- Chemical treatment to improve usable strength of Ion-exchanged cover glass

Hoikwan Lee*, Byeongbeom Kim, Yuri Kim, Minki Kim, Seungho Kim and Seongtaek Lee

Display Research Center, Samsung Display Co., Ltd., Giheung-gu, Yongin-city, Gyeonggi-do, Korea

Glass leaching, including

dissolution and hydrolysis, was introduced to mend surface flaws in

ion-exchanged glass. The leaching behavior on the glass surface was analyzed by

using a spectrophotometer, AFM, a confocal LCM, a surface stress meter and TEM.

The results revealed that a silica-rich nano layer was formed on the surface of

the glass after soaking in an acidic solution by dissolution of alkali ions

from glass surface, and the formed layer including the flaws on the surface of

the glass were completely removed after being exposed to an alkaline solution.

We also found that leaching an aqueous solution increased the mechanical

strength dramatically in ion-exchanged glass without degradation of surface

quality.

Keywords: Ion exchange, Cover glass, Usable strength, Chemical treatment, Silica-rich layer

Glass is now commonly used in many portable electronic

displays, mobile phones and tablets, as a protective cover for the devices. The

ion exchange process, Nullification of Surface Damage, is generally conducted

to improve the mechanical properties which are dependent on the compressive

stress at the surface and the depth of penetration of larger ions. Thus far,

the ion exchange method has been widely used for the strengthening of cover

glass because the generated compressive stress prevents crack propagation in

glass adequately. However, due to recent requirements for thin, light-weight

and unbreakable devices, the glass used is getting thinner and thinner,

and the ion exchange method has limitations to meeting the unbreakable

glass requirements due to unavoidable nano damages on the surface of the glass

which are more critical when the local bending is made by blunt impact [1-6].

In order to meet the requirements, functional coatings are

used on glass with organic and inorganic materials to minimize the stress

concentration in the crack tip. Teisseire et al. reported that

edge-strengthening of flat glass increased with acryl coating [7]. Also, there

are several reports with silica-like coating, diamond-like coating and

sapphire-like coating to increase the glass hardness as well as the glass

strength by reducing the role of stress corrosion at the crack tip that is

promoted by moisture at the surface [8-10]. However, the organic coating is

accompanied by hardness reduction as well as

reliability issues, and the inorganic coatings have some

side effects such as transmittance reduction, reduction of compressive stress

due to the relatively high processing temperature, cost increase, etc. The most

critical problem of the coating method is that it couldn’t be free from surface

damages due to the inability to mend surface damage thoroughly [11].

Chemical etching or healing, to remove surface damages and

bring back a pristine state, is studied; but it has not met the surface quality

required. Etching with hydrofluoric acid is a well-known and easy method to

increase glass strength by enlarging the radius of the crack tip [12-14].

However, the etched surface becomes very uneven and the crack maintains its

original depth as etching proceeds. The greatest disadvantage is that the

microcracks become visible etch pits. Thus it is not very attractive as a

commercial technology [15-17].

Therefore in this study, we introduced the chemical

cleaning method of using glass leaching to include glass

dissolution and hydrolysis. A silica-rich nanolayer is placed on

the surface of the glass reaching the lowest depths of the flaws, and it is

formed uniformly by exposing the glass to an aqueous acid solution and leaching

the alkali ions. The formed silica-rich nanolayer is then

removed completely by soaking the glass to an aqueous alkaline solution. The

formation of silica-rich nanolayer is confirmed and characterized by using UV-VIS

spectra, AFM, LCM and TEM. The thickness of nanolayer is varied with time,

temperature, and pH. The tested glass has shown excellent mechanical

performance without a trade-off among the strength, surface quality, and

hardness.

The samples of glass used in this study are commer- cially available alkali-aluminosilicate

(Corning Gorilla 3 & Gorilla 5 Glass, Corning, USA) specially designed for

ion exchange up to a great CS (Compressive Stress) and deep DOL (Depth of

Layer). The samples of glass were cut to desired size (typically mobile phone

with dimensions 70 mm × 150 mm) and put through a

mechanical machining and surface finishing process to make a 2D or 2.5D shape.

The samples of glass were strengthened by ion exchange

processes with the recipe provided by the glass maker. The Gorilla 3

sampleswere treated with a single step process and the Gorilla 5 samples were

strengthened by a 2-step process. Prepared samples satisfied all specifications

required for a cove glass.

Acidic solutions were prepared with the three different

acids (H2SO4 70% Hangseong Chem, CAS NO: 7664-93-9, HCl

35% Hangseong Chem, CAS NO: 7647-01-0, HNO3 60% SN Chem CAS NO:

7697-37-2) and distilled water. Specimens were immersed in the acidic solution

(60 liter) in a plastic bath. The solution was stirred with a

Teflon-coated stirrer and heated with a Teflon-coated heater during the

experiment, and the leaching behaviors were monitored as a function of the time

and temperature. The formed silica-rich nanolayer was removed with alkaline

solution prepared by using NaOH (Soda Flakes 98% YoungJin Chem.)

and distilled water.

The formation and removal of the silica-rich nanolayer

was confirmed and characterized by using spectropho- tometer (CM-3600d, Konica Minolta), AFM

(NX-20, Park Systems), LCM (Laser Con-focal Microscope), FSM (a surface stress

meter FSM-6000LE; Orihara, Toshima, Japan) and TEM. The thickness of the

silica-rich nanolayer was dependent on time, temperature, and

pH level of the solutions. Its effect on the mechanical property of

glass was tested with a dynamic impact test with a 150 g steel ball.

When ordinary glass was exposed to an aqueous solution,

alkali ions from the glass were extracted into the solution, and an alkali

deficient leached layer that is also a silica-rich nanolayer is formed on the

glass surface. The thickness of silica-rich nanolayer depends on the glass

composition and test conditions such as time, temperature and pH of the

solution [18-21]. One interesting finding is that the silica-rich nanolayer

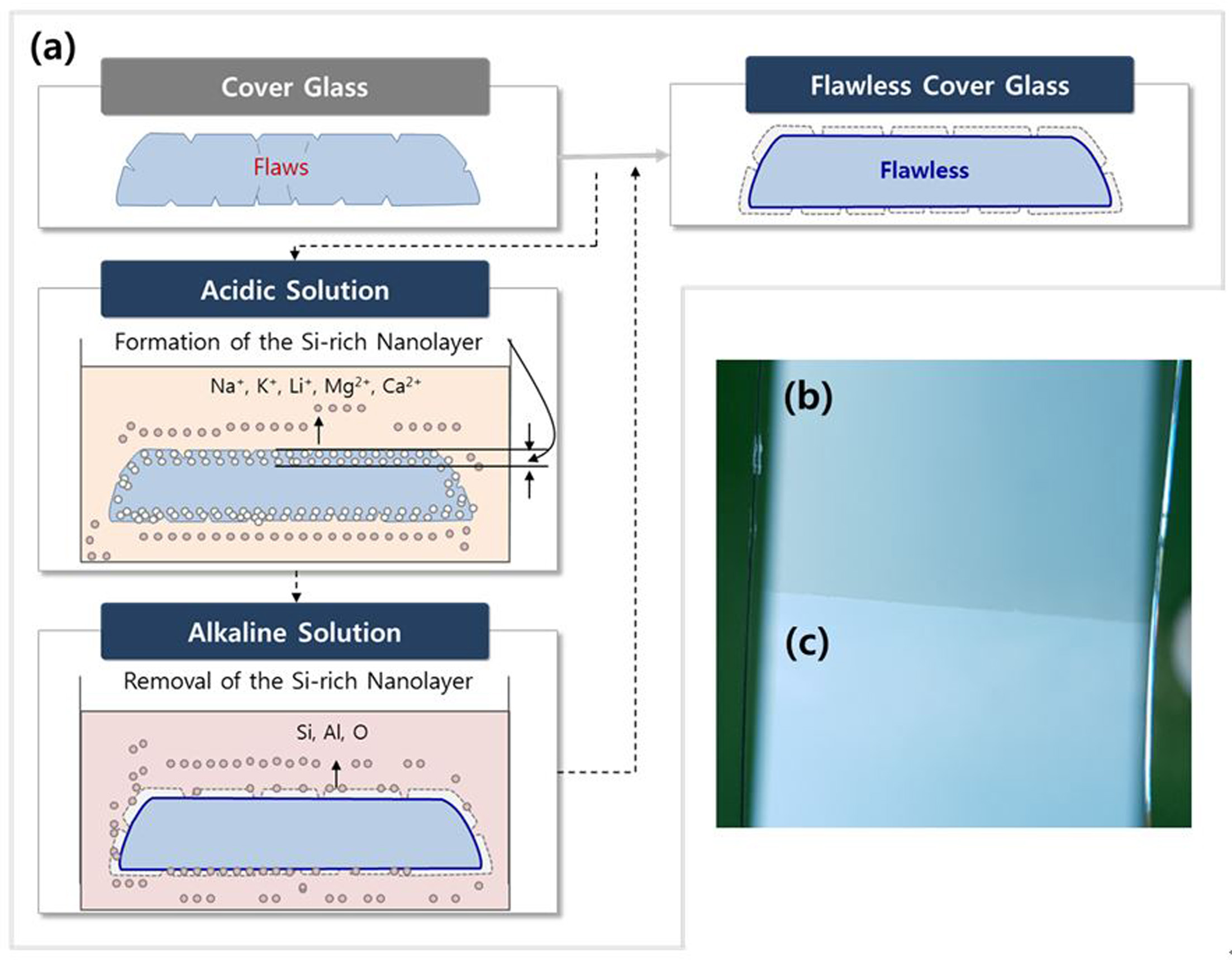

formed on glass surface became susceptible to decom- position in alkaline solution. Figure 1(a)

shows the processes when a sample of glass is exposed to an acidic solution as

well as alkaline solution. Here a silica-rich nanolayer was formed on glass

surface including the flawed areas with a thickness of 200~ 1000 nm in

order to improve the glass strength further. This thermodynamic prediction has

been verified by Shamy, Lewins and Douglas [22]. To observe the formation of

silica-rich nanolayer, half of the sample of glass was sealed with masking tape

after exposure to an acidic solution followed by an alkaline solution soak.

Figure1 (b, c) shows the top view of glass surface before and after alkaline

solution exposure. Fig. 1(b) indicates the silica-rich layer formed on the

glass surface after soaking it with an acidic solution, and Figure 1(c) shows

the silica-rich layer was removed with an alkaline solution.

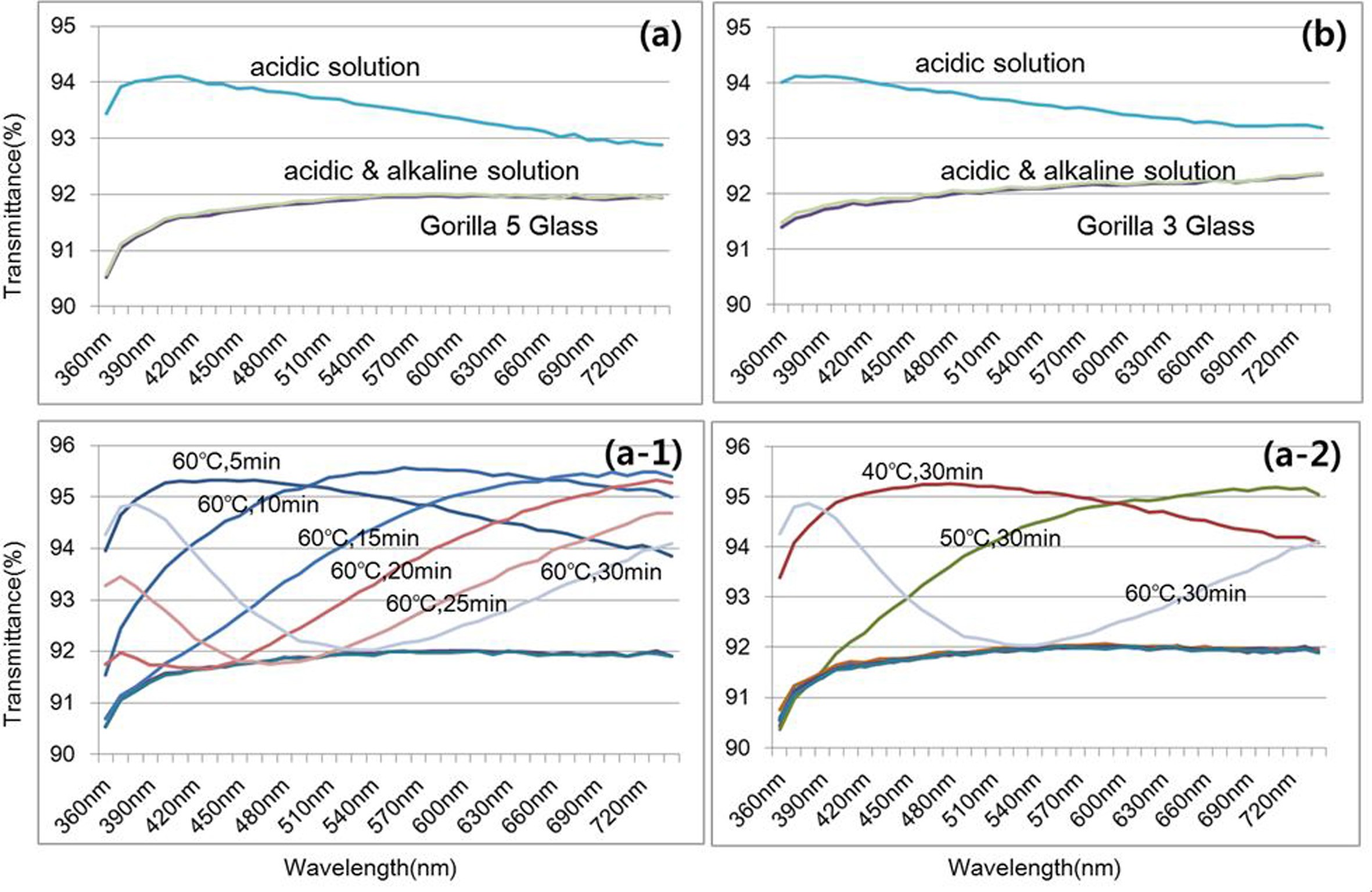

Transmittance spectra of the Gorilla 3 & 4 glass

samples are presented in Fig. 2(a, b) respectively. Both glass

samples show transmittance increase after exposure to an acidic

solution due to the formation of silica-rich nanolayer which is a relatively

low density that reduces the reflectance. The transmittance quickly recovered

to a pristine state by removing the silica-rich nanolayer in an alkaline

solution. Fig. 2(a-1, a-2) shows the time and

temperature dependence of the silica-rich nanolayer. The maximum

transmittance point moving to high wavelength means that

the silica-rich nanolayer is getting thicker with the increase of time. The

results indicate that temperature and time are important factors in deter- mining the thickness of the silica-rich

nanolayer, and the glass samples with relatively thick silica-rich

nanolayer easily return to a pristine surface after exposure to an

alkaline solution.

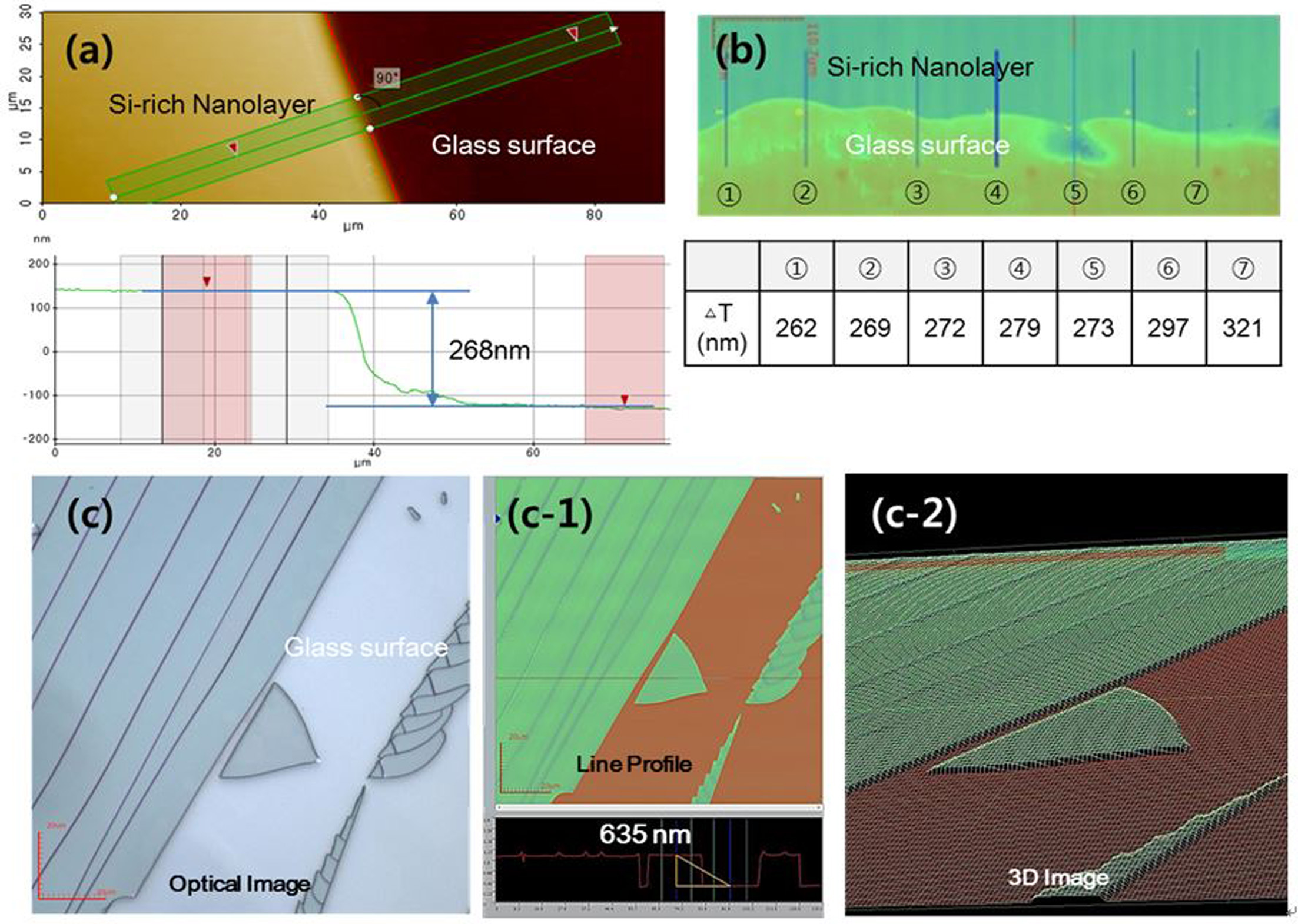

The measurements at the borderline were carried out with

the same samples in Fig. 1(b, c). As shown in Fig. 3(a), AFM indicates

268 nm as the thickness of the silica-rich nanolayer and this value was

confirmed with LCM measurement at 8 points. Mechanical impact with

a steel ball made the silica-rich nanolayer separate. As seen in Fig. 3(c, c-1,

c-2), approximately 635 nm thick silica-rich layer was separated

successfully, and the removed surface was as flat as pristine glass.

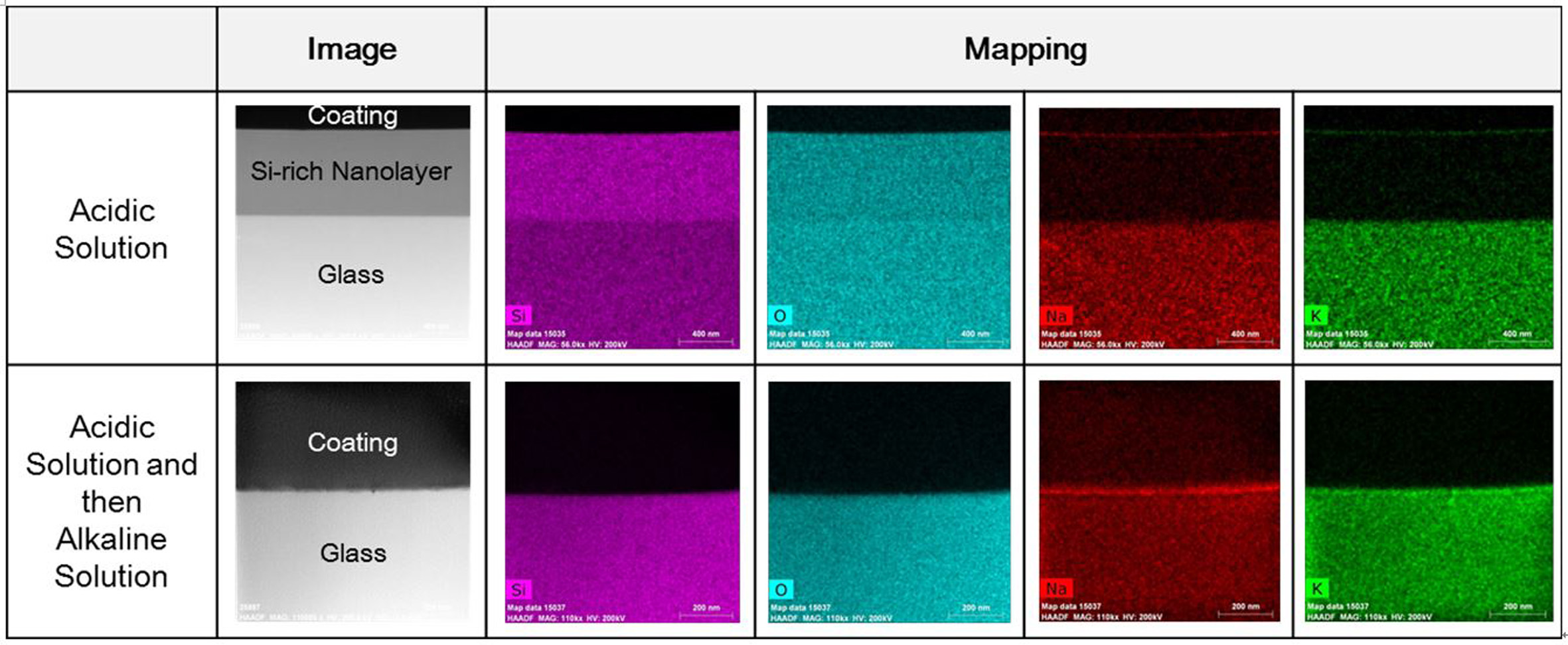

The glass compositions in the silica-rich layer were analyzed

with TEM EDS mapping and shown in Fig. 4. The results indicate that the

silica-rich layer consists of Si and O ions and Na and K ions were leached out

to a certain depth. It is confirmed again that the silicon-rich layer was

completely removed after exposure to an alkaline solution.

In order to prove the effect of the leaching process on

the mechanical strength of glass, the silica-rich nanolayer with a thickness of

300~400 nm was formed by exposing the sample to an acidic solution and

removed by dipping the sample in an alkaline solution. To measure the glass

surface strength before and after the leaching process, ball drop testing was

conducted by impacting the center of the glass surface with a 150 g steel

ball. Height was increased at intervals of 5 cm until the breaking point

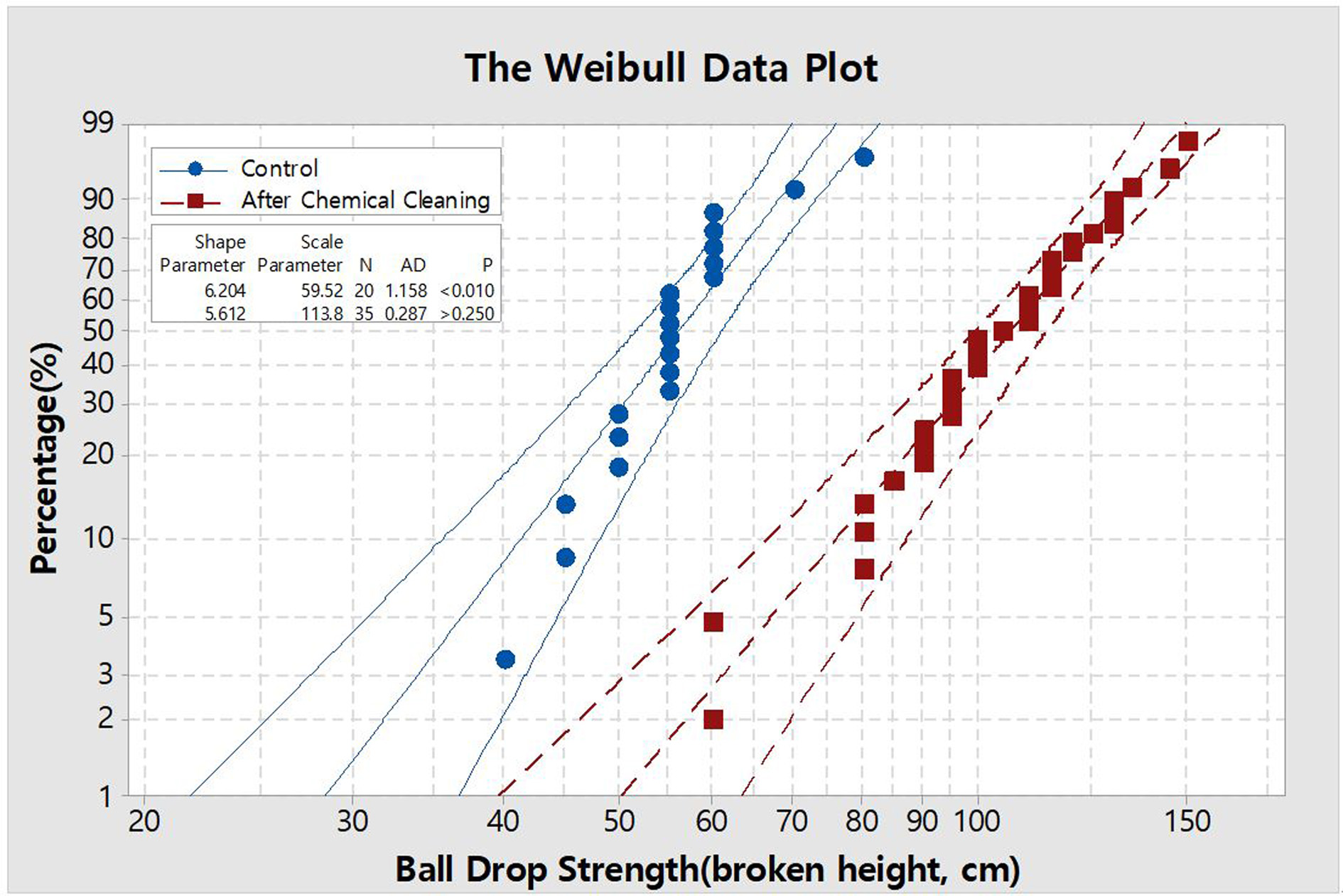

was found. The results are presented with a Weibull plot as seen in Fig. 5. In

terms of the scale parameter of 63.2%, it is clear that the surface is

strengthened as the leaching process increases 1.9 times. The more interesting

point is that the surface quality was as good as pristine glass and there was

no known side effects caused by this process.

In this study, glass leaching was introduced to improve

mechanical property of chemically strengthened glass. A

silica-rich layer that reached flaw depths was formed on the surface of the

glass by exposing the glass to an acidic solution. The thickness of silica-rich

layer was controllable by adjusting the time and temperature of the solution.

The formation of a silica-rich layer was confirmed with naked eye, and the

thickness was measured by AFM and LCM. TEM mapping

revealed that the silica-rich layer was composed of Si &

O, and the layer was removed completely after being soaked in an alkaline

solution.

In order to see the effect of the leaching process on

glass surface strength, a ball drop test was performed with a 150 g steel

ball. The glass strength increased with the thickness of silica-rich layer and

saturated at 300 nm. When the silica-rich layer was thicker than

1000 um, the glass strength was decreased due to the loss of compressive

stress. The saturation point was selected in the range of 300~400 nm, and

the reduction of compressive stress was 30~40 MPa. An interesting point is

that this method doesn’t have trade off among the strength, surface quality,

hardness and long-term reliability. This work will serve as a foundation for

mending surface flaws in ion-exchanged glass.

|

Fig. 1 (a) Leaching process to form and remove the Si-rich Nanolayer (including flaws), (b) top view of glass surface (Si-rich Nanolayer)

after soaking in acidic solution, (c) top view of glass surface (Pristine surface) after soaking in acidic and alkaline solution. |

|

Fig. 2 Comparison of transmittance (a,b) of Gorilla 5 & 3 glass samples after exposing the glass samples to an aqueous acid solution and

alkaline solution respectively, transmittance variation as a function of soaking time (c) and temperature (d) in acidic solution. |

|

Fig. 3 Thickness of silica-rich nanolayer at the boundary (a) with AFM analysis and (b) with LCM analysis, (c) uniformity after removal of

silica-rich nanolayer. |

|

Fig. 4 TEM EDS mapping on fractured glass surface as a function of the chemical cleaning process. |

|

Fig. 5 Weibull plots for data sets of ball drop strength with 150 g steel ball; 95% confidence intervals. |

Leaching of glass made the silica-rich nano layer on

ion-exchanged glass, and removed it as well. The thickness of the silica-rich

layer was varied as a function of the glass soaking time and the temperature of

the acidic solution within the range of 100 nm ~1500 nm. The alkaline

solution caused the glass to have a pristine surface by removing the

silica-rich layer composed of Si and O. We also demonstrated that leaching can

improve the strength of ion-exchanged glass dramatically (up to two

times the original strength) without any degradation of surface

quality.

- 1. K. Kawamoto, T. Murata, S. Miwa, M. Ohji, and H. Yamazaki, SID DIGEST (2014) 1240-1243.

-

- 2. H. Ikeda, K. Kinoshita, M. Fukada, K. Kawamoto, T. Murata, K. Choju, M. Ohji, and H. Ymazaki, SID DIGEST (2014) 1365-1367.

-

- 3. D.R. Uhlmann and N.J. Kreidl, Glass Science and Technology: Academic Press (1980) 214-270.

-

- 4. A.K. Varshneya, INT. J. APPL. GLASS SCI. 1[2] (2010) 131-142.

-

- 5. F. Rehouma and K.E. Aiadi., Int. J. Commun. 4[1] (2008) 148-155.

- 6. A.K. Varshneya and W.C. LaCourse, Ceram. Trans. 29 (1993) 365-376.

- 7. J. Teisseire, D. Dalmas, S. Lohou, C.D. Silva, and E. Barthel, Int. J. of Fracture 170 (2011) 115-121.

-

- 8. C.R. Lin, D.H. Wei, C.K. Chang, and W.H. Liao, Phys. Procedia. 18 (2011) 46-50.

-

- 9. Rubicon Technology, Sapphir EX durable coatings. www.rubicontechnology.com

- 10. S.A. Mahadik, M.S. Kavale, S.K. Mukherjee, and A.V. Rao, Appl Surf. Sci. 2[257] (2010) 333-339.

-

- 11. D. Hanft, J. Exner, M. Schubert, T. Stocker, P. Fuierer, and R. Moos, J. Ceram, Sci. Tech. 06[03] (2015) 147-18

- 12. T. Suratwala, W. Steele, L. Wong, M.D. Feit, P.E. miller, R. Dylla-Spears, N. Shen, and R .Desjardin, J. Am. Ceram. Soc. 98[8] (2015) 2395-2402.

-

- 13. L.M. Cook, J. Non-Cryst. Solids 120[1-3] (1990) 152-171.

-

- 14. T.P. Dabbs and B.R. Lawn, J. Am. Ceram. Soc. 65[3] (1982) C37-C38.

-

- 15. E.K. Pavelchek and R.H. Doremus, J. Maer. Sci. 9 (1974) 1803-1808.

-

- 16. B.A. Proctor, Appl. Mater. Res. 3 (1964) 28-37.

- 17. V.A. Ryabov and V.V. Kupfer, Glass Ind. 51 (1970) 268-271.

- 18. L.L. Hench, J. de Phys. C9 (1982) 625-636.

-

- 19. M.M. Smedskjaer, J. Deubener, and Y. Yue, Chem. Mater. 21 (2019) 1242-1247.

-

- 20. M.D .Bardi, R. Wiesinger, and M. Schreiner, J. Non-Cryst. Solids. 360 (2013) 57-63.

-

- 21. F. Farges, M.P. Etcheverry, A. haddi, P. trocellier, E. Curti, and G.E. Brown, AIP Conference Proceedings 882 (2007) 44-51.

-

- 22. T.M. El-Shamy, J. Lewins, and R.W. Douglas, Glass Technology 3[13] (1972) 81-87.

This Article

This Article

-

2020; 21(5): 547-551

Published on Oct 31, 2020

- 10.36410/jcpr.2020.21.5.547

- Received on Mar 16, 2020

- Revised on Apr 20, 2020

- Accepted on May 4, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Hoikwan Lee

-

Display Research Center, Samsung Display Co., Ltd., Giheung-gu, Yongin-city, Gyeonggi-do, Korea

Tel : +82-031- 5181-6566

Fax: +82-031-8000-6822 - E-mail: hoikwanlee@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.