- Parametric optimization in squeeze casting of AA6061- Si3N4 composites using Taguchi method

M Thirumal Azhagana,* and B Mohanb

aDepartment of Production Technology, MIT Campus, Anna University, India 600044

bDepartment of Mechanical Engineering, CEG Campus, Anna University, India 600025This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Squeeze casting process is widely employed for the production of automotive and aerospace components. The research on squeeze casting is largely focused on light weight alloys nowadays. In particular, the research on squeeze casting is highly concentrated upon aluminium alloys and their composites in the recent years. In this attempt, aluminium alloy AA6061 was reinforced with silicon nitride (Si3N4) particles and the different grades of composites were developed by squeeze casting process. The parametric optimization was done by using Taguchi method. The parameters namely pressure, die temperature and weight percentage of Si3N4 particles were varied each at three levels. The mechanical properties exhibited by the squeeze cast composites were evaluated. It was observed that the component which was produced at the near optimal parameter setting (pressure of 100 MPa, die temperature of 275 oC and 6% of Si3N4) yielded higher values for mechanical properties of the components

Keywords: Squeeze casting, AA6061, Si3N4, Impact strength, Microhardness.

Nowadays, aerospace and automotive industries are searching for lighter and stronger materials as reduction in weight results in reduced energy consumption and increased fuel efficiency [1, 2]. The demand behind the light weight components is met by the development of metallic materials and alloys of aluminium, titanium and magnesium [3, 4]. The components of aluminium alloy are widely used in the said industries because of their good castability, excellent machinability, high strength-to-weight ratio, and good corrosion resistance properties. Even though aluminium alloy has many advantages, major limitation in aluminium alloy is its strength, which acts as barrier in most of its applica- tions. In order to improve the strength of aluminium alloys, nowadays researchers are moving towards aluminium matrix composites reinforced with ceramic particles [5].

The most commonly used ceramic reinforcements in aluminium alloys which resulted in better mechanical properties are SiC, SiO2, Si3N4, AlN, TiB2, TiC, B4C, BN, Graphite and Zirconium. Amongst these reinforcements, Si3N4 exhibits better corrosion resistance due to the formation of silicon oxynitride protective layer such that Si3N4 particles are utilized in this work. Gravity and pressure die casting processes are mostly employed to process aluminium alloys but the cast components are prone to various defects such as porosity, blow holes, segregation and hot tears etc. As the industries are in competitive pressure, the scenario drives them to seek out newer processes which have the capability to eradicate the defects in the cast products [6, 7]. This can be made possible by squeeze casting process as it has the potential to produce quality products without defects. Squeeze casting process is the pressurized solidification of molten metals. The process of squeeze casting involves the following steps [8-12].

• Preheating the die and the punch mounted on the hydraulic press.

• Pouring molten metal into the preheated die cavity

• Applying pressure over the molten metal until the completion of solidification

• Withdrawing punch and separating the solidified casting

As the high pressure is applied during the solidifi- cation of molten metal, porosities due to gas and shrinkage are prevented or eliminated in this process. With the application of pressure, the contact between the molten metal and the die wall improves which in turn leads to the increase in the cooling rate of the molten metal and as a result, fine grained casting with enhanced mechanical properties is formed [13-23].

Meanwhile some researchers like Vijian (2006), Senthil et al. (2012) Thirumal Azhagan et al. (2014) indicated that the casting parameters need to be optimized to produce defect free components. Though research papers on squeeze casting have been appearing in the literature frequently, it appears that so far not much work has been attempted to predict the influential process parameter for producing squeeze cast components. In order to fill this gap, this research work focuses on the study of the influence of the process parameter namely, ‘pressure’ in improving the mechanical properties such as impact strength and microhardness exhibited by squeeze cast components of AA6061-Si3N4 using Taguchi method. This method can also be used to provide the near optimum setting for each parameter and parameter combination at which the process has to be run in order to obtain the best yield [12-15, 24].

Taguchi method uses special set of arrays called as orthogonal arrays to conduct the experiments. The number of experiments required can be drastically reduced by choosing orthogonal arrays such that enormous amount of time and cost can be saved. The quality characteristics frequently used are nominal-the-best, smaller-the-better and larger-the-better. As this research is focused to enhance the impact strength and the microhardness exhibited by the squeeze cast com- ponents, ‘larger the better’ type quality characteristic is considered in this work.

The die set employed in this research was fabricated using H11 die steel. Squeeze casting dies are exposed to severe thermal and mechanical cyclic loading, which may cause thermal fatigue, cracking, erosion, corrosion and indentation. Hence a suitable die material should have good hot hardness, adequate toughness and espe- cially a high degree of cleanliness and uniform micro- structure. Currently H11 tool steel is a widely used die material in squeeze casting process. The presence of chromium upto 5.50% in H11 tool steel resists softening while used at higher temperatures. The other alloying elements such as molybdenum, silicon and vanadium act as strengthening agents when H11 tool steel is employed in hot working applications.

The Hydraulic press used to apply the pressure over the molten alloy during solidification was shown in Fig. 1. The die set and the punch were fitted on to the hydraulic press. The die set was preheated by means of a ceramic electrical heater. The muffle furnace which was used to melt the aluminium alloy AA6061 was shown in Fig. 2. After reaching the molten state, preheated Si3N4 particles were added slowly to the molten alloy and were simultaneously stirred at a speed of 250 rpm by using a stirrer. The average grain size of silicon nitride (Si3N4) particles employed in the research work was 52 microns. Different grades of AA6061-Si3N4 composites were produced by varying the Si3N4 reinfor- cements in the weight percentages of 2%, 4% and 6% respectively. The formation of clusters occurred during stirring when the percentage of reinforcements were increased beyond 6% such that the weight percentage of Si3N4 reinforcements was restricted only to 6% in this attempt.

The molten mixture was then poured into the die and the pressure of 100 MPa was applied on the molten alloy with the help of punch fitted onto the hydraulic press. The influence of applied pressure on mechanical properties of squeeze cast aluminium alloys was experi- mentally evaluated by Vijian & Arunachalam (2005 & 2006), Senthil & Amirthagadeswaran (2012), Thirumal Azhagan et al. (2015 &2020) and they concluded that the pressure in the range of 100 MPa was found to yield appreciable improvement in mechanical properties of the castings. Hence, squeeze pressure of 100 MPa was applied on the molten mixture for a period of 30 seconds in this attempt.

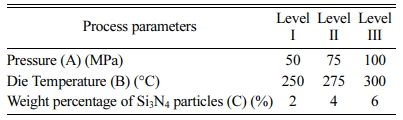

The casting was ejected from the die upon solidifi- cation. The major parameters considered in this work are pressure (A), die temperature (B) and weight percentage of Si3N4 particles (C) respectively and the details are presented in Table 1. The said parameters were assigned in (L934) orthogonal array and nine experiments were conducted and the components were produced by varying the parameters each at three levels. The components so produced are shown in Fig. 3.

|

Fig. 1 Hydraulic Press |

|

Fig. 2 Muffle Furnace. |

|

Fig. 3 Squeeze cast components. |

Impact test

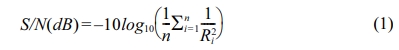

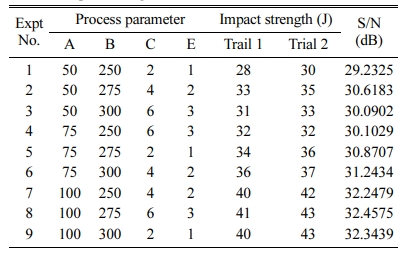

The impact tests were performed using Charpy Impact tester. The test specimens were made as per ASTM E23 Standard and were shown in Fig. 4. The impact strength exhibited by the test specimens and their S/N ratio values were presented in the Table 2. The S/N ratios for the impact strength values were found using Eq. (1).

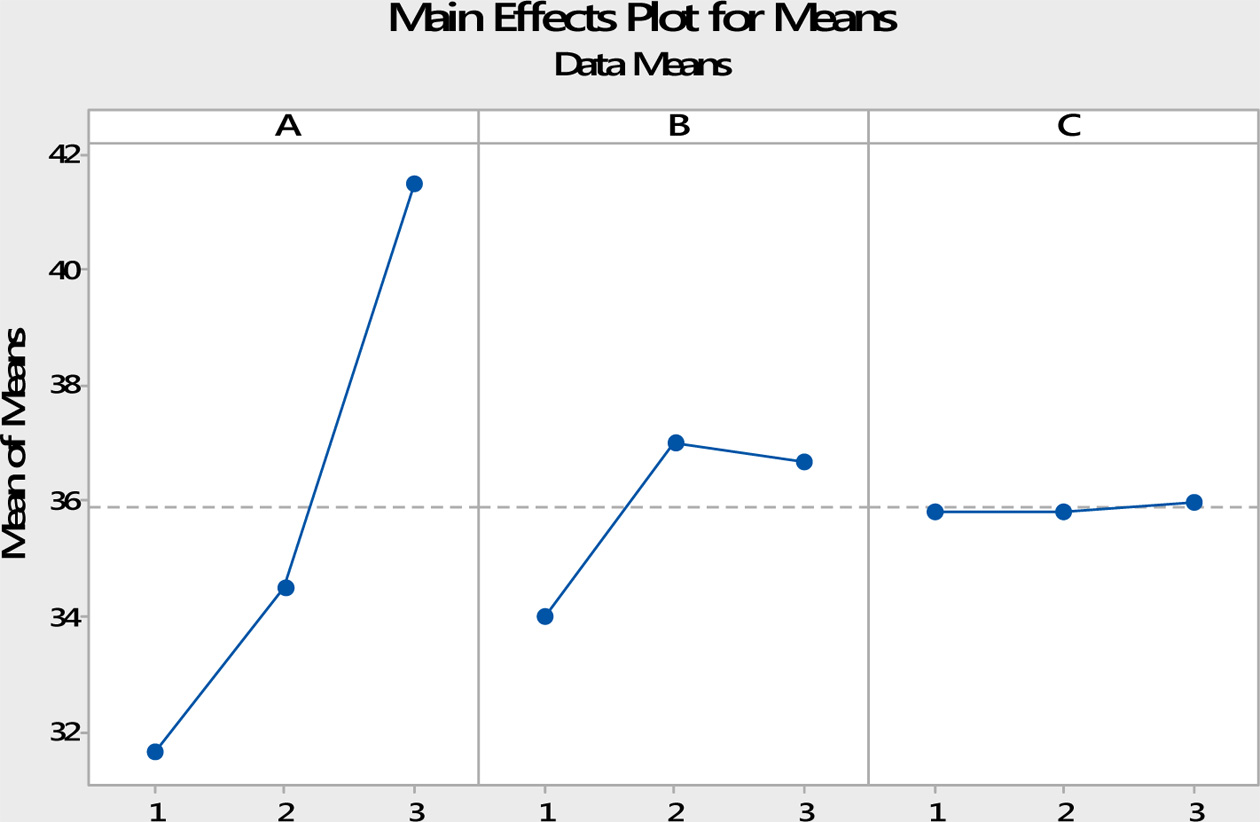

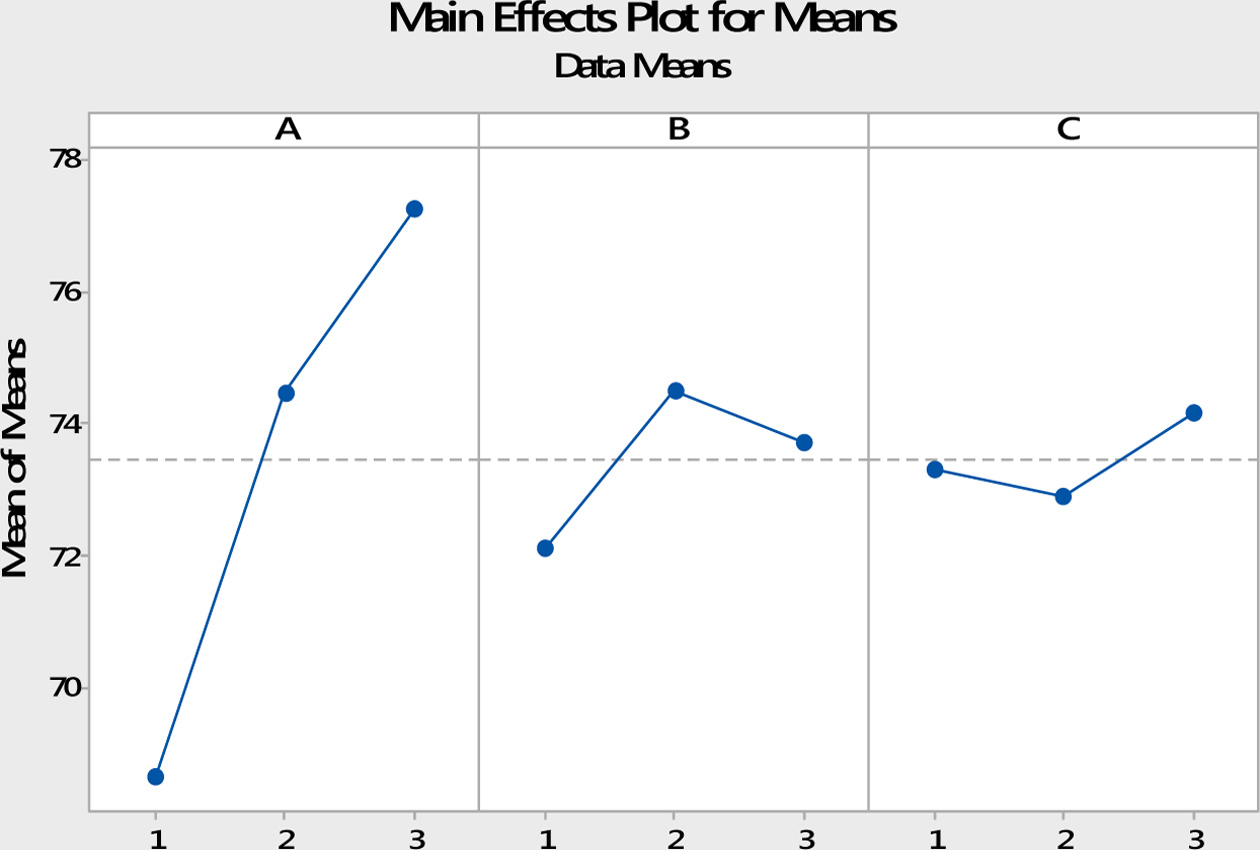

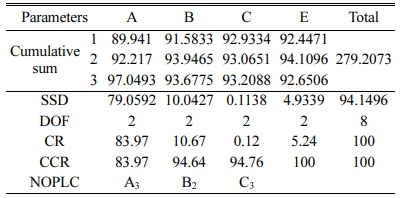

The individual contribution ratio of each process parameter, near optimal process parameter level com- bination and the most dominant process parameter towards the enhancement of impact strength can be obtained by computing Pareto ANOVA. The Pareto ANOVA for impact strength is given in Table 3. The individual contribution ratio of each process parameter was obtained from Table 3 where pressure (A) contri- buted 83.97%, die temperature (B) contributed 10.67% and weight percentage of Si3N4 particles (C) contributed 0.12% towards the impact strength exhibited by the squeeze cast components of AA6061. From the Table 3, it was evident that the most influential process parameter involved in this study was pressure (A) as it contributed 83.97% towards enhancement of impact strength. From the Table 3, third level of pressure (100 MPa), second level of die temperature (275 oC) and third level of weight percentage of Si3N4 particles (6%) was obtained as near optimal parameter level combina- tion. It is also pictorially depicted in Fig. 5.

Microhardness Test

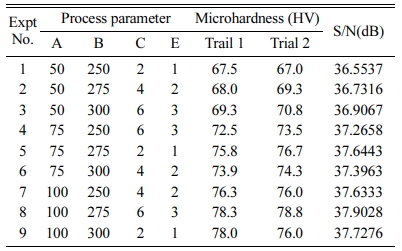

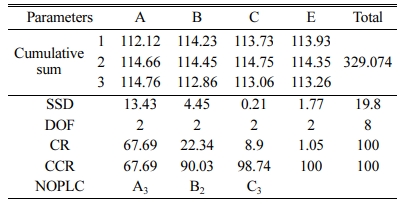

Vicker’s Hardness Testing Machine was used to conduct microhardness tests. The test specimens are shown in Fig. 6. The tests were conducted as per ASTM E10 standard. The micro hardness values and their corresponding S/N ratios are presented in the Table 4. The S/N ratios for the microhardness values were found using Eq. (1). The Pareto ANOVA for microhardness is given in Table 5. The individual contribution ratios of the process parameters observed were 67.69% for pressure (A), 22. 34% for die tem- perature (B), and 8.9% for weight percentage of Si3N4 particles (C) respectively. It was clear from Table 5, that the squeeze pressure (A) was the most influential process parameter as it contributed 67.69% towards the enhancement of microhardness. From the Table 5, third level of pressure (100 MPa), second level of die tem- perature (275 oC) and third level of weight percentage of Si3N4 particles (6%) was obtained as near optimal parameter level combination. As the hard Si3N4 particles act as barriers to the movement of dislocations within the AA6061matrix, the microhardness of the composites increases. The results confirmed the increase in micro hardness by using Si3N4 as reinforcement in AA6061 matrix. It is also pictorially depicted in Fig. 7. These levels can enhance the microhardness of the components. But the actual scenario will be known only after the confirmation test.

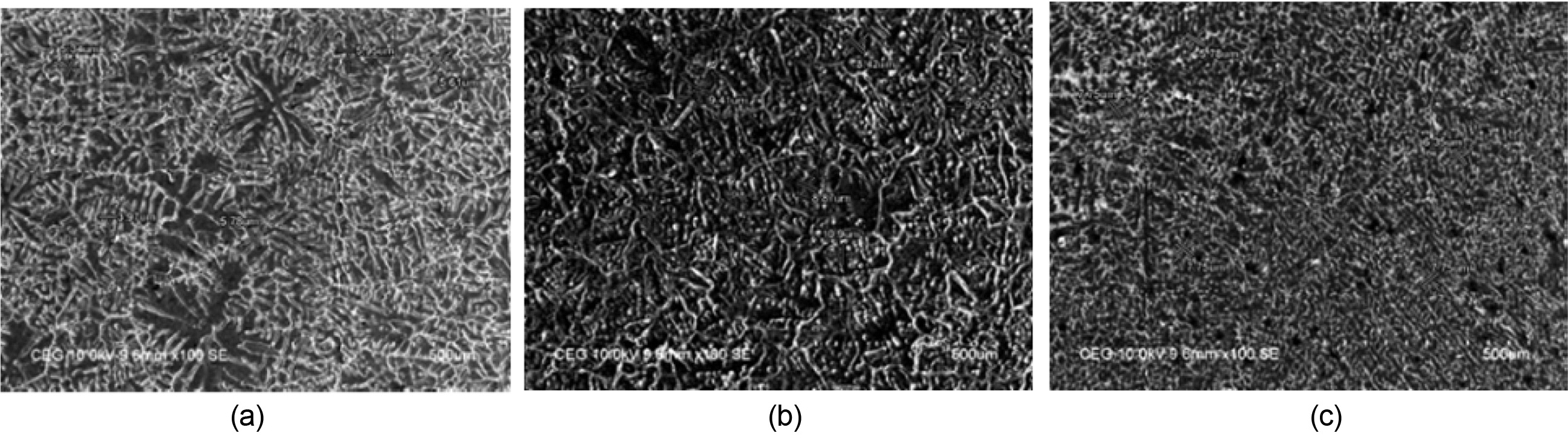

The Confirmation test was conducted at the near optimal setting condition (pressure of 100 MPa, die temperature of 275 oC and weight percentage of Si3N4 particles of 6%) and the components were produced. The test specimens exhibited enhanced impact strength (45 J) and enhanced microhardness values (80 HV) than the components produced during initial experimental runs. The SEM Micrographs were obtained at three level of squeeze pressures namely 50 Mpa, 75 Mpa and 100 Mpa and were shown in Fig. 8(a-c) respectively. It was observed from the Figs. 8(a-c), the microstructure obtained at 100 MPa was a refined one and the size of the grains were smaller compared to the other micrographs.

The influence of pressure in squeeze casting process was experimentally evaluated by Vijian & Arunachalam (2005 & 2006), Senthil & Amirthagadeswaran (2012), Thirumal Azhagan et al. (2014 & 2015) and they con- cluded that the mechanical properties were improved as well as the microstructures were refined in squeeze casting because of the application of pressure on the molten alloy during solidification. The result obtained in this study is well consistent in principle with the results obtained in similar works. To be very precise, level three of pressure namely 100 MPa was found to yield appreciable improvement in the mechanical pro- perties exhibited by squeeze cast components of AA6061.

|

Fig. 4 Impact strength specimens. |

|

Fig. 5 Response curve for impact strength. |

|

Fig. 6 Microhardness specimens. |

|

Fig. 7 Response curve for microhardness |

|

Fig. 8 (a-c). SEM Micrographs: (a) SEM micrograph at 50 Mpa, (b) SEM micrograph at 75 Mpa c.SEM micrograph at 100 Mpa. |

The squeeze casting of AA6061 components were done as per the experimental conditions of (L934) orthogonal array. The squeeze cast parameters were varied each at three levels and squeeze cast components were produced. The specimens were made as per the ASTM standards and the impact strength and the microhardness of the components were evaluated. It was observed that the component which was produced at the near optimal parameter setting A3 B2 C3 (pressure of 100 MPa, die temperature of 275 oC and weight percentage of Si3N4 particles of 6%) yielded higher values for impact strength and microhardness. From the results, it is evident that when the level of pressure applied (100 MPa) is kept at the highest level, the hydraulic shock encountered at the molten alloy causes the rapid heat transfer rate thereby promoting rapid solidification which in turn leads to the formation of fine grained structure such that the squeeze cast components exhibited improved mechanical properties.

The authors are grateful to the Department of Production Technology, MIT Campus for supporting this research work.

- 1. B.-K. Hwu, S.-J. Lin, and M.-T. Jahn, Mat. Sci. Eng. A 206[1] (1996) 110-119.

-

- 2. X.N. Zhang, L. Geng, and G.S., Wang, J. Mater. Process. Tech. 176[1-3] (2006) 146-151.

-

- 3. M.R. Ghomashchi and A. Vikhrov, J. Mater. Process. Tech. 101[1-3] (2000) 1-9.

-

- 4. P. Vijian and V.P. Arunachalam, J. Mater. Process. Tech. 170[1-2] (2005) 32-36.

-

- 5. S.M. Skolianos, G. Kiourtsidis, and T. Xatzifotiou, Mat. Sci. Eng. A 231[1-2] (1997) 17-24.

-

- 6. K. Sukumaran, K.K. Ravikumar, S.G.K. Pillai, T.P.D. Rajan, M. Ravi, R.M. Pillai, and B.C. Pai, Mat. Sci. Eng. A 490[1-2] (2008) 235-241.

-

- 7. M.T. Azhagan, B. Mohan, and A. Rajadurai, Appl. Mech. Mater. 541- 542 (2014) 349-353.

-

- 8. M.T. Azhagan, B. Mohan, and A. Rajadurai, IJET 6[1] (2014) 183-189.

- 9. P. Vijian and V.P. Arunachalam, Int. J. Adv. Manuf. Tech. 33[11-12] (2007) 1122-1127.

-

- 10. M. Thirumal Azhagan, B. Mohan, and A. Rajadurai, Appl. Mech. Mater. 766-767 (2015) 422-426.

-

- 11. P. Vijian and V.P. Arunchalam, J. Mater. Process. Tech. 180[1-3] (2006) 161-166.

-

- 12. P. Senthil and K.S. Amirthagadeswaran, J. Mech. Sci. Technol. 26[4] (2012) 1141-1147.

-

- 13. P. Vijian and V.P. Arunachalam, J. Mater. Process. Tech. 186[1-3] (2007) 82-86.

-

- 14. M. Bangaru, T.A. Murugan, and R. Arunachalam, in Proceedings of the ASME 2015 International Mechanical Engineering Congress & Exposition IMECE, November 2015, edited by ASME (ASME, 2015) p.1-8.

-

- 15. M.T. Azhagan and B. Mohan, Mater. Today: Proc. 28 (2020) 931-935.

-

- 16. P. Senthil and K.S. Amirthagadeswaran, Arab. J. Sci. Eng. 39[3] (2014) 2215-2225.

-

- 17. A. Onat, H. Akbulut, and F. Yilmaz, J. Alloy. Compd. 436[1-2] (2007) 375-382.

-

- 18. L. Poovazhagan, K. Kalaichelvan, and A. Rajadurai, Trans. Indians. Inst. Met. 67[2] (2014) 229-237.

-

- 19. G.C.M. Patel, A.K. Shettigar, and M.B. Parappagoudar, J. Manuf. Process. 32 (2018) 199-212.

-

- 20. W. Jianga, J. Zhua, G. Li, F. Guan, Y. Yu, and Z. Fan, J. Mater. Sci. Technol. 88 (2021) 119-131.

- 21. M. Lakshmanan, J. SelwinRajadurai, V. Chakkravarthy, and S. Rajakarunakaran, Mater. Lett. 285 (2021) 1-4.

-

- 22. A. Gnanavelbabu, K.T.S. Surendran, P. Loganathan, and E. Vinothkumar, J. Alloy. Compd. 856 (2021) 158-173.

-

- 23. J. Zhu, W. Jiang, G. Li, F. Guan, Y. Yu, and Z. Fan, J. Mater. Process. Tech. 283 (2020) 1-11.

-

- 24. Y.-C. Lin, J.-C. Hung, H.-M. Chow, and A-C. Wang, J. Ceram. Process. Res. 16[2] (2015) 249-257.

This Article

This Article

-

2021; 22(4): 470-474

Published on Aug 31, 2021

- 10.36410/jcpr.2021.22.4.470

- Received on Feb 2, 2021

- Revised on Mar 29, 2021

- Accepted on Apr 19, 2021

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- M Thirumal Azhagan

-

Department of Production Technology, MIT Campus, Anna University, India 600044

Tel : +91 9962593286 - E-mail: thirumalazhaganm@gmail.com, E-mail: thirumalazhag

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.