- Production and microwave electromagnetic shielding effectiveness of polyaniline-La2Ti2O7:Er,Yb composites

Ethem İlhan Şahina,d,*, Selim Burak Cantürkb, Mehriban Emekc, Seval Gençb and Mesut Kartale

aDepartment of Satellite Communications and Remote Sensing, İstanbul Technical University, Maslak, Istanbul 34469, Turkey

bDepartment of Metallurgical and Materials Engineering, Marmara University, Goztepe, Istanbul 34722, Turkey

cDepartment of Physics, Golbasi Vocational School, Adiyaman University, Gölbaşi ,Adıyaman 02040, Turkey

dAdvanced Technology Research and Application Center, Adana Alparslan Türkeş Science and Technology University, Adana 01250, Turkey

eDepartment of Electronics and Communication Engineering, İstanbul Technical University, Maslak, Istanbul 34469, TurkeyThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

In this research, La2Ti2O7 doped with erbium-ytterbium was produced by using solid state technique. A series of compounds with the chemical equation (La1−x−yREx−y)2Ti2O7 were doped with (Er3+, x = 0.025, 0.050 ) and (Yb3+ y = 0.02 ) rare earth ions prepared by conventional solid state reaction method at 1350 oC for 24 h. X-ray diffraction (XRD), scanning electron microscopy (SEM) and energy-dispersive X-ray spectroscopy (EDS) were carried out for the structural analysis, which showed that second phase did not form in (La1−x−yREx−y)2Ti2O7. Additionally, the polyaniline- erbium, ytterbium doped La2Ti2O7 composites were fabricated via hot pressing using the compositions of (La0.955Yb0.02Er0.025)2Ti2O7, (La0.93Yb0.02Er0.05)2Ti2O7 and aniline. The weight ratios of erbium-ytterbium doped lanthanum titanate and aniline were 1:1 and 1:3 respectively, and epoxy resin was utilized to develop microwave shielding effectiveness composites. The microwave shielding effectiveness performances of polyaniline- La2Ti2O7: erbium-ytterbium composites were examined by shielding effect in 0-8 GHz using two-port vector network analyzer. A minimum of - 34.37 dB shielding effect performance was obtained in 6.27 GHz at the thickness of 2.0 mm. This shielding effect performance can be adjusted easily by managing the content of polyaniline in the composites for the needed frequency bands

Keywords: Shielding effect, La2Ti2O7, Polyaniline, Polymer-matrix composite

Lanthanum titanate is a branch of the ferroelectric class, often known as the strontium pyroniobate group, with a perovskite-like layer structure (PLS). Single crystals of lanthanum titanate exhibited high piezoelectric and electrooptic effects [1], and to be ferroelectric with an exceptionally high Curie temperature (Tc = 1500 oC) [2]. Two modifications have been documented to a room temperature structure of La2Ti2O7, one with symmetry P21 [3, 4] and the other with symmetry Pbn21 [5]. The structure be transformed into the orthorhombic space group Cmc21 at approximately 780 oC, and transforms into the paraelectric phase with Cmcm symmetry at 1500 oC [6]. From this high-temperature model structure derive the numerous polymorphs over all A2B2O7 PLS substances. It is recognized as corner-shared boil octahedra and 12-coordinated A cations inside the perovskite-like slabs, that are connected on their boundaries by A cations. The structure’s anisotropy is anticipated to result in dielectric and electrical properties becoming anisotropic. La2Ti2O7 is a suitable choice for high-temperature piezoelectric and electrooptic applications, due to its exceptionally high curie temperature. La2Ti2O7 ceramics are frequently referred as a low-temperature capacitance parameter (TCC) substance, they are dielectric at microwave frequency [7].

Sources like television equipment, radio, cellular telephone, computer, radar and other systems are the origin for emitted electromagnetic fields [8]. EMI might also occur because of distance sources like radio transmitters, antennas and lightning that produce load electromagnetic fields close for plane waves [9]. Hence, Electromagnetic interference (EMI) may become a challenge once spreaded electromagnetic fields interact with other electrical gadgets functions. EMI can interfere with sensitive electronic components, disrupt electrical circuits and cause immediate accidents. It may also cause interruptions in television service equip- ment, telecommunication devices, medical instruments, military and aircraft equipment. For instance, five blackhawk helicopters crashed moments after being placed to service in the late 1980s [10, 11]. EMI from very powerful radar and radio transmitters in the electronic flight control system are discovered to be the cause of such crashes [11]. Due to the rapid growth of consumer, military, science electronic devices and communication tools, growing interest has been shown in the production of materials which could protect against electromagnetic radiation to prevent interference. In order to stop harmful radiation and shielding electronic devices, it is necessary to have a shielding effectiveness material that filters interference. Shielding effective materials are required to be strong and light. As effective shielding options, metals, metal filled plastics, metal powder, aluminum frames, nickel-coated reinforced polymers with polyacrylonitrile (PAN), coatings, metallic nickel and copper fabrics and, most lately, nano reinforced polymer composites (NRPCs) are available [11, 12]. Typical drawbacks observed with products used for EMI prevention are correlated with weakness to corrosion, long processing cycles, high production cost of equipment, complexity of material use in building articles with complex geometry, short service life using conductive layers owing to abrasion and wear, and high reinforcement concentration. Apparently, reinforced polymer matrices solved few of these drawbacks, as they are light substances which are also appropriate for structural elasticity, resistance to corrosion and rapid production, in order to achieve reasonable shielding effect performance, high intrinsic conductivity and/or high loading of functional fillers are typically required [12].

Conductive polymer composites are excellent candidates for EMI shielding. Polyaniline (PANI) is a conductive polymer used to absorb microwaves however PANI has just dielectric loss. This restriction prevents its utilization as a single microwave absorbent substance [13, 14]. Polyaniline (PANI) is known of many conductive polymers for its peculiar chemical and physical properties, inexpensive, better environmental stabilization and easiness of manufacture. Composites of polymers and organic/inorganic filling materials [16-18].

Shielding effectiveness materials are used as blockers to decrease the electromagnetic field in space, such as radar frequency shielding is typically the purpose of preventing radar frequency and electromagnetic radiation.

In previous studies, Colemanite/PANI/SiO2 composites has a width of 1.5 mm sample thickness and a maximum -41.1 dB electromagnetic shielding effectiveness at 16.09 GHz frequency [19]. Morever, Wang Y. et al. [20] reported the NiFe2O4@SiO2@ reduced graphane oxide composite as a potential electromagnetic interference shielding material. For example, in another study, the maximum electromagnetic shielding effectiveness of 0.25 wt% MWCNT composites were measured as -39 dB at 1.6 GHz [21]. On the other hand, the electromagnetic shielding effectiveness of the prepared SAC-rGO/epoxy composites were measured as shielding effect of -22.6 dB at 0.5 wt% sulfanic acid azocromotrop-reduced graphene oxide loading [22].

As another example in the literature, radiation shielding performance of concrete with electric arc furnace oxidizing slag aggregate was measured [23].

The shielding effect value is related to how far the incoming electromagnetic wave crosses. For the shielding value of -10 dB, it is understood that the incoming electromagnetic wave is reduced by 90% and 10% passes to the opposite side. [10,15].

In this study, for its first time, the single phase La2Ti2O7 ceramic became adjusted by doping Er, Yb in different ratios instead of La in the La2Ti2O7 ceramic composition using the solid state process. New Er,Yb doped La2Ti2O7 and new Er,Yb doped La2Ti2O7: PANI were produced.

Preparation of Er,Yb doped lanthanum titanate

The nano powders La2O3, Yb2O3, TiO2 and Er2O3 were thoroughly mixed with stoichiometric quantities. La2O3 (99.5 percent) and TiO2 (> 99.0 percent) were acquired from Aldrich powders from Merck, Yb2O3 (99.9 percent) and Er2O3 (99.9 percent) from sigma powders.

In this method, ball milling for 20 h was used to stir powders and zirconia balls used to help increase the mixture.

The resulting mixture was calcinated at 180 oC for 2 h after ball-milling followed by sintering at 1350 oC for 24 h.

X-ray diffractometry (XRD- D2 Phaser Bruker AXS) using Cu-Ka radiation (λ = 1.5406 Ǻ) in the range 2θ:10 - 70o and at a scan rate of 1o/min was utilized in order to identify the phases in the Er, Yb added sintered samples. XRD was utilized to as particular the solubility point, which is described as the quantity that can be added without disordering the original structure of (La2Ti2O7).

Microstructure surface area, phase classification and also morphology of specimen powders were performed by scanning measurements of electron microscopy (SEM; Jeol JSM 5910 LV). Powder samples were placed on the carbide tape as well as coated with gold-palladium to improve conductivity. Energy dispersive spectroscopy (EDS) analysed the purity of the La2Ti2O7 phosphors.

The two-port vector network analyzer (R & S FSH-K42) device in the frequency range of 0 - 8 GHz was utilized in order to determine the microwave shielding effect performances of the PANI- La2Ti2O7: Er, Yb composites.

Preparation of polyaniline/La2Ti2O7:Er,Yb composites

The La titanate Ni ferrite which has the compositions of (La0.955Yb0.02Er0.025)2Ti2O7, (La0.93Yb0.02Er0.05)2Ti2O7 (account for 100 wt.% and 33 wt.% of aniline quantity), and 1 ml aniline monomer were applied to 35 mL hydrochloric acid solution (0.1 mol L-1) and dispersed for 30 min. by mechanic agitation. In a 15 mL HCI solution (1 mol L-1), 2.49 g of ammonium persulfate (APS) was dissolved. By stirring quickly, the APS solution was then slowly activated dropwise to the above mentioned mixture solution. Polymerization was completed in an ice-water bath at 0 oC for 12 h. The composites were produced by filtering and washing the reaction mixture with deionized water, and ethanol, which was then vacuum-dried for 24 h at 60 oC. Er,Yb doped Lanthanum titanate/PANI composites with different molar ratios [(Aniline/(La0.955Yb0.02Er0.025)2Ti2O7, Aniline/(La0.93Yb0.02Er0.05)2Ti2O7 = (3:1,1:1)] were produced to evaluate the effect of the Polyaniline content on the electromagnetic shielding effectiveness characteristics. New Er and Yb added La2Ti2O7 ceramic were obtained as a PANI based composite. PANI-La2Ti2O7:Er,Yb were fabricated at different ratios by hot pressing.

Preparation of epoxy-polyaniline based Er, Yb doped La2Ti2O7 composites

The composites were prepared via molding and curing the admixture of powders and epoxy compositions of Er,Yb added Lanthanum titanat/ PANI. The powder to epoxy mixing ratio was 2:1 by weight. The molding was carried out at around 5 MPa pressure and 100 oC for 1 h in a hydraulic press. For shielding effect measurements, pellets with diameter of 20 mm and a thickness of 2 mm were pressed. Microwave shielding effectiveness composites were produced by using epoxy at distinct rates of aniline / Er, Yb doped Lanthanum titanate as in 1/1 and 3/1.

XRD analysis

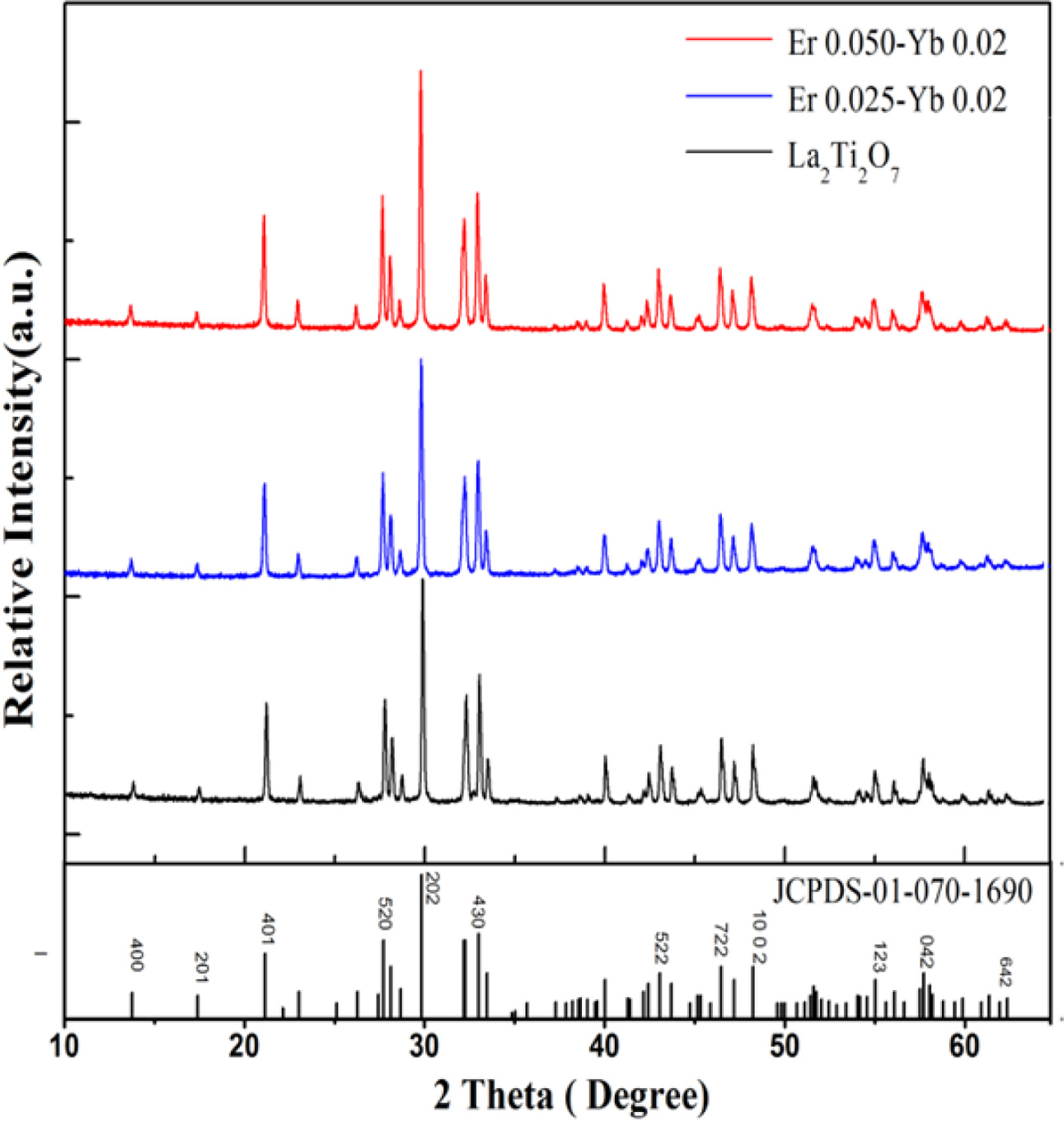

The La2Ti2O7 compound is a suitable host for trivalent rare-earth ions such as Yb3+, Er3+ ions, owing to they can substitute La3+. The Er3+ and Yb3+ ions were doped into La2Ti2O7 (JCPDS Card No : 01-070-1690) compound to replace La ion since they have close ionic radii values. In compound of La2Ti2O7, due to ionic radius near to each other. Yb3+/Er3+ co-doped in site of Lanthanum. Using the (La(1-x-y)Ybx Ery)2Ti2O7 formula, Yb x=0.02 stable and Er in x=0.050 and 0.025 doped (Fig. 1). Biggest peak were seen at two theta value of 29.8 and this peak belong to (202) plane.

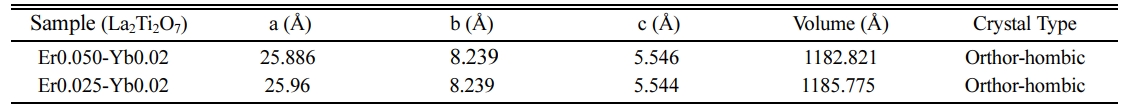

The entire product samples display singular phase orthorhombic structure without having signs of impurities due to the fact there is an absolute corresponding fitting with (JCPDS Card No :01-070-1690) no extra peaks were noticed. This might points out that Yb and Er doping with stated rates doesn't result in second phase formation and also fully dissolves in the lattice providing a substitutional solid solution. The most significant notification to be made is that a detailed examination of peaks reveals a presence of a slight shift in the peak positions to left side with increase of doping concentration, this effects can be acquired owing to the increase in the lattice parameters in Table 1. Increament in dopant content (Yb-Er) phosphors show bigger unit volume due to the rising addition of rare earth ions into the crystal structure which leads to increase in values of lattice parameters. Thus, it leads to slight increase in the lattice.

SEM Images and EDS investigation

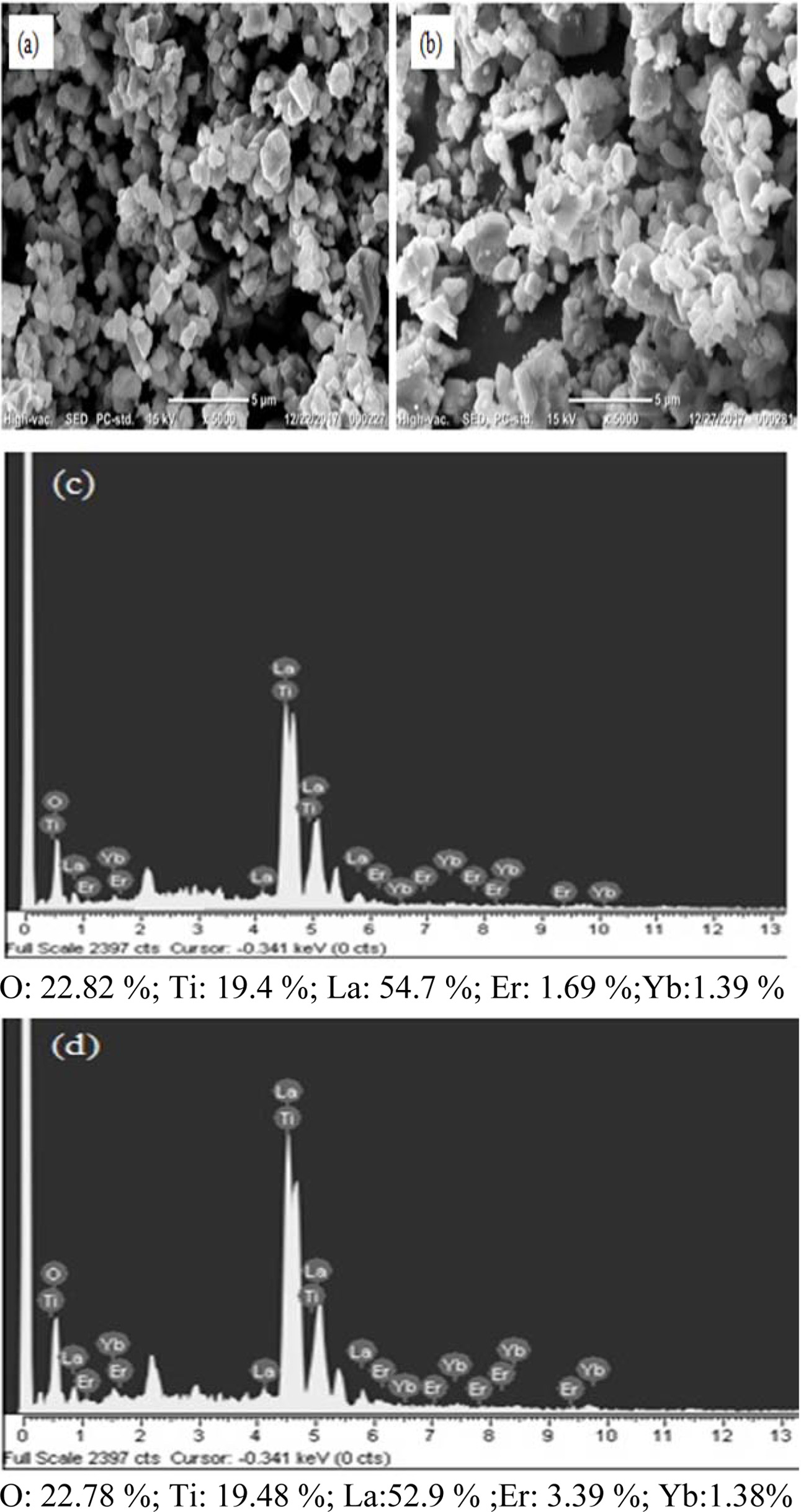

SEM micrographs reveal that there is no any second phase or impurity in the microstucture,as observed in XRD. SEM images for the Er, Yb doped Lanthanum titanate structure showed that there is only phase (Fig. 2(a) and (b)). Backscattered electrons do not show any phase contrast indicating no any other second phases.

Some spherical but mostly shapless nano particle structures observed. It can be deduced from the majority of the SEM images, there is agglomeration and melt down in the structure.

The EDS analysis was carried out and the images are illustrated in Fig. 2(c) and (d). Similar results were obtained for the EDS analysis of Er (x = 0.025) and Yb (y = 0.02) doped La2Ti2O7 particles compared to the theoretical composition of Er doped La2Ti2O7 ( 22.82 wt% of O, 19.4 wt% of Ti, 54.7 wt% of La, 1.69 wt% of Er, 1.39 wt% of Yb).

Weight percentages obtained from EDS results were close to the calculated values in the beginning of experiments. The EDS spectrum did not detect any other peaks or impurities. Both Au and Pd elements were due to coating made on the samples. In addition, it was expected that there might be little negligible variation in weight percentages due to the EDS instrument’s own calibration during the experimental process.

EMI shielding measurements of Er,Yb doped lanthanum titanate

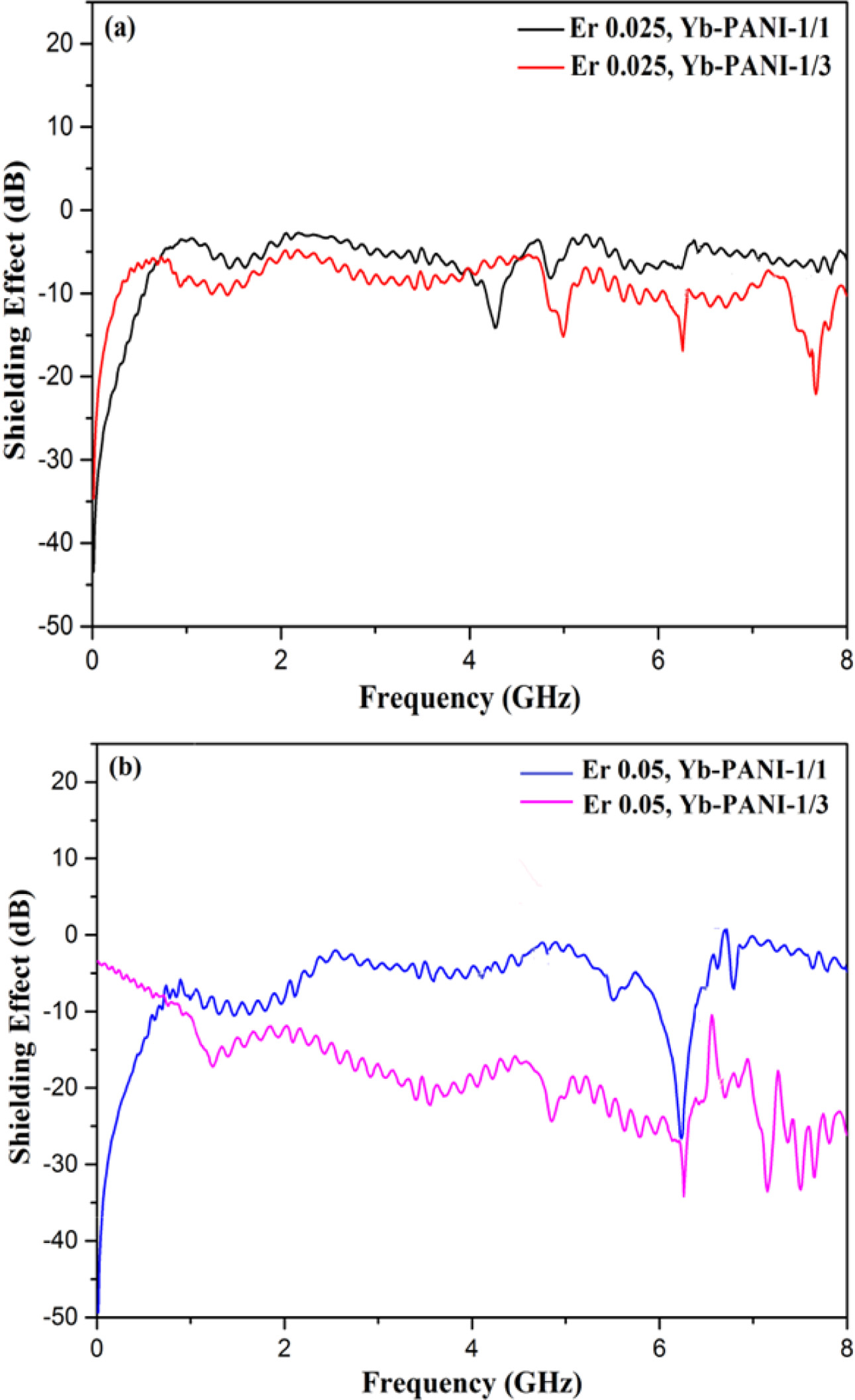

Fig. 3 exhibits the frequency dependency of the shielding effect of the epoxy- PANI/La2Ti2O7:Er,Yb composites with in 0-8 GHz frequency range. Among the PANI- La2Ti2O7: Er,Yb composites, It is observed that epoxy- La2Ti2O7: Er,Yb /Aniline: 1/3 has more visible efficacy on microwave shielding effectiveness features than epoxy-La2Ti2O7: Er,Yb /Aniline: 1/1.

The PANI/Lanthanum titanate compositions (La0.955 Yb0.02Er0.025)2Ti2O7/Aniline: 1/1) powders and epoxy indicated just one band at 4.27 GHz with -13.98 dB. In addition, in the 4.17 GHz and 4.35 GHz frequency range, this composite achieves shielding effect of lower than -10 dB.

Epoxy-PANI/Lanthanum titanate compositions (La0.955 Yb0.02Er0.025)2Ti2O7/Aniline :1/3) reach to -21.92 dB and -16.96 dB,- 14.99 dB, at 7.67 GHz and 6.27 GHz, at 4.99 GHz, respectively (Fig. 3(a)). Furthermore, it accomplished a shielding effect which is lower than - 10 dB in the frequency bands among 4.81 and 5.07 GHz, 6.08 GHz and 6.31 GHz, 7.62 GHz and 7.88 GHz.

The compositions reach to a shielding effectiveness of -26.44 dB at 6.23 GHz for epoxy-PANI/Lanthanum titanate compositions (La0.93Yb0.02Er0.05)2Ti2O7/Aniline: 1/1) (Fig.3(b)). Moreover, it achieved a shielding effect lower than -10 dB in the frequency bands between 0 and 0.62 GHz, 5.99 GHz and 6.38 GHz, respectively.

When Lanthanum titanate powder content decreases, PANI/Lanthanum titanate compositions (La0.93Yb0.02 Er0.05)2Ti2O7/Aniline: 1/3) reach to the -34.37 dB and -33.51 dB, -33.25 dB, at 6.27 GHz and at 7.15 GHz, at 7.5 GHz, respectively. In addition, this composite material achieved a shielding effect of below -10 dB in the frequency band between 0.92 GHz and 6.54 GHz, 6.64 GHz and 8 GHz, respectively. The best absolute shielding effectiveness was attained with the (La0.93 Yb0.02Er0.05)2Ti2O7/ Aniline: 1/3 composition (Fig. 3(b)) which indicates a worth lower than -10 dB in the frequency band between 0.92 GHz and 6.54 GHz.

In Fig. 3. b, for Er (x = 0.050), when Er element locates into La2Ti2O7 compound to replaces La ion, the solubility rised (within the solubility limit) and designed its environment with respect to Er element, increased the wave interference by the rising the surface area and enhanced the effectiveness of shielding. As PANI amount increases, and powder amount reduces, the shielding effectiveness is improved. Impedance matching was achieved through the use of PANI. PANI effect has increased the shielding effectiveness.

In addition, interfacial polarization exhibits a crucial role with in efficacy of electromagnetic shielding material among PANI and Er doped La2Ti2O7. The efficiency of microwave shielding effectiveness often be attached to adapting the irradiation impedance to the surface of the material. The matching transmission impedance between the composites ingredients is raised by PANI.

It is realized that the property of electromagnetic shielding effectiveness is really on account of the ferroelectric Lanthanum titanate. Meantime, due to the strength of the conductive polymer PANI, the sharp shielding effect peaks appear. In particular, the conducting polymer PANI was used to decrease the effect of available eddy currents, as the permeability of high frequency ferroelectric matters would reduce the eddy currents produced by EM waves. Electrical loss is caused by PANI. This had been combined through ferroelectric materials lıke lanthanum titanate and provided for regulation of EM shielding effectiveness with the dielectric shielding effect. In addition, the modifications lıke magnetocrystalline anisotropy of the material, saturation magnetization, dielectric properties and resonance frequency shifting of the material were known. So, the effectiveness of this is obvious in the material, and the shielding effect peak is moved to the area of higher frequencies. Shielding effect curves can possess small blips.

New Er,Yb doped La2Ti2O7 and new Er,Yb doped La2Ti2O7: PANI were produced, PANI based Er,Yb doped La2Ti2O7 composite have a high shielding effect ratio for electromagnetic waves in a broadwidth range, Microwave shielding effect of new composites are modified by controlling the Er,Yb doped Lanthanum titanate and PANI content in this process. Studies show that doping and PANI affect Lanthanum titanate structure. Er affected permeability of material and contributes to the shielding effectiveness.

|

Fig. 1 X-ray powder diffraction patterns of Er and Yb doped (La(1−x−y)YbxEry)2Ti2O7 composition with (Er, x = 0.025, 0.050) and (Yb, y = 0.02) sintered for 24 h at 1350 oC. |

|

Fig. 2 SEM images of Er and Yb doped (La(1−x−y)YbxEry)2Ti2O7 sintered for 24 h at 1350 oC (a) Er (x = 0.025) and Yb (y = 0.02) at 5000, (b) Er (x = 0.050) and Yb (y = 0.02) at 5,000, (c) EDS analysis of Er and Yb doped (La1−x−yREx−y)2Ti2O7, Er (x = 0.025) and Yb (y = 0.02) 5,000, (d) EDS analysis of Er and Yb doped (La1−x−yREx−y)2Ti2O7, Er (x = 0.050) and Yb (y=0.02) 5000. |

|

Fig. 3 Microwave shielding properties of the epoxy-PANI (La(1−x−y)YbxEry)2Ti2O7 : Er, Yb composites: (a) Er (x = 0.025) and Yb (y=0.02)-added La titanat / Aniline compositions weightiness rate was altered as 1:1, 1:3; (b) Er (x = 0.050) and Yb (y = 0.02) -added La titanate/Aniline compositions weightiness rate was altered as 1:1, 1:3. |

|

Table 1 Calculated lattice parameters of Er and Yb doped La2Ti2O7 samples (La(1−x−y)YbxEry)2Ti2O7 composition with (Er, x = 0.025, 0.050) and (Yb, y=0.02)) |

Er, Yb doped La2Ti2O7 were produced along with (La(1−x−y)YbxEry)2Ti2O7 compositions by using solid state technique and PANI- La2Ti2O7:Er,Yb composites were fabricated for its first time in research, to the best of our information. It is determined that the solubility in La2Ti2O7 was (x = 0.05) for Er.

SEM analysis also supported the XRD results, as it showed single phase at x = 0.025 and x = 0.050 for Er doping, at x = 0.02 for Yb doping. The minimum shielding effect point shifts toward higher frequency with a decrease of doped La2Ti2O7 content for epoxy-PANI/La2Ti2O7: Er,Yb compositions. Among epoxy-PANI/La2Ti2O7: Er,Yb compositions, (La0.955Yb0.02Er0.025)2 Ti2O7/Aniline: 1/3 and the (La0.93Yb0.02Er0.05)2Ti2O7/Aniline: 1/3 provided the best overall results of the shielding effect in the needed frequency bands.

The microwave shielding effect characteristic was obtained as 6.27 GHz and 2.0 mm in thickness with the minimal SE of -34.37 dB by La0.93Yb0.02Er0.05Ti2O7/Aniline: 1/3 composite. It is possible to modulate the microwave shielding properties simply by controlling the PANI content and the effect of Er and Yb dopant on the samples for the frequency bands necessary. The PANI/Er doped La titanate composites have an en- couraging potential as microwave shielding efficiency due to the simple and low cost preparation methods and better shielding efficiency results. The dopants and polyaniline were used to enhance the microwave shielding effectiveness properties of La2Ti2O7.

Microwave shielding characteristics of Er and Yb added La2Ti2O7:PANI composites indicate a strong variability with high concentrations of Er adding. The best shielding effect value is attained from (La0.93Yb0.02 Er0.05)2Ti2O7/Aniline: 1/3 of the composition with a value below -20 dB and between 5.38 GHz and 6.49 GHz, 7.3 GHz and 8 GHz. The second shielding effect performance is obtained from (La0.93Yb0.02Er0.05)2Ti2O7 /Aniline: 1/3 composition at the score of less than -10 dB and among 0.92 GHz and 6.54. The polyaniline content plays a significant exhibition in the variation of the shielding effectiveness properties. The microwave shielding effect properties of the PANI based Er and Yb added La2Ti2O7 composites can be examined for a wider range of concentration of Er dopant greater than 0.05 used in this study.

Er and Yb added La2Ti2O7:PANI can be regarded as a candidate for a wide range of microwave shielding effectiveness. The formation of doped materials is a further field of research for La titanate. Dopants and PANI polymer are being used in order to enhance the microwave shielding effectiveness characteristic of La2Ti2O7. The microwave shielding effectiveness and microwave absorbing properties of PANI based-single phase Er and Yb doped La2Ti2O7 at Radar and higher frequency ranges can be investigated.

Marmara University and Istanbul Technical University funded this research. In addition, this research is attributed to Salim Sahin who died in 2014, and to Prof. Dr. Ayhan Mergen who died in 2017. The writers thank them and Prof. Dr. Mustafa Kibaroglu (MEF University) for their advice and endless assistance.

- 1. M. Kimura, S. Nanamatsu, K. Doi, S. Matsushita, and M. Takahashi, Jpn. J. Appl. Phys. 11[6] (1972) 904.

-

- 2. P.A. Fuierer and R.E. Newnham, J. Am. Ceram. Soc. 74[11] (1991) 2876-2881.

-

- 3. M. Gasperin, Acta Cryst. B 31[8] (1975) 2129-2130.

-

- 4. U. Balachandran and N.G. Eror, J. Mater. Res. 4[6] (1989) 1525-1528.

-

- 5. K. Scheuncmnnn and H.K. Muller-Buschbaum, J. Inorg. Nucl. Chem. 37[9] (1975) I879-1881.

-

- 6. N. Ishizawa, F. Marumo, S. Iwai, M. Kimura and T. Kawamura, Acta Cryst. B 38[2] (1982) 368-372.

-

- 7. S. Marzullo and E.N. Bunting, J. Am. Ceram. Soc. 41[1] (1958) 40-41.

-

- 8. N. Janda, in “Development of a predictive shielding effectiveness model for carbon fiber/nylon based composites (Michigan Technological University, 2003) p.15-25.

- 9. P.F. Wilson, M.T. Ma and J.W. Adams, IEEE Transactions on Electromagnetic Compatibility 30[3] (1998) 239-250.

-

- 10. D.D.L. Chung, J. Mater. Eng. Perform. 9[3] (2000) 350-354.

-

- 11. P. Glatkowski, P. Mack, J.L. Conroy, J.W. Piche and P. Winsor, in “Electromagnetic shielding composite comprising nanotubes (US patent, 2001) US6265466B1.

- 12. P.R. Nahass, S.O. Friend, and R.W. Hausslein, in “High strength conductive polymers (US Patent, 1997) 5,651,922.

- 13. K. Lakshmi, H. John, K.T. Mathew, R. Joseph, and K.E. George, Acta Materialia 57[2] (2009) 371-375.

-

- 14. Z. He, Y. Fang, X. Wang, H. Pang, Synth. Met. 161[5-6] (2011) 420-425.

-

- 15. T.H. Ting, R.P. Yu, and Y.N. Jau, Materials Chemistry and Physics 126[1-2] (2011) 364-368.

-

- 16. C.C. Yang, Y.J. Gung, W.C. Hung, T.H. Ting and K.H. Wu, Compos. Sci. Technol. 70[3] (2010) 466 - 471.

-

- 17. M.O. Ansari, F. Mohammad, Sensors and Actuators B 157[1] (2011) 122-129.

-

- 18. E.I. Sahin, S. Paker, and M. Kartal, J. Chem. Soc. Pak. 41[2] (2019) 246-256.

- 19. E.I. Şahi̇n, M. Emek, B. Ertug, and M. Kartal, Beykent Üniversitesi Fen ve Mühendislik Bilimleri Dergisi 13[1] (2020) 34-42.

-

- 20. Y. Wang, W. Zhang, C. Luo, X. Wu, Q. Wang, W. Chen, and J. Li, Ceram. Int. 42[15] (2016) 17374-17381.

-

- 21. F. Tariq , M. Shifa, M. Tariq, S.K. Hasan, and R.A. Baloch, Advanced Materials Research 1101 (2015) 46-50.

-

- 22. S. Chhetri, P. Samanta, N.C. Murmu, S.K. Srivastava, and T. Kuila, AIMS Materials Science 4[1] (2016) 61-74.

-

- 23. H.S. Lim, H.S. Lee and S.J. Kwon, J. Ceram. Process. Res. 20[4] (2019) 363-371.

This Article

This Article

-

2021; 22(2): 208-213

Published on Apr 30, 2021

- 10.36410/jcpr.2021.22.2.208

- Received on Sep 7, 2020

- Revised on Dec 6, 2020

- Accepted on Dec 29, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Ethem İlhan Şahin

-

aDepartment of Satellite Communications and Remote Sensing, İstanbul Technical University, Maslak, Istanbul 34469, Turkey

dAdvanced Technology Research and Application Center, Adana Alparslan Türkeş Science and Technology University, Adana 01250, Turkey

Tel : +90 322 455 00 00 Fax: +90 322 455 00 02 - E-mail: shnethem@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.