- Investigations on aluminium hybrid composites reinforced with ZrB2/Al2O3/Multi-Walled Carbon Nanotube (MWCNT) for aerospace applications

Elaya Perumal Aa,*, Jinu GRa, Vidhyalakshmi Sb and Amal Bosco Jude Sc

aUniversity College of Engineering, Nagercoil, Kanyakumari, Tamilnadu, 629004, India

bNagercoil, Kanyakumari, Tamilnadu, 629004, India

cUniversity VOC College of Engineering, Thoothukudi, Tamilnadu,628008, India

The Aluminium Alloy (AA7050)

hybrid composites (AAHC’s) reinforced with 2-10 wt.% ZrB2

ceramic particles, 1-5 wt.% Al2O3 particles and

0.5-2.5 wt.% MWCNT in novel Vibro-compo casting through liquid casting

route. The ZrB2 and Al2O3 have been

introduced in the conventional method, and MWCNT is injected by argon gas.

Then, the stirring process was carried out in different temperatures to enhance

wettability between reinforcements and matrix. The developed AAHC’s were

characterised using a Scanning Electron Microscope (SEM) and Energy-dispersive

X-ray spectroscopy analysis (EDS). The mechanical properties like hardness,

tensile, impact and fatigue tests were performed on all the casted samples

elaborately. The dispersion of ZrB2 ceramic

particles and its implanting over the ductile Al7050 matrix was effectively

obtained, which shown superior mechanical properties when compared to

monolithic Al7050 alloy. The specimen contained 1.5%MWCNT + 6%ZrB2 + 3%Al2O3

reveals the greater tensile strength, which is 30.73% higher than the base

material. Besides, the EDS results ensured the manufacturing of Al 7050/MWCNT + ZrB2 + Al2O3

metal matrix composites successfully, and no other intermetallic phases were identified.

Keywords: ceramics, composite materials, metal matrix composites, mechanical properties, metals

Aluminium alloy hybrid composites are undergoing a

revolution in the aerospace industry. The AAHC has received much attention in

the past decade. Within the next few years, AAHC, likely to become a

significant composite material in aircraft. Currently, aluminium alloy 7050 is

used in the wing spar of aircraft structure [1], but it

has average strength level. In order to overcome this

disadvantage, researchers were focused on this aluminium alloy 7050 to

reinforce with TiC [2] and TiB2 [3]. Al3Zr

dispersoids were reinforced in aluminium alloy 7050

[4]. The Al2O3, ZrB2, SiC, TiC TiB2

are the most common ceramic materials chosen to reinforce aluminium alloys

[5-11]. This paper seeks to address the introduction of multi

reinforcements such as MWCNT, ZrB2, Al2O3

on aluminium alloy 7050. Several authors have attempted to define AAHC’s, but

as yet there are still no accepted results on AAHC’s. In the literature, there

are many composites by aluminium alloy 7050 much work on the potential of AAHC

has been carried out. The first studies on AAHC found that aluminium alloy 7050

was reinforced with TiC particles [2]. Experiments on aluminium alloy 7050

reinforced com- posite were performed

by a group of researchers [3]. Lin K [3] has developed and investigated the

machina- bility parameters of TiB2

particles reinforced with aluminium alloy 7050. They draw focus

on monophonic reinforcements such as TiB2. It was

suggested [12] that, the introduction of ZrB2 particles

on aluminium alloy 6061 has enhanced the properties of composites, and this

seems to be a positive approach. Research has tended to focus on the monophonic

introduction of reinforcement rather than the multi-entry of

reinforcements on aluminium alloy 7050. Baradeswaran

[13] contended that aluminium alloy 7075 metal matrix composite

enhances the mechanical properties, but they failed to provide adequate

information for multi-entry reinforce-

ments. The reinforcements phase have been tried with different weight

percentages to improve the mechanical and metallurgical properties of the

composite [14-19]. Literature survey reveals that aluminium alloy 7050 rarely

reinforced with MWCNT, TiC, TiB2, ZrB2 and Al2O3

in the liquid casting route. Similarly, few research

works are identified in hybrid composites using aluminium alloy 7050 as matrix

phase. This present work AA7050/MWCNT/ ZrB2/Al2O3

hybrid composites were developed through the Vibro compo casting

method to get superior interface bonding and increase wettability. Thus, the

key objective of this research work is to investigate the influence of the

MWCNT, ZrB2 and Al2O3 particles on

the mechanical properties such as tensile, microhardness, impact, fatigue and

characterised by SEM and EDS on hybrid composites.

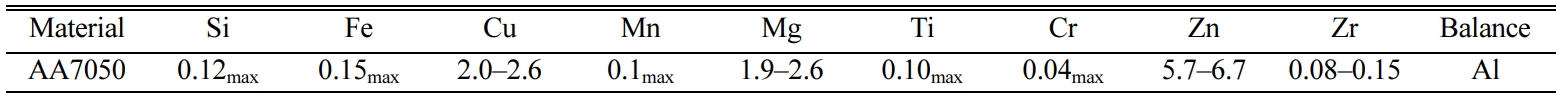

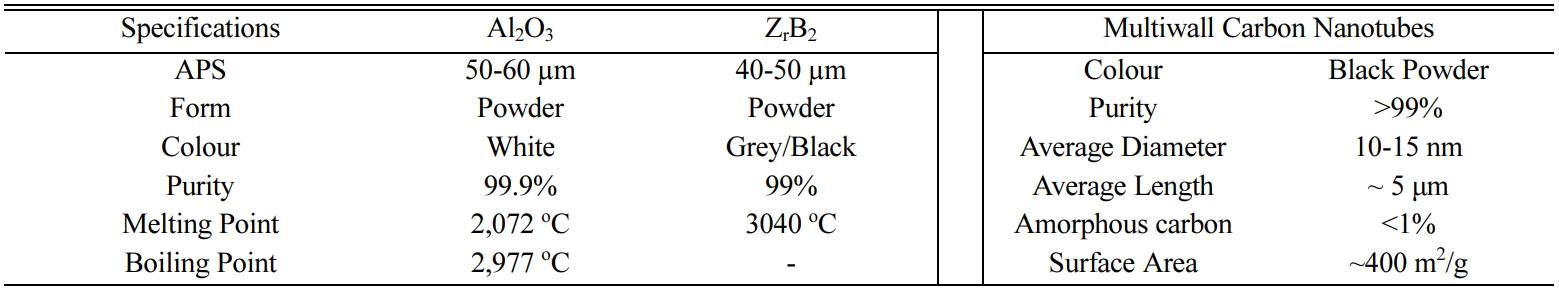

Materials

In an attempt to do AAHC, Aluminium Alloy 7050-T7451

chosen as matrix phase and its chemical composition given in Table 1. The

Multiwall Carbon Nanotubes (MWCNT), ZrB2 and Al2O3

were chosen for the reinforcement phase and their specifications

mentioned in Table 2. The MWCNT supplied by AdNano

Technologies, Catalytic carbon vapour deposition (CCVD)

process were used to produce ultrapure multiwall Carbon Nanotubes. The

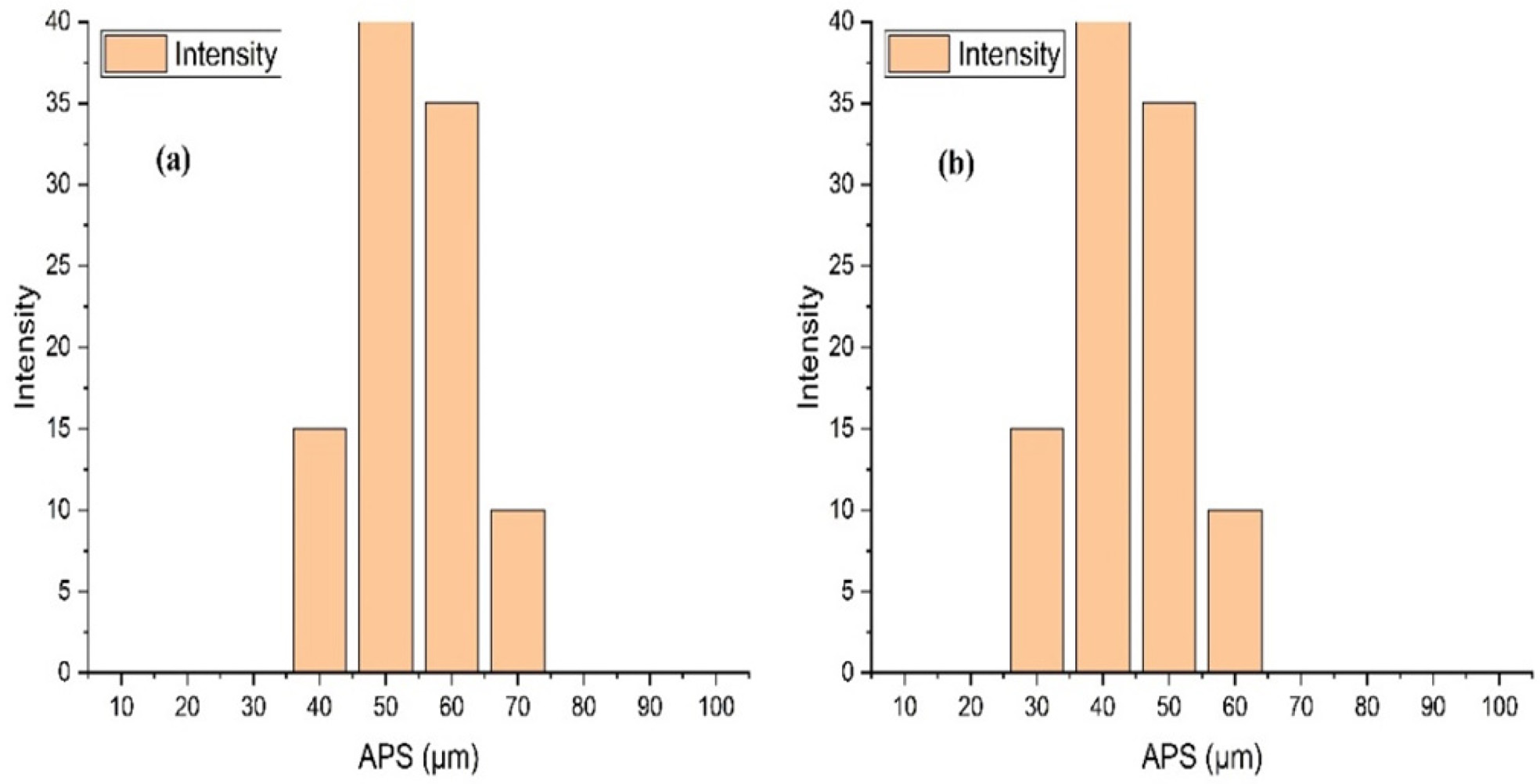

received Al2O3, ZrB2 particles have

been examined to confirm the size of the particles using Average particle size

analyser. The average particle size of Al2O3 is

50 µm and ZrB2 is 40 µm is confirmed, as shown

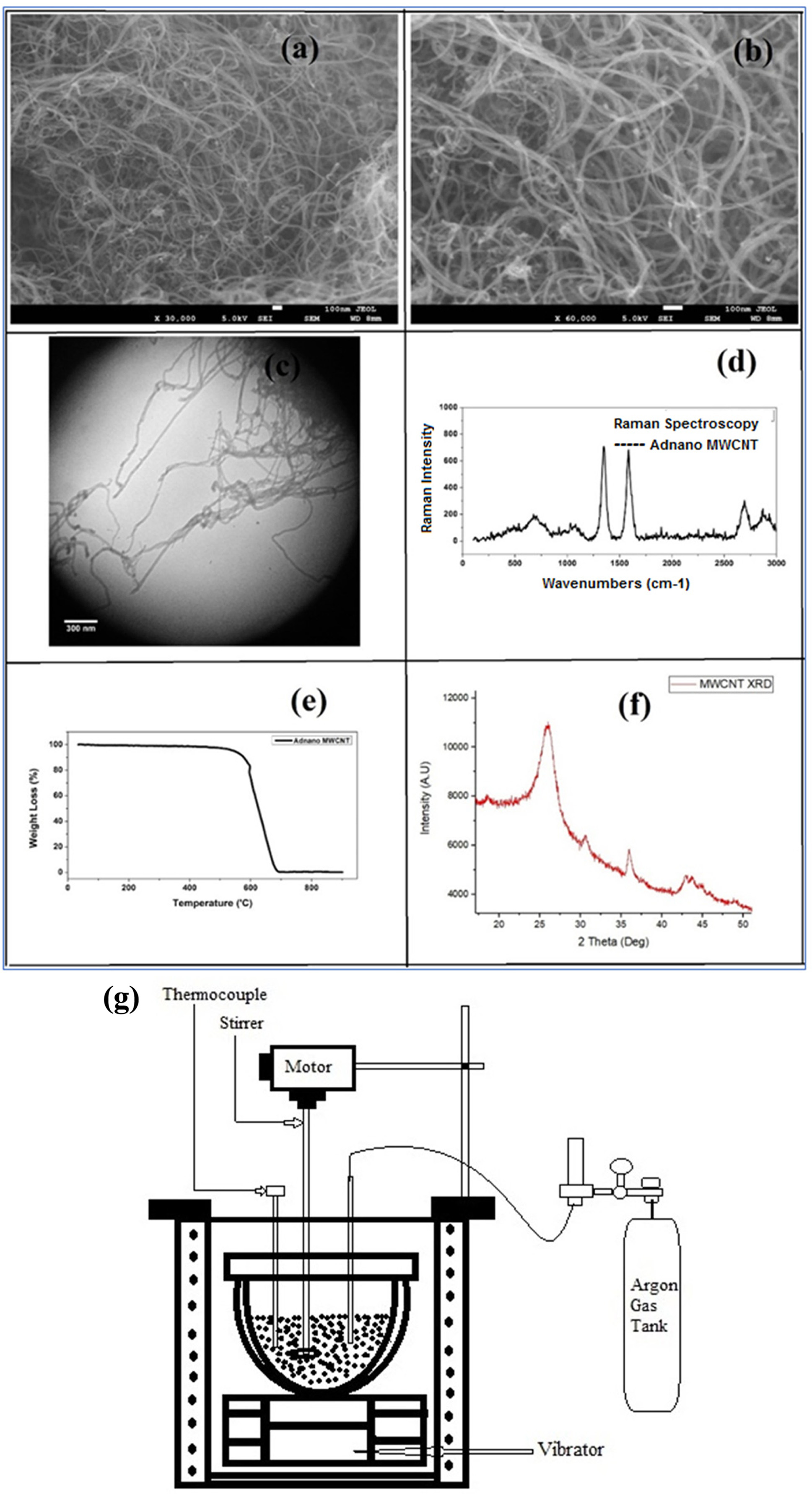

in Fig. 1(a) and 1(b). Similarly, the received MWCNT’s are analysed by scanning

electron microscopy equipment in the 100 nm × 60,000 and

100 nm × 30,000 scale. The SEM results confirm the presence of

MWCNT’s, as shown in Fig. 2(a) and 2(b). Transmission

Electron Microscopic analysis results are

shown in Fig. 2(c). The Raman spectroscopy examination

was conducted on MWCNT’s, and its results show good agreement with wavenumber

and Raman intensity in Fig. 2(d). The percentage of weight loss

examination of the MWCNT was performed against temperature; weight

loss percentage is nearly to zero at 700 oC in Fig.

2(e). XRD analysis was done on MWCNT, and the result exhibits the

chemical composition peaks of MWCNT’s are shown in Fig. 2(f).

Fabrication

method

The fabrication of composites carried out through liquid

metallurgy route via Vibro compo casting method. In this

work, a specific vibrator is attached with a crucible for superior dispersion

of MWCNT in the aluminium matrix. This method is in line with a substantially

the same as that used by Abbasipour [20] compo casting setup with some

modifications. The apparatus is consisting of alumina crucible with muffle

furnace, coated steel stirrer, reinforcement injection tube, crucible with a

vibrator is attached with the compo casting equipment, which is shown in Fig.

2(g). The melt temperature has measured by using the K-type thermocouple, and

Argon gas is used to inject the reinforcements to the vortex melt. The compo

casting equipment can easily be customised to suit all the conditions. It was

decided that the best equipment for this investigation because it is one of the

most suitable methods for casting Carbon Nanotubes. All samples

have prepared in the following two routes. Initially, ZrB2 and

Al2O3 introduced in the traditional

route, and MWCNT’s are injected and stirred in different temperatures

to enhance wettability between reinforcements and matrix. Crucible

was allowed to vibrate and preheated at 600 oC then

aluminium alloy 7050 is melted at 700 oC. The Preheated

ZrB2 and Al2O3 were mixed with

aluminium melt then stirred at speed 450RPM. MWCNT were injected by

argon gas to the semi-solid aluminium melt then stirred at 250RPM to enhance

good wettability of MWCNT’s. Finally, the molten metal has poured in

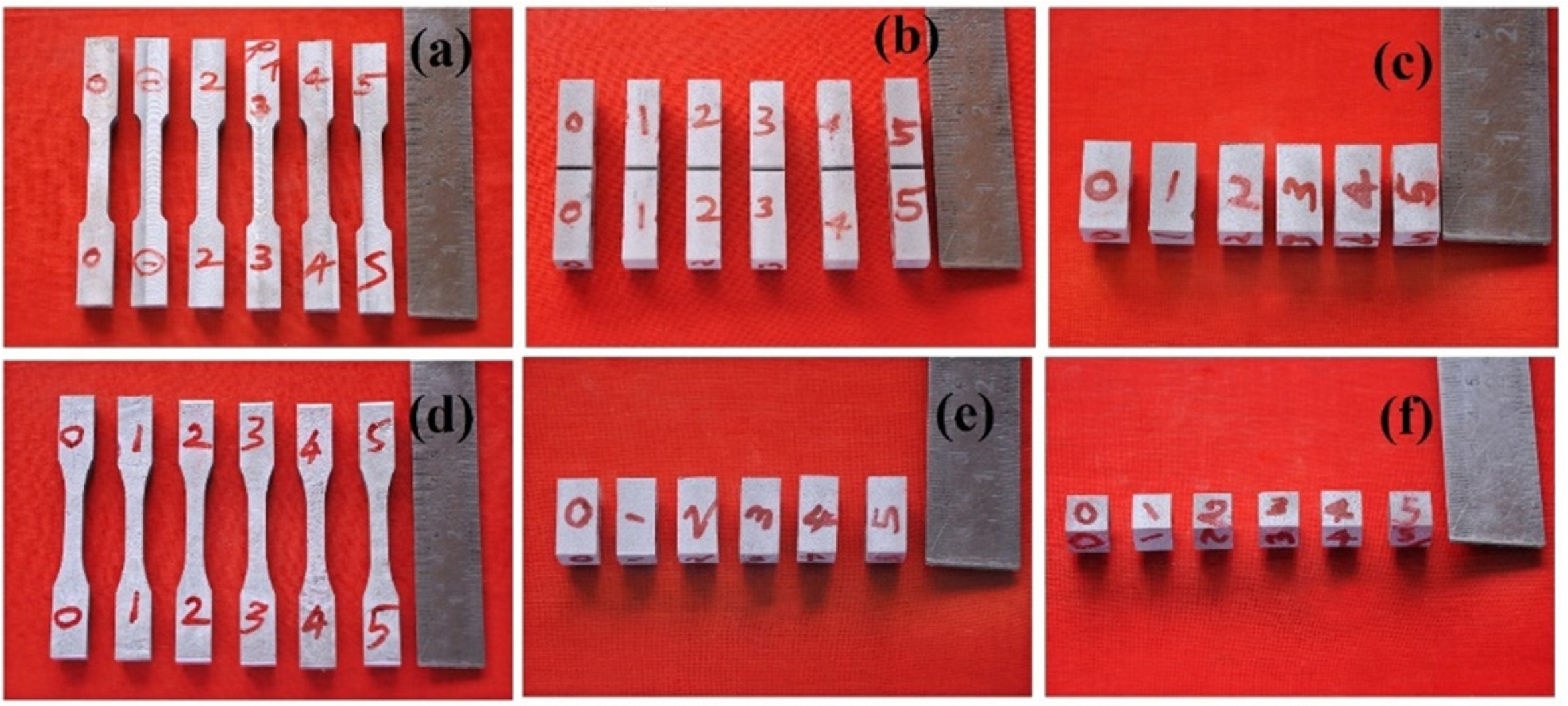

100 × 100 × 10 mm sized dye. Then, the samples were machined

as per various ASTM standards by ELECTRA wire

EDM machine (SPRINTCUT WIN-Pulse Generator: ELPULS 40A

DLX. Fig. 3(a)-3(f) show the machined samples for various mechanical and

tribological investigations.

Characterisation

The Tensile strength analysis has carried out on the

100 × 6 × 12 mm sized samples shown in Fig. 3(a) as

per ASTM standard E8M04 by Computerised Universal Testing

Machine TMC– CUTM – 50 kN model, Chennai. Then,

Microhardness examinations were Examined on the

20 × 10 × 6 mm sized samples shown in Fig. 3(c) as per

ASTM standard E18M by using Microhardness Testing Machine, Mitutoyo– HM113

Model, Japan. Izod impact tests have performed on

75 × 10 × 10 mm sized samples shown in Fig. 3(b) as

per ASTM standard D256 using Impact testing machine. Fatigue strength investigation

was conducted using computerised fatigue equipment supplied by AVJ

Engineering Services Coimbatore. Similarly,

material characterisations such as Scanning Electron Microscope – SEM, JEOL–

JSM 6390, Japan and Energy Dispersive Spectroscopy – EDS, Oxford Instruments–

INCA Energy 250 LN2 Closed, UK was used and conducted.

|

Fig. 1 (a) Average particle size analysis of Al2O3 reinforcement, (b) Average particle size analysis of ZrB2 reinforcement. |

|

Fig. 2 (a), (b) and (c), Scanning Electron Microscopic and Transmission Electron Microscopic images of MWCNT’s, (d) Raman

spectroscopy analysis of MWCNT, (e) Weight loss analysis of MWCNT against temperature, (f) XRD analysis of MWCNT’s, (g) Schematic

Diagram of Stir casting setup. |

|

Fig. 3 Machined samples for Tensile, Impact, Micro Hardness, Fatigue, SEM and EDAX Investigations. |

Mechanical

properties of AA7050/MWCNT/ ZrB2/Al2O3

AAHC’S Tensile test

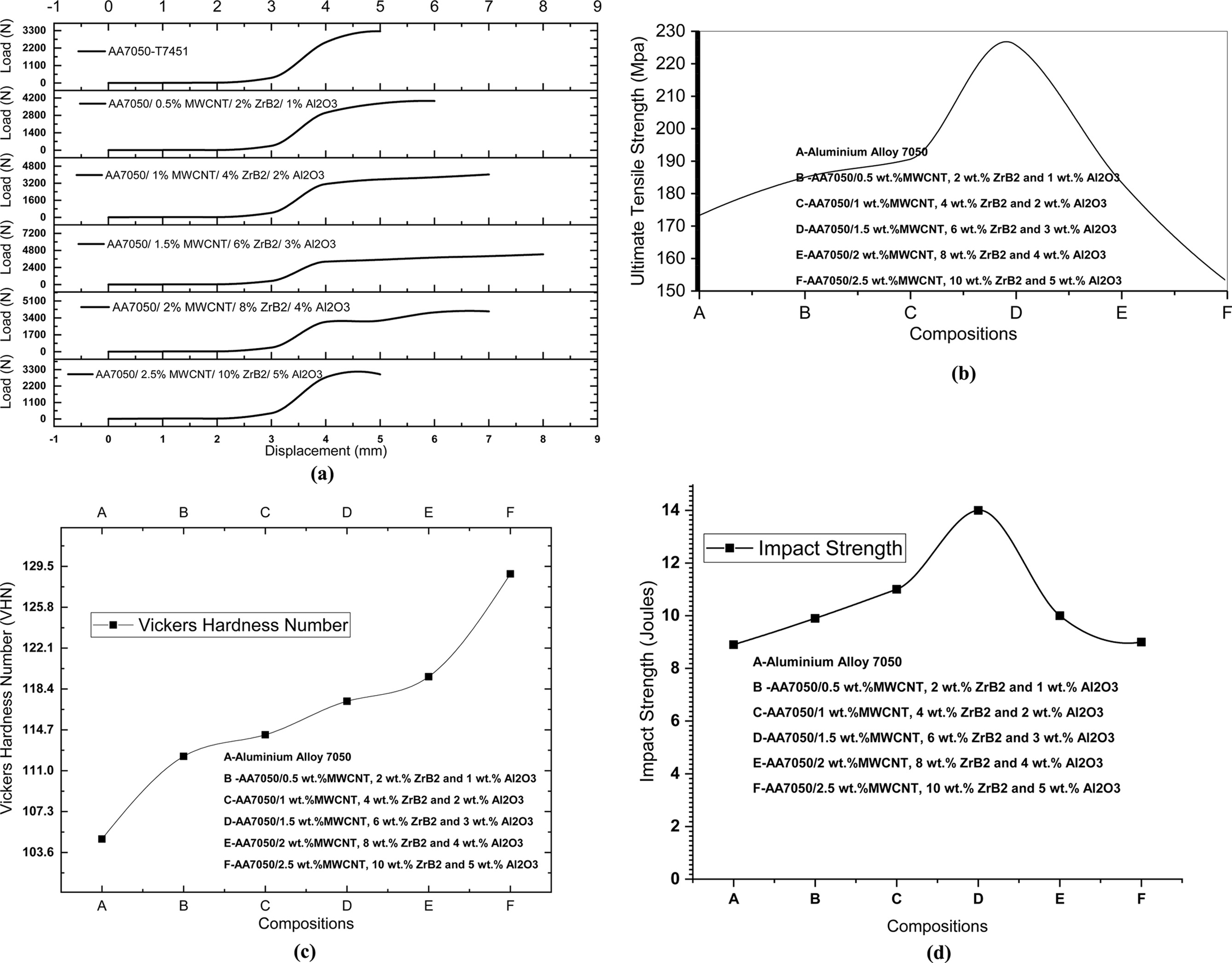

The internal resistive force against the load of the

composites was enhanced due to superior dispersion in matrix till the AA7050/

(1.5%MWCNT + 6% ZrB2 + 3%Al2O3)

composite, as shown in Fig. 4(a). From the Fig. 4(b), the ultimate tensile

strength of B, C and D composites are in increase trend while other two in downfall.

The ultimate tensile strength of E and F composites are decreasing due to the

increment of MWCNT, ZrB2 and Al2O3

particles and porosity due to the new cluster formation. The ZrB2

particles are surrounded by MWCNT’s. There is no Interfacial bonding due to the

lack of aluminium matrix phase in those composites. It is due to

the non-uniform dispersion between matrix and reinforcements.

Micro hardness test

The Vickers microhardness values of all casted samples are

examined. The Vickers Hardness Number is directly proportional to the

reinforcement’s weight percentage. An increasing trend was observed on AA7050/(0.5%MWCNT + 2%

ZrB2 + 1%Al2O3), AA7050/ (1%MWCNT + 4%ZrB2 + 2%Al2O3),A7050/(1.5%MWCNT + 6%ZrB2+3%

Al2O3),AA7050/(2%MWCNT + 8% ZrB2

+ 4% Al2O3)andAA7050/(2.5%MWCNT + 10% ZrB2 +

5% Al2O3) composites as shown in Fig. 4(c),which reveals

the increase of ZrB2, Al2O3 and

MWCNT rein- forced with aluminium

matrix enhance the Vickers hardness value. Al2O3 ceramic

particle was obstacles for the dislocation movement [21-23].

The Al2O3 particles protect the

aluminium alloy 7050 from infiltration and cutting of

slides on the surface of the composites [24, 25].

Impact test

Impact test results reveal the increasing trend in impact

strength till the AA7050/(1.5%MWCNT + 6% ZrB2 + 3%Al2O3)

composite, as shown in Fig. 4(d). Then,

downfall trend is observed in AA7050/(2% MWCNT + 8%ZrB2 + 4%Al2O3),

and AA7050/(2.5% MWCNT + 10%ZrB2 + 5%Al2O3)

composites due to its fragile nature because of more percentage of

reinforce- ments in

the aluminium matrix. The AA7050/(0.5% MWCNT + 2%ZrB2 + 1%Al2O3),

AA7050/(1%MWCNT + 4%ZrB2 + 2%Al2O3)

and AA7050/(1.5%MWCNT/6% ZrB2/3%Al2O3)

composites ensure the proper wettability and superior dispersion of

reinforcements in the aluminium alloy 7050

matrix.

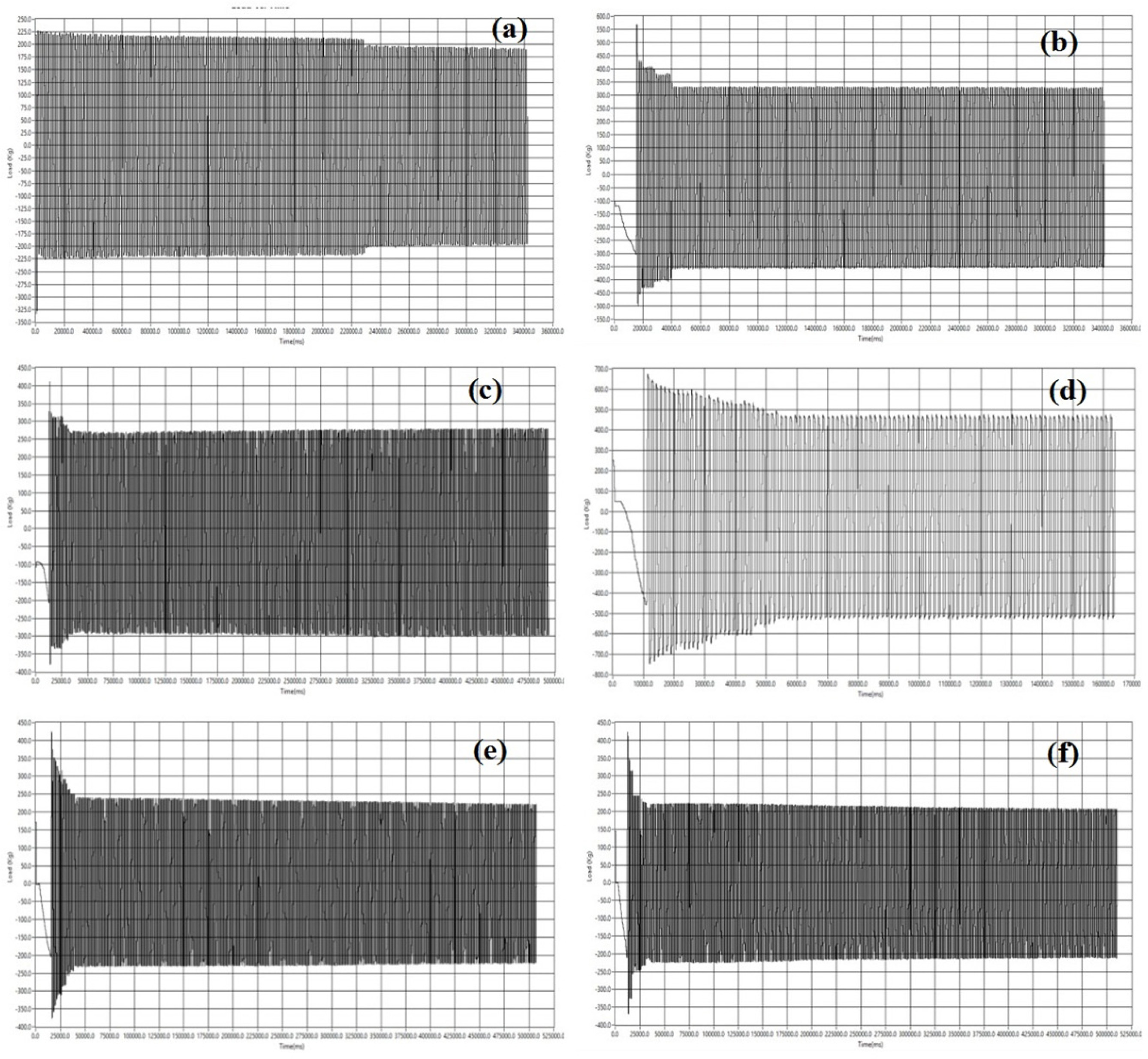

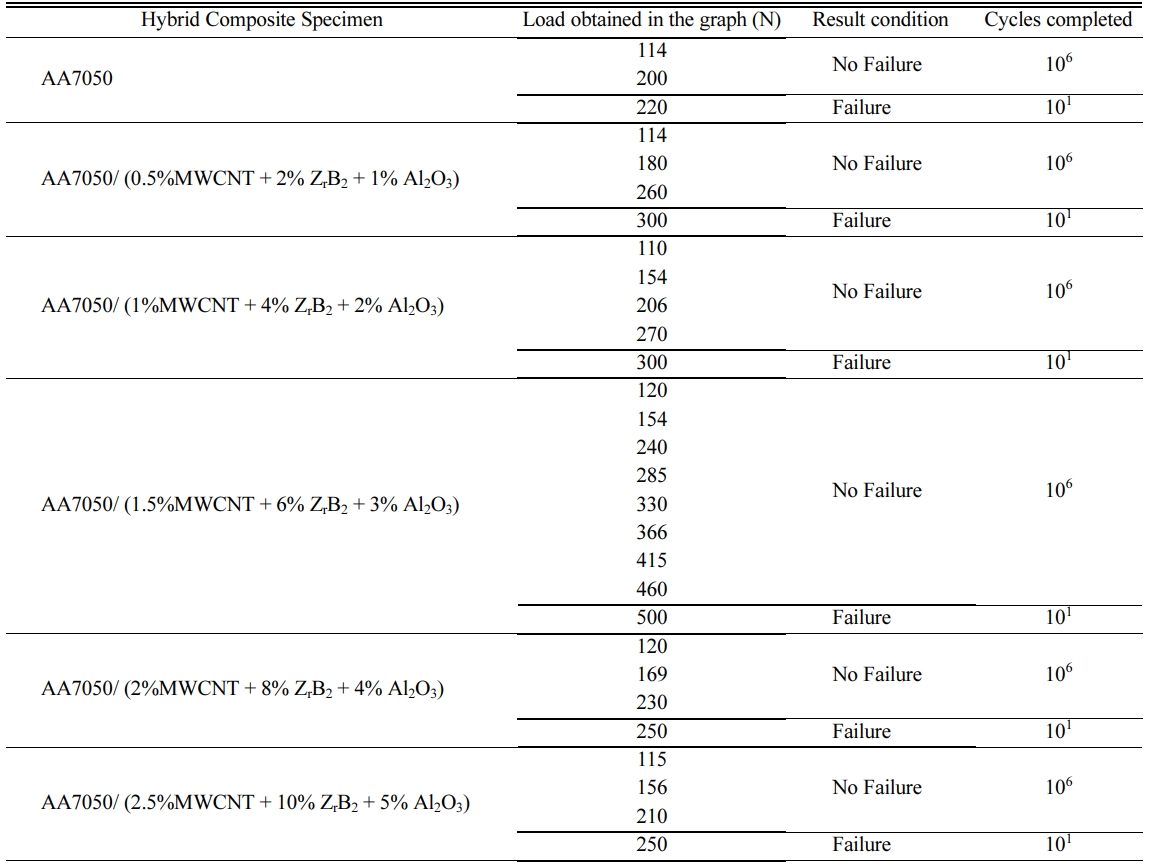

Fatigue test

The fatigue strength was examined on all casted composites

as results shown in Fig. 5(a) to 5(f). The hybrid composite

revealed the fatigue resistance concerning load and time mentioned in Table 3.

Fig. 5(a) shows the casted aluminium alloy AA7050 has an average

fatigue strength. The increasing fatigue strength

identified in Fig. 5(b) to 5(d). The AA7050 specimen has fatigue

strength up to 200N load at 106 cycles then

failures at 101 cycles when the load increased

to 220N. Similarly, the fatigue strength and failure limit for all casted

composites were mentioned in Table 3. The composite AA7050/(1.5%MWCNT + 6%ZrB2 + 3%Al2O3

has enhanced fatigue strength to withstand the cyclic

stresses. These cyclic stresses lead to fatigue cracking, which is below the

static yield strength of the hybrid composite. The Fig. 5(e) and 5(f) show the

fatigue strength was significantly reduced in E and F hybrid composites

due to the existence of higher reinforcement percentage,

which leads to brittle phenomenon [26-30].

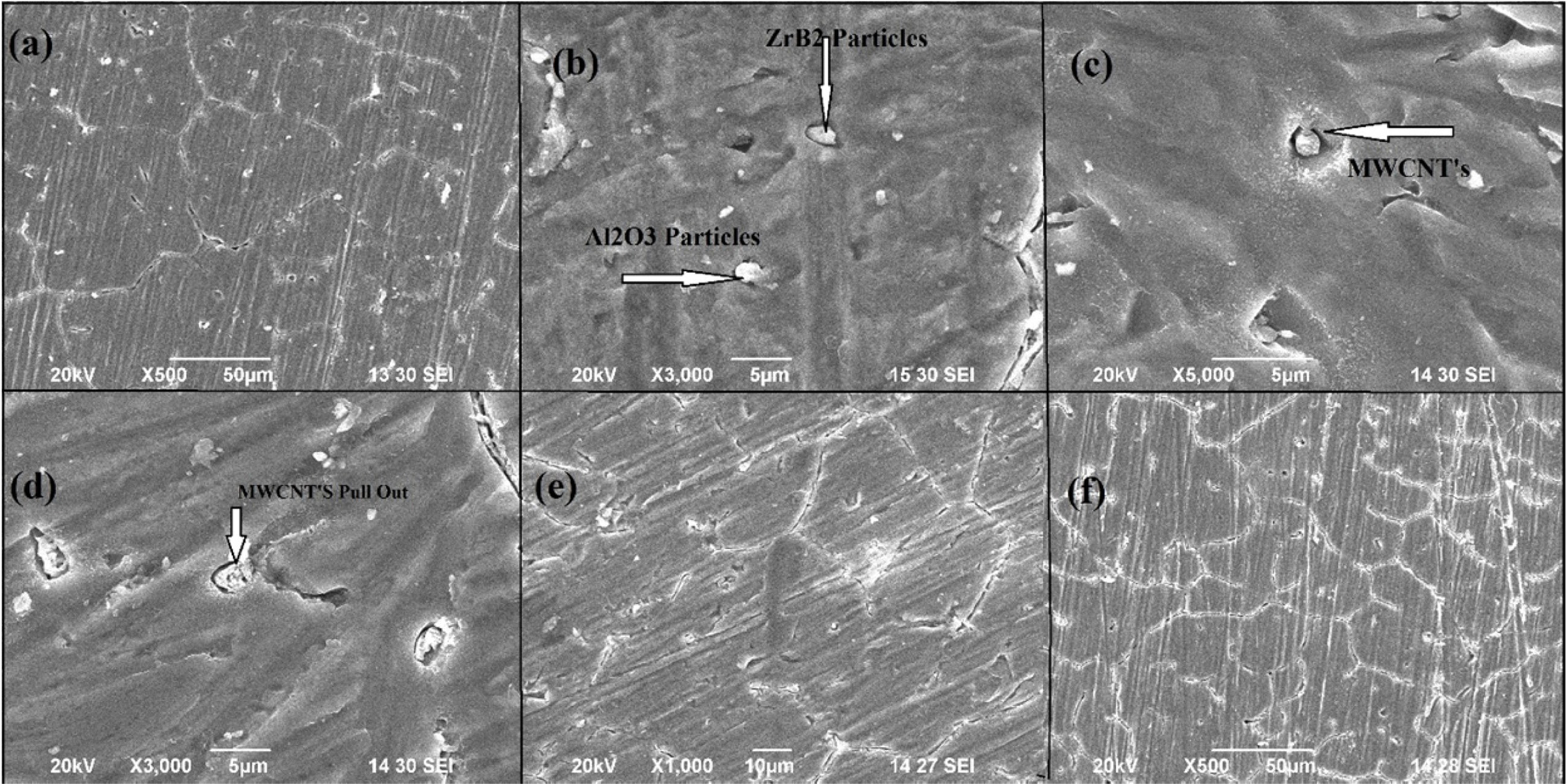

Microstructure

of MWCNT/ ZrB2/ Al2O3 AAHC’S

The SEM images of casted MWCNT/ ZrB2/

Al2O3 AAHC’S is depicted in Fig.

6(a) - 6(f). Fig. 6(a) indicates the SEM

image of the casted Aluminium Alloy 7050. The SEM microstructure image of

hybrid composite AA7050/(0.5%MWCNT + 2% ZrB2 + 1%Al2O3)

is shown in Fig. 6(b), which reveals the porosity and shrinkages presence are

less, which ensures the quality of Vibro compo casting and the similar trend

was absorbed in the AA7050/(1%MWCNT + 4% ZrB2 + 2%Al2O3

hybrid composite shown in Fig. 6(c). The SEM

microstructure image of AA7050/(1.5%MWCNT + 6%ZrB2 + 3%Al2O3)

exposes the dendritic structure of matrix alloy has disappeared due to the

presence of the MWCNT, ZrB2, and Al2O3

reinforcements as shown in Fig. 6(d). The SEM microstructure

images of AA7050/(2%MWCNT + 8%ZrB2 + 4%Al2O3)

and AA7050/(2.5%MWCNT + 10%ZrB2 + 5%Al2O3)

are shown in Fig. 6(e) and Fig. 6(f). This reinforcement particles

influence the grain formation in the semi-solid state of composite material and

enhance the better solidification. More grain refinement has been achieved by

finer grains due to reinforcements. The

intragranular distributions have found on casted samples, which

enhances the mechanical and tribological properties. The

influencing parameters for the distribution of reinforcements are

convection current, buoyant motion and movement of particles [31]. The

solidification front’s velocity has a significant role in deciding intra or

intergranular distribution. It has formed when the velocity of the

solidification front is above the critical velocity, which is

between 10-3 to 10-5 m/s [32]. The temperature gradient

is the influencing factor for the critical velocity and particle size. The SEM

images are showing the clear interface between the aluminium matrix and the

following reinforcements MWCNT, ZrB2, and Al2O3.

Moreover, no reaction products and interfacial reactions

are identified between the reinforcements. Various researchers reported that

the reaction products would surround the particle and weaken the

interfacial strength when a reaction occurs [33-36].

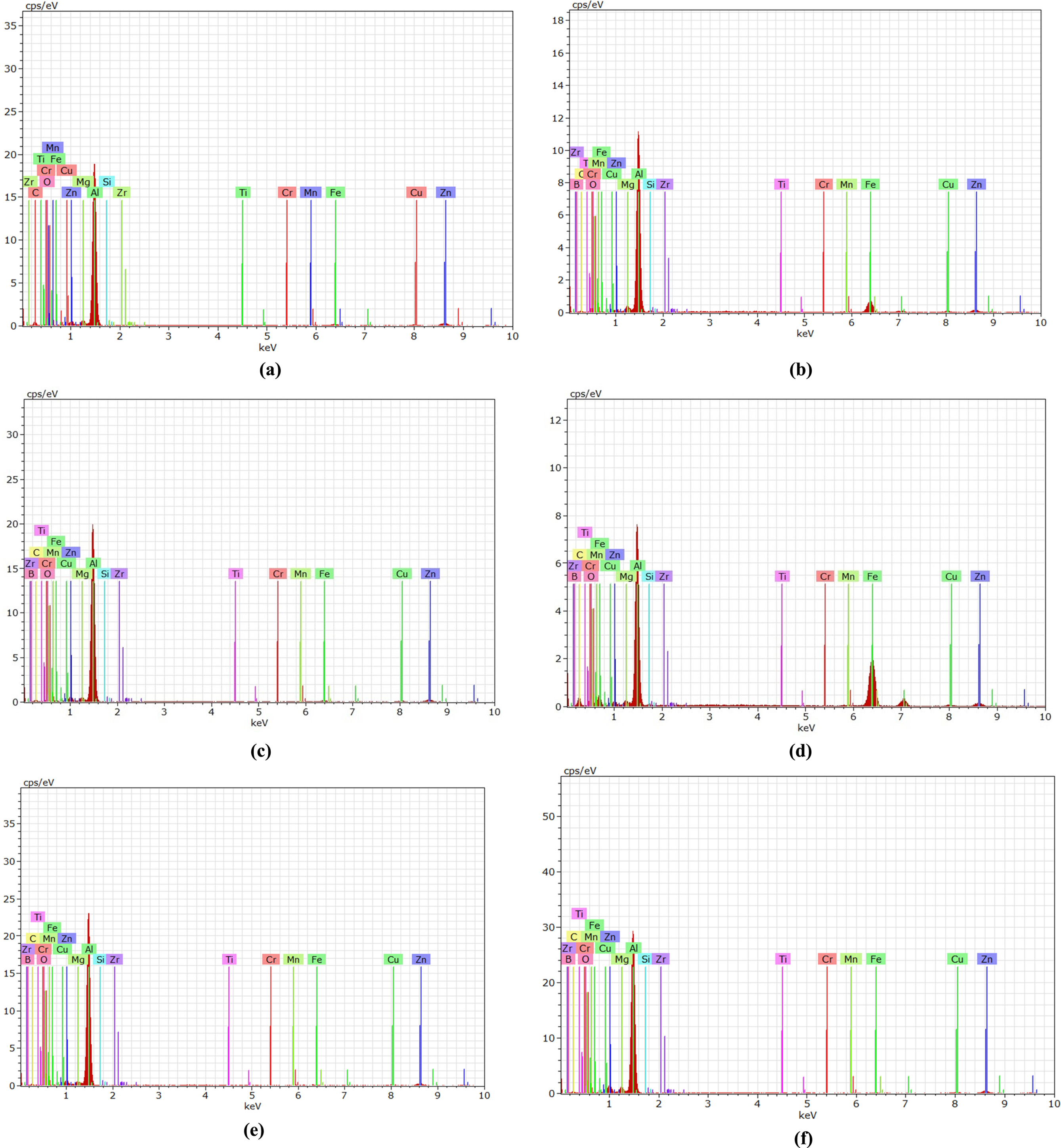

EDAX

Results of MWCNT/ ZrB2/ Al2O3

AAHC’S

Fig. 7(a) shows the Energy Dispersive Spectrum of cast

Aluminium Alloy 7050 and with its elements. The high-intensity

peak elements are representing Aluminium, zinc,

copper and magnesium, and low-intensity peak elements for ferrous,

Silicon, Manganese, Titanium, Chromium and Zirconium are identified.

The Fig. 7(b) shows EDS analysis of hybrid composite

AA7050/(0.5%MWCNT + 2%ZrB2 + 1%Al2O3)

with Carbon, Zirconium diboride and alumina. Similarly, no other elements

present in the AA7050/ (1%MWCNT + 4% ZrB2 + 2%Al2O3)

hybrid composites as Fig. 7(c) and hybrid composite

AA7050/(1.5%MWCNT + 6%ZrB2 + 3%Al2O3)

as Fig. 7(d). The presence of elements of AA7050-MWCNT/ZrB2/Al2O3

is rich in the casted samples

AA7050/(2%MWCNT + 8%ZrB2 + 4%Al2O3)

and AA7050/(2.5%MWCNT + 10%ZrB2 + 5%Al2O3)

as shown in Fig. 7(e) and 7(f). The EDS result reveals that no elemental

presence due to its interfacial reaction between the matrix and

reinforcements.

|

Fig. 4 (a) Load versus displacement curve for the tensile test of Hybrid composites, (b) Ultimate tensile strength of Hybrid composites, (c)

Vickers Hardness Number of Hybrid composites, (d) Impact Strength of Hybrid composites. |

|

Fig. 5 Results of fatigue cycles for time and Load; (a) AA7050, (b) AA7050/(0.5%MWCNT + 2%ZrB2 + 1%Al2O3), (c) AA7050/

(1%MWCNT + 4%ZrB2 + 2%Al2O3), (d) AA7050/(1.5%MWCNT + 6%ZrB2 + 3%Al2O3), (e) AA7050/(2%MWCNT + 8%ZrB2 + 4%Al2O3),

(f) AA7050/(2.5%MWCNT + 10%ZrB2 + 5%Al2O3) |

|

Fig. 6 (a) SEM microstructure images of AA7050, (b) SEM microstructure images of AA7050/(0.5%MWCNT + 2%ZrB2 + 1%Al2O3), (c)

SEM microstructure images of AA7050/(1%MWCNT+4%ZrB2 + 2%Al2O3), (d) SEM microstructure images of AA7050/

(1.5%MWCNT + 6%ZrB2 + 3%Al2O3), (e) SEM microstructure images of AA7050/(2%MWCNT + 8%ZrB2 + 4%Al2O3), (f) SEM

microstructure images of AA7050/(2.5%MWCNT + 10%ZrB2 + 5%Al2O3). |

|

Fig. 7 (a) EDS test analysis of AA7050, (b) EDS test analysis of AA7050/(0.5%MWCNT + 2%ZrB2 + 1%Al2O3), (c) EDS test analysis of

AA7050/(1%MWCNT + 4%ZrB2 + 2%Al2O3), (d) EDS test analysis of AA7050/(1.5%MWCNT + 6%ZrB2 + 3%Al2O3), (e) EDS test

analysis of AA7050/(2%MWCNT + 8%ZrB2 + 4%Al2O3), (f) EDS test analysis of AA7050/(2.5%MWCNT + 10%ZrB2 + 5%Al2O3). |

|

Table 3 Fatigue Load obtained, cycles completed and result in the condition of Hybrid composites |

The Mechanical characteristics and microstructure study of

Vibro-compo cast AA7050 + MWCNT + ZrB2

+ Al2O3 aluminium hybrid composites were studied in

detail. The following achieved conclusions are drawn:

The superior interface bonding and wettability between the

reinforcement and AA 7050 matrix were achieved by novel Vibro compo casting

method. The ultimate tensile strength is enhanced by about 30.73% in Hybrid

composite compared with the base material. The impact strength and

microhardness of AA7050 hybrid composite reveal the increasing trend. The

tension-tension fatigue strength of hybrid composites confirms the

superior fatigue strength against the applied cyclic

loadings. The SEM images show the uniform dispersion between the matrix and

MWCNT, ZrB2 and Al2O3

reinforcements. EDS results reveal all elements of both matrix and

reinforcements are present in casted hybrid composite materials.

Corresponding author (A. ELAYA PERUMAL) gratefully

acknowledges the financial support from the Ministry of

Social Justice & Empowerment and Ministry of Tribal

Affairs, Government of India. This research work was supported by the Ministry

of Social Justice & Empowerment and Ministry of Tribal Affairs, Government

of India, under RGNF Scheme [Award Number:

F117.1/201617/RGNF201517SCTAM 25495]

There is no conflict of interest.

- 1. P. Rambabu, N.E. Prasad, V.V. Kutumbarao, and R.J.H. Wanhill, in “Aerospace Materials and Material Technologies” (Springer Singapore, 2017) p.29-52.

-

- 2. A. Ranganathan, P.V. Akshay Krishnan, A.S. Nambiar, S. Mohan Kumar, and V. Ravi Kumar, Mater. Today Proc. 5[11] (2018) 25368-25375.

-

- 3. K. Lin, W. Wang, R. Jiang, and Y. Xiong, Int. J. Adv. Manuf. Technol. 100[1-4] (2019) 143-151.

-

- 4. J.D. Robson and P.B. Prangnell, Acta Mater. 49[4] (2001) 599-613.

-

- 5. J.J. Zhuang, X.Y. Zhang, B. Sun, R.G. Song, and H. Li, Gongcheng Kexue Xuebao/Chinese J. Eng. 39[10] (2017) 1532-1539.

-

- 6. V. Mohanavel, S. Suresh Kumar, T. Sathish, and K.T. Anand, in: Mater. Today Proc. 5[5] (2018) 13601-13605.

-

- 7. M.T. Sijo and K.R. Jayadevan, Procedia Technol. 24 (2016) 379-385.

-

- 8. K. Ravi Kumar, K. Kiran, and V.S. Sreebalaji, J. Alloys Compd. 723 (2017) 795-801.

-

- 9. A. Chandana, I.D. Lawrence, and S. Jayabal, in: Mater. Today Proc. 5[6] (2018) 14317-14326.

-

- 10. S. Poria, P. Sahoo, and G. Sutradhar, Silicon 8[4] (2016) 591-599.

-

- 11. M. Narimani, B. Lotfi, and Z. Sadeghian, Surf. Coatings Technol. 285 (2016) 1-10.

-

- 12. S.R. Ruban, K.L.D. Wins, M.M. Boopathi, and A.A. Richard, Int. J. Mech. Eng. Technol. 9[2] (2018) 88-94.

- 13. A. Prakash, M. Dharmendira Kumar, A. Baradeswaran, R. Padma Priya, and A. Bagubali, J. Balk. Tribol. Assoc. 24[1] (2018) 1-14.

- 14. N. Panwar and A. Chauhan, in: Mater. Today Proc. 5[2] (2018) 5933-5939.

-

- 15. R. Sharma, S.J. P, K. Kakkar, K. Kamboj, and P. Sharma, Int. Res. J. Eng. Technol. 4[2] (2017) 832-842.

- 16. N. Gangil, A.N. Siddiquee, and S. Maheshwari, J. Alloys Compd. 715 (2017) 91-104.

-

- 17. S.T. Mavhungu, E.T. Akinlabi, M.A. Onitiri, and F.M. Varachia, Procedia Manuf. 7 (2017) 178-182.

-

- 18. C.T. Lynch and J.P. Kershaw, in “Metal Matrix Composites” (CRC, 2018) p.1-170.

- 19. Yashpal, Sumankant, C.S. Jawalkar, A.S. Verma, and N.M. Suri, in: Mater. Today Proc. 4[2] (2017) 2927-2936.

-

- 20. B. Abbasipour, B. Niroumand, and S.M. Monir Vaghefi, Trans. Nonferrous Met. Soc. 20[9] (2010) 1561-1566.

-

- 21. K. Shirvanimoghaddam, S.U. Hamim, M. Karbalaei Akbari, S.M. Fakhrhoseini, H. Khayyam, A.H. Pakseresht, E. Ghasali, M. Zabet, K.S. Munir, S. Jia, J.P. Davim, and M. Naebe, Compos. Part A Appl. Sci. Manuf. 92 (2017) 70-96.

-

- 22. Ş. Karabulut, U. Gökmen, H. Çinici, Compos. Part B Eng. 93 (2016) 43-55.

-

- 23. S. Sahraeinejad, H. Izadi, M. Haghshenas, A.P. Gerlich, Mater. Sci. Eng. A 626 (2015) 505-513.

-

- 24. V. Mohanavel, K. Rajan, P. V. Senthil, and S. Arul, in: Mater. Today Proc. 4[2] (2017), 3093-3101.

-

- 25. B.C. Kandpal, J. Kumar, and H. Singh, in: Mater. Today Proc. 4[2] (2017) 2783-2792.

-

- 26. R. Narayanan, C. Saravanan, V. Krishnan, and K. Subramanian, Mech. Mech. Eng. 19[1] (2015) 23-30.

- 27. D. Patidar and R.S. Rana, in: Mater. Today Proc. 4[2] (2017) 2981-2988.

-

- 28. M. Shukla, S.K. Dhakad, P. Agarwal, and M.K. Pradhan, in: Mater. Today Proc. 5[2] (2018) 5830-5836.

-

- 29. G. Moona, R.S. Walia, V. Rastogi, and R. Sharma, Indian J. Pure Appl. Phys. 56[1] (2018) 164-175.

- 30. V.C. Kale, IOSR J. Mech. Civ. Eng. 12[6] (2015) 31-36.

- 31. R. Bauri, D. Yadav, and G. Suhas, Mater. Sci. Eng. A 528[13-14] (2011) 4732-4739.

-

- 32. G. Wilde, M. Byrnes, J.H. Perepezko, J. Non. Cryst. Solids 250-252 (1999) 626-631.

-

- 33. P.S. Bains, S.S. Sidhu, and H.S. Payal, Mater. Manuf. Process. 31[5] (2016) 553-573.

-

- 34. A. V. Muley, S. Aravindan, and I.P. Singh, Manuf. Rev. 2[15] (2015) 1-13.

-

- 35. M.O. Bodunrin, K.K. Alaneme, and L.H. Chown, J. Mater. Res. Technol. 4[4] (2015) 434-445.

-

- 36. M. Kannaiyan, J.G. Raghuvaran, K. Govindan, and E.P. Annamalai, J. Ceram. Process. Res. 21[1] (2020) 26-34.

-

This Article

This Article

-

2020; 21(5): 524-532

Published on Oct 31, 2020

- 10.36410/jcpr.2020.21.5.524

- Received on Mar 4, 2020

- Revised on Mar 27, 2020

- Accepted on Apr 2, 2020

Services

Services

- Abstract

introduction

materials and methods

results and discussion

conclusion

- Acknowledgements

- Conflict of Interest

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Elaya Perumal A

-

University College of Engineering, Nagercoil, Kanyakumari, Tamilnadu, 629004, India

Tel : +91-8903966003 - E-mail: skyforplay@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.