- Enhanced efficiency of near-UV LEDs by surface plasmon and magnetic field effects from metal films

Sang-Hyun Honga, Jae-Joon Kimb, Byeong-Hyeok Kimc, Na-Yeong Kimd and Jang-Won Kange,*

aGIST Central Research Facilities, Gwangju Institute of Science and Technology, Gwangju 61005, South Korea

bSchool of Materials Science and Engineering, Gwangju Institute of Science and Technology, Gwangju 56212, South Korea

cAdvanced Radiation Technology Institute, Korea Atomic Energy Research Institute, Jeolabuk-do 61005, South Korea

dAdvanced Photonics Research Institute, Gwangju Institute of Science and Technology, Gwangju 61005, South Korea

eDepartment of Physics, Mokpo National University, Muan, Jeollanam-do 58554, South KoreaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

The enhanced efficiency of the near-UV (NUV) LEDs was demonstrated by the combinatory effects of surface plasmons (SP) from the Ag p-electrode and out-of-plane magnetic fields from additional Co/Pt multi-layers. By utilizing an InGaN/GaN-based NUV-LED epilayer including either 100 or 40 nm p-GaN layers, four different flip-chip LEDs were fabricated by selectively adding Co/Pt ferromagnetic multi-layers on the Ag p-electrode. NUV-LEDs with Co/Pt ferromagnetic multi-layers on 100-nm-thick p-GaN showed a 10.1% enhancement of integrated electroluminescence (EL) intensity at a forward current of 20 mA, mainly due to the out-of-plane magnetic field effect. In LEDs with a 40 nm p-GaN layer, which is consistent with the penetration depth of SP fields, a further increase of 13.8% can be achieved in the integrated EL intensity at 20 mA, resulted from the additional coupling effect with SP fields. These results indicate that the combination of Ag and Co/Pt multi-layers, as the p-electrode of flip-chip LEDs, can increase the efficiency in NUV flip-chip LEDs due to efficient couplings of SP fields and an out-of-plane magnetic field with carriers injected into quantum wells

Keywords: Surface plasmon, Magnetic field, Light-emitting Diode, Near-ultraviolet, Flip-chip

Near-UV (NUV) LEDs can be applied in a variety of areas, such as biochemical detectors, counterfeit currency detectors, medical equipment, high-density storage, light sources for photometric detectors and light excitation sources for white LEDs [1-5]. However, the low internal quantum efficiency (IQE) in NUV-LEDs, which is about half that of commercial green and blue LEDs, is the main obstacle hampering various applications of NUV-LEDs. Compared to the multiple quantum wells (MQWs) of InGaN/GaN-based green and blue LEDs [6, 7], the low indium content of the InGaN layer in NUV-LED QWs results in insufficient carrier confine- ment, low IQE and low radiative efficiency [8-12]. To overcome this problem, several groups have attempted to replace the barrier layer from GaN to AlGaN (or InAlGaN), which has resulted in better carrier confine- ment in MQWs. However, replacement of GaN barrier layer with AlGaN can result in a large increase of the quantum confined stark effect due to the lattice mismatch between layers of InGaN and AlGaN. Thus, an alter- native approach is required to improve the device per- formance in InGaN/GaN-based NUV-LEDs.

As an alternative, the IQE of LEDs can be further increased by surface plasmons (SPs) coupling with excitons in QW, leading to an increase in the emission rate of QWs [13-18]. Device designs have been pro- posed to realize SP-enhanced LEDs using various metal nanometer-scale structures, such as thin films, grating, disk arrays and particles. The proposed structures can be limited in achieving SP-enhanced LEDs because of practical problems, such as leakage due to a thin p-GaN layer, short propagation length of SPs at the operating wavelength, and surface recombination at nanostructure surfaces. As another approach, when an inhomogeneous magnetic field is applied to the QW active layer, especially in GaAs/AlGaAs heterostruc- tures and InGaN/GaN QWs, carriers are localized at the active layer [19-21], thus enhancing the radiative recombination rate. In addition, under the current injec- tion condition, applying a magnetic field to an LED can modify carrier transport in the active region via the Lorentz force acting on moving charged carriers [22-25]. This enables control of the radiative recombination rate. Accordingly, it has been reported that a gradient magnetic field applied to the active layers can increase the efficiency of LEDs by enabling an increase in the lateral carrier drift and radiative recombination rate of electron and hole pairs in the MQWs [19].

Metallic layers, such as the ohmic contact and reflector, are essential components in conventional LEDs. Thus, an LEDs structure combined with effects from metallic layers can increase the IQE of InGaN/GaN-based NUV-LEDs. In this study, we demonstrated that the efficiency of NUV-LEDs can be increased by both SPs and magnetic field effects from designed metal films. Exploiting a flip-chip LED structure, an Ag layer was used as both the p-ohmic reflector and plasmonic metal layer. Moreover, to investigate the effect of a magnetic field on LEDs, additional Co/Pt multi-layers were fabricated onto the Ag p-ohmic reflector layer. Using a combination of Ag and Co/Pt multi-layers, we provide a systematic comparison of device performance for SP and magnetic field effects in InGaN/GaN-based NUV-LEDs.

To investigate NUV-LED performance with SP and magnetic field effects, NUV-LED epilayers were fabri- cated on double-sided polished c-plane sapphire by MOCVD. After growth of a GaN layer (25 nm) at 550 oC, a undoped GaN layer (2 μm) and a n-GaN layer (2 μm) were grown at 1020 oC. Then, five pairs of InGaN/GaN QWs, consisting of undoped InGaN (well, 3 nm) and Si-doped GaN (barriers, 12 nm) were grown at 770 oC, followed by growth of a p-GaN (100 nm) at 950 oC. The wavelength from the NUV-LEDs was 409 nm. Note that a relatively thin p-GaN layer (40 or 100-nm) was used to increase the interaction between the MQWs and metallic layers (SPs and magnetic field). To fabricate 300 × 300 µm2 NUV-LEDs, a dry etching was performed by an inductively-coupled plasma method (source gases: Cl2/H2/Ar), until the n-GaN layer for n-type ohmic contact. Then, Ag/Ni and Cr/Au layers (120/2 and 50/150 nm) were used as the reflector layer and p- and n-contacts, respectively.

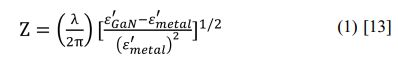

Fig. 1(a) shows a schematic illustration of NUV-LEDs with four different metal layer designs in the flip-chip LED structure. To test the magnetic field effect in NUV-LEDs with the p-GaN layer (100 nm), we fabricated devices with a ferromagnetic Co/Pt multi-layer on a Ag/Ni layer (Device #2 in Fig. 1(a)) and compared it to the device without the ferromagnetic layer (Device #1 in Fig. 1(a)). The ten period Co/Pt (1/1.5 nm) multi-layer was deposited onto the Ag/Ni reflector layer shown in the optical microscopy (OM) image of Fig. 1(b), using direct current magnetron sputtering. To turn aside oxidation of the magnetic layer, a Ta layer (3 nm) was deposited on the Co/Pt multi-layer as a capping layer. In the Co/Pt multi-layer, out-of-plane magnetization was maintained due to strong perpendicular magnetic anisotropy (PMA) [26]. Thus, the Co/Pt multi-layer does not require an additional magnetization process, such as applying high temperatures and an external magnetic field. However, the p-GaN layer thickness is likely much thicker than the penetration depth of the SP field. The penetration depth (Z) of the SP field in the GaN layer can be calculated by the following equation (1):

where ε'GaN and ε'metal are the dielectric constants of GaN and metal. And λ is the resonance wavelength of the SP field. The effective depth of the p-GaN layer for SP-QW coupling is calculated to be approximately 41 nm by considering the emission wavelength of our sample (409 nm) and the dielectric constants for GaN and metal film (Ag). According to this estimation, we performed the ICP etching process to obtain a 40-nm-thick p-GaN layer (Device #3 in Fig. 1(a)), as shown in Fig. 1(c) by the scanning electron microscopy (SEM). This enables more efficient SP coupling with excitons in the QWs. Additionally, to investigate the device performance for both SP coupling and magnetic field effects, an LED with Co/Pt multi-layers was fabricated (Device #4 in Fig. 1(a)). The SP resonance energy for the Ag film and GaN layer is ~3 eV (410 nm) when using the dielectric constants of the Ag film and GaN layer [13]. Therefore, the thickness of the spacer layer and SP characteristic wavelength are suitable for SP coupling with NUV emission.

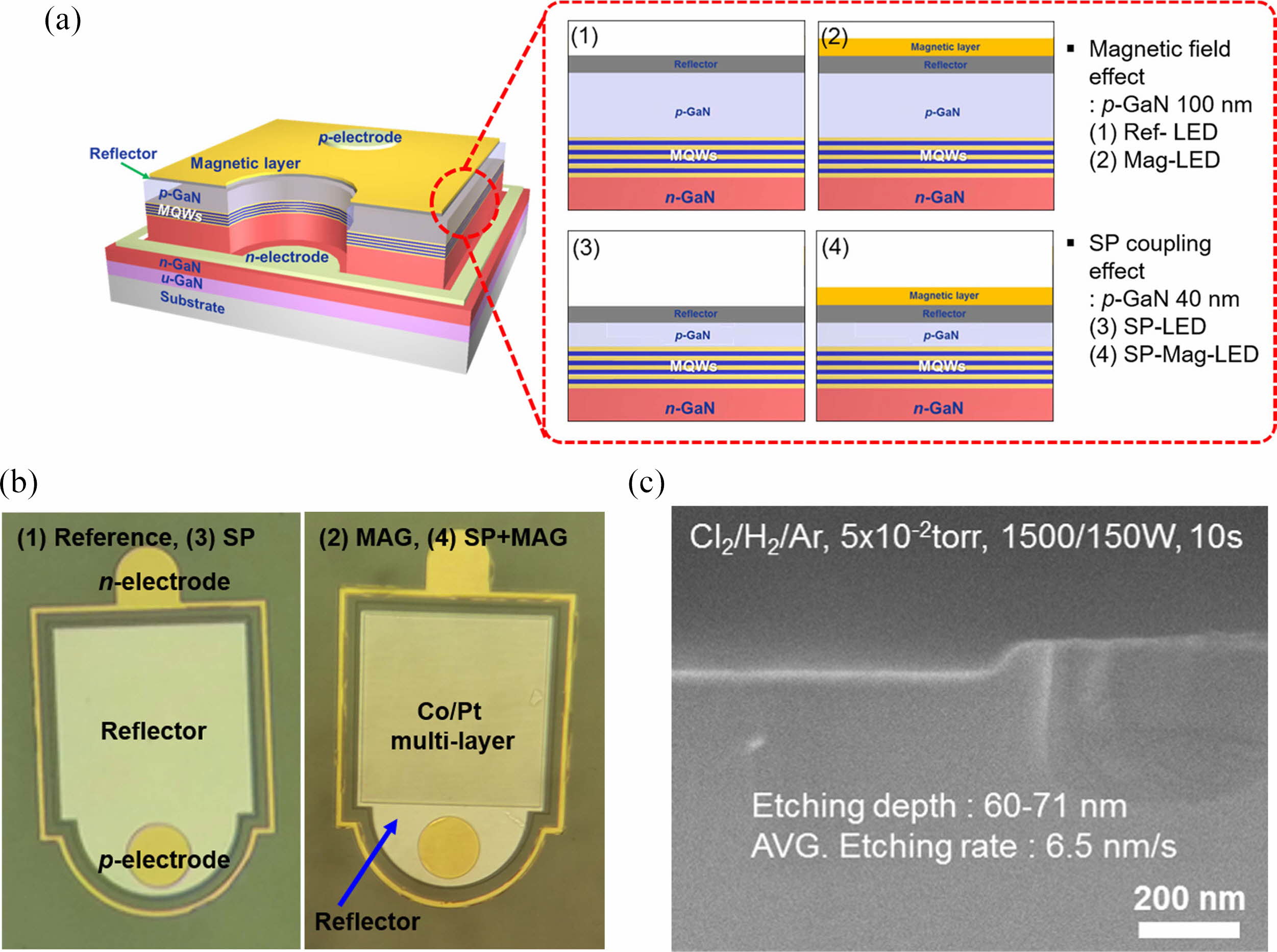

The ferromagnetic property of the Co/Pt multi-layer was investigated using vibrating sample magnetometer (VSM) measurements, as shown in Fig. 2. The struc- ture of Co/Pt multi-layer for the VSM measurement is displayed in Fig. 2(b). The VSM results for the Co/Pt multi-layer show a rectangular loop hysteresis. A saturation magnetization is 180 emu/cm3 at 300 K, confirming the ferromagnetic property in the Co/Pt multi-layer. The Co/Pt multi-layer facilitates the out-of-plane magnetization [26], enabling to application of a magnetic field to the out-of-plane direction of the LED wafer. In the flip-chip LED structure, the current flows along the out-of-plane direction of the LED wafer. Therefore, under an out-of-plane magnetic field, the charge carriers are subjected to the Lorentz force in the in-plane direction, readily leading to the lateral localization of injected carriers. Thus, our device structure can provide enhanced lateral confinement of injected electrons and holes due to the out-of-plane magnetic field, resulting in enhanced radiative efficiency in the MQWs.

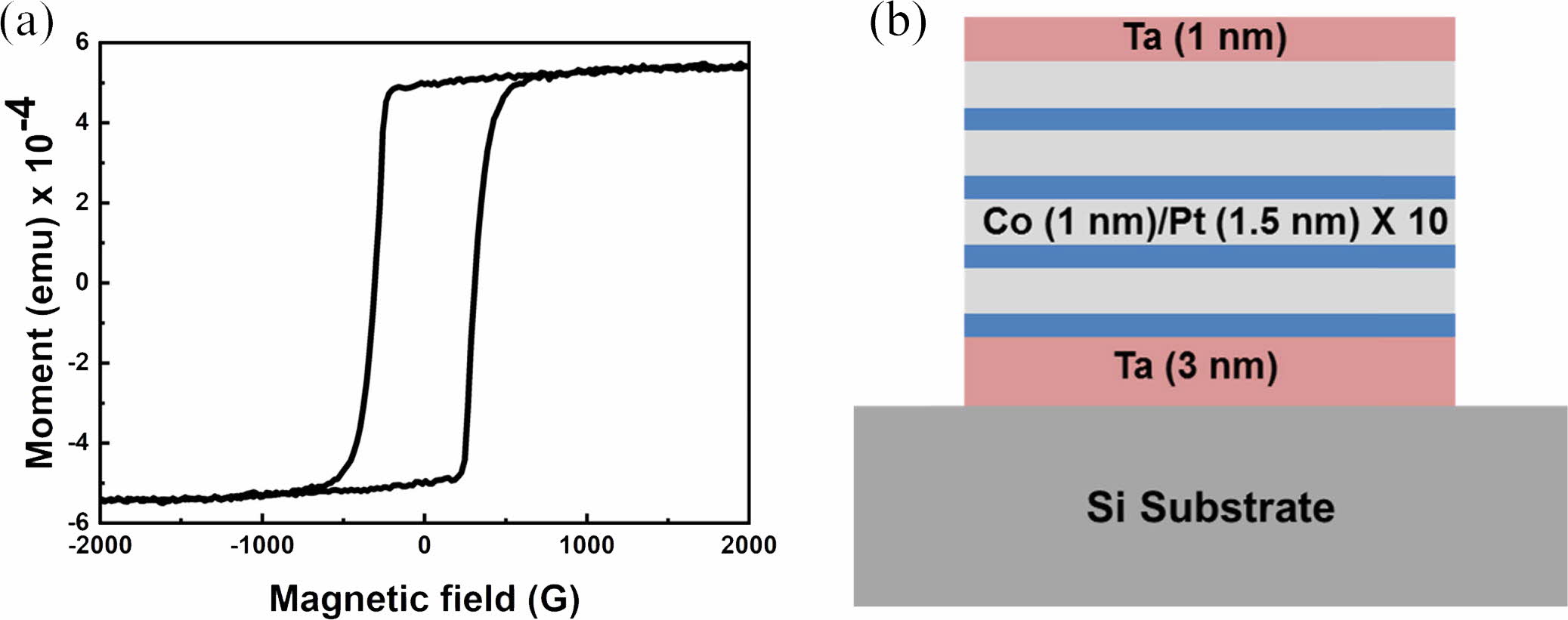

Fig. 3(a) shows the current-voltage (I-V) characteristics of NUV-LEDs (p-GaN: 100 nm) without and with Co/Pt multi-layers (Device #1 and #2, respectively). The forward voltages (Vf) of NUV-LEDs with and without the Co/Pt multi-layer are 3.40 and 3.41 V at 20 mA, indicating that the Vf is almost the same regardless of the existence of Co/Pt multi-layer. Additionally, the series resistance (Rs) of NUV-LEDs was slightly in- creased from 16.5 to 18.1 Ω by adding the Co/Pt multi-layers, showing a minor increase by the presence of Co/Pt multi-layer. The minor increase in Rs is mainly attributed to the magnetoresistance, due to the magnetic field-induced carriers drift in the in-plane orientation of the LED structure [19]. Also, the magnetoresistance, which is measured in the LEDs with Co/Pt multi-layers, implies that the out-of-plane magnetic field can affect the carriers injected into the LEDs. To investigate the magnetic field effect on NUV-LEDs, we also measured the electroluminescence (EL) intensity for Device #1 and #2. The integrated EL intensities were measured from the bottom side of the NUV-LEDs structure by using an optical fiber, US-VIS spectrometer (USB4000, Ocean Optics, USA), and semiconductor parameter analyzer (HP-4155A, HP, USA). Fig. 3(b) shows the integrated EL properties of NUV-LEDs with and without Co/Pt multi-layers as a function of injection current. The results show that the integrated EL intensity of the NUV-LED with the Co/Pt multi-layer is higher than that without the Co/Pt multi-layer. Compared to the NUV-LED without the Co/Pt multi-layer (Device #1), the integrated EL properties of the NUV-LED with the Co/Pt multi-layer is increased by 10.1% at 20 mA. Recently, it has been shown that the external magnetic field can increase the radiative recombination rate in the MQWs due to the lateral drift and localized carriers in the minimum potential regime of the indium-rich region [23, 24]. Similar to the previous reports, the improvement of EL properties in the NUV-LED with the Co/Pt multi-layer can be interpreted to enhance the radiative efficiency in the NUV MQWs by introducing the out-of-plane magnetic fields.

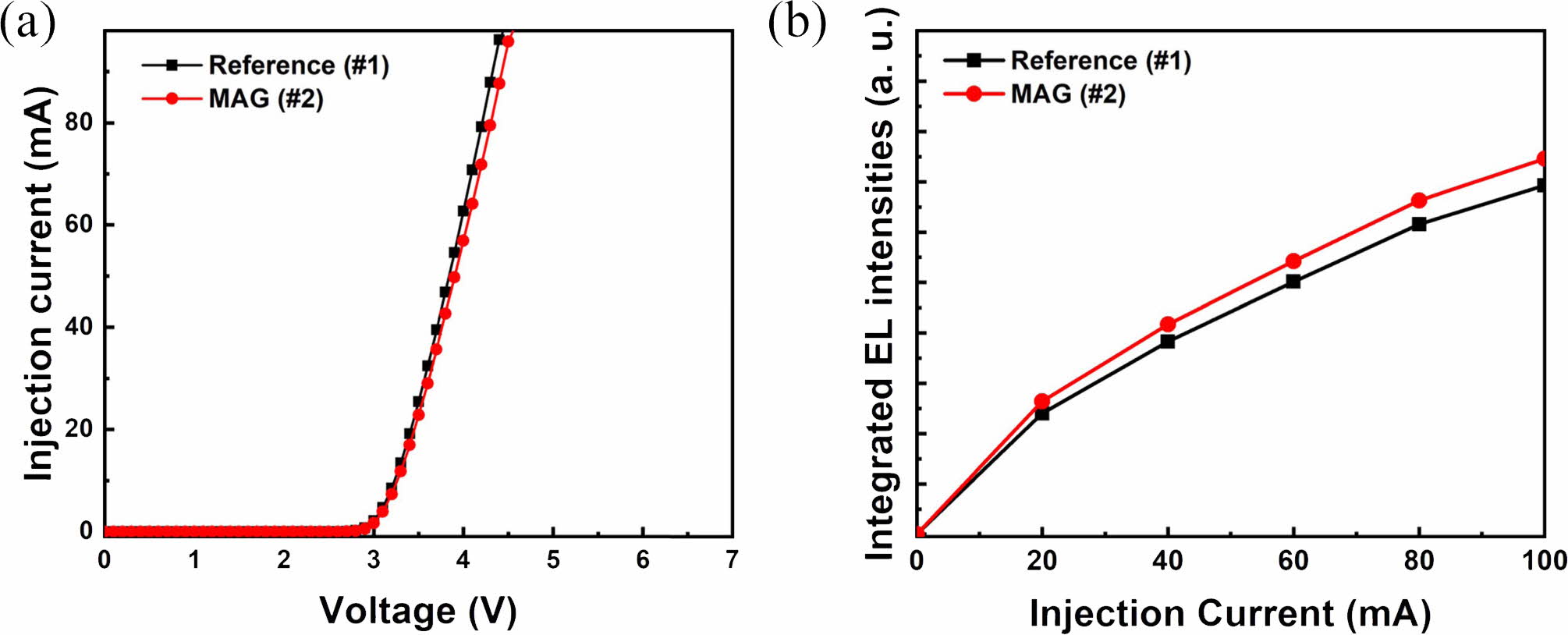

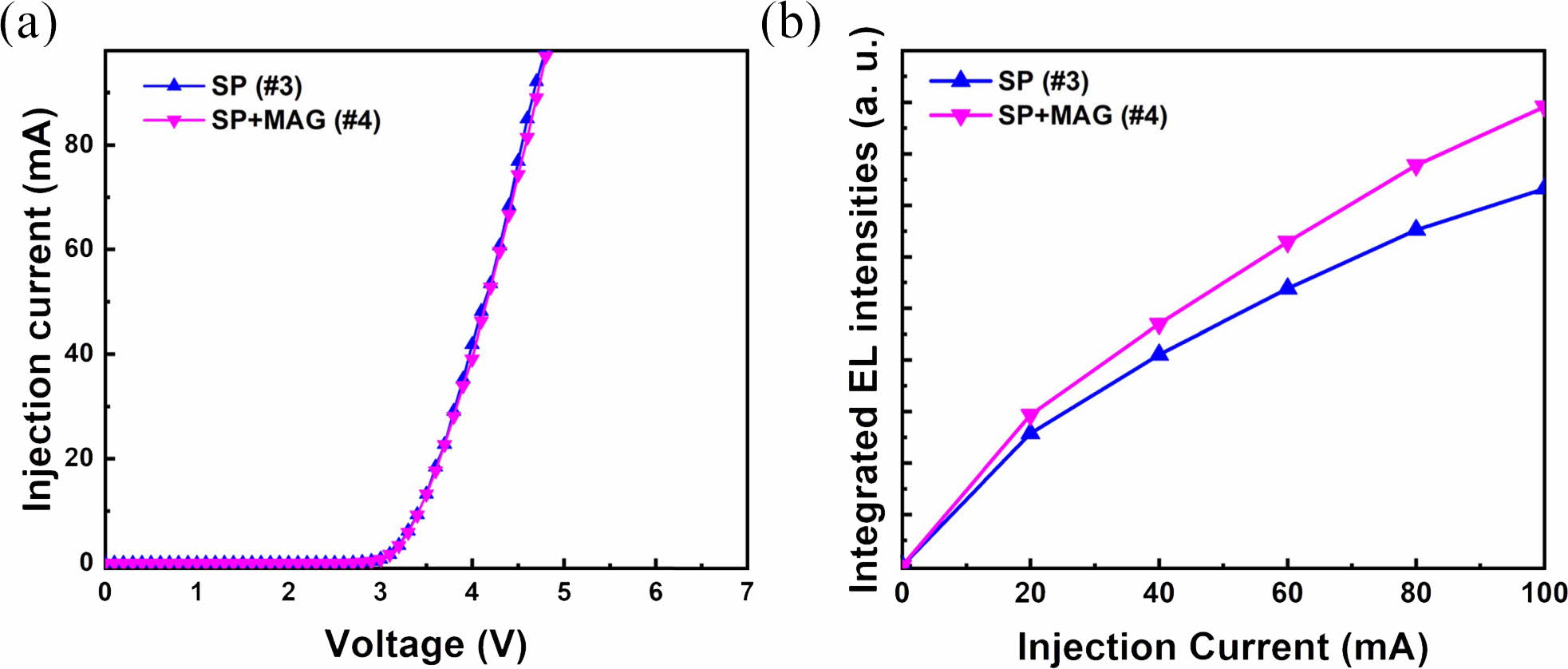

To understand the combined effect of the out-of-plane magnetic and SP coupling, the LED performance was investigated for Device #3 and #4 with 40-nm-thick p-GaN. Fig. 4(a) shows the I-V characteristic of Device #3 and #4 (p-GaN: 40 nm). Similar to the results for Device #1 and #2, the Vf is almost the same (3.6 V at 20 mA) without respect to the existence of the Co/Pt multi-layer. The Rs of NUV-LEDs is increased from 23.7 to 26.1 Ω by the magnetoresistance induced from the Co/Pt multi-layer, suggesting that the recom- bination of injected carriers is strongly affected by the magnetic field from Co/Pt multi-layer. Compared to the LEDs with p-GaN thickness of 100 nm (Device #1 and #2), the overall increase of Vf and Rs might be a result of etching damage in the p-GaN layer with 40 nm thickness, which was etched to obtain efficient SP coupling with the Ag layer. However, even though the electrical properties of the LED, such as Vf and Rs, was degraded by thinning process of the p-GaN layer, the integrated EL properties of the NUV-LED with the Co/Pt multi-layer (Device #4) is much enhanced by 13.8% at an injected current of 20 mA compared to the referenced LEDs of Device #1, as shown in Fig. 4(b). This indicates that the emission efficiency in NUV-LEDs can be increased by both SP and magnetic field effects. Furthermore, the integrated EL intensity between Device #1 and #3 was compared to estimate only the SP effects, excluding the magnetic field effect by Co/Pt multi-layer. For NUV-LEDs without the Co/Pt multi-layer, the integrated EL intensity of Device #3 is increased by 7.3%, compared to Device #1, at a current injection of 20 mA. This indicates that the thinner p-GaN layer can also increase efficiency due to efficient coupling with SPs. Therefore, our systematic comparison indicates that InGaN/GaN-based NUV-LED efficiency can be enhanced by SP coupling and an out-of-plane magnetic field from Ag and Co/Pt multi-layer films.

|

Fig. 1 (a) Schematic illustration of NUV-LEDs with four different metal layer designs in the flip-chip LED structure. (Device #1: Ag/Ni layer on 100 nm-thick p-GaN, Device #2: Co/Pt multi-layer and Ag/Ni layer on 100 nm-thick p-GaN, Device #3: Ag/Ni layer on 40 nm-thick p-GaN, Device #4: Co/Pt multi-layer and Ag/Ni layer on 40 nm-thick p-GaN). (b) OM images of flip-chip LED design with different metallic layers. (c) SEM image of 40 nm-thick p-GaN layer after the ICP etching process. |

|

Fig. 2 (a) VSM characteristics of the Co/Pt multi-layer, showing a rectangular loop hysteresis with a saturation magnetization of 180 emu/ cm3 (@ 300 K). (b) Schematic diagram of Co/Pt multi-layer, which is composed of the top (1 nm) and bottom (3 nm) Ta capping layers and 10 pairs of Co (1 nm)/Pt (1.5 nm) layers. |

|

Fig. 3 (a) I-V characteristics of NUV-LEDs (p-GaN: 100 nm) with and without Co/Pt multi-layers (Device #1 and #2), showing a minor increase in series resistance due to the magnetic field effect on carrier transport. (b) Integrated EL intensity of NUV-LEDs (p-GaN: 100 nm) with and without Co/Pt multi-layers (Device #1 and #2), showing that the integrated EL intensities of NUV-LEDs with Co/Pt multi-layers are increased by 10.1% at a current injection of 20 mA. |

|

Fig. 4 (a) I-V characteristics of NUV-LEDs (p-GaN: 40 nm) with and without Co/Pt multi-layer (Device #3 and #4). (b) Integrated EL properties of NUV-LEDs (p-GaN: 40 nm) with and without Co/Pt multi-layer (Device #3 and #4), showing that the integrated EL intensities of NUV-LEDs with Co/Pt multi-layers are increased by 13.8% at a current injection of 20 mA. |

In conclusion, we have demonstrated that the effici- ency of InGaN/GaN-based NUV-LEDs can be improved by using the combined layers of Ag p-ohmic and ferromagnetic Co/Pt multi-layers on a thin p-GaN layer. Since the SP resonance can result from the Ag layer, the resonant coupling of the SPs with the excitonic emission of MQWs active layer allows us to increase the radiative recombination rate, utilizing the distance control between Ag p-ohmic and MQWs region. Also, the out-of-plane magnetic field arising from the additional Co/Pt multi-layer enables the lateral con- finement of electrons and holes injected into the active layer, thus, enhancing the radiative recombination rate in NUV-MQWs. First, regardless of the p-GaN thickness in the flip-chip LED structure, we showed that the emission efficiency of NUV-LEDs can be increased by the out-of-plane magnetic field from the Co/Pt multi-layer. This layer resulted in increased output power of 10.1% and 13.8% for 100-nm and 40-nm-thick p-GaN layers, respectively. Also, the larger increment (13.8%) of the output power in the LED with thinner p-GaN (40 nm) indicates that an efficient SP coupling effect with an Ag layer can be achieved by reducing the p-GaN thickness in the flip-chip structure of InGaN/GaN-based NUV-LEDs. Our results suggest that the emission efficiency in InGaN/GaN-based NUV-LEDs can be increased by a combination of SP coupling and the out-of-plane magnetic field effect from Ag and Co/Pt multi-layer films.

This research was supported by research funds of Mokpo National University in 2020.

- 1. P. Waltereit, O. Brandt, A. Trampert, H.T. Grahn, J. Menniger, M. Ramsteriner, M. Reiche, and K.H. Ploog, Nature 406 (2000) 865-868.

-

- 2. A. Khan, K. Balakrishnan, and T. Katona, Nat. Photon. 2 (2008) 77-84.

-

- 3. T. Wang, Y.H. Liu, Y.B. Lee, J.P. Ao, J. Bai, and S. Sakai, Appl. Phys. Lett. 81[14] (2002) 2508-2510.

-

- 4. A. Knauer, H. Wenzel, T. Kolbe, S. Einfeldt, M. Weyers, M. Kneissl, and G. Tränkle, Appl. Phys. Lett. 92 (2008) 191912.

-

- 5. A. Yasan, R. McClintock, K. Mayes, D. Shiell, L. Gautero, S.R. Darvish, P. Kung, and M. Razeghi, Appl. Phys. Lett. 83[23] (2002) 4701-4703.

-

- 6. K.R. Song, D.S. Oh, M.J. Shin, and S.N. Lee, J. Ceram. Process. Res. 13[S2] (2012) s295-s299.

- 7. D. Min, G. Yoo, Y. Ryu, S. Moon, K. Lee, and O. Nam, J. Ceram. Process. Res.14[4] (2013) 521-524.

- 8. M. Kunzer, U. Kaufmann, K. Köhler, C.C. Leancu, S. Liu, and J. Wagner, Phys. Stat. Sol. (c) 4[7] (2007) 2822-2825.

-

- 9. S. Watanabe, N. Yamada, M. Nagashima, Y. Ueki, C. Sasaki, Y. Yamada, T. Taguchi, K. Tadatomo, H. Okagawa, and H. Kudo, Appl. Phys. Lett. 83[24] (2003) 4906-4908.

-

- 10. A. Laubsch, M. Sabathil, J. Baur, M. Peter, and B. Hahn, IEEE Trans. Electron Devices 57[1] (2010) 79-87.

-

- 11. A.M. Ficher, Z. Wu, K. Sun, Q. Wei, Y. Huang, R. Senda, D. Iida, M. Iwaya, H. Amano, and F.A. Ponce, Appl. Phys. Express 2 (2009) 041002.

-

- 12. M. Peter, A. Laubsch, W. Bergbauer, T. Meyer, M. Sabathil, J. Baur, and B. Hahn, Phys. Stat. Sol. A 206[6] (2009) 1125-1129.

-

- 13. K. Okamoto, I. Niki, A. Shvartser, Y. Narukawa, T. Mukai, and A. Scherer, Nat. Mater. 3 (2004) 601-605.

-

- 14. M.K. Kwon, J.Y. Kim, B.H. Kim, I.K. Park, C.Y. Cho, C.C. Byeon, and S.J. Park, Adv. Mater. 20 (2008) 1253-1257.

-

- 15. D.M. Yeh, C.F. Huang, C.Y. Chen, Y.C. Lu, and C.C. Yang, Appl. Phys. Lett. 9 (2007) 171103.

-

- 16. H.S. Chen, C.F. Chen, Y. Kuo, W.H. Chou, C.H. Shen, Y.L. Jung, Y.W. Kiang, and C.C. Yang, Appl. Phys. Lett. 102 (2013) 041108.

-

- 17. C.Y. Cho, J.J. Kim, S.J. Lee, S.H. Hong, K.J. Lee, S.Y. Yim, and S.J. Park, Appl. Phys. Express 5 (2012) 122103.

-

- 18. C.Y. Cho, S.J. Lee, J.H. Song, S.H. Hong, S.M. Lee, Y.H. Cho, and S.J. Park, Appl. Phys. Lett. 98 (2011) 051106.

-

- 19. J.J. Kim, Y.C. Leem, J.W. Kang, J. Kwon, B. Cho, S.Y. Yim, J.H. Baek, and S.J. Park, ACS Photonics 2 (2015) 1519-1523.

-

- 20. B. Arnaudov, T. Paskova, O. Valassiades, P.P. Paskov, S. Evtimova, B. Monemar, and M. Heuken, Appl. Phys. Lett. 83[13] (2003) 2590-2592.

-

- 21. Q.X. Zhao, B. Monemar, P.O. Holtz, T. Lundström, M. Sundaram, J.L. Merz, and A.C. Gossard, Phys. Rev. B 50[11] (1994) 7514-7517.

-

- 22. J. Lee, X. Gao, L.D.A. Hardy, and H.S. White, J. Electrochem. Soc. 142[6] (1995) L90-L92.

-

- 23. S.R. Ragsdale, J. Lee, X. Gao, and H.S. White, J. Phys. Chem. 100 (1996) 5913-5922.

-

- 24. M. Shao, L. Yan, H. Pan, I. Ivanov, and B. Hu, Adv. Mater. 23 (2011) 2216-2220.

-

- 25. J.D. Jackson, in “Classical Electrodynamics” (John Wiley & Sons Inc, 1999) p.191-194, p.404-409.

-

- 26. S. Emori and G.S.D. Beach, J. Appl. Phys. 110 (2011) 033919-1-033919-5.

-

This Article

This Article

-

2022; 23(2): 121-125

Published on Apr 30, 2022

- 10.36410/jcpr.2022.23.2.121

- Received on Mar 31, 2021

- Revised on Aug 11, 2021

- Accepted on Aug 28, 2021

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jang-Won Kang

-

GIST Central Research Facilities, Gwangju Institute of Science and Technology, Gwangju 61005, South Korea

Tel : +82-61-450-2322 - E-mail: kangjw@mokpo.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.