- Influences of polymers on the properties of cement-sodium silicate grouts with a high water-binder ratio

Rongfeng Lin, Lei Yang*, Shucai Li, Rangjie Li, Xiangchao Sheng and Guangxiao Song

Geotechnical & Structural Engineering Research Center, Qianfoshan Campus, Shandong University, Lixia District, Jinan City, Shandong Province, China

This study investigates the

influence of redispersible latex powder and hydroxy propyl methyl cellulose on

the physical and mechanical properties of cement-sodium silicate grouts with a

high W/B ratio. The rheological properties, setting time, compressive strength,

autogenous shrinkage sulfate attack resistance and permeability of the grouts

were assessed and compared. The microstructures were investigated in terms of

crack development. The results show that satisfactory properties and

durability, such as an initial setting time extension of 20~55%, an autogenous

shrinkage reduction of 0.332~1.21‰, and a permeability addition of

0.1–0.4 MPa, were obtained in cement-sodium silicate grouts with the

addition of two polymers. The flexural strength of cement-sodium silicate

grouts with redispersible latex powder was improved after curing in water and

sulfate attack by 3 wt% sodium sulfate. However, the addition of two polymers

reduced the compressive strength of all grouts except for the redispersible

latex powder content of 3%. These research results can provide a technical

reference for grouting material selection and mixing ratio adjustment.

Keywords: Cement sodium silicate grout, Redispersible latex powder, Hydroxy propyl methyl cellulose, Physical and mechanical properties, Microstructure

Cementitious grouts are often used for geological

strengthening and water control (GSWC) in grouting reinforcement engineering based

on cost, application technology and environmental

conservation. For resisting dilution and

scour of moving water during grout injection, rapid

setting times and accelerators are required [1, 2]. Sodium silicate solution

(SSS) is frequently used as an accelerator because of its efficiency and

storage and handling benefits to promote agglomeration and

solidifi-cation of

cement grout against gushing water [3-6]. The advantage of cement-sodium

silicate (CS) grouts lies in their short gelation time and high compressive

strength in the early stage, so they are widely used for strengthening weak

strata and plugging leaks. Previous studies on CS grouts have mainly focused on

the influence of the change of the double liquid volume ratio or the addition

of admixtures and additives on the physical and mechanical properties [7-11].

When CS grouts are in the condition of water enrichment, sodium hydroxide and

other substances are easily dissolved, which will easily cause alkali pollution

to groundwater and the environment. Moreover, the alkalinity decrease of the

concretion can easily lead to the decomposition of hydrated calcium silicate

gel and other substances and ultimately lead to structural destruction of the

concretion [12, 13]. When the solidified body of CS grouts is in

a dry condition, the silica gel will dehydrate, which will

result in shrinkage and cracking [14].

Adding a small amount of polymer to the cement mixture can

significantly enhance the performance of the final material, which is called

polymer-modified cement-based material (PMC) [15]. Polymer can

signifi- cantly

improve the tensile strength, flexural strength, flexibility, compactness and

durability of cement-based composite material and has a wider adaptability to

engineering compared with ordinary cement-based material slurry [16]. PMC has

good flexibility and bonding properties, which can lap the cracks caused by

shrinkage between particles and prevent the occurrence of cracks [17].

To date, polymers have become

an important com- ponent of

cement-based materials. However, most studies focus on the effects of polymers

on mortar and concrete properties [16-20]; the combined effects of polymer and

CS grouts have received less attention, especially concerning high water-to-binder (W/B)

ratios. This study experimentally

investigated the effects of redispersible latex powder (RLP) and hydroxy propyl

methyl cellulose (HPMC) on the

physical and mechanical properties of CSG with a high W/B ratio, considering

varied mixing amounts of polymers, and performed a microanalysis based on

scanning electron microscopy (SEM) to analyze the microstructure. According to

the main results of this study, some suggestions are also proposed for further studies

and engineering applications.

Experimental

materials

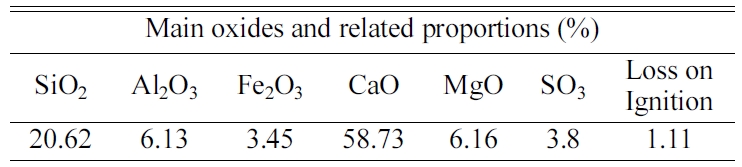

In this study, ordinary Portland cement (OPC) with the

strength grade of P. O 42.5 according to the China National Standards

GB175-2007 was used, and its chemical composition, which was provided by the

manufacturer, is listed in Table 1. A commercial SSS was adopted as the

accelerator for the grout. The density was 1.26 g/cm3, and the

concentration and modulus values (Ms, SiO2 to Na2O ratio)

of SSS used were 25 wt% and 2.6, respectively. In addition, two main types

of polymers with a solid content of 99%, including RLP, which is based on the

copolymer of vinyl acetate and ethylene, and HPMC, which has a viscosity of

100,000, were used.

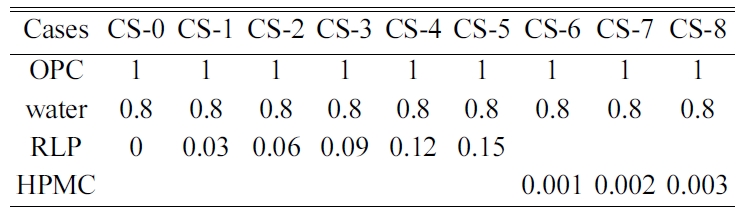

Based on practical engineering and commonly used mixtures

of CS grouts, the W/B ratio of the cement slurry was 0.8, and the designed

volume ratio (VR, OPC paste to sodium silicate) was 3. During the experi- ment, the mixing amount of RLP and HPMC was

changed to investigate their effects on the physical and mechanical properties

of CS grouts, while the amounts of other components remained

constant. To conveniently assess and compare the results, the

mix proportions were converted and expressed in Table 2, in which the data

denote the proportions relative to the mass of OPC.

Mix

design and specimen preparation

CS grouts adopt a dual-liquid grouting process. OPC slurry

and SSS are used as two liquids, which are then mixed and injected into the

formation. OPC slurry with or without polymer is used as the A liquid, and

alkaline SSS is used as the B liquid in this paper. The OPC powder, polymer

powder and water were fully blended for 240 s in a cement slurry mixer in

accordance with the predetermined W/B ratio. Then, a certain volume of SSS was

poured into the mixer and blended with the prepared OPC slurry for 5 s to

obtain fresh CS grouts. The stirring rate was approximately 285 r/min to

ensure thorough mixing of the components. After stirring, the fresh slurry was

cast into molds and kept in the molds for 2 h to avoid breaking when the

specimen was exposed to air for a long time. The molds used to create the

following specimens: a height of 40 mm, an inside diameter at the bottom

of 70 mm, and an inside diameter at the top of 60 mm conical ring for

final setting time; a 40×40×40 mm cube for the compressive strength test;

a 25×25×280 mm prism (with two copper measuring heads embedded 15 mm

at both ends) for the shrinkage test; a truncated cone shape with a

70 mm top diameter, an 80 mm bottom diameter and a

30 mm height for the penetration test; and a 40×40×160 mm prism for

the rapid sulphate resistance test.

Then, the specimens were demolded and cured in water at a

temperature of 20±2 oC for a certain period because

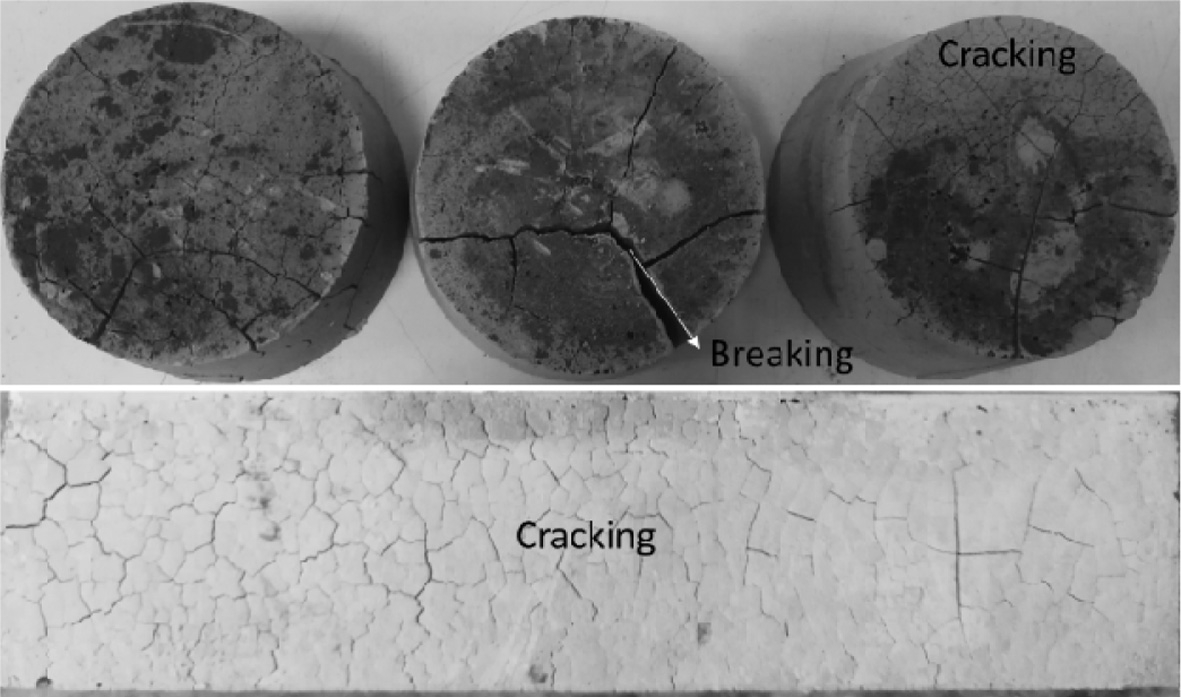

the specimens that were exposed to air suffered

cracking and breaking (Fig. 1). Three specimens were made for each mixture to

reduce deviations. The rapid stirring time used for the CSG was mainly because

of their rapid setting time, which might lead to layered gelation of the

specimens without adequate time for casting.

Methods

The initial setting time cannot be obtained by using the

method of the ASTM C191-13 standard because the real W/B ratio of the proposed

CS grouts was 1.15 and was rapid-setting. However, the final setting of the CS

grouts adopts the method of this standard for testing. The initial setting time

is usually determined by the “pour cup method”. A and B liquid that had been

weighed were placed in two plastic cups. Liquid A was added to liquid B, the

timer was started, and then the liquid was poured back into the A cup and

repeated at the specified frequency. The initial setting time was the time at

which the surface of the CS grouts remained at 45o once the plastic

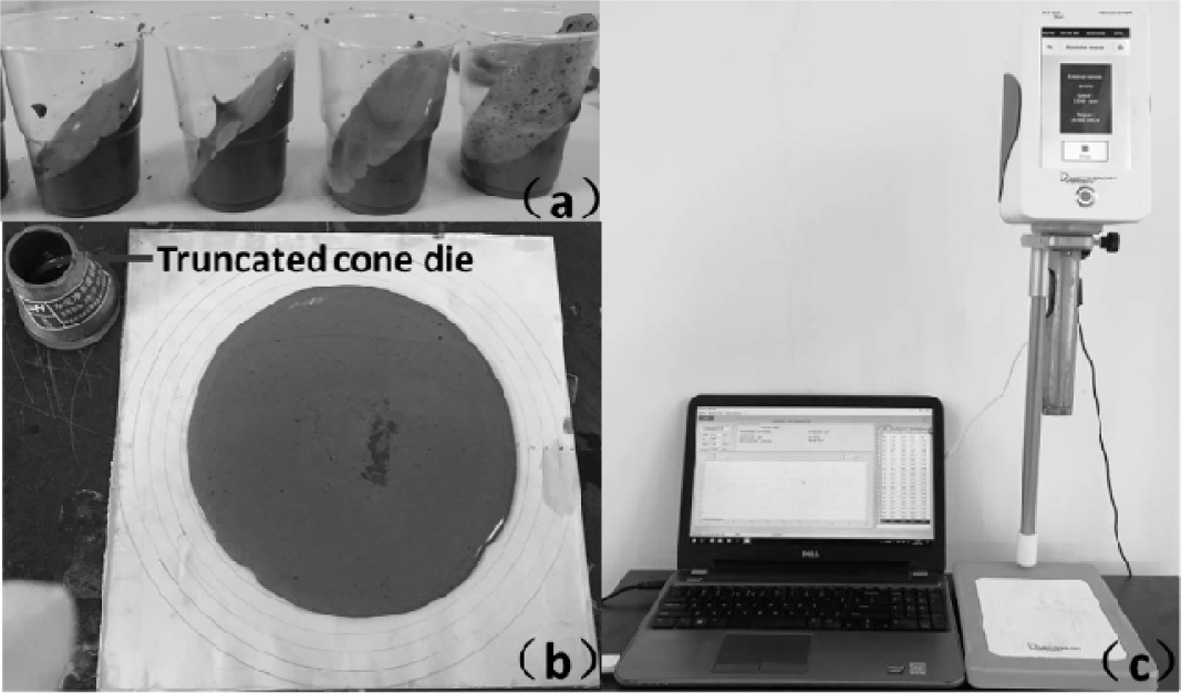

cup was straightened [9]. The gelatinized CS grouts with inclined surfaces in

plastic cups are shown in Fig. 2a.

Although the incorporation of the polymer might prolong

the setting time of the CS grouts, the slurry loses fluidity in only a few tens

of seconds. The time and accuracy requirements required for the viscometer to

test the rheological properties of the slurry cannot be met. Therefore, the

yield stress and plastic viscosity of OPC slurry incorporating RLP and HPMC

were tested to illustrate the effect of the polymers on the

rheological properties. The fluidity was determined by a truncated

cone die according to the national standard (GB/T 8077-2012) of China, and it

was conducted using smooth copper cones with dimensions of 60 mm in

height, 36 mm in bottom diameters and 60 mm in top diameters. The

mixed A liquid was injected into the truncated cone die, and the truncated cone

die was lifted to determine the maximum diameter of the slurry flowing

freely on the glass plane (Fig. 2b). The rheological

characteristics were tested with a VISCO-RM100 from LAMY RHEOLOGY (Fig. 2c).

The slurry was mixed evenly and then moved to the test container. The shear

stresses at speeds of 5, 20, 30 and 50 rpm were tested in 30 seconds,

and then plastic viscosity and yield stress were obtained through data

analysis.

The compressive strength test was conducted according

to ASTM Standard C942-15. Strength at 3, 7, 14, 28 and 56 d was tested to

determine the development of compressive strength.

The period was 28 d for the penetration test according

to the industrial standard (JGJ/T 70-2009) of China.

The shrinkage test was performed after demolding according

to ASTM C157. The lengths (Li) at 1, 2, 3, 7, 14, 28, 35, 42, 49, 56 and

63 d were measured to determine the development of shrinkage with the length

change rate (LCR) using the standard prescribed formula: LCR = (the

initial lengths- Li)/250. However, the curing method of the specimen was

changed to water curing since the CS grouts for GSWC in projects were always

immersed in water and seldom suffered drying-wetting cycles. Additionally,

specimens with a high W/B ratio, as shown in Fig. 1, were easily cracked and unable

to mold in the air. Hence, the volume stability of the CS grouts was performed

through autogenous shrinkage instead of natural drying shrinkage

in this paper, which had been previously used in the literature [6]. Finally,

the microstructures of the 28 d hardened CS grouts were investigated using SEM

(Thermo Fisher 250 from FEI). The appearance of crystals was examined under a

magnification of 2000 times.

|

Fig. 1 Cracking and breaking of specimens in the air during the curing process. |

|

Fig. 2 The experimental instruments for the (a) setting time test, (b) fluidity test and (c) viscosity test. |

Rheological

properties

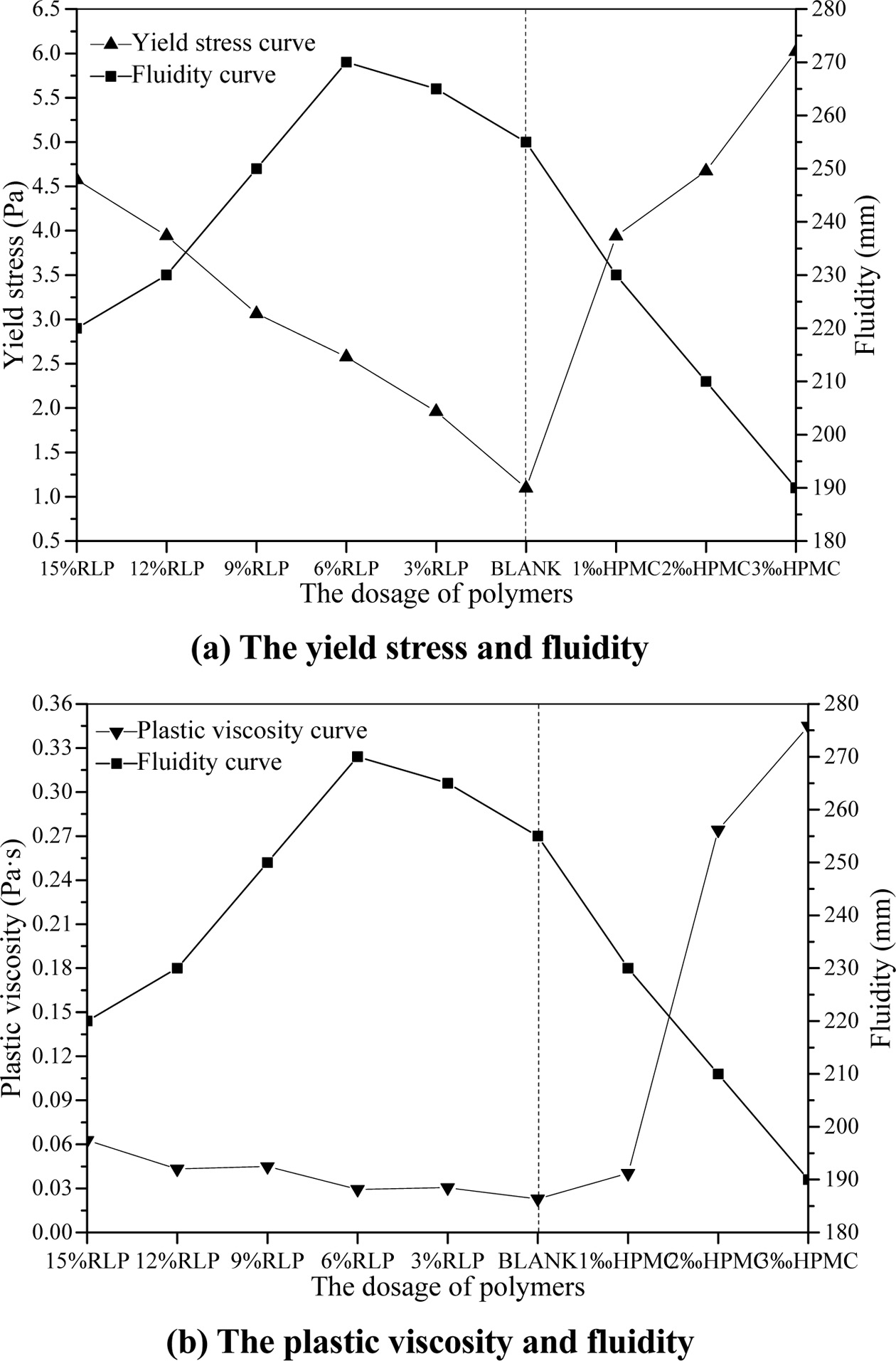

The rheological properties of cement slurry with and

without polymers with a W/B ratio of 0.8 can be approximated by the Bingham

model [21], which can be characterized by yield stress and plastic viscosity.

It can be seen from Fig. 3 that when the content of RLP is increased from 3% to

15%, the yield stress and plasticity viscosity of the slurry show an increasing

trend, the yield stress increases by 79~319%, and the growth amplitude of the

plastic viscosity reaches 29~175%. RLP has certain water-reducing and

air-entraining effects [16, 18]. When the mixing amount of RLP is less, the

introduction of a proper amount of bubbles and the formation of

the emulsion by dissolving RLP during the mixing of slurry

will result in the “rolling ball” and lubricating effect, which will increase

the fluidity of the slurry. However, the introduction of more than a certain

amount of bubbles will reduce the fluidity of the slurry. RLP will absorb more

free water with the increase of the mixing amount, which will lead to the

reduction of the fluidity and the increase of the cohesion of the slurry.

Therefore, the yield stress and plastic viscosity tend to increase with

increasing dosage of RLP. This also explains why the grout

fluidity first increases and then decreases.

When the amount of HPMC increases from 1‰ to 3‰, the slope

of the yield stress and plastic viscosity curves increases more obviously

compared with the effect of RLP. The increase amplitude of yield stress reaches

259~449%, and the increase amplitude of plasticity viscosity reaches 77~141%.

This is mainly because the hydroxyl group and the oxygen atom on the ether bond

of the HPMC molecule form the hydrogen bond with the water molecule, which will

lead to the reduction of the free water in the slurry. The polymer’s long chain

will adsorb and fix more water with the increase of the mixing amount, which

leads to the weakening of the lubrication effect of the cement particles and

the increase of the frictional force. Therefore, the yield stress and plastic

viscosity of the slurry increase, and the fluidity of the slurry decreases.

Setting

time

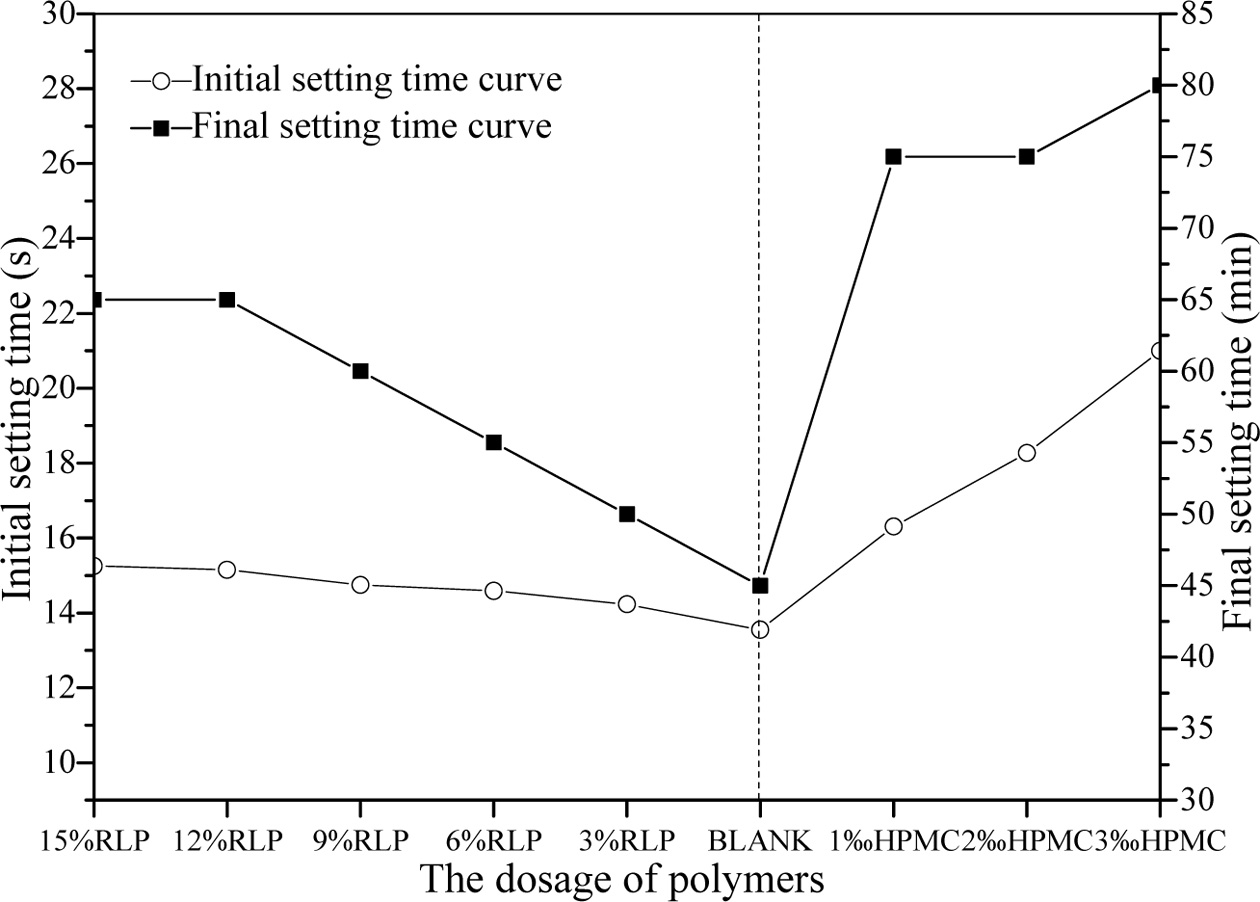

As shown in Fig. 4, the setting time of CS grouts greatly

affects their diffusion distance in strata and the anti-dilution performance in

moving water. When the amount of RLP increases from 3% to 15%, the initial and

final setting time of the slurry show an increasing trend, but the change of

initial setting time is smaller, and the final setting time is up to 44% longer

than that of the blank group (CS-0). When the dosage of HPMC increases from 1‰

to 3‰, the initial setting time is 20~55% longer than that of the blank group,

and the final setting time is prolonged 67~78%. Polymer particles form

emulsions in water that increase the viscosity of the slurry, but this has a

very weak effect on the reaction of SSS and calcium hydroxide (CH) formed by

the hydration of cement. The polymer particles in the emulsion are adsorbed on

the surface of hydration products and nonhydrated cement particles that hinder

the contact between the SSS and CH produced by the hydration of cement, thus

delaying the hydration of CS grouts. In addition, the high amount of polymer

has a more serious effect on the setting time of the slurry.

Compressive

strength

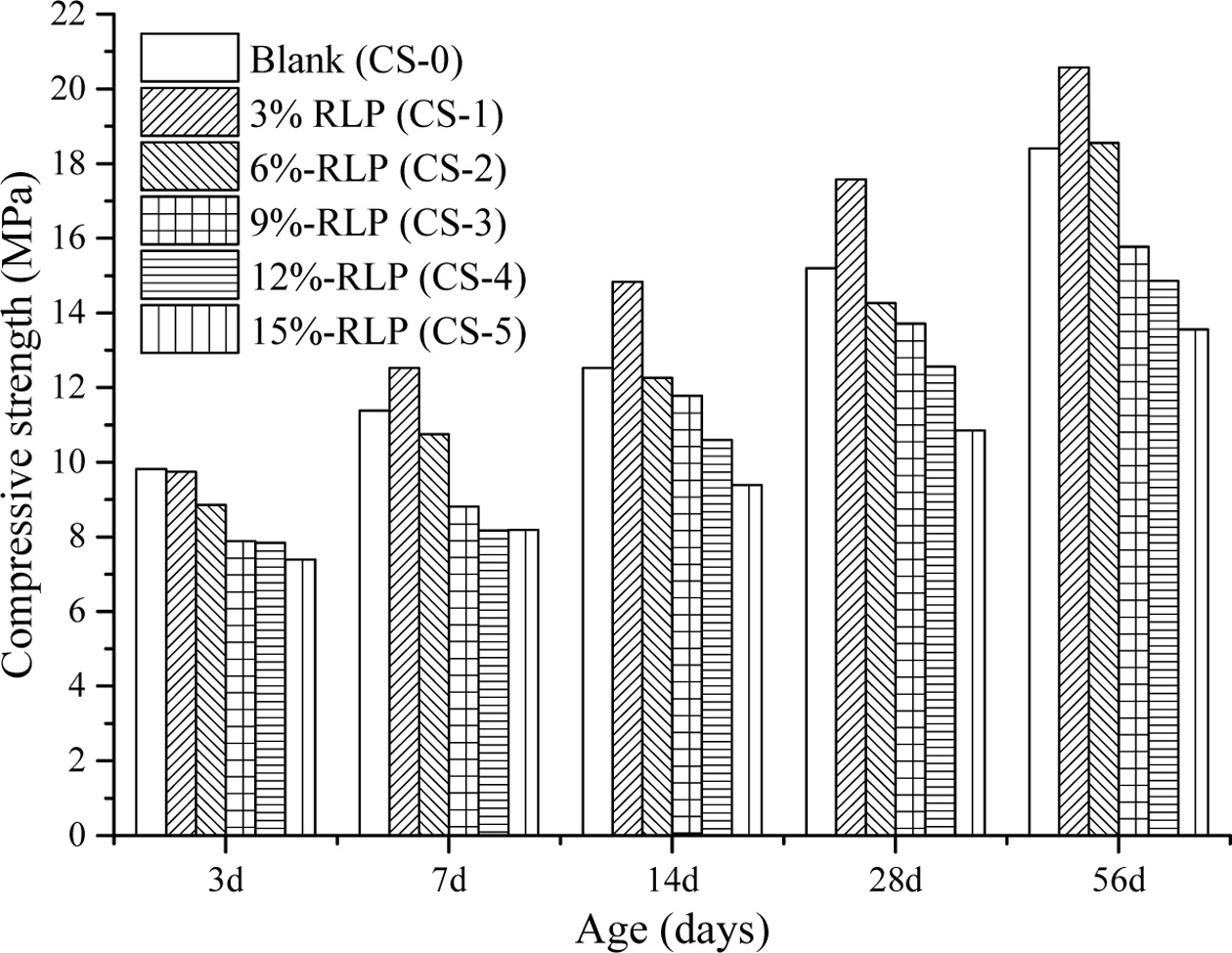

As shown in Fig. 5, the compressive strengths of CS grouts

show a trend of increasing first and then decreasing with the increase of the

mixing amount, which is similar to other results noted in the literature [19].

The peak value appears at the dosage of 3%. The compressive strengths increase

by 12~18% from 7 d to 56 d before the peak compared with the blank group. Then,

the compressive strengths show a decreasing trend. With the amount of RLP

ranging from 6% to 15%, compressive strengths at 3 d reduce the range from 10%

to 25%, compressive strengths at 7 d reduce the range from 6% to 28%,

compressive strengths at 14 d reduce the range from 2% to 25%, compressive

strengths at 28 d reduce the range from 6% to 29%, and compressive strengths at

56 d reduce the range from 8% to 26% compared with the blank group.

The compressive strengths of CS grouts can be affected by

the following factors. First, some RLP particles fill smaller pores, which will

make the material more compact and improve the compressive strengths.

Second, the polymer forms thin films between cement

particles to increase the flexibility, which has a negative impact on the

compressive strength. Finally, RLP introduces a large number of bubbles, which

will reduce the strength. When RLP is mixed with a low amount (3%), the

compressive strength is improved because of the filling effect of RLP particles

on smaller pores. With the increase of the mixing amount, the compressive

strength decreases gradually due to the increasing

air-entraining content and monolithic flexibility.

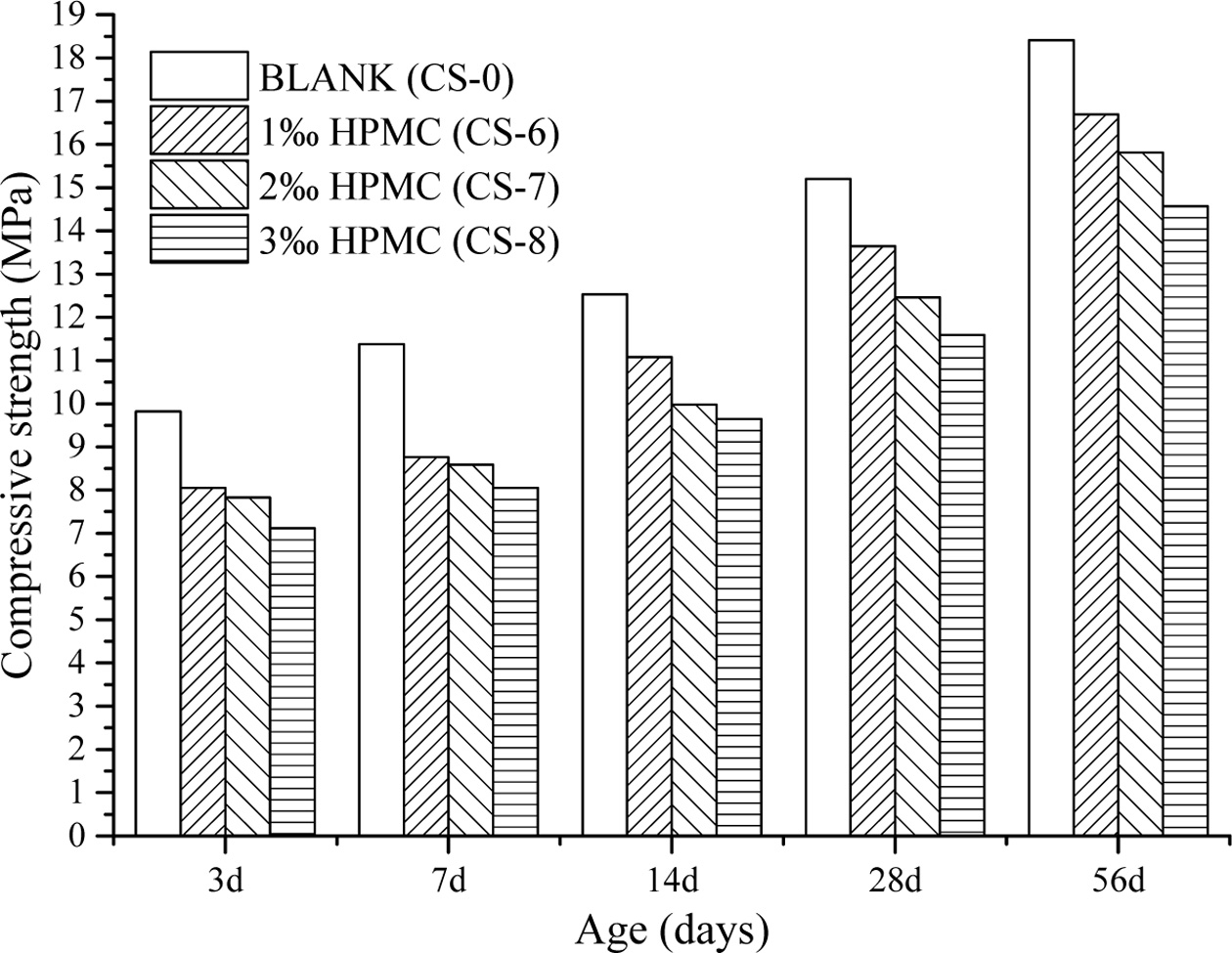

Fig. 6 shows the compressive strengths of specimens with

different amounts of HPMC. The compressive strengths of the CS grouts decrease

gradually with increasing dosage of HPMC. When the dosage of HPMC

increased from 1‰ to 3‰, compressive strengths at 3 d

reduced the range from 18% to 27%, com-

pressive strengths at 7 d reduced the range from 23% to 29%, compressive

strengths at 14 d reduced the range from 12% to 23%, compressive strengths at

28 d reduced the range from 10% to 24%, and compressive strengths at 56 d

reduced the range from 9% to 21% compared with the blank group. The influencing

factors of HPMC are similar to those of RLP on the compressive strength.

However, the molecular structure of HPMC has a large number of hydrophilic

groups (hydroxyl ether group) and hydrophobic groups (methyl

glucose ring) [22]. The effect of air entrainment is stronger than that of RLP,

which leads to an increase in air content in the concretion body and a decrease

in mechanical properties.

Autogenous

shrinkage

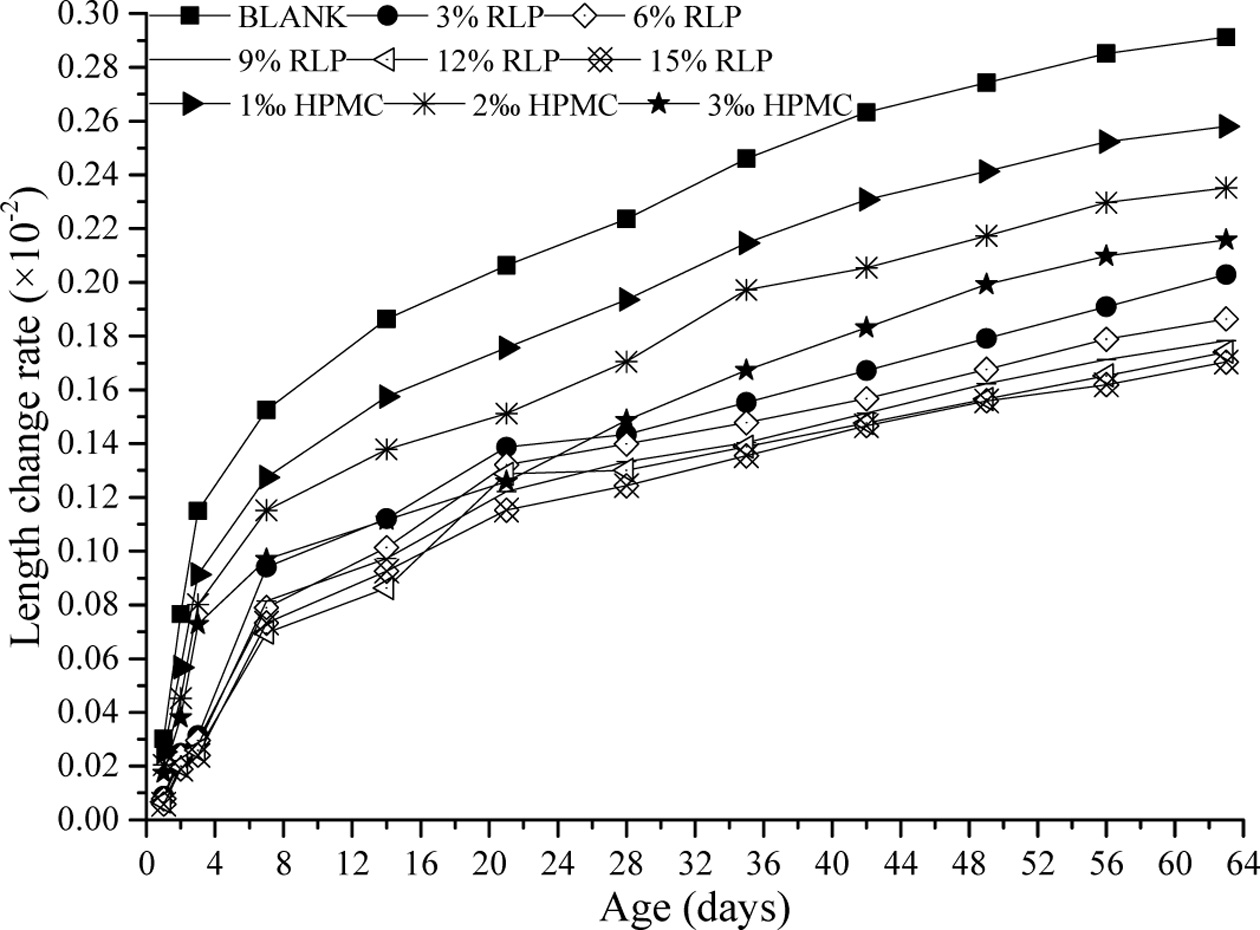

Shrinkage is an important parameter affecting the

long-term durability of grouting. The shrinkage causes cracking of the

concretion body, and the connecting cracks will produce seepage channels.

Therefore, the development of autogenous shrinkage at 63 d was studied

(Fig. 7). Approximately half of the shrinkage in the blank group occurred in

the first week, which was similar to that observed for CS grouts with W/B

ratios in the range of 1.1–2.5 and the dosage of SSS in the range of

4.4–7.5 wt% [14]. The addition of RLP significantly reduces the shrinkage

of CS grouts, but the increase in amplitude of the shrinkage becomes small,

which can be seen from the fact that the slope of the curve becomes flatter.

With the increase of RLP, LCR at 63 d decreases by 0.883–1.21% compared with

the blank group. Although the mixing of HPMC also reduces the shrinkage of CS

grouts, the magnitude of the reduction is smaller than that of RLP. When the

dosage of HPMC increases from 1‰ to 3‰, the LCR of CS grouts shows a decreasing

trend, and the LCR at 63 d decreases by 0.332–0.754% compared with CS-0.

The addition of the two polymers reduces the number of

large cracks, which was verified in microstructure analysis. This is mainly

because the tiny pores introduced by the polymer are uniformly distributed in

the slurry, which can reduce the stress concentration inside the

concretion body. The polymer film formed on the surface of cement

particles and hydration products improves the bonding strength

between particles, which can also effectively absorb the

energy required by microcrack growth because of its relatively low elastic

modulus and high deformation capacity [23-25], thus significantly

improving the crack resistance and shrinkage performance

of CS grouts.

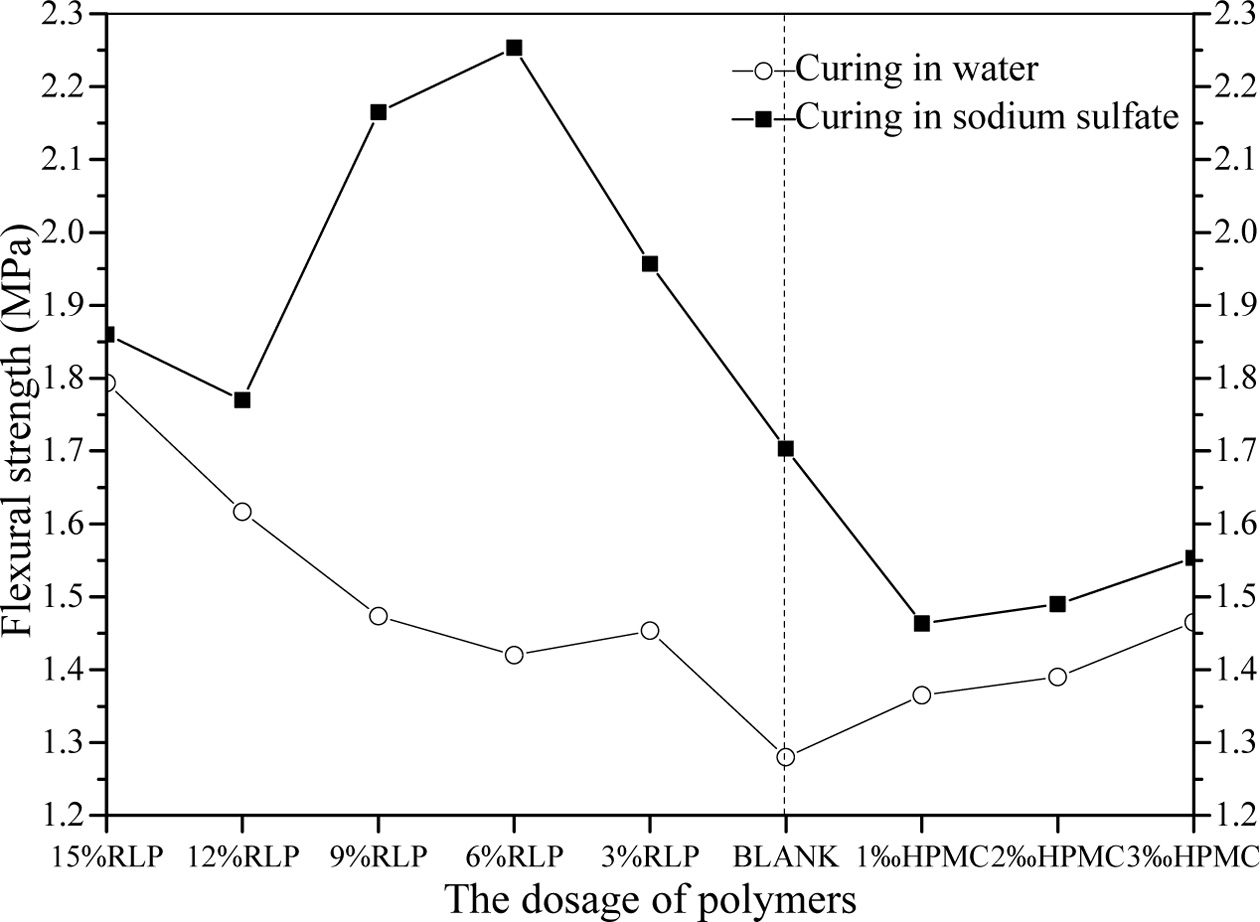

Sulfate

attack resistance

Sulfate erosion has become an important factor affecting

the durability of cement-based materials. Erosion of cement-based materials by

external sulfates may lead to cracking, breaking and spalling because sodium

sulfate reacts with calcium hydroxide to generate newly expanded ettringite and

gypsum [26]. The concretion body of CS grouts is easily eroded by sulfate ions

in groundwater. The resistance to sulfate, which relates to the durability of

CS grouts, is evaluated by measuring the flexural strength after sulfate

attack. Two groups of samples were cured in water and

3 wt% sodium sulfate solution. The influences of polymer

and sodium sulfate on the flexural strength of CS grouts at 28 d were

tested and analyzed. During the test, no cracks were found on the surfaces of

all samples.

It can be seen from Fig. 8 that when the sample is cured

in water, the flexural strength of samples mixed with RLP and HPMC is higher

than that of the blank group. In addition, the flexural strength shows an

increasing trend with increasing RLP, and the increase range is from 11% to

40%. The effect of HPMC on the flexural strength is significantly weaker than

that of RLP, which only increases by 7~14%. In sodium sulfate

solution, RLP also increases the flexural strength, but the flexural strength

first increases and then decreases with increasing RLP. Moreover, the

incorporation of HPMC reduces the flexural strength compared with the blank

group. It should be noted that sodium sulfate does not have a negative effect

on the flexural strength through the comparison of the test results of the two

curing methods. The main reason is that there are a large number of pores in

the concretion body because of the high W/B ratio of CS grouts. Although sodium

sulfate reacts with calcium hydroxide and calcium aluminate to generate newly

expanded ettringite, its volume expansion does not cause the volumetric

instability, but fills and compacts the pores which will make the concretion

body denser and improve the flexural strength.

In brief, adding a proper amount of RLP can signifi- cantly improve the flexural

strength and sulfate resistance of CS grouts. However, CS grouts

mixed with HPMC are not suitable for the formation with high sulfate content.

Permeability

The permeability of CS grouts is the most basic factor

that determines their durability under a certain underground water pressure.

The leakage of under- ground water

through grouts will seriously affect the quality of the grouting reinforcement

area. Therefore, the permeability of CS grouts at 28 d was evaluated by testing

the ultimate hydraulic pressure before leakage or failure.

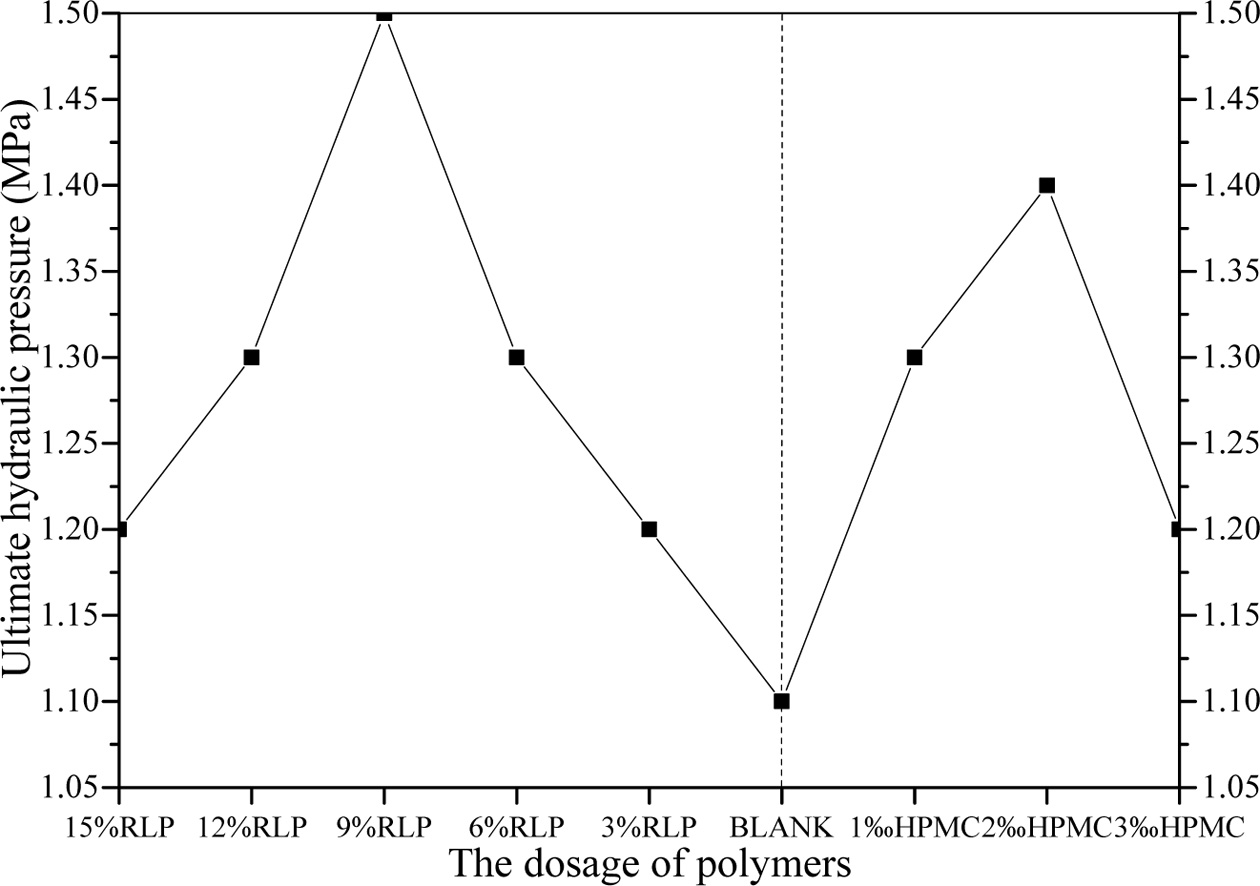

As shown in Fig. 9, the ultimate hydraulic pressure of CS

grouts doped with polymer increases by 0.1–0.4 MPa, significantly improving the

permeability. The optimal dosages of RLP and HPMC are 9% and 2‰, respectively.

In the concretion body, the film formed by the polymer is distributed among the

cement hydrates to form a network and effectively fill the pores. These two

actions prevent the connection of pore channels and thus improve the

compactness of CS grouts.

Microstructure

analysis

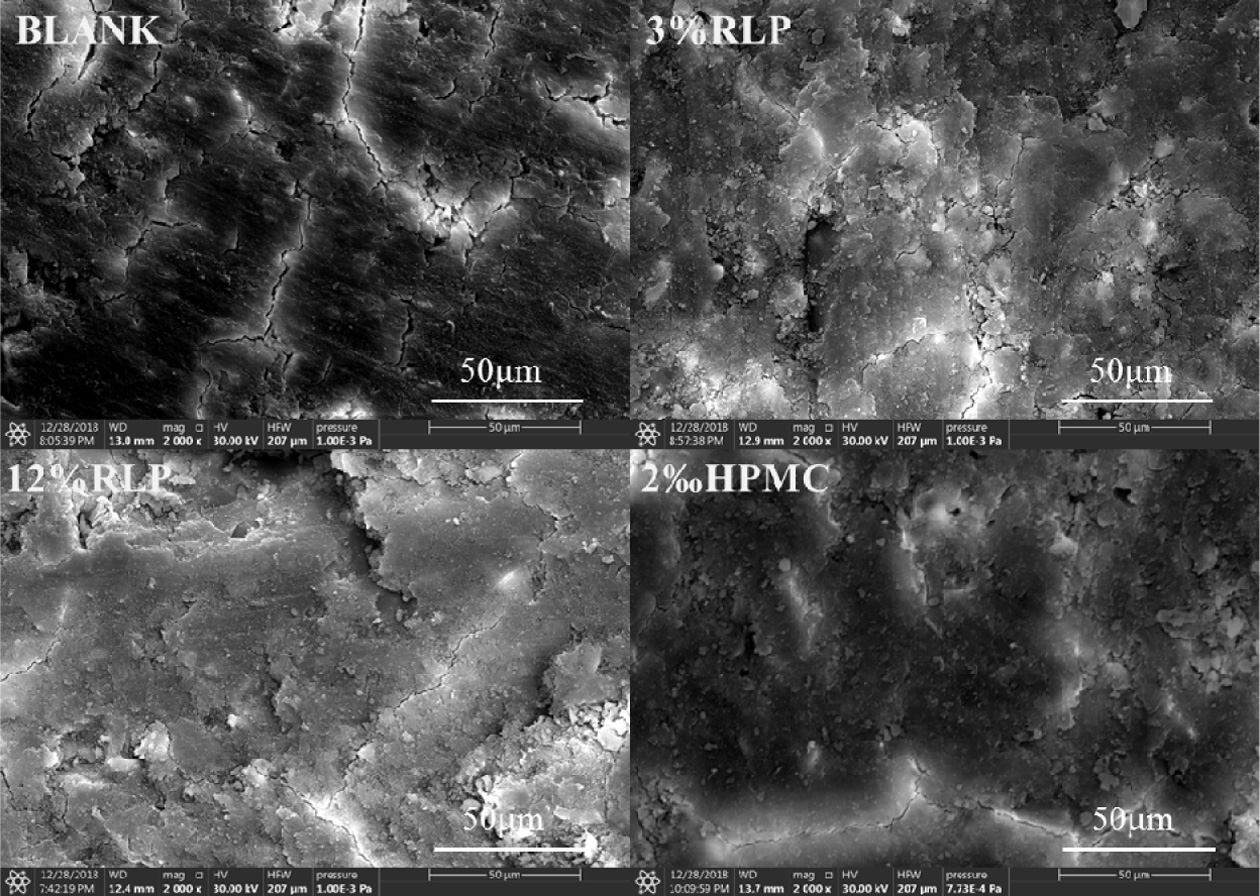

The fresh uncarbonized concretion body was observed

to obtain the microstructure of the sample section. The microstructure of CS-0

(BLANK), CS-1 (3% RLP), CS-4 (12% RLP) and CS-7 (2‰ HPMC) at 28 d, which was

imaged at 2000-fold magnification by SEM, is shown in Fig. 10.

The adhesion between particles is improved because the

addition of polymer significantly improves the roughness of the fracture

surface compared with the blank group, which can be used to explain why the

flexural strength is increased to some extent. The addition of RLP and HPMC

significantly reduces the number and width of cracks compared with the blank group

in Fig. 11, which also explains why the autogenous shrinkage

is improved.

|

Fig. 3 The rheological properties of fresh slurry. |

|

Fig. 4 The setting times of grouts. |

|

Fig. 5 Compressive strengths of specimens with different amounts of RLP. |

|

Fig. 6 Compressive strengths of specimens with different amounts of HPMC. |

|

Fig. 7 The autogenous shrinkage characteristics of grouts. |

|

Fig. 8 The 28 d flexural strength after curing in water and sodium sulfate with 3 wt%. |

|

Fig. 9 The ultimate hydraulic pressure of the grouts at 28 d. |

|

Fig. 10 Micrographs of specimens under a magnification of 2000 times. |

This paper mainly studies the influence of RLP and HPMC on

the physical and mechanical properties of CS grouts with a high W/B ratio. With

the variation of mixing amounts of polymers, the rheological

properties, setting time, compressive strength,

autogenous shrinkage, sulfate attack resistance and permeability are

tested and assessed. The main conclusions are summarized as follows:

(1) The yield stress and plastic viscosity of the cement

slurry incorporating RLP and HPMC increased significantly, which would be

beneficial for improving the resistance to dispersion in water.

(2) The effect of HPMC on CS grout setting time was better

than that of RLP. The initial setting time was prolonged by 20~55%, and the

final setting time was prolonged by 67~78%. These time could provide references

for grout material selection in the grouting project.

(3) The reduction of autogenous shrinkage was more

significant when RLP was incorporated into CS grouts. The addition

of the two polymers significantly inhibited the

formation of new cracks.

(4) Although two polymers had a negative impact on the

compressive strength of CS grouts except for the RLP content

of 3%, they increased the flexural strength. CS grouts

with the proper amount of RLP had a superior sulfate attack

resistance when exposed to sulfate-rich environments.

(5) The ultimate hydraulic pressure increased 0.1–0.4 MPa

when RLP and HPMC were incorporated into CS grouts. The durability under a

certain underground water pressure was improved.

The authors are thankful for the financial support

provided by the National Natural Science Foundation of China (51979153) and

Shandong University from Project Entrusted by Enterprises and Public

Institutions (11441655).

- 1. W. Cui, J. Huang, H. Song, and M. Xiao, Constr. Build. Mater. 156 (2017) 184-198.

-

- 2. M.R. Azadi, A. Taheri, and A. Taghichian, J. Rock. Mech. Geol. Eng. 9[4] (2017) 623-637.

-

- 3. D. Ravikumar and N. Narayanan, Cement. Concrete. Comp. 44 (2013) 58-68.

-

- 4. H.J. Dou, in “Investigation on the performance and microscopic characteristics of complex cementitious-sodium silicate two-shot grouting materials” (China University of Geosciences, 2014) p.1.

- 5. S.Z. Liu, in “Experimental study on mechanical properties of cement sodium silicate slurry under salt erosion” (Hunan University of Science and Technology, 2016) p.1.

- 6. P. Tu, in “Durability experiment and evaluation theory of grouting concretion stone” (Central South University, 2012) p.2.

- 7. J.K. Yang, H.J. Lu, J.X. Li, and D.F. Zhu, Journal of Dalian University of Technology. 56[3] (2016) 252-256.

- 8. F. Chen, B.L. Huang, M.F. Ba, and X.D. Bao, Acta Mater. Compositae Sin. 30[6] (2013) 139-145.

- 9. M.Y. Wu, Q.C. Wang, R.L. Zhang, H.X. Tian, K. Zhang, and X.L. Wang, Bull. Chin. Ceram. Soc. 35[09] (2016) 2741-2746.

- 10. Q.W. Guo, X.B. Yin, Y.J. Chen, and X.F. Wan, J. Chongqing Jiaotong Univ. 34[01] (2015) 40-43.

- 11. Y.J. Chen and X.F. Wan, Bull. Chin. Ceram. Soc. 33[07] (2014) 1846-1851.

- 12. FH. Heukamp, FJ. Ulm, and JT. Germaine, J. Mater. Civ. Eng. 17[3] (2005) 307-312.

-

- 13. J.-S. Ryu, N. Otsuki, and H. Minagawa, Cement. Concr. Res. 32[10] (2002) 1539-1544.

-

- 14. Z. Yu, L.C. Yang, S.H. Zhou, Q.M. Gong, and H.B. Zhu, Constr. Build. Mater. 189 (2018) 550-559.

-

- 15. Y. Ohama, Cement Concrete Comp. 20[2] (1998) 189-212.

- 16. X.L. Han, X.M. Chen, H.Z. Jiao, G.D. Sun, and T.F. Dong, Bull. Chin. Ceram. Soc. 37[08] (2018) 2457-2462.

- 17. W. Zhao, D.X. Li, and Q.H. Li, Materials Review: Review article. 24[06] (2010) 136-140.

- 18. P.M. Wang, G.R. Zhao, and G.F. Zhang, J. Chin. Ceram. Soc. 46[02] (2018) 256-262.

- 19. H.X. Zhao, T.F. Hua, X.J. Ma, and H. Zhou, Concrete. 6 (2015) 121-123.

- 20. J.-B. Lee, S.-H. Park, and S.-S. Kim, J. Ceram. Process. Res. 18[3] (2017) 220-229.

- 21. W.J. Ruan, Chin. J. Rock Mech. Eng. 24[15] (2005) 2709-2715.

- 22. Z.H. Ou, B.G. Ma, and S.W. Jian, Bull. Chin. Ceram. Soc. 31[1] (2012) 96-98.

- 23. J. Do and Y. Soh, Cem. Concr. Res. 33[10] (2003) 1497-1505.

-

- 24. J.H. Peng, J.B. Mao, J.X. Zhang, J.D. Qu, and C. Teng, Bull. Chin. Ceram. Soc. 30[04] (2011) 915-919.

- 25. M.R. Zhou and W.H. Zhang, Concrete. 6 (2007) 71-73.

- 26. K. Liu, L. Mo, M. Deng, and J. Tang, Adv. Cem. Res. 27[8] (2015) 477-486.

-

This Article

This Article

-

2020; 21(4): 393-399

Published on Aug 30, 2020

- 10.36410/jcpr.2020.21.4.393

- Received on Sep 6, 2019

- Revised on Mar 9, 2020

- Accepted on Jun 29, 2020

Services

Services

- Abstract

introduction

experimental materials and methods

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Lei Yang

-

Geotechnical & Structural Engineering Research Center, Qianfoshan Campus, Shandong University, Lixia District, Jinan City, Shandong Province, China

Tel : +86 0531-88399712

Fax: +86 0531-88395984 - E-mail: yanglei@sdu.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.