- Synthesis and properties of ultrafine YAG powder via low-temperature microwave hydrothermal method

Yue Liua,b, Jieguang Songa,b,*, Lin Chenb,*, Huihui Luob, Guojian Lina, Peng Chenb, Chenhui Weia and Jingjing Liua

aSponge City Research Institute of Pingxiang University, Pingxiang 337055 China

bKey Laboratory for Industrial Ceramics of Jiangxi Province, Pingxiang University, Pingxiang 337055 China

Yttrium aluminum garnet (YAG)

has good optical properties and has been widely used in engineering. The

preparation of conventional YAG powder is costly due to its high synthesis

temperature, so lowering the synthesis temperature is the most effective way to

save cost. The ultrafine oxide composite powder was rapidly synthesized using

the microwave hydrothermal method at a low temperature. The effect of

temperature and its performance. Differential thermal analysis and XRD phase

analysis showed the mixed solution of Al(NO3)3 and Y(NO3)3

at pH=9 and C(Al3+)=0.42 mol·L−1. SEM, zeta

potential, and particle size analysis revealed that the microwave hydrothermal

reaction temperature was 170 oC, and the high-purity ultrafine

YAG powder was calcined at 928 oC, which was lower than

conventional calcination temperature. The synthesized ultrafine spherical YAG

powder had a small particle size and a uniform distribution.

Keywords: Ultrafine YAG powder, Synthesis temperature, Composite powder, Microwave hydrothermal method

Ceramics, as an important part of industrial ceramics, has

been extensively investigated because of its high-temperature performance. The

most common ones are Al2O3 ceramics, SiC ceramics, and Si3N4

ceramics [1-3], but the sintering temperature of several ceramics is usually

high, accompanied by high cost, long preparation period,

and limited existing research. YAG is a complex oxide

formed by the reaction of Y2O3 and Al2O3,

which belongs to the cubic system and has a garnet structure [4]. YAG ceramics

have excellent high-temperature mechanical properties and chemical stability.

YAG powder, which is the main material of YAG ceramics, has been widely

explored. In optics, YAG is the best choice for the selection of laser matrix

materials [5-6].

YAG is prepared mainly through hydrothermal, coprecipitation,

mixed calcination, and sol-gel methods, et al. [7-10]. These

synthetic methods have their own advantages and disadvantages. Although the

cycle of ultrafine YAG powder preparation via coprecipitation is short, it

results in large locally precipitated particles because of the influence of

diffusion time when a precipitant is added during

precipitation. The hydrothermal method yields ultrafine YAG powder

with a small particle size and a uniform distribution, but the pre- paration cycle is longer and the error is

larger than those of other methods.

Coprecipitation and hydrothermal methods result in YAG

powder with good dispersibility. However, in comparison with coprecipitation,

the hydrothermal method has the advantages of yielding YAG powder with a small

particle size and a uniform distribution, but the preparation cycle is long and

costly [11-12]. Therefore, finding a method with a short period, low cost, and

excellent powder performance is the current research direction concerning

ultrafine YAG powder preparation. In terms of the shortcomings of the

hydrothermal method, this study adopts the microwave hydrothermal method to

help prepare ultrafine YAG powder. This method results in ultrafine YAG powder

with a small particle size, a uniform distribution, and a considerably

shortened preparation cycle [13-15].

In this paper, ultrafine YAG powder was prepared through

microwave hydrothermal synthesis technology with a considerably shorter

preparation cycle than the traditional hydrothermal method, and the process conditions

in the YAG ultrafine powder synthesis process were

started. The lowest synthesis temperature in the range was used to analyze the

variables and determine the optimum conditions for the lowest synthesis

tem- perature of

ultrafine YAG powder to reduce the sintering temperature

and cost of YAG ceramics. The findings are also the innovation of this paper.

The main raw materials were aluminum nitrate Al(NO3)·9H2O

(analytical grade), yttrium nitrate Y(NO3)· 6H2O

(analytical grade), and ammonia water. Analytically pure Al(NO3)3·9H2O

(purity: 99.99%) was weighed with a beaker, deionized, dissolved,

and stirred thoroughly with a magnetic stirrer to obtain

Al (NO3)3 at a concen-

tration of 2.0826 mol·L−1. The pure Y(NO3)3·6H2O

(purity: 99.99%) solid was weighed into a beaker, dissolved in deionized water,

and fully dissolved by stirring with a magnetic stirrer to obtain an Y(NO3)3

solution with a concentration of 2.4866 mol·L−1. The precursors

of YAG, Al(OH)3, and Y(OH)3 were obtained

by adjusting the pH of the mixed solution of Al(NO3)3-Y(NO3)3

by using the aqueous ammonia solution to carry out precipitation reaction and

obtain Al(OH)3 and Y(OH)3. Different concentrations of

Al(NO3)3 and Y(NO3)3 mixed

solutions were prepared according to a Y:Al ratio of 3:5 and adjusted to

different pH values by using a pH-adjustable aqueous ammonia solution. The

mixed precipitates of the YAG precursors Al(OH)3 and Y(OH)3

obtained after precipitation were subjected to microwave hydrothermal

decomposition by using a microwave hydrothermal synthesizer to obtain a mixed

precipitate of Al2O3-Y2O3.

Thereafter, the obtained mixed precipitate was filtered to

obtain white composite powder that was then subjected to

differential thermal analysis. The temperature of the YAG crystal phase was

determined using a DSC-TG curve via a STA 449 F3-type comprehensive thermal analyzer

(NETZSCH, Germany) and calcined in a programmed furnace to analyze the

temperature. After calcination, the phase was conducted by using a D8 Advance

X-ray powder diffractometer (Bruker, Germany). Surface morphology and particle

size (D50) were examined using a Zetasizer Nano Zeta

potential and particle size analyzer (Malvern, UK),

respectively.

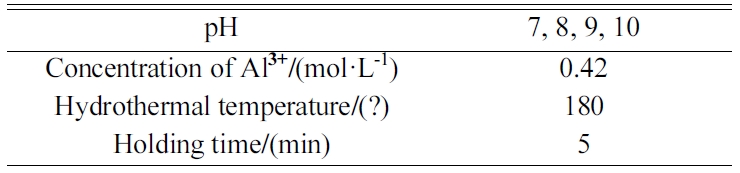

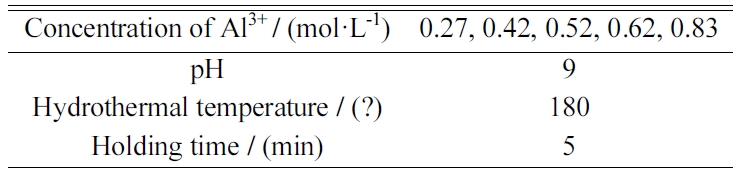

Effect

of pH on the properties of YAG ultrafine powder

The prepared mixed solution of C(Al3+)=0.42 mol·

L−1 and C(Y3+)=0.25 mol·L−1 was adjusted

to different pH values. The microwave hydrothermal temperature was 180 oC

and the holding time was 5 min (Table 1). White precipitated powder was

filtered and dried to obtain a composite powder.

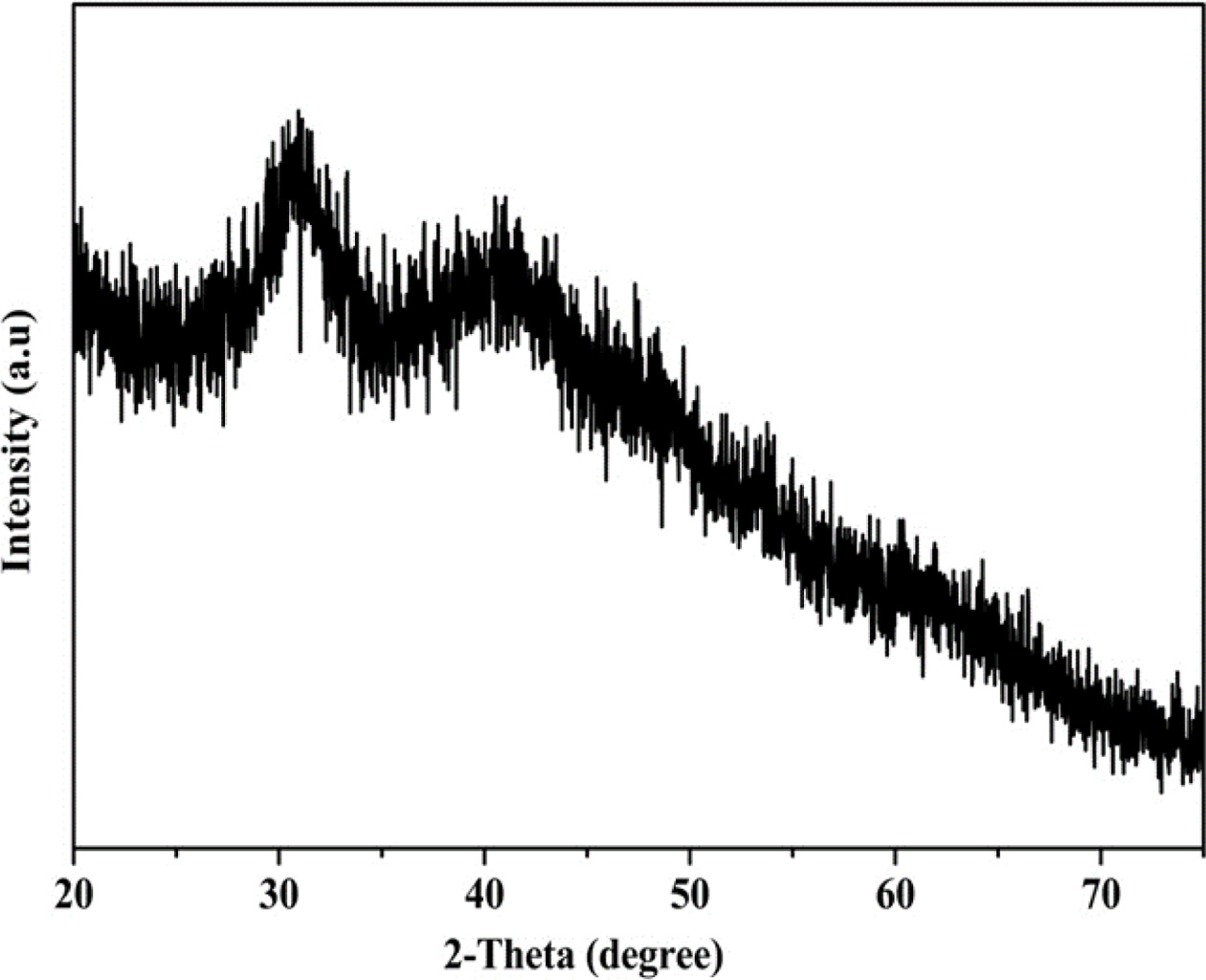

Fig. 1 shows the XRD pattern of the YAG precursor in a Cu

target with a source of Ka-ray (λ = 1.5405 nm) and a scan range

of 2θ from 10° to 80°. The XRD pattern of the YAG precursor after thermal

decom- position by microwave. The YAG

precursor did not decompose into an oxide at a hydrothermal temperature of

180 oC (Fig. 1).

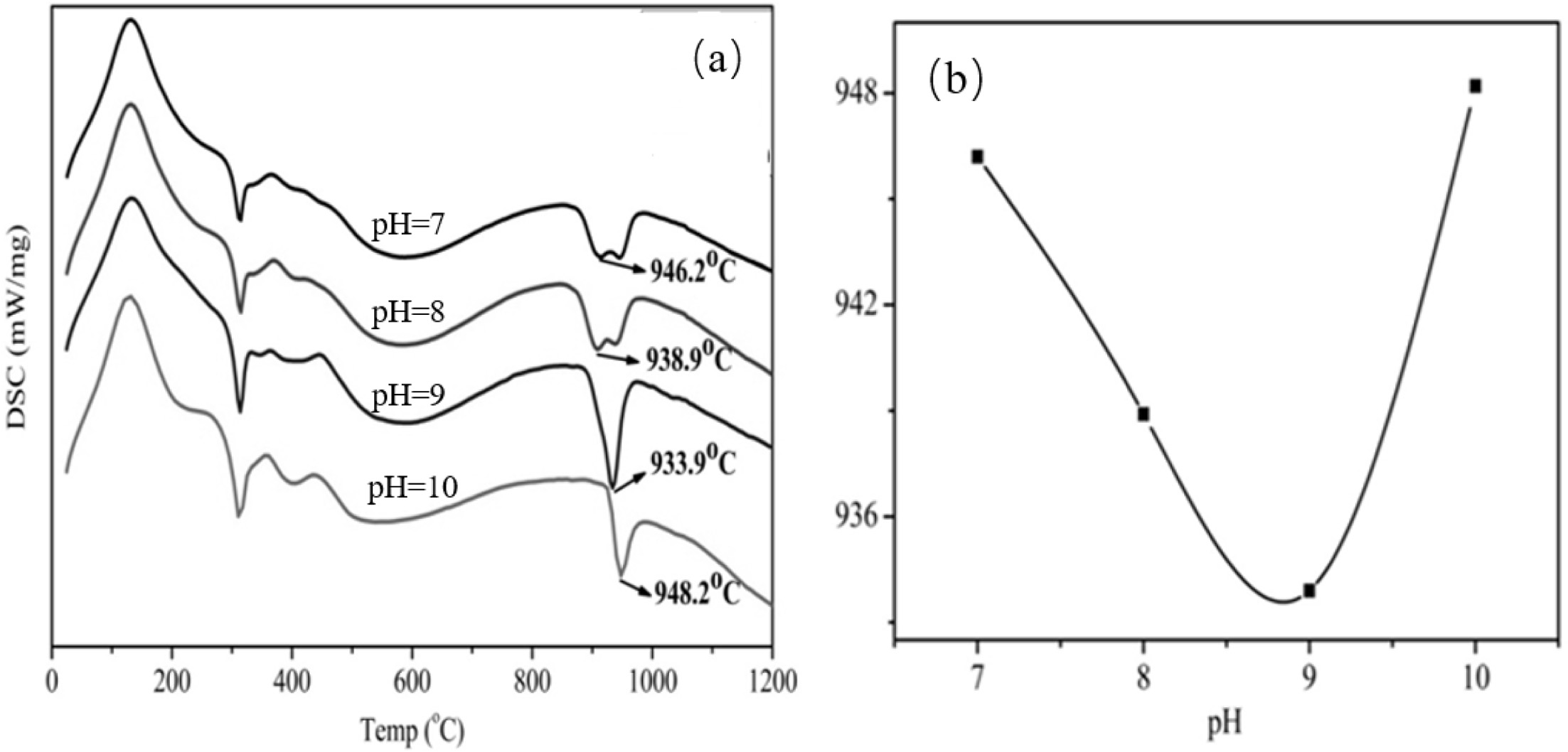

Fig. 2a is a DSC curve of YAG precursor after microwave

hydrothermal decomposition in an air atmosphere at a heating rate of

15 K/min from 25 oC to 1200 oC.

An endothermic peak appeared at approximately 150 oC,

and this observation was caused by the dehydra- tion

decomposition reaction of Y and Al hydroxides and the evaporation of adsorbed

water. An exotherm occurred at approximately 940 oC. The peak

did not lose weight because of the crystallization of the amorphous

powder into the YAG phase. Fig. 2b illustrates the

synthesis temperature and pH of YAG obtained by preparing the ultrafine YAG

powder under different pH conditions. The relationship curve shows that the

tem- perature of the YAG crystal phase

initially decreases and then increases as the pH of the mixed mother salt

solution increases. At pH=9, the temperature of the YAG crystal phase is

relatively low, and the tem- perature

is 933.9 oC.

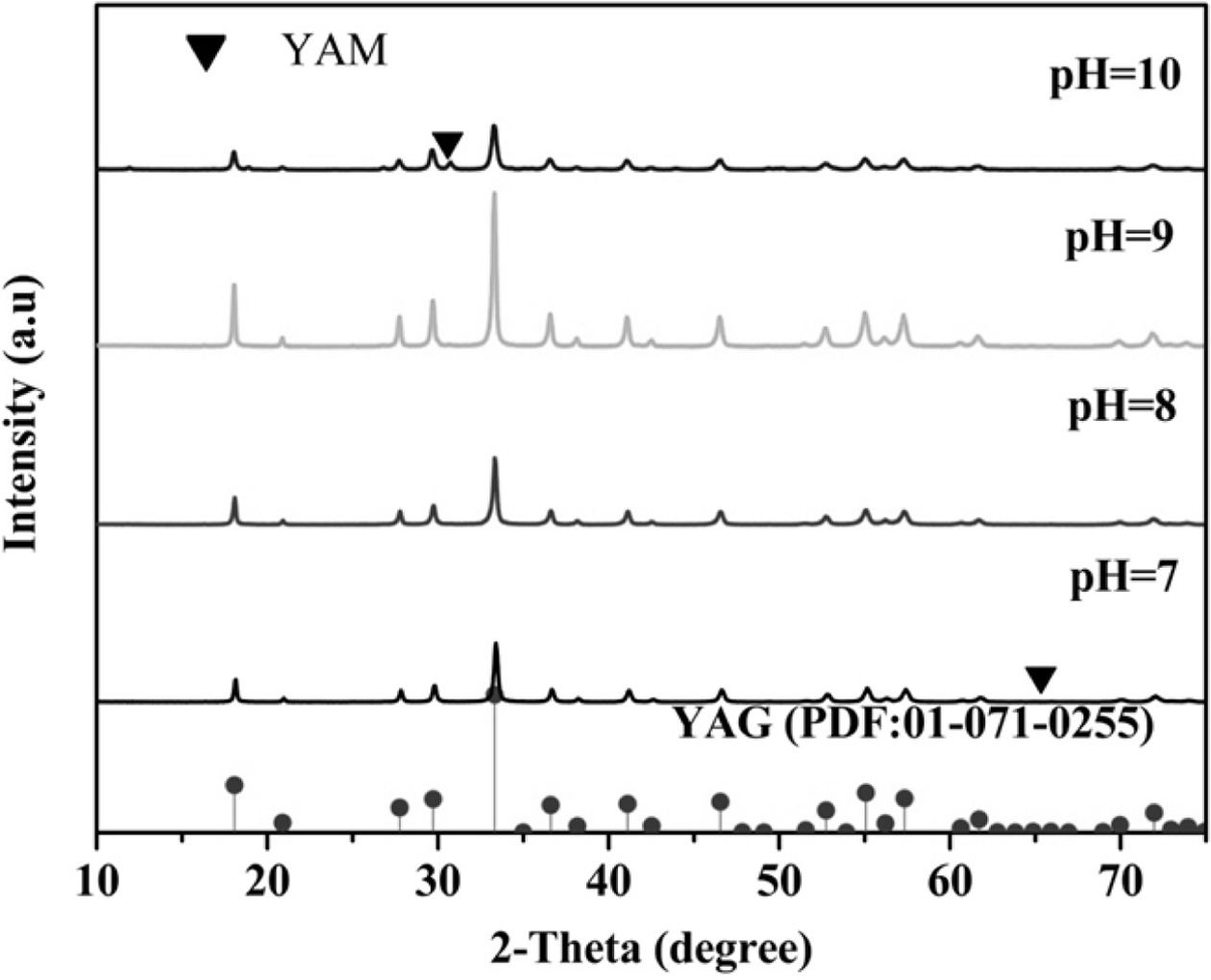

Fig. 3 is the XRD pattern of the YAG precursor after

calcination. At pH=8 and 9, pure cubic phase ultrafine YAG powder

can be synthesized, but the low calcination temperature

is observed at pH=9. ultrafine YAG powder and high

crystallinity. At this time, Y:Al=3:5 may result in the lower potential energy

of YAG synthesis and lower synthesis temperature. When pH=10, the intermediate

phase Y4Al2O9 (YAM) appears, and Y:Al= 2:1

mainly because a certain content of AlO2− is formed at a high

concentration of OH− so that the ratio of Y:Al is greater than 1,

leading to the appearance of the intermediate YAM phase of YAG

during calcination. When pH=7, the YAM phase appears because of the low

concentration of OH−, and Al3+ cannot be completely precipitated,

so the Al(NO3)3-Y(NO3)3 mixed salt

solution is not completely converted into hydroxide precipitate

[16-18]. The ratio of Y:Al does not reach 3:5, resulting in the occurrence of

the intermediate YAM phase of YAG during calcination. At pH=9 of the mixed

mother salt solution, the pure cubic phase ultrafine YAG powder

was synthesized at a low temperature (933.9 oC) under the

condition of Y:Al=3:5.

Effect

of Concentration on the Properties of YAG Ultrafine Powder

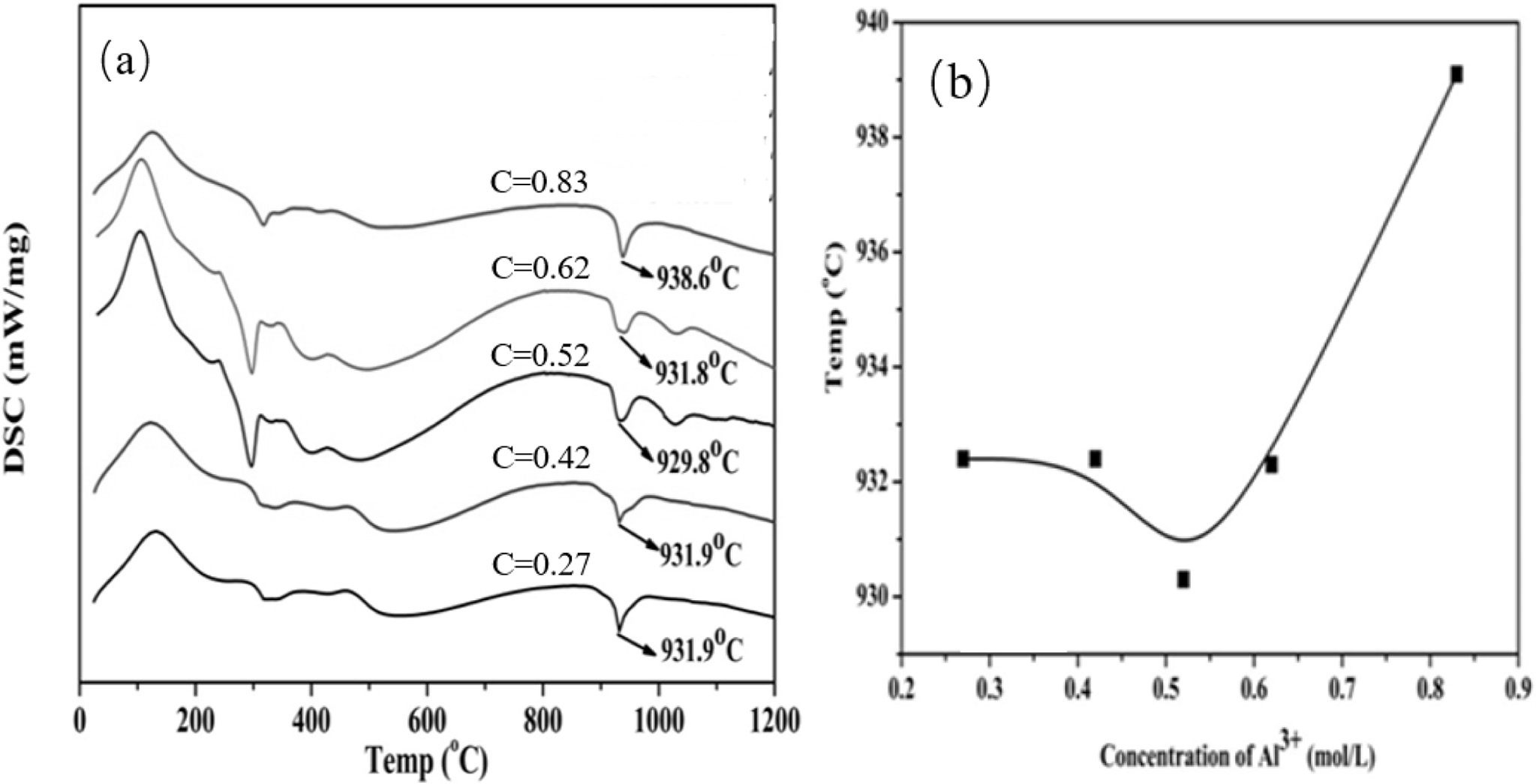

Fig. 4a shows the DSC curve of the synthetic powder.

An endothermic peak appears at approximately 150 oC, and this

peak is caused by the decomposition of the hydroxide of Y and Al and the

adsorbed water. An exothermic peak appears at approximately 940 oC,

and no loss of weight is observed because of the crystalli- zation of the amorphous powder into the YAG

phase. Fig. 4b shows the synthesis temperature of YAG and the Al3+

concentration in the mixed parent salt solution. The relationship curve (Fig.

4b) illustrates that the temperature of the YAG crystal phase

initially decreases and then increases as the concentration of Al3+

in the mixed mother salt solution increases. At 0.52 mol·L−1 concentration,

the YAG crystal phase is produced at a lower temperature, and the temperature

is 929.8 oC.

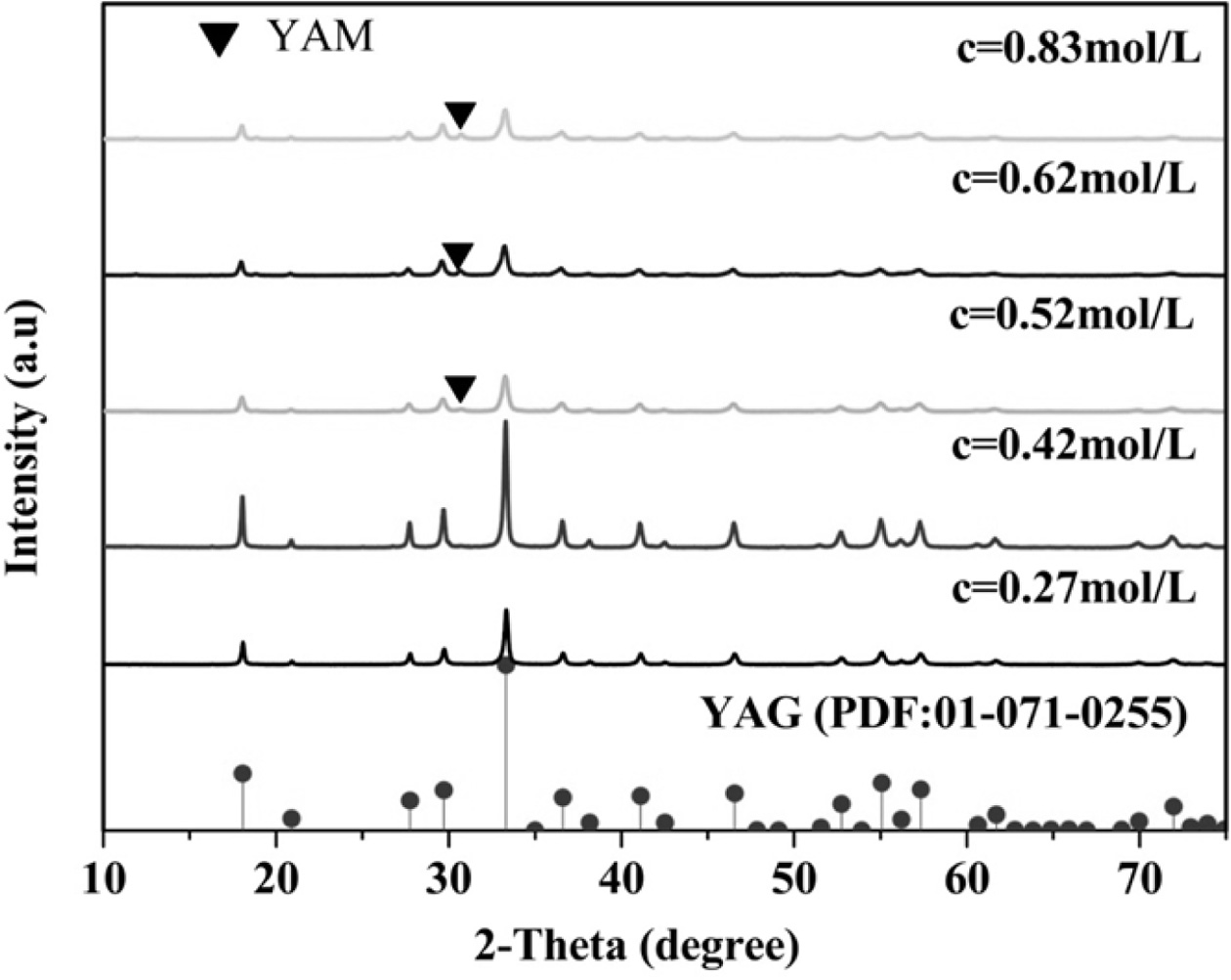

Fig. 5 shows the XRD pattern of the YAG precursor after

calcination. When the Al3+ concentration in the mixed salt solution

is less than 0.52 mol·L−1, a pure cubic-phase ultrafine YAG

powder can be produced, and the Al3+ concentration in the mixed salt

solution is 0.42 mol·L−1, which is synthesized. The ultrafine

YAG powder has a strong peak and a high degree of crystallinity. When the

concentration of Al3+ in the mixed salt solution is greater than or

equal to 0.52 mol·L−1, the YAM phase is produced, and the synthesis

temperature of the ultrafine YAG powder increases as the concentrations

increase. In the reaction of a dilute solution system, Al3+

precipitates earlier than Y3+ does because Ksp of the solubility

products Y3+ and Al3+ is different. However, the formed

Al(OH)3 cannot be nucleated, making Y3+ precipitate in

the outer layer of Al3+ to form a unique inclusion structure in high

con- centration systems. This

phenomenon may be due to the incomplete conversion of Al3+ to Al(OH)3

precipi- tation or AlO2−,

resulting in the precipitation of Al(OH)3 in the

solution [19-21]. Less, eventually Y:Al=2:1, and the YAM phase

is produced after calcination. Therefore, under the

same conditions, when the concentration of Al3+ in the mixed salt

solution is 0.42 mol·L−1, a pure cubic-phase ultrafine YAG

powder can be synthesized at a calcination temperature of 931.9 oC.

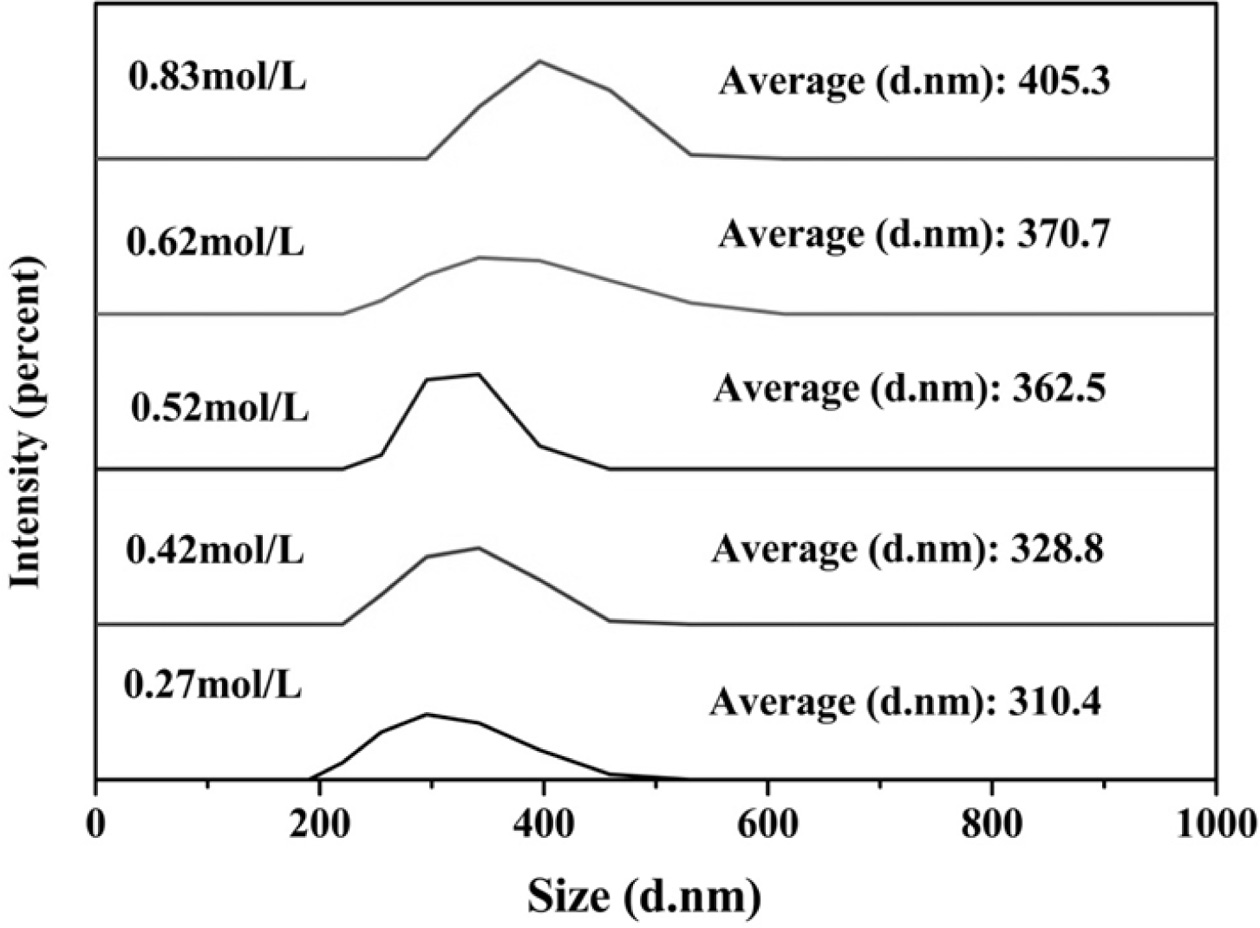

Fig. 6 is a comparison of the particle size of the

ultrafine YAG powder prepared at different Al3+ concentrations. Fig.

6 shows that the particle size of the prepared ultrafine YAG powder also

increases as the concentration of the reaction mother salt solution increases.

Thus, the higher the concentration is, the higher the formation temperature of

the YAG crystal phase will be.

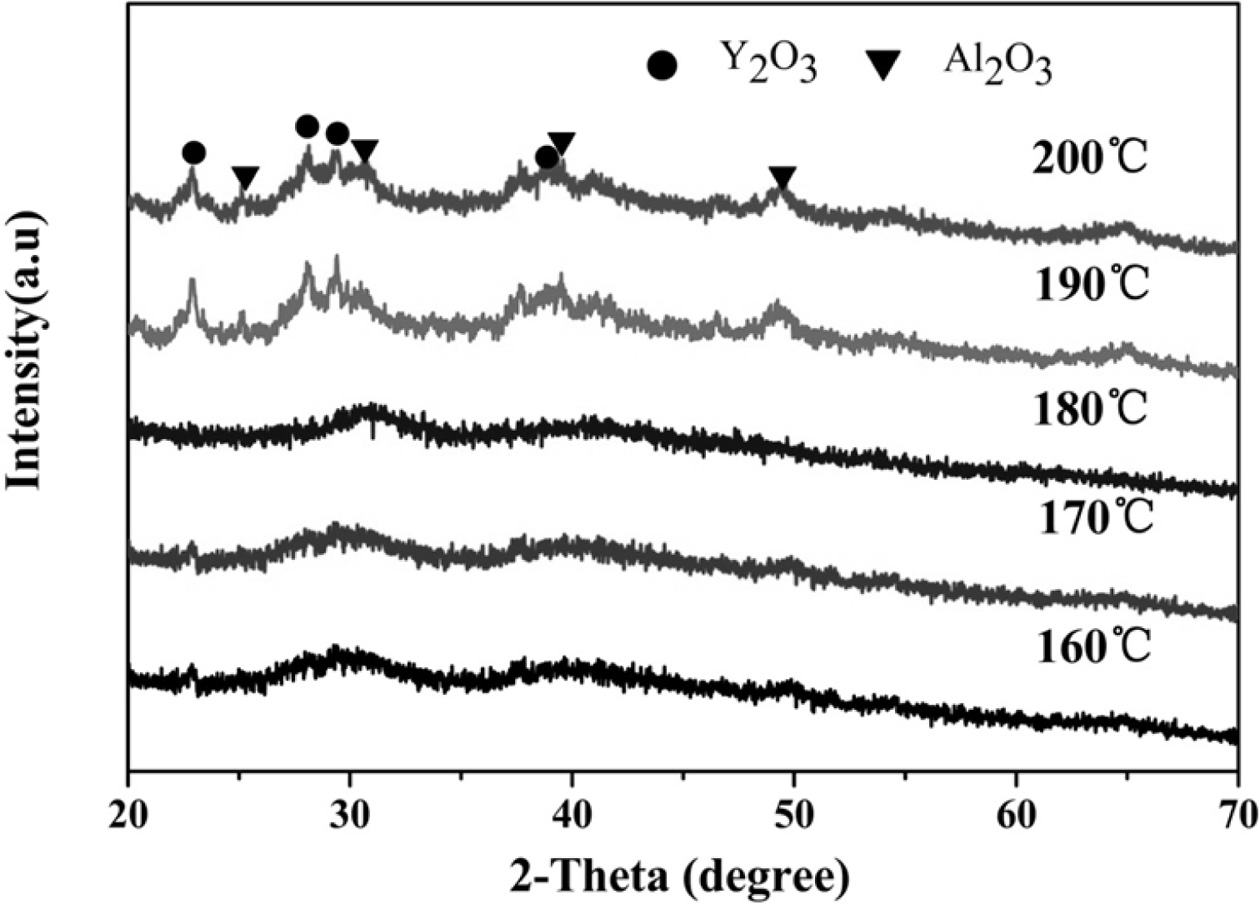

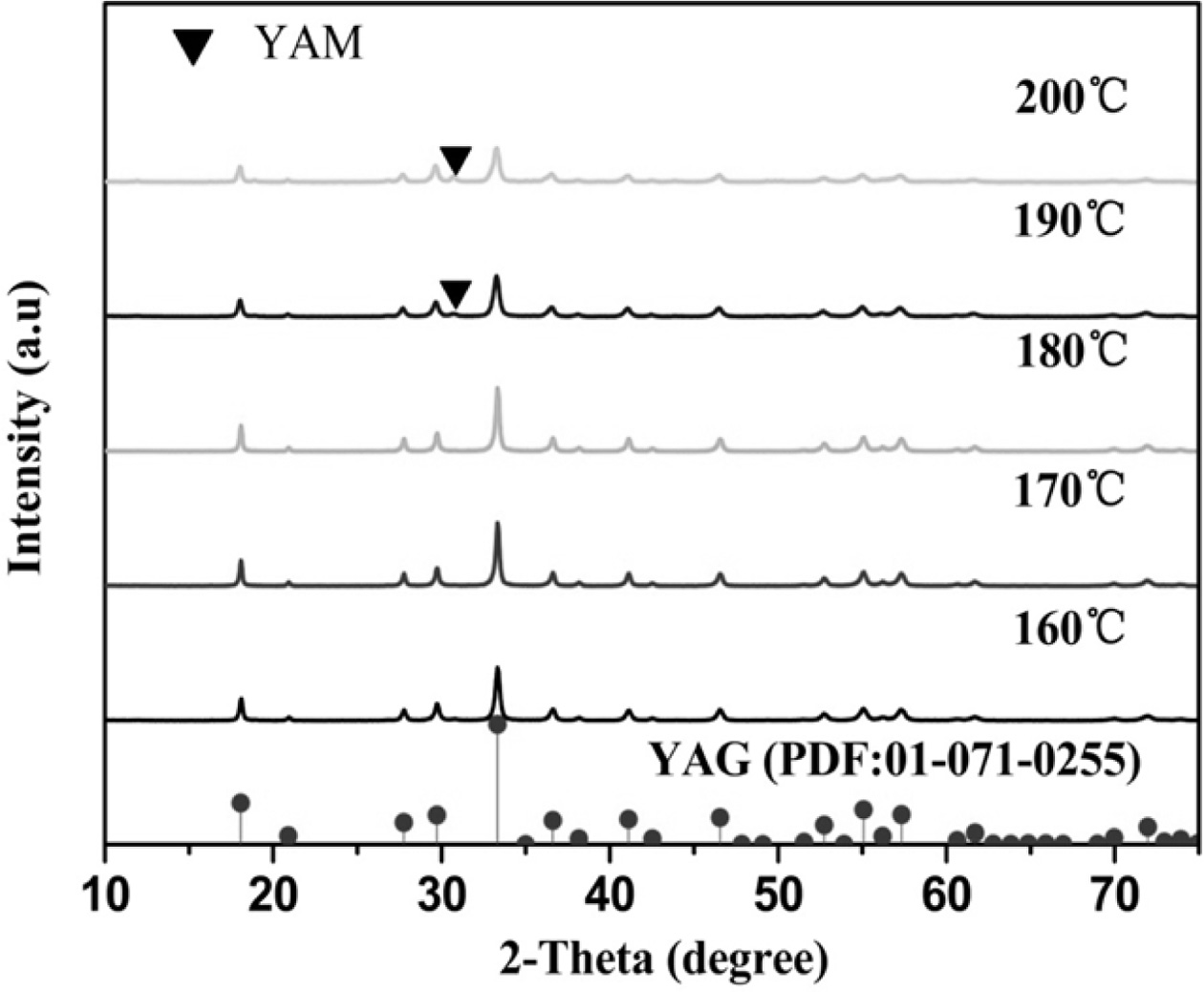

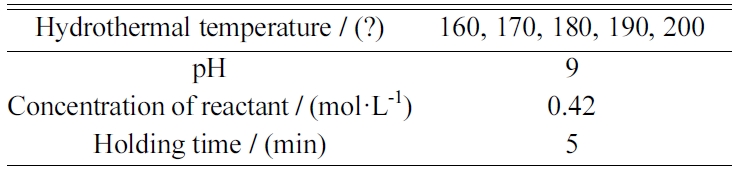

Fig. 7 shows the XRD pattern of the YAG precursor after

microwave hydrothermal decomposition. YAG precursors have crystal phases of γ-Al2O3

and Y2O3 under the experimental parameters of the

microwave hydrothermal temperatures of 190 oC and 200 oC

and the holding time of 5 min, respectively.

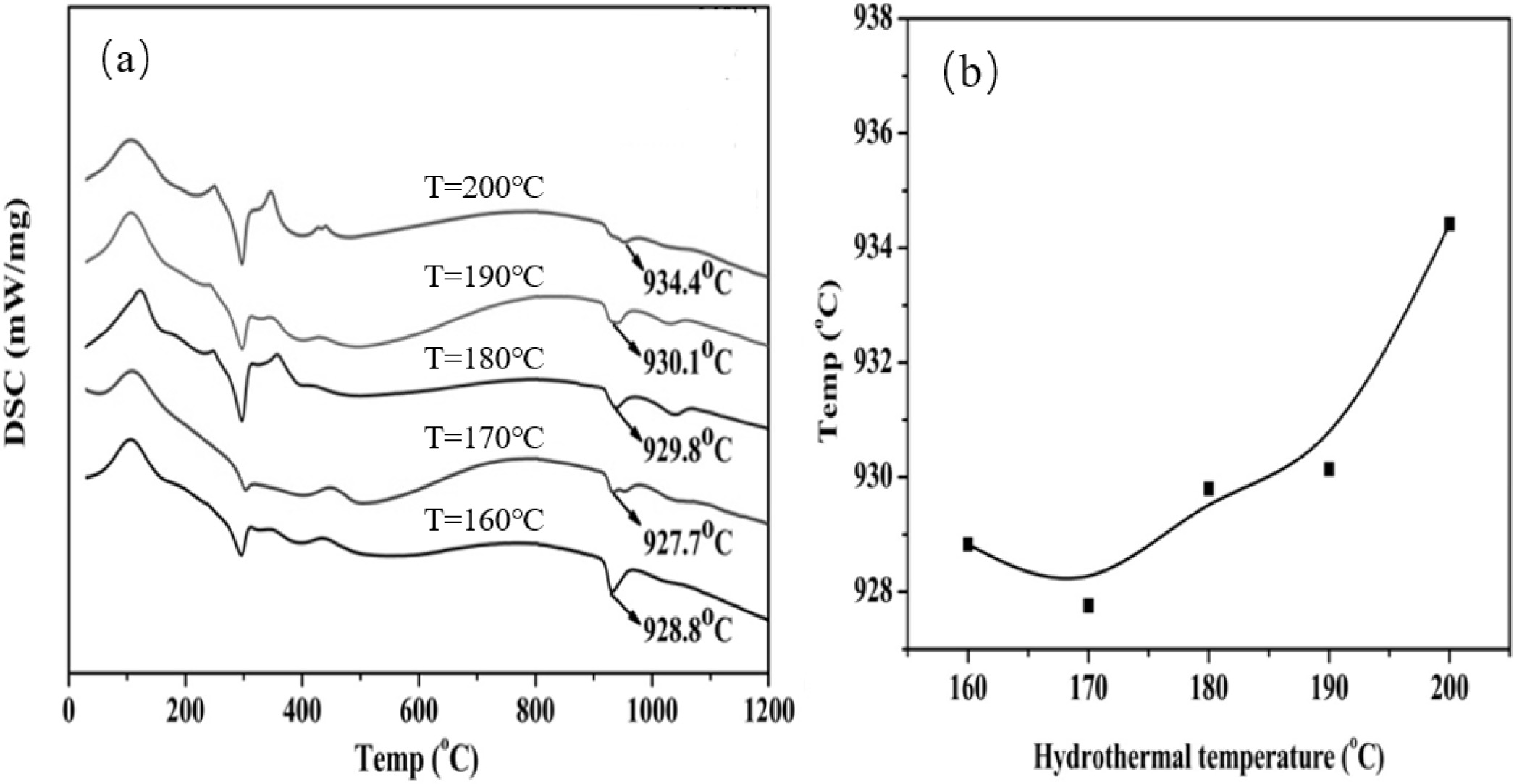

Fig. 8a is the DSC curve of the powder. An endothermic

peak appears at about 150 oC because of the decomposition of

the hydroxide of Y and Al and the evaporation of the adsorbed water. An

exothermic peak appears at approximately 940 oC, and no weight

loss is observed because of the crystallization of amorphous powder into the

YAG phase. Fig. 8b shows the relationship between the synthesis temperature of

YAG and the temperature of microwave hydrothermal reaction. When the

temperature of microwave hydro- thermal

reaction is 170 oC, the YAG crystal phase produces a low

temperature of 927.7 oC.

Fig. 9 illustrates the XRD pattern of the YAG precursor

after calcination via microwave hydrothermal decomposition. The

intermediate-phase YAM of YAG occurs when the hydrothermal temperatures are

190 oC and 200 oC, and only the pure

cubic-phase ultrafine YAG powder can be produced at the hydrothermal

temperatures of 170 oC and 180 oC,

respectively, and the water is hot. The ultrafine YAG powder prepared at 170 oC

has a lower synthesis temperature and a calcination temperature

of only 927.7 oC. Therefore, at 170 oC, it can

provide the energy required for the decomposition of the YAG precursor

hydroxide precipitate into the corresponding oxide to form a crystal phase

[22-24]. As the temperature continues to increase, the energy also increases,

so the formed grains grow and the particle size becomes coarse.

Consequently, the calcination temperature of the ultrafine YAG

powder further increases. When the hydrothermal temperatures are 190 oC

and 200 oC, the intermediate-phase YAM of YAG appears because

the crystal phases of Al2O3 and Y2O3

appear in microwave hydrothermal reaction in the YAG precursor. Large amounts

of Al2O3 and Y2O3 decompose, and

solid phase reaction is formed during calcination. The intermediate-phase YAM

of YAG inevitably occurs because the solid phase reaction in YAG is gradual.

Under other conditions, at the micro-

wave water temperature of 170 oC, a pure cubic-phase

ultrafine YAG powder can be synthesized at a low calcination temperature

(927.7 oC).

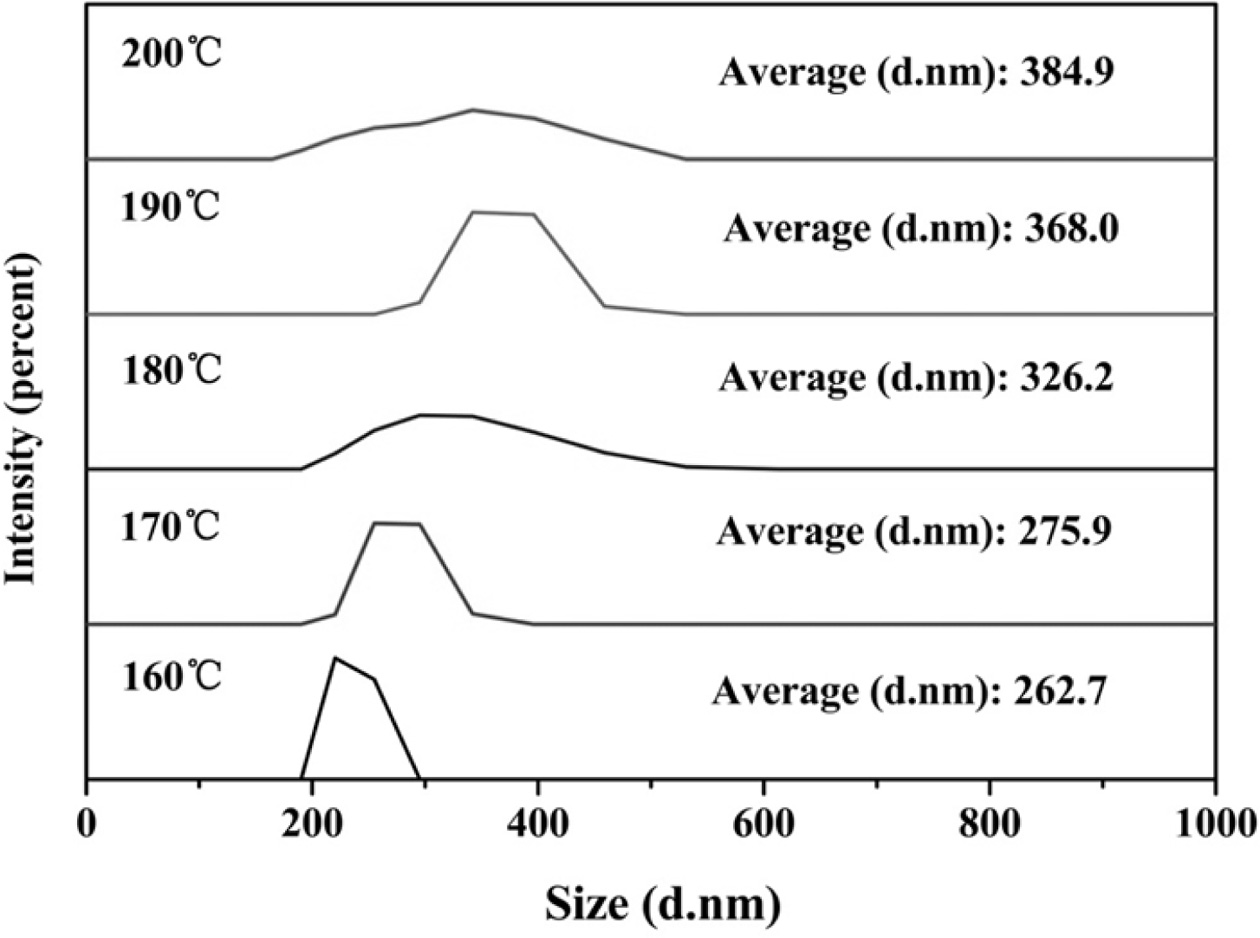

Fig. 10 shows a chart of the analysis of the particle size

of the ultrafine YAG powder, indicating that the particle size of the prepared

ultrafine YAG powder also continuously increases as the microwave water tem- perature increases because in the microwave.

During the hydrothermal process, an increase in temperature causes

the crystal grains to grow continuously, resulting in a large

particle size of the synthesized ultrafine YAG powder and a high temperature of

the crystal phase.

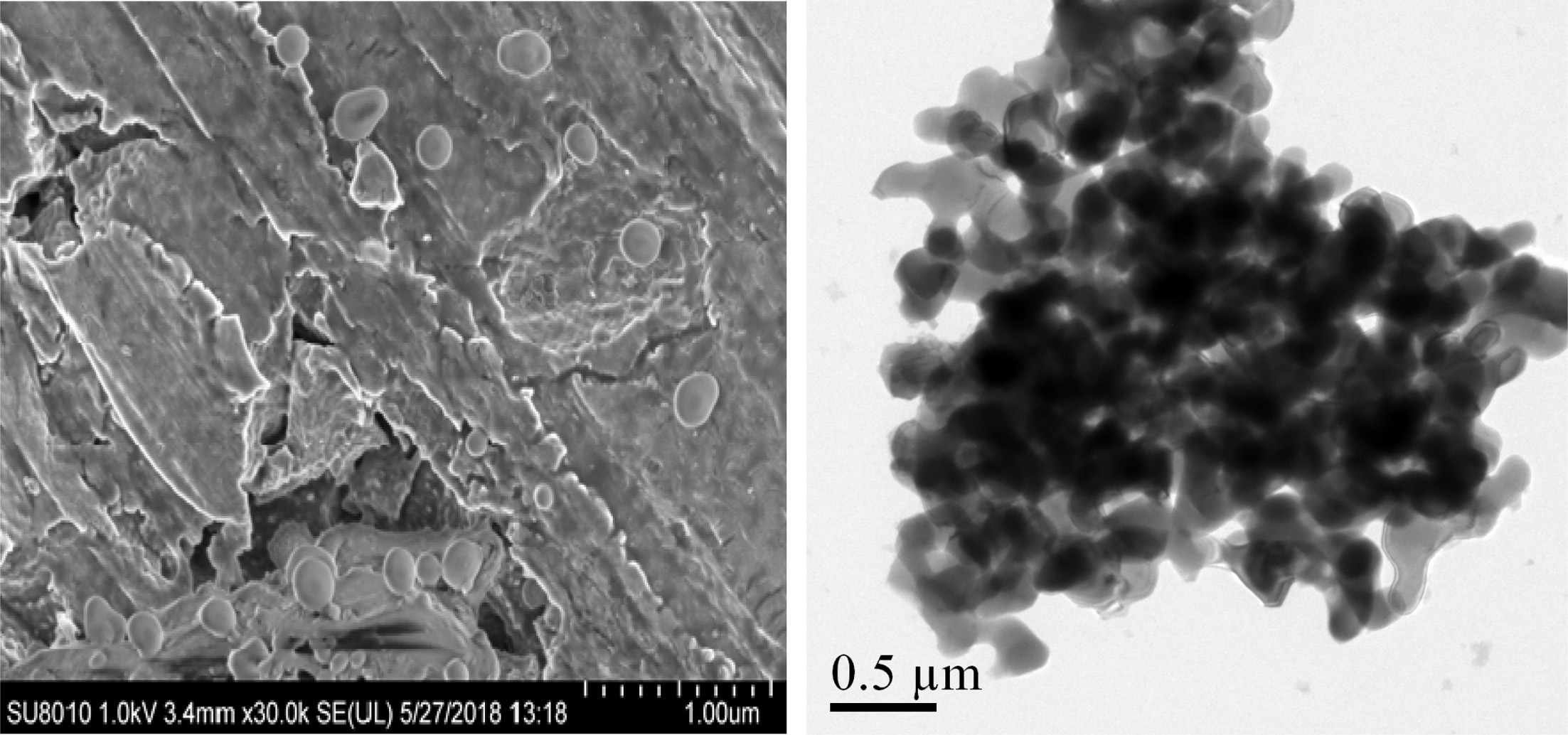

Fig. 11 illustrates a mixture of Al(NO3)3

and Y(NO3)3 calcined at 927.7 oC

under the experimental conditions of pH=9, C(Al3+)=0.42 mol·L−1,

and a microwave hydrothermal reaction temperature of 170 oC.

Fig. 11 also shows the scanning electron micrograph of the pure cubic-phase

ultrafine YAG powder. The ultrafine YAG powder synthesized under the

experimental con- ditions is

approximately spherical, and the particle diameter is approximately

200 nm. It can be seen from the figure that the particle size of the

powder is very small and has a spherical shape. Due to the small particle size,

the powder has a large specific surface area, a high specific surface energy,

and is prone to agglomeration. Table 2 Table 3

|

Fig. 1 XRD pattern of YAG precursor after microwave hydrothermal decomposition. |

|

Fig. 2 DSC curves of ultrafine powders (a- prepared at different pH; b-the relation of synthesis temperature and pH curve). |

|

Fig. 3 XRD patterns of calcined ultrafine powders prepared at different pH. |

|

Fig. 4 (a) DSC curves of ultrafine powders prepared at different concentrations;(b) YAG synthesis temperature-concentration curve. |

|

Fig. 5 XRD patterns of calcined ultrafine powders prepared at different reaction concentrations. |

|

Fig. 6 Effect of different concentration of Al3+ on particle size of YAG ultrafine powder. Effect of hydrothermal temperature on the properties of YAG ultrafine powder. |

|

Fig. 7 XRD spectra of YAG precursor after microwave hydrothermal decomposition. |

|

Fig. 8 (a) DSC curves of powders prepared at different hydrothermal temperatures; (b) YAG synthesis temperature-hydrothermal temperature curve. |

|

Fig. 9 XRD patterns of calcined ultrafine powders prepared at different hydrothermal temperatures. |

|

Fig. 10 Effect of different hydrothermal temperature on particle size of YAG ultrafine powder. |

|

Fig. 11 SEM and TEM patterns of YAG ultrafine powder. |

|

Table 1 Microwave hydrothermal synthesis conditions at different pH conditions. |

|

Table 2 Microwave hydrothermal synthesis conditions of YAG mixed solutions at different Al3+ concentrations. |

|

Table 3 Microwave hydrothermal synthesis conditions of YAG at different hydrothermal temperatures. |

YAG precursor oxide was synthesized using the microwave

hydrothermal method. After calcination, the powder was analyzed, and the

following conclusions were drawn: as the Al3+ concentration in the

mother salt solution increased, the particle size of the prepared ultrafine

YAG powder also increased. As the microwave hydrothermal

temperature increased, the particle size of the prepared ultrafine YAG powder

increased. With microwave hydrothermal synthesis, the process

conditions of high-purity ultrafine YAG powder were pH=9, C(Al3+)=0.42 mol·L−1,

microwave hydrothermal reaction temperature=170 oC,

and calcination=928 oC. The body had a particle size of about

200 nm, and its shape was almost spherical. This study provided a reference for

the low-temperature synthesis of high-purity and high-performance ultrafine YAG

powder.

The authors are thankful for the financial support provide

by the Science and Technology Found of the Educational Department of Jiangxi

Province, China (GJJ181107), Teaching Reform Research Fund for Higher Education

of Jiangxi Province (JXJG-18-22-2), The 13th Five-Year Plan for Educational

Science in Jiangxi Province (20YB259), The Science and Tech- nology Support Project of Pingxiang City

(PST2019-01) and the Science and Technology Found of Jiujiang University, China

(2019D0207).

- 1. Y. Hu, Z. Xiao, and H.P. Wang. Ceram. Int. 45 (2019) 3710-3714.

-

- 2. J.G. Song, L. Chen, and Y. Xiang. Solid State Phen. 279 (2018) 104-108.

-

- 3. Q.M. Liu, S.Z. Huang, and A.J. He. J. Mater. Eng. 47 (2019) 1-10.

- 4. L.X. Wang, D.F. Sun, and Q. Li, X. Wang. Chin. J. Lumin. 41 (2020) 160-167.

-

- 5. H. Wang, X. Zhang, and N. Wang. Sci. Adv. 3 (2017) 1-9.

- 6. N. Arai, and K.T. Faber. Script. Mater. 162 (2019) 72-76.

-

- 7. X.L. Ma, Z.L. Lv, and H.B. Tan. J. Phys. Chem. Solid. 130 (2019) 276-281.

-

- 8. J.G. Song, F. Wang, and M.H. Xu. J. Ceram. Proc. Res. 13 (2012) 154-157.

- 9. M. Rahmani, O. Mirzaee, and M. Tajally. Ceram. Int. 44 (2018) 23215-23225.

-

- 10. Y. Liu, X.Q. Yang, and J.G. Song. J. Ceram. Proc. Res. 20 (2019) 436-441.

- 11. T.D. Afolabi, M. Ariff, and A.H. Mazlan. Int. J. Appl. Ceram. Tech. 15 (2018) 1060-1071.

-

- 12. J.G. Song, M.H. Xu, and G.C. Ji. J. Ceram. Proc. Res. 14 (2013) 27-30.

- 13. Z.T Wang, V. Valtchev, and X.M. Li. Nano. Meta. Chem. 49 (2019) 44-50.

-

- 14. G. Zhang, B.X. Jiang, and L. Zhang. Ceram. Int. 44 (2018) 18949-18954.

-

- 15. J. Kraxner, J. Chovanec, and K. Haladejova. Mater. Lett. 204 (2017) 181-183.

-

- 16. G.H. Zhou, G.C. Xu, and J. Liu. Int. J. Adv. Manuf. Tech. 95 (2018) 1677-1684.

- 17. M. Singlard, F. Remondiere, and S. Oriol. J. Sol-Gel Sci. Tech. 87 (2018) 496-503.

- 18. J. Hostasa, V. Necina, and T. Uhlírova. J. Eur. Ceram. Soc. 39 (2019) 53-58.

- 19. X. Wang, Y.J. Zhong, and D. Wang. J. Am. Ceram. Soc. 100 (2017) 1-7.

- 20. J.G. Song, L.M. Zhang, and J.G. Li. Synt. Reac. Inorg. M. 36 (2006) 529-533.

-

- 21. Z.N. Magdalena, and H. Krzystof, Process. Appl. Ceram. 1 (2007) 69-74.

- 22. Y. Liu, Z.F. Zhang, and J. Halloran. J. Am. Ceram. Soc., 81 (1998) 629-645.

-

- 23. S. Bhattacharyya, and S. Ghatak. Ceram. Int. 35 (2009) 29-34.

-

- 24. P. Palmero, and R. Traverso. Mater. 7 (2014) 7145-7156.

-

This Article

This Article

-

2020; 21(4): 488-494

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.488

- Received on Feb 25, 2020

- Revised on May 16, 2020

- Accepted on Jun 10, 2020

Services

Services

- Abstract

introduction

experimental materials and methods

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Jieguang Song a,b, Lin Chen b

-

aSponge City Research Institute of Pingxiang University, Pingxiang 337055 China

bKey Laboratory for Industrial Ceramics of Jiangxi Province, Pingxiang University, Pingxiang 337055 China

Tel : +86 799 6682251

Fax: +86 799 6682171 - E-mail: sjg825@163.com, rymw27@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.