- Revised on Mar 11, 2022

- Accepted on Mar 21, 2022

Services

Services

- Abstract

introduction

experimental methodology

results and discussion

conclusions

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Senthilkumar KM

-

Faculty of Mechanical Engineering, Kumaraguru College of Technology, Coimbatore, India

Tel : +91 9894863150 - E-mail: drkmsenthilkumar2014@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.