- Development of bamboo stem Ash-Al-Hybrid reinforced with Al2O3 produced by stir casting technique

T. Nithyanandhana and R. Ramamoorthib,*

aAsst. Professor, Sri Krishna College of Technology, Coimbatore

bProfessor, Sri Krishna College of Engineering & Technology, CoimbatoreThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Aluminium matrix composites (AMCs) are the emerging and competent materials for numerous structural applications owing to their virtuous mechanical and physical characteristics. The inclusion of reinforcements into the metallic matrix enhances the specific strength, stiffness, hardness, creep, wear and fatigue properties related to general materials used for engineering applications. In this research work an attempt has been made to examine the fundamental mechanical properties of Al6063 hybrid metal matrix composite with two different fillers such as Al2O3 and Bamboo stem ash (BSA) as reinforcements by means of stir casting route. The mechanical properties of the resultant composites are observed as per ASTM standards and microstructural study is used to characterize the distribution of reinforcements. The result reveals that there is an enhancement in mechanical properties of the resultant composite material by the inclusion of Al2O3 and BSA reinforcements, this in turn recommend that this Al6063 composite has a substantial potential in various engineering applications as compared to pure Al6063.

Keywords: Al6063, Aluminium oxide, BSA, stir casting method, microstructure, SEM Analysis, tensile strength, impact strength, and hardness

The development of low cost and high performance advanced materials for various engineering applications has continued to draw the attention of researchers in material engineering field. Many researchers developed numerous composite materials by using different type of matrix, reinforcement size, shape and volume as well as suitable processing technique depending upon the requirement and application. The aluminium based alloys are realized as very encouraging among other metal matrix composites as an approach to attain a light material with enriched mechanical properties. In fact, some engineering properties which are considered weak for aluminium alloys could be dramatically improved by adding a hard phase either in particulate or in fiber form [1-3]. The selection of reinforcement material for Al matrices is quite critical to assure the optimal combinations of properties are harnessed [4]. The development of Aluminium Metal Matrix Composites was to reduce the cost and also improve the Material Properties by using of Agro and local Industrial Waste as Reinforcements [5].

Graphite, silica sand, fly ash and rice husk ash and are a few examples of industrial and agro materials that have been used as reinforcement in aluminium matrix composites [6-9]. Alaneme and Olusegun et al. studied the microstructure and mechanical behavior of aluminium alloy reinforced with various proportions of BSA and silicon carbide. The results revealed that the fracture toughness and tensile strength of the all hybrid com- posite are superior to that of single reinforced and non-reinforced material [10]. Ravi Kumar et.al investigated the mechanical properties of aluminium metal matrix with reinforcement of coconut shell ash and zirconium oxide. The result of this investigation shows that the density increased with percentage of reinforcement. The hardness of the reinforcement would be increased with the maximum percentage of zirconium. The impact strength is higher in 10% of zirconium in the aluminium metal matrix [11].

Rajesh & Mohammed Kaleemulla et al developed and studied the hybrid aluminium matrix composite reinforced with silicon carbide (SiC) and aluminium oxide (alumina) by using stir casting. The Hardness test and wear test were performed on the specimens that are prepared by stir casting techniques. They concluded that the inclusion of silicon carbide and alumina particles in Al7075 alloy reduces the wear rate at high speed of the disc and improves the hardness of the composite material [12]. Johny James S et al. examined that the Hybrid Aluminium Metal Matrix Composite Reinforced with SiC and TiB2 fabricated by using stir casting technique. This reinforced composites produced the result to improve the hardness and tensile strength of the composite materials. The two reinforced materials are equally distributed in the aluminium alloy through the micro structure test.it has been proved that he wear resistance will be increased in the more reinforced composites [13]. Atuanya C U et al. investigated that the microstructure and properties of the aluminium alloy reinforced with silicon carbide and Bamboo leaf stem ash by using stir casting technique. This result shows that the particles of silicon carbide and bamboo leaf stem ash are evenly distributed in the aluminium alloy. The tensile strength and hardness values are improved by 16.93% and 12.15% at 15 wt% BLSAp. The density and impact energy is slightly reduced by 14.91% and 18.64% at 15 wt% BLS Ap [14].

Pitchayyapillai G et al. examined the Al6061 Hybrid Metal Matrix Composite Reinforced with Alumina and Molybdenum Disulphide is fabricated by using stir casting method. This metal matrix composites improved the mechanical properties such as tensile and hardness value would be increased in more percentage of alumina. The wear resistance of the composites are also increase in a maximum percentage of alumina [15]. Kenneth Kanayo Alaneme et al. investigated the Microstructure, mechanical and fracture properties of groundnut shell ash and silicon carbide dispersion strengthened aluminium matrix composites. The result of this investigation found that the tensile and hardness strength increased with increase percentage of the reinforcement in the aluminium alloy. The percentage of elongation improved marginally with increases percentage of GSA content. Fracture toughness is also improved with an increased in GSA content [16].

Bharath V & Madev Nagaral et al. have done an experiment of mechanical and wears properties of aluminium alloy with reinforcement of aluminium oxide by using stir casting method. The result found that the particles of the aluminium oxides are uniformly distri- buted in the aluminium alloy. The hardness and the tensile strength of the composites are increased with increasing weight % of aluminium oxide [17]. Kenneth Kanayo Alanemea et al. examined the Corrosion and wear behaviour of Al-Mg-Si alloy matrix hybrid com- posites reinforced with rice husk ash and silicon carbide by using double stir casting method. This result shows that the corrosion resistance of the composites are improved in 3.5% of NACL solution. The wear resistance of the hybrid composite are increased with maximum percentage of the silicon carbide [18].

Oluyemi Ojo Daramola & Olusegun Adebayo Ogunsanya et al. have done an experiment on Mechanical properties of Al 6063 metal matrix composites reinforced with 2, 4, 6 and 8 vol.% agro-wastes silica particles prepared by double stir casting method. The results showed that the ultimate tensile strength, hardness values and impact strength of the developed composites increased with increase in the silica volume fractions while the percentage elongation and fracture toughness decreased with increase in silica volume fractions [19]. Pridhar T & Boopathi C et al. has done an experiment on the Mechanical properties of Al7075 with reinforcement of alumina and boron carbide particulates prepared by stir casting techniques. In this experimental, reinforcement alumina has various altitude of 2, 4, 6, 8 and 10 wt% and other one boron carbide has 5 wt% kept as constant for all specimens. The result concludes that the properties would be improved in reinforcement materials [20].

Bamboo stem ash particles (BSA) can be one of the most inexpensive and low density reinforcement. Hence, composites with BSA as reinforcement are likely to overcome the cost barrier for wide spread applications in automotive, Marine and small engine applications. It is therefore expected that the incorporation of BSA in aluminium alloy will promote yet another use of this low-cost waste by-product and at the same time, have the potential for conserving energy-intensive aluminium and thereby, reducing the cost of aluminium products.

In this present work was to study the microstructural behaviour of aluminium metal matrix with different percentage of Agro waste reinforcements and to improve the Mechanical properties of the composite Materials (Al-Al2O3-BSA). Mechanical properties like density, hardness, impact strength, flexural strength and elongation of the hybrid composites were studied. The micro structure of the composite specimens is going to study by using optical microscope and SEM analysis.

Aluminium 6063

Al 6063 is an alloy used in this work as shown in Fig. 1, because it has good mechanical and chemical properties. This alloy has well in heat treatment and weldable process. This alloy was purchased from the delars in Coimbatore metal mart, Tamil Nadu. Al 6063 is used for various applications such as frames, auto- mobiles, aerospace and marine engineering. It has a good surface completion material, high corrosion resistance mostly suited for welding.

Aluminium Oxide (Al2O3)

Aluminium oxide is the reinforced particle used in this work because it makes the material as high hardness while added to the aluminium alloy. It was purchased from the dealers in Coimbatore metal mart Tamil Nadu. The particles were sieved to a size of 350 µm. The chemical properties of the aluminium oxide are tabulated. Fig. 2 shows the aluminium oxide particle.

Bamboo Stem Ash (BSA)

The waste dried Bamboo stem of 20 kg were cut with the aid of hack saw. The reinforcing filler was produced by burning some dried bamboo stem using a metallic drum which served as burner. The dried bamboo stem was ignited using charcoal and allowed to burn completely inside the drum. The process was then conditioned in a furnace at a temperature of 600 oC for 5 h. The charcoal is crushed by using rammer. The mass of the rammer was maintained by 10 kg. The ash obtained from the above process was using a digital sieve shaker. The bamboo ash was sieved to sizes of 350 µm. The Fig. 3 shows the prepared of BSA particle.

Experimental setup

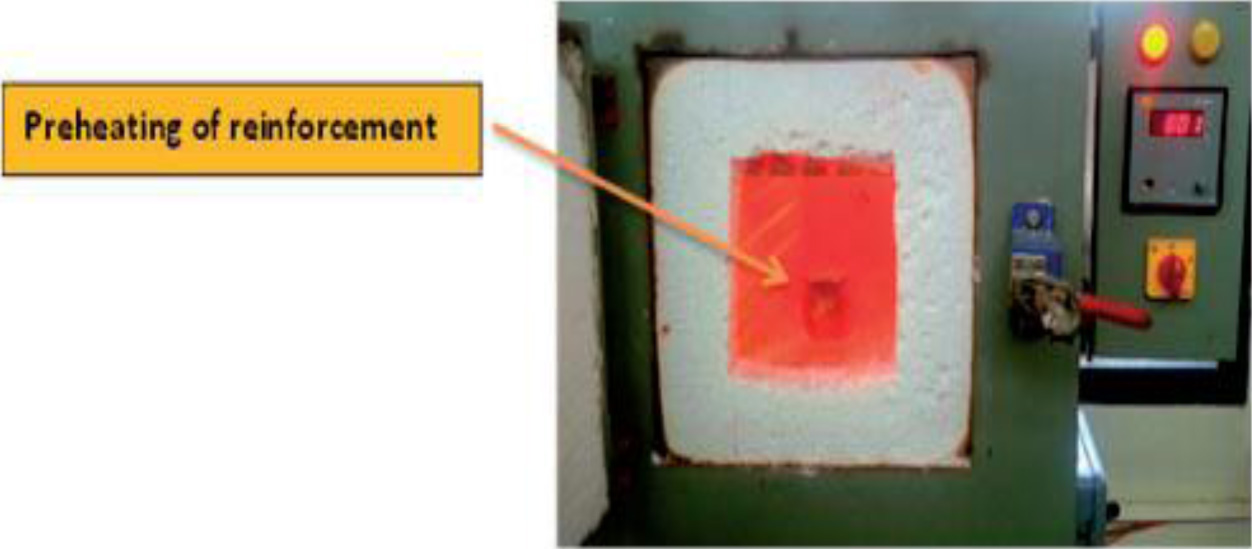

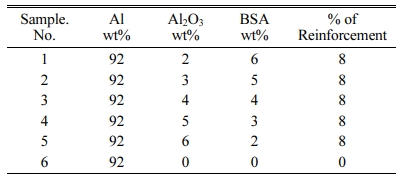

The production of hybrid aluminium metal matrix composites in this work was fabricated by using stir casting method is shown in Fig. 4. The pure aluminium alloy is cut into small pieces and put into furnace. The reinforcement particles are preheated separately at a temperature of 250 oC in the Electrical Resistance furnace was done to aid removal of moisture content and improves wettability with the molten aluminium is shown in Fig. 5. The aluminium was melted in the furnace, at a temperature of 715 oC, and then the preheated BSA and aluminium oxide were charged into the melt while stirring of the slurry was performed for 5-10 min. After completing the stirring process, the melted composite was poured in the mould which spinner along its central axis for 30 min. After this, the stir casting machine was switched off and the metal matrix composite was left to cool at room temperature for few minutes then the cast composite is to be removed. This procedure was repeated for all other compositions. The size of the composite are maintained 30 ´ 300 mm length. Totally six samples are fabricated in different weight percentage of reinforcements. The composition and weight percen- tage of the each sample are tabulated in the Table 1. The Fig. 6 shows the samples of composite materials.

Preparation of testing samples

Preparation of metallographic specimens

The composite specimen are machined and reduced to diameter of 15mm and length of 5mm and they were mounded and well Polished with 200, 400, 600, 800, 1,000 and 2,000 grit emery paper followed by double disk polishing machine and etching was made using keller (solvent) on the surfaces of the specimens as shown in Fig. 7. The examination of the micro structure was done by using optical microscope.

Hardness test

The cast Aluminium/Al2O3/BSA hybrid composites were subjected to hardness test to analyse the effect of Al2O3/BSA. The composite specimens are machined and reduced to diameter of 30 mm and length of 25 mm are polished in double disk polishing machine to get a good surface finish for doing hardness test.The hardness test is conducted through Brinell hardness tester. In this hardness tester having a load carrying capacity of 250 Kgf is used in the study. The polished composite specimen was experimented using a ball indenter of 5 mm in diameter. All the experiments in hardness test were conducted in five places on the surface of the each sample and the average values were used for the study. The Fig. 8 shows the samples of composition for hardness test as per standard.

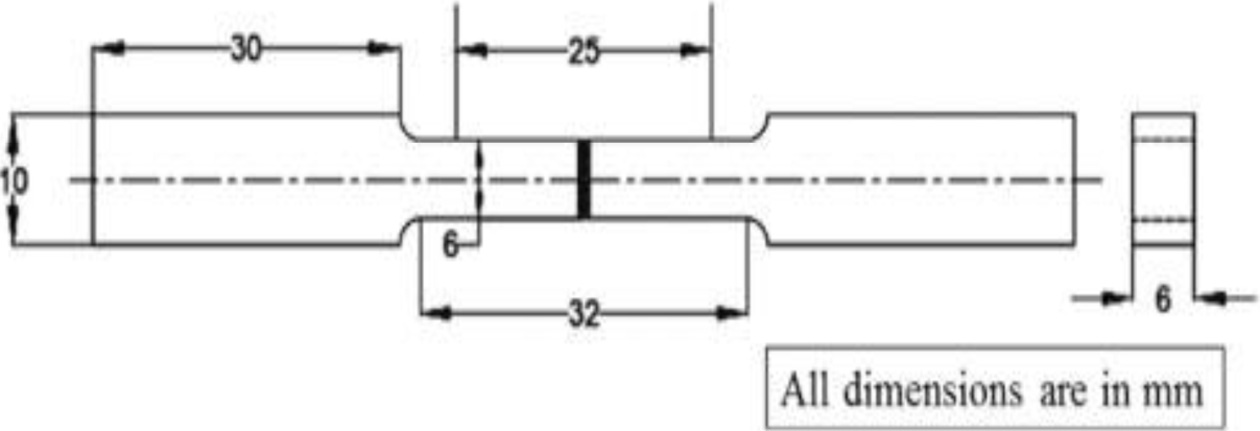

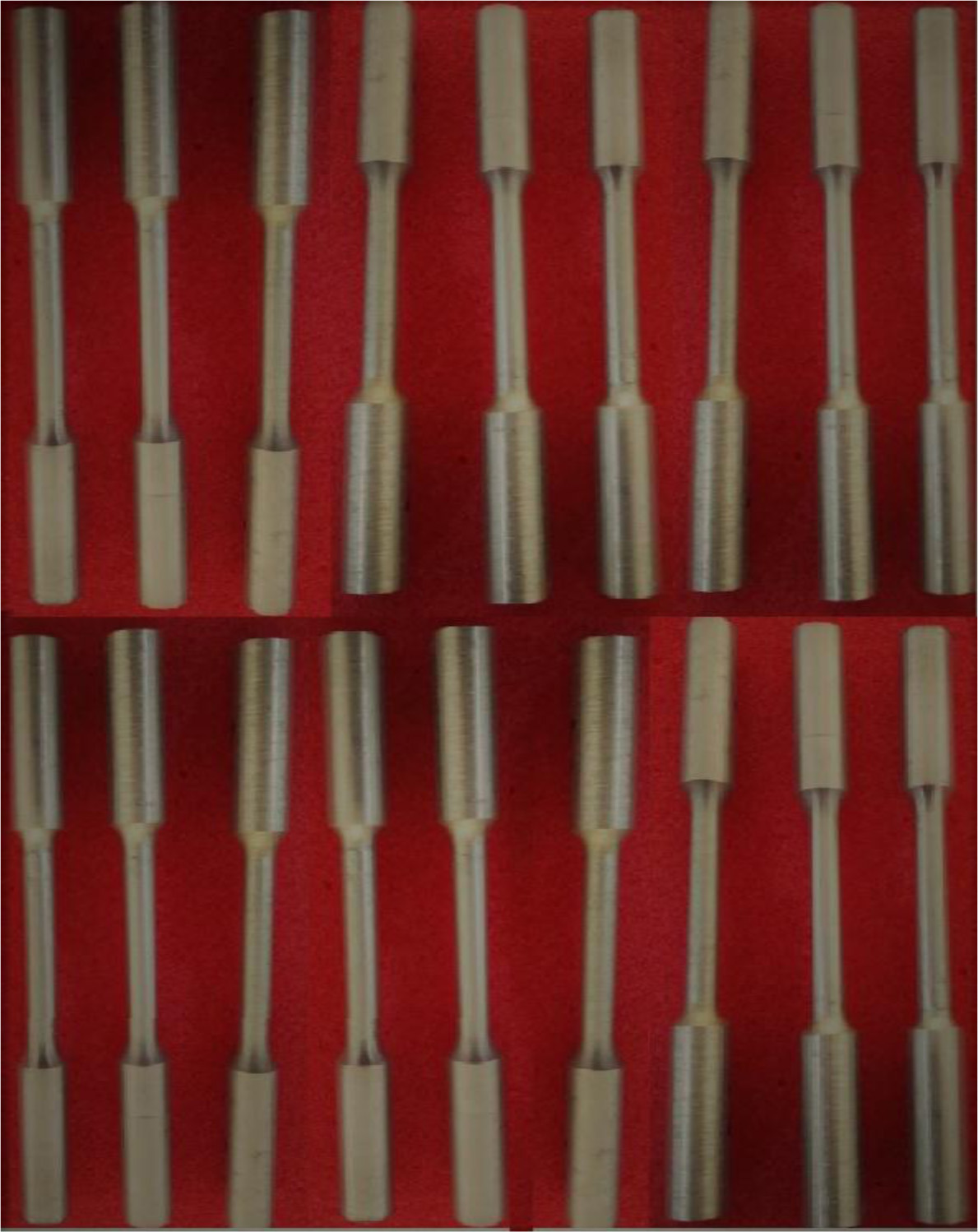

Tensile test

The aluminium hybrid composites are subjected to tensile test for finding the deformation of each com- position. This test are conducted in the room temperature using Universal Testing Machine, having a load capacity of 20 KN. The specimen was prepared as per ASTM E08 standard shown in Fig. 9. In order to increase the accuracy of the result, all the experiments in the tensile test are conducted for three specimens in each com- positions and finally the mean value is consider for the study. The Fig. 10 shows the samples of composition for tensile test as per standard.

Impact test

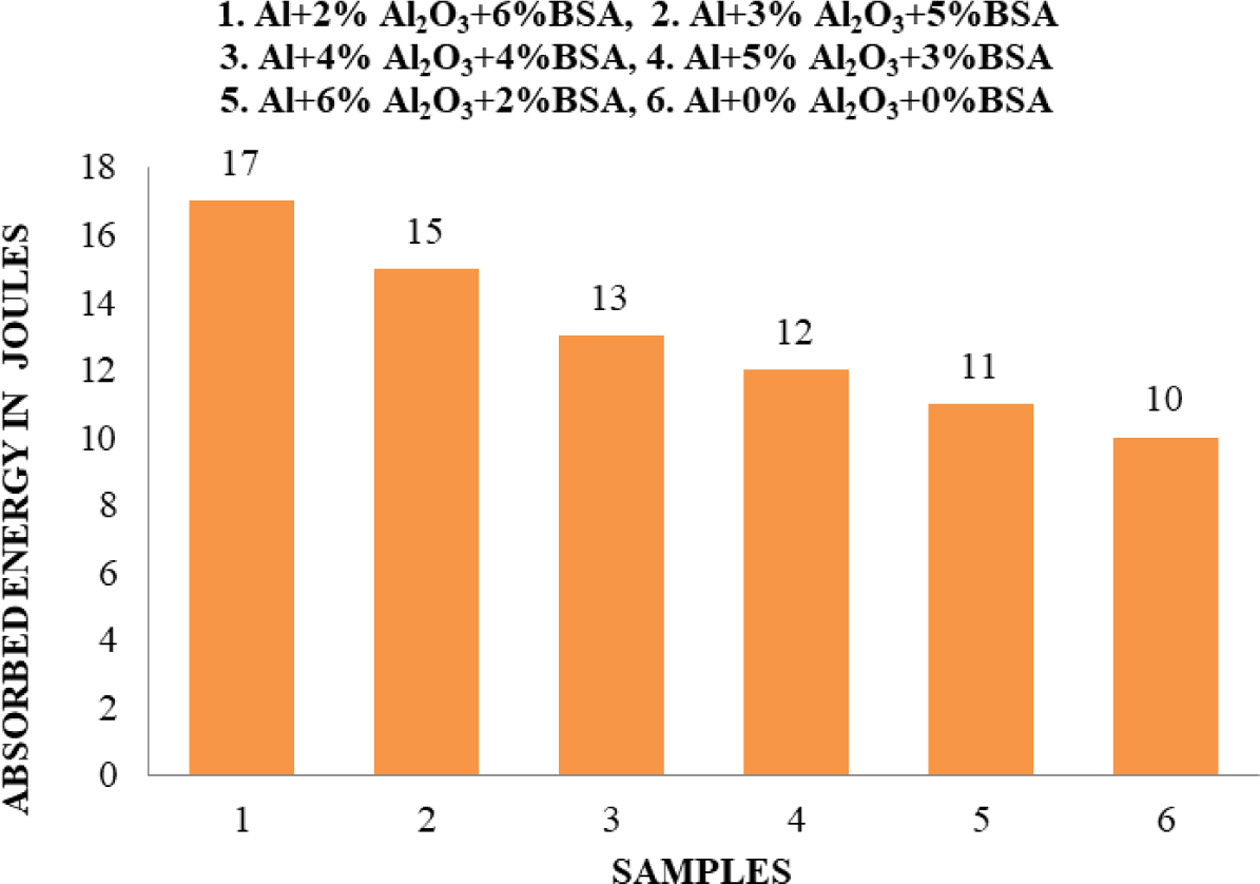

The reinforced hybrid composites materials are subjected to impact test for analysing the toughness and ability to absorb energy for the each different weight percentage of the composition. The specimen for this test are prepared as per ASTM of square bar (55 mm x 10 mm x 10 mm) with 45 degree V notch cutting at the mid span of the specimen, and the impact test was carried out in room temperature. The reading is evaluated using Charpy V-notch impact testing machine. All the experiments of this test are conducted for three specimens in each reinforced samples to reduce the inaccuracy of the result. At last the average value of the reading is considered to the study.

|

Fig. 1 Al 6063. |

|

Fig. 2 Aluminium Oxide (Al2O3). |

|

Fig. 3 Bamboo stem ash. |

|

Fig. 4 Stir casting setup. |

|

Fig. 5 Electrical resistance furnace. |

|

Fig. 6 Samples of composite materials. |

|

Fig. 7 Samples of metallographic specimen of composites. |

|

Fig. 8 Samples of hardness test of composites |

|

Fig. 9 Geometry of uniaxial tensile test specimen as per ASTM standard. |

|

Fig. 10 Samples of tensile test of composites. |

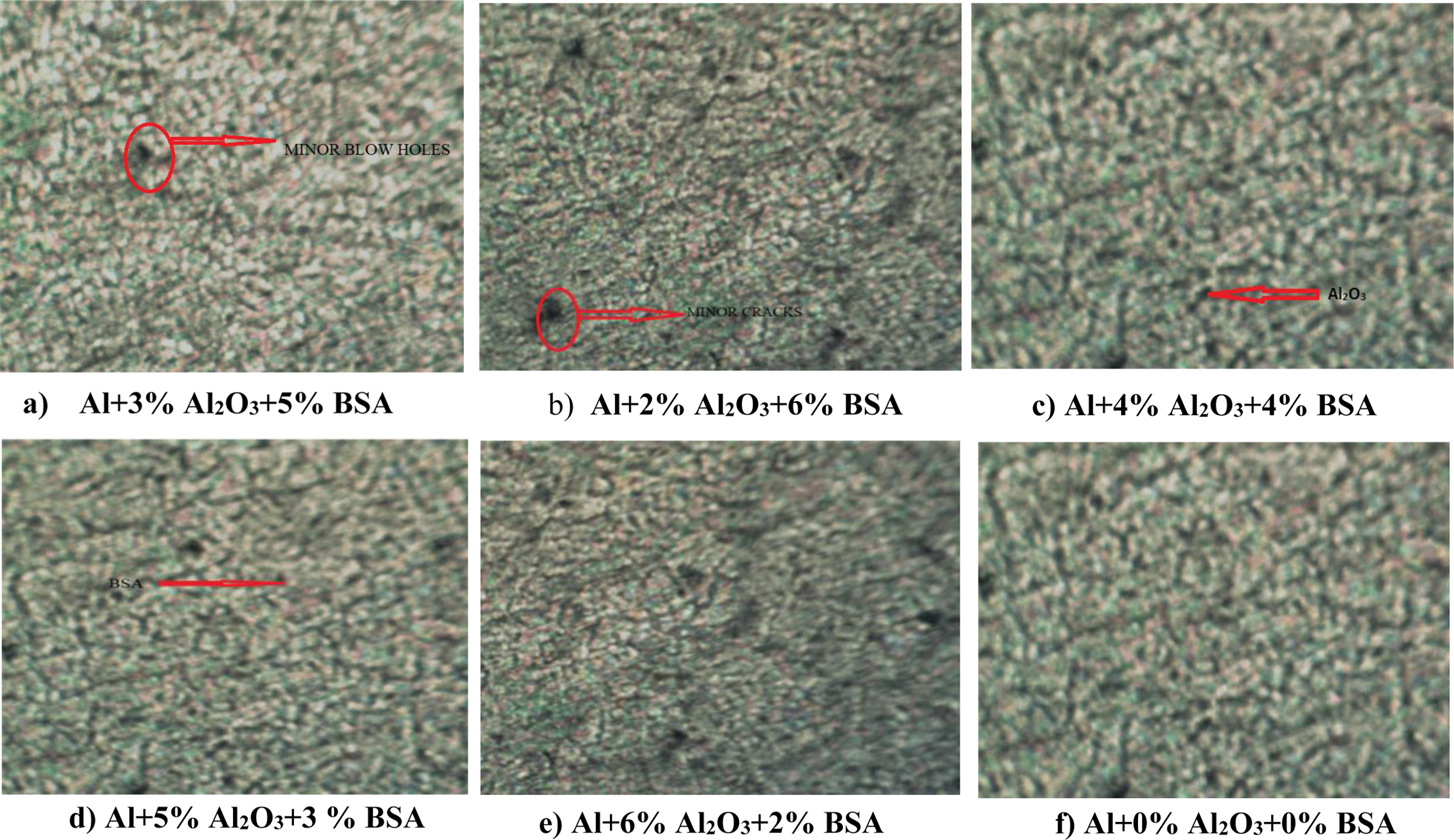

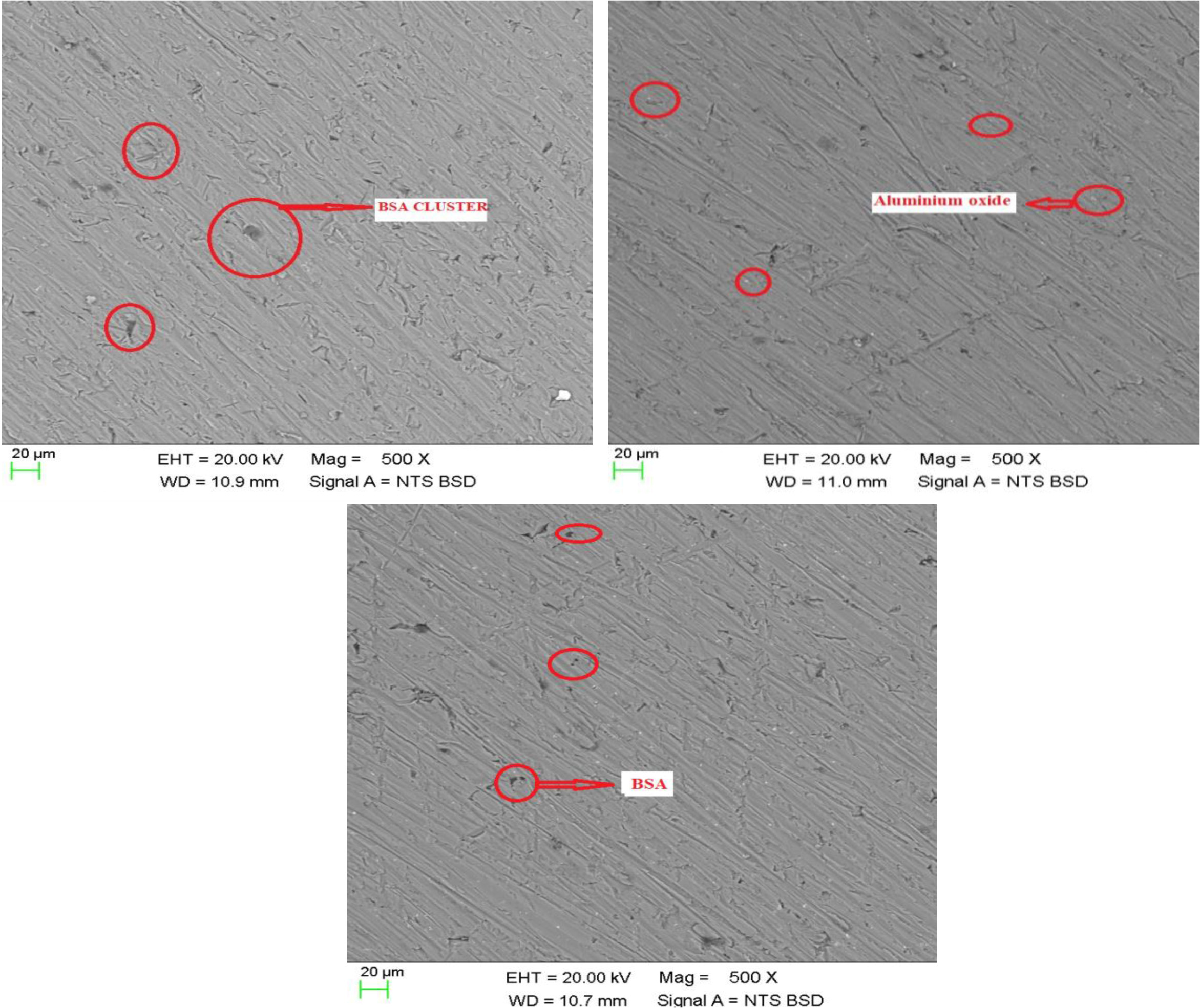

Effects of aluminium oxide and BSA on micro- structure study

Fig. 11. Show that 50x Magnification of the optical micrographs for Aluminum hybrid composites reinforced with BSA and Al2O3. It was observed that the reinforcing particles (BSA and Al2O3) are equally spaced and uniformly dispersed in the Aluminum matrix with fine grain refinement and good structure. The photomicro- graph also clearly reveals the increased filler contents in the composites. From the Fig. 11, it is clearly observed that the grain size reduces as the percentage of BSA particles increases. The good formation of structure and the grain refinement are obtained due to the addition of BSA and Al2O3 particles in the matrix alloy. Because of effect of process parameters such as wt% of reinfor- cement, preheating temperature of reinforcement, stirring speed, die preheating temperature with optimal level, uniform distribution of BSA particles throughout the matrix can be noticed from the micrographs. From this study, we can understand that the processing parameters in the stir casting method play an important role in the betterment of improved mechanical properties. Distribution of reinforced particulates is influenced by process of solidification. From the micrograph it is clearly shows that the bonding between three constituent phases is excellent. From this study we can found that mechanical and tribological properties are the main role to develop the composites. Due to the effect of choosing optimal process parameters, the BSA particles and BSA surround- ed by Al2O3 that forms clusters are also uniformly distributed in the base matrix alloy. The Micrograph shows that the minor cracks and blow holes are formed in the higher percentage of BSA particle compare with other reinforcements. With the increase in BSA particles the nucleation sites also get increased, and it also makes more chance of cracks and blow holes in the composites.

The SEM microstructure of the cast aluminium/Al2O3/BSA is appeared in Fig. 12. Homogeneous dissemination of Al2O3 and CBA particles is important to have a composite with reliable mechanical properties. It tends to be seen that pores are absent in the com- posites demonstrating a legitimate projecting. Uniform dispersion of Al2O3 and CBA particles is seen along the surface. The high contrast particles demonstrate the presence of Al2O3 and CBA separately. Grouping of CBA is additionally seen along some surface because of the likelihood that the CBA particles may coast because of its less thickness prompting a non-uniform combination. Uniform dispersion impacts a solid in- terfacial holding strength between the grid and support, in this way improving the mechanical properties of composites.

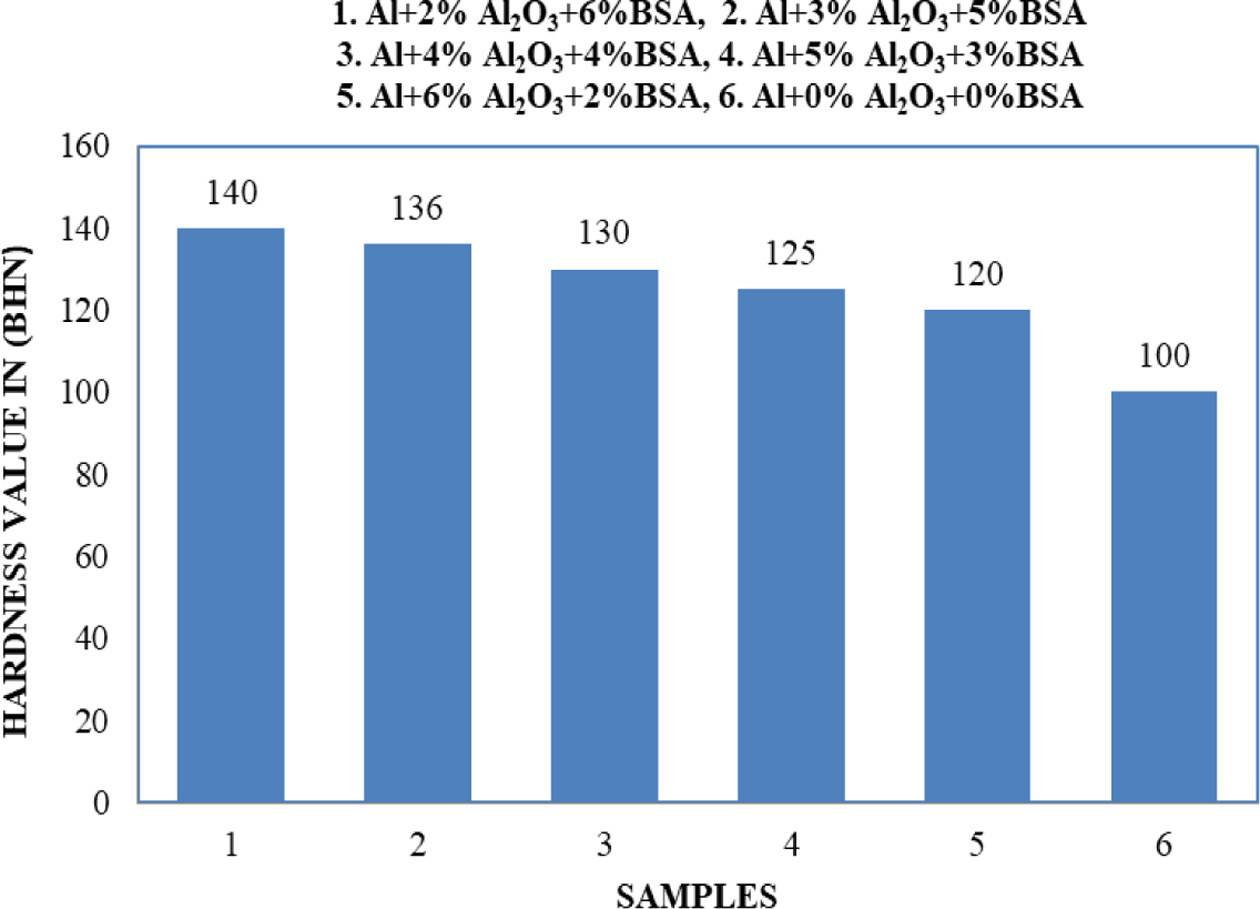

Effects of aluminium oxide and BSA on hardness test

The effect of adding different weight percentage of Al2O3 and BSA in aluminium matrix is shown in Fig. 13. The Fig. 12 show that the sample 1 which contains 6 wt% of BSA and 2 wt% of Al2O3 having higher hardness value of 140 BHN (Brinell Hardness Number) and the sample 6 having lower hardness value of 100 BHN which contains non-reinforced aluminium. This result also shows that the hardness values of the composites are higher that than of the Pure aluminium alloy. The hardness value increases in the percentage of BSA reinforcement increases up to 6 wt% and the value decreases in the percentage of aluminium oxide reinforcement increased up

to 6 wt%. Hence from the above analysis we can say that the strength of the aluminium metal matrix composite is more at 6 wt% of BSA and 2 wt% of aluminium oxide.The improvement in the hardness values may be attributed to the presence of reinforcement is uniformly distributed by reduced grain size.it is observed that as the volume % of the BSA particle increases, the hardness of the composite was also increased.

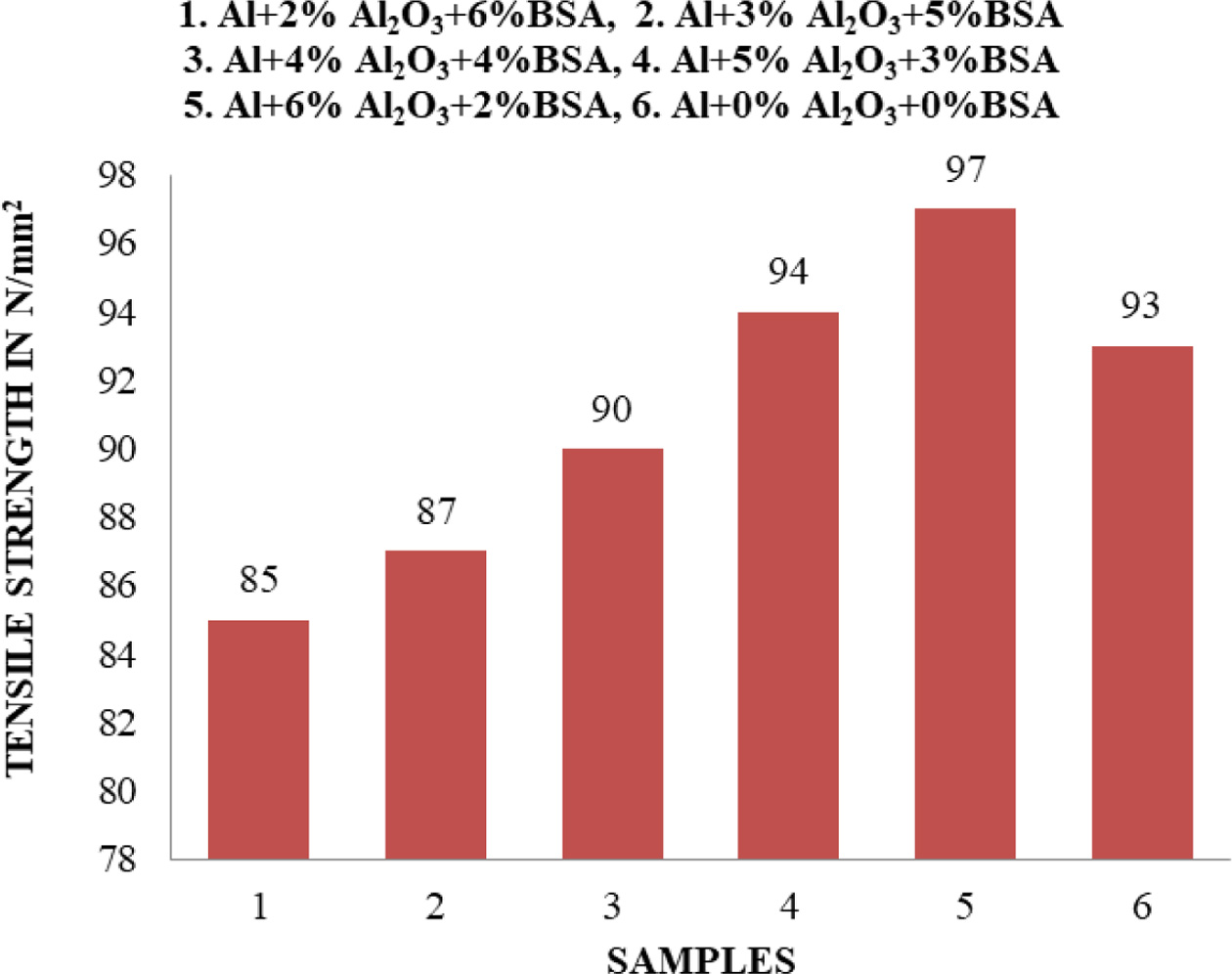

Effects of aluminium oxide and BSA on tensile strength

Influences of adding different weight percentage of Al2O3 and BSA in aluminium matrix is shown in Fig 14. The result shows that the sample 5 having higher tensile value which contains 2 wt% of BSA and 5 wt% of Al2O3 and the sample 1 having less tensile value which contains 6 wt% of BSA and 2 wt% of Al2O3. This result also shows that the tensile values of the sample 1 (2% Al2O3 & 6% BSA), sample 2 (3% Al2O3 & 5% BSA) & sample 3 (4% Al2O3 & 4% BSA) are slightly decreased that than of the Pure aluminium alloy. The tensile values of the samples 4 (5% Al2O3 & 3% BSA) & sample 5 (6% Al2O3 & 2% BSA) are slightly increased compare to pure aluminium alloy. Hence from the above analysis we can say that the stiffness of the aluminium metal matrix composite is more at 2 wt% reinforcement of BSA and 6 wt% reinforcement of aluminium oxide. From Fig. 13 the tensile stress of the composite is found to decreases as the content of BSA particulates is increased up to 6% by weight. This happens because of the presence of blow holes and porosity in the maximum reinforcement of BSA samples and also the presence of aluminium oxide the hardness increased, the high hardness makes the less tensile strength. The work (Olaniran O et al., 2017) showed that when BSA particulate increases up to 5% properties such as tensile strength increases. This happens because of the mould has less porosity and blow holes. In another study (C. U. Atuanya et al., 2018), also compare the percentage of BSA content with tensile strength increases with the BSA content up to 15%, this happens because of less porosity and single reinforcement added in the aluminium, if more than one reinforcement they are may not be evenly distributed.

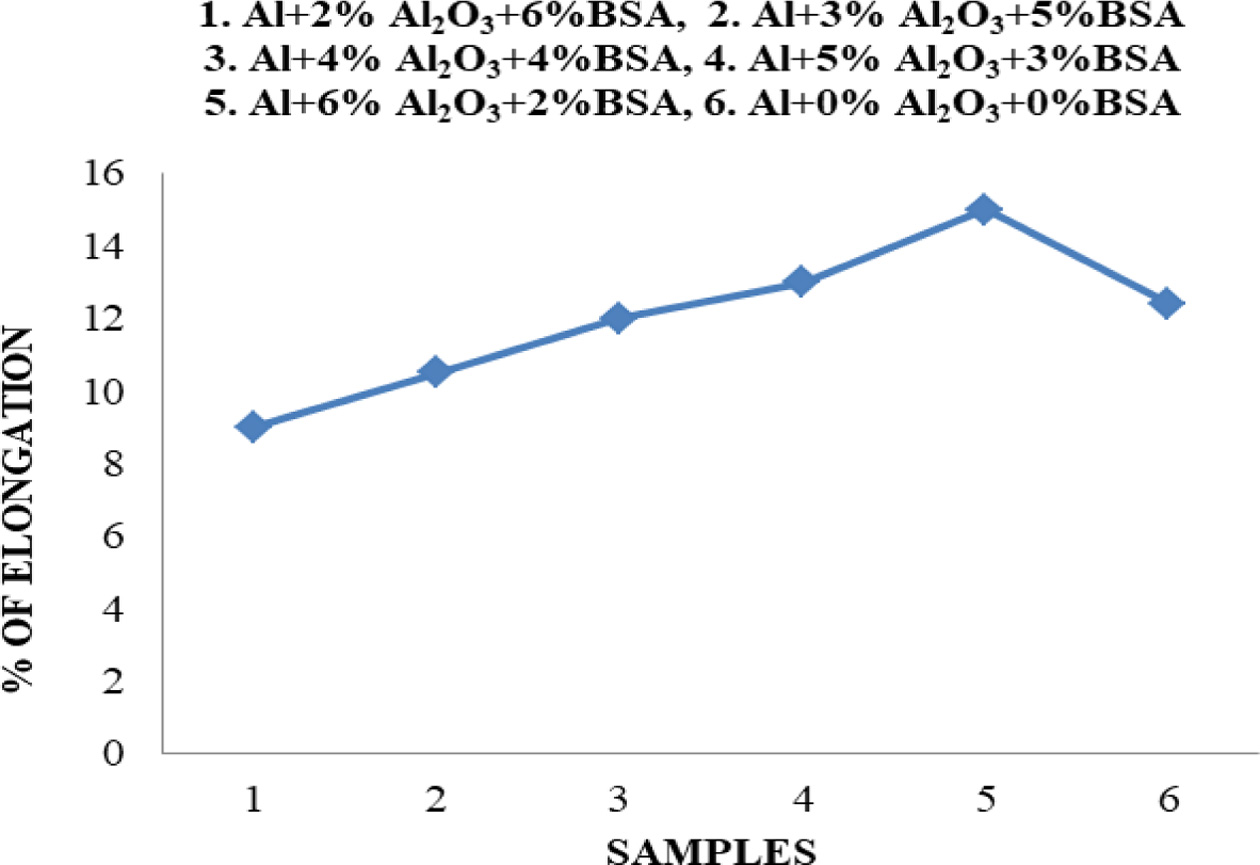

The effect ofelongation of Composites due to tensile load for various percentages of particulates was shown in Fig. 15. It was observed that the maximum percentage of elongation 15% occurs in sample 5 (6% Al2O3 & 2% BSA) and the minimum percentage of elongation 9% occurs in sample 1 (2% Al2O3 & 6% BSA).

Effects of aluminium oxide and BSA on impact strength

The impact of adding different weight percentage of Al2O3 and BSA in aluminium matrix is shown in Fig. 16. The figure show that the sample 1 which contains 6 wt% of BSA and 2 wt% of Al2O3 having higher impact energy value of 17 Joules and the sample 6 having lower impact energy value of 10 Joules which contains only pure aluminium alloy. This result also shows that the impact values of the composites are higher that than of the Pure aluminium alloy. The impact value increases in the percentage of BSA reinforcement up to 6% and Al2O3 decreases up to 2% and the impact value decreases in the non-reinforced aluminium alloy. Hence from the above analysis we can say that the energy absorbing metal in the aluminium metal matrix com- posite is more at 6% reinforcement of BSA and 2% reinforcement of aluminium oxide. This improvement in the impact values shows high toughness of the metal matrix. The analysis of this result, impact of the com- posites is found to increase as the content of BSA particulates is increased up to 6% by weight. The work of (C. U. Atuanya et al., 2018) showed that when BSA increases up to 15% properties such as impact strength reduces This happens because of increasing quantities of SiC particles react with each other and settle down so there is a chance for improper boding between two reinforcement. In another study, (Neelima et al., 2011) also compare the percentage of SiC content with impact strength increases with the SiC content up to 1.5% after which it drops. The percentage of elongation was proportional to the SiC percentage.

|

Fig. 11 Optical micrographs of the composites with different percentage of BSA and Al2O3. |

|

Fig. 12 SEM of the Aluminium composite specimens. |

|

Fig. 13 Chart for hardness test. |

|

Fig. 14 Chart for tensile strength. |

|

Fig. 15 Chart for variation of percentage of elongation |

|

Fig. 16 Chart for impact strength |

The microstructural studies and mechanical behavior of Al-Al2O3/BSA matrix composites containing 2:6, 3:5, 4:4, 5:3, 6:2 and 0:0 wt% Aluminium oxide and Bamboo Stem Ash as reinforcement were investigated. The results show that

• From Microstructural Studies, it was reasoned that the reinforcements are consistently appropriated in the Aluminum Metal Matrix, which impacts the mechanical properties. The composites were manu- factured with least porosity by Stir casting Technique in presence of Al2O3/BSA particles in alloy was appeared in optical Micro Structure.

• The composites were manufactured with least porosity by mix projecting strategy and presence of Al2O3 and BSA particles in aluminum combination was confirmed by SEM Analysis.

• The hardness value of the all reinforced hybrid composites are increased, compare to non-reinforced aluminum alloy.

• By analysis of the graph, we can conclude that aluminium metal matrix composite having the maxi- mum tensile strength in the composition of 6 wt% of aluminium oxide and 2 wt% of BSA Reinforcements.

• The impact toughness of the all reinforced hybrid composites was superior to that of non- reinforced aluminium alloy.

• This study has proved that the natural waste Bamboo stem can be used to improving the properties of Al6063 alloy.

- 1. D.J. Lloyd, Int. Mater. Rev. 1 (1994) 1-39.

- 2. J.J.M. Hillary, R. Ramamoorthi, J.D.J. Joseph, and C.S.J. Samuel, J. Compos. Mater. 10 (2019) 1-10.

- 3. D.S. Prasad, C. Shoba, and N. Ramanaiah, J. Mater. Res. Technol. 3[1] (2014) 79-85.

-

- 4. S. Valdez, B. Campillo, R. Perez, L. Martinez, and H. Garcia, Mater. Lett. 62[17-18] (2008) 2623-2625.

-

- 5. A. Apasi, P.B. Madakson, and D.S. Yawns, Int. J. Eng. Sci. Res. Technol. 3 (2012) 1190-1198.

- 6. F.C.R. Hernandez and H.A. Calderon, Mater. Chem. Phys. 132[2-3] (2012) 815-822.

-

- 7. H. Zuhailawati, P. Samayamutthirian, and C.H.M. Haizu, J. Phys. Sci. 18 (2007) 47-55.

- 8. K.V. Mahendra and K. Radhakrisna, J. Compos.e Mater. 44[8] (2010) 989-1005.

-

- 9. K.K. Alaneme and P.A. Olubambi, J. Mater. Res. Technol. 2[2] (2013) 188-194.

-

- 10. K.K. Alaneme, S.J. Olusegun, and M.O. Bodunrin, Tribology in Industry 35 (2013) 25-35.

- 11. K. Ravi Kumar, T. Pridhar, and V.S. Sree Balaji, J. Alloys Comp. 765 (2018) 171-179.

-

- 12. A.M. Rajesh and M. Kaleemulla. Mater. Sci. Eng. 149 (2016) 1-12.

-

- 13. S. Johny James, K. Venkatesan, P. Kuppan, and R. Ramanujam, Procedia Eng. 97 (2014) 1018-1026.

-

- 14. C.U. Atuanya, A.T. Esione, and F.A. Anene, J. Chin. Adv. Mater. Soc. 10 (2018) 1-10.

- 15. G. Pitchayyapillai, P. Seenikannan, K. Raja, and K. Chandrasekaran, Adv. Mater. Sci. Eng. 10 (2016) 1-9.

- 16. K.K. Alaneme, M.O. Bodunrin, and A. Awe, J. King Saud Univ., Eng. Sci. 30[1] (2018) 96-103.

-

- 17. V. Bharath, N. Madev, V. Auradib, and S.A. Koric, Procedia Mater. Sci. 6 (2014) 1658-1667.

-

- 18. K.K. Alanemea, T.M. Adewale, and P.A. Olubambi, J. Mater. Res. Technol. 3[1] (2014) 9-16.

- 19. O.O. Daramola, O.A. Ogunsanya, O.S. Akintayo, I.O. Oladele, B.O. Adewuyi, and E.R. Sadiku, J. Pract. Technol. 33 (2018) 89-104.

- 20. T. Pridhar and C. Boopathi, Dig. J. Nanomater. Biostructures 11 (2016) 845-852.

- 21. O. Olaniran, B.O. Adewuyi, O.A. Olaseinde, A. Oyetunji, and H.K. Talabi, Am. J. Eng. Res. 6 (2017) 312-317.

- 22. D.C. Neelima, V. Mahesh, and N. Selvaraj, Int. J. Appl. Eng. Res. 4 (2011) 793-799.

- 23. R. Singh and E. Singla, Int. J. Appl. Eng. Res. 7 (2012) 1-11.

- 24. Y. Pazhouhanfar and B. Eghbali, Mater. Sci. Eng. 710 (2018) 172-180.

-

- 25. M. Arulraj, P.K. Palani, and M. Sowrirajan, Int. J. Comput. Mater. Sci. Surf. Eng. 8[2] (2019) 145-166.

-

- 26. M. Arulraj and P.K. Palani, J. Braz. Soc. Mech. Sci. Eng. 40[1] (2018) 1-10.

-

- 27. K.K. Alaneme, I.B. Akintunde, P.A. Olubambib, and T.M. Adewale, J. Mater. Res. Technol. 2[1] (2013) 60-67.

-

- 28. K.K. Alaneme, I.B. Akintunde, P.A. Olubambib, and T.M. Adewale, J. Mater. Res. Technol. 2 (2013) 60-67.

- 29. T.P.D. Rajan, R.M. Pillai, B.C. Pai, K.G. Satyanarayana, and P.K. Rohatgi, Compos. Sci. Technol. 67[15-16] (2007) 3369-3377.

-

- 30. K. Ravi Kumar, T. Pridhar, and V.S. Sree Balaji, J. Alloys Comp. 765 (2018) 171-179.

-

This Article

This Article

-

2021; 22(4): 369-376

Published on Aug 31, 2021

- 10.36410/jcpr.2021.22.4.369

- Received on May 27, 2020

- Revised on Mar 5, 2021

- Accepted on Apr 19, 2021

Services

Services

Shared

Correspondence to

Correspondence to

- R. Ramamoorthi

-

Professor, Sri Krishna College of Engineering & Technology, Coimbatore

Tel : +918086955836 Fax: +0422-2607152 - E-mail: anandhan8.mech@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.