- Evaluation of the crack formation of feldspathic ceramic reinforced with bor chemicals

Mustafa Hayati Atalaa,*, Esma Başak Gül Aygünb and Arife Doğanc

aIstanbul Medeniyet University, Faculty of Dentistry, Department of Prosthodontics, İstanbul, Turkey

bCukurova University, Faculty of Dentistry, Department of Prosthodontics, Adana, Turkey

cGazi University, Faculty of Dentistry, Department of Prosthodontics, Ankara, Turkey

The purpose of the current

study was to improve the mechanical strength and reduce the micro-cracks on the

microstructure of the dentin ceramic through addition of various boron

compounds (borax, boric acid). Following addition of borax and boric acid (1,

2, 3% of the weight percent) to the traditional feldspathic porcelain; crack

lengths, flexural strength and fracture toughness were analyzed. The data

analyses were performed by using one-way ANOVA (p<0.05). Differences between

groups were determined by Tukey HSD. The results of the present study suggested

that the crack lengths were decreased and the fracture toughness were increased

in all boric acid added groups (p<0.05). The group containing 1% boric acid

had significantly decreased the biaxial flexural strength value compared to the

control group (p<0.05). The Vicker’s hardness value of the group containing

1% borax was found to be significantly lower (p<0.05). The present study

demonstrated that various proportions of borax and boric acid addition in

dentin ceramic had reduced the formation of cracks. The current study could be

a good starting point on reinforcement of dental ceramics with a possible

outcome that will reduce the failures of dental restorations.

Keywords: boric acid, borax, feldspathic ceramic, mechanical features

The function, phonation and aesthetic deficiencies

resulting from damage or loss of teeth and surrounding tissues are restored

with appropriate prosthetic restorations. For nearly a hundred years, dentists

have been searching for the ideal restoration material. Although in recent

years, amalgam, composites and restorative cements have been used successfully,

they are not suitable for multi-faceted restorations.

Currently, dental ceramics are widely used in restorative dentistry.

They are used as monolithic restorations, porcelain inlays, onlays and metal

veneering materials due to the material quality and their aesthetic

appearance. Moreover, ceramic materials are chemically stable, have

long-lasting color stability, excellent biocompatibility and have an acceptable

wear resistance.

Dental ceramics are different from other restorative

materials, including metal and acrylic resin, by their chemical, physical,

mechanical and thermal properties. Even though conventional dental ceramics are

resistant to heat, they are fragile. Therefore, they have limited strength and

fracture toughness. Sudden changes in temperature and/or force can result in

fractures [1].

The ceramic used in dentistry is a not fully fused glass

derivative formed by sintering process. The sintering process can be defined as

a complex sequence of high temperature reactions that occur above the softening

point of the porcelain and lead to the partial melting of the glassy matrix by

combining the powder particles [2]. However, during the cooling of the sintered

dental ceramic to room temperature, micro-cracks occur

on the ceramic surface due to the volumetric

contraction of the material. Due to the shortcomings that occur during the

preparation and modeling of the ceramic as well as the faults that occur during

the sintering and cooling in the oven, these micro-cracks may spread to even

the deeper layers. The number, depth, width and even direction of these micro

cracks play an active role on the mechanical strength of the material

[3].Generally, these cracks or defect regions act as zones where stress is

concentrated. Previous cracks or subsequent cracks may result in larger cracks

and their propagation in the presence of stress. Such an expansion of cracks

causes catastrophic failure in material [4]. Fracture toughness is the

mechanical resistance of the brittle material to crack formation and the

destructive propagation of cracks under stress [5]. Therefore,

improving the fracture toughness of porcelain is an utmost

important criterion for extending the clinical performance of porcelain

restorations by improving low fracture strength in the mouth [1]. Recently,

there has been a focus on reinforcing ceramic materials by introducing

particles, whiskers, or fibers into matrix structure to improve the mechanical

properties and prevent crack propagation.

Boric oxide is a glassy solid, does not exist in nature

and is never used in the free state. The value of the boron mines is generally

measured by the amount of B2O3 (boric oxide) and the ones

with a high content of B2O3 are considered to be more

valuable. Borates (Boric oxide) plays an important structural function as a

network former, which is similar to that of silica. Borates with its flux and

binding properties can be used as an initiator for glass formation in that they

reduce the glass viscosity, decrease surface tension and crack

propagation. Moreover, they help to reduce thermal expansion,

and, hence, cause an increase in thermal shock resistance. They increase the

mechanical strength and scratch resistance of ceramic structure and provide

resistance to chemicals. Substituting boric oxide for a portion of the silica

content is a sure means of reducing the melting temperature of the glaze

without causing a devitrivication. Although small amounts of boric oxide

improve the mechanical properties of glaze, larger quantities

have adverse effects on crazing resistance [6-8].

Boric acid and sodium tetraborates are used for the

inserting boric oxide into ceramic structure. Boric acid is an inorganic binder

that is widely used in ceramic industry. Boric acid contains 56.3% boric oxide

[6, 7]. Borax is the most produced refined product after boric acid, which is

used as a strong melting agent in glaze. It reduces the viscosity and surface

tension and creates resistance to scratches, cracks and surface staining. Since

borax and boric acid are resistant to heat, they are used for making heat

resistant materials. Borax contains 36.52% of boric oxide [6-8]. Boric acid and

borax are widely used in glass, porcelain, and ware industry, especially in the

production of special glasses, where certain properties, including heat

resistance, surface hardness and durability, are desired [8].

The aim of the current study is to evaluate the

differences in the mechanical resistance of feldspathic ceramics with the

addition of borax and boric acid in varying amounts because they are so widely

used in glass and porcelain industry.

In this study, different proportions of borax and boric

acid were added into the feldspathic porcelain to examine the crack length,

hardness, flexural strength and fracture toughness. A feldspathic

porcelain [Ceramco 3 (Dentsply Degudent GmbH, USA)] dentin powder,

which is a Type 1 dental ceramic (DIN EN ISO 6872 standard) containing

opacifier, color pigment, 80-95% sodium potassium aluminasilicate and 0-20% tin

oxide, was used as a test material.

Boric acid and borax compounds and dentin porcelain powder

were dispersed in ethyl alcohol in a concentration of 1, 2 and 3%. “Ceramco 3”

commercial dentin porcelain powder by weight was homogenized by sonication for

half an hour in an ultrasonic bath and stirred for 4 hours with a magnetic

stirrer (Heidolph MR Hei-Standart, Nuremberg, Germany). The alcohol was

evaporated off and the samples were dried under vacuum for 24 hours.

Powder mixtures were prepared in 6 groups. Boron acid and

boron free dentin porcelain powder were used as a control group. In each group,

20 disc samples were prepared by using metal molds

(thickness 1.2 ± 0.2 mm; diameter

15 mm), where the sizes were determined by the standards for the flexure

test of Type 1 ceramics. Ten of these samples were used to determine the

biaxial flexural strength, and the rest of the samples were used to detect

Vickers' stiffness and crack size.

The samples were prepared by a baking process, where the

samples were first kept at 650 oC for 4 min with a

temperature rise of 50-70 oC per minute. When the temperature reached

910 oC, baking process was finished

within 2 minutes. The final surface conditioning of the

samples was performed using the diamond burs with a grain size of

15-20 µm. A total of 10 test specimens were prepared for 7 groups with a

thickness of 1.2 ± 0.2 mm and a diameter of 15 mm. After

final surface treatment, the samples were cleaned for 3 minutes in ultrasonic

bath (Euronda; Erosonic Energy, Italy) that contained distilled water.

Biaxial

Flexural Strength Test

For the biaxial flexural strength test, a testing machine

(Instron 5565A, Instron UK, England) with the lower

part containing 3-stainless steel balls (diameter of

2.5 mm) with an angle of 120° between them, was placed on a table

(diameter of 10 mm) and the piston head with a pin having a diameter of

1.4 mm was used. The load was applied vertically to the center of the

sample at a speed of 1 mm /min. A thin and soft film layer was placed

between the sample and the piston head to obtain an even

distribution of the applied forces.

The force at the time the sample got fractured was recorded

in Newton by the computer and then converted to MPa.

Vickers

Hardness Test and Fracture Toughness

After the samples were embedded in acrylic molds, their

surfaces were polished for 30 seconds on a sanding machine (Phoenix Beta,

Buehler, USA) at a speed of 300 rpm by pouring 0.3 µm grain size of

Al2O3 solution on a velvet cloth under cooling water.

Vickers micro hardness tester (Shimadzu HMV-2000, Germany)

was used to measure the Vickers hardness value (VHN)

after a 19.6 N load. Following the hardness tests,

acceptable crack models were examined with SEM (LEO, EVO

40, Cambridge-England). The samples were plated with

gold-palladium (Au-Pd) to determine crack lengths in the coating apparatus

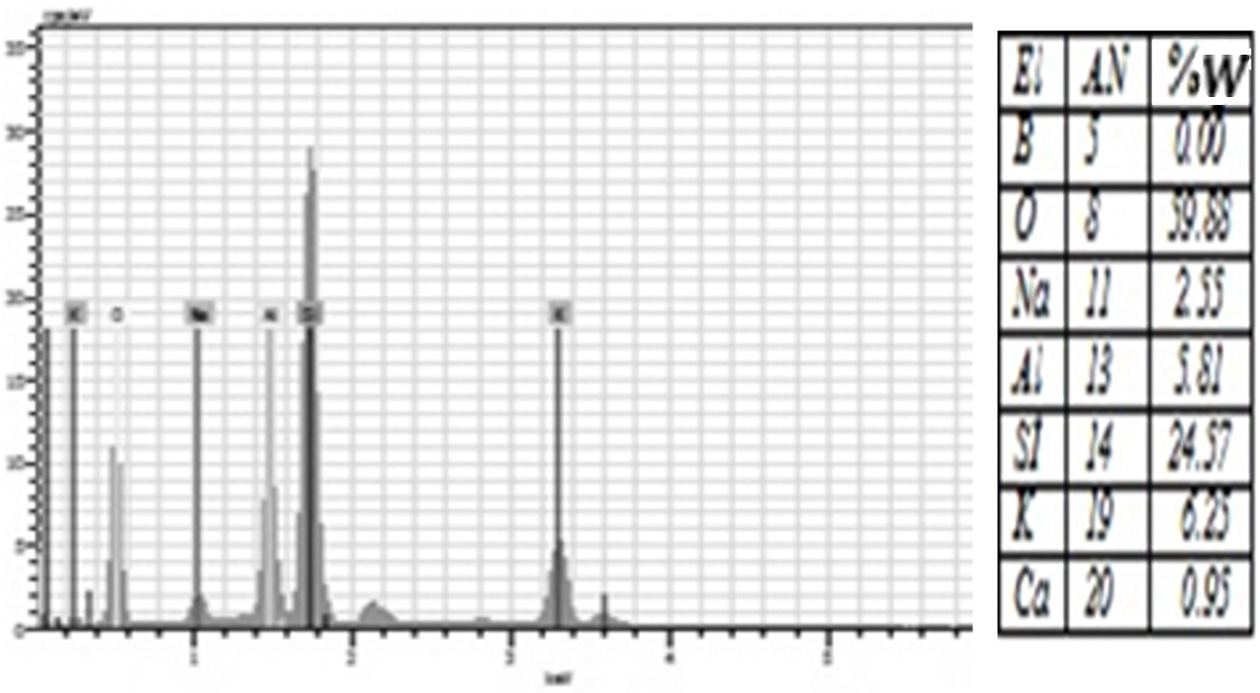

(BAL_TEC; SCD50, Liechtenstein). Chemical analysis of the sintered

samples was done by EDS (Bruker, 125 eV, Minden-Germany) connected to SEM

unit.

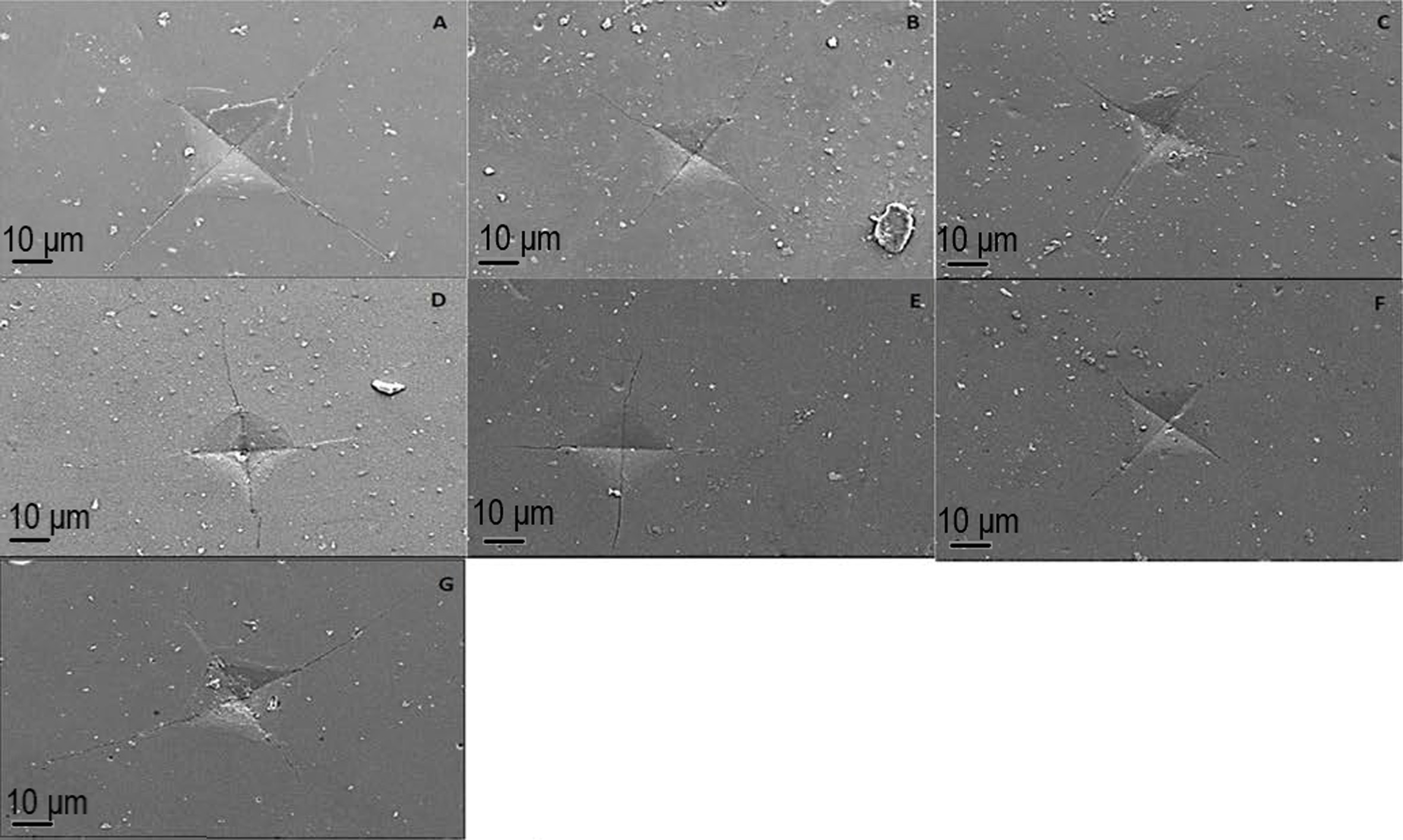

Acceptable crack models were created with a 19.6 N

load with Vickers micro hardness tester (Shimadzu HMV-2000, Germany). It was

noted that the cracks were removed from the corners of the vickers indentation,

but not from the branch. Moreover, the average of the cracks was at least twice

the diagonal length. Reindentations were made for unacceptable crack models.

Crack lengths were determined by SEM device (LEO, EVO 40, Cambridge-England).

For each samples, traces of cracks that did not branch out

of the four corners of the Vickers indentation were measured. The crack length

was measured from the center of indentation in accordance with the literature.

The length of the fissures extending from all four corners were determined by

means of arithmetic mean and the crack length was determined by means of

arithmetic mean of the length of the cracks stretching from the four corners[5,

9]. Then, for the 10 samples in each group, the fracture toughness value was

calculated with the formula found by Anstis et al. [10] and it was expressed in

MPa.m0.5.

In this study, due to the fact that boric acid and borax

additions were as low as 1, 2 and 3% by weight and that the value of the

elastic modulus could not be found exactly, the calculation of fracture

toughness was performed by assuming the constant was 0.88 instead of using E /

H. [11].

Kıc = 0.016 (E/H)0,5 (P/c1,5)

(KIC: Fracture toughness value (MPa.m0.5);

E: Elastic Modulus; H: Hardness; P: Applied Force (N); c: Crack Length (m).

Crystallographic analyzes of the prepared samples were

analyzed using computer controlled X-ray diffrac- tometer (RigakuRadB-DMAX-II, Woodlands-USA).

IBM SPSS for Windows version 22 software was used for

statistical evaluation. The quantitative data definition for the variables were

presented as arithmetic mean (mean) ± standard deviation (SD).

Shapiro Wilk normality test was used to determine the normal distribution of

quantitative data (p>0.05). One-way analysis of

variance was used for intergroup comparison and Tukey

HDS test was used to determine the group that caused the difference.

Statistical significance was accepted as p < 0.05.

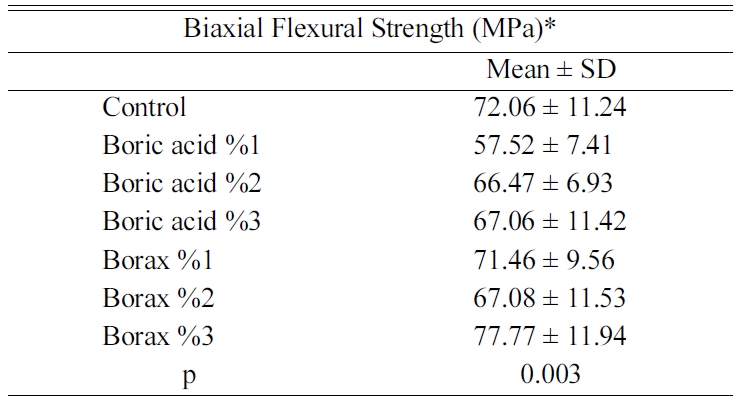

Biaxial

Flexural Strength Test

Biaxial flexural strength test results were presented in Table

1. The results demonstrated a significant difference between the

groups (p = 0.003; p < 0.01). The biaxial flexural

strength values of the group boric acid 1% was found to be significantly lower

than the control group (p = 0.034;

p < 0.05), the borax 1% (p = 0.048;

p < 0.05) and the borax 3%

(p = 0.001; p < 0.01). The mean values of biaxial

flexural strength of the other groups were similar to each other

(p > 0.05).

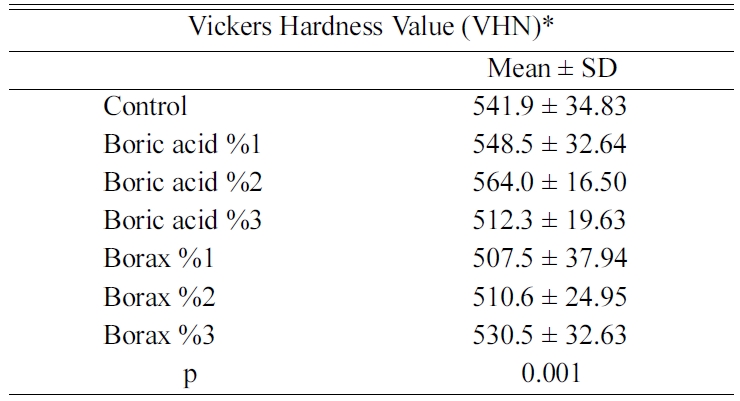

Hardness

Test

The mean and standard deviation values of the hardness

test results are given in Table 2. The Vickers hardness

values of the groups were significantly different

(p = 0.001; p < 0.01). The mean Vickers hardness value

of the group boric acid 2% was significantly higher than the groups of boric

acid 3% (p = 0.004; p < 0.01), borax 1%

(p = 0.001; p < 0.01) and borax 2% (p = 0.003; p < 0.01).

Moreover, the mean Vickers hardness value of the 1% of boric acid group was

significantly different than borax 1% group (p = 0.042;

p < 0.05) The Vickers hardness value was not significantly

different between the other groups (p > 0.05).

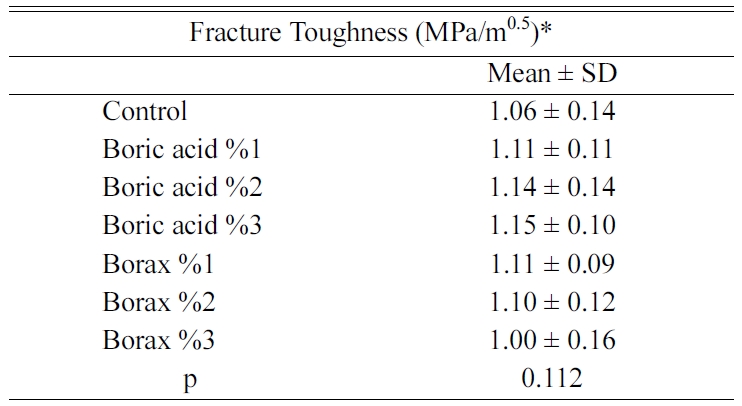

Fracture

Toughness

Fracture toughness values were determined by using crack

length values that were monitored by SEM. Mean and

standard deviation values of fracture toughness are given

in Table 3. SEM images obtained from the groups are also presented in Figure 1.

Although, 1%, 2% and 3% boric acid addition and 1% and 2%

borax addition had increased fracture toughness values, the mean fracture

toughness between the groups were similar to each other (p = 0.112;

p > 0.05).

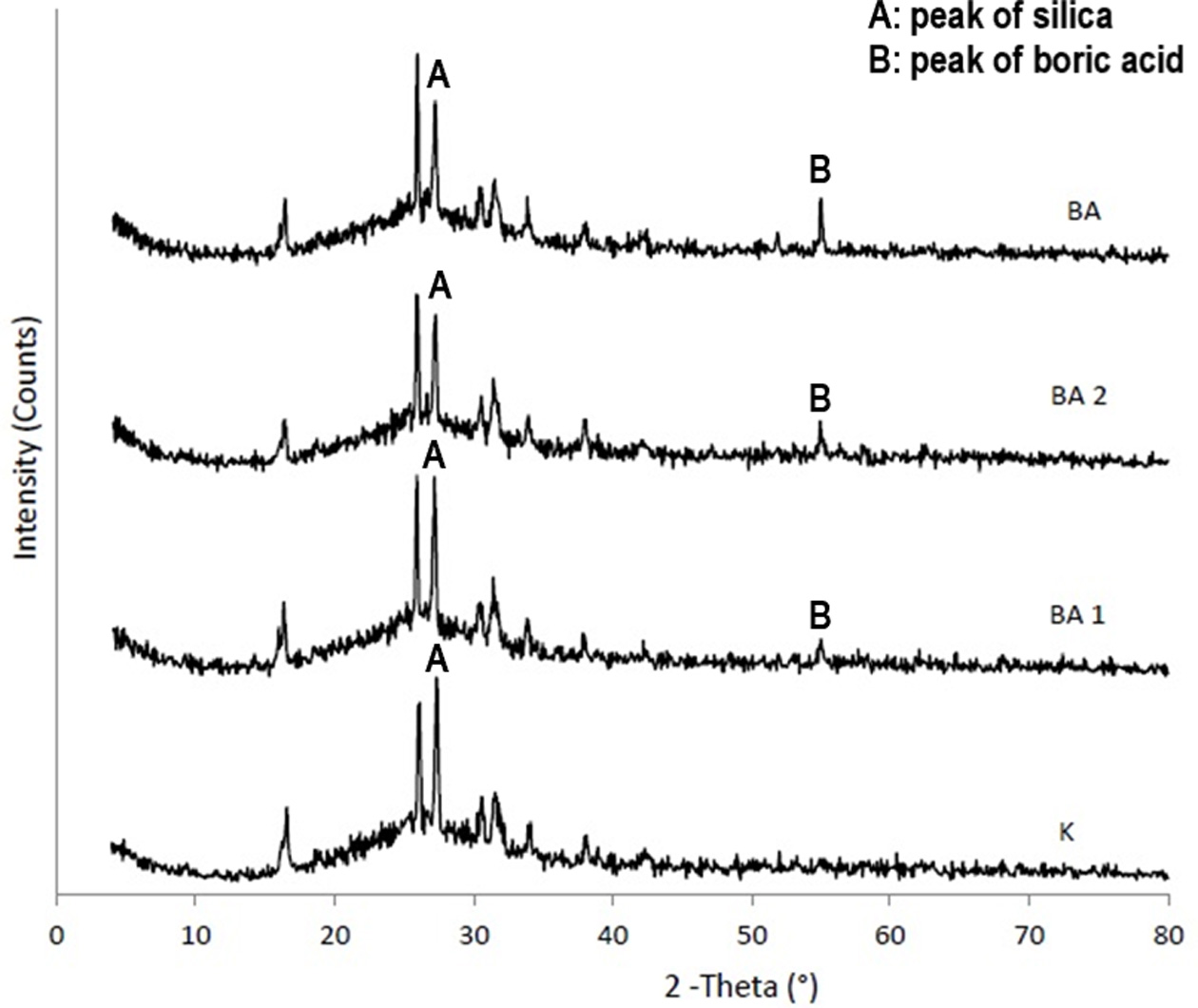

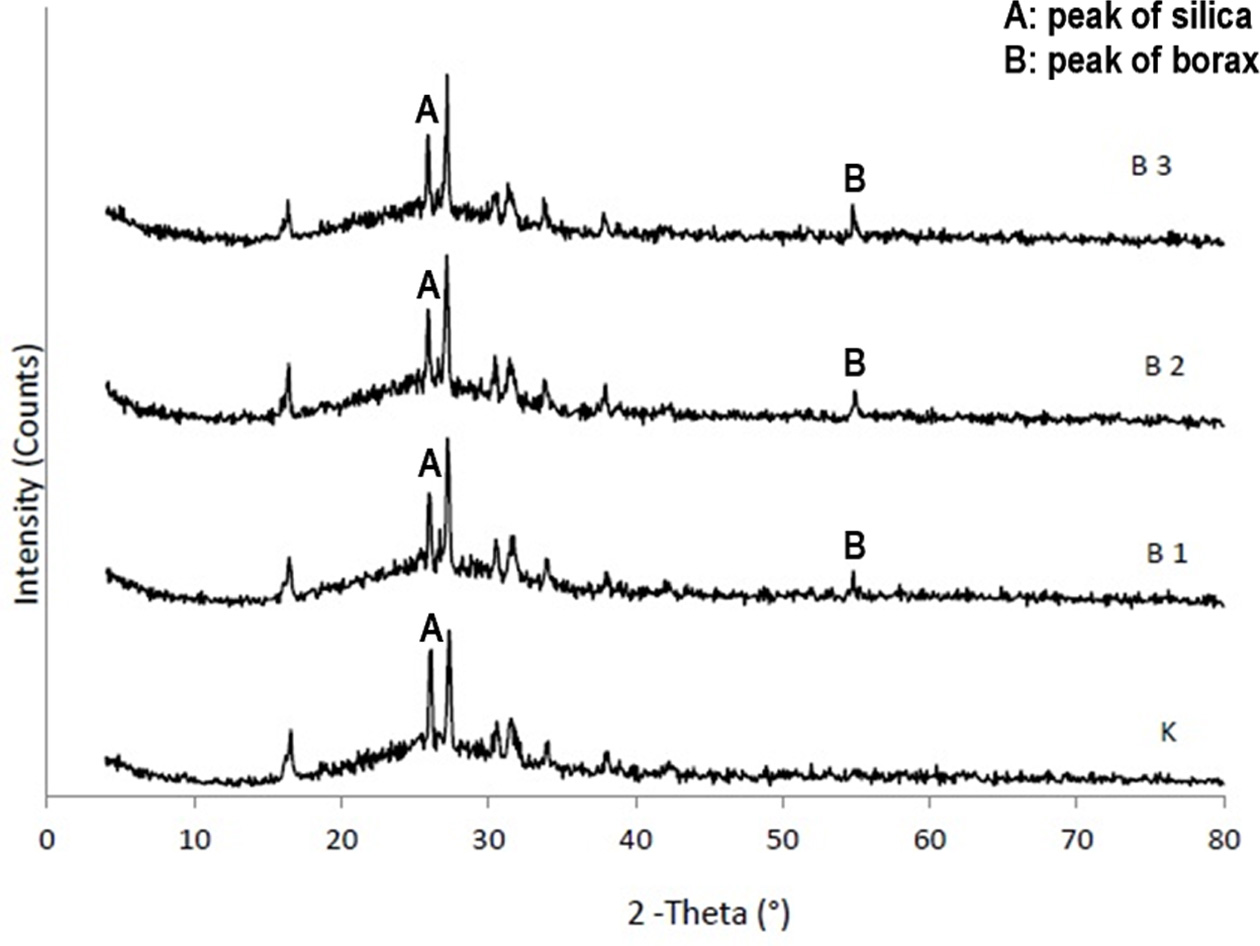

XRD

Analysis

When XRD patterns of boric acid added groups and control

groups in Figure 2 as well as borax added groups and control groups in Figure 3

were examined, it was observed that the main phase was silica. The results

demonstrated that boric acid and borax added to the feldpastic matrix enters

the structure from the decreased intensity of 2q

peaks of silica at 27° and the increased intensity of 2q peaks of boron compounds at 55°.

Since the position and shape of the XRD peaks of the feldpastic phase were

similar, addition of boric acid and borax did not change the crystal structure

of the main phase.

Besides the excellent esthetic features, low tensile and

shear strength of ceramic restorations makes them fragile

during chewing. The main reason for the failures is the

formation of cracks and their propagation [12]. Feldspathic porcelain is the

most commonly used ceramic in dentistry. However, containing large

amounts of glassy phase reduces its

durability [13, 14]. Therefore, ceramic restorations are subjected

to firing in the laboratory. During the cooling of the restorations to the room

temperature, volumetric contractions in the material caused the formation of

micro cracks on the surface of the porcelain. These micro cracks can

propagate even deeper. In addition, the final conditioning of the

restoration surface also adversely affects the micro cracks. As a result, the

negative impact of the layer containing the micro-cracks further changes the

mechanical properties of the ceramic material [3, 15].

Boron compounds are used to strengthen the mechanical

properties of ceramics. Boron oxide may undergo normal glass form, but it is

generally used as a binder and network former. Borate plays a significant role

in glazing technology and is the second most important constituent after the

silica. It has been reported that strength to the mechanical resistance and

scratch formation increases with the amount of borate in the content of ceramic

glazures [6].

Boron oxide (B2O3) acts as a glass

modifying agent by reducing the viscosity and softening temperature of the

silica network, such as alkali metal ions. Boron oxide has its own network

structure, which enters between the three-dimensional silica

network structures. Such silica tetrahedrans is partially degraded by

the boron-oxygen (-Si-O-B-) interaction occured between oxides in silica

tetrahedral and boron compounds. This allows coefficient of softening

temperature and thermal expansion of silica network structure to decrease

compared with pure silica [16].

Boric acid and borax are inorganic binders which are

widely used in ceramic industry [7, 17]. It is stated in the literature that

they provide resistance to scratches, cracks and surface staining by decreasing

viscosity and surface tension [7, 17, 18]. In previous studies, the amount of

boric acid used ranged between 1% and 3% by weight [7, 18].

Structures with a low coefficient of thermal expansion

have higher thermal shock resistance due to less stress [19]. Therefore, dental

ceramics have low thermal shock resistance, since they have high expansion

coefficient. In the current study, the addition of boric acid and borax, which

has its own network structure, was expected to reduce thermal expansion

resistance and decrease the formation of cracks by lowering the thermal

expansion coefficient in the silica structure of feldspathic porcelain.

It was determined that the crack lengths were generally

reduced by 1, 2 and 3% boric acid addition, respectively.

The crack lengths demonstrated a tendency to reduce

with the addition of 1% and 2% borax, but the

difference was not statistically significant. Moreover, the

addition of 3% borax was found to increase the crack length. Since each group

was treated with similar final surface conditioning process, it could mimic the

difference between the groups. However, glaze application

in future studies can provide better understanding.

One of the factors affecting the mechanical behavior of

ceramics against forces is the presence of crystal structures such as alumina,

leucite and zirconium oxide [20-22]. These crystals arrest the progression of

cracks within the structure, since it is difficult to penetrate into the

crystal [1]. Because dental ceramics contain a high proportion of glassy

phases, cracks can easily progress further. However, alumina particles, which

are added to the ceramic structure, are more difficult to break than glass, a

higher amount of energy is required for the formation of fracture. Hence, it

makes the crack pro- gression

more difficult. Therefore, alumina-glass composi- tion is twice as endure as the

glass phase [22-24].

Hammouda and Beyari [25] added yttrium, which is a

partially stable zirconium, to the conventional dental porcelain by 3, 5 and 7%

by mass and reported that 3 and 5% addition elevated the flexural resistance

but decreased the hardness and increased its radiopacity. Some researchers have

added wollastonite, which is an industrial mineral and defined as natural

calcium metasilicate, and reported that the addition of 2% wollastonite to the

porcelain powder increases the flexural resistance of the dental alumina or

porcelain [26]. Moreover, Medeiros et al. [27] performed

reinforce- ment studies

with porcelain and reported that addition of Gadolinium Aluminum Perovskit

(GdAlO3 / Al2O3) fibers increased the

resistance of porcelain. Bayca [17] reported that addition of ulexite, is a

boron mineral, to ceramic body decreased the sintering temperature of the

tiles, however there is an increase in the bending strength of the ceramic

tiles.

Boric acid and borax have a similar structure with silica

and they are used as a dissolver in ceramic industry. Therefore, the aim of the

present study was to investigate the effects of the addition of crystalline

boric acid and borax compounds on the mechanical properties of feldspathic

porcelain.

The International Organization for Standardization (ISO

6872) proposed and assigned the biaxial flexural strength examination with a

three-point bending test to measure the flexural resistance (flexing endurance)

of dental ceramics [28]. The three point bending test is susceptible to cracks

and superficial pits formed on the sample surface and edges as the samples are

prepared. The formation of these cracks, defects and pits on the surface

significantly affect the results that will be analyzed [9, 29, 30]. In

addition, the fact that the dimensions and volumes of the samples are very

different from those of dental restorations and the risk of porosity formation

during the preparation of samples are also disadvantages of this method [31].

For these reasons, in the present study, biaxial flexuaral strength test was

preferred to determine the flexural resistances of the disc-shaped samples in

accordance with the 6872 standard prepared by ISO for durability testing.

Feldspathic porcelain is the most widely used dental

ceramic, but its flexural resistance is only between 60 and 70 MPa;

therefore, it requires a metal infrastructure to be strengthened [32]. Many

studies have been conducted to investigate the mechanical properties of

feldspathic porcelain [33-35]. In our study, piston test was used on three balls

and in parallel with the literature, the flexural resistance of conventional

felds- pathic Ceramco 3 porcelain used

for the control group was established to be 72.06 ± 11.24 MPa.

It is deter- mined that all values

found in the test result are above 50 MPa, which is the lowest value according

to ISO 6872 “Dental Ceramics” standard, and it is compatible with dental

ceramic standard.

The atomic bonds in the ceramic crystal are both covalent

and ionic and have no free electrons. These strong atomic bonds provide

stability, hardness and resistance to chemicals. However, they adversely affect

other conditions, including low thermal conductivity and increased fragility

[36].

In our study, it was observed that 2% and 3% boric acid

additions did not cause a significant change in flexural resistance

(p = 0.003; p < 0.01). The flexural resistance of the

feldspathic porcelain group with 1% boric acid was found to be

57.52 ± 7.41 MPa and was significantly lower than the control

group (p = 0.034; p < 0.05). The results of the current

study showed that the addition of 1% boric acid did not reduce the hardness of

the structure. It is thought that the silica tetrahedrals in the

three-dimensional network structure may have reduced the amount of Si-O

binding. As a result, the atomic bonds in the ceramic crystal may stay

stronger.

Although flexural–strength was similar between the control

and borax added groups (p = 0.003; p < 0.01), a

numerical increase was observed with the addition of 3% borax compared to the

control group. The addition of 3% borax may have entered the complex with its own

cage structure by greatly reducing the Si-O connec- tions and covalent bonds in

the three-dimensional network composition of the silica tetrahedrals. While it

decreases the stability and hardness of the material, borax slightly increases

flexural resistance due to its unique lattice structure. The hardness of the

materials are directly related to the crystal structures and bond strength

between atoms. As the bond strength increases, the hardness

of the minerals increases[37].

The hardness value of the restorative materials used in

the mouth is important. If their hardness is higher than that of dental enamel,

they can cause damage to the natural teeth. Therefore, the hardness value of

the material should be close to the enamel. On the other hand, if the hardness

value of the ceramic material is higher than that of the enamel, then the

abrasion effect is reduced with the glaze layer[37,38].In the light of these

findings, in the present study, Vickers hardness test method was used

considering the fragile and sensitive structure of dental ceramics. Moreover,

cracks were determined by Vickers hardness measuring device.

In this study, the hardness value of Ceramco 3 feldspathic

porcelain and the hardness value of boric acid and borax added feldspathic

porcelain samples were compared. The hardness value of 1% and 2% of borax added

groups were significantly lower than the control group (p = 0.042;

p < 0.05). The decrease in the 3% borax added group was not

statistically significant (p > 0.05). The addition of 1, 2, and 3%

borax through its cage structure reduced Si-O connections in the three-dimensional

network structure of silica tetrahedrals. However, it

is believed that this application reduced the strength of the atomic

connections in the ceramic crystal and decreased the hardness. In addition, the

addition of 1, 2, and 3% of borax did not have any effect to

increase the abrasiveness of feldspathic porcelain.

On the other hand, the addition of 1 and 2% of boric acid

showed no significant difference in the hardness value of the control group. It

is thought that it did not decrease the stability and hardness of the structure

by reducing the Si-O connections that affect the stability of

the ceramic structure. However, its addition improves the amount.

It can be claimed that the addition of 3% boric acid greatly reduced the Si-O

connections in the three-dimensional network of the silica tetrahedrals.

Moreover, its addition also reduced the softening temperature,

the expansion coefficient, and atomic bonds while

decreasing the intermittent space, thus reducing the hardness.

The indentation fracture toughness technique is relatively

simple to apply; it only requires a smoothly polished surface for the sample to

be measured. When the literature is examined, it is seen that this technique is

generally used to determine the fracture toughness of ceramic materials

[39-42]. Therefore, in the current study, indentation fracture toughness test

method was used to evaluate fracture toughness.

Hammouda and Beyari [25] evaluated the fracture toughness

of conventional dental porcelain, which was treated with

3, 5 and 7% of yttrium stabilized tetragonal zirconium

polycrystalline (Y-TZP). Their results showed that the

fracture toughness value of the conventional feldspathic

porcelain was 0.538 ± 0.049 MPa.m0.5. However,

the fracture toughness values of 3, 5 and 7% yttrium partially stable zirconium

addition groups were 1.424 ± 0,064 MPa.m0,5,

0.782 ± 0.106 MPa.m0,5, 0.489 ± 0.069 MPa.m0,5

respectively. These results suggest that increased particle

size reduces the fracture toughness when other microstructural variables are

assumed constant.

Yoshimura et al. [43] evaluated the fracture toughness of

high heat alumina core ceramics, feldspathic porcelain, hot press

leucite based glass ceramics, glass ceramics and glass infiltrating alumina

ceramics reinforced with hot press lithium disilicate according to Astm e399

standards. The fracture toughness values were 0.67 ± 0.08 MPa.m0,5,

0.84 ± 0.07 MPa.m0,5, 0.96 ± 0.03 MPa.m0,5,

1.81 ± 0.18 MPa.m0,5 and

2.91 ± 0,20 MPa.m0,5, respec- tively. Researchers have stated that the

materials they used may have different mechanical properties and that the

highest fracture toughness value of glass infiltrating alumina ceramic may be

related to the high elastic modulus and fracture surface energy.

In this study, the fracture toughness value of the control

group was 1.06 ± 0.14 MPa.m0.5, while the fracture

toughness values of 1, 2, and 3% boric acid added groups were

1.11 ± 0.11 MPa.m0.5, 1.14 ± 0.14 MPa.m0.5,

1.15 ± 0.10 MPa.m0.5, respectively.

Although there was a quantitative difference between the groups, it was not

statistically significant. With the addition of boric acid, the Si-O connection

amount of the silica tetrahedrals in the three-dimensional network structure

could be reduced as well as the softening temperature and thermal expansion

coefficient of the porcelain may also be decreased. Thus, the distance between

the particles has diminished and the crack propagation may have been more

difficult. Therefore, it is thought that the fracture toughness of the

structure may be elevated. In addition, boric acid has a less complex

structure, which has a better penetration into the silica structure and higher

ability to fill the gaps in the structure. As a result, elevated fracture

toughness may be resulted in increase of the numerical value.

Similar effects were achieved with 1 and 2% Borax

additions. While the fracture toughness of the ceramic structure is increased,

the addition of 3% borax may significantly reduce the connections

and covalent bonds in the Si-O network which affect the

stability of the ceramic structure and damaged it. As a result, the fracture toughness

value was reduced. Moreover, with the wider lattice structure of borax,

interactions within the structure have been reduced with respect to particle

sizes. As a result, the fracture toughness value may be decreased as the

percentage by weight in the structure increases.

On the other hand, the fracture toughness values of

feldspathic porcelain with 1, 2 and 3% borax added groups were

1.11 ± 0.09 MPa.m0.5,

1.11 ± 0.09 MPa.m0,5 respectively.

It was determined that the addition of borax in the ratio of 1% and 2% in

fracture toughness value was 1.00 ± 0.16 MPa.m0,5,

but this increase was not statistically significant. However, the addition of

3% borax was found to cause a relative decrease in fracture toughness.

Several techniques have been proposed in the literature to

examine the formation and length of cracks in dental materials. These are SEM,

light microscope, a convergent laser scanning microscope and transillumi- nation (posterior light imaging) technique

[44-46]. Among them, SEM analysis is an effective and widely accepted method

for the examination of properties, such as surface topography, dispenser and

connections [47]. Therefore, in the present study, SEM technique was used to

determine the crack length. Moreover, chemical analyses of samples were

evaluated with EDS detector connected to SEM unit.

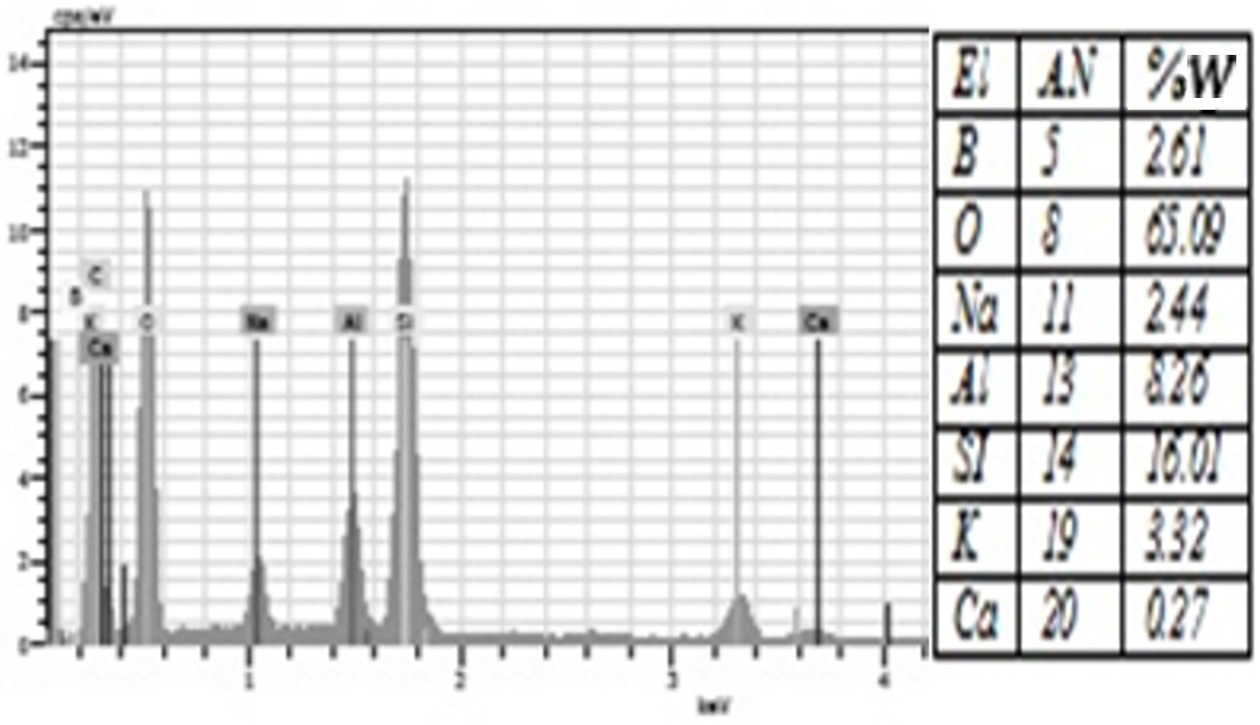

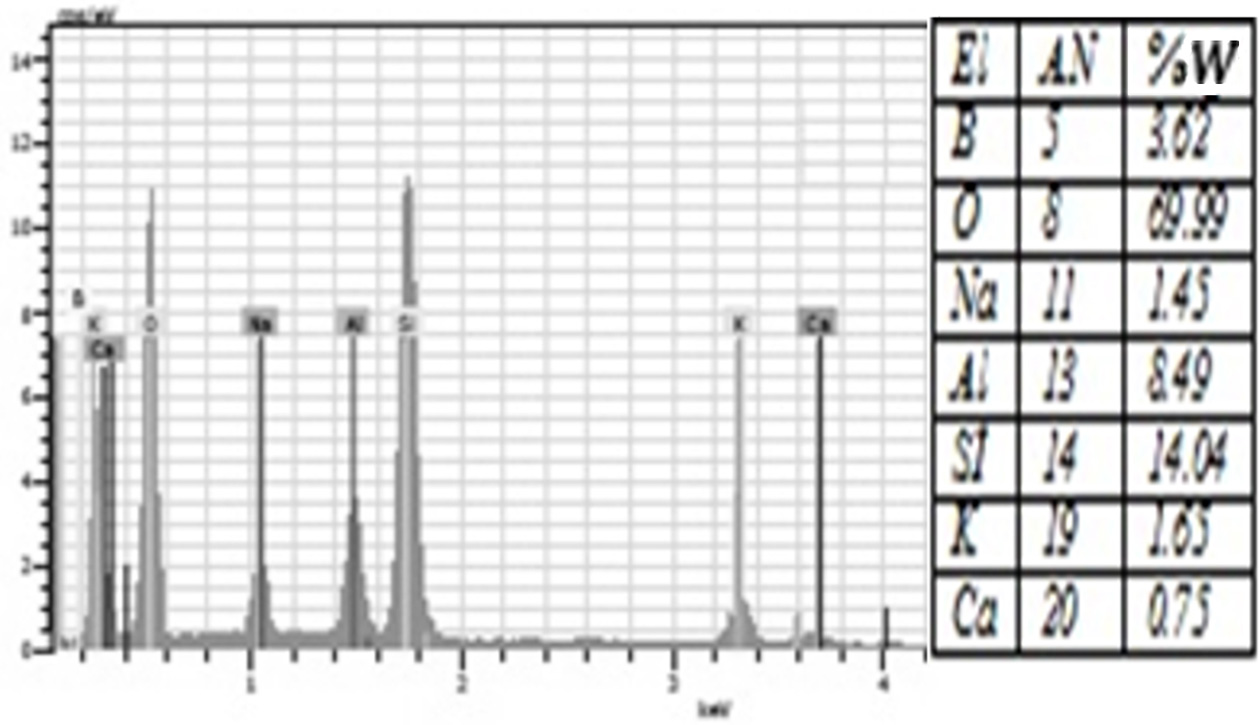

It has been observed that using Vickers micro hardness

device, traces were formed within cracks that did not progressively advanced

through porosities. The image of these traces is consistent with the literature

[5]. In addition, images of boric acid and borax added groups were uniform and

homogeneous that were consistent with the image of the

unadulterated feldspathic porcelain group. These results

suggested that boric acid and borax additions did not damage the feldspathic

porcelain structure. Moreover, EDS analysis showed that all groups were rich in

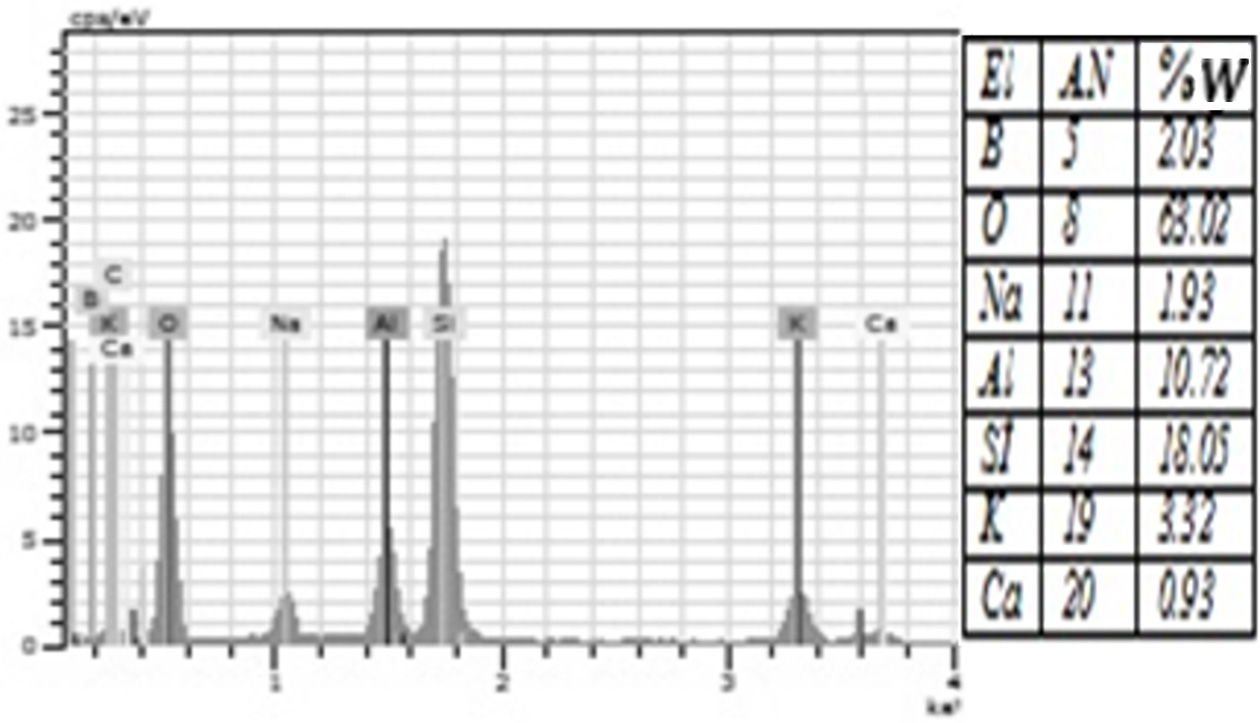

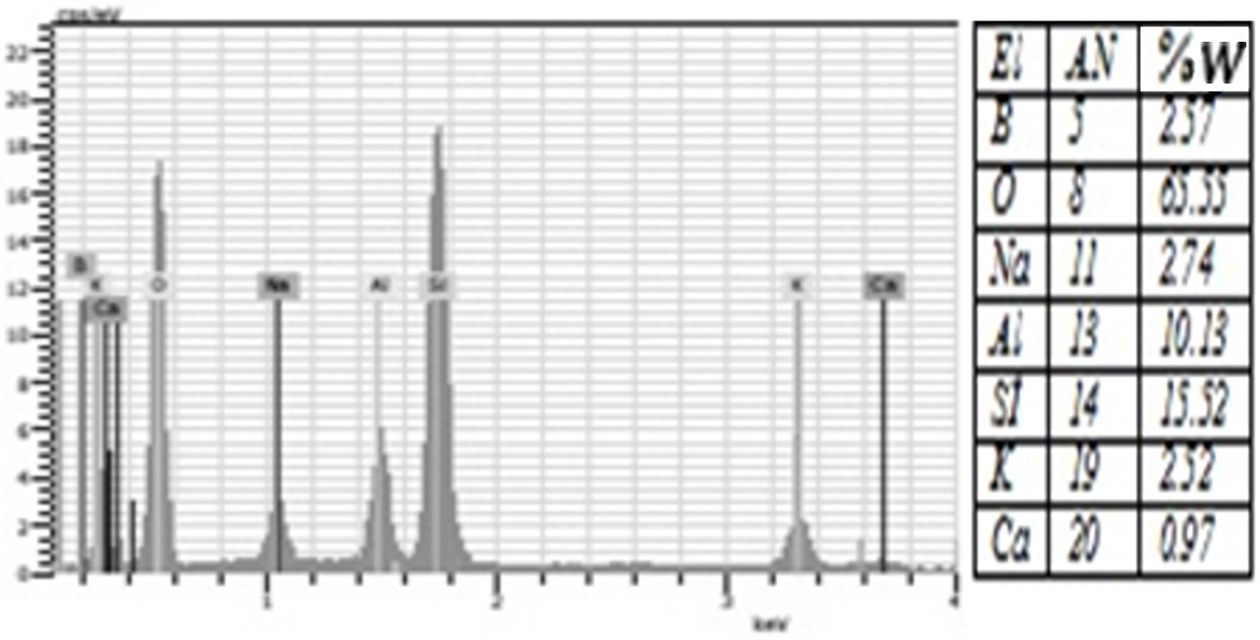

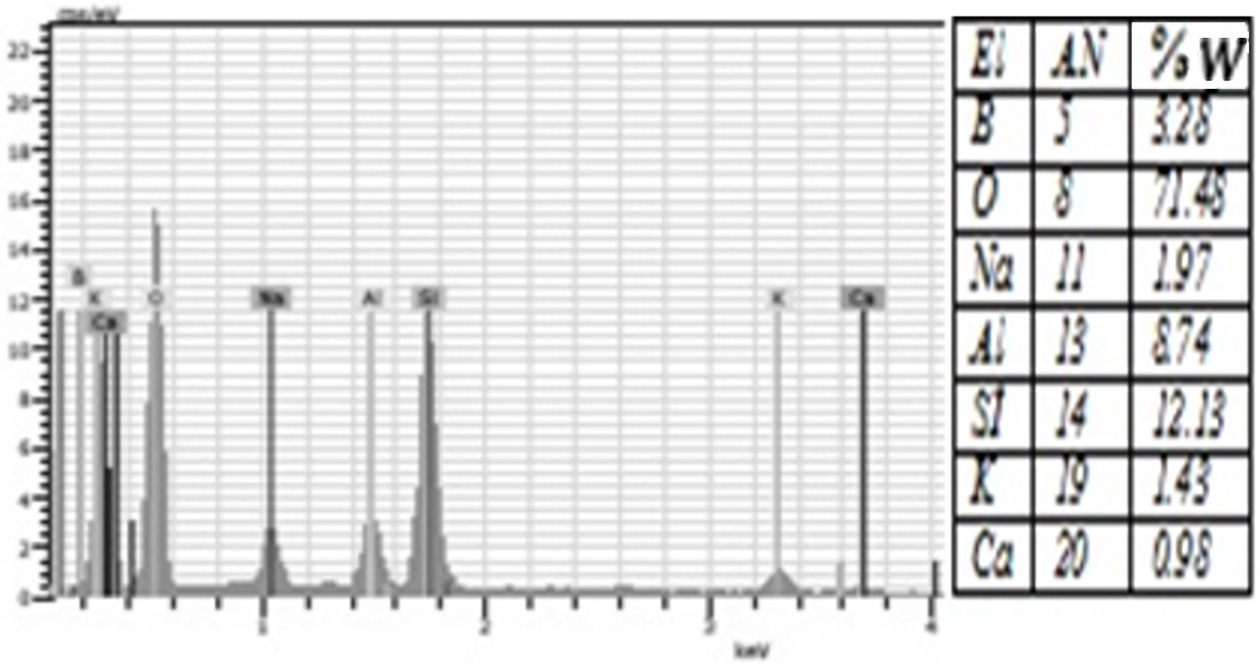

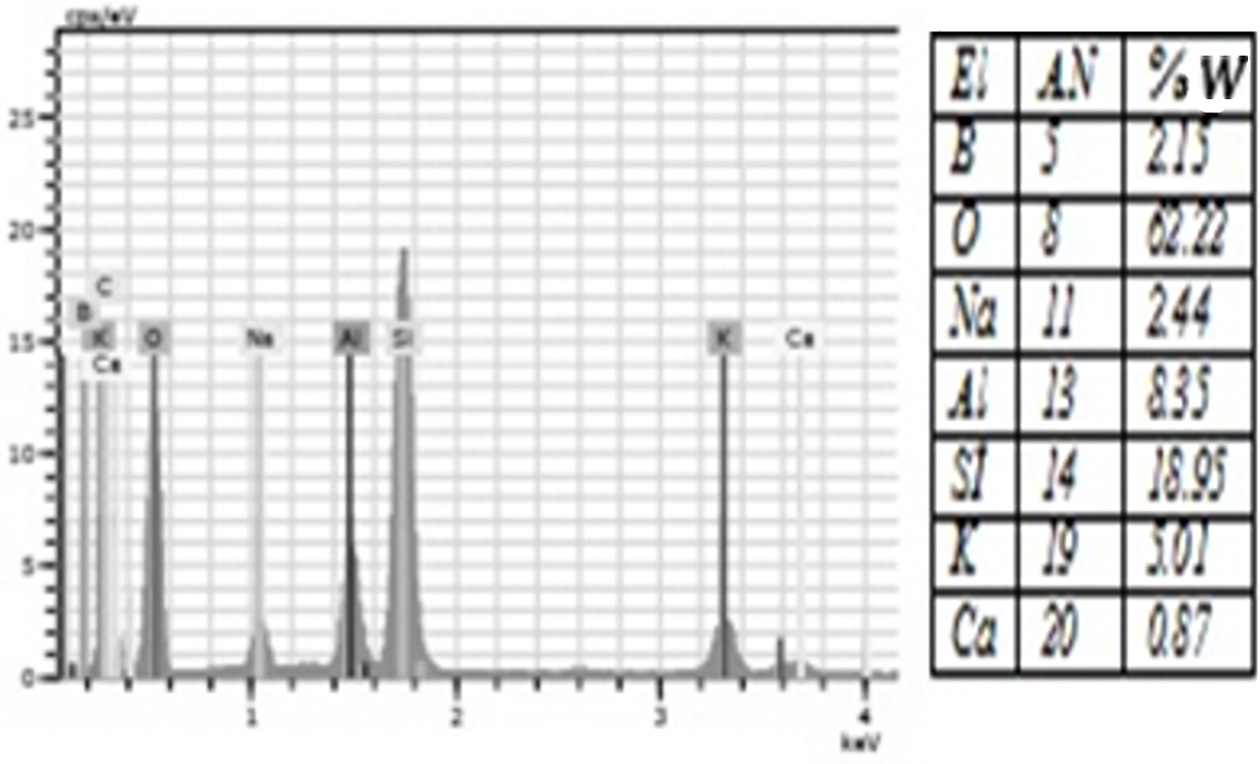

silicon and oxygen elements (Figure 4-10). The detection of boron in

borax and boric acid added groups following the analyses of

individual elements suggested the involvement of borax and boric acid in the

porcelain structure.

X-ray diffraction method (XRD) is widely used to determine

different crystal structures and knitting parameters in the materials. In the

present study, XRD analyzes were performed to investigate the effect of boron

compounds on ceramic structure. When the XRD graphs were obtained from sintered

unadulterated feldspathic porcelain group, the boric acid and borax added

groups were examined. It was observed that the silica was

the main phase. These findings are compatible with the

structure of the feldspathic porcelain and also support the result of EDS

analysis. XRD patterns of borax and boric acid added groups were different from

the control group. The entrance of boric acid and borax to the Feldpastic

matrix was observed from decreased intensity of the 2q

peak of silica at 27° and from the 2q

peaks of boric acid or borax at 55°. As the positions and shapes of XRD peaks

of the Feldpastic phase did not change, it was concluded that addition of borax

and boric acid did not change the crystal structure of the main phase. The SEM

images of the sintered porcelain samples obtained from the control, borax and

boric acid groups support that the crystal structure did not change. In

addition, XRD results are consistent with EDS analysis results.

Fig. 5 Fig. 6 Fig. 7 Fig. 8 Fig. 9

|

Fig. 1 SEM images of crack formation on sintered samples. (A) SEM Image (×1000) of crack formation in control group at (B) SEM Image (×1000) of crack formation in %1 boric acid added group (C) SEM Image (×1000) of crack formation in %2 boric acid added group, (D) SEM Image (×1000) of crack formation in %3 boric acid added group, (E) SEM Image (×1000) of crack formation in %1 borax added group, (F) SEM Image (×1000) of crack formation in %2 borax added group, (G) SEM Image (×1000) of crack formation in %3 borax added group. |

|

Fig. 2 Comparative XRD results of boric acid added groups compared with control group. |

|

Fig. 3 Comparative XRD results of borax added groups compared with control group. |

|

Fig. 4 The amount of elements contained in the control group according to EDS analysis. |

|

Fig. 5 The amount of elements contained in the %1 Boric Acid group according to EDS analysis. |

|

Fig. 6 The amount of elements contained in the %2 Boric Acid group according to EDS analysis. |

|

Fig. 7 The amount of elements contained in the %3 Boric Acid group according to EDS analysis. |

|

Fig. 8 The amount of elements contained in the %1 Borax added group according to EDS analysis. |

|

Fig. 9 The amount of elements contained in the %2 Borax added group according to EDS analysis. |

|

Fig. 10 The amount of elements contained in the %3 Borax added group according to EDS analysis. |

Within the limits of current study, reinforcement of

feldspathic ceramic with small quantities of boric acid or borax resulted in an

increased fracture toughness value compared to the control group. This may

indicate that boron products also have fluxing effect on dental ceramics. On

the other hand, biaxial flexural strength of feldspathic ceramic decreased with

the addition of varied amounts boric acid and borax but was not significant

compared to the control group. It is considered that the

current study could be a good starting point for future studies on

reinforcement with boron compounds of feldspathic dental ceramic

and innovation of different high technology dental ceramics

with strengthening properties.

This study was supported by İnönü University Scientific

Research Project Department (Project no: 2013/185).

- 1. K.J. Anusavice, C. Shen, and H.R. Rawls, in “Phillips' science of dental materials” (Elsevier Health Sciences, 2013) p.418-474.

- 2. I.L. Denry, Crit. Rev. Oral Bio. Med. 7 (1996) 134-43.

-

- 3. K. Anusavice and B. Hojjatie, J. Dent. Res. 70 (1991) 1009-1013.

-

- 4. M. Albakry, M. Guazzato, and M.V. Swain, J. Biomed. Mater. Res., Part B 71 (2004) 99-107.

-

- 5. S.S. Scherrer, I.L. Denry, and H.A. Wiskott, Dent. Mater. 14 (1998) 246-255.

-

- 6. S. Stefanov, Glass Tech. 41 (2000) 193-196.

- 7. Ö. Cengiz and A. Kara, AKU-J. Sci. Eng. 9 (2009) 29-35.

- 8. S. Cook, in “Ceramic engineering and science proceedings” (Wiley Online Library, 2002) p.47-55.

-

- 9. H. Yilmaz, C. Aydin, and B.E. Gul, J. Prosth. Dent. 98 (2007) 120-128.

-

- 10. G. Anstis, P. Chantikul, B.R. Lawn, and D. Marshall, J. Amer. Cer. Soc. 64 (1981) 533-538.

-

- 11. P. Chantikul, G. Anstis, B.R. Lawn, and D. Marshall, J. Amer. Cer. Soc. 64 (1981) 539-543.

-

- 12. M.A. Rosenblum and A. Schulman, J. Amer. Dent. Assoc. 128 (1997) 297-307.

-

- 13. R. Seghi, T. Daher, and A. Caputo, Dent. Mater. 6 (1990) 181-184.

-

- 14. L.K. Weinstein and A.B. Weinstein, US Patent No. 3,052,982 (1962).

- 15. R. Cook, B. Lawn, T. Dabbs, and P. Chantikul, J. Amer. Cer. Soc. 64 (1981) C-121-C-122.

-

- 16. M. Kah, in “Comparison of Surface Treatments on the Strength of Dental Porcelain”. (The University of Sydney, 1992) p.11.

- 17. S.U. Bayca, J. Ceram. Process. Res. 10 (2009) 162-166.

- 18. T. Aydın and A. Kara, AKU-J. Sci. Eng. 9 (2009) 53-60.

- 19. R.E. Loehman, in “Characterization of ceramics” (Momentum Press, 2010) p.169-187.

- 20. A.S.C. Nathan, R. Tah, and M.K. Balasubramanium, J. Oral Biol. Craniofac. Res. 8 (2018) 221-224.

-

- 21. R. Tokunaga, H. Takahashi, N. Iwasaki, M. Kobayashi, K. Tonami, and N. Kurosaki, Dent. Mater. J. 27 (2008) 347-355.

-

- 22. H. Fischer and R. Marx. J. Dent. Res. 80 (2001) 336-339.

-

- 23. W.J. O'Brien, in “Dental materials and their selection” (Quintessence Publishing Company, 2002) p.212-229.

- 24. A. Shenoy and N. Shenoy, J. Conserv. Dent. 13 (2010) 195.

-

- 25. I.M. Hamouda and M.M. Beyari, Int. J. Sci. Re.s Know. 1 (2013) 404.

-

- 26. N.V. Asar, T. Korkmaz, and E.B. Gül, Mater. Des. 31 (2010) 2540-2545.

-

- 27. I.S. Medeiros, L.A. Luz, H.N. Yoshimura, P.F. Cesar, and A.C. Hernandes, J. Mech. Beh. Biomed. Mater. 2 (2009) 471-477.

-

- 28. ISO, No. 6872 (2008) p.11-21.

- 29. B. Ersu, M. Yenigül, and I. Tulunoğlu, J. Hacettepe Univ. Fac. Dent. 31 (2007) 71-78.

- 30. A. Miller, J. Long, B. Miller, and J. Cole, J. Prosth. Dent. 68 (1992) 38-41.

-

- 31. J.R. Kelly, Dent. Mater. 11 (1995) 103-110.

-

- 32. J.W. McLean, Oper. Dent. 16 (1991) 149-156.

- 33. R.A. Giordano, L. Pelletier, S. Campbell, and R. Pober, J. Prosth. Dent. 73 (1995) 411-418.

-

- 34. M.A. Kılıçarslan and A. Zaimoğlu, J. Istanbul Univ. Fac. Dent. 32 (1998) 28-33.

- 35. R.R. Seghi, J.A. Sorensen, R. Seghi, and J. Sorensen, Int. J. Prosth. (1995) 8.

- 36. A. Zaimoğlu, G. Can, E. Ersoy, and L. Aksu, in “Diş hekimliğinde maddeler bilgisi” (AÜ Publisher, 1993) p.515.

- 37. J.D. Hudson, G.R. Goldstein, and M. Georgescu, J. Prosth. Dent. 74 (1995) 647-654.

-

- 38. D. Jagger and A. Harrison, J. Prosth. Dent. 72 (1994) 320-323.

-

- 39. A.S. Rizkalla and D.W. Jones, Dent. Mater. 20 (2004) 198-206.

-

- 40. J. Gong, Z. Zhao, and Z. Guan, J. Euro. Cer. Soc. 21 (2001) 941-946.

-

- 41. G. Elssner, H. Hoven, G. Kiessler, and P. Wellner, in “Ceramics and ceramic composites: materialographic preparation” (Elsevier, 1999) p.151-153.

-

- 42. M. Guazzato, M. Albakry, S.P. Ringer, and M.V. Swain, Dent. Mater. 20 (2004) 441-448.

-

- 43. H.N. Yoshimura, C.C. Gonzaga, P.F. Cesar, and W.G. Miranda Jr, Ceram. Int. 38 (2012) 4715-4722.

-

- 44. M.K. Etman. J. Prosthodontics 18 (2009) 550-559.

-

- 45. N. Beck, F. Graef, O. Gerstbrein, and M. Karl, J. Prosth. Dent. 104 (2010) 301-305.

-

- 46. I. Denry, J. Mackert Jr, J. Holloway, and S. Rosenstiel, J. Dent. Res. 75 (1996) 1928-1935.

-

- 47. D. Xie, W. Brantley, B. Culbertson, and G. Wang, Dent. Mater. 16 (2000) 129-138.

-

This Article

This Article

-

2020; 21(4): 407-415

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.407

- Received on Nov 25, 2019

- Revised on Mar 11, 2020

- Accepted on Mar 16, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Mustafa Hayati Atalaa

-

Istanbul Medeniyet University, Faculty of Dentistry, Department of Prosthodontics, İstanbul, Turkey

Tel : +90-216-280-3803

Fax: +90-216-602-28-05 - E-mail: hayatiatala@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.