- Effect of annealing temperature on the optical properties of a bulk GaN substrate

Hee Ae Leea, Joo Hyung Leea, Seung Hoon Leea, Hyo Sang Kangb, Seong Kuk Leeb, Nuri Oha, Won Il Parka and Jae Hwa Parkb,*

aDivision of Materials Science and Engineering, Hanyang University, Seoul 04763, Republic of Korea

bAMES Micron Co. LTD, 32 Singok-ro, Gochon-eup, Gimpo-si, Gyeonggi-do, 10126, Republic of Korea

Variation of optical

properties in a bulk GaN substrate have experimentally investigated with

respect to different annealing conditions of 700 - 1,000 oC.

As-annealed GaN was characterized by scanning electron microscopy,

photoluminescence, and Raman spectroscopy. The experimental results

demonstrated that the crystallinity and internal residual compressive stress of

GaN are most effectively improved when heat-treated at 900 oC for

three hours. The optical characteristics were also improved by enhancing the

quality of the GaN substrate by decreasing both the defect density and the

residual stress. It was also confirmed that the effect of the heat treatment

was excellent given that impurities were effectively removed by this process.

Keywords: Hydride vapor phase epitaxy, Gallium nitride, Optical property, Crystallinity, Residual stress, Defect density

GaN is a III-V compound semiconductor with a wide band

gap. Therefore, it is a material that is expected to be applied to

light-emitting devices operating in the blue or ultraviolet range [1, 2]. It

has a number of excellent properties, such as very good luminescence,

structural stability at high temperatures, high hardness, high thermal

conduction, and good chemical stability. Therefore, it

can be used in a wide variety of applications, not only in

optical devices but also in high-power and high-temperatures

devices. Based on these characteristics, numerous

studies have sought to apply GaN to high-brightness light-emitting diodes (LED)

and laser diodes (LD). Recently, it is also the subject of increasing

interest regarding its application to power and communication

semiconductors such as those that power RF and other devices [3-7].

The characteristics of the substrate are very important

when attempting to produce a GaN device capable of high brightness and high

performance. The GaN single crystal difficult the growth for ingot single

crystal which can get the substrate of high quality. Because ingot growth

requires a pressure above 6 GPa and a temperature above 2,200 oC due

to the properties of nitrogen [8]. Therefore, the growth of GaN depends on epitaxial

growth, mainly using a heterogeneous substrate. Heterogeneous

substrates mainly utilize sapphire substrates for economic

reasons [9-11]. Sapphire impedes the acquisition of a high-quality GaN

epi-layer due to its large lattice mismatch and difference in the thermal

expansion coefficient from that of GaN. Hence, the interior of GaN single

crystal grown on sapphire has a high density (typically in the range of 108~109

cm-2)

of threading dislocations and residual stress [12-14].

These dislocations and defects

play a role in reducing the lifetime and efficiency of these devices by

creating, for example, a center of non-radiation recombinations or charge

leakage paths [15, 16]. The residual stress changes the crystalline symmetry

and exerts an effect the basic physical properties of the materials and the

structure of the electronic band [17]. When the residual stress inside the GaN single

crystal increases, it generates or propagates cracks to mitigate the stress resulting

in new defects. These act the factors that deteriorate the quality of the GaN

substrate, including optical and electronic properties [18-20]. In addition, a

damage layer is formed under the surface of GaN during

mechanical polishing, a step during the substrate manufacturing process, resulting in deterioration of the optical and

electrical properties of the device [21, 22]. For use in high-quality

electronic and optical devices, there is a need for a method capable of

mitigating these problems and

improving the properties of GaN. Annealing is known to be a feasible

method for improving the elec- tronic and optical properties of nitride

semiconductors [3, 23]. However, most

of the annealing studies involving

GaN focused on dopant implantation. Few studies have concentrated on the

effects of a heat treatment on the optical damage recovery of mechanically

polished bulk GaN [21, 24]. Therefore, in this work, Therefore, in this work,

we investigated variations of the optical characteristics after a heat

treatment for bulk GaN substrate grown on a sapphire substrate using the hydride vapor phase epitaxy (HVPE) technique.

Bulk single-crystal GaN was grown at a thickness of 1.0 mm

or more on a c-plane sapphire (0001) substrate using a HVPE system. GaCl gas as

a Ga source was formed by reacting metal Ga with HCl gas at 700 - 800 oC.

This gas was reacted with NH3 gas, which was used

as an N source, and single-crystal GaN was grown at a

sustained growth rate of 100 μm/h at a temperature of 1,000 - 1,100 oC.

Fig. 1 shows the bulk single-crystal GaN after growth. The as-grown bulk

single-crystal GaN was separated from the sapphire substrate by a laser lift

off (LLO) process. The separated GaN was fabricated on

a two-inch GaN substrate with a thickness of 1.0 mm

after polishing. The GaN substrate was then cut into pieces 10X10 mm2 in size.

The GaN specimens were annealed in the temperature

range of 700 - 1,000 oC for one to five hours using an

independently fabricated annealing furnace. N2 ambient was used to

prevent the disassociation of nitrogen at the high temperatures used. We

analyzed the defect density of the GaN single crystal according to the heat

treatment condition after chemical etching using a melt with a KOH/NaOH

eutectic composition [25]. We confirmed etch pits on the surface of the

as-etched GaN via scanning electron microscopy (SEM, JSM-5900LV, JEOL, Japan)

when analyzing the dislocation density. Raman spectroscopy (JASCO, NRS-3100,

England) was used to characterize the residual stress, with the excitation

laser source and power level set to 532 nm and 1.3 mW,

respectively. The optical properties were analyzed by a

photoluminescence analysis (PL, Dongwoo Optron, MonoRa750i, Korea) at room temperature. During this process, the excitation

source used was a 325 nm He-Cd laser, of which the energy exceeds that of the

band gap energy of GaN. The power of the laser was set to 2.5 mW.

|

Fig. 1 Image of a 2-inch bulk GaN grown by HVPE. |

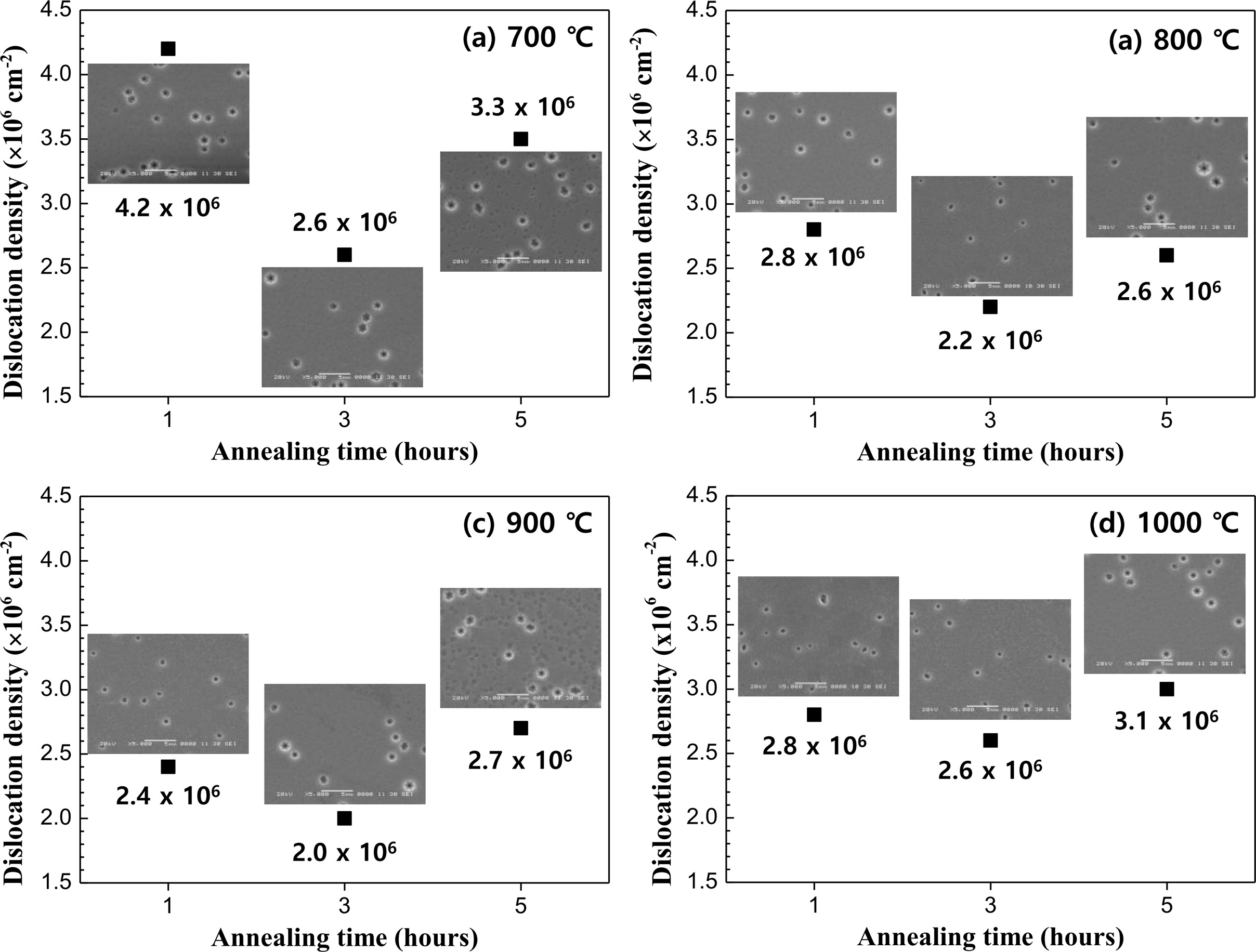

The dislocation density of the GaN substrate is a major

measure of the quality of single-crystal GaN, and a lower dislocation density

indicates good quality of the single crystal [26]. Etch pits existent in the

GaN single crystal are a type of defect deriving from

threading dislocations generated at the interface. Therefore, the

dislocation density can be obtained by calculating the density using the number

of observed etch pits [27]. For the measurement a value of etch pit density

(EPD) is calculated from the number of etch pits N within the measuring field

according to equation (1):

Here, aF

is the measuring field. The value of aF

must be given in cm to obtain the local EPD in cm-2

[28]. Fig. 2 presents the results after measuring the variation of the etch pit

density using an etchant with a KOH/NaOH eutectic composition after the heat

treatment. The dislocation density decreased and then increased again with an

increase in the annealing time at all temperatures after annealing. In other

words, it was observed the same trend which the crystallinity increasing and

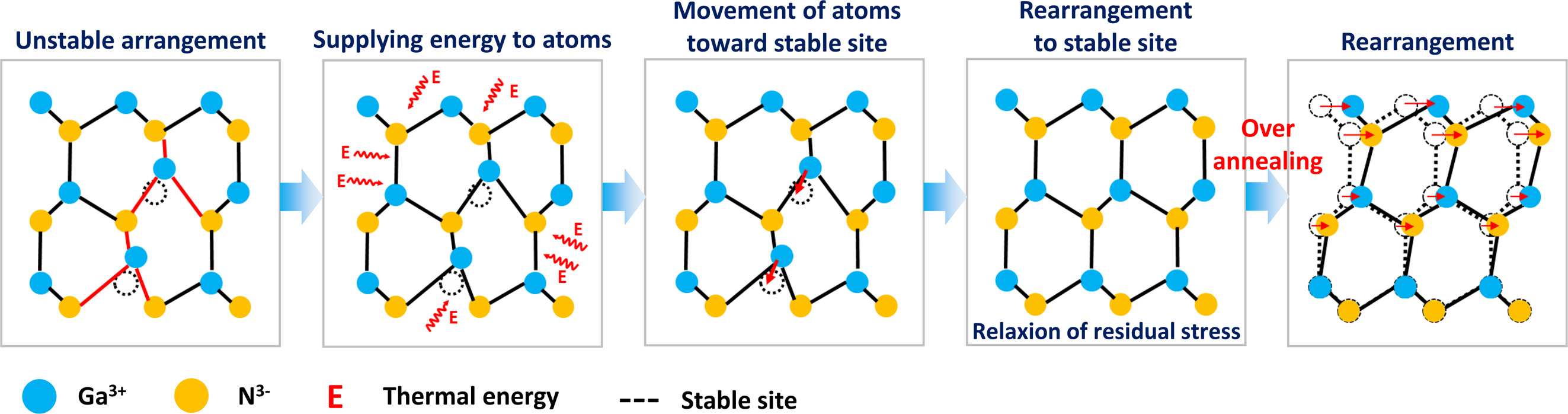

then decreasing. As shown in Fig. 3, an unstable lattice with high energy in

the material move in a direction such that the internal energy is reduced when

receiving energy above a critical level thermal energy by

annealing. As such, the crystallinity improves as atoms

move to stable sites and are rearranged [29]. This is the effect of the

annealing. However, the effect of annealing decreases due to the excessive heat

energy during the annealing process with increase in the heat treatment time.

Therefore, it was considered that the dislocation density was reduced after

annealing for five hours. The results of a dislocation density analysis via EPD

showed that the lowest dislocation density arose after the

sample was annealed for three hours throughout the heat

treatment temperature range, meaning that the crystallinity is most effectively

improved during the heat treatment at that time.

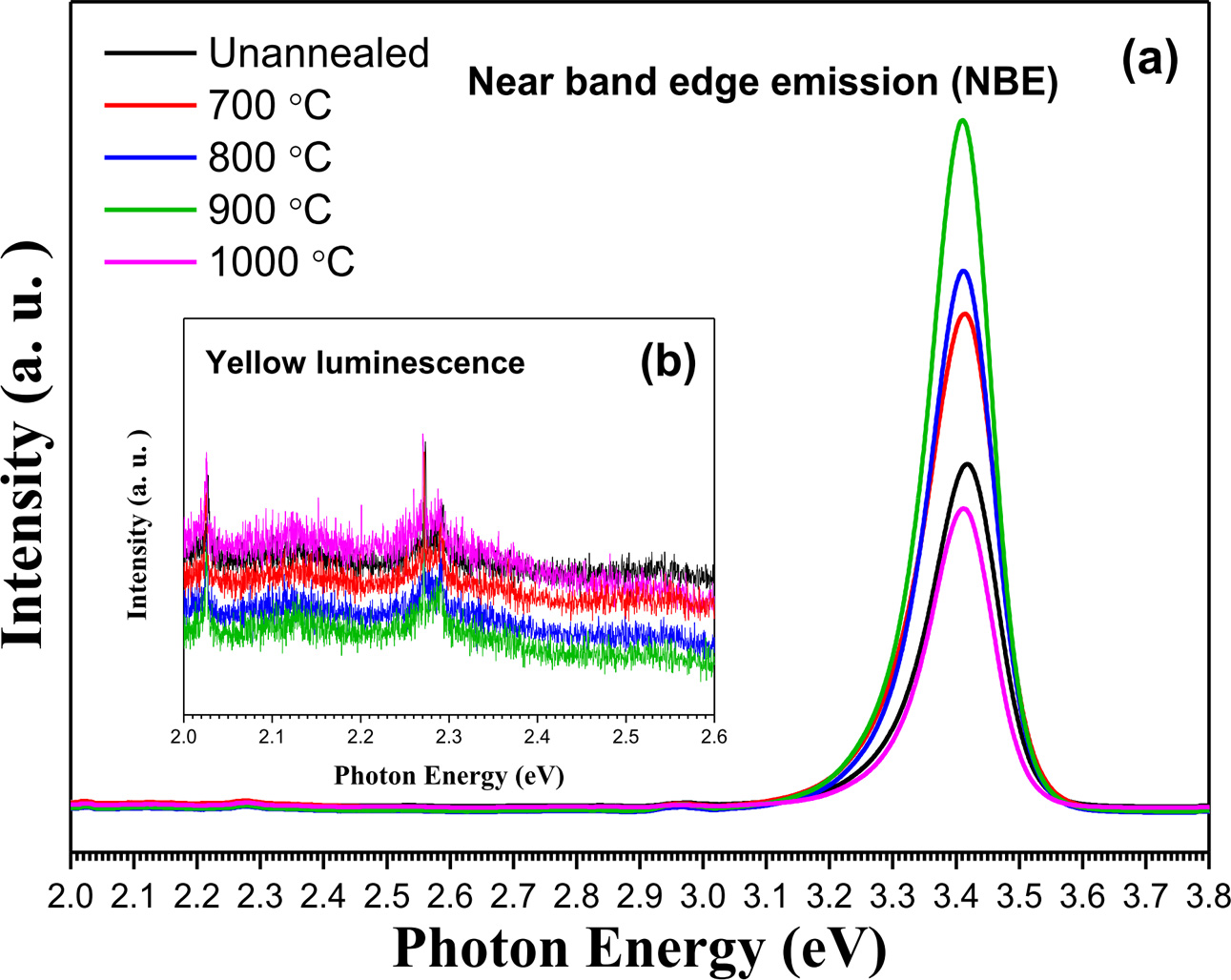

Fig. 4 shows the PL spectra measured at room temperature

for specimens annealed for three hours, at which the effects of the heat

treatment were best in all temperature ranges. The strong peak around 3.4 eV in

the PL spectra of all samples is nearly identical to that of about 3.41 eV,

which is the band gap energy of GaN. This indicates with regard to near-band

edge emission (NBE) which the luminescence caused by the death of excitons

around the energy gap. The intensity of the NBE peak increased with an increase

in the annealing temperature in the PL spectrum, meaning that the quality of

the substrate was improved [30]. However, the intensity of the peak decreased

again at 1,000 oC because the improved crystal quality was

reduced via nitrogen dissociation at a high temperature. The nitrogen can

dissociate at high temperatures of 1,000 oC or more below 4.5

GaP [31]. In other words, the nitrogen-vacancy was created due to the thermal

decomposition in high temperature and acted as a non-radiative recombination

center, resulting in a decrease in the intensity of the NBE peak. These trends

match the result of the dislocation density via measurement for EPD.

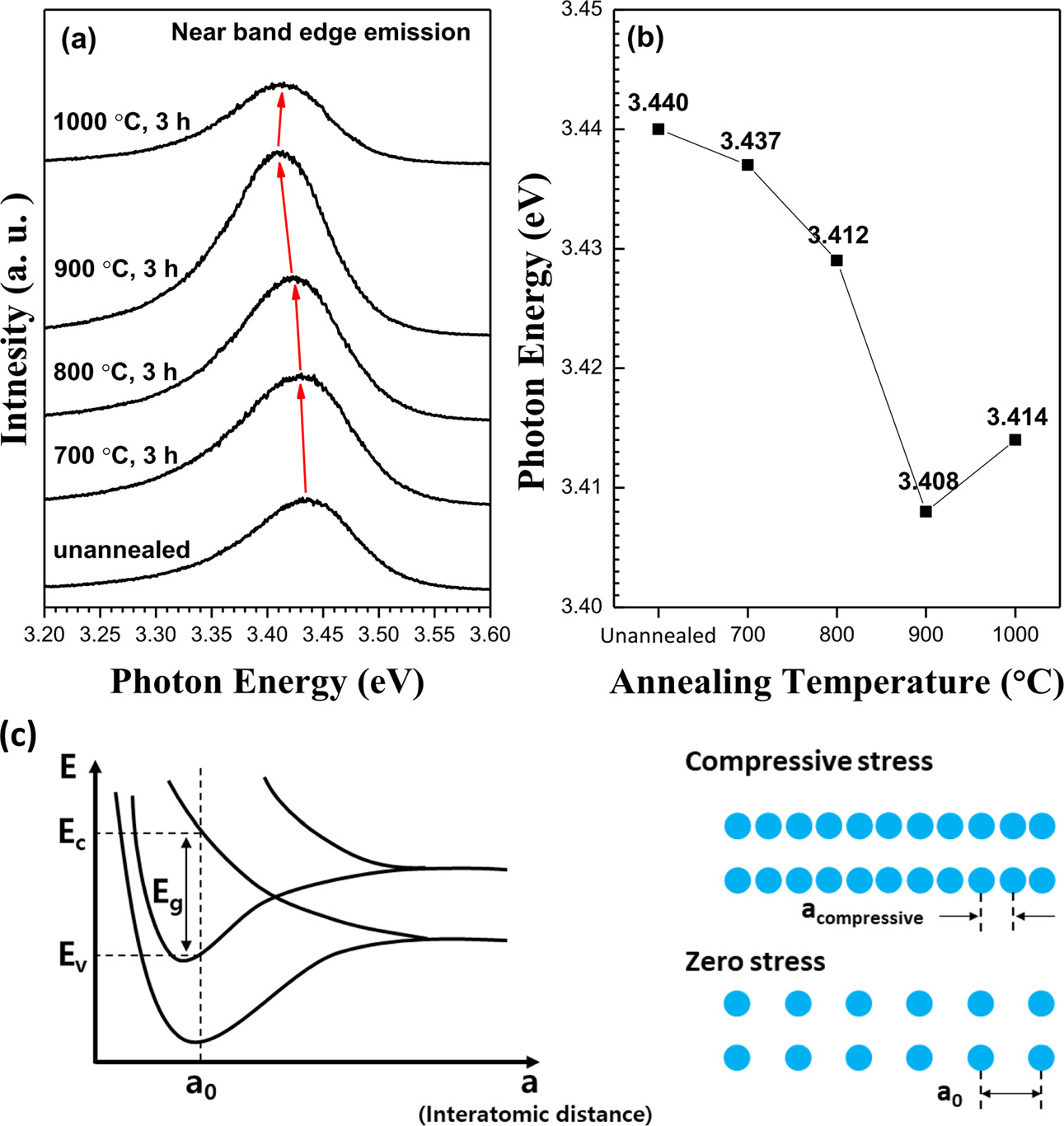

Fig. 5(a) shows a blue shift that indicates that the NBE

peak shifts toward a lower energy level with an increase in the annealing

temperature. A blue shift in the PL spectrum can appear when the interatomic

distance of the material increases, as shown in Fig. 5(c). This is believed to

stem from the fact that the interatomic distance was widened because it relaxed

the residual compressive stress generated by the difference in the thermal

expansion coefficient at the interface between the sapphire and the GaN later via

the heat treatment. To confirm this change precisely, we indicate numerically

the variation of the position of the NBE peak in Fig. 5(b). The position of the

NBE peak decreased with an increase in the annealing temperature,

showing its lowest value at the temperature of 900 oC.

Therefore, it was considered that annealing at the corresponding temperature

most effectively relaxed the residual

compressive stress.

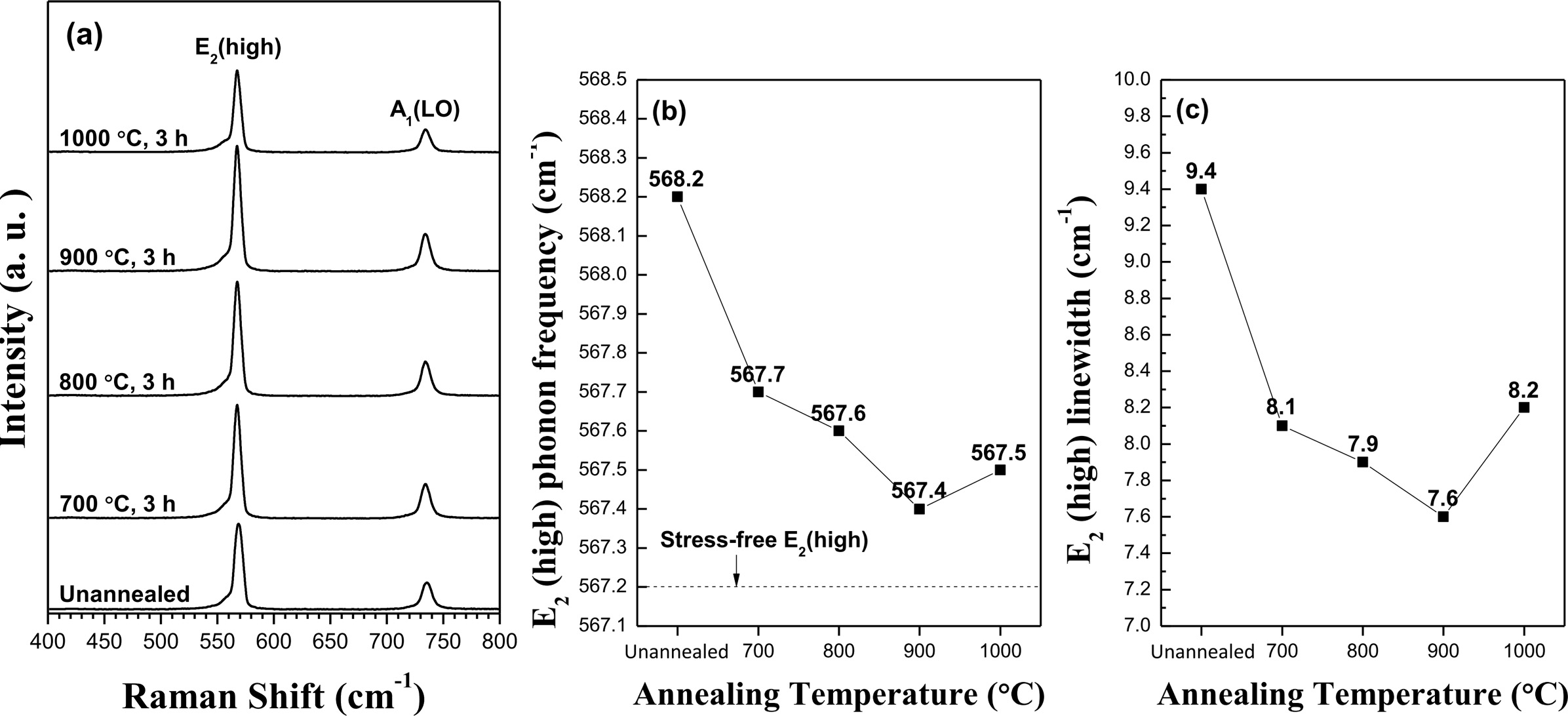

To characterize the residual stress existent in the

internal material after annealing, we undertook Raman measurements, as

indicated in Fig. 6(a). The Raman frequency modes of GaN, having

a hexagonal symmetric structure (C6v), are 2A1,

2E1, 2E2, and 2B1. For bulk GaN, six phonon

frequency modes exist: A1(TO) = 531.8

cm-1,

E1(TO) = 558.8 cm-1,

E2(low) = 144 cm-1,

E2(high) = 567.2 cm-1,

A1(LO) = 734 cm-1,

and E1(LO) = 741 cm-1.

The E2(high) mode of GaN is the mode that most sensitively reacts to

stress present inside the crystal or to external pressure. It has been reported

that the tensile stress arises during the move to a low phonon frequency and

that compressive stress arises when moving to a high phonon frequency based on

the E2(high) mode value of a stress-free crystal (about 567.2 cm-1)

[32]. For example, in the presence of tensile stress, the atomic spacing will increase

with an expansion of the lattice, and the phonon frequency will decrease. On the other hand, in the presence of

compressive stress, the atomic spacing will decrease with a contraction of the lattice, and the phonon

frequency will increase [33]. Fig.

6(b) shows the variation of the E2(high) mode peak. The E2(high)

mode, which appears strongly in the Raman spectrum, shifted to a lower

frequency with an increase in the heat treatment temperature. We confirmed that

the E2(high) value after annealing at 900 oC was

closest to the value indicated by the dotted line in a stress–free condition

which has a value when the internal stress of bulk GaN is free. This means that

the residual compressive stress of GaN substrate was relaxed with an increase

in the annealing temperature. This matches the result showing the blue shift of the NBE peak in the previously described

PL spectrum. Also, the intensity of E2(high)

mode peak varies with crystallinity, as the phonon vibrations are

sensitive to atom compositions. Therefore, higher crystal quality revealed more distinct E2 high phonon vibration

peaks [34]. We observed that the intensity of the E2(high) mode peak

was most strongly at 900 oC in Fig. 6(a). This is considered that

due to the crystallinity improved with relaxing residual stress. Moreover, the

full width at half maximum (FWHM) of E2(high) is affected by the

quality of the crystal [35]. Defects in the crystal decrease the effective wavelength of phonons by contributing

to the scattering of phonons, and the

FWHM of the phonon peak is reduced with a decrease in the defect density [36].

Fig. 6(c) indicates the variation of the FWHM of the E2(high) mode.

The FWHM of the E2(high) mode shows a decreasing trend with an

increase in the temperature to 900 oC, past which it increased

again at 1,000 oC. This is consistent with the result of

the dislocation density described above.

Thus, we confirmed that the crystallinity was most improved at a heat treatment temperature of 900 oC.

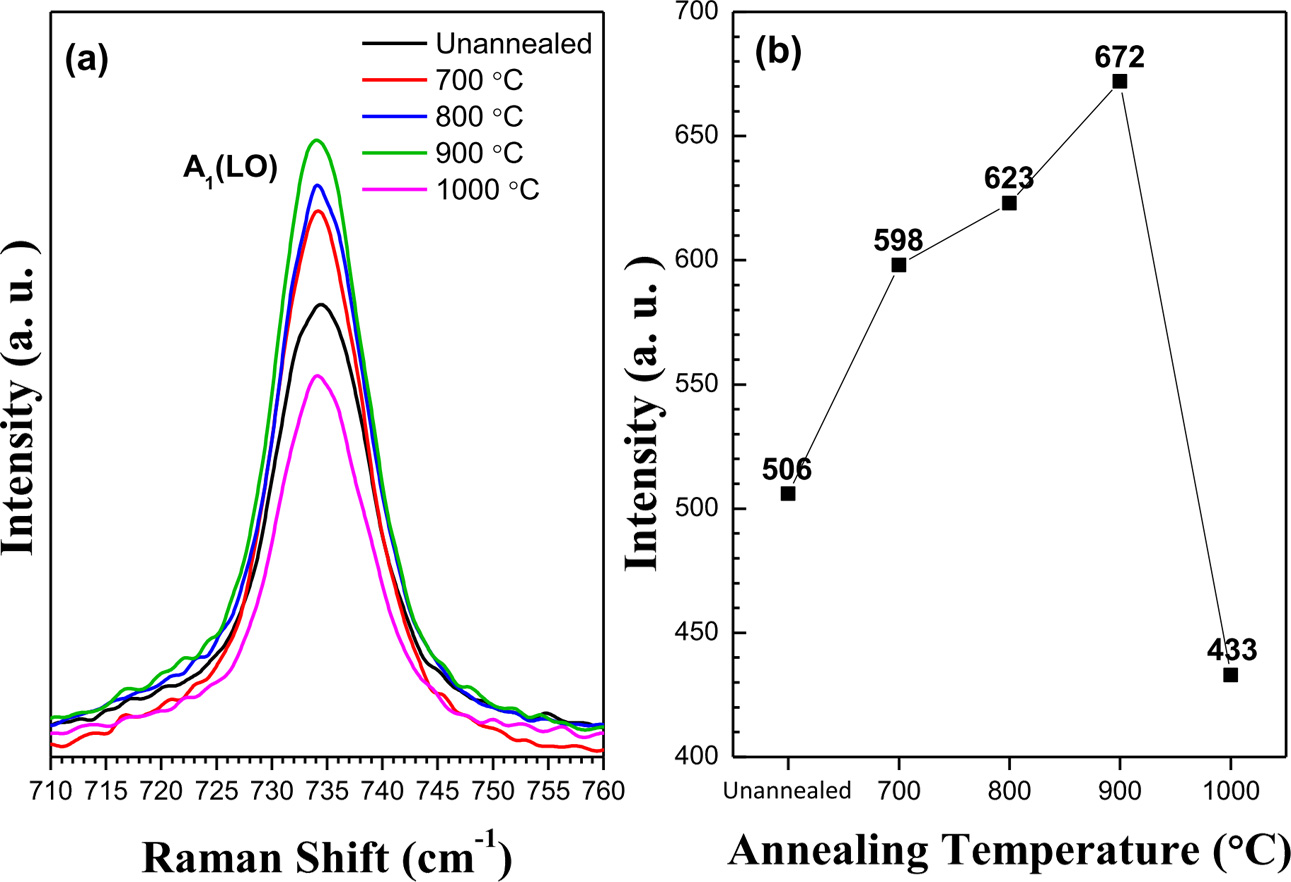

On the other hand, the yellow luminescence (YL) band at

around 2.2 eV in the PL spectrum and the A1(LO) mode at about 734 cm-1

in the Raman spectrum are peaks caused by defects and impurities. Fig. 4(b)

shows the spectrum around 2.2 eV, in which YL is generated by defects or

impurities of the crystal at a deep level. These YLs greatly degrade the

optical properties of GaN because they are related to structural defects such

as stacking defects and dislocations [37, 38]. In particular, this is a factor

that interferes with the realization of full color via the saturation of blue

emission during the manufacturing of LEDs [39]. We confirmed that the intensity

of the YL band decreased with an increase in the heat treatment temperature and

that it scarcely appeared at 900 oC. Recently, it has been reported

that nitrogen vacancies [40], C-O-related impurities [41], and Si impurities

exist in dislocations [42] and cause this YL band. However, this has not been

clearly verified.

The A1(LO) mode in the Raman spectrum changes

of its frequency according to the number of impurities contained in the

internal defects [43]. The intensity of the Al(LO) mode decreases

with an increase in the carrier concentration when the number of impurities

increases [44]. Fig. 7(a) shows the variation of the A1(LO) mode

peak before and after annealing. The intensity of the A1(LO) mode

peak increased with an increase in the heat treatment temperature. Fig. 7(b)

presents a graph that quantifies the variation of the intensity of the A1(LO)

mode peak. The intensity of the A1(LO) mode increased the most after

annealing at 900 oC. Thus, it can be determined that defects in the

crystal decreased because the number of impurities decreased after annealing

under the this conditions. However, the intensity of the peak of the A1(LO)

mode decreased after annealing at 1,000 oC. This

is considered to have occurred because the carrier concentration

was increased due to nitrogen vacancies, leading to the disassociation of

nitrogen at a high temperature. In other words, it is likely that the heat

treatment effect deteriorated as nitrogen vacancies acted as defects.

|

Fig. 2 Etch pit density of the (0002) GaN after annealing at (a) 700, (b) 800, (c) 900, and (d) 1,000 oC. |

|

Fig. 3 Schematic of behavior of atoms during heat treatment. |

|

Fig. 4 (a) the PL spectra for specimens annealed for three hours (b) the spectrum of yellow luminescence around 2.2 eV |

|

Fig. 5 (a) the shift of NBE peak in PL spectrum for bulk GaN

unannealed and annealed, (b) the variation of the position of the

NBE peak, and (c) the formation of energy bands in crystals [45,

46]. |

|

Fig. 6 (a) Raman spectra of GaN single crystal unannealed and annealed, the variation of (b) the E2 (high) and (c) the FWHM of the E2 (high)

mode. |

|

Fig. 7 (a) the spectra of A1 (LO) mode for the GaN unannealed

and annealed and (b) the variation of the intensity of the A1 (LO)

mode peak. |

We annealed a bulk GaN under various conditions. We

confirmed that the dislocation density of a bulk GaN substrate was reduced when

a heat treatment at all temperatures for three hours via an EPD analysis. Based

on this, we analyzed the optical characteristics of specimens

annealed for three hours in the temperature range of

700 - 1,000 oC. It was observed that the optical

properties of annealed bulk GaN were best after annealing at 900 oC

with an increase in the intensity of the NBE peak as the temperature was

increased up to the temperature range of 700 - 900 oC.

As a result of Raman measurements, the residual compressive stress was found to

be relaxed with an increase in the heat treatment temperature, showing a value

closest to the stress-free value at 900 oC. This

confirmed that impurities in the crystal were effectively

controlled under this condition via the variation for the YL band of the PL and

A1(LO) Raman modes. When annealing at a temperature of 1,000 oC, the effect of annealing was

found to have decreased upon an evaluation of the optical

properties and residual stress. This likely occurred due to

nitrogen vacancies which were generated given the nitrogen

dissociation that occurred at a high temperature and functioned as defects. All

things considered, the relaxation of the residual stress and the

crystallinity are superior when the heat treatment takes place at 900 oC

and lasts for three hours in the case of a bulk GaN

substrate with a thickness of 1 mm. Therefore, it could be

confirmed that the optical properties were most

effectively improved because the effect of annealing was best

under the this condition.

This work was supported by the Industrial Strategic

Technology Development program funded by the Ministry of Trade Industry &

Energy of Korea (Project No. 10080599). Raman analysis were supported by

Hanyang LINC Analytical Equipment Center (Seoul).

- 1. H. Morkoç, S. Strite, G. B. Gao, M. E. Lin, B. Sverdlov, and M. Burns, J. Appl. Phys. 76 (1994) 1363-1398.

-

- 2. S. Yoshida, S. Misawa, and S. Gonda, J. Appl. Phys. 53 (1982) 6844-6848.

-

- 3. I. Susanto, K.-Y. Kan, I.-S. Yu, J. Alloys Compd. 723 (2017) 21-29.

-

- 4. A. Bchetnia, I. Kemis, A. Touré, W. Fathallah, T. Boufaden, B. El Jani, Semicond. Sci. Technol. 23 (2008) 125025.

-

- 5. J. A Freitas Jr, J. Phys. D: Appl. Phys. 43 (2010) 073001.

-

- 6. H. Lei, H.S. Leipner, J. Schreiber, J.L. Weyher, T. Wosiʼnski, I. Grzegory, J. Appl. Phys. 92[11] (2002) 6666-6670.

-

- 7. R. Dwiliʼnski, R. Doradzinski, J. Garczynski. L. Sierzputowski, R. Kucharski, M. Zajac, M. Rudzinski, R. Kudrawiec, J. Serafinczuk, W. Strupinski, J. Cryst. Growth. 312 (2010) 2499-2502.

-

- 8. S. Krukowski, Cryst. Res. Technol. 34[5-6] (1999) 785-795.

-

- 9. C.-F Zhu, W.-K. Fong, B.-H. Leung, C.-C. Cheng, and C. Surya, IEEE Trans. Electron Devices 48[6] (2001) 1225-1230.

-

- 10. J. A Freitas Jr, J. Phys. D: Appl. Phys. 43 (2010) 073001.

-

- 11. J.H. Park, H.A. Lee, J.H. Lee, C.W. Park, J.H. Lee, H.S. Kang, H.M. Kim, S.H. Kang, S.Y. Bang, S.K. Lee, K.B. Shim, J. Ceram. Proces. Res. 18[2] (2017) 93-97.

- 12. K. Motoki, SEI Technical 70 (2010) 99-136 .

- 13. S.T. Kim, Y.J. Lee, D.C. Moon, C.H. Hong, T.K. Yoo, J. Crys. Growth 194 (1998) 37-42.

-

- 14. H. Iwata, H. Kobayashi, T. Kamiya, R. Kamei, H. Saka, N. Sawaki, M. Irie, Y. Honda, H. Amano, J. Cryst. Growth 468 (2017) 835-838.

-

- 15. M. Matys, M. Miczek, B. Adamowicz, Z.R. Zytkiewicz, E. Kaminska, A. Piotrowska, and T. Hashizume, Acta Physica Polonica A 120 (2011) A73-A75.

-

- 16. K. Motoki, SEI Technical 70 (2010) 28-35.

- 17. V. Darakchieva, T. Paskova, M. Schubert, H. Arwin, P.P. Paskov, B. Monemar, D. Hommel, M. Heuken, J. Off, F. Scholz, B. A. Haskell, P. T. Fini, J. S. Speck and S. Nakamura, Phys. Rev. B 75 (2007) 195217.

-

- 18. H. Fujikura, T. Inoue, T. Kitamura, T. Konno, T. Suzuki, T. Fujimoto, T. Yoshida, M. Shibata, T. Saito, Phys. Status Solidi B 2018 (2018) 1-11.

- 19. D. Pastor, R. Cuscó, L. Artús, G. González-Díaz, E. Iborra, J. Jiménez, F. Peiró, E. Calleja, J. Appl. Phys. 100 (2006) 043508.

-

- 20. J. Guo, H. Fu, B. Pan, R. Kang, Chin. J. Aeronaut. (2020)

- 21. J.H. Ryu, D.K. Oh, S.T. Yoon, B.G. Choi, J.W. Yoon, K.B. Shim, J. Cryst. Growth 292 (2006) 206-211.

-

- 22. D.K. Oh, S.Y. Bang, B.G. Choi, P. Maneeratanasarn, S.K. Lee, J.H. Chung, J.A. Freitas Jr, KB. Shim, J. Cryst. Growth 356 (2012) 22-25.

-

- 23. M.Y. Lee, and H.S. Im, J. Korean Phys. Soc. 60[10] (2012) 1809-1813.

-

- 24. T.W. Kang, S.U. Yuldashev, D.Y. Kim, T.W. Kim, Jpn. Appl. Phys. 39 (2000) L25-L27.

-

- 25. J.H. Park, Y.P. Hong, C.W. Park, H.M. Kim, D.K. Oh, B.G. Choi, S.K. Lee, K.B. Shim, J. Korean Cryst. Growth Cryst. Technol. 24 (2014) 135-139.

-

- 26. Y. Saighsa, in “Advanced Piezoelectric Materials” (Woodhead Publishing. 2010) p.171-203.

-

- 27. J. Chen, J.F. Wang, H. Wang, J.J. Zhu, S.M. Zhang, D.G. Zhao, D.S. Jiang, H. Yang, U. Jahn and K.H. Ploog, Semicond. Sci. Technol. 21 (2006) 1229-1235.

-

- 28. SEMI, No.M83-1112 (2014) p.10.

- 29. W.F. Smith, J. Hashemi, in “Foundation of Materials Science and Engineering, 4th edition” (SciTech Media, 2005) p.217-220.

- 30. Y. Inoue, T. Hoshino, S. Takeda, K. Ishino, A. Ishida, and H. Fujiyasu, Appl. Phys. Lett. 85 (2004) 2340-2342.

-

- 31. B.N. Feigelson, R.M. Frazier, M. Gowda, J.A. Freitas Jr, M. Fatemi, M.A. Mastro, J.G. Tischler, J. cryst. Growrh 310[17] (2008) 3934-3940.

-

- 32. G. Nootz, A. Schulte, L. Chernyak, A. Osinsky, J. Jasinski, M. Benamara, Z. Liliental-Weber, Appl. Phys. Lett. 80[8] (2002) 1355.

-

- 33. F.C. Wang, C.L. Cheng, Y.F Chen, C.C. Yang, Semicond. Sci. Technol. 22 (2017) 896-899.

-

- 34. K. Upadhyaya, S. Sharvani, N. Ayachit, and S.M. Shivaprasad, RCS Adv. 9 (2019) 28554-28560.

-

- 35. J.M.H. MSci, in “Raman scattering in GaN, AlN, and AlGaN: Basic Material Properties, Processing and Devices” (University of Bristol, 2002) p.63.

- 36. M.A. Reshchikov, Phys. Status Solidi. C 8 (2011) 2136-2138.

-

- 37. J. Neugebauer, and C.G. Van de Walle, Appl. Phys. Lett. 69[4] (1996) 503-505.

-

- 38. D.O. Demchenko, I.C. Diallo, and M.A. Reshchikov, Phys. Rev. Lett. 110 (2013) 087404.

-

- 39. K.H Kim, “The study on GaN grown by hydride vapor Variation of optical characteristics with the thickness of bulk GaN grown by HVPE 13 phase epitaxy” (Korea Marintime University, 2004) p.46.

- 40. M.H. Lee, “A study on the fabrication GaN substrates by HVPE method” (Hanbat National University, 2003) p.37.

- 41. L. Li, J.Yu, Z. Hao, L. Wang, J. Wang, Y. Han, H. Li, B. Xiong, C. Sun and Y. Luo, Comput. Mater. Sci. 129 (2017) 49-54.

-

- 42. H. Gu, G. Ren, T. Zhou, F. Tian, Y. Xu, Y. Zhang, M. Wang, Z. Zhang, D. Cai, J. Wang and K. Xu, J. Alloys Compd. 674 (2016) 218-222.

-

- 43. Y.J. Lee and S.T. Kim, Korean J. Met. Mater. 8 (1998) 591.

- 44. M. Seon, T. Prokofyeva and M. Holtz, Appl. Phys. Lett. 76 (2000) 1842-1844.

-

- 45. https://en.wikipedia.org/wiki/Band_gap

- 46. N. Sharma, M. Hooda, and S.K. Sharma, Indian J. Phys. 93 (2019) 159-167.

-

This Article

This Article

-

2020; 21(5): 609-614

Published on Oct 31, 2020

- 10.36410/jcpr.2020.21.5.609

- Received on Aug 19, 2020

- Revised on Oct 10, 2020

- Accepted on Oct 12, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jae Hwa Park

-

AMES Micron Co. LTD, 32 Singok-ro, Gochon-eup, Gimpo-si, Gyeonggi-do, 10126, Republic of Korea

Tel : +82-70-4710-2881

Fax: +82-31-992-2700 - E-mail: jhpark@amesmicron.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.