- Role of earthenware in food processing applications

J.H. Choia, S.M. Kima, K.S. Hana, U.S. Kima,* and M.S. Kimb

aKorea Institute of Ceramic Engineering and Technology, Icheon, Korea

bDepartment of Food Science and Nutrition, Dankook University, Cheonan, KoreaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

Korean earthenware (also known as onggi) has been reported to play an active role in improving the fermentation quality of foods such as fermented soy products, as well as simply serving as a storage container. In this study, we conduct a region-wise analysis of the effects of the onggi shape, chemical composition, and gas-permeation characteristics on the total phenolic content and antioxidant activity of the soy sauce stored in these containers during its fermentation. During the fermentation process, the amount of antioxidant produced in the soy sauce increases with increase in the container diameter relative to the height. The antioxidant amount also increases with decrease in the amounts of alkali and alkaline earth metal oxides in the clay chemical composition and increase in the gas permeability of the onggi. Of all the onggi considered in our experiments, the Gangjin onggi exhibits the widest diameter relative to its height, least amounts of alkali and alkaline earth metal oxide components, and highest gas permeability. The antioxidant power is highest in the soy sauce fermented in the Gangjin onggi, corresponding to a total phenolic content value of 16.6 mg GAE/ml and FRAP of 54.3 mg AAE/ml.

Keywords: Earthenware, Shape, Chemical composition, Gas permeation, Fermentation

Korean earthenware, called onggi, is often referred to as “breathing pottery” for its unique porosity characteristics [1]. Unlike porcelain such as celadon or white porcelain, earthenware retains its open porosity even after sintering, and gas and liquid can permeate through the pores. Therefore, earthenware containers provide optimum conditions for the fermentation aging of foods such as soy sauce, soybean paste, and vinegar, which utilizes the growth of aerobic bacteria in the early stage of the fermentation process [2-4].

Onggi is formed by removing impurities from sedi- mentary clay containing large-sized silica, preparing the clay body, and stacking it while uniformly controlling the clay thickness on a potter’s wheel. The resulting specimen is subjected to drying in the shade for a long time, and a glaze prepared by mixing wood ash and clay is applied to it. Subsequently, the final onggi container is produced by sintering the piece once at ~ 1,200 oC [5, 6]. Onggi has a higher flux content than porcelain, and therefore, it has a relatively low sintering temperature (1,180-1,200 oC). In addition, because it uses materials with a wide particle size distribution and many large particles (> 150 µm), open pores are formed during the densification process, which enables the permeation of gas or liquid [7-9].

Onggi differs in the manufacturing method, shape, and size depending on the geographical region of origin, because the characteristics of the clay available, food culture, and climatic conditions are also different between each region [10-12]. Because onggi clay uses raw materials collected from the vicinity of the pottery workshops in these regions, the composition and particle size of the clay vary by region, which leads to region-wise differences in the properties and characteristics of the onggi, such as the color and pore structure. In particular, the shape of onggi is known to have a correlation with the sunlight and temperature of the region. In areas with low levels of sunlight and temperature, the opening or mouth of the container is enlarged for sufficient exposure to UV rays during the fermentation aging period of foods.

Soy sauce is one of the traditional fermentation-based seasonings in Asian countries, with soy forming the main ingredient [13-15]. The container utilized for the fermentation process of soy sauce forms one of the major factors that determine the quality of the soy sauce along with the ingredients used and/or the recipe of the soy sauce. According to a recent study, soy sauce subjected to fermentation in onggi exhibits increased protease activity due to the active growth of fermentation-related microorganisms when compared with this activity for glass, plastic, and stainless containers. Consequently, the amount of glutamic acid associated with the taste also increases [16].

Against this backdrop, in this study, we analyzed onggi from five geographically representative regions in Korea: Gangjin, Jeju, Ulsan, Yeoju, and Yesan, and we conducted fermentation-aging experiments using soy sauce to examine the resulting total phenolic content and ferric reducing antioxidant power (FRAP) of the sauce according to the onggi characteristics. By analyzing the correlation between the onggi properties and the soy-sauce fermentation aging process, we aim to demonstrate that onggi not only acts as a storage container, but also plays an active role in the fermenta- tion aging process of the sauce.

In this study, finished onggi products were collected from the Gangjin, Jeju, Ulsan, Yeoju, and Yesan regions and used in experiments. These places are representative of the main onggi workshops in Korea. The onggi used in the experiment were selected based on the 45l volume, and the various products and cross-section images are shown in Fig. 1.

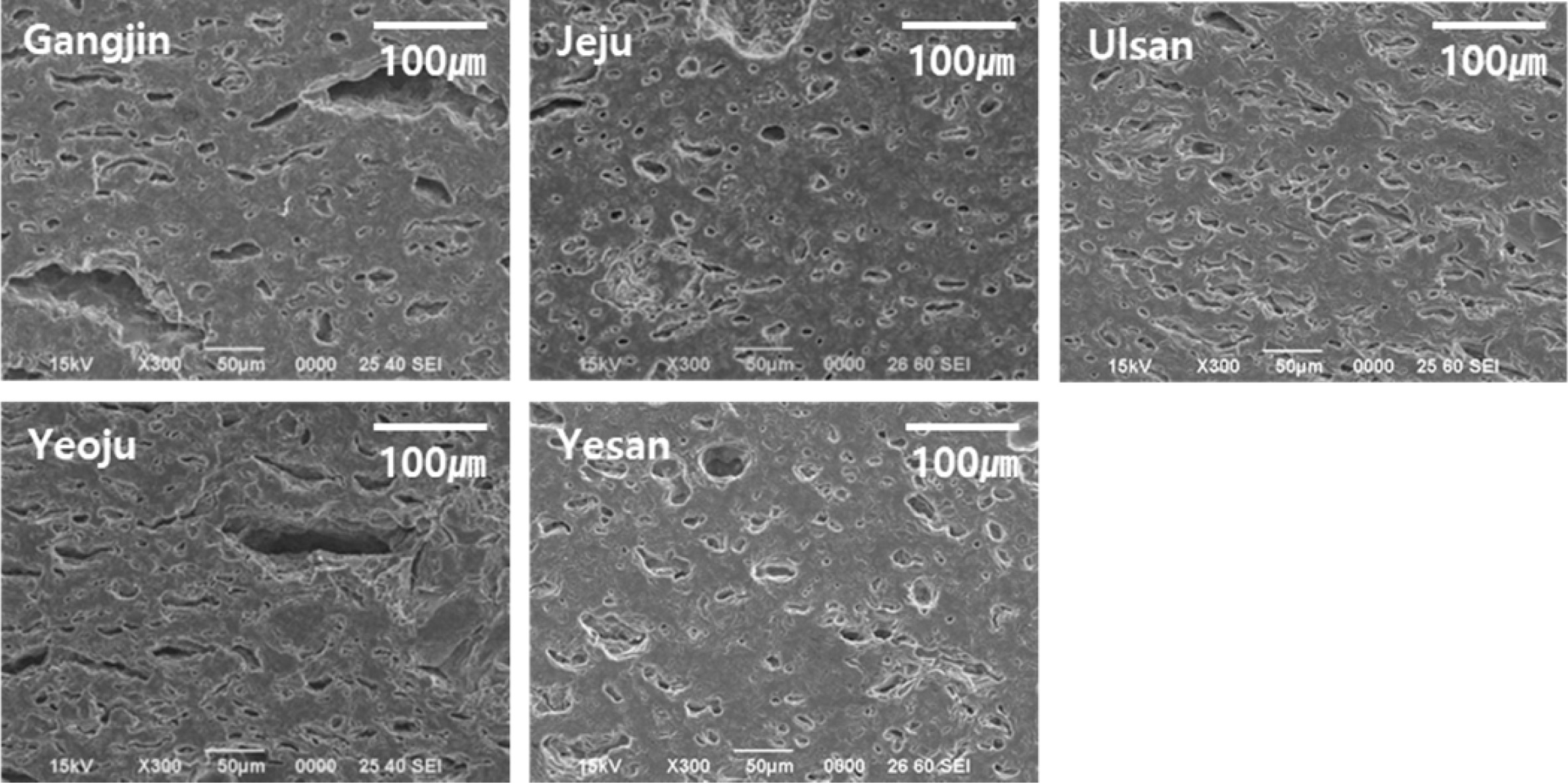

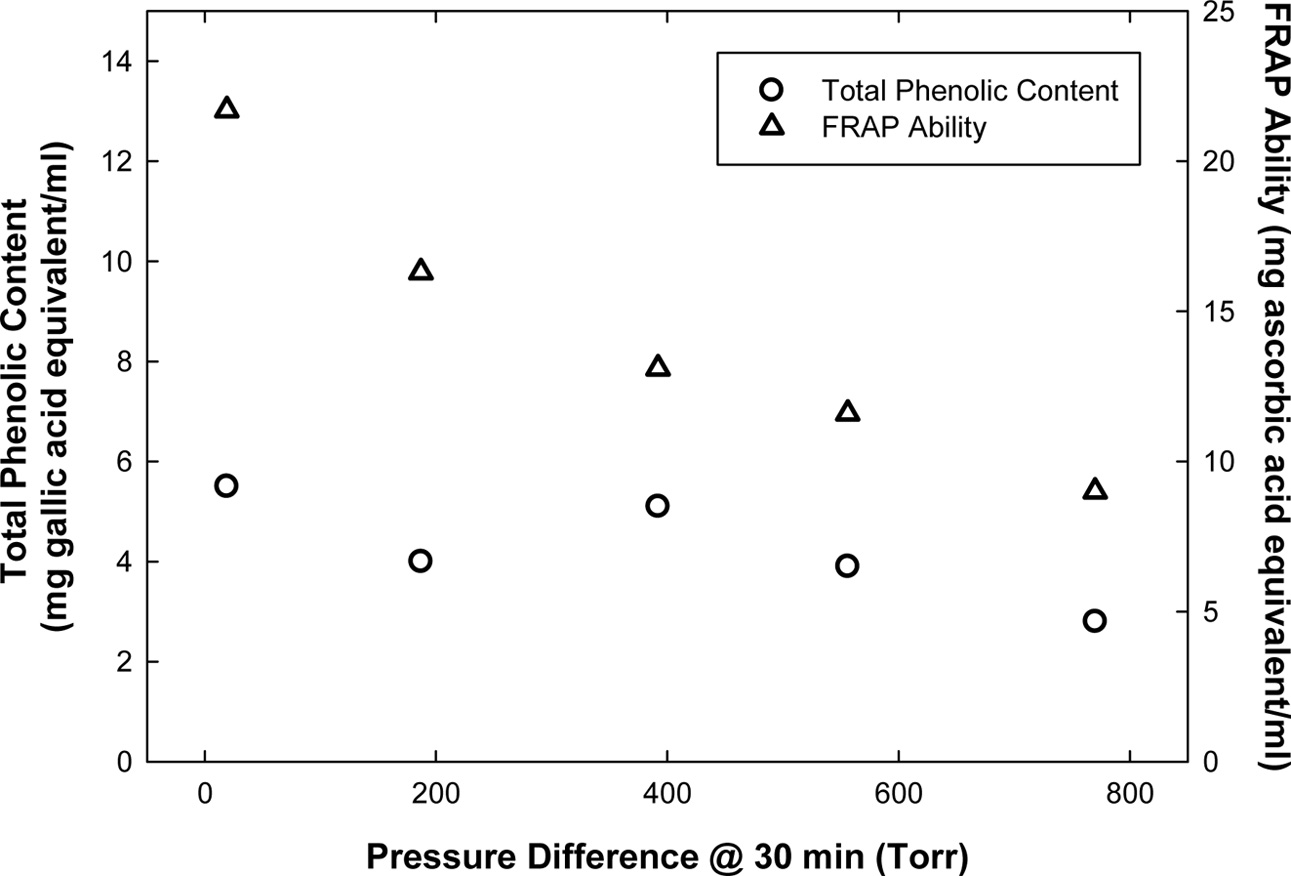

Table 1 lists the measurement results of the heights and diameters of the various onggi containers. In the study, each onggi specimen was partially cut and subjected to chemical composition analysis with the use of inductively coupled plasma spectroscopy (ACE, NTM Co., USA). The apparent porosity of each onggi was measured by means of the immersion method (KSL 4008). To analyze the gas-permeation characteristics of the onggi specimens, we measured the pressure change over time using a permeation analyzer fabricated at the Korea Institute of Ceramic Engineering and Technology [9]. The overall pore shape and distribution of the onggi specimens were analyzed with a scanning electron microscope (SEM, JSM-6701F, JEOL, Japan).

To analyze the changes in antioxidant properties of the soy sauce during the fermentation process in the onggi, we filled each onggi specimen with 38 kg of soy sauce, which was fermented for 120 days in the natural state. Soy sauce prepared as per the traditional recipe (Doorae Food Co., Sangju, Korea) was purchased for use in the experiments. The average temperature during the fermentation period was 20.0 oC (42.6 oC max, -4.4 oC min).

The total phenolic content was measured according to the method of Ferreres et al. [17]. After adding 1 mL of 50% Folin-Ciocalteu reagent to 100 μL of soy sauce diluted 10 times with distilled water, the solution was stirred. Subsequently, 300 μL of 1 N Na2CO3 was added, and the solution was left to react at room temperature for 90 min. The absorbance of the reaction solution at 750 nm was measured with the use of an ultraviolet-visible (UV-Vis) spectrophotometer (Ultrospec 2100 pro, GE Healthcare, UK). For the standard curve, gallic acid was used, and the total phenolic content was measured as milligrams of gallic acid in 1 mL of the sample. The ferric reducing antioxidant power (FRAP) value was measured following the method of Benzie and Strain [18]. After adding 1.5 mL of a FRAP solution to 50 μL of soy sauce diluted 50 times with distilled water, the solution was left for reaction for 30 minutes at 37 oC, and the absorbance of the reaction solution was measured at 593 nm. A standard curve was created using ascorbic acid, and the FRAP of the sample was measured as milligrams of ascorbic acid in 1 mL of the sample.

|

Fig. 1 Images of onggi (upper row) examined in our study and corresponding cross-sections (bottom row), classified as per geographical regions of origin. |

Regional onggi characteristics

Table 1 summarizes the dimensions of the onggi specimens by region. We note from the table that the heights of the onggi from Gangjin, Ulsan, and Yesan regions are similar at 44-46 cm, and the Jeju onggi exhibits the greatest height at 61.56 cm. The Gangjin and Jeju onggis are over 140 cm in diameter, followed by the Yesan, Yeoju, and Ulsan onggis. Here, we note that the height and diameter of the onggi vary depending on the region; this variation is known to be due to regional differences in the food culture and climate conditions [10, 11].

Upon examining the cut sections of the onggi (Fig. 1), we find that the cross-sectional thicknesses of the upper, middle, and lower sections appear different between the specimens, depending on the shape and manufacturing technique. The Gangjin and Yeoju onggis, which have a large diameter, exhibit similar thicknesses of the upper and lower sections, but the thickness of the middle section is relatively small. In particular, the Gangjin onggi shows a large thickness difference of ~4-5 mm between the upper/lower and middle sections. On the other hand, the Yesan onggi exhibits very little difference in thickness between the upper, middle, and lower sections, while the Jeju onggi exhibits a middle section that is thicker by 1 mm than the upper and lower sections. The Ulsan onggi exhibits similar upper- and middle-section thicknesses, but the lower section is thinner by ~1 mm.

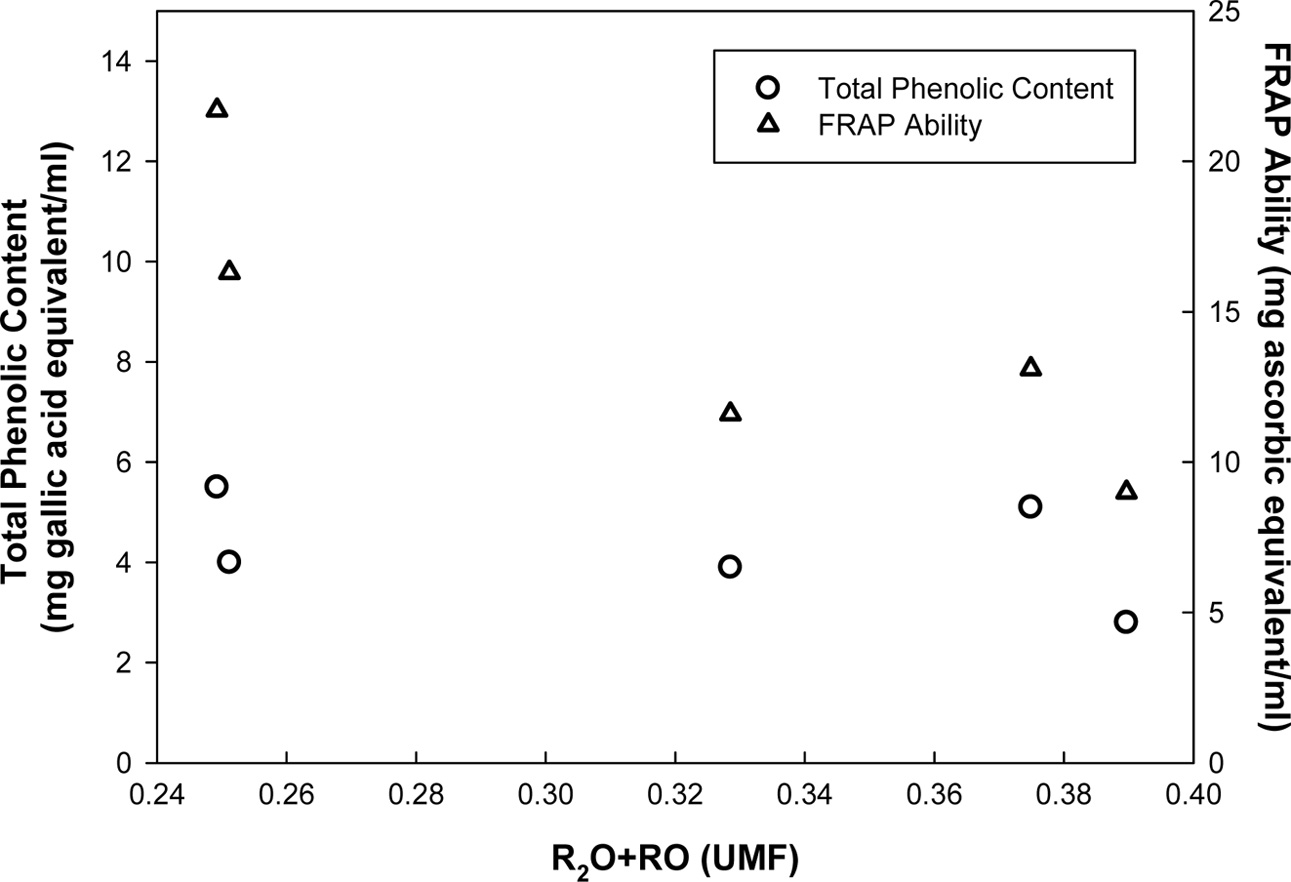

Table 2 lists the chemical composition analysis results of the onggi specimens of each region. In the case of alkali (R2O = Na2O + K2O) and alkaline earth (RO = MnO + CaO + MgO) metal oxides, which act as fluxes in pottery, the Ulsan and Jeju onggis exhibit slightly higher values than onggis from other regions. For the Ulsan onggi, R2O = 3.68 and RO = 1.80%, which are the highest values among the onggis. As regards the Jeju onggi, we note that the amounts of the MnO and MgO are higher than the corresponding ones of the specimens from the other regions.

It can be observed that the Fe2O3 content varies widely depending on the region. The Jeju onggi exhibits the highest Fe2O3 content at 7.13%, followed by the Yeoju, Ulsan, and Yesan onggis at 4.40%, and the Gangjin onggi at 2.39%; this value is lower than the Fe2O3 content of a typical onggi. Here, we remark that Jeju is a region formed by volcanic activity, and its geological structure and composition are very different from other regions, and this variation is reflected in the chemical composition of the onggi [19]. We note that the TiO2 content of the Jeju onggi is also higher than those of the specimens from the other regions.

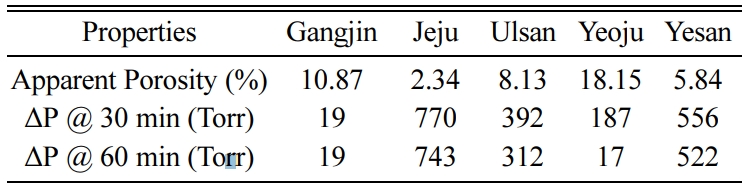

Table 3 summarizes the apparent porosity and gas-permeation characteristics of the onggis. As regards porosity, the Yeoju onggi exhibits the highest value at 18.15%, while this value for the Gangjin onggi is 10.87%. It can be observed that the Jeju onggi exhibits the lowest porosity at 2.34%.

To analyze the gas-permeation characteristics of the onggi, we applied a pressure of 1,000 Torr to one side of the cut specimens, and after 30 and 60 min, we measured the pressure difference between the two sides. We note from Table 3 that the Gangjin and Yeoju onggis afford complete permeation within 60 min and the pressure difference disappears, and in terms of time, the Gangjin onggi shows faster permeation. The Yeoju onggi exhibits the highest porosity, but its permeability is lower than that of the Gangjin onggi. This is because the Yeoju onggi’s overall porosity is high, but there is a difference in the pore structures between the two specimens.

The Ulsan and Yesan onggis do not show complete permeation; however, the results indicate the slow progress of permeation. The Jeju onggi exhibits some permeation, but also shows a large pressure difference of 743 Torr even after the measurement at 60 min. From these results, we find that the porosity and permeation characteristics are not linearly proportional, and it is conceivable that they are affected by another factor, the pore structure.

Fig. 2 shows the results of the cross-sectional SEM observations of the onggi for the comparison of the pore shape and distribution of each onggi. Although a uniform pore distribution and high porosity can be observed on the whole, there is a difference in the shape and size of the pores. The Gangjin and Yeoju onggi exhibit fine pores in the range of 10-30 µm as well as large pores of >150 µm. On the other hand, in the Jeju, Ulsan, and Yesan onggis, no large pores are present, but fine pores of 20 μm or smaller can be observed.

Total phenolic content and antioxidant activities of soy sauce aged in onggi

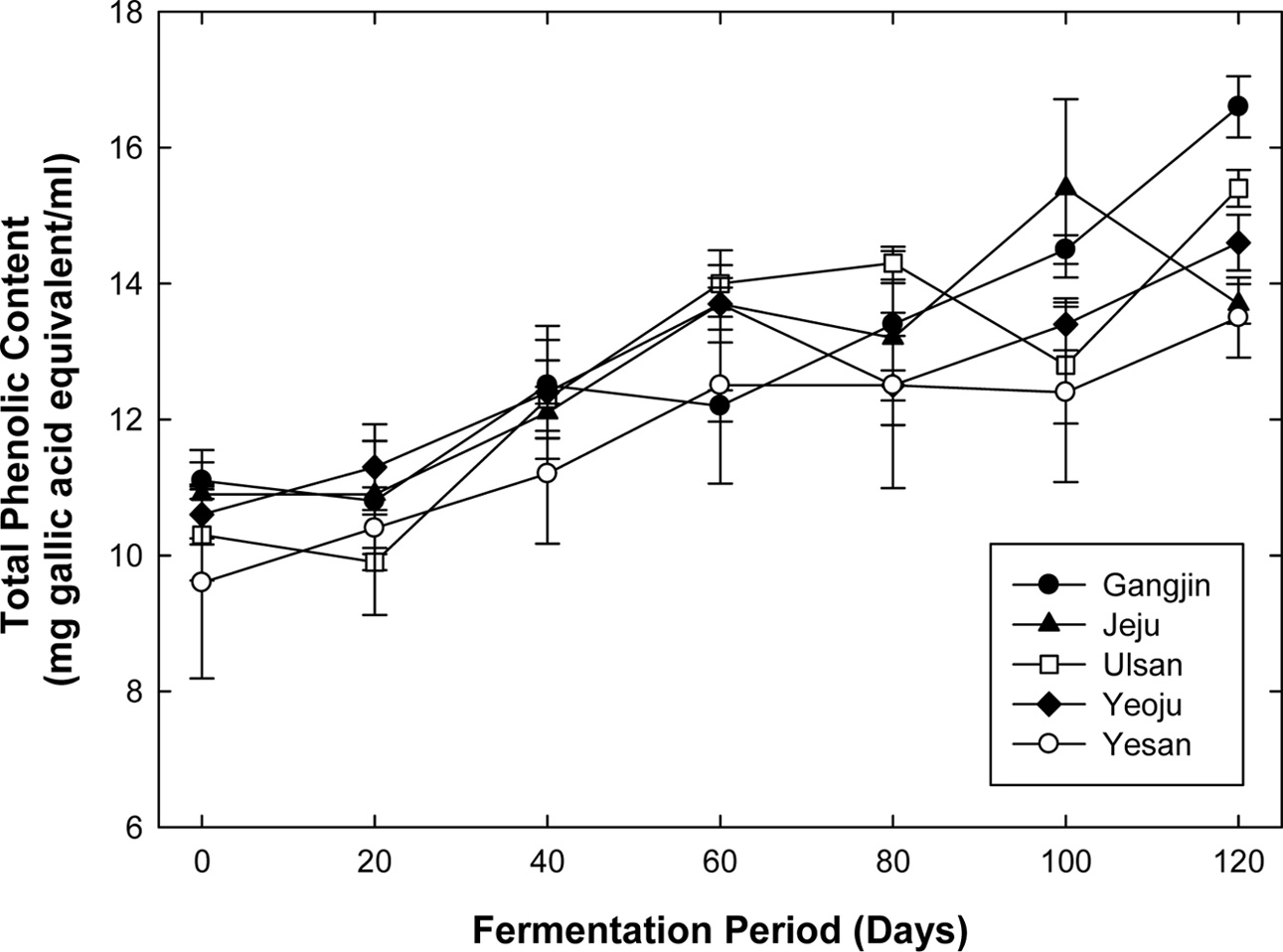

Fig. 3 shows the changes in the total phenolic content of the soy sauce fermented for 120 days in each onggi specimen. We note from the figure that as the soy-sauce fermentation progresses, the total phenolic content tends to increase overall. Over 120 days of fermentation, the total phenolic content increases by 4.12 mg gallic acid equivalent (GAE)/mL on average. As regards the total phenolic content, the soy sauce fermented in the Gangjin onggi exhibits the highest value with 16.6 mg GAE/mL, and the sauce in the Yesan onggi exhibits the lowest content at 13.5 mg GAE/mL. The oxygen entering the onggi affects the growth of aerobic bacillus, which form the main fermentation bacteria of the soy sauce, and also affects the secretion of enzymes such as protease, thereby increasing amounts of the various decomposition products of the soy sauce.

S.K. Lee et al. measured the total phenolic content of 17 commercial soy sauces prepared by the traditional Korean method using the same analysis technique as in this study [20]. Although the container and period of soy sauce are not specified in the literature, it can be judged that the fermentation process is lasted for at least 2-3 months using onggi from the phrase “soy sauce manufactured by the traditional method”. Total phenolic content was highest at 11.20 mg GAE/mL in soy sauce from Jeolla Province (Muju), and the lowest at 2.37 mg GAE/mL in soy sauce from Gangwon Province (Pyeongchang). J.S. Kim et al. analyzed the change in total phenolic content of soy sauce prepared with different types of soybeans during the 180 days fermentation period [21]. The total phenolic content was increased in all samples during the fermentation period, and was influenced by the preparation method of raw materials and the temperature during the fermentation period. Compared with these two cases, the total phenolic contents in this study were relatively high, indicating that the fermentation product was actively produced during the fermentation process. However, considering the difference in raw materials and fermentation conditions, the results are in a reasonable range.

Phenolic compounds are metabolites that are widely distributed in plant systems; such compounds include flavonoids, catechins, phenolic acids, etc., and they demonstrate high antioxidant and antibacterial activities [17, 22, 23]. It has been reported that soy sauce and soybean paste, which are traditional fermentation foods based on soybeans, exhibit increased extraction of phenolic compounds such as tocopherol, isoflavones, and phenolic acids with antioxidant power as fermentation progresses [24, 25].

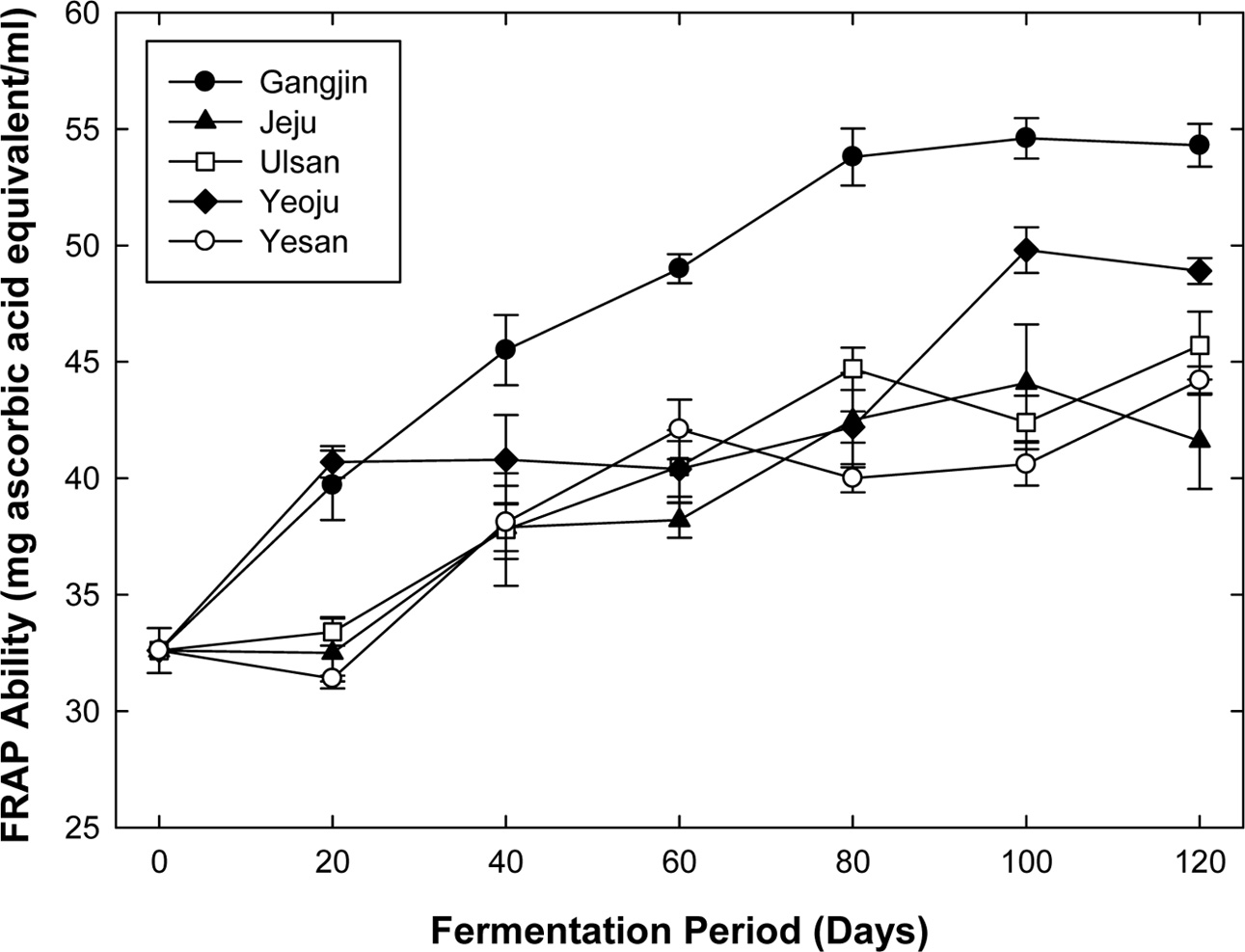

Next, we focus on ferric reducing antioxidant power (FRAP), which reflects the ability of phenolic compounds to reduce Fe3+ to Fe2+. The FRAP value increases in proportion with the antioxidants contained in plasma; here, we note that FRAP measurement forms one of the methods to directly measure antioxidant power [18]. From Fig. 4, we note that the FRAP values are significantly different according to the soy-sauce fer- mentation period and by region.

We first note that all soy sauces exhibit an increase in FRAP during the fermentation process. In the Gangjin onggi soy sauce, FRAP increases at a faster rate than other soy sauces for 80 days. On the 120th day, we observe the highest FRAP value of 54.3 mg ascorbic acid equivalent (AAE)/mL in the Gangjin onggi soy sauce, followed by the Yeoju (48.9 mg AAE/mL), Ulsan (45.7 mg AAE/mL), Yesan (44.2 mg AAE/mL), and Jeju (41.6 mg AAE/mL) soy sauces. In this regard, Park et al. have reported that the total amounts of phenolic compounds and flavonoids in soybean fermen- tation foods demonstrate a high correlation with anti- oxidant activities that show ferric reducing power [25].

Correlation between onggi characteristics and anti- oxidant properties of soy sauce

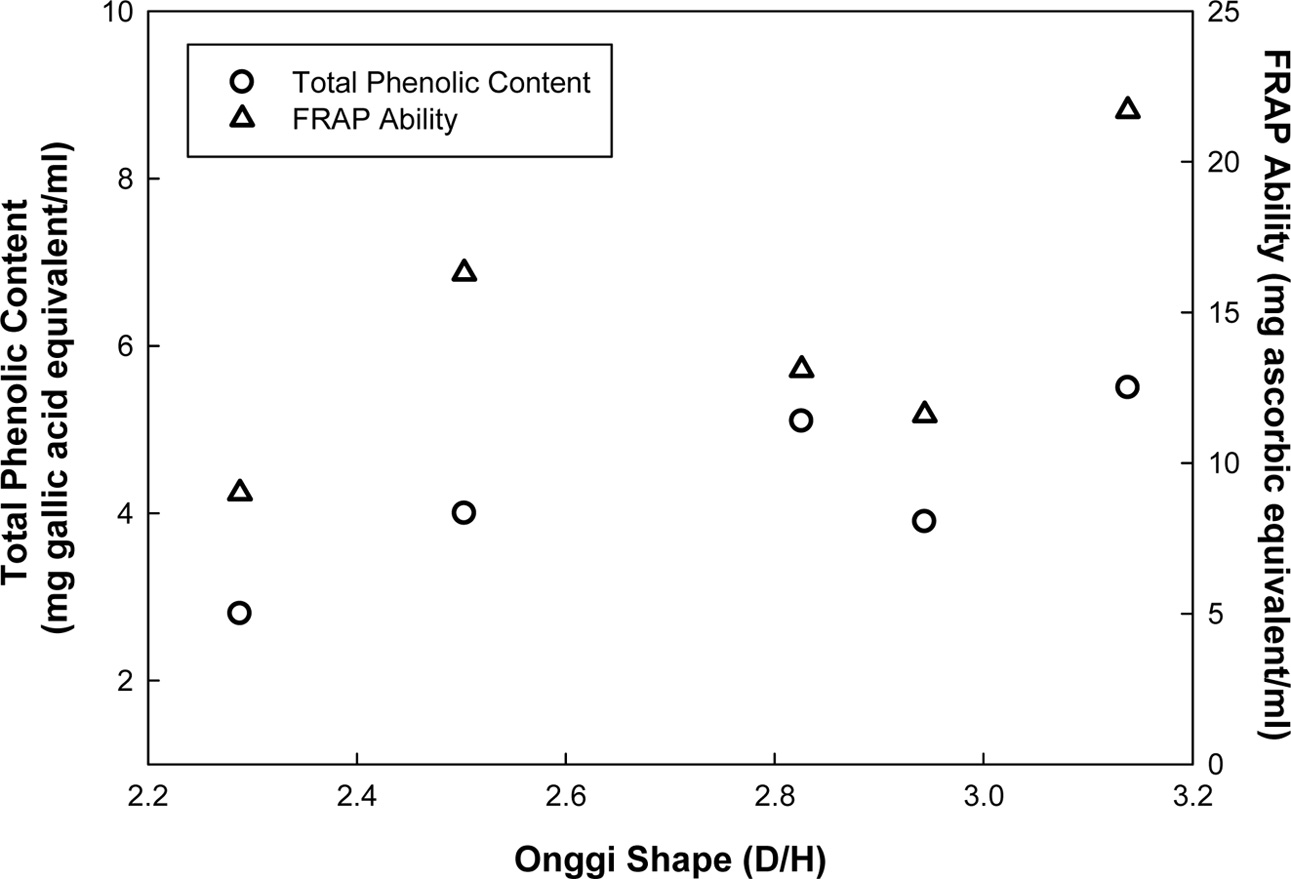

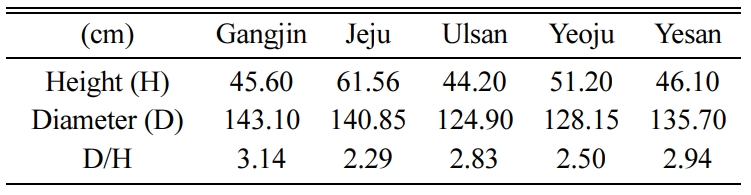

In the next phase of the study, we investigated the effect of the onggi shape, chemical composition, and gas permeation on the production of antioxidants during the soy-sauce fermentation process. Fig. 5 shows the effect of the onggi shape on the antioxidant characteristics of the soy sauce. From the figure, it can be observed that as the onggi diameter increases relative to the onggi height, the production of antioxidants generally increases. We note here that larger onggi diameters correspond to larger surface areas, which will increase the amount of heat delivered to the soy sauce under fixed sunlight and temperature conditions, thus promoting the production of antioxidants [26].

It is expected that the leaching of ions will occur because the onggi is in contact with the soy sauce. In general, it is known that the leaching of alkali and alkaline earth metal ions with a small ion radius occurs in large quantities [27]. The glaze covering the onggi clay body is a mixture of wood ash and clay, which is similar in composition to the clay body. In addition, the onggi clay body directly contacts the soy sauce owing to its pore characteristics, thereby resulting in the leaching of ions from the clay body. In this regard, the effect of the amount of alkali and alkaline earth metal oxides, which are the easiest to elute among the chemical components of onggi clay body, on the production of antioxidants is shown in Fig. 6. From the figure, it can be observed that the amount of antioxidant production decreases as the content of alkali and alkaline earth metal oxides increases.

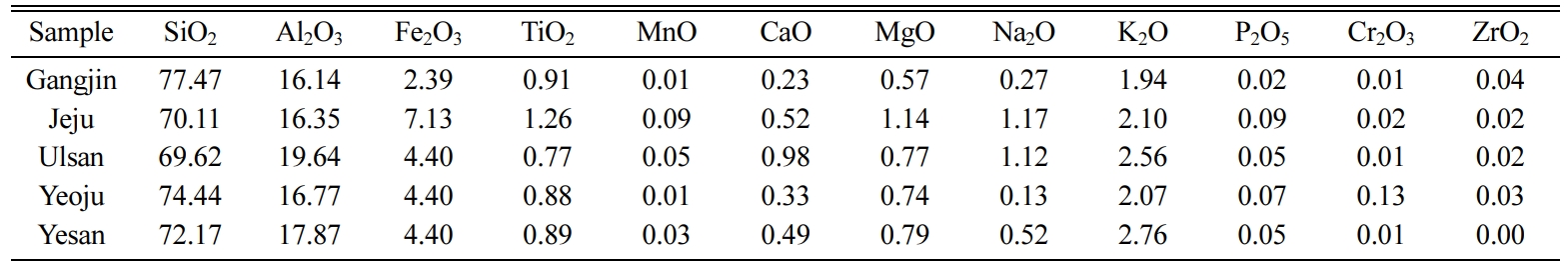

Based on our analysis of the collected data, we find that the onggi porosity, absorption rate and bulk density also affect the production of antioxidants, and we note that the gas-permeation characteristics exert the greatest influence (Fig. 7). Here, we note that while several variables were considered to quantitatively represent the gas-permeation characteristics of the onggi, the pressure difference in the specimen after 30 min of the permeation test was the most effective in this regard. As regards Fig. 7, we note that the increase in pressure difference (x-axis) corresponds to deterioration of the gas-permeation characteristics of the onggi. From the results, it can be observed that as the gas permeability of the onggi improves, the total phenolic content and ferric reducing antioxidant power (FRAP) ability increase. In particular, the FRAP ability shows both a large change and tendency of change.

S. K. Jung et al. reported the effect of onggi with different porosity on fermentation of soy sauce [3, 7]. As the porosity of onggi increased, the protease activity and microbial changes of soy sauce tended to decrease. When the porosity of onggi is increased, the salt content becomes relatively high due to the water loss of soy sauce during the fermentation period, which has a negative effect on the growth of aerobic bacteria. This led to a decrease in the number of bacteria and yeasts that affect the flavor and antioxidant of the soy sauce. These results are contrary to the positive effect of porosity on the antioxidant properties of soy sauce in this study. However, in both cases, I would like to point out that the porosity was intentionally increased by changing the clay body composition or the glaze application method. In other words, unlike commercial onggis used in this study, onggi with excessive porosity seems to have a negative effect on the experimental results. Comprehensively judged together with the results of this study, there must be an optimal porosity of onggi that positively affects the flavor and antioxidant properties of soy sauce.

|

Fig. 2 Scanning electron microscope (SEM) observations of pore structures in onggis. |

|

Fig. 3 Change in total phenolic content of soy sauce according to fermentation time in each onggi specimen. |

|

Fig. 4 Ferric reducing antioxidant power (FRAP) variation according to fermentation time in each onggi. |

|

Fig. 5 Correlation between onggi shape and antioxidant production. |

|

Fig. 6 Correlation between alkali and alkaline earth metal oxide content of onggi clay components and antioxidant production. |

|

Fig. 7 Correlation between gas-permeation properties and antioxidant production ability of onggi. |

In this study, we compared the antioxidant activities observed during the fermentation aging process of soy sauces in onggi specimens classified based on their geographical region of origin. Onggi uses clay that is collected in the origin region, and therefore, differences in the chemical composition and particle size arise, thereby resulting in differences in the porosity and gas-permeation properties of various onggi containers. In addition, differences in the local sunlight and climatic conditions are reflected in the shape of onggi. We found that the Ulsan, Yeoju, and Yesan onggis had similar shapes and dimensions, but the Gangjin onggi exhibited a bulging shape with a diameter of 143.10 cm, and the Jeju onggi had an elongated shape with a height of 61.56 cm. In terms of chemical composition, the Ulsan onggi had the highest amount of alkaline and alkaline earth metal oxide components among all specimens, the Gangjin onggi had the lowest Fe2O3 content at 2.39%, and the Jeju onggi had the highest amounts of Fe2O3 and TiO2. In the case of the Gangjin and Yeoju onggi with their high porosity, the gas permeability was also high, but the porosity and gas-permeation charac- teristics were not linearly proportional. The Gangjin onggi, which showed the second highest porosity at 10.87%, exhibited the highest gas permeability. In the Gangjin and Yeoju onggis, which have good gas per- meation properties, we observed that micropores with sizes of 10-30 µm coexisted with large-sized pores of >150 µm.

The total phenolic content and antioxidant activities increased with the fermentation progress of the fer- mented soy sauces in all the onggi specimens. The Gangjin onggi soy sauce exhibited the highest total phenolic content (16.6 mg GAE/ml) and ferric reducing antioxidant power (FRAP) (54.3 mg AAE/mL) among all the onggis. On the other hand, the Yesan onggi exhibited the lowest total phenolic content (13.5 mg GAE/mL), and the Jeju onggi exhibited the lowest FRAP value (41.6 mg AAE/mL).

In this study, we investigated the effect of the onggi shape, chemical composition, and gas-permeation pro- perties on antioxidant production during soy-sauce fer- mentation. We found that during the fermentation process, the amount of antioxidant generated by the soy sauce increased with the onggi diameter increase relative to the height, decrease in alkali and alkaline earth metal oxides in the clay chemical composition, and increased gas permeability of the onggi. In particular, there was a clear correlation between the onggi gas-permeation properties and the soy-sauce FRAP ability.

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MSIT). [2018M3C1B505215]

- 1. S.S. Hong, in “Breathing Pottery, Onggi” (Booksea, 2010) p.149-170.

- 2. K.I. Han, M.J. Kim, H.J. Kwon, Y.H. Kim, W.J. Kim, and M.D. Han, J. Kor. Food. Nutr. 26[2] (2013) 249-257.

-

- 3. K.S. Lee, Y.B Lee, D.S. Lee, and S.K. Chung, Int. J. Food Sci. Tech. 41[10] (2006) 1158-1163.

-

- 4. S.K. Chung, K.S. Lee, and D.S. An, Korean J. Packag. Sci. Tech. 14[1] (2008) 9-14.

- 5. S.K. Kim, M.S. Han, E.J. Moon, Y.H. Kim, J.J. Hwang and H.Y. Lee, J. Conserv. Sci. 26[3] (2010) 311-324.

- 6. R. Sayers and R. Rinzler, in “The Korean Onggi Potter” (Smithsonian Institution Press, 1987) p. 17-54.

-

- 7. S.K. Chung, K.S. Lee, and D.S. Lee, Korean J. Food Sci. Technol. 38[2] (2006) 215-221.

- 8. J.K. Jeong, Y.W. Kim, H.S. Choi, D.S. Lee, S.A. Kang, and K.Y. Park, Int. J. Food Sci. Technol. 46[10] (2011) 2015-2021.

-

- 9. S.M. Kim, H.G. No, U.S. Kim, and W.S. Cho, J. Kor. Ceram. Soc. 51[1] (2014) 11-18.

-

- 10. Y.S. Park and R. Whitfield, in “Handbook of Korean Art: Earthenware and Celadon” (Laurence King Publishing Ltd., 2003) p. 8-77.

- 11. J.H. Kim, Korean J. of Cultural Heritage Studies. 48[2] (2015) 142-157.

-

- 12. S.H. Na, in “Korean Traditional Crafts, Earthenware” (Ewha Woman’s University Press 2006) p. 105-145.

- 13. S.Y. Park, H.S. Kwak, M.G. Oh, Y.S. Lee, Y.H. Jeong, and M.S. Kim, Appl. Biol. Chem. 59[1] (2016) 33-41.

-

- 14. S. Kaneko, K. Kumazawa, and O. Nishimura, J. Agric. Food Chem. 60[15] (2012) 3831-3836

-

- 15. Y. Feng, Y. Cai, G. Su, H. Zhao, C. Wang, and M. Zhao, Food Chem. 145[15] (2014) 126-134.

-

- 16. S.K. Chung, K.S. Lee, and S.H. Cho, Korean J. Food Preserv. 11[2] (2004) 233-239.

- 17. F. Ferreres, D. Gomes, P. Valentão, R. Gonçalves, R. Pio, E.A. Chagas, R.M. Seabra, and P.B. Andrade, Food Chem. 114[3] (2009) 1109-1027.

-

- 18. I.F. Benzie and J.J. Strain, Anal. Biochem. 239[1] (1996) 70-76.

-

- 19. D.W. Kang, D.C. Kim, J.D. Ko, S.R. Hong, and K.C. Song, J. Korean Soc. Soil Sci. Fert. 30[1] (1997) 3-15.

- 20. S.K. Lee, Y.H. Jeong, S.B. Yim, and S.R. Yu, J. Korean Soc. Food Sci. Nutr. 44[9] (2015) 1399-1406.

-

- 21. J.S. Kim, H.O. Kim, G.S. Moon, and Y.S. Lee, J. East Asian Soc. Dietary Life, 18[6] (2008) 981-988.

- 22. T.S. Tyug, K.N. Prasad, and A. Ismail, Food Chem. 123[3] (2010) 583-589.

-

- 23. D. Malenčić, M. Popović, and J. Miladinović, Molecules 12[3] (2007) 576-581.

-

- 24. G.S. Moon and H.S. Cheigh, Korean J. Food Sci. Technol. 19[6] (1987) 537-542.

- 25. J.W. Park, Y.J. Lee, and S. Yoon, Korean J. Food Culture. 22[3] (2007) 353-358.

- 26. K. Sharma, E.Y. Ko, A.D. Assefa, S.Y. Nile, E.T. Lee, and S.W. Park, J. Food Drug Anal. 23[2] (2015) 243-252.

-

- 27. G. Perera and R.H. Doremus, J. Am. Ceram. Soc. 74[7] (1991) 1554-1558.

-

This Article

This Article

-

2021; 22(1): 91-97

Published on Feb 28, 2021

- 10.36410/jcpr.2021.22.1.91

- Received on Aug 15, 2020

- Revised on Oct 31, 2020

- Accepted on Nov 11, 2020

Services

Services

- Abstract

introduction

experimental procedures

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- U.S. Kim

-

Korea Institute of Ceramic Engineering and Technology, Icheon, Korea

Tel : +82-31-645-1422 Fax: +82-31-645-1485 - E-mail: ukim@kicet.re.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.