- Nitrilotriacetic acid functionalization on Fe3O4 nanoparticle via amino and carboxylic functionalization

Jin Soon Hana,**, MiRae Youma,**, Hyun-Hee Choib, Yeon-Gil Jungb, Sung-Churl Choia and Gye Seok Ana,*

aHanyang university 04763 Division of Materials Science and Engineering, Hanyang University, 222 Wangsimni-ro, Seongdong-gu, Republic of Korea

bSchool of Materials Science and Engineering, Changwon National University, 20 Changwondaehak-ro, Changwon, Gyeongnam 51140, Republic of Korea

Since chelating chemical had

focused for enhancing bio-susceptibility and ability for the binding with

biomaterials, in this study, Nitrilotiriacetic acid (NTA) was utilized for the

developing chelate ligand attached superparamagnetic nanoparticle. In order to

conjugate NTA, carboxylic group was needed on the surface of substrate particle

for building peptide bond with amine group which was branched from the NTA

structure. Therefore Fe3O4 nanoparticle was

functionalized with various of amine precursor (Polyethyleneimine (PEI),

(3-Aminopropyl)triethoxysilane (APTES)), and carboxyl precursor (Polyacrylic

acid (PAA)) before the conjugation of NTA. Then NTA conjugation behavior was

estimated which is varied with the type of amine precursor which affects to the

surface properties.

Keywords: Magnetic nanoparticle, Chelate ligand, Nitilotriacetic acid, Functionalization

Chelate-based sensors play an important role in environmental

and biological fields as metal and chemical detectors, humidity sensors, and

biosensors, among others [1-5]. Metal ions act as stimulators by attaching

solely to the chelate ligand on the surface of the sensing particle; however,

the sensing particles can be stimulated by the secondly attached

chemical on the particular pair of chelate and metal ion. These

mechanisms were usually determined by the types of chelates, which were

represented by nitrilotriacetic acid (NTA), ethylenediamine

diacetate (EDDA), and ethylene-

diaminetetraacetic acid (EDTA) with different functional

groups and affinities for other materials [6]. Owing to these mechanisms,

chelates have been applied for sensing metal ions, chemical

reagents, and biomaterials. Especially in the case of

biosensors, they have been utilized for sensing protein or DNA, which is

directly connected to protein and genetic engineering [5, 9, 10].

To reinforcing sensing and recollecting, the

introduction of

magnetic properties was assumed as an effective way

for mass controlling particles by inducing a magnetic field. Fe3O4,

in particular, has paramagnetic properties that ensure reversible mobility in a

sensor particle. Therefore, nanoparticles having higher efficiency than the first

attached substrate have been utilized [10-14]. The surface plasmon resonance

(SPR) bio-sensor chip was based on the high refractive index of Fe3O4,

which was directly connected to the efficiency [15, 16]. In the case

of NTA, as an enzyme-free biosensor, the efficiency of the

sensor and controllability of nanoparticles have been the areas of focus [14,

17].

However,

nanoparticles were reported to have unexpected

toxicity that could cause DNA damage. There are many factors that determine the

toxicity of nanoparticles, including its concentration, particle size,

existence of coating layer, and total surface area [18].

To

further functionalize Fe3O4, various types of materials

were applied on its surface, such as noble metals,

carbon materials, and other chemical reagents [10-13]. For example, Fe3O4-Au

composite particle coated with horseradish peroxidase was utilized with

graphene sheets–Nafion film for detecting hydrogen peroxide based on its high surface activity [11].

Carbon-coated Fe3O4

with TiO2 layer was used as a photoelectrochemical biosensor for uric acid

[12]. In the case of NTA, NTA had

been built on intermediate polyacrylamide via the polymerization

process for separating his-tagged protein. Since γ-methacryloxypropyl

trimethoxysilane was polymerized to prepare the substrate layer of

NTA, the magnetic property of NTA attached Fe3O4

nanoparticle was reinforced;

however, this requires certain conditions, including prolonged reflux and noble

gas injection for protection [14].

In order to utilize this NTA conjugating method into mass

production, building these conditions with large scale were not preferred. And

the magnetic properties about Fe3O4 nanoparticle had been

decreased after the NTA conjugation with reflux condition. With these aspect,

utilizing the NTA attached Fe3O4 nanoparticle into

genetic or protein technology had been carried out only in a small scale, and

another method had to be established in order to get over this situation.

In this study, we methodologically reviewed the effects of

intermediate functionalization on the NTA attachment process on the surface of

Fe3O4 and the properties of NTA-attached Fe3O4

nanoparticles. In the first method, (3-aminopropyl)triethoxysilane (APTES) and

polyethylenimine (PEI) were utilized to attach the amine group on the Fe3O4

nanoparticle. Then, NTA was conjugated with the cross-linker before the amino-functionalized

Fe3O4 nanoparticle and NTA. The second

method involved direct conjugation via carboxylic functionalization with

polyacrylic acid (PAA), which did not require a cross-linker between the

particle and NTA. By comparing these samples, a more adequate method

for fabricating NTA attached Fe3O4 nanoparticle

was established.

Materials

The Fe3O4 nanoparticles were

prepared as starting materials following a previously reported polyol-based

method. [19, 20] APTES (Sigma Aldrich, USA) and PEI (Mw:

~ 25,000, branched, Sigma Aldrich, USA) were used for amino

functionalization, and PAA (Mw ~ 450,000,

Sigma Aldrich, USA) was used for carboxylic

functionalization. Then, Nα,Nα-Bis(carboxymethyl)-L-lysine hydrate (ABNTA, C10H18N2O6 · xH2O,

Sigma Aldrich, USA) was prepared as a chelate chemical. Glutaraldehyde solution

(GLH; 25%, Sigma Aldrich, USA) was also prepared for the cross-linker.

Amino

functionalization using APTES with the core-shell Fe3O4@SiO2

nanoparticle

Fe3O4 nanoparticles (2 g) were

prepared with a mixed solvent containing 450 mL ethyl alcohol and 50 mL

distilled water after the previously reported in-situ SiO2

coating process [19, 20, 27]. The dispersed solution

was set for stabilization and adjusted to basic pH. Then, 4 wt% of APTES was

injected dropwise as an ethyl alcohol-based solution for the amine attached

silicate precursor. After 8 h of vigorous stirring, the amino-functionalized

nanoparticle was collected by the magnetic field and washed with ethyl alcohol

and distilled water for several times.

Amino

functionalization using PEI with Fe3O4 nanoparticle

The prepared Fe3O4 nanoparticles (2

g) were dissolved in 100 mL of distilled water and 4 wt% of PEI

solution. Next, this solution was mixed for 30 min at room temperature before

heating to 80 oC. It was then reacted for 10 h with vigorous

stirring and cooled down until it reached the room temperature. The reacted

particle nanoparticle was collected by inducing magnetic field and stored as a

solution with distilled water after washing it several times with distilled

water.

Formation

of NTA chelating ligand on the surface of amino-functionalized Fe3O4

A total of 0.1 g of both distinctly amino-functionalized

Fe3O4 nanoparticles with APTES and PEI were prepared as a

solution with 100 mL of distilled water and mechanically stirred before the

reaction. Then, the glutaraldehyde solution was injected and mechanically

stirred for 8 h [21]. The particles were collected via the induced magnetic

field and washed with distilled water for removing the unreacted reagent and

modifying their acidity to the neutral state. Then, they were

re-dispersed at 100 mL of distilled water and mixed with the ABNTA

solution. Reaction occurred under the vigorous stirring

condition at room temperature for 24 h. Finally, the chelating ligand-attached

Fe3O4 nanoparticles were collected via magnets. It was

then washed and stored with distilled water.

Chelate

functionalization of Fe3O4 nanoparticle via carboxylic

functionalization with PAA

A dispersed solution (300 mL) containing 10 g Fe3O4

nanoparticles was prepared after washing several times with distilled water.

Then, PAA was prepared as a 100 mL solution with 4 wt% of

concentration. These solutions were mixed in a round bottom flask

and heated to 75 oC for 4 h. The mixed solution was mechanically

stirred at 300 rpm until the solution cooled down to room temperature. Next,

0.25 g of PAA-attached Fe3O4 was re-dispersed in 100 mL

distilled water and mixed with 100 mL ABNTA to obtain a concentration of 0.1 wt%.

These solutions were reacted for 8 h via mechanical stirring.

Then, the reacted Fe3O4 nanoparticle was washed

and stored in distilled water.

Characterization

The surface functional group of as-synthesized Fe3O4,

amino-functionalized Fe3O4, and NTA-attached Fe3O4

was analyzed via Fourier-transform infrared spectroscopy (FTIR, IRAffinity-1S,

Shimadzu, Japan) at 500 ~ 4,000 cm-1.

The FTIR spectra was used to judge the success of functionalization of Fe3O4

with the existing peaks of amine or carboxyl group of APTES, PEI, and NTA

and the differences in micro structure between different amine reagents.

Microscopic analysis was also conducted using a transmittance electron

microscope (HRTEM, Tecnai G2 F30 S-Twin, FEI, Netherlands) for the visual

identification of the coating layer on Fe3O4 particles.

Then, using the Zeta potential (Zetasizer, Malvern, USA), the changes on the

surface charges of Fe3O4 particles were observed after

amino functionalization and NTA attaching. Finally, the magnetic

properties of the as-synthesized and NTA-attached Fe3O4

particles were identified using a vibrating sample

magnetometer (VSM, Lake shore 7400, USA).

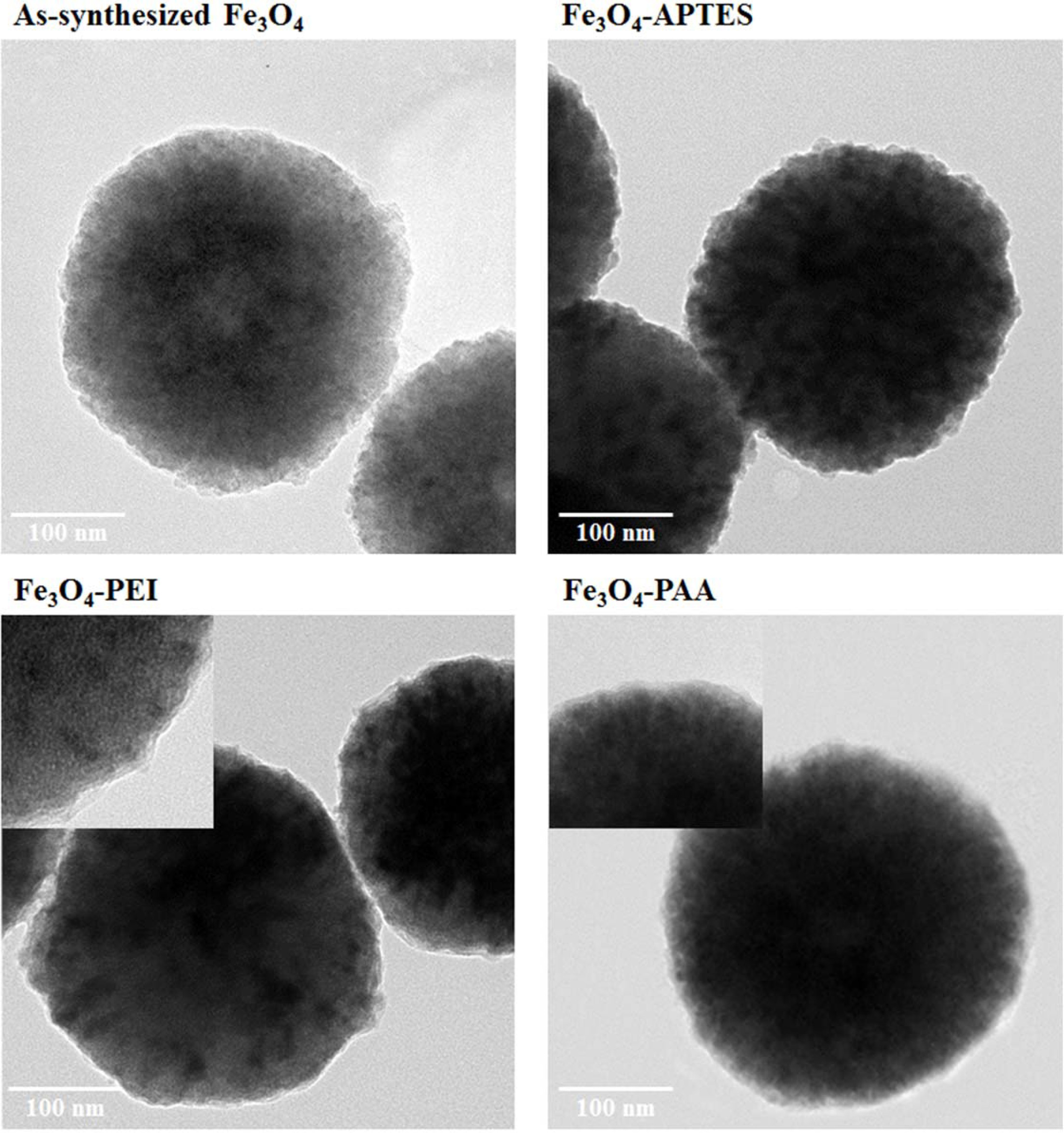

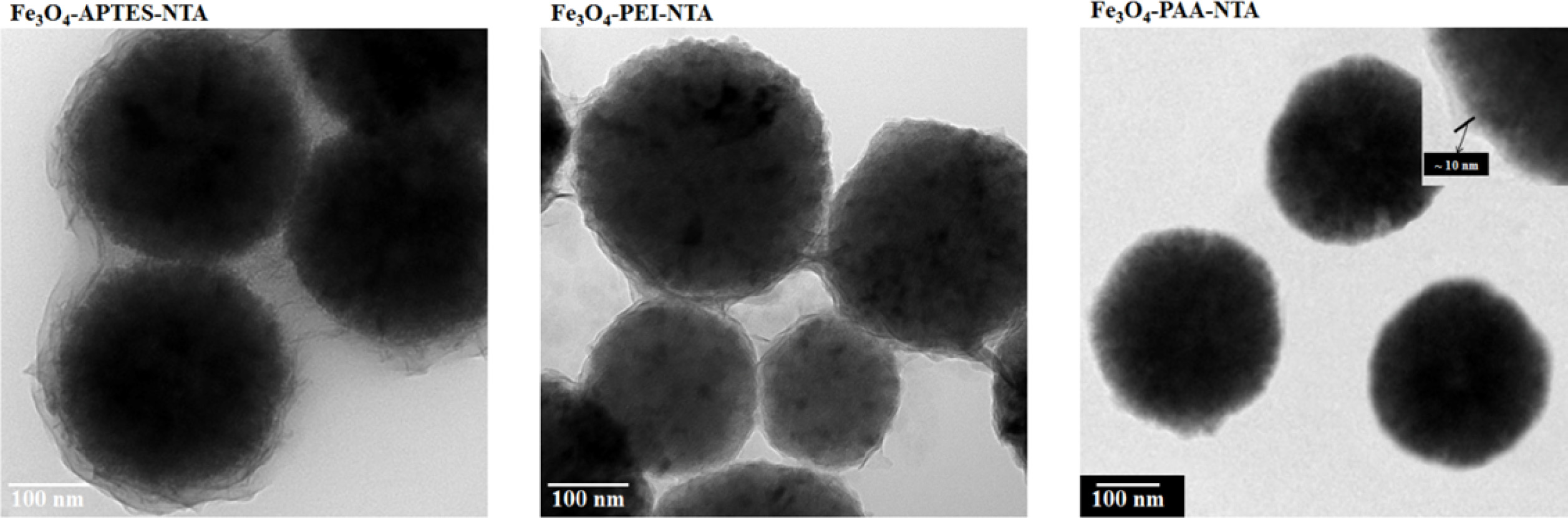

Morphological

changes of Fe3O4 and intermediate functionalized Fe3O4

A transmittance electron microscopy (TEM) analysis was

performed to examine the surface and micro-

structure of the as-synthesized Fe3O4

nanoparticles, amino-functionalized Fe3O4 with APTES and

PEI, and carboxyl-functionalized Fe3O4 with PAA (Fig. 1).

The as-synthesized Fe3O4 nanoparticles

were observed about 300 nm in size. In the case of APTES-modified

particles, the observed particle size and the morphology were almost identical

to those of the as-synthesized particle. However, the Fe3O4

particles functionalized with PEI were found to be semi-spherical in shape,

with a size of approximately 300 nm. A coated layer with a thickness of

3 ~ 4 nm was formed on the surface of the PEI-treated Fe3O4

particles. In contrast, to be functionalized into carboxylic acid, the

PAA-treated Fe3O4 nanoparticles had a smooth and opaque

layer on their surface, with a thickness of 5–6 nm. The core size of

PAA-treated Fe3O4 was approximately 320 nm, which

was slightly greater than the as-synthesized Fe3O4, and it

had an almost perfectly spherical shape, in comparison with the

PEI-treated Fe3O4 particles.

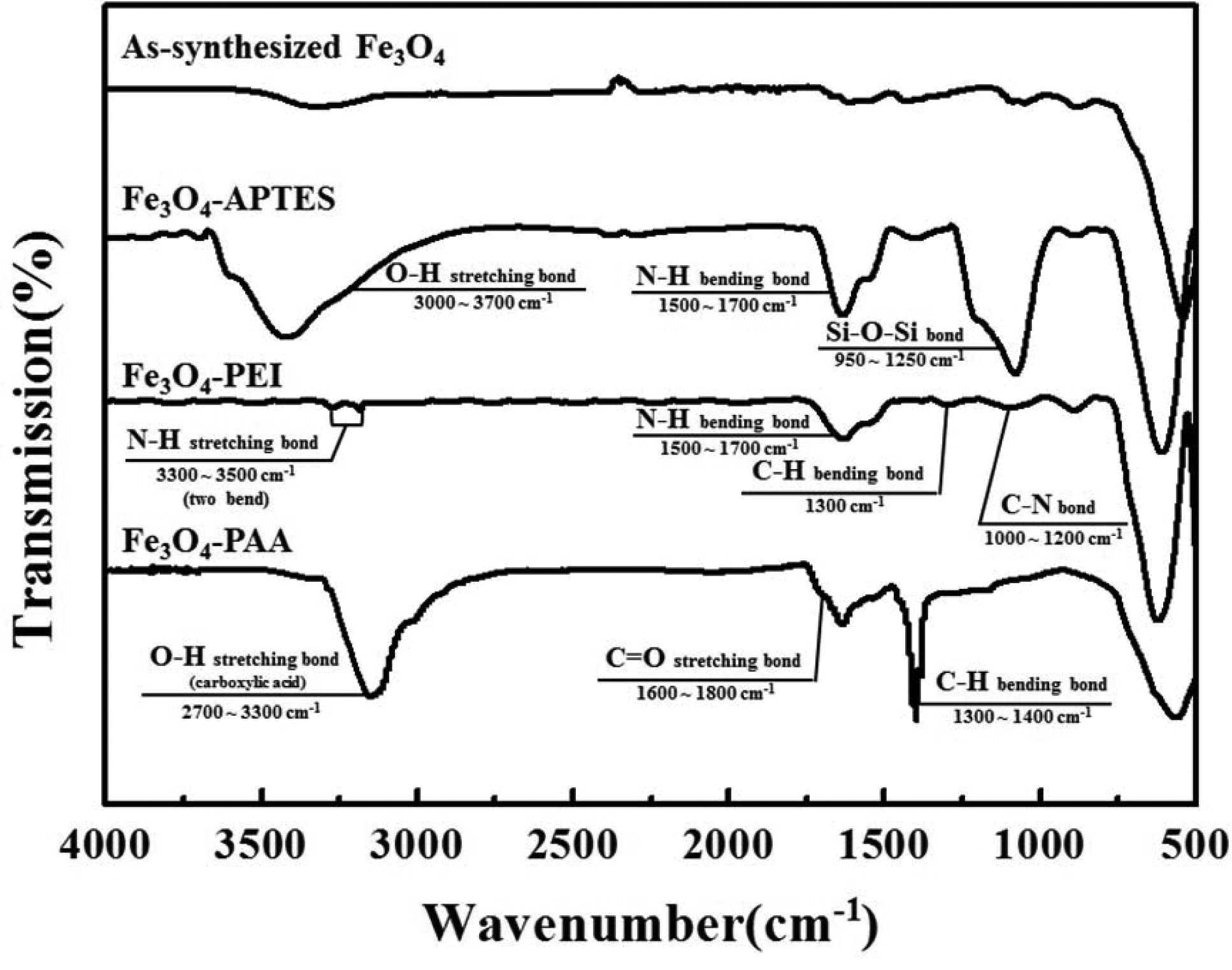

Functional

group on the Fe3O4 and intermediate functionalized Fe3O4

The FT-IR spectra of as-synthesized Fe3O4,

amino-functionalized Fe3O4 with APTES and PEI, and

carboxyl-functionalized Fe3O4 with PAA are illustrated in

Fig. 2. The Fe–O peak was observed at around 600 cm-1

for each particle [22]. After surface modification, a distinctive amine peak

was observed at 1,500 ~ 1,700 cm-1

owing to the bending of the N–H bending bond. Because the condensation of SiO2

was accompanied by the functionalization of APTES, an O–H stretching peak and

Si–O–Si peak were observed at around 3,000 and 950 ~ 1,250 cm-1, respectively. In the

case of another amino functionalization with

PEI, the polymeric carbon chains were

stuck on the surface of the particle; thus, the C–H bending peaks were observed

at 1,300 cm-1.

Additionally, in the spectrum of PEI used particle, C–N bending

and N–H stretching bonds were observed at 1,000 ~ 1,200 and

3,300 ~ 3,500 cm-1,

respectively, and these ranges were where the intensive peaks from O–H

stretching bond and Si–O–Si bond were found in the spectrum of the APTES used

particle [22, 23, 25]. Although some differences were observed, it was

confirmed that both surface-treated particles were successfully functionalized

with the amine group. In contrast, in the case of PAA treatment, the C–H

bending bond derived from the polymeric carbon chain was observed at

1,300 ~ 1,400 cm-1,

which was similar to the PEI-treated particles. Significant carboxylic bonds

were also found at 1,600 ~ 1,800 and 3,000 cm-1 for

the C=O and O–H stretching bonds, respectively. The O–H stretching bonds were

observed at 2,700 ~ 3,300 cm-1,

which was slightly lower than the range for the APTES-treated particles

(3,000 ~ 3,700 cm-1)

[25]. Considering the difference in the O–H stretching bond, we

determined that the carboxyl group was successfully attached on

the surface of Fe3O4 and that most of the O–H bonds

originated from the carboxylic acid instead of the hydroxyl group.

Discussion

about intermediate functionalization process of Fe3O4

As mentioned above, differences were observed in the

amino-functionalized particles with APTES and PEI, from the aforementioned

analysis. The functionalization mechanism with APTES is based on

hydrolysis and condensation, similar to the Stöber method [23].

During APTES treatment, the existing SiO2 layer was

etched with an ammonia solution, and the unreacted hydroxyl groups were exposed

via a hydrolysis reaction. These hydroxyl groups were used for the condensation

site with APTES, and this functional group was observed in the FT-IR spectrum

of Fe3O4 with APTES, at 3,000 ~ 3,700 cm-1.

However, as evident in the functionalized Fe3O4 with PEI

and PAA, the functionalization process did not include an intermediate layer;

thus, these precursors were directly attached to the surface of the Fe3O4

nanoparticles. However, owing to the molecular structure of APTES, Si–O–Si bond

could not be formed continuously; thus, the coated layer was not observed on

the surface of APTES-treated particles. In the case of PEI- and PAA-treated

particles, directly bound carbon chains created an opaque layer on the surface

of the Fe3O4 nanoparticle.

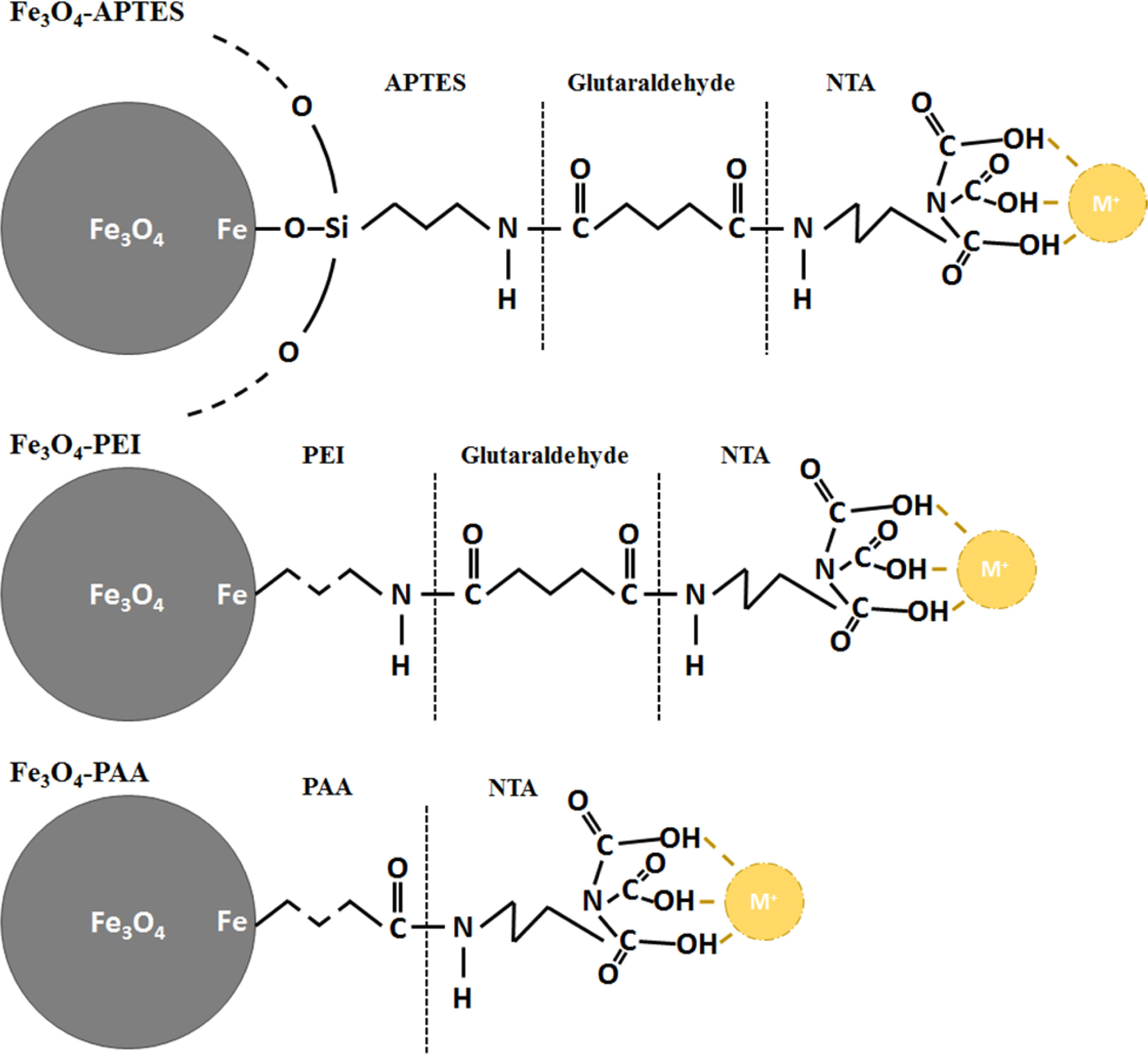

Scheme

about NTA conjugation and intermediate functionalization process of Fe3O4

Fig. 3 shows the chemical structures of Fe3O4

functionalized using various methods, along with a brief scheme of the

NTA-attaching mechanism on the surface of Fe3O4

nanoparticles. Because a condensation reaction involving electrostatic

attraction was used in the NTA-attaching mechanism, in the case of amine, the

Fe3O4 particles were attached with glutaraldehyde before

the conjugation with NTA. As evident from the FT-IR spectra, the intermediate

SiO2 layer or carbon chain exhibited the most significant difference

between APTES- and PEI-treated Fe3O4. This difference

could derive different conjugation properties with glutaral- dehyde owing

to the different concentrations of activation sites,

electrostatic force, and chemical affinity with glutaraldehyde. Then,

glutaraldehyde formed another peptide bond with the amine group of NTA, which

could attach with several metal ions, such as Ni and W. However, PAA-treated Fe3O4

particles contained carboxylic acid, which could form peptide bonds with the

amine group. Therefore, PAA-treated Fe3O4 could be conjugated

with NTA directly, and glutaraldehyde was not required as a cross-linker. The

absence of a cross-linker and the reversal in the pH value and surface charge were different

for the APTES- and PEI-treated particles, and these could be affected after the

NTA conjugation.

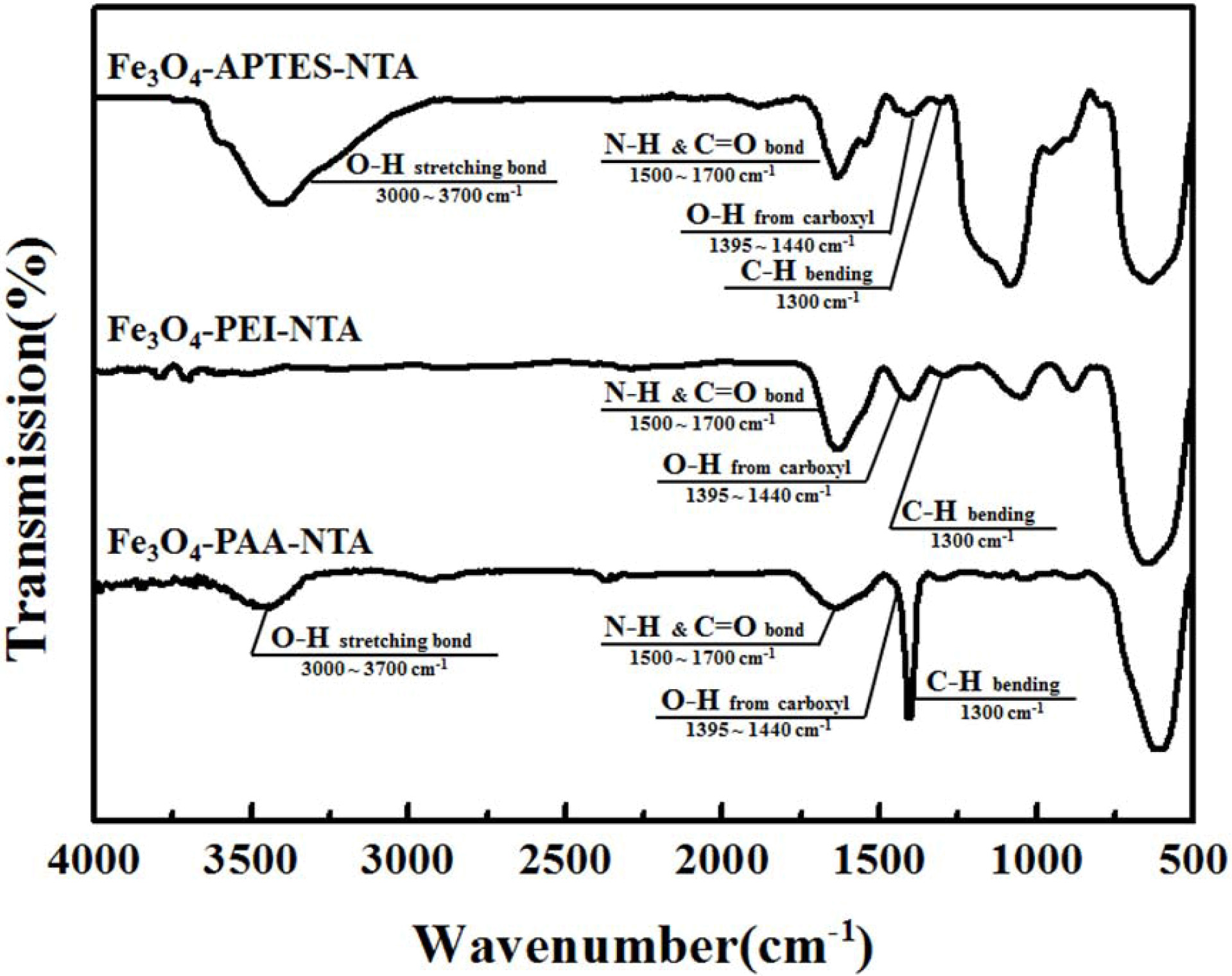

Morphological

changes of NTA conjugated Fe3O4

The FT-IR spectra of NTA-attached Fe3O4

particles obtained via various types of intermediate

functionalization are shown in Fig. 4. An emphasized peak was

observed in the spectrum of the NTA-attached particles, in contrast

to the APTES-attached particles. Distinctive peaks, which were observed in the

FT-IR spectrum of Fe3O4 with APTES shown in Fig. 2, were

also observed at 600 cm-1 (Fe–O)

and 1,300 cm-1 (C–H).

A C=O peak, the representative bonding of a carboxyl group, co-existed with the

N–H peak at 1,500 ~ 1,700 cm-1

[23, 24]. These distinctive peaks of NTA were also observed

in the FT-IR spectra of the NTA-attached particles on the PEI. These peaks were

in contrast to the spectrum of PEI-attached Fe3O4

nanoparticles. Normally, most of differences on FTIR spectra of each NTA

attached particle could be found almost same with that of amino-functionalized

specimen [14, 22, 23]. In contrast, NTA-attached

Fe3O4 nanoparticles obtained via carboxylic

functionalization with PAA had distinctive NTA peaks at 1,300 cm-1

(C–H), 1,395 ~ 1,440 cm-1 (O–H),

and 1,500 ~ 1,700 cm-1

(N–H and C=O co-exist), similar to other APTES- and PEI-treated particles;

however, their intensities were lower than those of other samples [22].

Additionally, the O–H stretching bond was shifted to 3,000 ~ 3,700

cm-1,

which was 2,700 ~ 3,300 cm-1

from the PAA-treated particles.

Considering these differences between the amino- or

carboxylic-functionalized and NTA-conjugated particles, it could be suggested

that NTA was successfully attached to the surface of the Fe3O4

particles.

Functional group on the NTA conjugated Fe3O4

In the TEM image of NTA attached on the APTES used Fe3O4

particle from Fig. 5, core-shell structure was observed spherical shaped Fe3O4

core and fluffy shell. The size of the core material was approximately 300

nm, and the surface of the coated layer was observed to be wavy.

However, the particles were covered with a coated layer under the agglomerated

state, instead of being individually coated. The thickness of the coated layer

was measured to be 15 ~ 30 nm, which was greater than that of

APTES-treated particle. In contrast, in the image of the PEI-treated Fe3O4

particles, round particles with a size of 300 nm were observed along with other

small particles (150 ~ 250 nm in size). These particles were

agglomerated and linked with a thin coated layer (8 ~ 15 nm). In the

case of the PAA-treated particles, the sizes of the core Fe3O4

particles were observed to be around 300 nm, similar to APTES- and

PEI-treated particles; however, unlike other samples, these

PAA-treated particles remained separated. The coated layer

covered the Fe3O4 nanoparticles individually

and observed around 10 nm.

Differences

about NTA conjugated Fe3O4 with various kind of

intermediate functionalization

Thus, the NTA was successfully attached to the surface of

the Fe3O4 nanoparticles, with the appearance of O–H and

C–H peaks in the FT-IR spectrum of NTA-attached particles

obtained via APTES or PEI treatment; hence, it was difficult to

identify the C=O bonds owing to the existence of N–H peaks.

However, these distinctive peaks were also observed in the

FT-IR spectrum of the NTA-attached particles with PAA. Because NTA was

conjugated with the same peptide bonding, it could be assumed that the pH

values of APTES-, PEI-, and PAA-treated particles or the existence of a

cross-linker affected the formation of the peptide bond. Hence, owing to these

differences in the FT-IR spectra, the thickness of the coated layer of each

NTA-attached particle increased; thus, NTA was observed to be successfully

conjugated on the surface of PAA-treated Fe3O4. However,

their coated status varied for different intermediate

functional groups. In the case of the amino-functionalized

particles with APTES or PEI, agglomeration occurred.

However, for carboxylic functionalization with PAA,

the particles remained separated. Additionally, because

difference of pH values and used cross linker could be the cause of this

result.

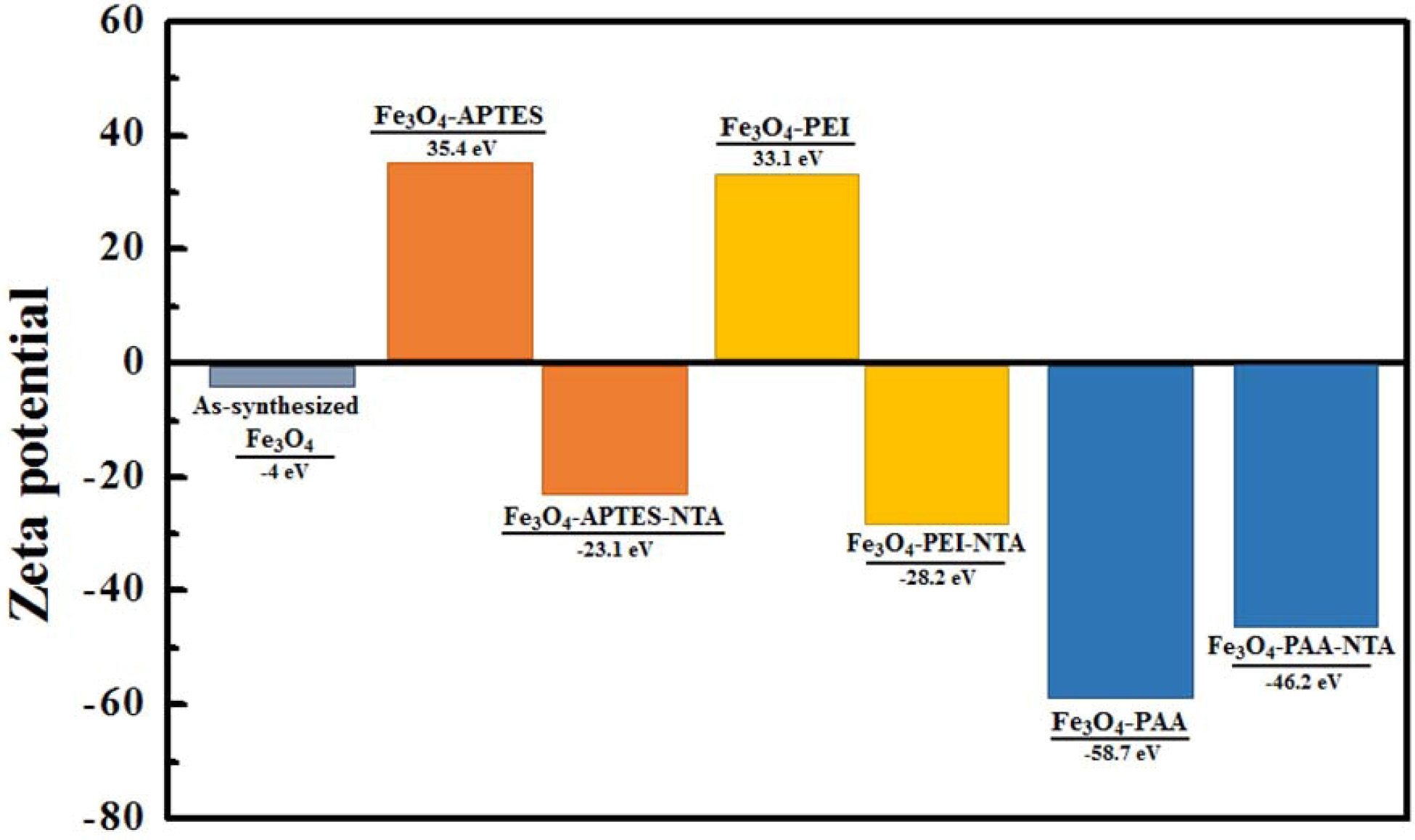

Surface

charges of NTA conjugated Fe3O4 with various kind of

intermediate functionalization

In order to analyze repulsion force on the particle

surface charge of each functionalization stage of Fe3O4

samples were exhibited at Fig. 6. As-synthesized Fe3O4

had a slight negative charge that could not produce a repulsive

force sufficient for stable dispersion. However, after

the APTES treatment, the surface charge increased to 35.4 eV

owing to the positive amine group [26]. However, the NTA-conjugation positive

charge was changed into a negative charge of -23.1 eV. A similar observation

was made for the PEI-treated particles, the surface charge of which changed

from 33.1 eV to -28.2 eV. However, after PAA treatment, a strong negative charge

(-58.7 eV) was formed on the surface of the particle, which changed into -46.2

eV upon NTA attachment.

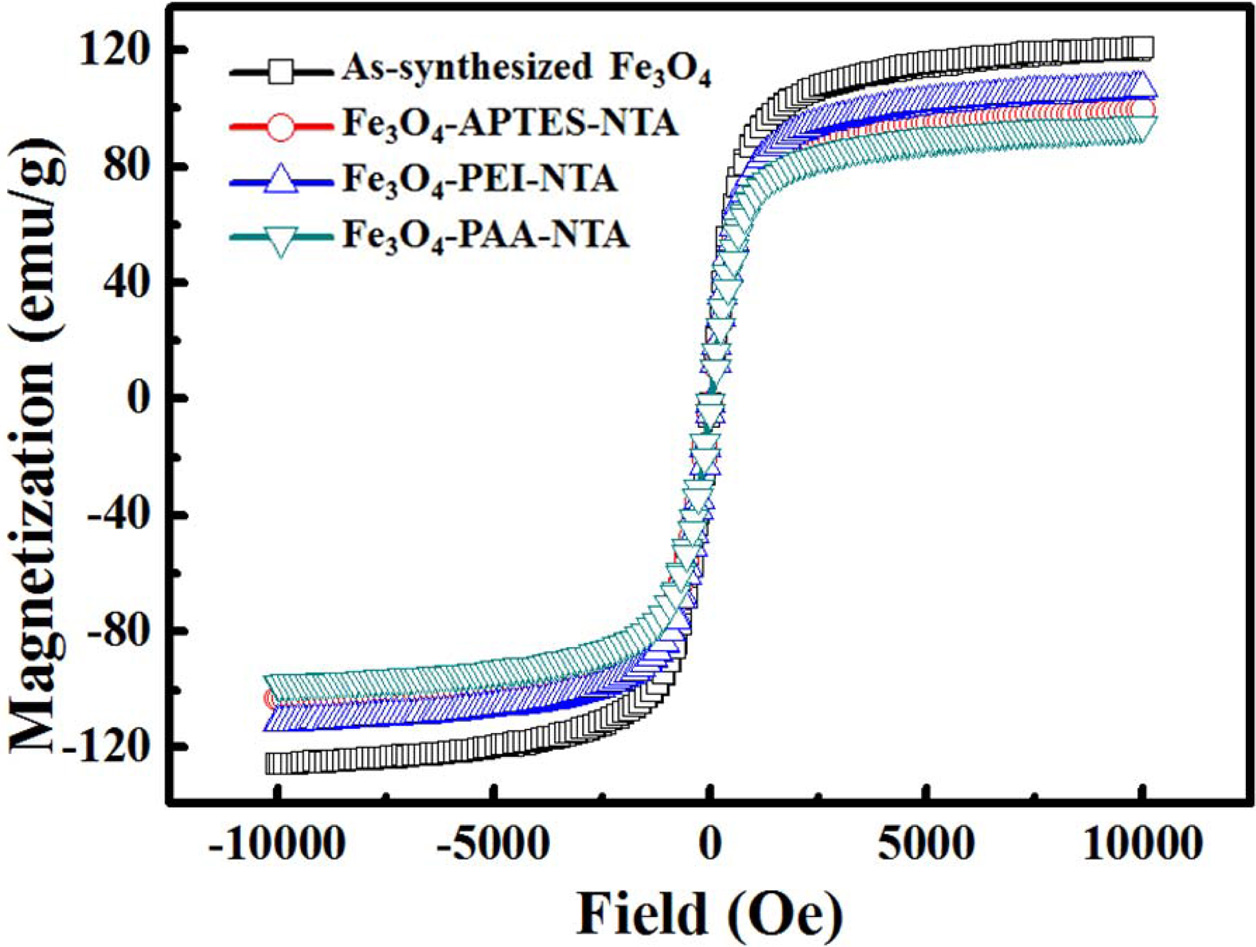

Magnetic

properties of NTA conjugated Fe3O4 with various kind of

intermediate functionalization

The hysteresis curves of as-synthesized Fe3O4

and NTA-attached samples obtained via APTES, PEI, and PAA treatment are shown

in Fig. 7. No coercivity or remnant magnetization was found in

any of the hysteresis curves, and each particle exhibited

paramagnetic curves. However, the saturated magnetization

of as-synthesized Fe3O4 was the highest, with a value of

120 emu/g. This was followed by the APTES- and PEI-treated samples, which

exhibited values of 106 and 98 emu/g, respectively; these

values were 88.3% and 81.7% of largest value of saturated magnetization,

respectively. The PAA-treated particles exhibited the lowest value, 94 emu/g,

which was 78.3% of that of as-synthesized Fe3O4.

Review

about NTA conjugated Fe3O4 with various kind of

intermediate functionalization

NTA was observed to be attached properly with the negative

surface charge after the NTA-attaching process. However,

the inversion of surface charge occurred in the amino-functionalized samples

with APTES and PEI. During this inversion, owing to the pH inversion and

changed functional group, the electrostatic force was weakened, and it was

difficult to maintain their dispersion stability; thus,

agglomeration occurred, which can be observed in the TEM images

mentioned above. The PAA-treated particles, however, underwent a slight decline

during the NTA conjugation process, and this charge was still strong enough for

the dispersion. Meanwhile, the magnetization of the NTA-attached

specimens was directly related to the reversible separation

and re-dispersion, considering the high saturated

magnetization and low remnant magnetization of these

specimens. The magnetic hysteresis curves of each specimen originated from its

Fe3O4 core particle and differed

owing to the coated layer or phase variation resulting

from external circumstances. During NTA conjugation via amino or carboxylic

functionalization, the Fe3O4 nanoparticles underwent

basic or acidic condition, which could damage the magnetic particles. However,

their paramagnetic properties remained intact, and their

saturated magnetization was sufficiently high for magnetic separation after the

NTA attachment.

|

Fig. 1 TEM images of as-synthesized Fe3O4 and intermediate functionalized Fe3O4 particles. |

|

Fig. 2 FT-IR spectra of as-synthesized Fe3O4 and intermediate functionalized Fe3O4 particles. |

|

Fig. 3 Scheme of chemical structures of NTA conjugated Fe3O4 particles through various types of intermediate functionalization. |

|

Fig. 4 T-IR images of NTA conjugated Fe3O4 particles through various types of intermediate functionalization. |

|

Fig. 5 EM spectra of NTA conjugated Fe3O4 particles through various types of intermediate functionalization. |

|

Fig. 6 urface charge of as-synthesized, intermediate functionalized, and NTA conjugated Fe3O4 nanoparticles. |

|

Fig. 7 Hysteresis loop of as-synthesized and NTA conjugated

Fe3O4 nanoparticles. |

In this study, chelate-functionalized Fe3O4

nanoparticles were fabricated through intermediate

functionalization with APTES, PEI, and PAA, and characterized for further

applications, which can be derived using metal-ion chelating. The peaks of the

FT-IR spectra indicated the alternation of the surface

functional group according to the

progression from the Fe3O4 nanoparticle synthesis to

the NTA attachment. Specifically, after NTA attachment, distinctive

peaks of NTA were observed, which were derived from the carboxyl group, amine

group, and peptide bonding. After NTA attachment, the surface charge

of the Fe3O4 nanoparticles was slightly weakened,

and electronic inversion occurred through amino func- tionalization. Owing to the

temporary lack of electrostatic repulsive force due to the

electronic inversion, the APTES- and PEI-treated particles were covered with an

NTA layer under an agglomerated state, unlike the PAA-treated particles.

In conclusion, NTA was successfully attached to the surface

of Fe3O4 nanoparticles through functionalization

using APTES, PEI, and PAA. Owing to the various functionalization chemicals,

the dispersion properties of the NTA-attached Fe3O4

particles were different. By further analyzing metal-ion chelating and

separating biomaterials, such as his-tag or DNA, NTA-attached superparamagnetic

nanoparticles can be used in various applications.

This work was supported by “Human Resources Program

in Energy Technology” of the KETEP and MOTIE of the

Republic of Korea (No. 20194030202450) and by the National Research

Foundation of Korea (NRF) grant funded by the Korea government (MSIP)

(2018R1A5A6075959).

- 1. M.T. Gabr and F.C. Pigge, Dalton T. 45 (2016) 14039-14043.

-

- 2. G.R. You, G.J. Park, S.A. Lee, K.Y. Ryu, and C. Kim, Sensor Actuat. B-Chem. 215 (2015) 188-195.

-

- 3. N.V. Petrochenkova, A.G. Mirochnik, T.B. Emelina, A.A. Sergeev, A.A. Leonov, and S.S. Voznesenskii, Spectrochim Acta A Mol. Biomol. Spectrosc. 200 (2018) 70-75.

-

- 4. F. Tudorache, I. Petrila, T. Slatineanu, A.M. Dumitrescu, A.R. Iordan, M. Dobromir, and M.N. Palamaru, J. Mater. Sci.: Mater. 27 (2015) 272-278.

-

- 5. S.-L. Kao, P. Venkatesan, and S.-P. Wu, New J. Chem. 39 (2015) 3551-3557.

-

- 6. N.E. Boland and A.T. Stone, Geochim. Cosmochim. Acta 212 (2017) 176-195.

- 7. W. Dong, Y. Bhide, S. Marsman, M. Holtrop, T. Meijerhof, J. de Vries-Idema, A. de Haan, and A. Huckriede, Biotechnol. J. 13 (2018) 1700645.

-

- 8. L. Li, Z. Huang, X. Fan, Z. Zhang, R. Dou, S. Wen, Y. Chen, Y. Chen, and Y. Hu, Electrochim. Acta 231 (2017) 354-362.

-

- 9. J. Li, L. Zhang, G. Wei, Y. Zhang, and Y. Zeng, Biosens. Bioelectron 69 (2015) 316-320.

-

- 10. A. Dutta Chowdhury, N. Agnihotri, R.A. Doong, and A. De, Anal Chem 89 (2017) 12244-12251.

-

- 11. Y. Xin, X. Fu-bing, L. Hong-wei, W. Feng, C. Di-zhao, and W. Zhao-yang, Electrochimi. Acta 109 (2013) 750-755.

-

- 12. C. Zhang, S. Si, and Z. Yang, Biosens. Bioelectron 65 (2015) 115-120.

-

- 13. S. Hu, W. Ouyang, L. Guo, Z. Lin, X. Jiang, B. Qiu, and G. Chen, Biosens. Bioelectron 92 (2017) 718-723.

-

- 14. H. Guo, M. Li, S. Tu, and H. Sun, IOP Conf. Ser.: Mater. Sci. Eng. 322 (2018) 022017.

-

- 15. Y. Wang, J. Dostalek, and W. Knoll, Anal. Chem 83 (2011) 6202-6207.

-

- 16. Q. Wu, Y. Sun, D. Zhang, S. Li, X. Wang, and D. Song, Biosens. Bioelectron 86 (2016) 95-101.

-

- 17. S. Yao, X. Yan, Y. Zhao, B. Li, and L. Sun, Mater. Lett. 126 (2014) 97-100.

-

- 18. G. Harris, T. Palosaari, Z. Magdolenova, M. Mennecozzi, J.M. Gineste, L. Saavedra, A. Milcamps, A. Huk, A.R. Collins, M. Dusinska, and M. Whelan, Nanotoxicology 9 (2015) 87-94.

-

- 19. G.S. An, S.W. Choi, D.H. Chae, H.S. Lee, H.-J. Kim, Y. Kim, Y.-G. Jung, and S.-C. Choi, Ceram. Int. 43 (2017) 12888-12892.

-

- 20. G.S. An, J.S. Han, J.R. Shin, D.H. Chae, J.U. Hur, H.-Y. Park, Y.-G. Jung, and S.-C. Choi, Ceram. Int. 44 (2018) 12233-12237.

-

- 21. S. Li, K. Yang, L. Liu, B. Zhao, Y. Chen, X. Li, L. Zhang, and Y. Zhang, Anal. Chim. Acta 997 (2018) 9-15.

-

- 22. G.S. An, S.W. Choi, T.G. Kim, J.R. Shin, Y.-I. Kim, S.-C. Choi, and Y.-G. Jung, Ceram. Int. 43 (2017) 157-161.

-

- 23. G.S. An, J.R. Shin, J.U. Hur, A.H. Oh, B.-G. Kim, Y.-G. Jung, and S.-C. Choi, J. Alloy. Compd. 798 (2019) 360-366.

-

- 24. G.S An, J.S. Han, J.R. Shin, J.H. Cha, B.-G. Kim., Y.-G. Jung, and S.-C. Choi, J. Alloy. Compd. 792 (2019) 1008-1012.

-

- 25. J.S Han, G.S. An, B.G. Park, and S.-C. Choi, J. Korean. Ceram. Soc. 55 (2018) 80-84.

-

- 26. J.U. Hur, J.S. Choi, S.-C. Choi, and G.S. An, J. Korean. Ceram. Soc. 57 (2020) 80-84.

-

- 27. A.H. Oh, H.-Y. Park, Y.-G. Jung, S.-C. Choi, and G.S. An, Ceram. Int. 46 (2020) 10723-10728.

-

This Article

This Article

-

2020; 21(5): 515-523

Published on Oct 31, 2020

- 10.36410/jcpr.2020.21.5.515

- Received on Feb 3, 2020

- Revised on Mar 31, 2020

- Accepted on Apr 7, 2020

Services

Services

- Abstract

introduction

experimental procedure

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Gye Seok An

-

Hanyang university 04763 Division of Materials Science and Engineering, Hanyang University, 222 Wangsimni-ro, Seongdong-gu, Republic of Korea

Tel : +8222200505

Fax: +8222916767 - E-mail: faustmaro@hanyang.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.