- Investigation of microstructures and properties of HVOF sprayed WC-10Co-4Cr coatings on high-hardness M42 steel

Xiaogang Lua,*,†, Zhenghua Linb,†, Peng Pana, Yunbo Chena, Lingli Zuoa and Chunming Lia

aState Key Laboratory of Advanced Forming Technology and Equipment, Beijing National Innovation Institute of Lightweight Ltd, Beijing 100083, China

bHengda New Materials Co., Ltd, Putian, Fujian, 351142, ChinaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

WC-10Co-4Cr have been well known material with attractive corrosion resistance and excellent hardness in the WC-based coatings. To widen the application of the WC-10Co-4Cr coatings deposited on high-hardness metal cutting tools, the investigation of its preparation parameters and properties are required. In this study, dense micro-structured WC-10Co-4Cr coatings deposited on high-hardness M42 steel were performed with high velocity oxy-fuel (HVOF) spray process. The prepared coatings exhibit excellent properties by improving the size of spray gun and injecting high flow nitrogen into the flame stream. A maximum micro-hardness of 1353.3 HV0.3 was achieved. In addition, the frictional properties of uncoated M42 steel and the WC-10Co-4Cr coating were comparably studied under dry sliding wear tests. A low friction coefficient of 0.34-0.37 was achieved for WC-10Co-4Cr coating, showing a 57% decrease than that of uncoated M42 steel. X-ray diffractometry was used to identify the phase composition, and scanning electron microscopy was adopted to characterize the microstructure of deposited coatings and worn-out surfaces

Keywords: M42 steel, WC-10Co-4Cr coatings, Microstructure, Micro-hardness, Frictional properties

Double metal band saw blade is one of the most advanced metal cutting tools in the world and widely used as cutting tools for ferrous and non-ferrous metals. The tooth material of band saw blade is usually made of M42 steel, which is mainly responsible for its high hardness, good cutting performance, and long service life [1-5]. However, failure problems are present during the longer hours of cutting, especially for tooth material, such as poor resistance to wear, fracture failure of tooth tip, obstruction of cutting and so on [2]. To improve the properties and service life of band saw blade, it is essential to take appropriate measures to modify and strengthen the surface of M42 steel. Nitriding, laser surface melting and plasma coating as the commonly surface modification treatments, have been used to protect the surface of M42 steel [6, 7]. However, the above methods have the characters of complex process, relatively low efficiency, high cost and poor bond strength, which greatly limit its industrial application [8-10].

Over the past decades, it has been reported that the technological relevance of High Velocity Oxygen Fuel (HVOF) sprayed WC-based coatings within the field of surface engineering with respect to their outstanding properties, such as their superior wear resistance, good corrosion resistance and high hardness [11-15].Compared with other spray coating techniques, the outstanding characteristics of HVOF spraying technology are as follows. Firstly, flame velocity with around speed of 550 m·s-1 can provide high flight kinetic energy for powder particles, which is beneficial to improve the adhesion of the coating. Secondly, relatively low particle temperature (about 2800 oC) can inhibit the carbide decomposition, resulting in a lower oxide content [16-19]. Coatings sprayed by HVOF method offer advantages in terms of porosity, densification, reasonably lower material cost, ease in processing, and excellent mechanical properties such as higher hardness and adhesive strength of coating. As an excellent alternative coating for electroplating hard chromium [20, 21], it is widely used for numerous industrial applications such as aerospace, ship, metallurgy, and cylinder to improve the service life and performance of components [22-27]. WC-10Co-4Cr is one of the most representative coating materials in WC-based coatings. In the elements of WC-10Co-4Cr coating, tungsten carbide, cobalt and chromium constitute a synergistic and mutually reinforcing system. As the commonly used cemented carbide, WC endows the coating with high hardness. Metallic phase Co is the ideal binder and Cr can effectively improve the corrosion resistance of the coating [5, 28-30].

In recent years, the researches of HVOF sprayed WC-10Co-4Cr coating mainly focuses on the influence of WC particle size and optimization of spray para- meters. The results indicate that they play a dominant role in mechanical properties, porosity, microstructure formation, residual stress, as well as cohesive strength between coatings and substrate. However, WC-10Co-4Cr coatings sprayed by HVOF method in many studies are deposited on soft metal materials such as 304 stainless steel, Q235 carbon steel, AISI 1045 steel and 45-steel [31-41]. Among these metal substrates, the Rockwell hardness of them is below 55 HRC. The conventional HVOF technology hardly to deposit ceramic coatings on high-hardness substrate with a value of exceeding 65 HRC, mainly due to the insufficient kinetic energy of in-flight particles, and resulting in poor bond strength between the coating and substrate. Few studies have been reported on the influence of spray process parameters such as spray gun size and gas flow rate, especially different spraying distance on the properties of coatings, which play an important role in microstructure formation. Under the condition of constant fuel kerosene and oxygen flow, the temperature and velocity of powder particles in high-speed flame flow will alter with the spraying distance. WC phase is easy to decarburize during thermal spraying, resulting in the formation of brittle W2C and CoxWyC phases, which can damage the wear resistance of coating. Researches show that the decarburization of WC is mainly influenced by the particle size of powder and the spray parameters. After the coating as-sprayed, residual stresses and porosity may also formed inside the coating which also affects the hardness and toughness [42-49].

In the present research work, WC-10Co-4Cr coatings were sprayed on high-hardness M42 steel with a function of spraying distance ranging from 230 mm to 400 mm, by enlarging the size of spray gun and injecting high flow nitrogen into the flame stream. The optimized method makes the pressure of the combustion chamber over 2.2 MPa, far exceeding 0.6-0.9 MPa pressure of the conventional HVOF spraying combustion chamber. Moreover, the influences of spraying distance for a certain spraying gun size on the micro-hardness was investigated.

Dense micro-structured WC-10Co-4Cr coatings were prepared by Praxair TAFA JP5000 supersonic flame spraying equipment. The spraying powder was commercial WC-10Co-4Cr powder with the composition of WC- 86 wt.%, Co- 10 wt.%, and Cr- 4 wt.%. The agglomerated size of the WC-10Co-4Cr powder was 15-45 μm, and the purity was 99.99%.

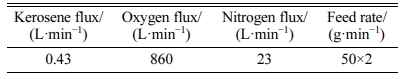

Before spraying, the M42 steel sample was diamond cut into cylindrical specimen with dimensions of Ø15 mm×8 mm for HVOF sprayed and micro-hardness measurement, and of 20 mm × 30 mm × 5 mm for friction testing. Then, the surface of specimen was cleaned in absolute alcohol by ultrasonic cleaning instrument for 15 minu to remove the contaminants. In order to obtain good bond strngth between the coating and substrate, the grit blasting was performed with brown corundum in size range of 0.3-0.9 mm. During the grit blasting process, the blowing pressure and the blasting angle were set to 0.4 MPa and 90o, respectively. The required substrate surface roughness had a value of Ra ≈3-5 μm. As the HVOF equipment, it possesses the advantages of ultra-high flame velocity, and its spraying flame velocity is above Mach 11. Oxygen and nitrogen were used as combustion supporting gas and powder carrier gas, respectively. Spray gun size was 6 feet, which was longer than the reported research [14-16]. The spraying distance was range from 230-400 mm. The other spraying process parameters were listed in Table 1.

The hardness measurement was done using an Agilent G200 nano-indentation tester. At least 10 points were measured under the same load of 2.94 N and a dwell time of 15 s to determine an average value of hardness. The sliding wear test in dry condition was conducted on a UMT3 machine. A Si3N4 ball with the dimension of Ø4 mm was used as the pair of friction. Coated and uncoated samples were pressed against with a load of 5 N, 10 N and 15 N, respectively. The friction testing was run for 15 min at a sliding frequency of 4 Hz, and the sliding distance was set as 5 mm. In order to obtain reliable data, tests at each load were repeated at least three times.

The spraying powder and prepared coatings were identified by X -ray diffraction (XRD) device with Cu Kα radiation to characterize the phase composition. The surface and cross section microstructures of coatings as well as their worn surfaces were observed with scanning electron microscope (SEM, ZEISS EVO18, Germany).

Characterization of coating

XRD analysis

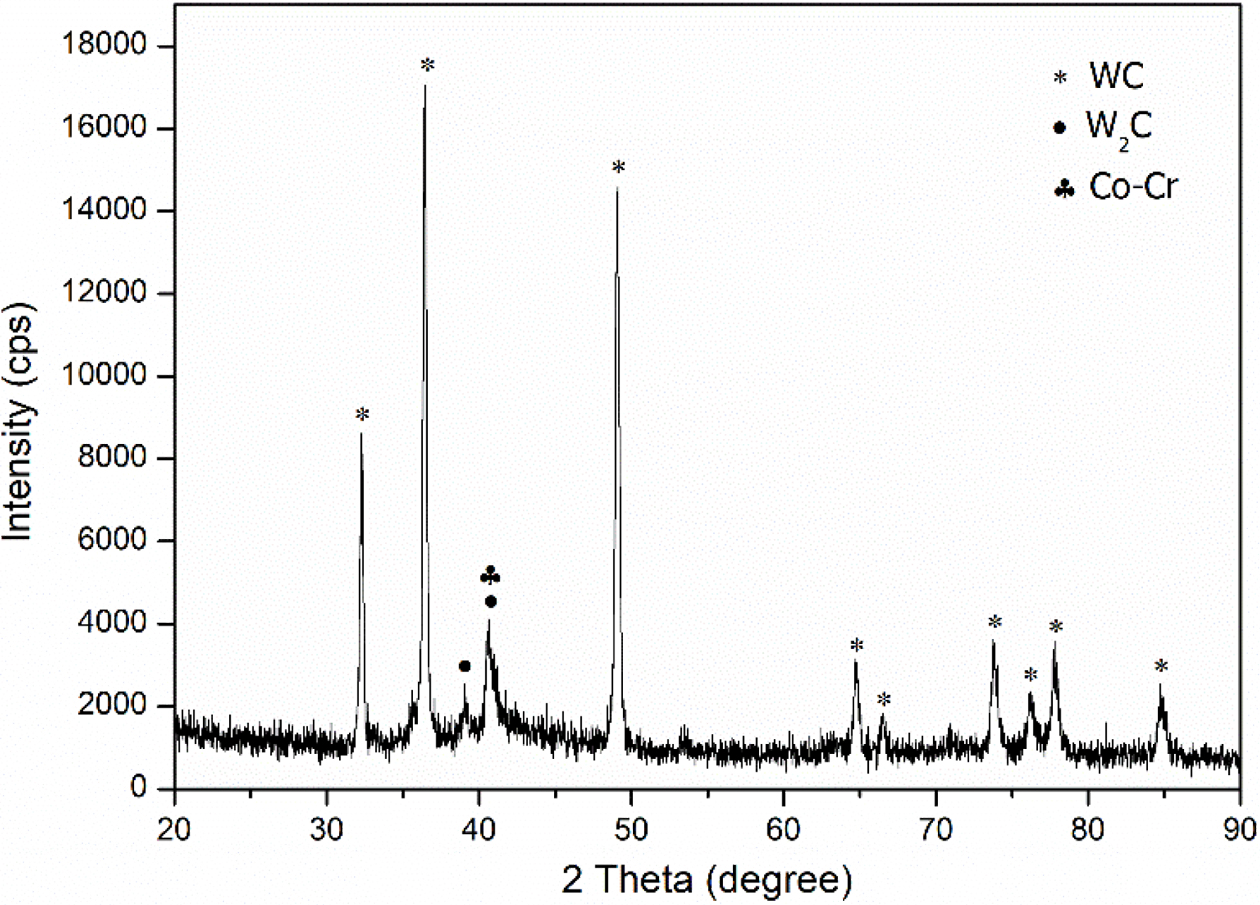

The XRD pattern of the HVOF-sprayed WC-10Co-4Cr coating is presented in Fig. 1. Most diffraction peaks belonging to WC are detected, indicating that the coating is mainly composed of WC phase. Some weak peaks corresponding to W2C and Co-Cr are also confirmed in the XRD result. The content of W2C and Co-Cr phase are relatively low, showing that HVOF method can effectively inhibit the generation of decarbonization phase, mainly due to the high flow nitrogen injected into the flame stream to increase the combustion chamber pressure. Compared to the traditional combustion chamber pressure (0.6-0.9 MPa), the combustion chamber pressure in our work exceeds 2.2 MPa, which provides higher flight speed for powder particles.

Microstructure

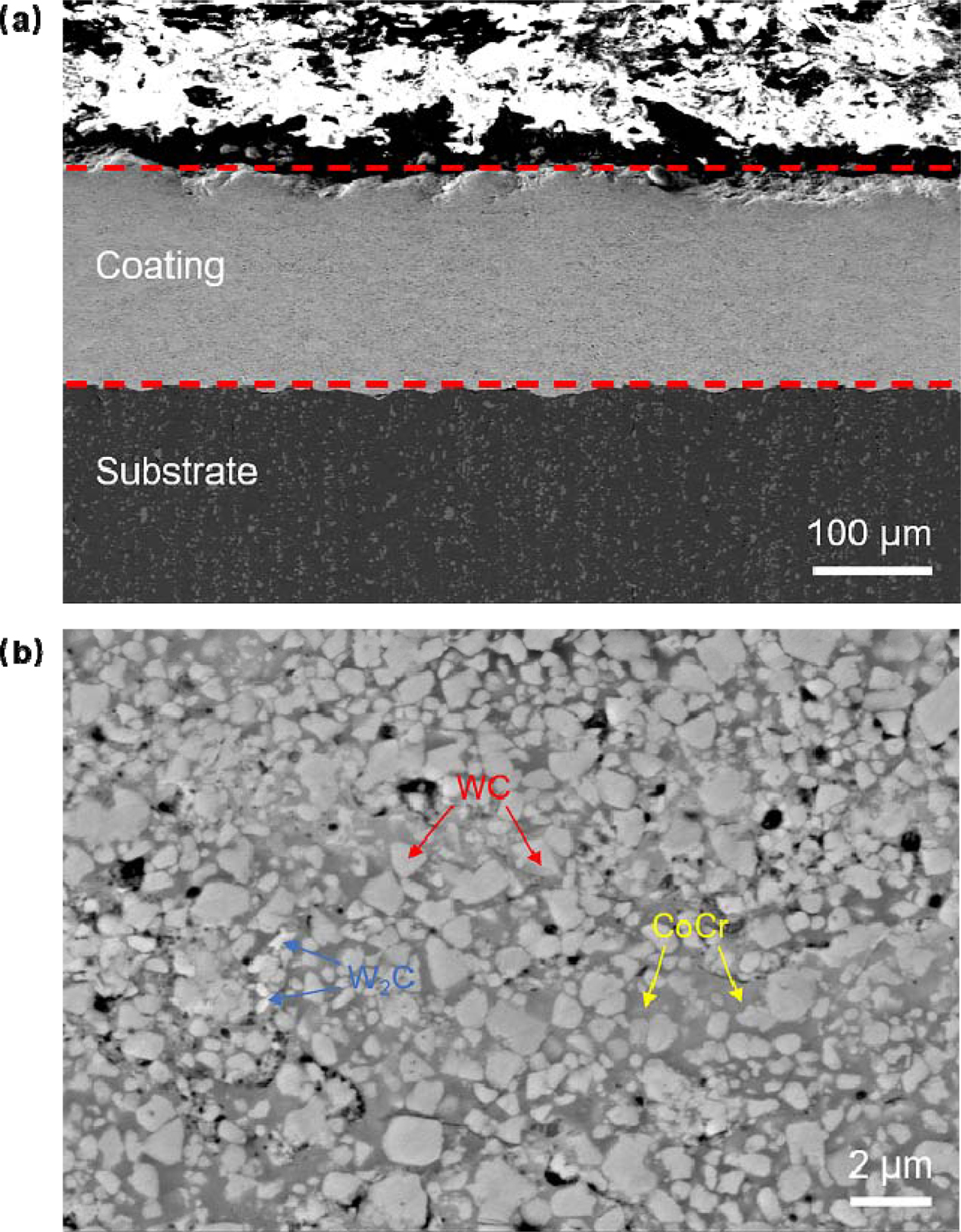

Fig. 2 shows the morphology of prepared coating obtained from HVOF-sprayed method with the spraying distance of 280 mm. The cross-sectional morphology (Fig. 2(a)) shows that the WC-10Co-4Cr coating is dense and continuous, without obvious delamination and cracks. The thickness of the coating is about 190 μm, and the bonding state between the M42 steel substrate and coating is realized by mechanically occluded. A high magnification image (Fig. 2(b)) reveals the presence of W2C (bright white) and Co-Cr (grey) in the prepared coating. The WC grains (grayish white) retain the blocky and angular shape, and are homogeneously distributed in the Co-Cr binder phase. These dispersed WC phase effectively ensure the high hardness of the coating. The aggregation of Co phase and the rich region of Cr phase are unconspicuous. Generally, the Cr -rich region possess the high elastic modulus, which makes the molten particles hardly to achieve “soft landing”, and the residual stress between the particles is accumulated due to the lack of elastic release. The residual stress increases linearly with the increase of Cr -rich region. Therefore, reducing the formation of Cr -rich region is beneficial to improve the performance of spayed coating. In addition, a small amount of W2C phase appears in the coating, which is far less than the reported research [32, 36], further demonstrating that the coating prepared by the HVOF sprayed effectively inhibits the phenomenon of oxidative decarburization. The presence of small quantities of W2C grains are reported to exhibit improved mechanical properties to coatings due to its high hardness of HV3000. The uniformly distributed Co-Cr compound as the soft phase in the coating, has contribution to the fracture toughness of coating, and hence can improve the wear resistance.

Micro-hardness of coating

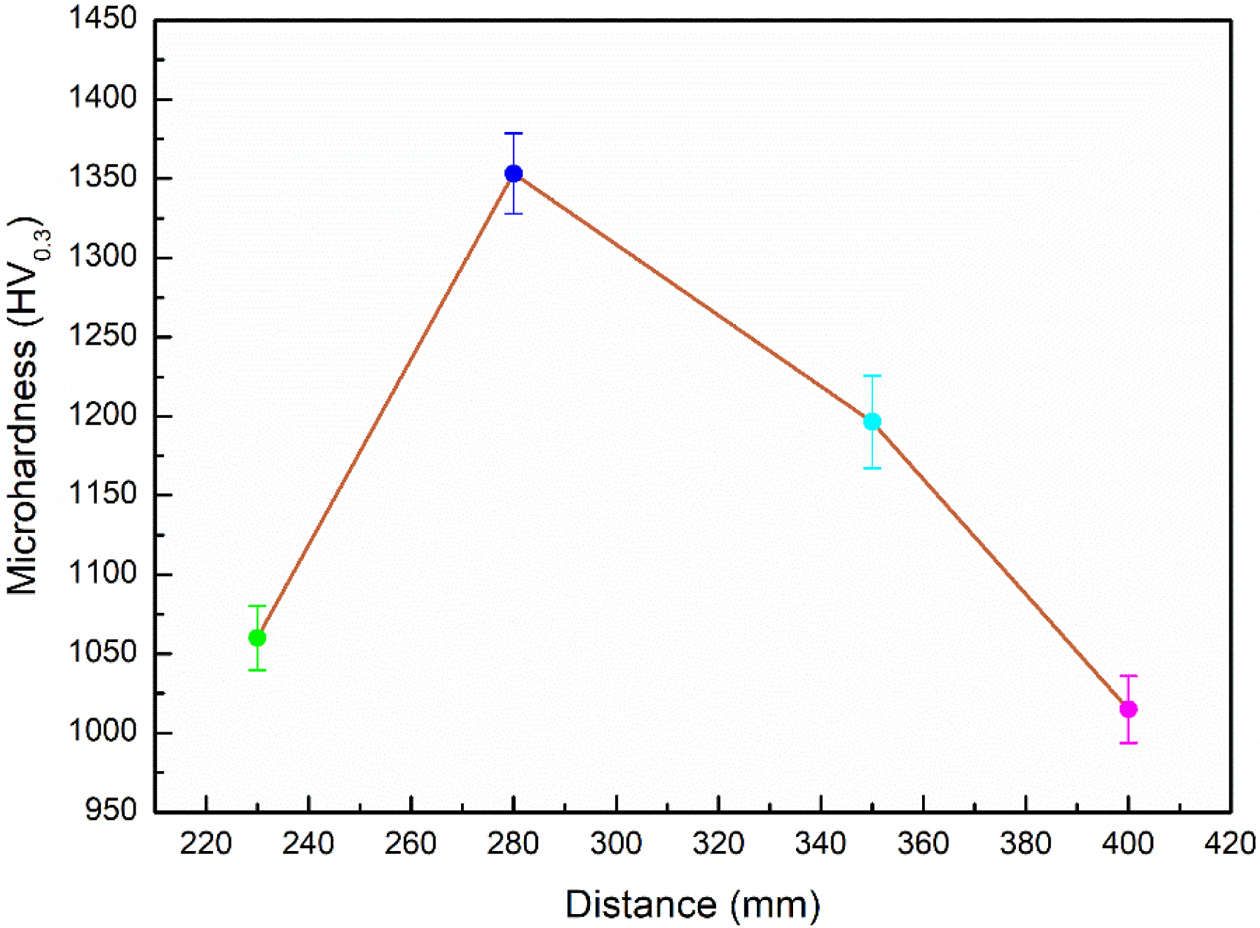

Fig. 3 presents the micro-hardness as a function of spraying distance ranging from 230 mm to 400 mm. A highest hardness of 1353.3 HV0.3 is achieved for spraying distance at 280 mm, which corresponds to a 43% increase, as compared with uncoated M42 steel. When the spraying distance exceeds 280 mm, the micro-hardness of WC-10Co-4Cr coating exhibits a sharp deterioration. When the spraying distance is smaller than 280 mm, the power particles are easy to rebound away the M42 substrate, resulting in an increase of porosity, which can greatly affect the hardness of the coating. With the increase of spraying distance, the micro-hardness didn't present a consistent tendency. The main reason is that the large spraying distance maybe decrease the kinetic energy of powder particles when they reaching the surface of M42 steel, which resulting in a poor densification of the coating.

Sliding wear behavior

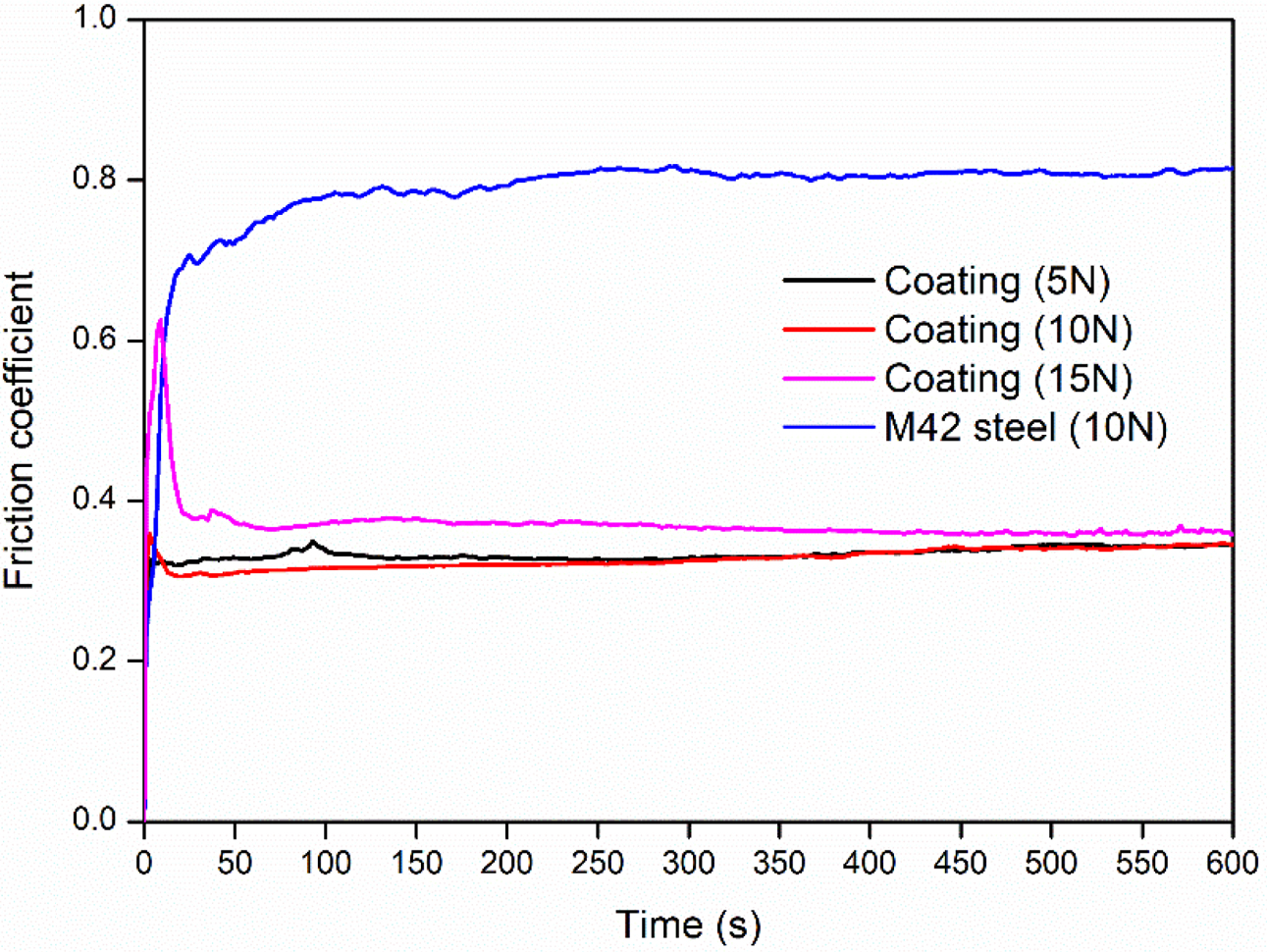

Fig. 4 represents frictional curves of WC-10Co-4Cr coatings and uncoated M42 steel under a function of loads. It is obvious that the friction coefficient of uncoated M42 steel specimens fluctuates greatly at the beginning of the test. After 100 seconds, the friction coefficient of the specimens tends towards stability. Owing to the severe wear on the surface of uncoated M42 steel material, its friction coefficient reaches about 0.79. It is noteworthy that, a moderate fluctuation of friction coefficient is obtained for WC-10Co-4Cr coatings with spraying distance of 280 mm. On applying loads of 5 N and 10 N, the coating shows a lower friction coefficient, only about 0.34, which corresponds to a 57% decrease as compared with uncoated M42 steel. Under a load of 15 N, the coating shows an initial running-in period up to 60 seconds, and then the coefficient of friction is measured to be a stable value of 0.37. Above results have been supported by dense microstructure and high hardness value of 1353.3 HV0.3 for the coating, which is higher than 946 HV0.3 for uncoated M42 steel material. The HVOF-sprayed WC-10Co-4Cr coating undergoes less plastic deformation and exhibits lower friction coefficient as compared with uncoated M42 steel material.

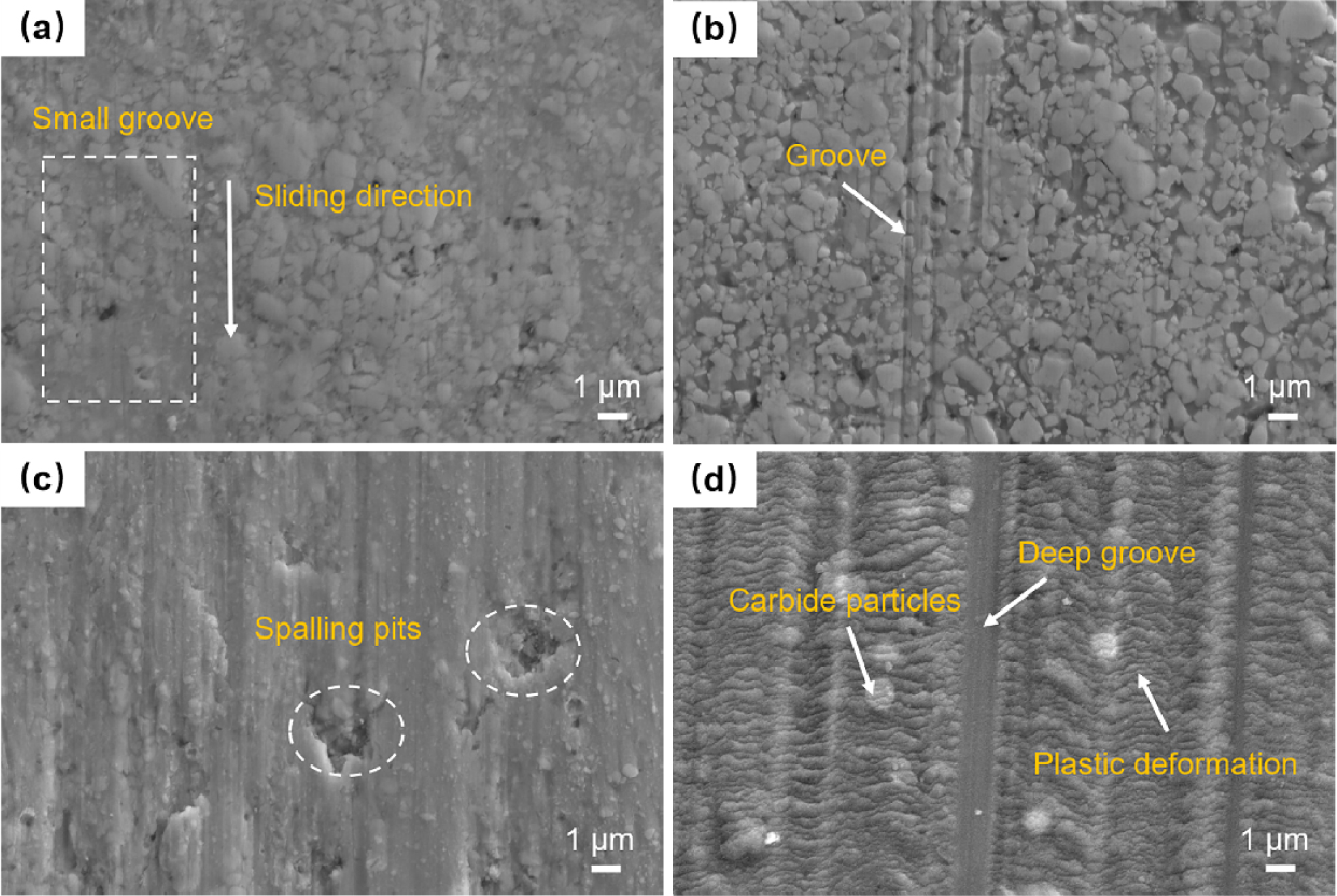

SEM micrographs of worn-out surface for WC-10Co-4Cr coatings under the dry sliding condition at a load of 5 N, 10 N and 15 N are shown in Fig. 5(a-c). The wear tracks of the coatings are smooth, and only few shallow and narrow grooves exist, which are parallel to the direction of sliding. The spalling pits marked in red color in Fig. 5(c) represent a small amount of WC particles pull-outs. The characteristics of worn-out surface of coatings indicate that the main wear mechanism is micro-cutting wear. For comparation, the worn surface of M42 steel subjected to dry sliding wear on applying a load of 10 N load is depicted in Fig. 5(d). The typical plastic deformation morphologies on the uncoated worn surface are observed. This phenomenon causes the materials removed from worn surface directly, sub- sequently forming a hump or skirt shape [50]. The above features suggest that the dominated wear mechanisms of uncoated M42 steel are influenced by severe micro-cutting wear and plastic deformation wear, which consequently enhance the friction coefficient.

During dry sliding progression, the soft binder metallic Co phase acts as solid lubricant in the coating. However, metallic phase is removed continuously with the increase of wear time, resulting in destabilized WC particles pulled out and leading to a slight increase friction coefficient under a load of 15 N. Hence, applying a higher load, a larger coefficient friction for coating was measured. Moreover, at the same load of 10 N, the average width of wear track on uncoated M42 steel was about 1.1 mm (Fig. 5(d)), but that on WC-10Co-4Cr coating was about 0.18 mm (Fig. 5(b)). The HVOF-sprayed WC-10Co-4Cr coating reinforcement is an effective way to decrease the wear damage of uncoated surface. The obvious improved of wear resistance is ascribed to the higher hardness and dense microstructure of the coating.

|

Fig. 1 XRD diffractogram of the HVOF-sprayed WC-10Co-4Cr coating |

|

Fig. 2 Micrographs of prepared coating with the spraying distance of 280 mm. (a) The cross-sectional morphology of WC-10Co-4Cr coating; (b) A high magnification SEM micrograph take from (a). |

|

Fig. 3 Micro-hardness of WC-10Co-4Cr coating changes as a function of the spraying distance. |

|

Fig. 4 Sliding friction coefficients of WC-10Co-4Cr coatings at different loads, compared with that of uncoated M42 steel. |

|

Fig. 5 SEM micrographs of worn-out surface at 5 N, 10 N and 15 N loads of the (a-c) WC-10Co-4Cr coating, compared with the (d) M42 steel at a load of 10 N. |

In summary, dense micro-structured WC-10Co-4Cr coatings deposited on high-hardness M42 steel have been prepared by HVOF spray process. The as-sprayed WC-10Co-4Cr coating is mainly composed of WC phase, with a very small quantity of W2C and Co-Cr phase. Under the spraying distance at 280 mm and the size of 6 feet spray gun, a highest micro-hardness of 1353.3 HV0.3 is achieved, increased by 140% as compared with the uncoated M42 steel. The frictional properties of uncoated M42 steel and the WC-10Co-4Cr coating are comparably studied under dry sliding tests. A low friction coefficient of 0.34-0.37 is achieved for WC-10Co-4Cr coating, showing a 57% decrease than that of uncoated M42 steel. Few destabilized WC particles are pulled out the worn surface, and the number and depth of wear track are greatly less than that of uncoated M42 steel. The enhanced frictional resistance is due to improved hardness and dense microstructure of theWC-10Co-4Cr coating.

This work was supported by Technology Development Fund Project of China Academy of Machinery Science and Technology (212004Q9), and Fujian Science and Technology Key Project (2020H4009).

- 1. P. Potočnik, T. Thaler, and E. Govekar, Procedia Cirp. 8 (2013) 469-474.

-

- 2. S.S. Wang, in “Study on Double Metal Band Saw Blade Heat Treatment and Surface Strengthening Technology” (Dalian University of Technology Press, 2014) p. 3-5.

- 3. X.F. Zhou, W.L. Zhu, H.B. Jiang, F. Fang, Y.Y. Tu, and J.Q. Jiang, J. Iron. Steel Res. Int. 23[8] (2016) 800-807.

-

- 4. Y. Niibo, K. Yuchi, S. Sameshima, and Y. Hirata, J. Ceram. Process. Res. 1[2] (2000) 83-87.

- 5. M.Y. Maximov, A.S. Verevkin, A.A. Orlova, P.A. Novikov, A.O. Silin, O.V. Panchenko, and A.A. Popovich, J. Ceram. Process. Res. 18[2] (2017) 103-107.

- 6. M.R. Kumar, C.K. Behera, S. Mohan, and S. Aich, Mater. Today. 18 (2019) 5416-5420.

-

- 7. R. Colaco, E. Gordo, E.M. Ruiz-Navas, M. Otasevic, and R. Vilar, Wear. 260 (2006) 949-956.

-

- 8. J.H. Lee, S.J. Lee, J.Y. Jeong, and S.J. Kim, J. Ceram. Process. Res. 15[6] (2014) 519-524.

- 9. E.R. García, J.M. Hernández, J.R. García, and E.R. Rangel, J. Ceram. Process. Res. 12[3] (2011) 319-321.

- 10. I. Lee, and I. Park, J. Ceram. Process. Res. 7[2] (2006) 132-135.

- 11. S. Hong, Y.P. Wu, W.W. Gao, J.F. Zhang, Y.G. Zheng, and Y. Zheng, Int. J. Refract. Met. Hard Mater. 74 (2018) 7-13.

-

- 12. T.K. Mishra, A. Kumar, and S.K. Sinha, Int. J. Refract. Met. Hard Mater. 94 (2021) 105404.

-

- 13. A.Z.P. Najib, Z. Kamdi, M.A.A. Patar, M.N.M. Hatta, M.Z. Yunos, and A.R. Ainuddin, Mater. Today. 29 (2020) 100-103.

-

- 14. I. Baumann, L. Hagen, W. Tillmann, P. Hollingsworth, D. Stangier, G. Schmidtmann, M. Tolan, M. Paulus, and C. Sternemann, Surf. Coat. Technol. 405 (2021) 126716.

-

- 15. M.J. Azizpour and M. Tolouei-Rad, Ceram. Int. 45[11] (2019) 13934-13941.

-

- 16. Z. Wei, Y.P. Wu, S. Hong, J.B. Cheng, L. Qiao, J. Cheng, and S.S. Zhu, Surf. Coat. Technol. 409 (2021) 126899.

-

- 17. S. Hong, Y.P. Wu, J.H. Wu, Y.Q. Zhang, Y. Zheng, J.H. Li, and J.R. Lin, Renewable Energy. 164 (2021) 1089-1099.

-

- 18. B. Sun, and H. Fukanuma, J. Therm. Spray Technol. 22 (2013) 263-271.

-

- 19. J.H. Choi, and D.B. Lee, J. Ceram. Process. Res. 7[2] (2006) 136-139.

- 20. K. Murugan, A. Ragupathy, V. Balasubramanian, and K. Sridhar, Surf. Coat. Technol. 247 (2014) 90-102.

-

- 21. S. Hong, Y.P. Wu, Y.G. Zheng, B. Wang, W.W. Gao, G.B. Li, G. Ying, and J.R. Lin, J. Mater. Eng. Perform. 23[4] (2014) 1434-1439.

-

- 22. J. Mao, M. Liu, Z.Q. Deng, C.G. Deng, C.M. Deng, and K.S. Zhou, Rare. Metal. Mat. Eng. 46[12] (2017) 3583-3588.

-

- 23. J.R. Lin, S. Hong, Y.A. Zheng, W. Sun, M. Kang, and X.Q. Fu, Int. J. Refract. Met. Hard Mater. 94 (2021) 105407.

-

- 24. A. Mateen, G.C. Saha, T.I. Khan, and F.A. Khalid, Surf. Coat. Technol. 206[6] (2011) 1077-1084.

-

- 25. W. Tillmann, L. Hagen, D. Stangier, M. Paulus, M. Tolan, R. Sakrowski, D. Biermann, and D. Freiburg, Surf. Coat. Technol. 374 (2019) 448-459.

-

- 26. X.Y. Cui, C.B. Wang, J.J. Kang, W. Yue, Z.Q. Fu, and L.N. Zhu, Eng. Failure Anal. 71 (2017) 195-203.

-

- 27. T. Wang, and F. Ye, Int. J. Refract. Met. Hard Mater. 71 (2018) 92-100.

- 28. R.J.K. Wood, Int. J. Refract. Met. Hard Mater. 28[1] (2010) 82-94.

-

- 29. H. Chen, C. Xu, J. Qu, I.M. Hutchings, P.H. Shipway, and J. Liu, Wear. 259[7-12] (2005) 801-806.

-

- 30. J.H. Jang, I.H. Oh, J.W. Lim, and H.K. Park, J. Ceram. Process. Res. 18[7] (2017) 477-482.

- 31. Q. Wang, X.B. Wu, L.X. Li, Z.G. Li, and S.X. Lin, Procedia Eng. 27 (2012) 1758-1765.

-

- 32. S. Hong, Y.P. Wu, Y.G. Zheng, B. Wang, W.W. Gao, and J.R. Lin, Surf. Coat. Technol. 235 (2013) 582-588.

-

- 33. S.W. Liu, H.J. Wu, S.M. Xie, M.P. Planche, D. Rivolet, M. Moliere, and H.L. Liao, Surf. Coat. Technol. 408 (2021) 126805.

-

- 34. M.S. Zoei, M.H. Sadeghi, and M. Salehi, Surf. Coat. Technol. 307 (2016) 886-891.

-

- 35. K. Kumari, K. Anand, M. Bellacci, and M. Giannozzi, Wear. 268[11-12] (2010) 1309-1319.

-

- 36. T.M. Gong, P.P. Yao, X.T. Zuo, Z.Y. Zhang, Y.L. Xiao, L. Zhao, H.B. Zhou, M.W. Deng, Q. Wang, and A.W. Zhong, Wear. 362-363 (2016) 135-145.

-

- 37. X. Ding, Y. Huang, C.Q. Yuan, and Z.X. Ding, Surf. Coat. Technol. 392 (2020) 125757.

-

- 38. X. Ding, D. Ke, C.Q. Yuan, Z.X. Ding, and X.D. Cheng, Coatings. 8[9] (2018) 307.

-

- 39. L. Thakur, and N. Arora, J. Mech. Sci. Technol. 27 (2013) 1461-1467.

- 40. "

- 41. X. Ding, X.D. Cheng, X. Yu, C. Li, C.Q. Yuan, Z.X. Ding, Trans. Nonferrous Metals Soc. China. 28[3] (2018) 487-494.

-

- 42. J. Liu, X.Q. Bai, T.Z. Chen, and C.Q. Yuan, Coatings. 9[9] (2019) 534.

-

- 43. L. Thakur, and N. Arora, Surf. Coat. Technol. 309 (2017) 860-871.

-

- 44. P.H. Shipway, D.G. McCartney, T. Sudaprasert, Wear. 259[7-12] (2005) 820-827.

-

- 45. D.A. Stewart, P.H. Shipway, D.G. McCartney, Wear. 225-229 (1999) 789-798.

-

- 46. D.A. Stewart, P.H. Shipway, D.G. McCartney, Acta Mater. 48[7] (2000) 1593-1604.

-

- 47. Y.F. Qiao, Y.R. Liu, and T.E. Fischer, J. Therm. Spray Technol. 10 (2001) 118-125.

-

- 48. Y.F. Qiao, T.E. Fischer, and A. Dent, Surf. Coat. Technol. 172[1] (2003) 24-41.

-

- 49. A.H. Dent, S. Depalo, and S. Sampath, J. Therm. Spray Technol. 11 (2002) 551-558.

-

- 50. Q. Zhan, L.G. Yu, F.X. Ye, Q.J. Xue, and H. Li, Surf. Coat. Technol. 206[19-20] (2012) 4068-4074.

-

- 51. D.G. Bhosale and W.S. Rathod, Surf. Coat. Technol. 390 (2020) 125679.

-

This Article

This Article

-

2021; 22(6): 649-654

Published on Dec 31, 2021

- 10.36410/jcpr.2021.22.6.649

- Received on May 17, 2021

- Revised on Sep 1, 2021

- Accepted on Sep 11, 2021

Services

Services

- Abstract

introduction

experimental details

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Xiaogang Lu

-

tate Key Laboratory of Advanced Forming Technology and Equipment, Beijing National Innovation Institute of Lightweight Ltd, Beijing 100083, China

Tel : +86-10-82415063 Fax: +86-10-82415063 - E-mail: 13121200806@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.