- K(Ta0.60,Nb0.40)O3/K(Ta0.40,Ta0.60)O3 heterolayered thin films for electrocaloric cooling device

Jiwon Kima, Jooseok Parkb and Sunggap Leea,*

aDepartment of Materials Engineering and Convergence Technology, RIGET, Gyeongsang National University, JinJu 52828, Republic of Korea

bBusiness Cooperation Center, Korea Institute of Ceramic Engineering and Technology, Jinju 52851, Republic of KoreaThis article is an open access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

In this study, K(Ta0.60,Nb0.40)O3/K(Ta0.40,Ta0.60)O3 heterolayered thin films were fabricated by spin coating method. KTN specimens were manufactured according to the number of coatings and were investigated in order to apply to cooling devices. KTN heterolayered thin films showed a polycrystalline KTN X-ray patterns with some pyrochlore phase. For the six-layer coated thin film of KTN, the values of dielectric constant, dielectric loss, remanent polarization and coercive field were 1423, 0.64, 19.94 μC/cm2 and 37.64 kV/cm at 28 oC. When a voltage of 330 kV/cm was applied to the 3 times coated KTN films, the electrocaloric property was 3 oC. When a voltage of 330 kV/cm was applied, the value of the electrocaloric temperature change (ΔT of the three-layer coated thin film

Keywords: Potassium tantalite niobate, Electrocaloric effect, Thin film, Solgel method.

Potassium tantalate niobate (KTN) material used in this study is a solid solution of KTaO3 and KNbO3, which has a perovskite structure. Since the advent of worldwide lead regulations, KTN has been increasingly studied as a substitute for lead zirconate titanate (PZT). K(Ta,Nb)O3 forms a solid solution in all compositions ranging from Ta:Nb and the curie temperature of KTN can be adjusted by controlling the Ta:Nb ratio [1-5]. It is known that it has good dielectric properties near the curie temperature (Tc) [6, 7].

Also, KTN has been shown to have good dielectric and pyroelectric properties, along with an electro-optic effect. Many studies have been conducted on KTN about its application to various fields due to its good dielectric, pyroelectric and electro-optic properties [8, 9]. In contrast, research for the application of the electro-caloric effect of KTN material is rare, especially in regard to the application of the electro-caloric effect of thin films made of KTN material in the hetero-layer. Therefore, it was judged that there is enough research value for this study be done.

Also, the most widely used cooling technology is vapor compression cooling technology. Freon gas was mainly used as a refrigerant in vapor compression technology, but it has been banned worldwide as it causes environmental problems. Accordingly, electrocaloric effect, magnetocaloric effect and thermoelectric effect have been studied as technologies to replace vapor compression cooling technology. However, there is a limit to applying the magnetocaloric effect due to the large and expensive magnets, and the thermoelectric effect due to the low energy efficiency, while the cooling devices using electrocaloric effect has high energy efficiency and can be miniaturized [10, 11]. Also, studies have been actively conducted since the release of studies that showed high efficiency when made into a thin film in the electrocaloric effect [12].

Electrocaloric effect (ECE) is a phenomenon in which a material shows a reversible temperature change under an applied electric field [13-15]. Due to the significant temperature dependence of polarization, perovskite structured ferroelectric materials have electrocaloric effect (ECE), which can be used to manufacture solid state cooling devices such as sensor, chip cooling and temperature control device in sensors.

So, this study investigated ferroelectric KTN(60/40)/KTN(40/60) thin films as an electro-caloric cooling devices. The thin films were fabricated by the Chemical Solution Deposition (CSD) method and the spin coating method, and the structural and electrical properties were investigated according to the number of layers of coating (3, 4, 5, 6 times).

In this study, KOC2H5 (Sigma Aldrich, USA, 99%), Ta(OC2H5)5 (Alfa aesar, USA, 99.999%), and Nb(OC2H5)5 (Alfa aesar, USA, 99.999%) were used as the starting materials and 2-Methoxy Ethanol as the solvent. 2MOE (2-Methoxy Ethanol) was added to the KOC2H5 and stirred until the powder was completely dissolved. After, KOC2H5 was heated to 120 degrees in a N2 atmosphere, mixed with Ta(OC2H5)5, and heated again. Finally, Nb(OC2H5)5 was added and refluxed at 120 degrees for 24 h. The coating solutions were spin coated at 2,500 rpm for 30 sec on Pt(111)/Ti/SiO2/Si substrate. Each layer was dried at 200 oC for 20 min, and 400 oC for 20 min to remove the organic materials. The KTN films were annealing at 750 oC for 2 h. The crystal structures of thin films were confirmed by X-ray diffraction (XRD) measurement. The surface and cross section morphology were studied by the field-emission scanning electron microscope (FE-SEM). For electrical measurements, Pt-upper electrode with a diameter of 500 μm was deposited on the film by dc sputtering method. Dielectric properties and polarization hysteresis loops were analyzed using an LCR meter (PM-6036, Fluke) and ferroelectric test system (RT66B, NM, USA).

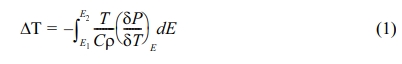

Fig. 1(a) shows X-ray diffraction (XRD) data of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films. A homogeneous KTN XRD patterns with a pyrochlore phase were shown in all specimens. As the coating number increased, the lattice constant of specimens decreased very slightly 3.983 Å to 3.976 Å. Also, the intensity of XRD peaks also increased. This crystallinity enhancement property is such that, as coating number increased, the underlying coating layer acts as a substrate, so that the crystallization of the upper layer is much better due to a decrease in the strain effect between the substrate and the thin films. In the graph 1(b) showing 50-52 degrees, a small peak is seen below 51 degrees in the 3 times coated KTN films, while a peak can also be seen above 51 degrees in the 4 times coated films. But, in the case of the 5 times and 6 times coated KTN films, due to the underlying layers affecting the crystal growth to the upper layers, two intensities of the underlying layers appear to be gathered in the middle and coexist.

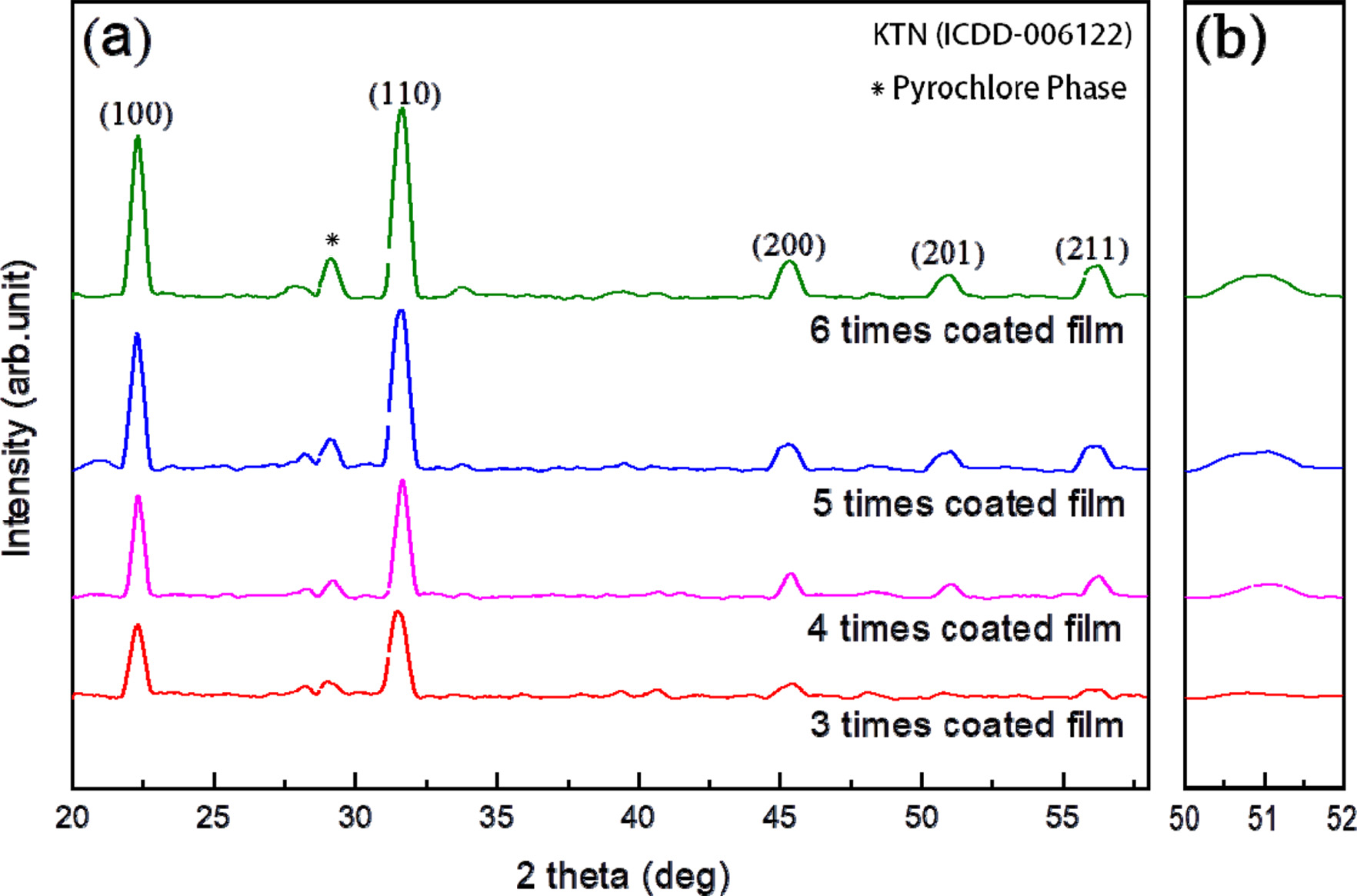

Fig. 2 shows the surface microstructure (SEM) of the K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films. Pores gradually decreased as the coating number increased. As the coating number increases, the grain size increased. The surface image showed fine micro- structures with large and small grains mixed together.

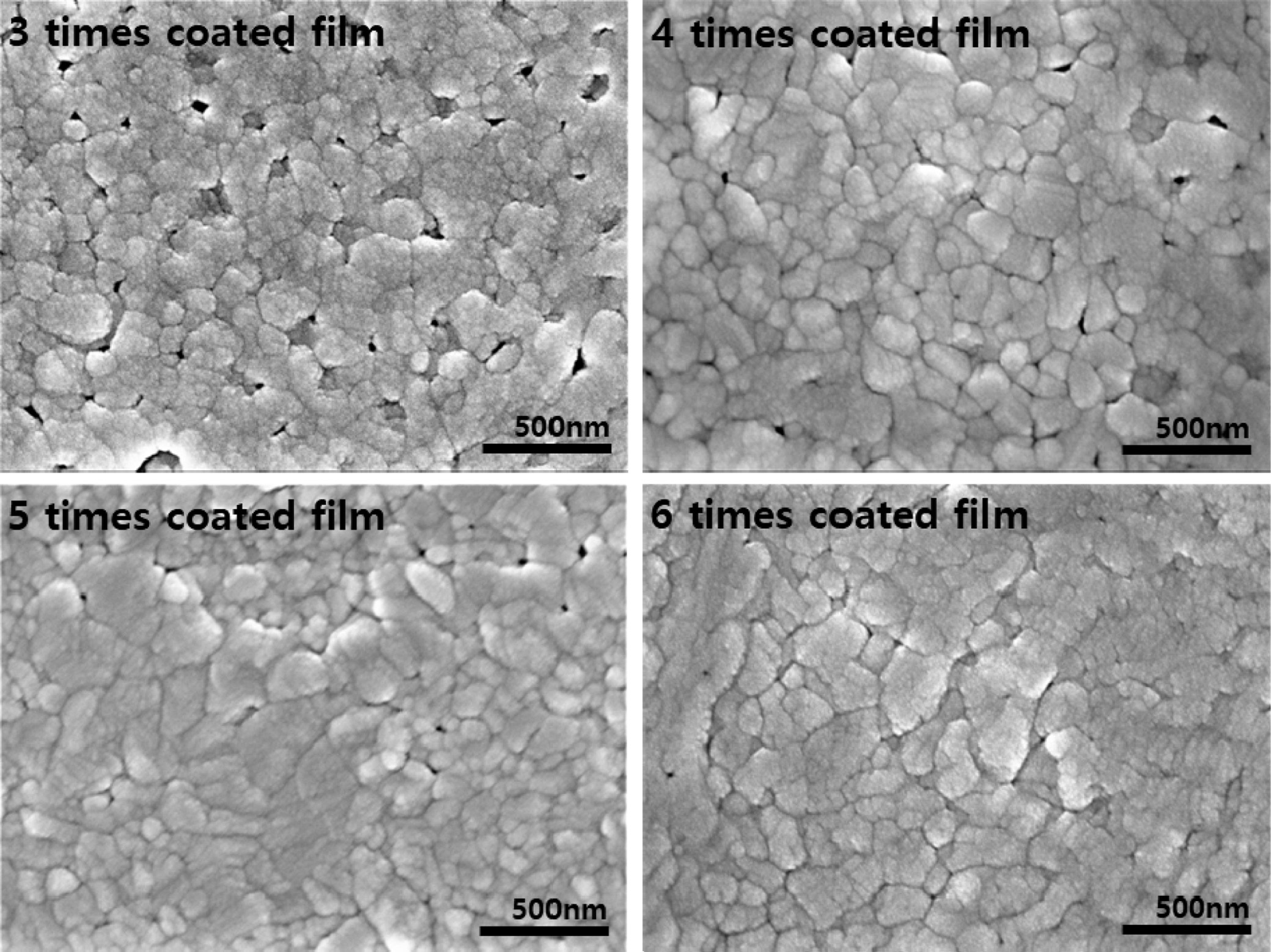

Fig. 3 shows the cross section microstructure (SEM) of the K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films. The average thickness of KTN thin films was 364.3 nm, and the average thickness of one time coated KTN thin film was about 80 nm. The interface between the KTN heterolayered thin film and Pt substrates was clearly observed. This is because ion diffusion did not occur at the interface.

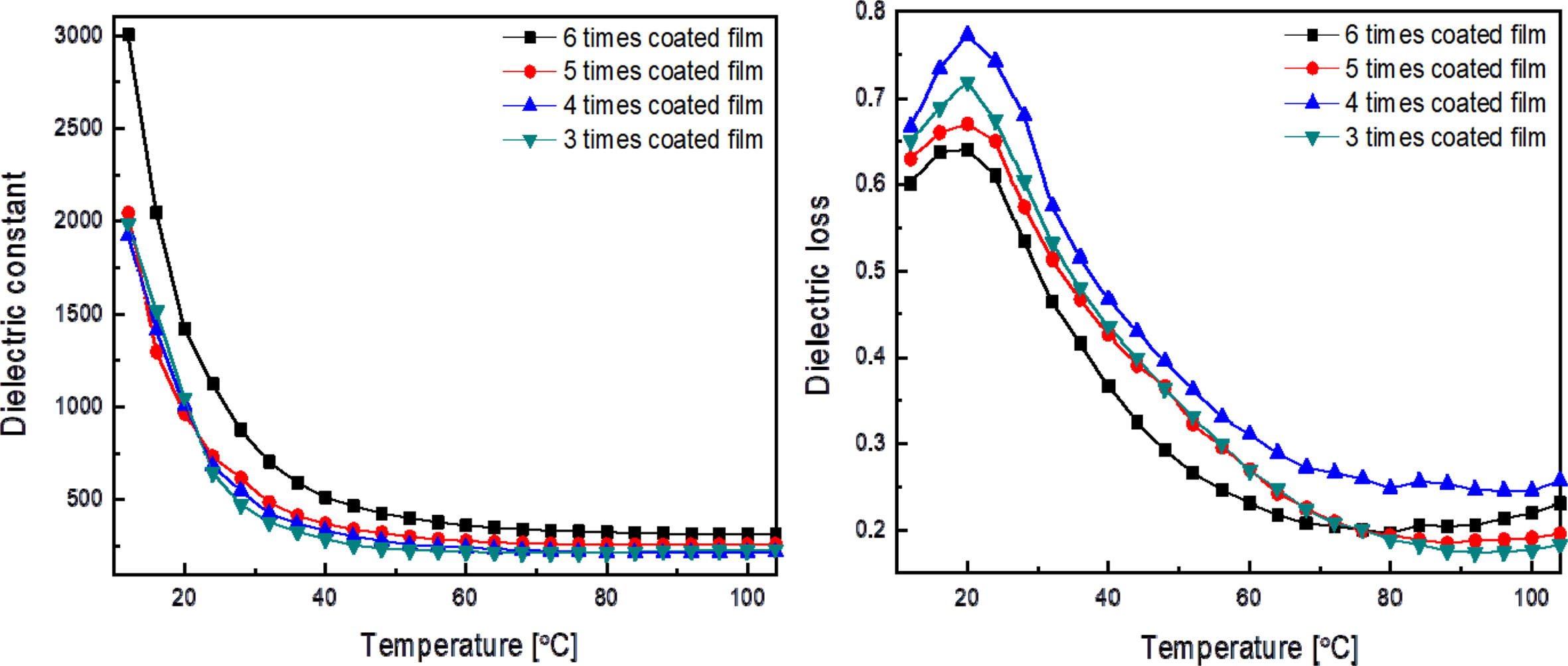

Fig. 4 shows the dielectric constant and dielectric loss of the K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films according to temperature changes. The dielectric constant continuously decreased as the measured tem- perature increased 10 oC to 100 oC, which means the phase transition temperature was below the measurement temperature. As the coating number increased, dielectric constant gradually decreased and saturates at about 60 oC. Also, dielectric constant tended to decrease by decreasing the number of KTN film coatings [15]. The dielectric constant and loss at 6 coated KTN heterolayered thin films were 877 and 0.534 at 28 oC, respectively.

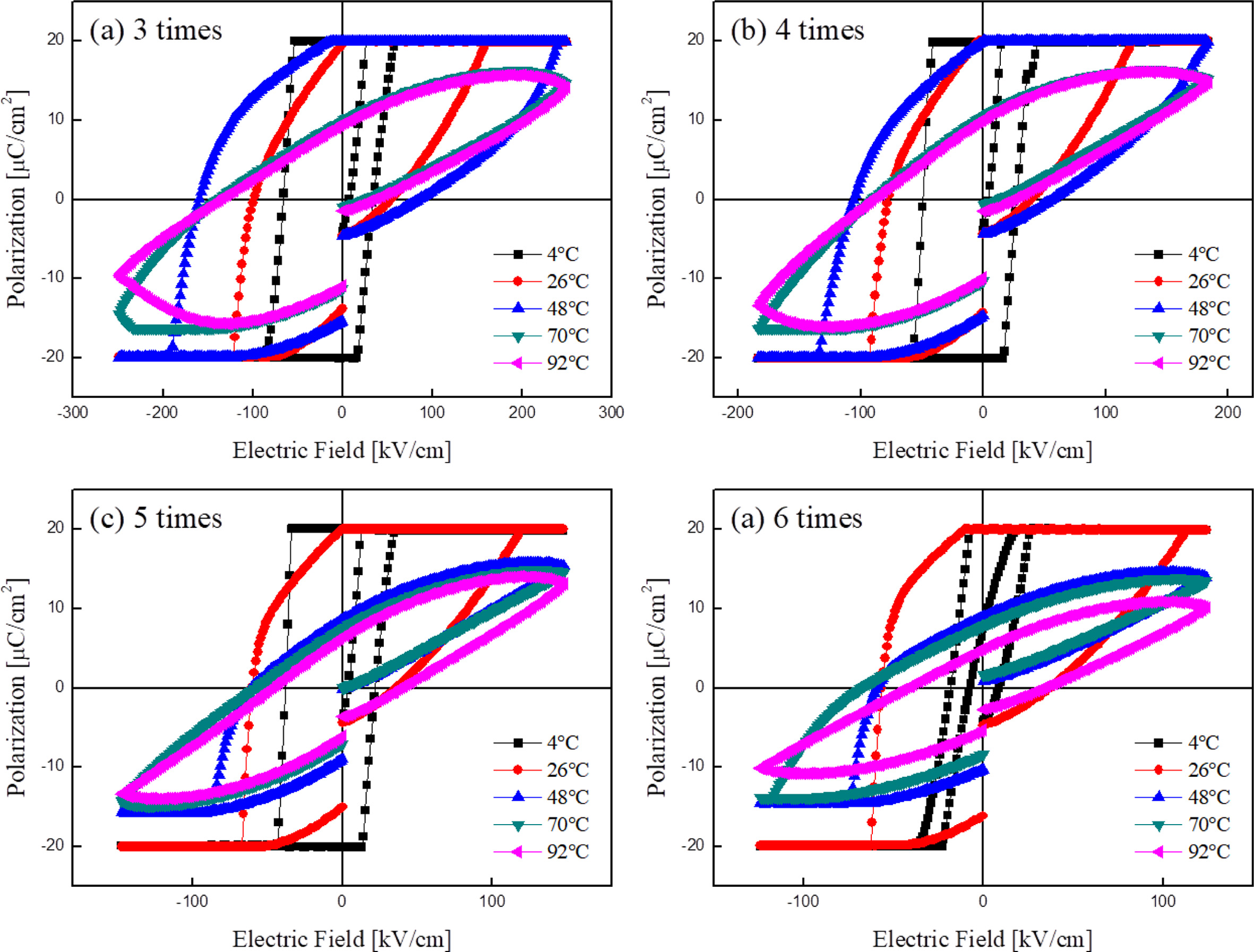

Fig. 5 shows the hysteresis loops of the K(Ta0.60Nb0.40)O3 /K(Ta0.40Nb0.60)O3 heterolayered thin films. The remanent polarization and coercive field decreased as the measured temperature was increased. In this hysteresis loops of 3, 4 times coated KTN thin film, a ferroelectric phase was observed up to 48 oC, but a paraelectric phase was observed above 70 oC. Unlike this, in the case of 5, 6 times coated film, a ferroelectric phase was observed only up to 26 oC, and a paraelectric phase was observed from 48 oC or higher. The dipole is disordered by external thermal energy because of the substrate suppress domain switching in the interface. The dipole of thin film is fixed. In this case, as the number of coatings increases and the thickness of the thin film is also increased, the effect of substrates decreases, so a dipole can easily disorder with less external thermal energy.

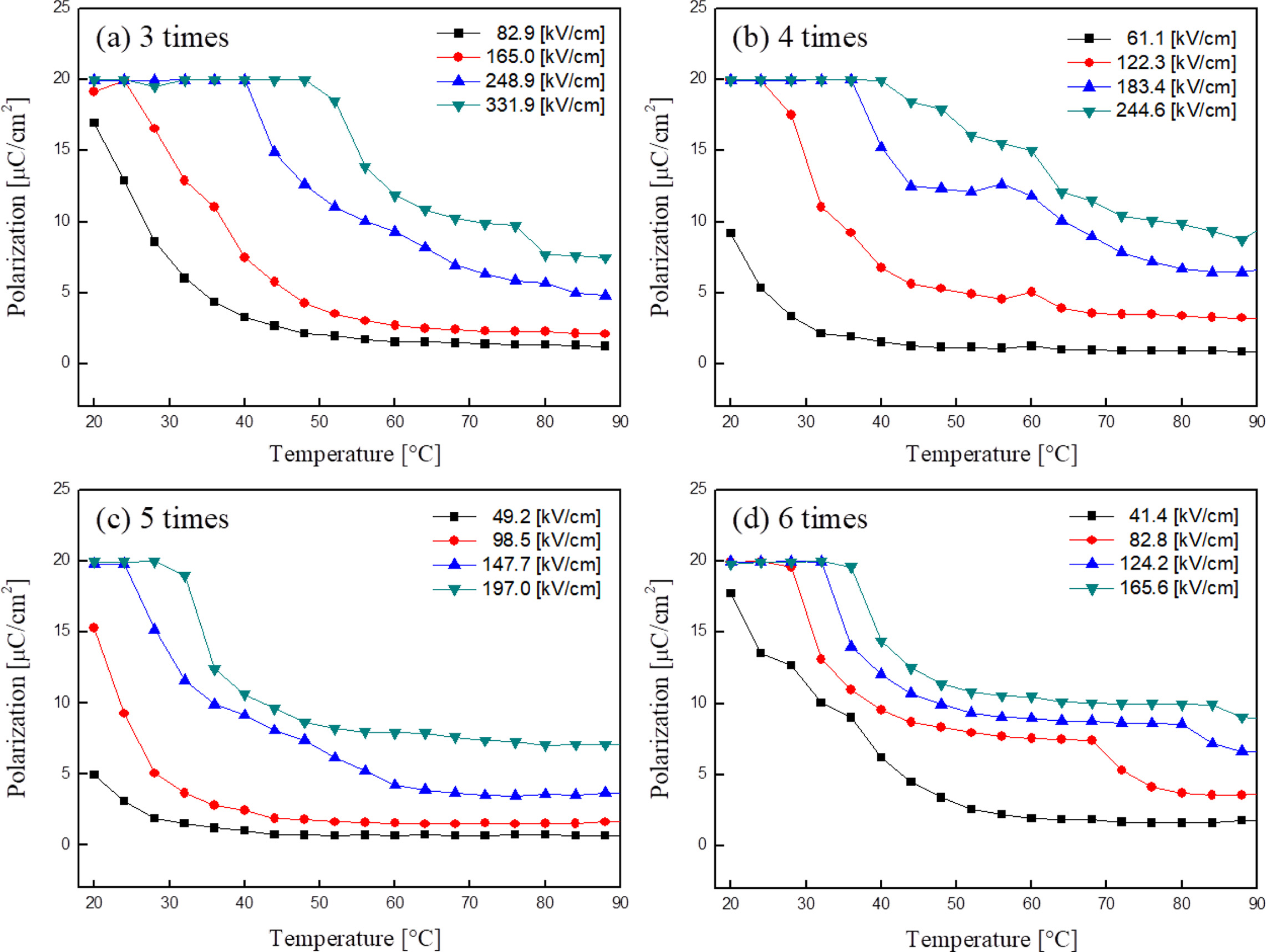

Fig. 6 shows the remanent polarization of the K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films according to the number of KTN coatings and temperature. In this graph, there is a part in which the remanent polarization value rapidly decreases as this part is shifted to a low temperature, while the number of KTN coatings increases. As analyzed in Fig. 5, this can be seen that the domain switching suppression effect decreases as the number of KTN coatings increases.

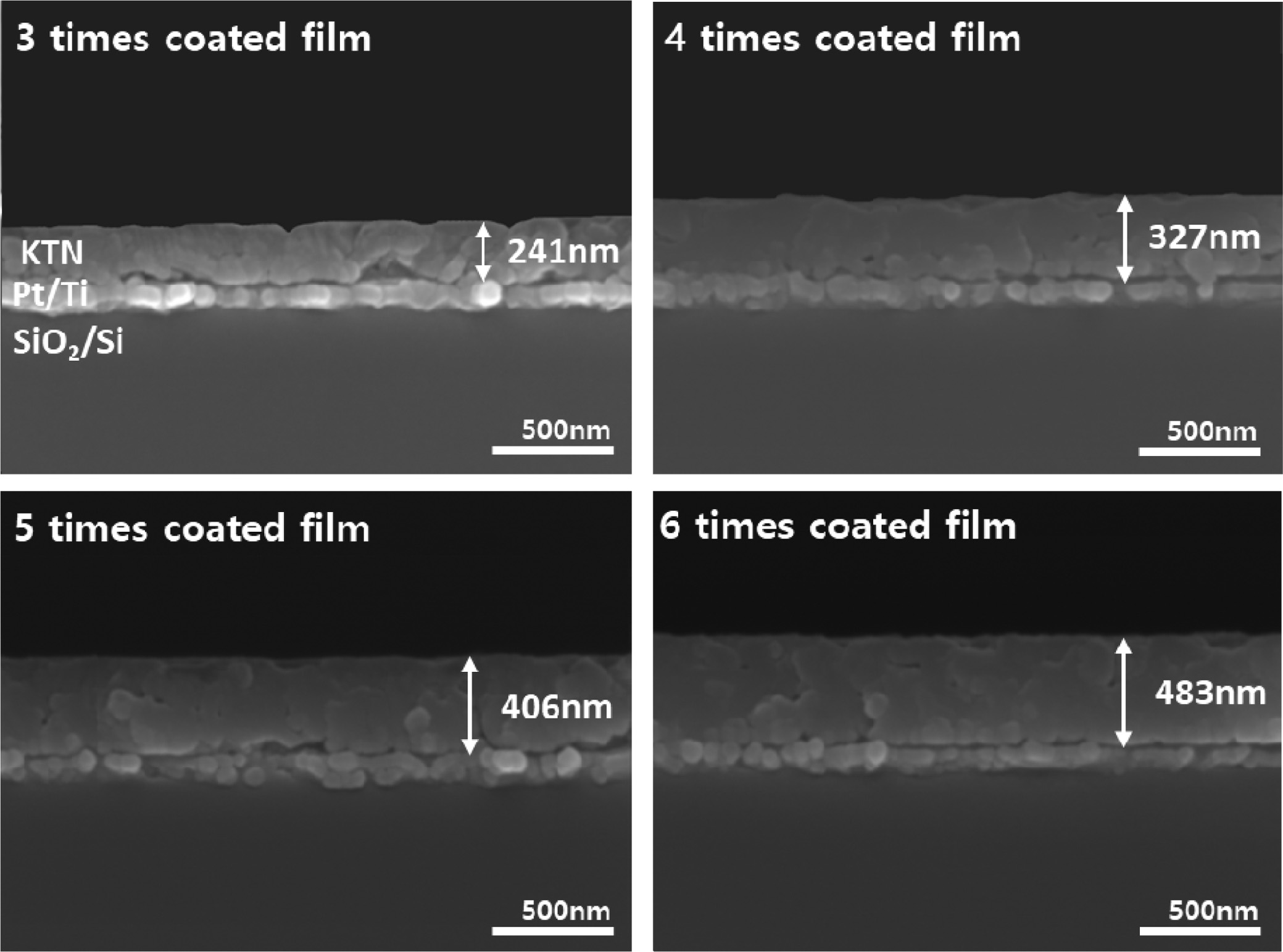

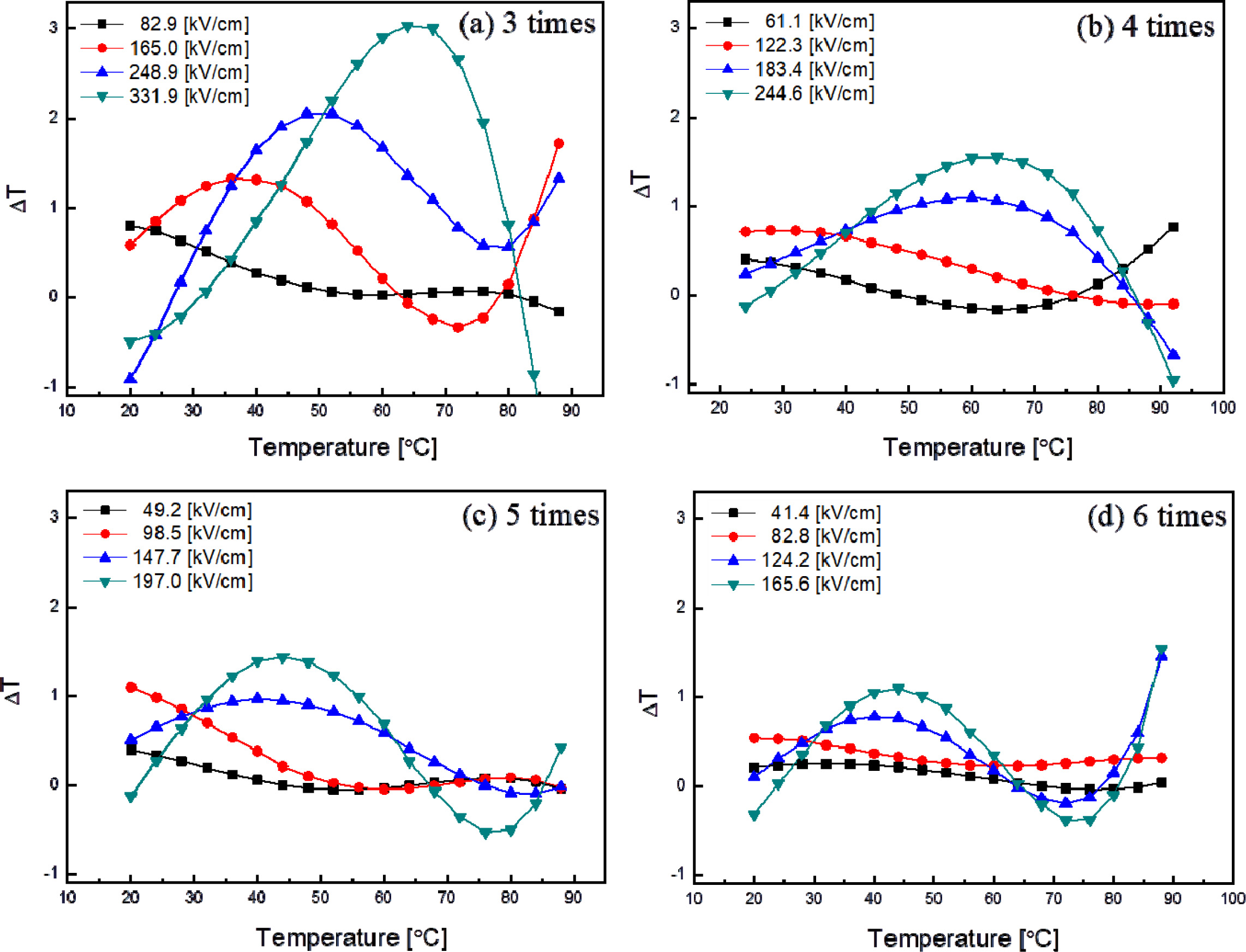

Fig. 7 shows electrocaloric temperature change ∆T of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 thin films according to the number of KTN coatings. The Electrocaloric effect (ECE) of KTN heterolayer thin films were characterized by indirect measurements and the temperature change was calculated using Maxwell’s relation as the following equation (1).

Here, ∆T, C and ρ is temperature change of adiabatic state, specific heat, theoretical density, respectively. At all layers, it was observed that the value of the electrocaloric properties increased as the applied voltage increased, and the it had the hightest value of the electrocaloric properties when the voltage of 331.9 kV/cm was applied at the 3 times coated layers.

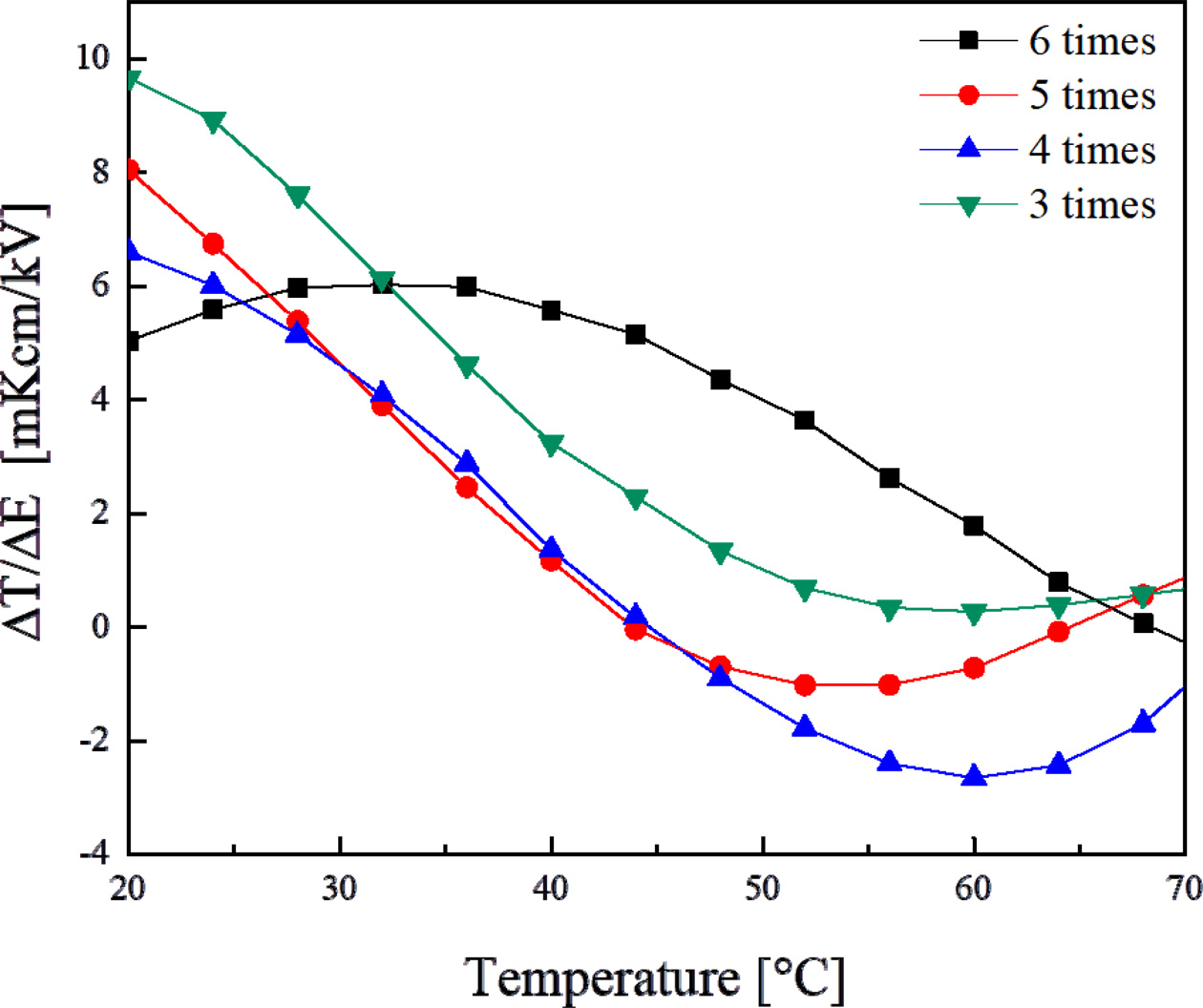

Fig. 8 shows Electrocaloric responsivity estimated at different electric fields according to the Maxwell relation. The maximum responsivity was obtained from six coated KTN thin film at low temperature (-50 oC) and three coated KTN thin film at high temperature (50-70 oC).

Comparing the ∆T value with BaSrTiO (BST) [16], which is the same lead-free materials with a perovskite structure, BST has a value of about 0.7 K under the same 330 kV/cm, whereas KTN has a significantly larger value of about 3 K. In addition, according to the electrocaloric responsivity, BST and KTN have a value of 2.10 mKcm/kV and 9.06 mKcm/kV, respectively, which can confirms that KTN has a good electrocaloric efficiency.

|

Fig. 1 X-ray diffraction patterns of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films. |

|

Fig. 2 FE-SEM surface images (x50,000) of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films. |

|

Fig. 3 FE-SEM cross-section images (x40,000) of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films. |

|

Fig. 4 Temperature dependence of dielectric constant and dielectric loss of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films. |

|

Fig. 5 Hysteresis loops of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films with variation of temperature. |

|

Fig. 6 Polarization of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films with temperature changes |

|

Fig. 7 Electrocaloric effects (T) of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films with variation of the temperature. |

|

Fig. 8 Electrocaloric responsivity of K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 heterolayered thin films. |

In this study, the heterolayered K(Ta0.60Nb0.40)O3/K(Ta0.40Nb0.60)O3 thin films were fabricated by spin coating method on Pt(111)/Ti/SiO2/Si substrates and varying coating number. As the coating number increased, the intensity of XRD peaks also increased. It was observed that the lower KTN film affected the upper KTN film’s crystallization. In all specimens, the dielectric constant gradually decreased as the coating number increased and saturates at about 60 oC. As the thickness of thin films was increased, the remanent polarization decreased sharply at low temperature. This is because as the thickness of thin film is increased, the effect of substrate decreases so the dipoles were more easily rotated and rearranged. Electrocaloric temperature change ∆T showed the maximum value of the ~3.03 oC under an applied electric field of 331.9 kV/cm.

The electrocaloric effect using K(Ta,Nb)O3 is environ- ment-friendly cooling technology that does not use harmful materials such as lead and refrigerants such as Frogen gas. Also, since it is made of a thin film, it is expected to be able to solve the problem of internal heating of small devices that is currently in problem.

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (No. 2017R1D1A3 B03032164).

- 1. S. Triewasser, Phys. Rev. 114[1] (1959) 63-70.

-

- 2. F. Jona and G. Shirane, Ferroelectric Crystals. 43 (1962).

- 3. A. Nazeri and M. Kahn, J. Am. Ceram. Soc. 75[8] (1992) 2125-2133.

-

- 4. E. Jabry, G. Boissier, A. Rousset, R. Carnet, and A. Lahrange, J. Phys. Colloque. 47[C1] (1986) 843-847.

-

- 5. S. Guillemet-Fritsch, J.L. Baudour, C. Chanel, F. Bouree, and A. Rousset, Solid State Ionics. 132[1-2] (2000) 63-69.

-

- 6. E.T.H. Wu, Diss. Abstr. Intj. 450 (1984) 314-315.

- 7. A. Nazeri, M. Kahn, B. Bender, and C. Allen, J. Am. Ceram. Soc. 77[9] (1994) 2450-2454.

-

- 8. S. Yagi and K. Fujiure, Physics Procedia. 56 (2014) 40-47.

-

- 9. H. Khemakhem, J. Ravez, and A. Daoud, Phys. Stat. Sol. 161[2] (1997) 557-564.

-

- 10. J.H. Yoo and S.J. Cho, Trans. Electr. Electron. Mater. 20[1] (2019) 36-39.

-

- 11. S.P. Alpay, J. Mantese, S. Trolier-McKinstry, Q. Zhang, and R.W. Whatmore, MRS Bulletin. 39[12] (2014) 1099-1111.

-

- 12. A.S. Mischenko, Q. Zhang, J.F. Scott, R.W. Whatmore, and N.D. Mathur, Science. 311[5765] (2006) 1270-1271.

-

- 13. M.E. Lines and A.M. Glass, in “Principles and Applica- tions of Ferroelectrics and Related Materials” (Clarendon Press, 1977) p. 148.

- 14. E. Fatuzzo and W.J. Merz, in “Ferroelectricity” (Amsterdam Press, 1967) p. 116.

- 15. T. Mitsui, I. Tatsuzaki, and E. Nakamura, in “An Intro- duction to the Physics of Ferroelectrics” (Gordon and Breach Press, 1976) p. 223.

- 16. S. Matsuo, T. Yamada, T. Kamo, H. Funakubo, M. Yoshino, and T. Nagasaki, J. Ceram. Soc. Jpn. 125[6] (2017) 441-444

-

This Article

This Article

-

2021; 22(1): 48-53

Published on Feb 28, 2021

- 10.36410/jcpr.2021.22.1.48

- Received on Jun 12, 2020

- Revised on Sep 2, 2020

- Accepted on Aug 22, 2020

Services

Services

- Abstract

introduction

experiment

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Sunggap Lee

-

Department of Materials Engineering and Convergence Technology, RIGET, Gyeongsang National University, JinJu 52828, Republic of Korea

Tel : +82-10-2686-4427 Fax: +82-55-772-1689 - E-mail: lsgap@gnu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.