- Impacts of praseodymium substitution on structural, spectral, magnetic and electrical properties of strontium W-type hexaferrites

Yujie Yang*, Xiansong Liu, Shuangjiu Feng, Qingrong Lv, Xucai Kan and Ruiwei Zhu

Engineering Technology Research Center of Magnetic Materials, School of Physics & Materials Science, Anhui University, Hefei 230601, P. R. China

Praseodymium substituted strontium W-type

hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

(0.00 ≤ x ≤ 0.40) were prepared via the conventional ceramic technique.

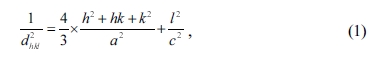

XRD analysis of W-type hexaferrites with Pr content (x) of 0.00 ≤ x ≤ 0.24

shows the single W-type hexaferrite phase. However, for the W-type hexaferrites

with Pr content (x) ≥ 0.32, the impurity phase (α-Fe2O3)

is detected. FE-SEM images show that the grains are platelet-like shapes. The

saturation magnetization (Ms), remanent magnetization (Mr)

and magneton number (nB) first increase with Pr content (x) from

0.00 to 0.16, and then decrease when Pr content (x) ≥ 0.16. The Mr/Ms

ratio, magnetic anisotropy field (Ha), coercivity (Hc)

and maximum energy product [(BH)max] increase with Pr content

(x) from 0.00 to 0.40. While the first anisotropy constant (K1)

increases with Pr content (x) from 0.00 to 0.16, and then decreases when Pr

content (x) ≥ 0.16. The DC electrical resistivity (ρ) decreases with Pr

content (x) from 0.00 to 0.40.

Keywords: W-type hexaferrites, Conventional ceramic technique, X-ray diffraction, Magnetic properties, Electrical resistivity

Hexagonal ferrites are playing a major role in the field

of permanent magnetic materials in the market because of

their low costs, high saturation magnetization, high

coercivity, and perfect chemical stability [1, 2]. Hexagonal ferrites have been

extensively used in microwave devices and electromagnetic wave absorbers

due to their high saturation magnetization, tunable dielectric properties, high

planar magnetic anisotropy, and perfect chemical stability [3]. Hexagonal

ferrites are classified into six different possible types based on the chemical

and crystalline structure, which include M, W, Y, X, Z

and U hexaferrites, depending upon their crystal

structure [4]. The strontium W-type hexaferrites (SrMe2Fe16O27)

have a crystalline structure as stacking of R (composition: SrFe6O11)

and S (spinel block, with composition: Fe6O8) stocks. The

main structure of W-type hexaferrites consists of SSRS*S*R*. The asterisk means

that the corresponding block is rotated 180o alone the c-axis [5].

In the W-type hexaferrites, the Fe3+ ions are distributed among

seven different crystal positions, such as four octahedral positions (12k, 4fVI,

6g, and 4f), two tetrahedral positions (4e, 4fIV), and one

hexahedral position (2d) [6].

Various methods have been proposed to synthesize the

W-type hexaferrites, such as the chemical co-preci- pitation method [7], sol-gel technique

[8], sol-gel auto combustion technique [9], citrate method [10], conven- tional ceramic technique [11], and

glass crystallization method [12]. In the present work,

the conventional ceramic technique has been used to synthesize the W-type

hexaferrites due to its numerous virtues, namely, simplicity, high productive

and well controllable grain size as compared with other methods.

Rare earth elements (RE) have typical relaxation

characteristics, which may affect the electromagnetic properties of

the ferrites [13]. Ahmad et al. studied La substituted W-type hexaferrites

BaZn2LaxFe16-xO27 (0 ≤ x ≤

1.0) synthesized by co-precipitation method and observed that the saturation

magnetization and remanence decreased with La content (x) from 0 to 1.0, while

the coercivity (Hc) increased with La content (x) from 0 to 1.0 [14]. Sadiq et al. worked on

Ce-substituted W-type hexagonal ferrites Sr3-xCexFe16O27

(0 ≤ x ≤ 0.10) prepared

by sol-gel method and found that with the doping of Ce3+ ions, the

grain size decreased and the saturation magnetization and coercivity increased

[15]. Xu et al. synthesized Nd3+ doped

W-type ferrites Ba1-xNdxCo2Fe16-xO27

(0.00 ≤ x ≤ 0.25) by sol-gel method,

and observed that the real part of complex permeability (ɛ′) and imaginary part

(ɛ″) increased with the addition of Nd3+ amount, while the imaginary

part of complex permittivity (μ″) increased and real part (μ′) went down when

Nd3+ ions doped Ba2+ ions [16]. Wang et al. fabricated

Sm-substituted W-type barium hexaferrites Ba1-xSmxCo2Fe16O27

(0.0 ≤ x ≤ 0.2) via conventional solid-state reaction, and found that ɛ′ and ɛ″

increased slightly with Sm3+ ions doping and the values of μ′ and μ″ were improved significantly when x = 0.15 [17].

Aen et al. synthesized the

Ho-substituted W-type hexagonal ferrites Ba1-xHoxCo2Fe16O27

(0.0 ≤ x ≤ 0.1) using the sol-gel auto combustion technique, and observed that

the DC electrical resistivity increased with increasing Ho3+ content

(x) and the Ho3+ substitution caused the dielectric constant (real

and imaginary part of complex permeability) and loss tangent to decrease [18].

Huang et al. have prepared Er3+-substituted W-type barium ferrites

Ba1-xErx(Zn0.3Co0.7)2Fe16O27

(0.00 ≤ x ≤ 0.20) by polymer absorbent combustion and observed that all XRD

patterns showed the pure phase of W-type barium ferrite when x ≤ 0.15, while

the impurity phase of ErFeO3

appeared when x = 0.20; and the electromagnetic properties were significantly improved when x =

0.10 [19]. Khan et al. synthesized Ce-Mn substituted W-type hexagferrites Sr1-xCexCo2MnyFe16-yO27

(0.00 ≤ x ≤ 0.06, 0.0 ≤ y ≤ 0.6) by chemical co-precipitation method and found

that the saturation magnetization, remanence, squareness ratio and coercivity

increased with increasing Ce-Mn concentration up to a certain substitution level, while the room temperature

resistivity decreased with increasing

Ce-Mn concentration [20]. Khan et al. prepared the Nd-Ni substituted

W-type hexagferrites Sr1-xNdxCo2NiyFe16-yO27

(0.00 ≤ x ≤ 0.10, 0.0 ≤ y ≤ 1.0) via the chemical co-precipitation method and observed that the saturation

magnetization, remanence, squareness

ratio and coercivity increased with increasing Nd-Ni concentration up to a x =

0.025, y = 0.25 and then decreased continuously, the increase in magnetic

properties is helpful for their applications in magnetic recording media [21].

However, the impact of praseodymium substitution on

magnetic properties of strontium W-type hexaferrites has not been

reported. Thus, in this work, we have fabricated praseodymium substituted

strontium W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

(0.00 ≤ x ≤ 0.40) by conventional

ceramic technique. Effects of praseodymium substitution

on the microstructural, spectral, magnetic and

electrical properties of strontium W-type hexaferrites were

systematically investigated for the first time.

Strontium carbonate (SrCO3) (99.5%),

praseodymium oxide (Pr6O11) (99.9%), zinc

oxide (ZnO) (99%), cobalt oxide (CoO) (99%), iron oxide (Fe2O3)

(99.3%) were used as raw materials. All regents were used as

received, i.e. no further purification of the chemicals was

carried out. The praseodymium substituted strontium W-type

hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

(0.00 ≤ x ≤ 0.40) were synthesized by the conventional

ceramic technique. The raw materials were stoichimetrically weighed,

and then ball-milled in water for 10 h in a ball mill. The ball-milled powder

was dried, and pressed into pellets with a diameter of 30 mm and a thickness of

16 mm. The pellets were calcined in a muffle furnace at 1,280 oC for

3.0 h in air to obtain W-type hexaferrite phase. Subsequently, the calcined

pellets were crushed by a vibration mill to obtain fine powders through a sieve

with a 200 mesh. And then, the crushed magnetic powders were

pressed into pellets with a diameter of 20 mm and a thickness of 8 mm. The

pellets were finally sintered in a muffle furnace at 1,205 oC

for 2.0 h in air, and used for the DC electrical resitivity measurement.

The phase and crystal structure of strontium W-type hexaferrites

were determined from the X-ray diffraction (XRD)

patterns. The X-ray diffraction patterns were recorded from a Rigaku X-ray

diffractomer equipped with Cu Kα (λ = 1.5406 Å) radiation. The 2θ

angles were scanned over a range between 20o and 80o with

equal steps of 0.01o. Fourier transform infrared (FTIR, Nicolet

6700, Thermo Scientific) was performed to investigate the metal ion stretching

and absorption bands in the wave number range of 400 to 4,000 cm-1. Field

emission scanning electron microscopy (FE-SEM, HITACHI

S-4800) was employed to determine the grain size and

morphology of strontium W-type hexaferrites. Magnetic

properties were measured at room temperature using

vibrating sample magnetometer (VSM) at the maximum magnetic field of 18800 Oe.

DC electrical resitivity (ρ) was measured at room temperature by two probe

method (Resistivity testing system, Ningbo rooko FT-353).

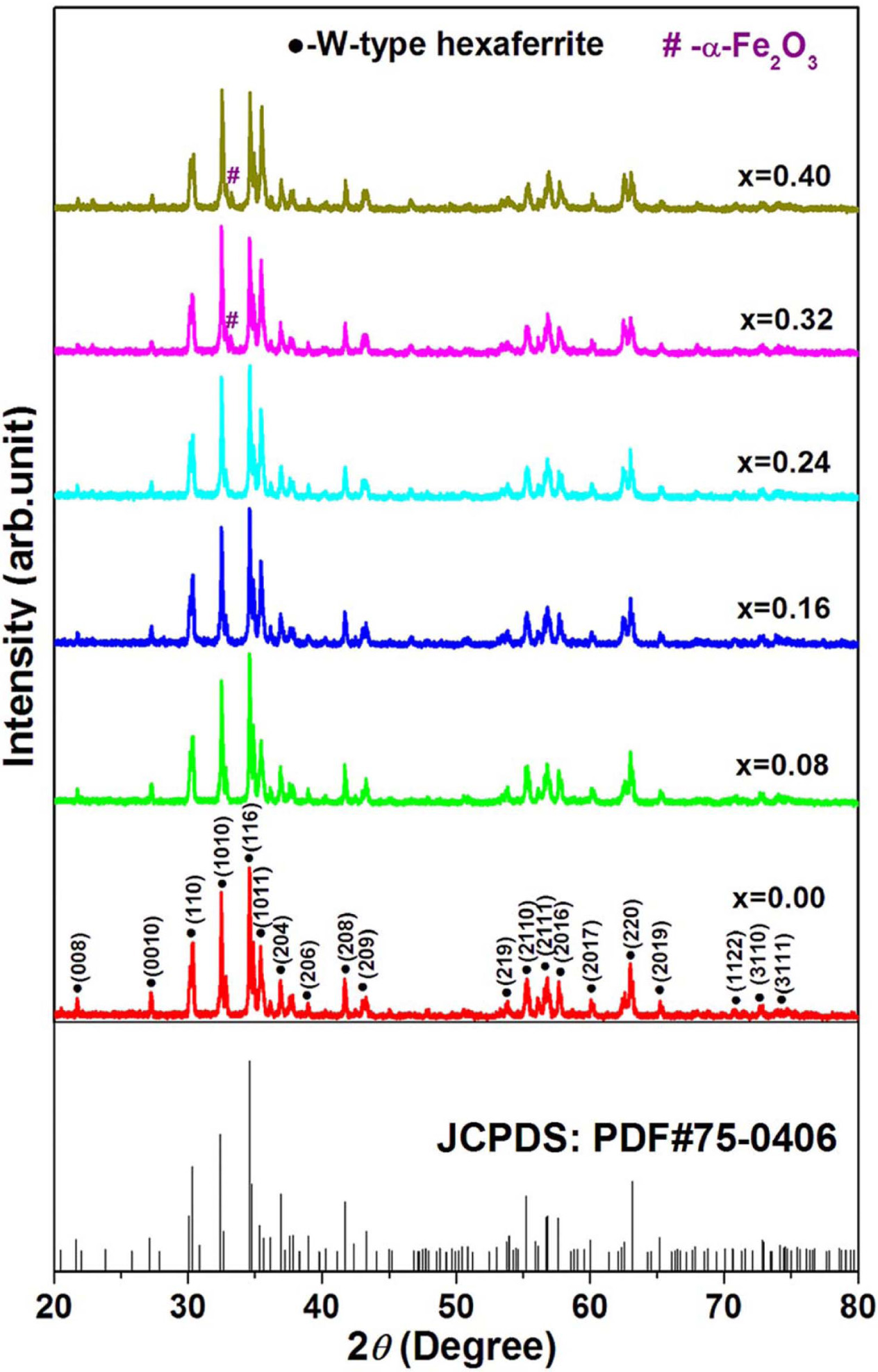

Fig. 1 presents the XRD patterns for strontium W-type

hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

(0.00 ≤ x ≤ 0.40). XRD patterns of all samples were indexed using the

standard pattern for W-type hexagonal ferrite (JCPDS card no.

75-0406). It can be observed from Fig. 1 that the W-type

hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

with Pr content (x) ≤ 0.24 are single-phased W-type hexaferrites, while for the

W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

at Pr content (x) ≥ 0.32, the W-type hexaferrite phase is a major phase and the

secondary phase α-Fe2O3 (JCPDS card no. 87-1166) is

observed.

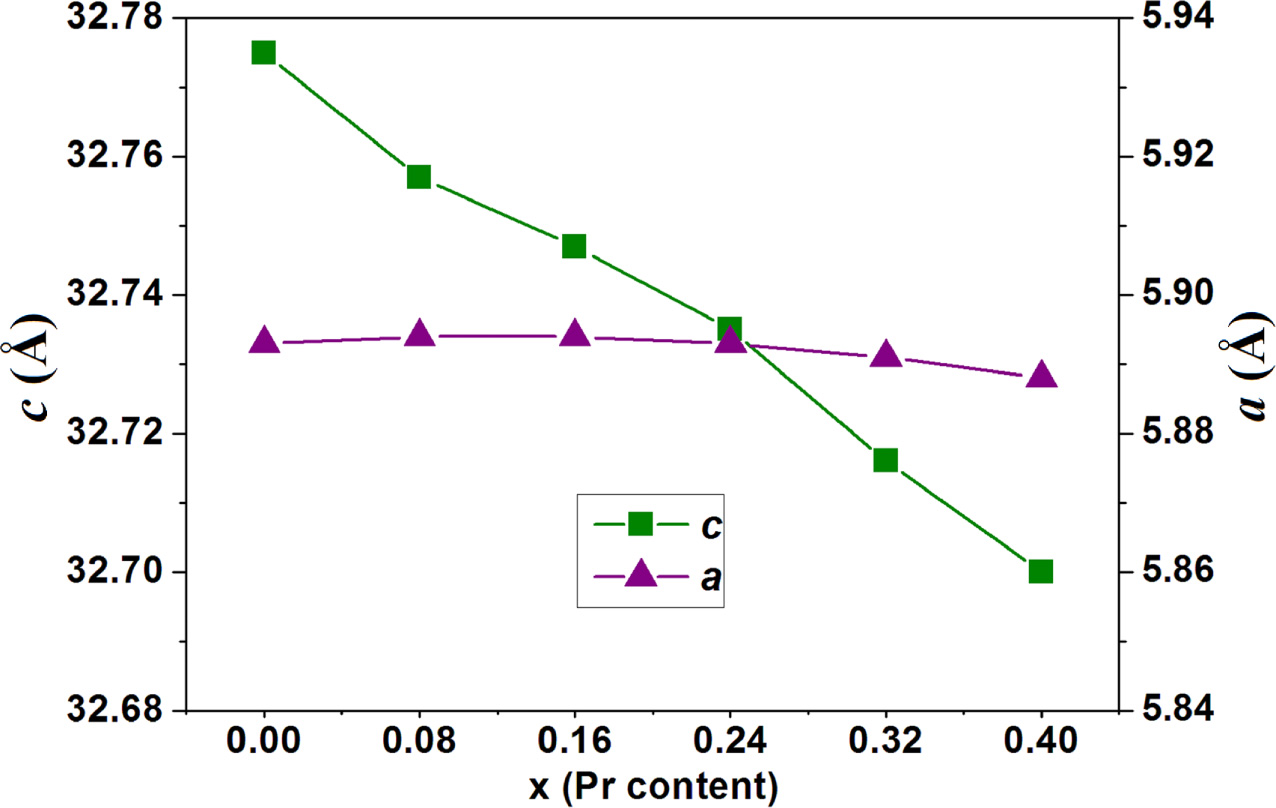

For W-type hexaferrites, lattice parameters a and c

were obtained from the values of dhkl corresponding to (1010)

and (116) planes using the following equation [22]:

where dhkl is the

inter planner spacing in the XRD pattern, and h, k and l are

the Miller indices. The variations of lattice parameters (a and c)

for the strontium W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

(0.00 ≤ x ≤ 0.40) are depicted in Fig. 2. By substituting the Sr2+ ions

with Pr3+ ions, the lattice parameter a reflects less

variation whereas the lattice parameter c decreases with increasing Pr

content (x) from 0.00 to 0.40. This is in agreement with the fact

that the hexaferrites display constant lattice parameter a and

changeable lattice parameter c [23]. For the strontium W-type

hexaferrites with Pr substitution, the decrease in lattice parameter c

is due to the difference in the ionic radii (Δr) of metal ions and the

number of ionic substitutions. It is known that the ionic radii of Sr2+,

Pr3+, Fe3+ and Fe2+ are 1.180 Å, 0.990 Å,

0.645 Å, and 0.78 Å, respectively. Substitution of Sr2+ (r =

1.180 Å) by Pr3+ (r = 0.990 Å) makes a negative difference in

the ionic radii of Δr = -0.190 Å. For Pr substituted W-type hexaferrites

Sr1-xPrxZn0.8Co1.2Fe16O27,

in order to compensate the excessive positive charges because of the

substitution of Sr2+ by Pr3+, some Fe3+ ions (r

= 0.645 Å) convert into Fe2+ ions (r

= 0.780 Å). This makes a positive

difference in the ionic radii of Δr = +0.135 Å. The above

two results exhibit that the crystal structures of strontium W-type hexaferrites

are contracted after being substituted by Pr3+ ions and the lattice

parameter c decreases with increasing Pr content (x).

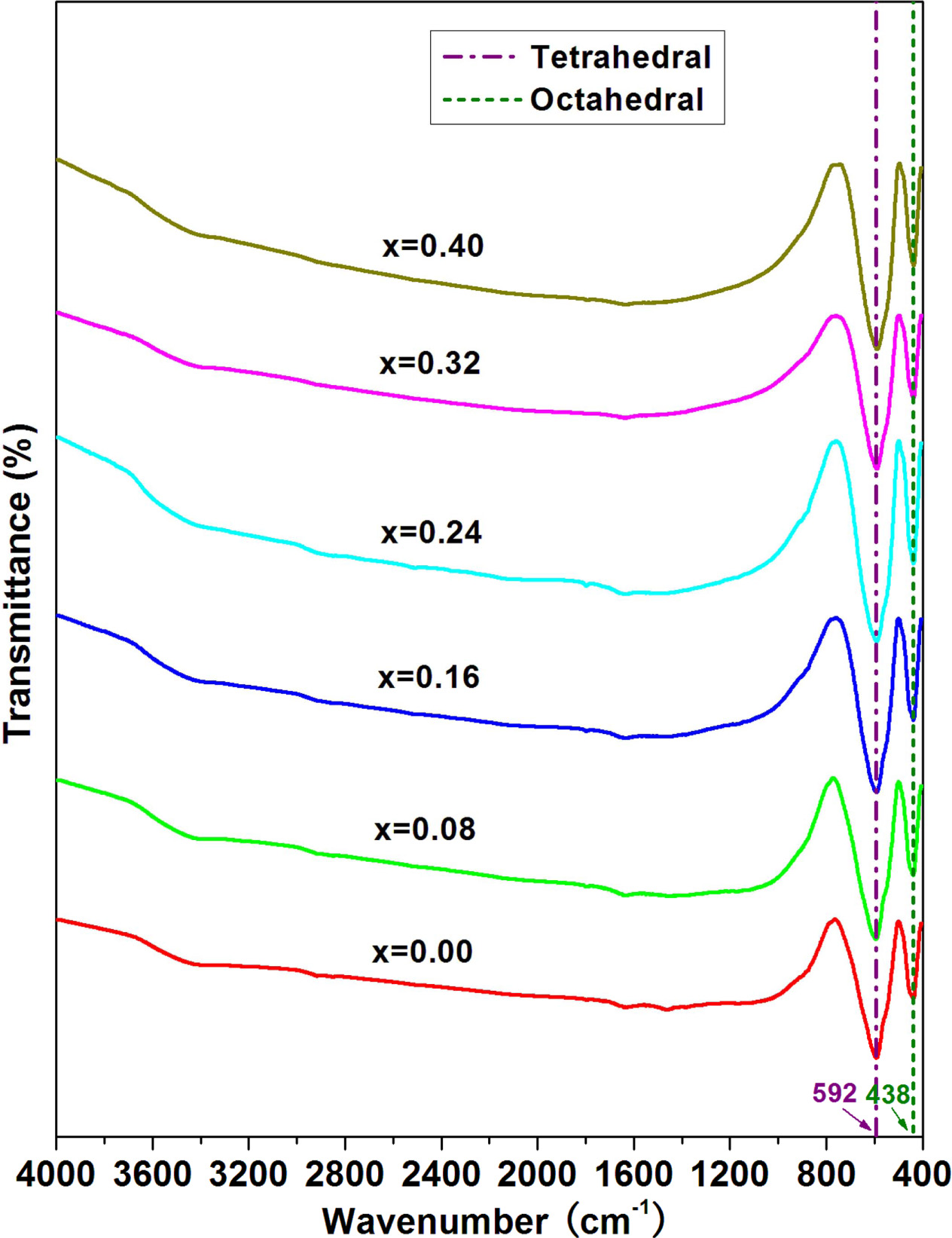

The FT-IR spectra of strontium W-type hexaferrites were

recorded in the wavenumber range of 400-4000 cm-1.

FT-IR spectra for strontium W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

(0.00 ≤ x ≤ 0.40) are illustrated in Fig. 3.

The absorption bands in the frequency range of 400-800 cm-1 are due to vibration

bonds of the hexagonal ferrites [24]. The

absorption band in the range 590-594

cm-1 is

caused by the stretching vibrations of tetrahedral metal ion and oxygen

bonding. And The absorption band in the range 438-440 cm-1 is

attributed to the stretching vibrations of octahedral metal ion and oxygen

bonding [25]. As seen from Fig. 3, the positions of

absorption bands do not change obviously, and the normal vibration mode of

tetrahedral cluster is higher than that of octahedral cluster. This is assigned

to shorter bond length of tetrahedral cluster and longer bond length of

octahedral cluster [26]. For all strontium W-type hexaferrites with different

Pr content (x), the absorption band at about 1,629 cm-1 and

about 3,389 cm-1 are

due to the stretching vibration of surface hedroxy group (-OH) because of water

in the W-type hexaferrites acquired from the process of preparation [27, 28].

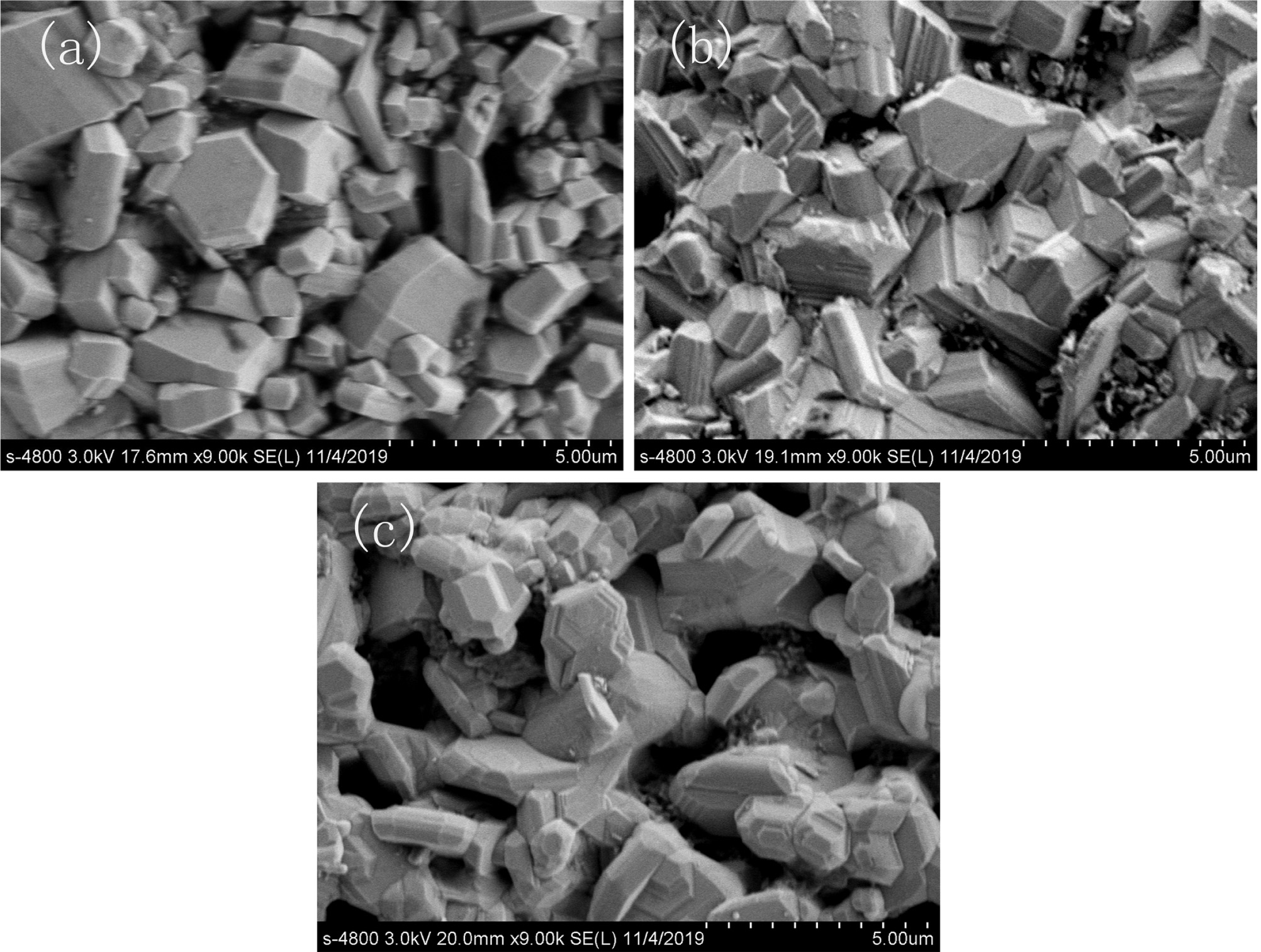

Fig. 4 provides the FE-SEM micrographs of strontium

W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

(x=0.00, 0.16, and 0.32) under 9k magnification. It can be noted that Pr

content (x) has no significant effect on the grain shape and morphology. The

grains are platelet-like morphology with the average grain

size of about 2.6 μm.

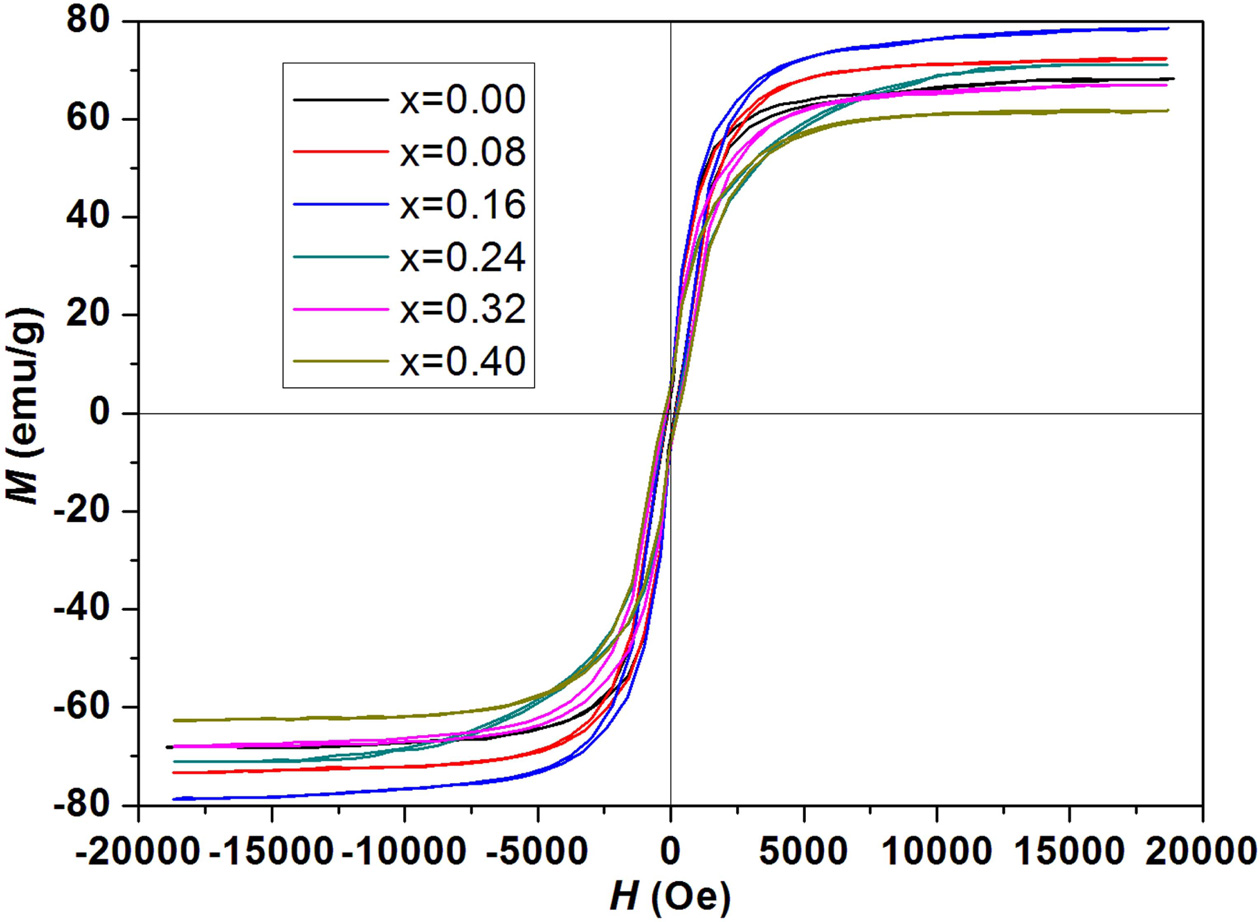

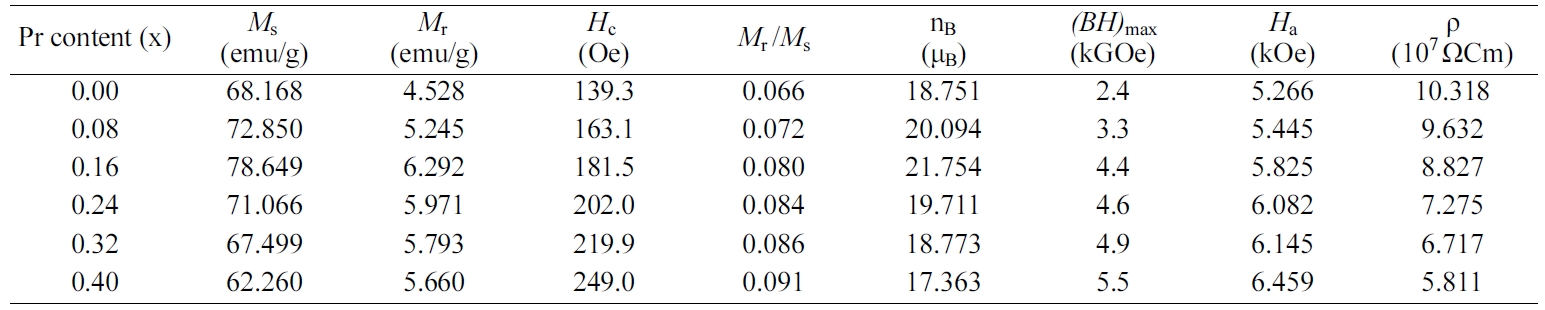

Magnetic hysteresis loops of strontium W-type hexaferrites

Sr1-xPrxZn0.8Co1.2Fe16O27

(0.00 ≤ x ≤ 0.40) are represented in Fig. 5. The values of hysteresis

parameteres are calculated from magnetic hysteresis loops with different Pr

content (x) and are tabulated in Table 1.

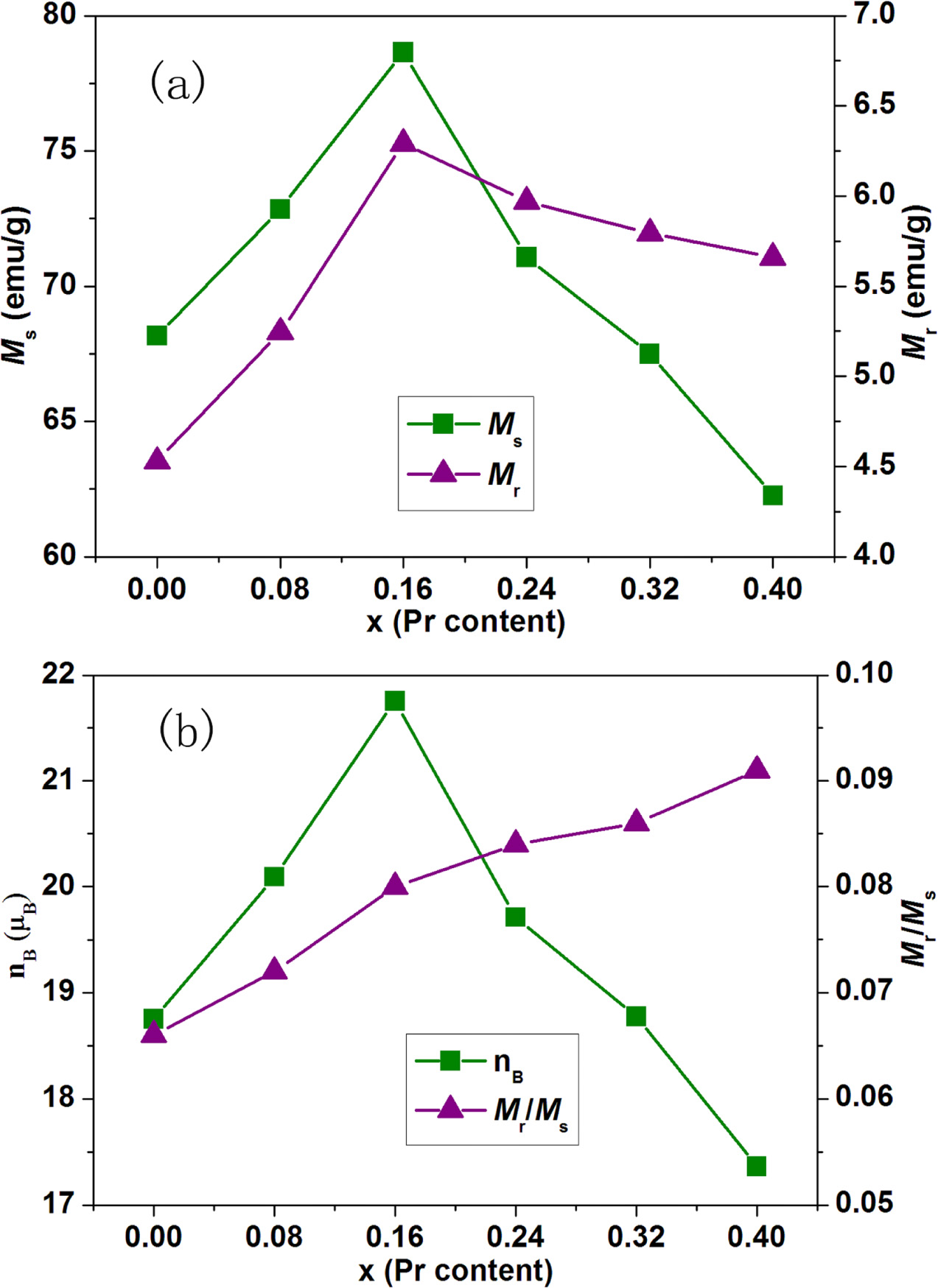

Fig. 6(a) describes the variations of saturation magnetization

(Ms) and remanent magnetization (Mr) as a

function of Pr content (x) for strontium W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27.

It is observed from Fig. 6(a) that the values of Ms and Mr

first increase from 68.168 and 4.528 emu/g at x = 0.00 to 78.649

and 6.292 emu/g at x = 0.16, respectively; and then decrease with Pr content

(x) from 0.16 to 0.40. The magnetic moment of Fe3+ and Fe2+ ions

is 5.0 μB and 4.0 μB, respectively. On the one hand, the

increase in Ms and Mr with Pr content (x)

from 0.00 to 0.16 can be attributed to the following reason. When Pr3+

ions substitute the Sr2+ ions in W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27,

the shrinkage of lattice parameter c as shown in Fig. 2 results in the

decrease of Fe-O which enhances the super-exchange interactions among the

sublattices [16, 29]. Therefore, Ms and Mr are

increased for the Pr substituted W-type hexaferrites (0.00 ≤ x ≤ 0.16). On the

other hand, with increasing Pr content (x) from 0.16 to 0.40, the

decreasing in Ms and Mr can be assignable

to the below three factors. Firstly, for the hexaferrites, the Fe3+

ions are arranged collinearly due to the superexchange

interactions. For the Pr substituted W-type

hexaferrites, in order to compensate the excessive positive

charges, the substitution of Sr2+ by Pr3+ causes some Fe3+

ions (5.0 μB) to convert into Fe2+ ions (4.0 μB).

Abundance of Fe2+ ions will cause the collinearity of the

superexchange interactions to break with increasing Pr content (x) from 0.16 to

0.40. This is spin canting or non-collinear magnetic order which results in the

decrease of Ms and Mr [33, 34]. Secondly,

the valence change of Fe3+ ions (5.0 μB) into Fe2+ ions

(4.0 μB) in order to balance the excessive positive charges

because of Sr2+ ions substituted by Pr3+ ions leads to

the decrease of net molar magnetic moment. This is magnetic dilution [29, 30].

As a result, the values of Ms and Mr decrease

continuously. Thirdly, for the W-type hexaferrites with Pr content (x) from

0.32 to 0.40, the secondary phase α-Fe2O3 is present as

shown in Fig. 1. As a secondary phase in the W-type hexaferrites, α-Fe2O3

has no contribution to the increase of Ms and Mr,

and can cause the values of magnetization to dilute. This leads to the decrease

of Ms and Mr.

The Bohr magneton number (nB) of strontium

W-type hexaferrites with different Pr content (x) was calculated by the

following relation [31]:

where M.W. is the molecular

weight and Ms is the saturation magnetization. The Mr/Ms

ratio is calculated from magnetic data. The variations of

magneton number (nB) and Mr/Ms

as a function of Pr content (x) for strontium

W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

are mentioned in Fig. 6(b). It is observed that the value of nB

increases from 18.751 μB at x = 0.00 to 21.754 μB at x =

0.16, and then decreases with increasing Pr content (x) from 0.16 to 0.40. nB

has the same varying trend as Ms exhibited in Fig. 6(a). This

shows that magnetic moment is the main mechanism behind the change of Ms.

The Mr/Ms ratio is known as squareness

ratio. As seen from Fig. 6(b), the value of Mr/Ms

ratio increases from 0.066 at x

= 0.00 to 0.091 at x = 0.40. This shows that the strontium W-type hexaferrites with

different Pr content (x) are

multi-domain structure.

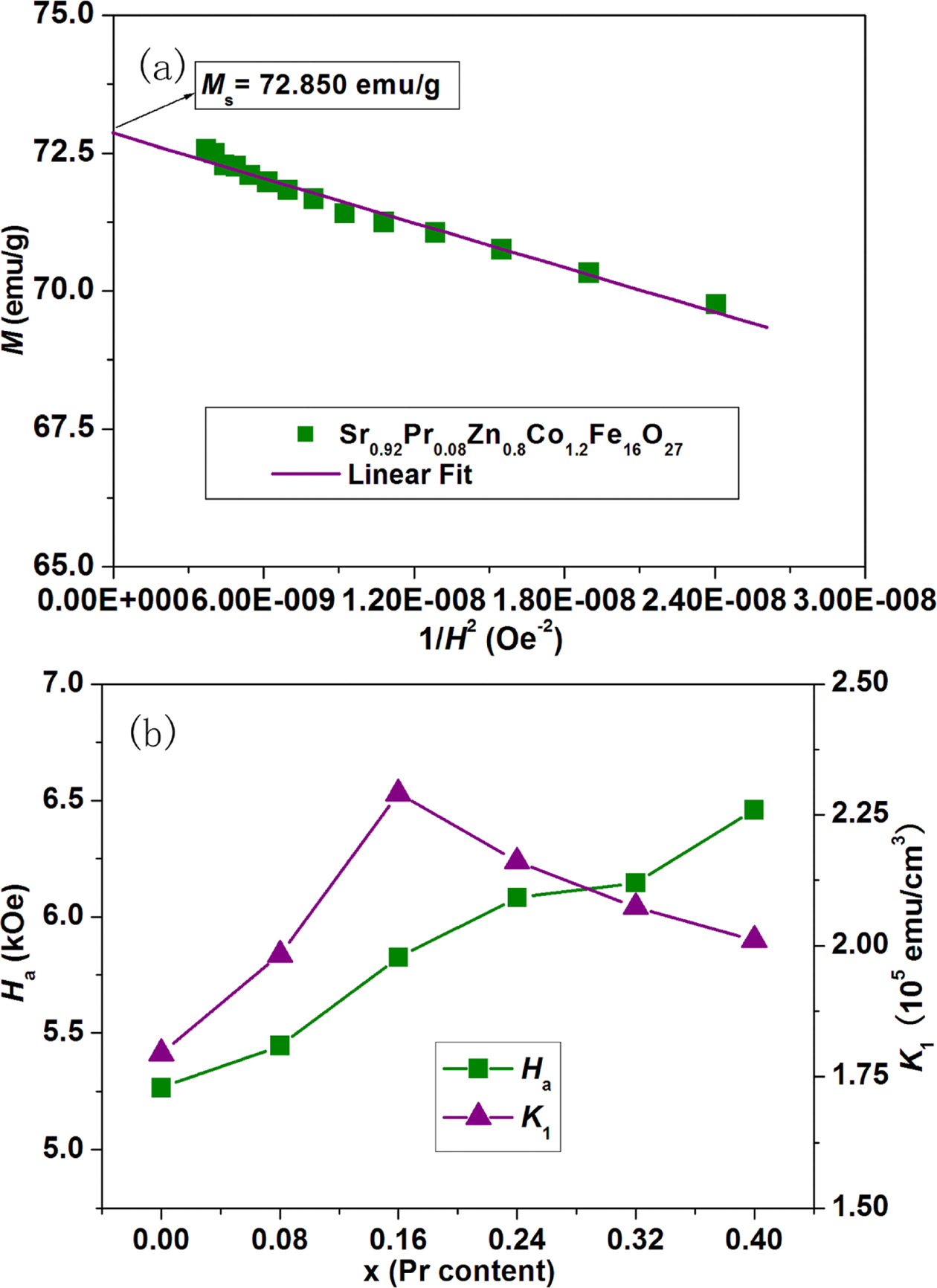

The magnetic anisotropy field (Ha) and

magneto- crystalline anisotropy

constant (K1) are determined according to the law of approach

to saturation [32]. The relationship between the magnetization (M) and

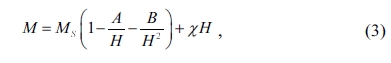

sufficiently high magnetic fields (H) is expressed as follows [33]:

where Ms is

saturation magnetization, A is a constant arising from the

inhomogeneities, the constant B is related with

the magnetic crystalline anisotropy constant, H is

the magnetic field in this region, and χ represents the high-field

differential susceptibility. The constant A is approximate to zero. χ

is neglected at high magnetic field. The M vs. 1/H2 plot

in the high magnetic field gives a straight line. Fig. 7(a) reveals the plot of magnetization of strontium W-type

hexaferrite Sr0.92Pr0.08Zn0.8Co1.2Fe16O27

as a function of 1/H2. The slope

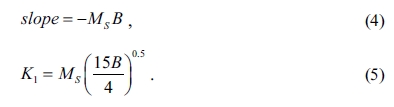

gives the value of B. The first anisotropy constant (K1)

can be calculated using the following equation [34]:

The calculated values of K1 can be used

to estimate the magnetic anisotropy field (Ha) of the W-type

hexaferrites by using the below expression [34]:

The variations of Ha and K1

as a function of Pr content (x) for strontium W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

are exhibited in Fig. 7(b). It could be seen that the value of K1

initially increases from 1.795×105 emu/cm3 at x = 0.00 to

2.291×105 emu/cm3 at x = 0.16, and then decreases when Pr

content (x) ≥ 0.16; while the value of Ha increases from

5.266 kOe at x = 0.00 to 6.459 kOe at x = 0.40 as a result of increasing Pr

content (x). The increase of Ha can ascribed to the following

two reasons. Firstly, for the hexaferrites, the low symmetry of trigonal

bipyramidal 2b site is the main contributor to the stronger uniaxial

magnetocrystalline anisotropy [35]. Substitution of Sr2+ (r =

1.180 Å) by Pr3+ (r = 0.990 Å) can lead to greater lattice

distortion and lower symmetry of trigonal bipyramidal 2b site [36]. This causes

Ha to increase. Secondly, it has been reported that Fe2+

ions could increase the magnetic anisotropy field because of strong

magnetocrystalline anisotropy of Fe2+ ions [37]. The number of Fe2+

ions increases with increasing Pr content (x) because the substitution of

Sr2+ by Pr3+ causes some Fe3+ ions to convert

into Fe2+ ions in order to compensate the excessive positive

charges. Thus, Ha is enhanced.

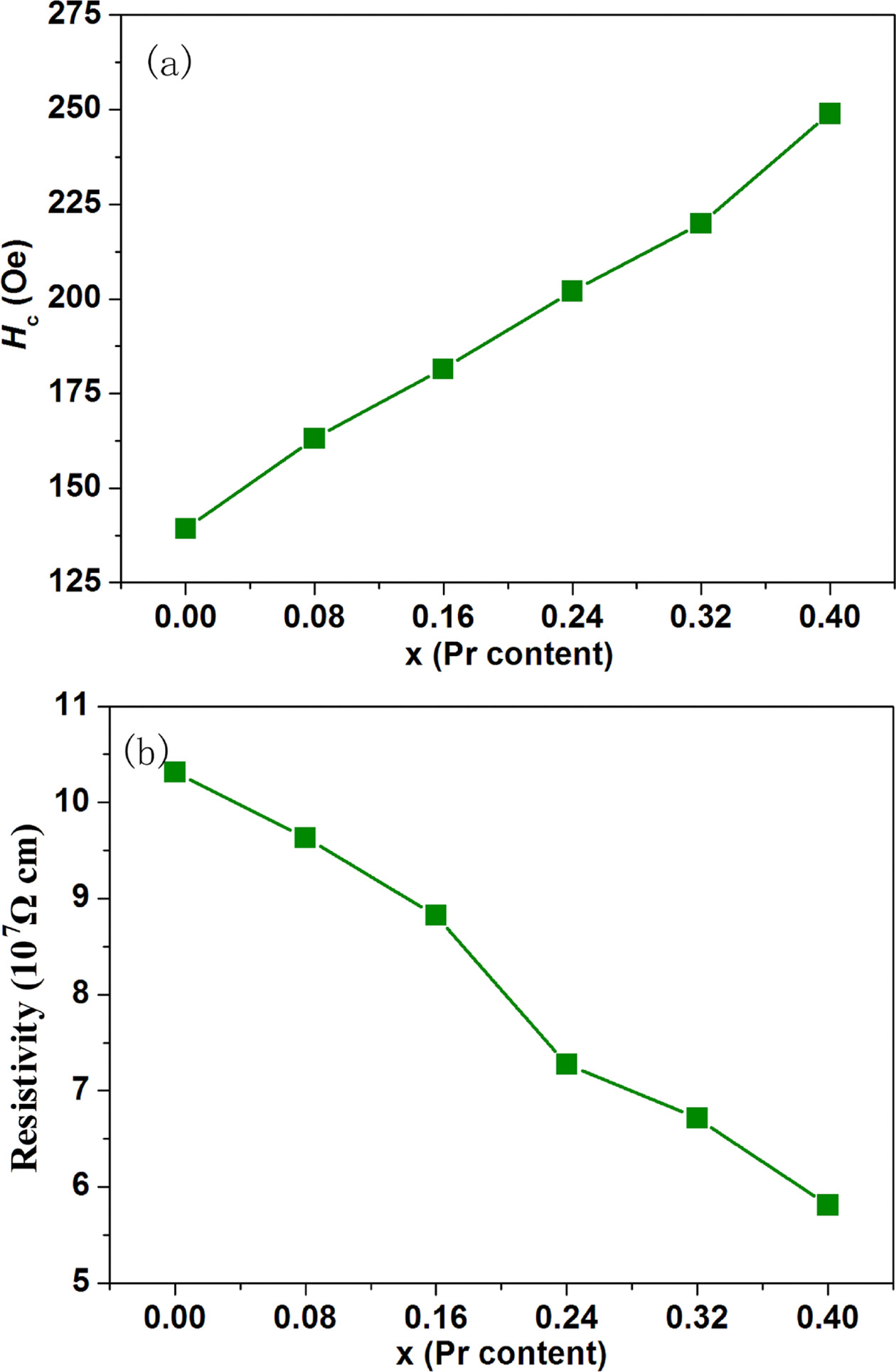

Fig. 8(a) represents the variation of coercivity (Hc)

as a function of Pr content (x) for strontium W-type hexaferrites Sr1-xPrx

Zn0.8Co1.2Fe16O27. It is worthy to

note that with increasing Pr content (x), the value of Hc

enhances from 139.3 Oe at x = 0.00 to 249.0 Oe at x = 0.40. The coercivity (Hc)

is corrected with the intrinsic magnetic parameters and microstructure based on

the following relation [38]:

where α is a microstructure factor

that raises with decreasing grain size, N is called the

demagnetizing factor determined by many factors one of which is aspect ratio

and μ0 is the permeability of free space. Fig. 4 shows

that the platelet-like shapes and average grain size are basically unchanged

with Pr substitution. Hence, α and N basically remain

constant. According to the relation (7), we can conclude

that the enhancement of coercivity (Hc) is primarily

due to the increase of magnetic anisotropy field (Ha) as

displayed in Fig. 7(b). As seen from Table 1, the value of

maximum energy product [(BH)max]

for strontium W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

increases with increasing Pr content (x) from 0.00 to 0.40. It is well known

that the maximum energy product can be

obtained by multiplying the corresponding B and H values at the point of

operation on the demagnetizing curves [39]. Therefore, the values of the

remanent magnetization (Mr) and coercivity (Hc)

have effect on the value of (BH)max.

As seen from Fig. 6(a) and Fig. 8(a), the changing trend of (BH)max are owing to

both the variation of Mr and variation of Hc.

Therefore, magnetic properties of the strontium W-type hexaferrites can be

increased with the substitution of Pr3+ ions for Sr2+

ions.

The variation of DC electrical resitivity (ρ) as a

function of

Pr content (x) for strontium W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27

is revealed in Fig. 8(b) and the values of ρ are also listed in Table 1.

It can be observed that ρ is obviously affected by Pr

content (x). With the increase of Pr content (x), the electrical resitivity (ρ)

decreases from 10.318×107 Ωcm at x = 0.00 to

5.8113×107 Ωcm at x =0.40. It is reported that the conductivity in

the hexaferrites can be attributed to the

hopping between Fe3+ and Fe2+ ions at the octahedral sites

[39]. For Pr substituted W-type hexaferrites Sr1-xPrxZn0.8Co1.2Fe16O27,

in order to compensate the excessive positive charges because of the

substitution of Sr2+ by Pr3+, some Fe3+ ions

convert into Fe2+ ions. This increases the number of Fe2+ ions

which leads to the increase of the hopping probability between the Fe3+

and Fe2+ ions. Thus, the above factors cause the electrical

resitivity (ρ) to decrease.

|

Fig. 1 XRD patterns of strontium W-type hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27 (0.00 ≤ x ≤ 0.40). |

|

Fig. 2 Variations of lattice parameters (c and a) for strontium Wtype hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27 (0.00 ≤ x ≤ 0.40). |

|

Fig. 3 FT-IR spectra for strontium W-type hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27 (0.00 ≤ x ≤ 0.40). |

|

Fig. 4 FE-SEM micrographs of strontium W-type hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27 with Pr content (x) of (a) x=0.00, (b) x=0.16, and (c) x=0.32. |

|

Fig. 5 Magnetic hysteresis loops of strontium W-type hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27 (0.00 ≤ x ≤ 0.40). |

|

Fig. 6 Variations of (a) saturation magnetization (Ms) and remanent magnetization (Mr), and (b) magneton number (nB) and Mr/Ms as a function of Pr content (x) for strontium W-type hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27. |

|

Fig. 7 (a) A plot of magnetization of strontium W-type hexaferrite Sr0.92Pr0.08Zn0.8Co1.2Fe16O27 as a function of 1/H2, and (b) variations of the magnetic anisotropy field (Ha) and first anisotropy constant (K1) as a function of Pr content (x) for strontium W-type hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27. |

|

Fig. 8 Variation of (a) coercivity (Hc), and (b) DC electrical resitivity (ρ) as a function of Pr content (x) for strontium W-type hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27. |

|

Table 1 Values of the hysteresis parameteres and DC electrical resitivity (ρ) for strontium W-type hexaferrites Sr1-x PrxZn0.8Co1.2Fe16O27 (0.00 ≤ x ≤ 0.40). |

This work was supported by the National Natural Science Foundation of

China (Nos. 51872004, 51802002),

Education Department of Anhui Province (Nos. KJ2013B293, KJ2018A0039).

- 1. L. Lechevallier, J.M. Le Breton, J.F. Wang, and I.R. Harris, J. Magn. Magn. Mater. 269[2] (2004) 192-196.

-

- 2. P. Shepherd, K.K. Mallick, and R.J. Green, J. Magn. Magn. Mater. 311[2] (2007) 683-692.

-

- 3. S.Wei, Y. Liu, H. Tian, H. Tong, Y.Liu, and B.Xu, J. Magn. Magn. Mater. 377 (2015)[1] 419-423.

-

- 4. R.C. Pullar, Prog. Mater. Sci. 57[7] (2012) 1191-1334.

-

- 5. D.M. Hemeda, A. Al-Sharif, and O.M. Hemeda, J. Magn. Magn. Mater. 315[1] (2007) L1-L7

-

- 6. X.Z. Zhou, I. Horio, A.H. Morrish, Z.W. Li, and K. Hanava, IEEE Trans. Magn. 27[6] (1991) 4651-4653.

-

- 7. M.J. Iqbal, R.A. Khan, S. Mizukami, and T. Miyazaki, J. Magn. Magn. Mater. 323[16] (2011) 2137-2144.

-

- 8. L. Deng, L. ding, K. Zhou, S. Huang, Z. Hu, and B.C. Yang, J. Magn. Magn. Mater. 323[14] (2011) 1895-1898.

-

- 9. M. Ahmad, I. Ali, F. Aen, M.U. Islam, M. N. Ashiq, S. Atiq, W. Ahmad, and M.U. Rana, Ceram. Int. 38[2] (2012) 1267-1273.

-

- 10. S. Ruan, B. Xu, H. Suo, F. Wu, S. Xiang, and M. Zhao, J. Magn. Magn. Mater. 212[1-2] (2000) 175-177.

-

- 11. F. Lv, X. Liu, S. Feng, K. Huang, X. Niu, X. Huang, F. Huang, Y. Ma, S. Jiang, and Y. Wu, Mater. Lett. 157[20] (2015) 277-280.

-

- 12. C. Sürig, K.A. Hempel, R. Müller, and P. Görnert, J. Magn. Magn. Mater. 150[2] (1995) 270-276.

-

- 13. F. Gu, G. Ji, J. Xu, H. Zou, S. Gan, and X. Xu, J. Magn. Magn. Mater. 324[6] (2012) 1209-1213.

-

- 14. M. Ahmad, F. Aen, M.U. Islam, S.B. Niazi, and M.U. Rana, Ceram. Int. 37[8] (2011) 3691-3696.

-

- 15. I. Sadiq, I. Khan, F. Aen, M.U. Islam, and M.U. Rana, Physica B 407[8] (2012) 1256-1261.

-

- 16. J. Xu, H. Zou, H. Li, G. Li, S. Gan, and G. Hong, J. Alloys Compd. 490[1-2] (2010) 552-556.

-

- 17. L.X. Wang, J. Song, Q.T. Zhang, X.G. Huang, and N.C. Xu, J. Alloys Compd. 481[1-2] (2009) 863-866.

-

- 18. F. Aen, M.F. Wasiq, M.U. Rana, H.M. Khan, and H.A. Khan, Ceram. Int. 42[14] (2016) 16077-16083.

-

- 19. X.G. Huang, J. Zhang, H.Z. Wang, S.T. Yan, L.X. Wang, and Q.T Zhang, J. Rare Earths 28[6] (2010) 940-943.

-

- 20. I. Khan, I. Sadiq, M.N. Ashiq, and M.-U.-D. Rana, J. Alloys Compd. 509[31] (2011) 8042-8046.

-

- 21. I. Khan, I. Sadiq, I. Ali, M.-U.-D. Rana, M. Najam-Ul-Haq, A. Shah, I. Shakir, and M.N. Ashiq, J. Magn. Magn. Mater. 397 (2016)[1] 6-10.

-

- 22. P. Kaur, S.B. Narang, and S. Bahel, Ceram. Int. 42[8] (2016) 9830-983.

-

- 23. M.J. Iqbal and M.N. Ashiq, Chem. Eng. J. 136[2-3] (2008) 383-389.

-

- 24. S. Güner, I.A. Auwal, A. Baykal, and H. Süzeri, J. Magn. Magn. Mater. 416 (2016) 261-268.

-

- 25. A.M. Shaikh, S.A. Jadhav, S.C. Watawe, and B.K. Chougule, Mater. Lett. 44[3-4] (2000) 192-196.

-

- 26. A. Pradeep and G. Chandrasekaran, Mater. Lett. 60[3] (2006) 371-374.

-

- 27. A. Ghasemi, Ceram. Int. 42[3] (2016) 4143-4149.

-

- 28. X. Liu, W. Zhong, S. Yang, Z. Yu, B. Gu, and Y. Du, J. Magn. Magn. Mater. 238[2-3] (2002) 207-214.

-

- 29. X.S. Liu, W. Zhong, S. Yang, Z. Yu, B.X. Gu, and Y.W. Dou, Phys. Stat. Sol. A 193[2] (2002) 314-319.

-

- 30. J. Tang, X.S. Liu, K.M. Ur Rehman, M.L. Li, C. Zhang, X.Y. Meng, H.H. Li, and C.C. Liu, J. Mater. Sci.: Mater. Electron. 28[16] (2017) 12086-12091.

-

- 31. M.G. Han, Y. Ou, W.B. Chen, and L.J. Deng, J. Alloys Compd. 474[1-2] (2009) 185-189.

-

- 32. R.E. El Shater, E.H. El-Ghazzawy, and M.K. El-Nimr, J. Alloys Compd. 739[6] (2018) 327-334.

-

- 33. Y. Yang, F.Wang, J. Shao, D. Huang, H. He, A.V. Trukhanov, and S.V. Trukhanov, J. Alloys Compd. 765[20] (2018) 616-623.

-

- 34. Z. Zhou, Z. Wang, X. Wang, X.Wang, J.Zhang, F. Dou, M. Jin, and J. Xu, J. Alloys Compd. 610[20] (2014) 264-270.

-

- 35. I. Bsoul, S.H. Mahood, A.-F. Lehlooh, and A. Al-Jamel, J. Alloys Compd. 551[4] (2013) 490-495.

-

- 36. S. Qunnunkad, Solid State Commun. 138[9] (2006) 472-475.

-

- 37. L. Peng, L.Li, X. Zhong, Y. Hu, and S. Chen, J. Magn. Magn. Mater. 428[8] (2017) 73-77.

-

- 38. K.H.J. Buschow and F.R. De Boer, in “Physics of Magnetism and Magnetic Materials” (Springer US, 2003) p.131.

-

- 39. M. El-Saadawy, J. Magn. Magn. Mater. 219[1] (2000) 69-72.

-

This Article

This Article

-

2020; 21(3): 378-385

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.378

- Received on Dec 15, 2019

- Revised on Mar 19, 2020

- Accepted on Mar 20, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Yujie Yang

-

Engineering Technology Research Center of Magnetic Materials, School of Physics & Materials Science, Anhui University, Hefei 230601, P. R. China

Tel : +86 551 63861257

Fax: +86 831 63861257 - E-mail: loyalty-yyj@163.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.