- Examination of wear properties of Al/B4C composites reinforced with irregularly shaped B4C

İsmail Topcu*

Department of Metallurgy and Materials Engineering, Alanya Alaaddin Keykubat University, Antalya, Turkey

This article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

In this study, Boroncarbide (B4C) powders were added as supplemental material to produce aluminum (Al) metal matrix composites (MMC) by mechanical alloying (MA) method. Three different B4C amount (5, 7,5, and 10 wt%) were used and three different temperatures (600, 620, and 640 oC) were applied for the sintering of the samples. Wear rate, hardness, and density of the produced composites were evaluated in order to investigate the effect of different B4C content and sintering temperatures. It was found that the increase in the B4C amount decreased the wear rate and density of the specimens while increasing the hardness. Moreover, the application of different temperatures had a positive effect on the density, hardness, and wear behavior of the specimens

Keywords: B4C, Mechanical properties, Sintering, Wear

Powder metallurgy (P/M) is a highly developed production method geared towards obtaining clearly shaped products by mixing alloyed powders prepared beforehand (mechanical alloying). The P/M process is a highly cost-effective and unique part production method in the production of simple or complicated parts in final dimensions. Metal matrix composites (MMC) consist of at least one metal and one reinforcement. In order to reach necessities that cannot be met with single-component materials and expected properties, materials such as fibers, intermetallic particles, com- pounds, oxides, carbides or nitrides are continuously used [1-4]. Today, MMC composite production has become more available by using various reinforcement particles with the process of liquid-phase sintering. The most important factor behind the development of MMC has become not only good mechanical and physical characteristics but also high-temperature capabilities increased by reinforcements [5]. In addition to the improved mechanical properties, properties such as the thermal expansion coefficient and wear resistance have been substantially increased by ceramic addition [6]. Among the extraordinary physical and mechanical properties of boron carbide is c-BN, which has the second highest hardness value following diamonds. In addition to this property, low density, high melting point and high wear resistance make this material attractive [7].

These elements, reinforced into metal matrix composites, may change the properties of these materials towards a better direction, and in this way, broaden their fields of application. In order for the properties of composites to be changed, carefully checking the size and reinforcement ratios provides various advantages [8, 9]. The need for light and high-strength materials has been known since the invention of the airplane. As the strength and hardness of a material increase, the amount of material that is needed to carry a certain load, its dimensions, and therefore its mass, decrease. This provides several advantages, such as increased loads and improved fuel efficiency in planes and automobiles [10].

MMC are preferred in specific application areas due to the high modulus of elasticity, strength and better wear resistance than that of conventional alloys. Several studies have investigated the wear resistance of Al MMC strengthened by different reinforcement components (SiC, Al2O3, TiC and B4C), especially under dry sliding conditions [11]. Wear occurs at three stages. These are the initial, mild and severe stages. Wear rate and stages are related to the process temperature; and especially at a critical temperature, the wear mechanism varies based on the mild to severe wear in the MMC. Hard particles increase the transition temperature by approximately 40-50 oC [12].

Wear is a surface phenomenon that occurs by separation and displacement of material. As a result of weight continuing for a certain period of time, change occurs in dimensions. Due to all the mechanical com- ponents, the sliding or rolling contact needs to cause an amount of wear. The parts in question are ball-bearings, gears, gaskets, guides, piston rings, splines, brakes and clutches [13]. The wear behaviours of Aluminium matrix composites (AMC) are definitely dependent on the reinforcement particles, particle size and ratio. If the reinforcement particle is well-bonded to the matrix, the wear rate of the composite continuously increases [14-16].

The purpose of this study is to investigate the effects of the 5%-10% B4C additions on the wear properties of the Aluminium matrix. Metallographic techniques were used for the characterization process. Wear tests on a disc and by disk were carried out on each sintered specimen with a B4C. Characterization was performed by scanning electron microscopy (SEM) and X-ray. By conducting hardness and density tests, the mechanical properties of these specimens were examined.

This study used 10 µm pure aluminum powder particles reinforced with B4C particles by

5% and 10% weight (wt.) and composites produced with this reinforcement. The materials that were subjected to the tests were produced with the powder metallurgy (P/M) technique. As the main matrix material, American-origin, atomized pure aluminum (Al) powders with 99.99% purity, 2.699 g/cm3 density and 10 μm nominal size produced by the firm Alfa Aesar, Johnson Matthey GmbH & Co. were utilized, while American-origin boron carbide (B4C) particles with a density of 2.52 g/cm3 and average sizes of 10-30 μm produced by the firm Alfa Aesar, Johnson Matthey GmbH & Co. KG were used as the reinforcement material.

The powder morphologies and microstructures of sintered specimens were examined by using a scanning electron microscope (SEM, JEOL Ltd., JSM5910LV). The determination of the microstructural phases were performed by a Rigaku X-ray diffractometer by using Cu/Kα radiation, 2o beam angle, diffraction angle in the range of 10-85o, increments of 0.02o and counting time of 1 s. An Energy Dispersive Spectrometer (EDS, OXFORD Industries INCAx-sight 7274, (133-eV re- solution) was also used for the analysis of the elements present in the microstructure.

During the production of the composites, 1% by weight acrowax binder and 5-10% B4C were mixed with aluminum particles. The mechanical alloying process was projected as approximately six hours in an attrition mill in 500 ml of ethanol. The ratio of the Al/B4C composite powder to the main mass was 1:5, the rotational speed was 400 rpm, and the diameter of the stainless-steel ball that was used was 10 mm. Sieving was carried out by 3 h of drying at 50 oC as a result of mechanical alloying. The composite powder specimens that were obtained after the drying and sieving processes were easily pressed by Cold Isostatic Pressing (CIP) at 400 MPa due to the ceramic behavior of B4C. A pure argon environment was selected as the sintering atmosphere, and sintering was performed for two hours. Metal aluminum experiences phase transformations at 600-640 oC. As the objective was high strength, the sintering temperature was selected as 600-640 oC.

Mechanical properties of composite specimens were determined by a micro hardness test. The tests were performed by a Future-Tech micro hardness device (FM-700, Future Tech Corp.) using a load of 500 g. The density of samples was measured by the Archimedes method (Switzerland-Presciva XB 320 M).

The produced composite samples were grounded by using x120, x240, x500, x800 grit papers and followed by Al2O3 paste polishing. The polished samples were etched with a Kroll solution (3 mL HP, 6 mL HNO3 inside 100 mL H2O). The microstructural analysis of specimens was performed by SEM.

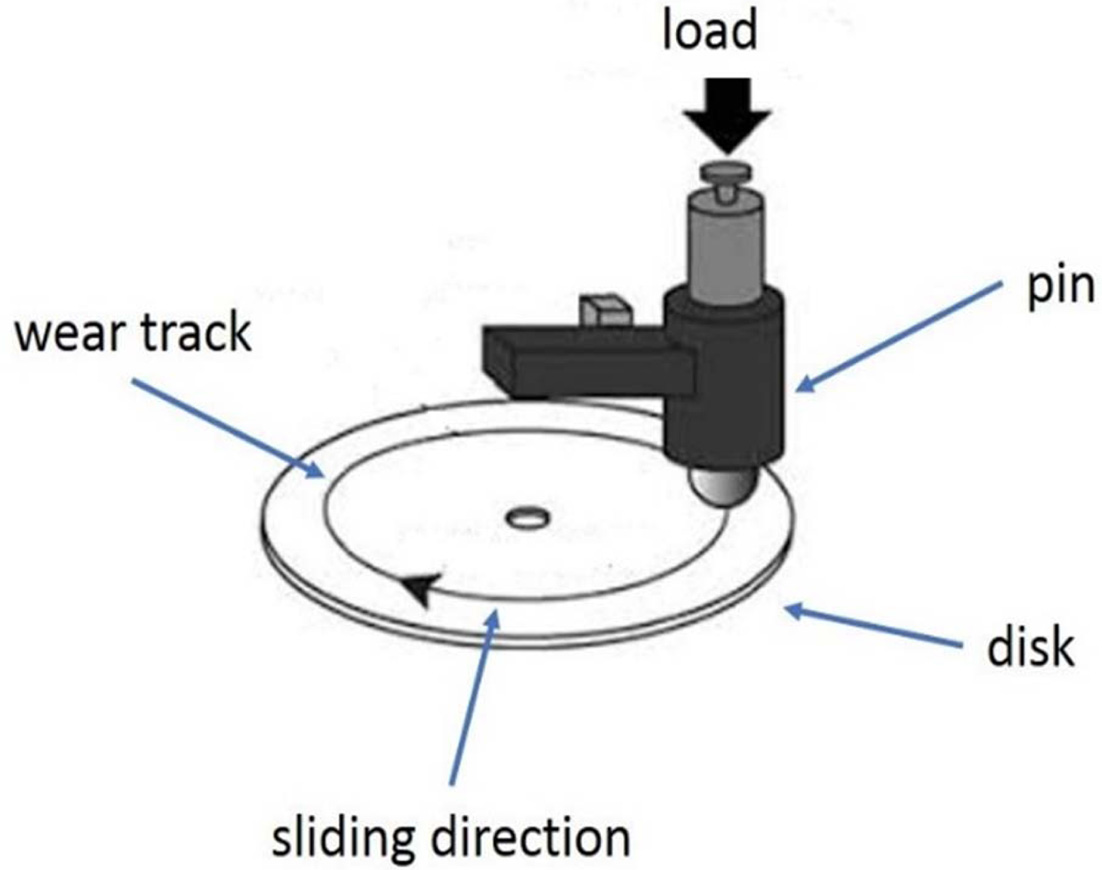

Wear tests were carried out at room temperature without a lubricant on a standard pin-on-disk machine with a D2 tool steel plate constantly rotating with the hardness degree of 65 HRC as the counter-surface. For the wear test, the specimen pin was selected with the dimensions of ∅10x10 mm, and the wear surface was polished up to a roughness value of 0.159 nm Ra. The test was conducted in four replications to provide repeatability for each specimen. The disk surface was grounded, and a roughness value of 0.830 um Ra was achieved. For all wear tests, the sliding rate, sliding distance and load were kept constant at 1.04 m/s, 3000 m and 9.8 N, respectively. All wear test specimens were carefully cleaned and dried. The specimens were cleaned with ethanol before and after the test to measure the loss of weight by a sensitivity of ± 0.0001 grams. To achieve good replicability in wear results, at least four tests were carried out in each test condition [19]. Wear surfaces were imaged by using a high-resolution SEM.

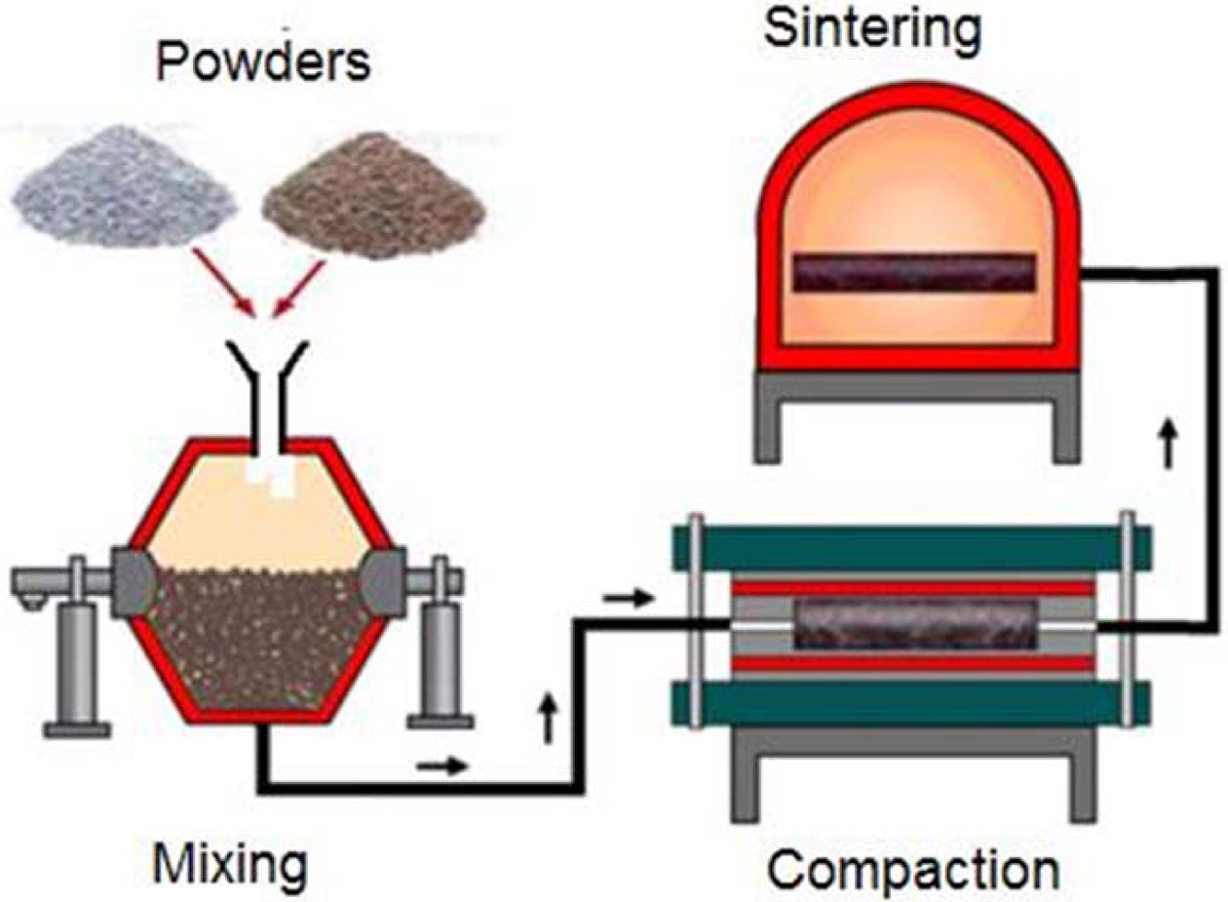

Aluminum matrix composite specimens were produced with the P/M method by adding 5, 10, and 15 wt.% of B4C as reinforcement. Sample production by -P/M is shown in Fig. 1. The Pin On wear test was performed in the apparatus shown in Fig. 2. (2)

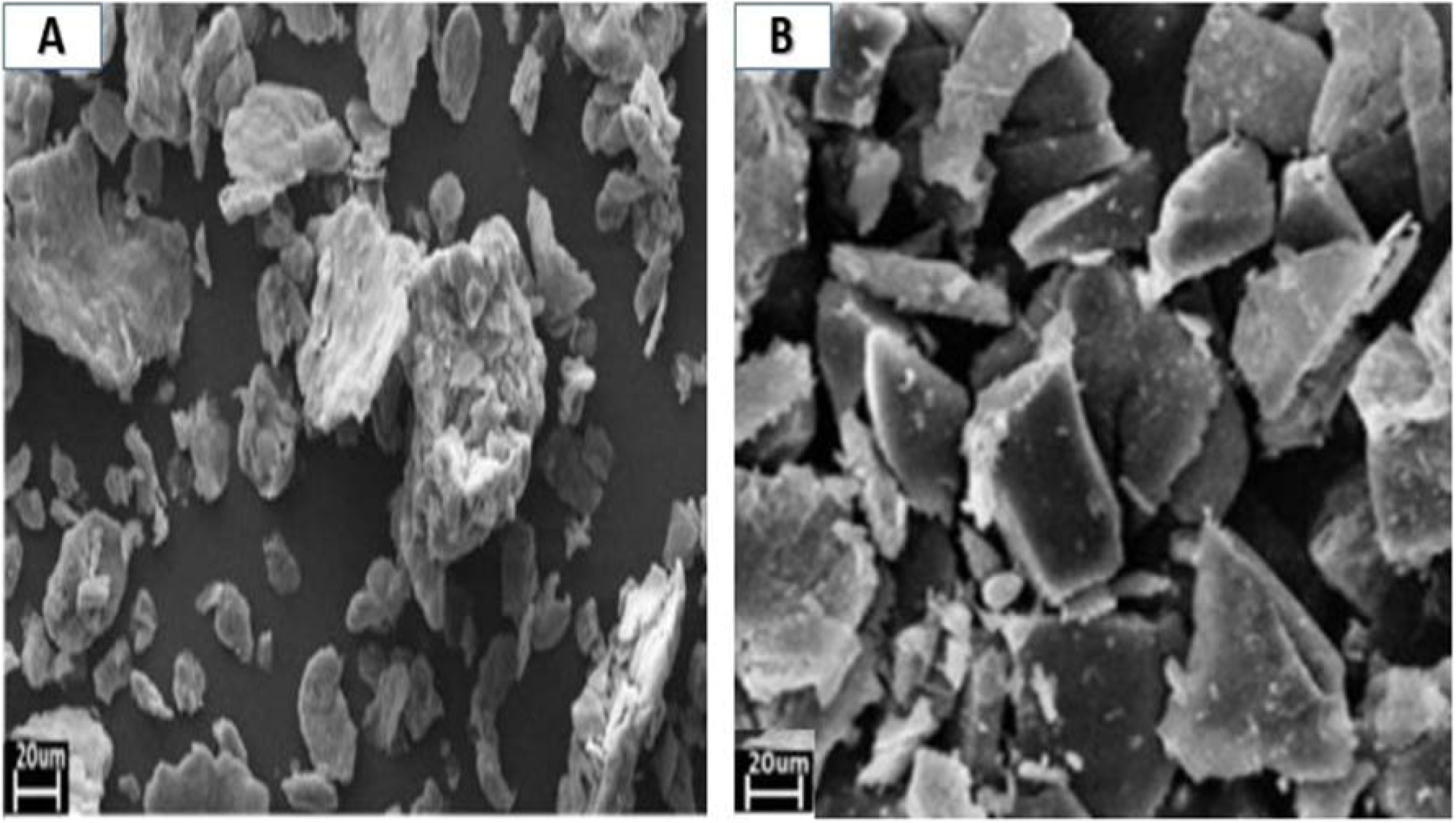

Images of the aluminum and boron carbide powders taken by the scanning electron microscope are shown in Fig. 3. As seen here, the aluminum powders that were used were irregular shape. The average grain size distribution was around 10 µ. (3)

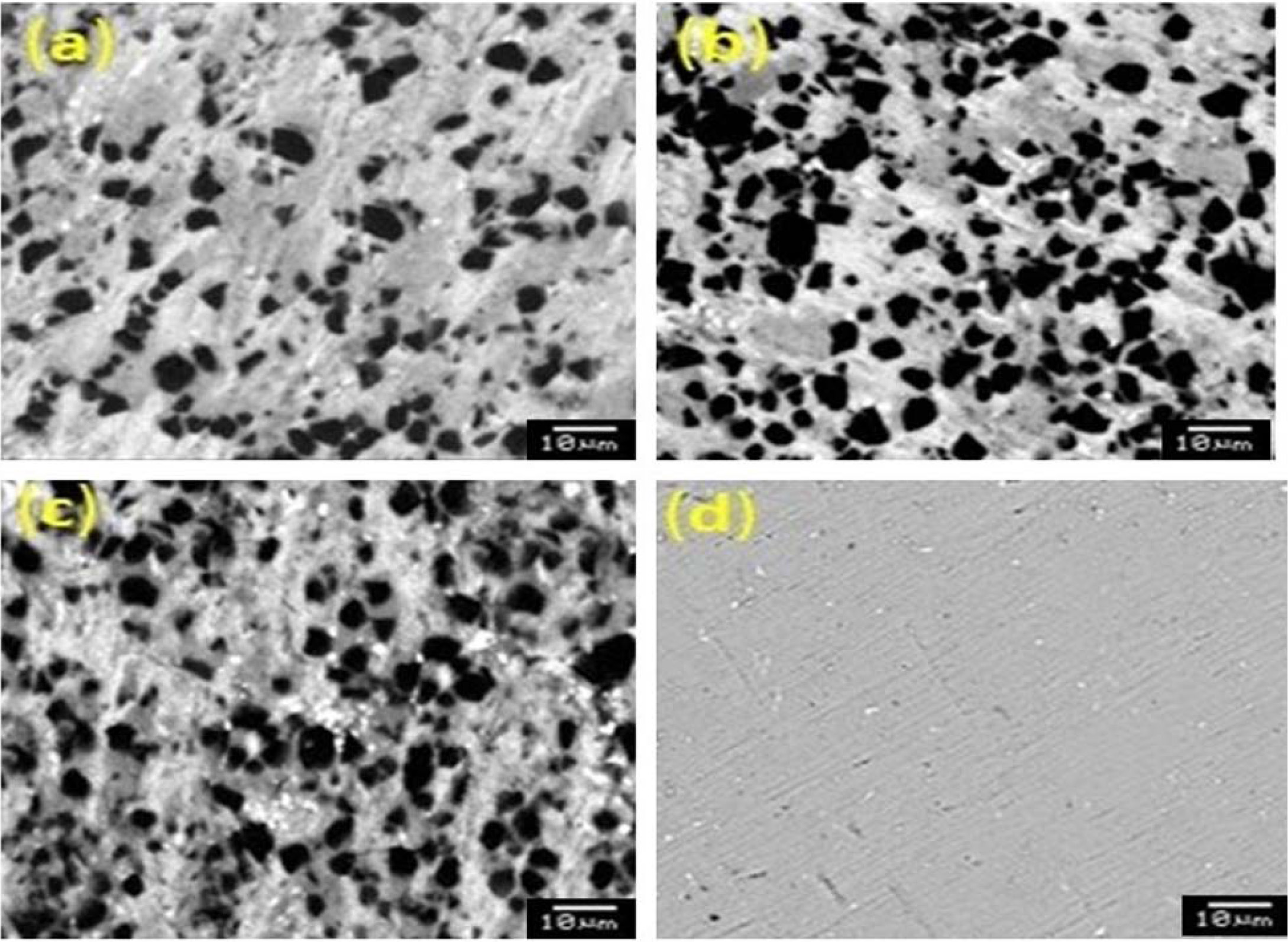

After the process of specimen preparation, the same magnification rate was used for all composite specimens that were prepared. The SEM images obtained from the flat cross-sections of the Al/B4C composite specimens may be seen in Fig. 4. The images clearly show the homogenous distribution of Al with B4C based on the reinforcement rate especially in the specimens with low reinforcement rates and the phases aluminum showed with B4C. There were also grey and darker areas in the structure. The grey areas corresponded to the carbide structures that formed, while the darker ones corresponded to the zone where porosity was occasionally intense with increased B4C amounts. The density and hardness values significantly increased by increased the sintering temperature especially in the specimen with a 10% B4C. As seen here, Al3BC were found only in the grey areas. The grey area increased optimally based on the increased ratio of B4C.

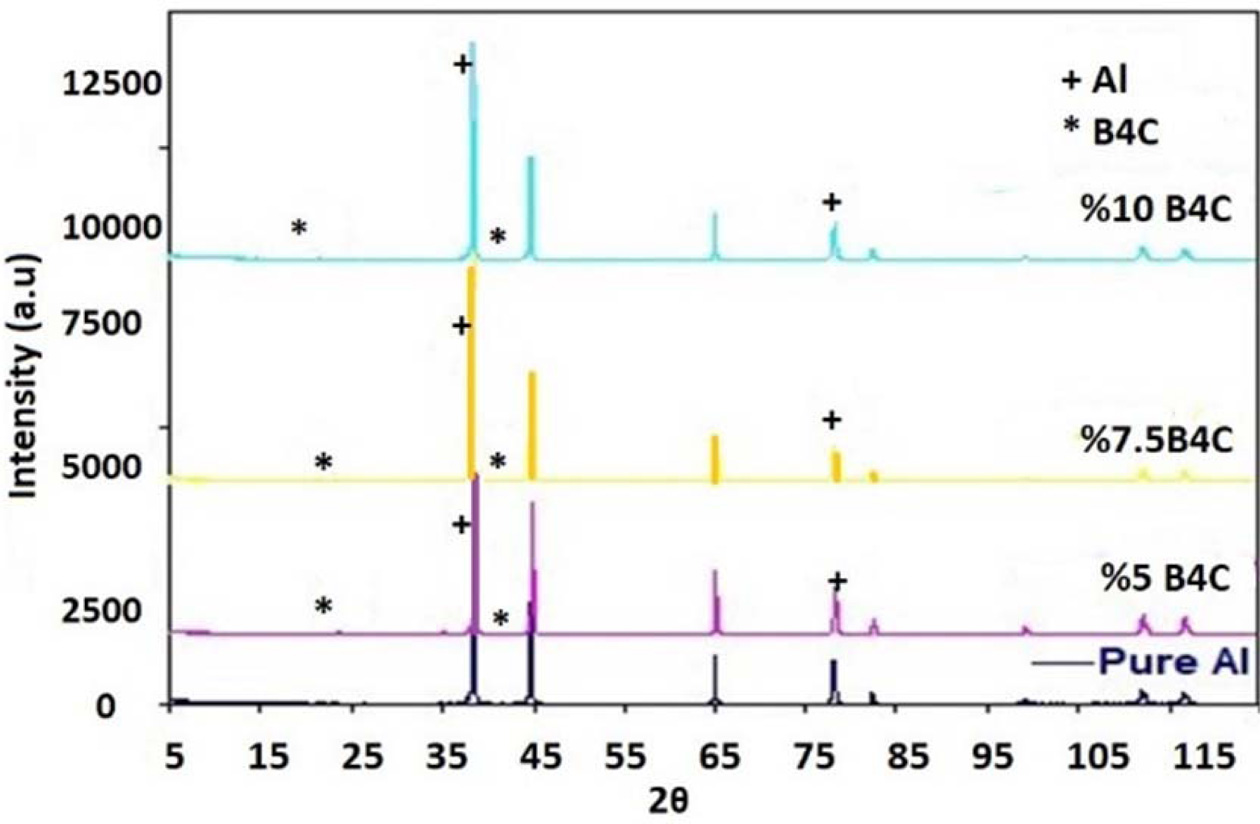

The purpose of the XRD analysis was to examine the various phases and reaction products in the Al/B4C composites. As seen in Fig. 5, in the XRD characterization examination on the pure aluminum and B4C powders, the peak belonging to the aluminum powder was seen at 38.70, the secondary peak was seen at 44.80, and similarly, the peaks belonging to the B4C appeared at 28.90 and 38.40, respectively.

The XRD results showed a more homogenous mixture with the 10% Al/B4C composite in comparison to the other reinforcement rates. The increase in reinforcement increased the peak magnitude of the composite (4).

As a result of B4C reinforcement, in the XRD char- acterization analysis of the Al/B4C composite material produced with the highest reinforcement ratio of 10%, aluminum metal powders showed the highest peaks on the (111) and (200) planes, while B4C ceramic powders showed the highest peaks on the (104) and (021) planes. In the XRD analysis of the Al/B4C composite specimen, it was very clearly observed that, as the B4C ratio increased, both peak magnitudes and peak areas noticeably increased for the B4C peaks [20, 21].

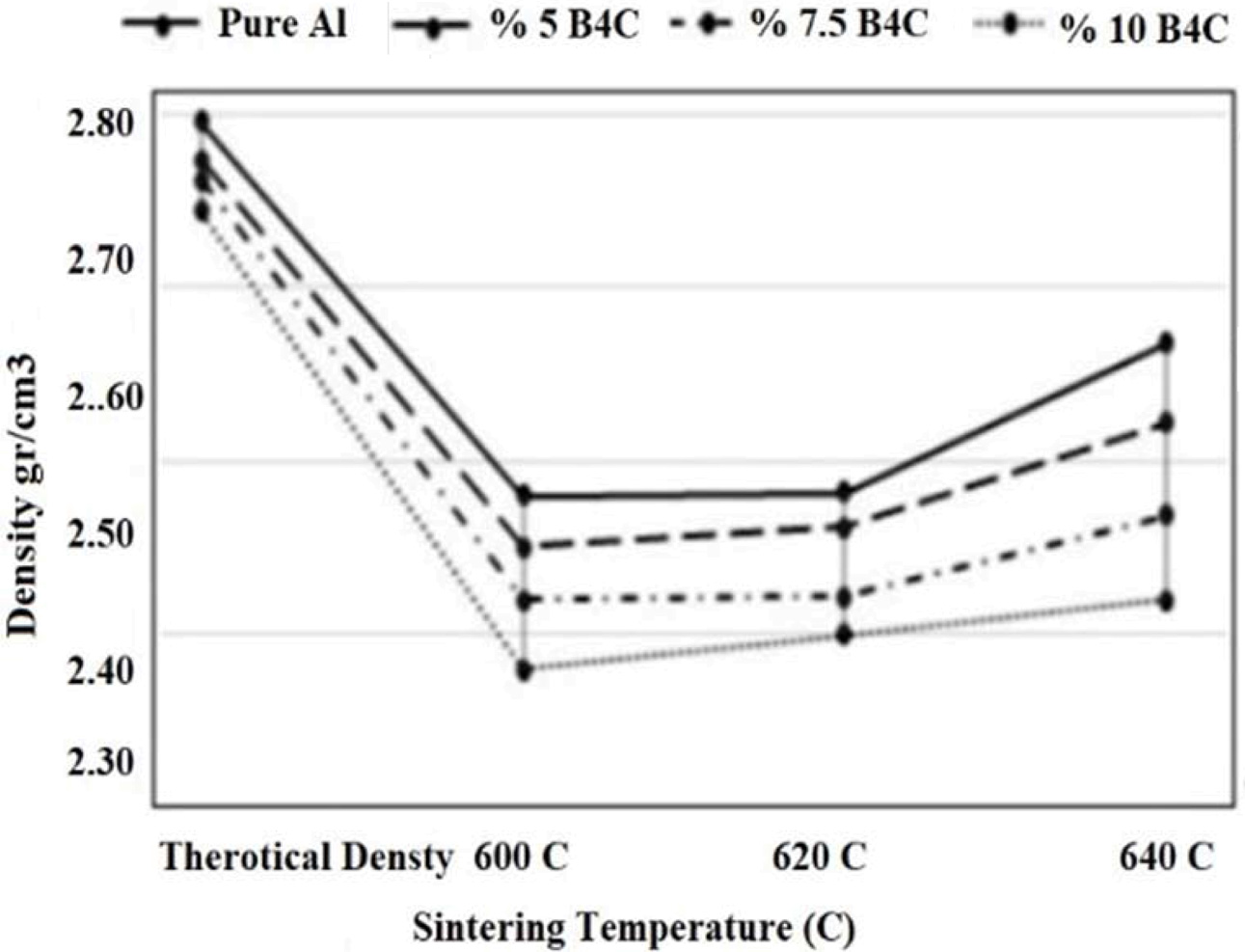

As seen in Table1, the highest peak was observed at the 10% reinforcement ratio of Al/B4C. The densities of the produced Al/B4C specimens were measured. They were found to be in agreement with the literature as they vary in the range of 95% to 97.5%. The main reason for this different ratio was that while B4C has a low density, the B4C rate increased, and porosity was encountered. Equation (1) shows the density calculations.

In Eq. (1), VL is the volume of the loose powder, VC is the volume of the compressed powder, ρG is the green density, and ρA is the apparent density.

The lowest density of the Al/B4C composite specimens was calculated in the specimen with a 10% reinforcement as the highest ratio of B4C by weight. Fig. 6 shows the density values of the composites that were produced by different ratios of reinforcements.

It was observed that the densities of the produced specimens decreased with the increase in the ratio of reinforcement, but they increased based on sintering temperatures. The tested specimens were the Al/B4C metal matrix composite specimens produced by P/M by reinforcing B4C into the Al matrix at different ratios. The expectation from the produced specimens as a result of the experiment was that density would reach the desired level in parallel with the literature (97.5%). The high sintering temperature that was applied and increasing B4C ratio [23, 24].

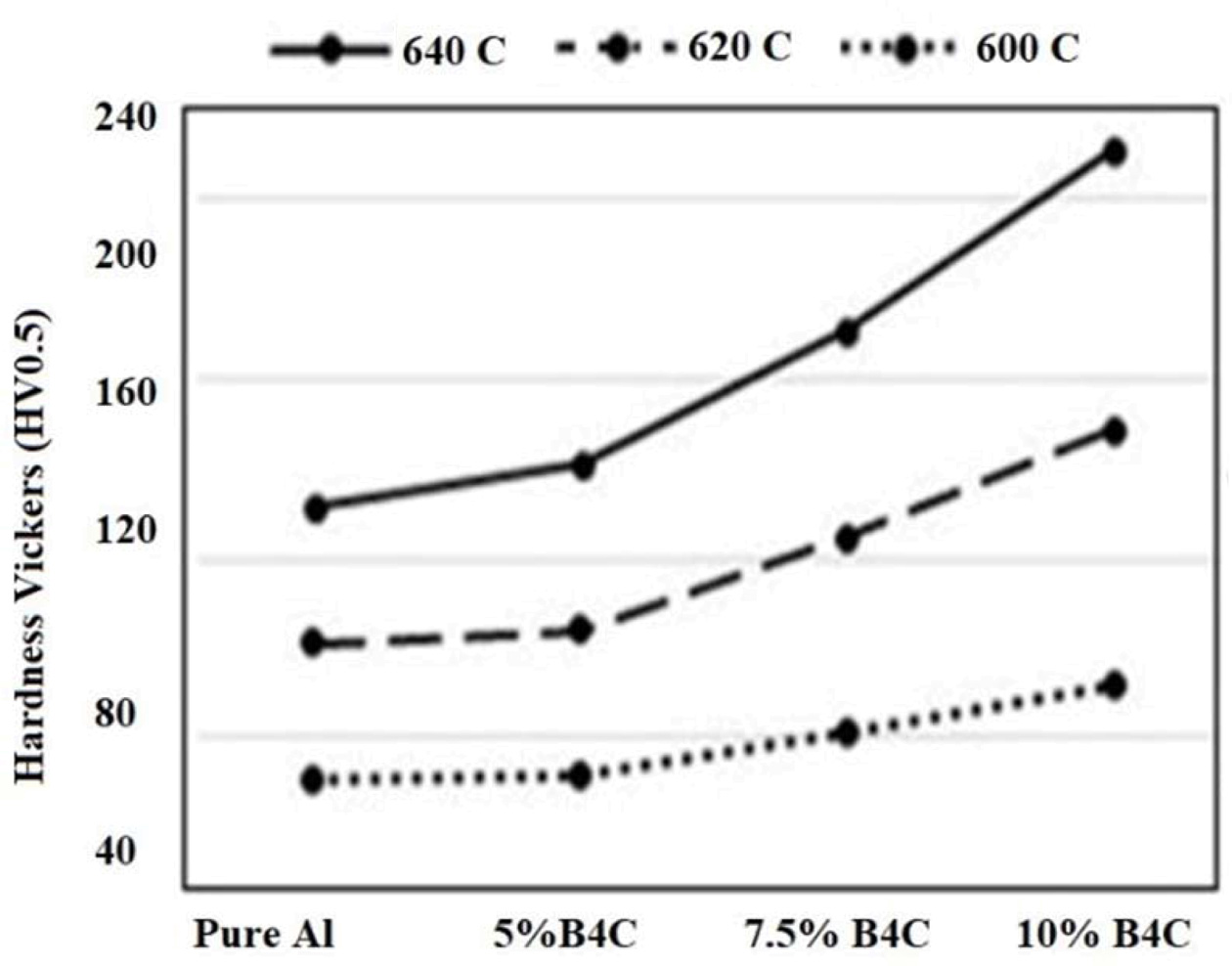

Hardness test was applied on the composite specimens that were produced and metallographically prepared. In this test, in order to make sure that the compressive trace covered both the matrix and the reinforcement material, 10 consecutive measurements were made with frequent intervals (150 μ), and the results were obtained by taking the average of the outcomes. The hardness values that were obtained represent the average hardness of the Al/B4C composites. Fig. 7 shows the results of hardness measurements.

The increased ratio of B4C by weight raised the hardness of the composite. Differences were observed in the measured hardness values of the specimens with different reinforcement ratios. The hardness values of composite materials increased due to the AlB2 and Al3BC phases formed by B4C and aluminum. As opposed to this, low hardness values were occasionally also observed, which may be explained by encountering the pure Al matrix in addition to increased B4C amounts [25].

Some researchers stated that the strength of the material increased with the increased B4C reinforcement ratios. As the reason behind this, they asserted that the carbon content of the structure and hardness values increased linearly. The carburized phase had higher surface tensions in comparison to other specimens and provided an increase in hardness [26]. Based on the assumption in question, the aluminum boride (AlB3) and aluminum-rich boride-carbide (Al3BC) structures that formed on the surface layer that was subjected to wear led to an increase in wear resistance.

Composite specimens that were produced in the same way as the surfaces which were metallographically prepared were subjected to wear tests. Different wear was calculated as both the covered path and loss of weight. The wear rate was calculated by using the following equation.

In Eq. (2), WS is the wear rate in mm3/Nm, Dm is the mass lost in the test specimens during N revolutions in g, q is the density of the test materials in g/cm3, L is the total sliding distance in m, and FN is the normal force on the pin in N.

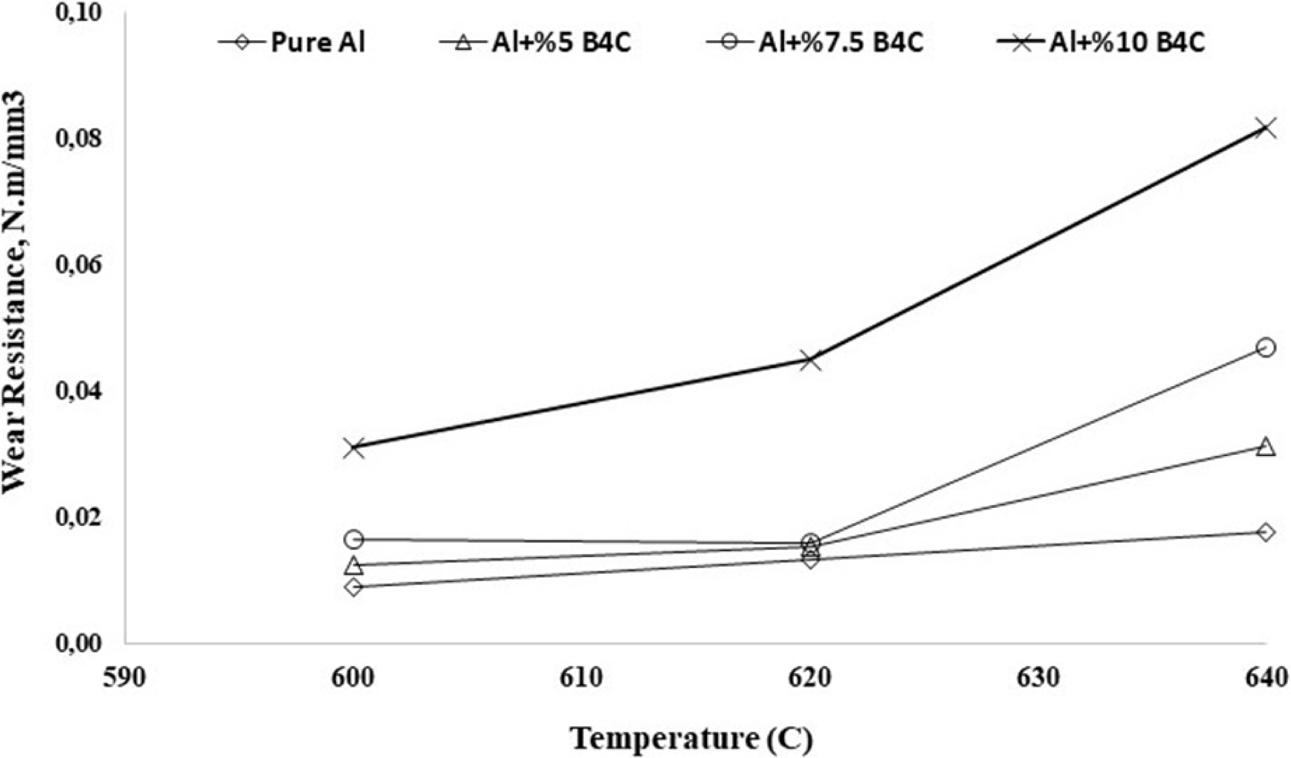

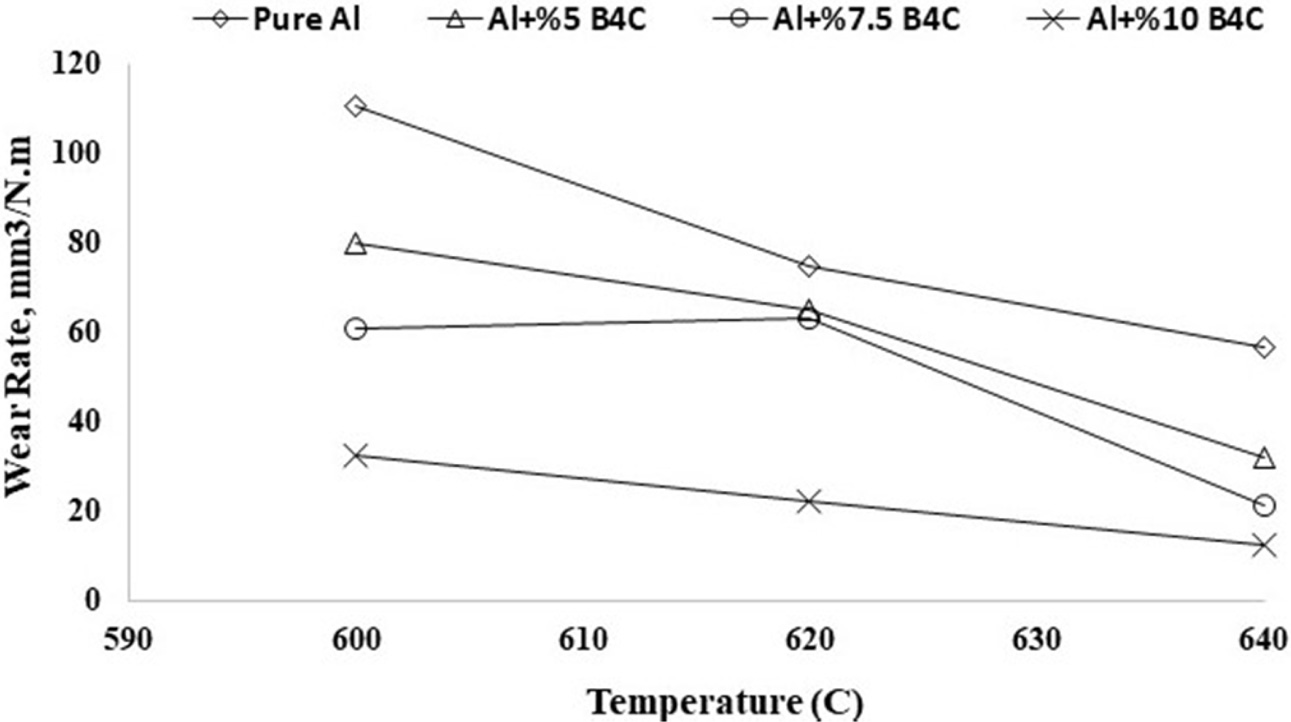

The total sliding distance was monitored by an automated recording device. The worn surfaces of all specimens were examined by using SEM. The constant weight of 10 N was used in the wear tests. As shown in Fig. 8 and Fig. 9, wear tests were carried out at three different sintering temperatures and three different compositions. In the study, an analysis was carried out by considering wear resistance and wear rates [28].

Since the load that was applied was constant at 10 N, for observing material losses, the ratio of B4C by weight was adjusted to 5, 10 and 10%. As seen in Figs. 8 and 9, as the B4C percentage ratio in the alloy increased, the wear rate of the specimens decreased. As the sliding distance increased, wear loss increased, and wear rate decreased. While the wear performance of the pure aluminum and the composite material with a 5% B4C reinforcement was especially poor, with the B4C ratio increased up to 7.5-10%, it was determined that the wear loss decreased noticeably. The lowest material loss was observed in the composite containing 10% B4C. Improved wear resistance may be attributed to the presence of the hard Al3BC phase and B4C in the composite. The 10% ratio of B4C by weight increased the observed wear loss. This may be explained by the higher ratio of the Al3BC phase in the composite. In further paths, it was observed that wear resistance decreased probably because of the decreased capacity for the load of the Al matrix to be effectively transferred to the B4C reinforcement. During wear tests, as the Al2B and Al3BC interface phases make fracturing difficult, their load carrying capacities increase. For this reason, the bonding between the reinforcement and the matrix is affected positively, and the wear resistance of the material increases. In addition to this, in general, improved wear resistance in composite specimens was attributed to the synergistic effect of the unique properties of B4Cs and the hard Al3BC interface product [29].

Larger mean roughness shows the irregularity of the Al2BC phase and may contribute to the presence of stress concentrations on the surface. This supported the previous proposition on the strong interface between the reinforcement and the matrix and the metallurgical bonding with a higher ratio of the B4C reinforcement.

A recent study suggested that wear behaviors are formed by metal residues that are produced and/or transferred during the sliding of the Al alloy. These were sintered on sanded, mixed, compressed and sometimes worn surfaces. During these activities, metal shavings react with oxygen, and this may be the cause of the oxide layers observed on worn specimen surfaces. In addition to this [28], the results of the study, as opposed to those reported by other researchers [30], stated that oxidative wear takes place during the dry sliding of an Al alloy in normal loads that are applied low. While it was supported by a relevant literature study that the adhesive wear mechanism changed in composites with 7.5 and 10% reinforcement, adhesive wear took place in the 5% B4C reinforced materials. Due to this, in parallel to the highest hardness values, the highest wear resistance was obtained with the 10% Al/B4C composites. This situation shows that reinforcement elements need to be at certain ratios. As expected, production of the Al MMCs with B4C reinforcement was effective in improving wear resistance and friction characteristics. In the literature review, why composites with low ratios of reinforcements have lower wear resistance and why wear resistance increases by increased ratios of reinforcements were very clearly explained.

|

Fig. 1 Fabrication stages of the B4C reinforced Al matrix composite. |

|

Fig. 2 The scheme of a pin on a disc wear device. |

|

Fig. 3 SEM micrographs of the B4C and Al particles a) Al and b) B4C. |

|

Fig. 4 Al/B4C composites sintered at 640 oC (a) 5% Al/B4C reinforced MMC, (b) 7.5% Al/ B4C reinforced MMC (c) 10% Al/B4C reinforced MMC (d) Pure Al with SEM photographs of different reinforced materials. |

|

Fig. 5 XRD pattern of different % content B4C composites in the Al Matrix. |

|

Fig. 6 Density values of the specimens produced by a 5-10% B4C reinforcement. |

|

Fig. 7 The hardness values of the Al/B4C composite specimens produced by a 5-10% B4C reinforcement. |

|

Fig. 8 Wear resistance test results of Al and (5-10% Al/B4C composites. |

|

Fig. 9 Wear rate test results of Al and (5-10% Al/B4C composites. |

This study researched the density, hardness, micro- structure and wear behaviors of composite (Al/B4C) specimens that were produced by different reinforcement ratios with Al/B4C. According to the findings of this study, the density of specimens got closer to the theoretical density, the desired levels (96-97.5%), by increased boron carbide contents.

As a result of the XRD analysis on the 10% Al/B4C composite that was prepared by mechanical alloying for 2 h in an attrition mill, it was determined that the peaks which occurred at different theta angles corres- ponded to the B4C particles in the rhombohedral structure, and the increased B4C content led to an increase in the peak area and magnitude of this reinforcement. The SEM images showed that most B4C powders were homogenously distributed into the main matrix, and there was no separation at a certain zone. In addition to this, by increased B4C ratios, the presence of the porous structure caused by reinforcement powders was observed very rarely. By increasing the ratio of the B4C by weight (up to 10%) and different sintering temperatures, especially the temperature of 640 oC, increased the hardness of the metal matrix composite. With the effects of different sintering temperatures in addition to the increased reinforcement ratio, there were decreases in weight losses and wear rates, while there was an increase in wear resistance.

The aforementioned increase occurred due to the aluminum-rich boride-carbide (Al3BC) phase that formed in the matrix as a result of sintering. Increased hardness with the addition of B4C may be attributed to the effect of dispersion strengthening. In the wear test that was carried out by also referring to the studies in literature, it was observed that the B4C reinforcement was positively effective on the wear resistance of the material, and it was thought to improve wear resistance.

This work was supported by the Scientific Research Project Program of Marmara University (FEN-K-070317-0107).

- 1. R.M. German, Sintering science 38 (2005) 522.

- 2. A. Panda, J. Dobransky, M. Jančik, İ. Pandova, and M. Kačalova, Tehnički Glasnik 57 (2018) 353-356.

- 3. I. Topcu, B.N. Çetiner, A.N. Güllüoglu, and H.Ö. Gülsoy, J. Chem. Soc. Pak. 42 (2020) 70-80.

- 4. K.W. Nam, J. Ceram. Process. Res. 13 (2012) 571-574.

- 5. J.U. Prakash, S. Ananth, G. Sivakumar, and T.V. Moorthy, Materials Todays 5 (2018) 7207-7216.

-

- 6. S.E. Shin and D.H. Bae, Compos. Part B Eng. 134 (2018) 61-68.

-

- 7. A.Canakci, Micro Nano Lett. 9 (2014) 109-112.

-

- 8. B. Manjunatha, H.B. Niranjan, and K.G. Satyanarayana, Mater. Sci. Eng. 14 (2018) 376.

- 9. Z.Y. Liu, S.J. Xu, B.L. Xiao, P. Xue, W.G. Wang, and Z.Y. Ma, Compos. Part Appl. Sci. Manuf. 43 (2018) 2161-2168.

-

- 10. N. Al-Aqeeli, K. Abdullahi, C. Suryanarayana, T. Laoui, and S. Nouari, Mater. Manuf. Process. 28 (2013) 984-990.

-

- 11. A. Canakcı, Powder Metall. and Metal Ceramics 53 (2014) 275-287.

-

- 12. H. Akbulut and Y. Kara, Journal of the Faculty of Engineering and Architecture of Gazi University 32 (2017) 321-332

- 13. F.K. Fırat and A. Eren, Architecture of Gazi University 30 (2015) 214-223

- 14. A. Baradeswaran, N.E. Perumal, R. Selvakumar, and I.R. Franklin, Mater. Des. 63 (2014) 620-632.

-

- 15. T. Varol and A. Canakci, Powder Technology 246 (2013) 462-472.

-

- 16. N.M. Sathiskumar, I. Dinaharan, and S.J. Vijay. Arch, Metall, Mater. 59 (2014) 83-87.

-

- 17. İ. Topcu, A.N. Güllüoğlu, M. Bilici, M.K, and H.Ö. Gülsoy, Journal of the Faculty of Engineering and Architecture of Gazi University, 34 (2019) 1441-1444.

- 18. G. Arslan and A. Kalemtaş, J. Eur. Ceram. Soc. 29 (2009) 473-480.

-

- 19. M. Rashad, F. Pan, Z. Yu, M. Asif, H. Lin, and R. Pan, Prog. Nat. Sci. Mater. Int. 25. (2015) 460-470.

-

- 20. J.H. Choi, G. Gyawali, D.R. Dhakal, S.B. Humam, B. Joshi, and S.W. Lee, J. Ceram. Process. Res. 21 (2020) 249-255.

-

- 21. Topcu, H.Ö. Gulsoy, N. Kadıoglu, and A.N. Gulluoglu, J. Alloys Compd. 482 (2009) 516-521.

-

- 22. M.E. Turan, Y. Sun, F. Aydin, H. Zengin, Y. Turen, and H. Ahlatci, Mater. Chem. Phys. 218 (2018)182-188.

-

- 23. H.Ö. Gülsoy, M.K. Bilici, Y.Bozkurt, and S. Salman, Materials and Design, 28 (2007) 2255-2259.

-

- 24. F. Xiaowei, L. Xiaoping, H. Xuguo, and L. Jianxin, J. Ceram. Process. Res. 11 (2010) 328-330.

- 25. A.E. Pramonoa, M.Z. Nuraa, J. Wahyuadi M. Soedarsonob, and N. Indayaningsihc. J. Ceram. Process. Res. 20 (2019) 1-7.

- 26. N. Saheb, A. Khalil, A. Hakeem, N. Al-Aqeeli, T. Laoui, and A. Qutub, J. Compos. Mater. 18 (2014).

- 27. X. X.Yang, H.J. Min, L.W. Jing, L. Y.Fu and L.L.Mei. J. Ceram. Process. Res. 7 (2006) 167-171.

- 28. J.W. Ana and D.S. Lima, J. Ceram. Process. Res. 3 (2002) 118-122.

- 29. L. Kumar, S. Nasimul Alam, and S.K. Sahoo, J. Compos. Mater. 51 (2017) 1099-1117.

-

- 30. M.M. Bastwros, A.M. Esawi, and A. Wifi, Wear, 307 (2013) 164-173.

-

This Article

This Article

-

2021; 22(3): 276-282

Published on Jun 30, 2021

- 10.36410/jcpr.2021.22.3.276

- Received on Apr 27, 2020

- Revised on May 25, 2020

- Accepted on Jun 10, 2020

Services

Services

- Abstract

introduction

experimental procedures

result and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- İsmail Topcu

-

Department of Metallurgy and Materials Engineering, Alanya Alaaddin Keykubat University, Antalya, Turkey

Tel : +90 242 510 61 20 Fax: +90 242 510 61 24 - E-mail: ismail.topcu@alanya.edu.tr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.