- Assessment of the partial and total replacement of feldspar by waste glass on porcelain properties

Marwa Marza Salman* and Hussein Talab Nhabih

Faculty of Materials Engineering, Babylon University, Babylon, Iraq

In this study, soda-lime

silica waste glass was used as partial and total replacement for feldspar in

porcelain. The prepared samples from feldspar, quartz, kaolin and different

percentages of waste glass by powder technology technique were sintered at

1,100 ºC and 1,200 ºC. The tests measured for samples involves

mechanical, physical and thermal properties. A results of these tests indicated

an increasing and decreasing in the samples properties with increasing of waste

glass additive, and that continues to 75% waste glass of feldspar. While X-ray diffraction

analysis indicated a presence of tridymite phase SiO2, mullite phase

2SiO2.3Al2O3 and anorthite phase CaAl2Si2O8

in the sample contained 100% waste glass of feldspar and fired at

1,200 ºC. This study showed possibility of replacement of feldspar used in

porcelain industry by waste glass as flux, and a percent of waste glass

additive, which gives the best properties of porcelain samples, is 75% wt. of

feldspar.

Keywords: soda-lime silica waste glass, porcelain, feldspar, fracture strength, kaolin

Reusing of some materials waste into ceramics manufacture

has been widely studied in the last years in order to economically justify the

great costs related to its manufacture as well as to evade landfilling these

wastes [1-5].

Porcelain products are made in most of world countries and

porcelain's technology is described in many papers

and diverse textbooks [6]. The term porcelain is more

accurately limited to translucent vitreous ware though it is occasionally used

to a variation of vitreous and semi vitreous ware. Porcelain is

a hard, fine-grained, nonporous [7]. A wide-ranging compositions of

triaxial ceramic which are utilized in the

industries of white ware essentially comprise quartz, feldspar

and kaolin. Porcelain shells and porcelain insulators are significant equipment

in the insulation operation of transformer substations and power plants and

supporting wire [8]. Materials of porcelain have high-interest

properties to various industrial applications, such as

high mechanical strength; low thermal conductivity; very low thermal expansion

and excellent thermal shock [9, 10].

One of the materials which use as flux in the industry of

porcelain is feldspar. Feldspar is forming around 60% of

earthly rocks by far the most plentiful group for minerals in

the earth crust. Potassium feldspar, sodium feldspar and mixed feldspars are

offered in most deposits. Feldspars are mainly utilized in

manufacturing applications because their alkali and alumina

content. The term feldspar includes a entire range of materials. More the

products we utilize as a basis in daily life are manufactured

by feldspar: glass for protection, glass for drinking, the

tableware from which we eat, fiberglass for insulation and the shower basins

and floor tiles in our bathrooms. Feldspar can be an essential part in our

daily life [11, 12].

The most common and cheapest form of glass is soda-lime

silica glass, where it forms 90% of glass made. It generally

comprises 5-12% lime, 12-18% soda, and 60-75% silica. Its resistance to thermal

shock and resistance to elevated temperatures are low, and resistance to the

corrosive substances is only fair. For soda-lime glass, the melting temperature

is 1,000 oC while the glass transition temperature is

520-600 oC [13]. A large volumes of waste container glass from

bottle banks produced worldwide are presently earth filled. The container glass

involves primarily sodium, calcium and silicon oxides (denoted to as

soda-lime-silica glass, which can be symbol with SLS glass), where SLS glass

includes primarily sodium, calcium and silicon oxides with other secondary

constituents, such as aluminium oxide (Al2O3) and

magnesium oxide (MgO). SLS waste glass is non-hazardous and its recycling can

significantly reduce the consumption of natural raw materials yielding both economical

and environmental benefits. The chemical composition of SLS glass is alike to

that of natural fluxes utilized in the industry of whitewares such as nepheline

syenite and feldspar [14].

Added glass is expected to act as a flux promoting the

formation of liquid phase and thus reducing the clay body

maturation temperature. Possible commixtures in glass

waste, such as ceramics and stones, can make as filler substance. Additional

interests of the recycled glass in the ceramic manufacturing

can be more practical in nature. The industrial ceramics

sector uses large volumes of materials, therefore large amounts of glass can be

recycled. At the same time, transportation costs can be kept at a minimum since

industries are usually geographically widespread. Furthermore, the reduced

specific heat of glass in conjunction with its low energy demand

for the physico-chemical transformations during firing and

the expected decrease in body maturation temperature can contribute to energy

saving [15]. In 2005, Pontikes Y., et al. investigated possibility of

introducing soda-lime silica scrap glass (SLS glass waste) for ceramics

production, the axes of research were: i) production of porcelain stoneware

tiles by substituting diverse quantities of sodium feldspathic sand and ii)

production of roofing tiles by substituting part of the standard clay mixture

[15]. In 2012 Çagatay K., et al. studied an use of borosilicate glass waste as

a fluxing agent in porcelain bodies [16]. In 2014, Tarnkamol T. and

Guilherme P. S. used soda-lime silica waste glass as partial substitution for

natural fluxes in whiteware formulations may significantly contribute to

continuous development of the glass industries and traditional ceramics [14].

In 2018, Khaled B., et al. studied the effects of waste glass recycling

which derived from broken car glass as partial substitution of potassium

feldspar in porcelain, a results of this study stated an important effects of

sintering temperature and waste glass recycling substitution on the physical

properties [9].

The present study aims to investigate an use effects of

soda-lime silica waste glass as partial and total replacement

for feldspar which uses as flux in porcelain industry

on the different properties for porcelain samples; such as

mechanical, physical and thermal properties; and to determine approximately the

percent of additive waste glass which gives more effect on the properties of porcelain samples.

Consequently, the contribution in a

development of the ceramics industries and an elimination of the large volumes

of waste container glass from the land, and that leads to an economical and

environmental benefits).

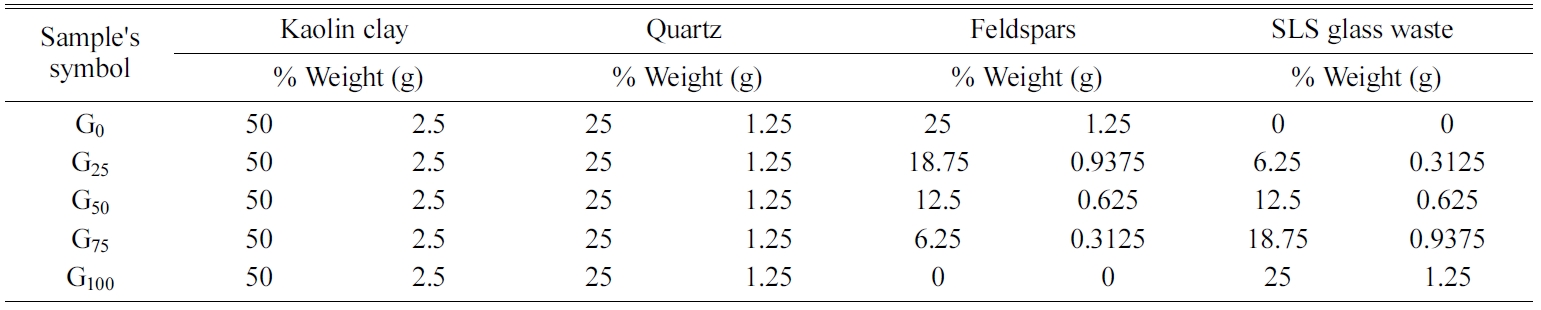

The current study utilizes available raw materials to

produce porcelain samples, where these samples were prepared from a blend of

kaolin clay, quartz as a filler, and feldspar and colorless soda-lime silica

glass waste as fluxing agents by using powder technology.

Materials

preparation

The grinding, sieving, weighting and mixing process were

made for the powders of materials which used in the present

study by use an electrical equipment prepared for that

purpose. Where these powders were mixed according to

the mixing percentages in Table 1 by use the

electrical mixer for 3 h to obtain a homogeneous mixture.

Samples

formation

A steel die with diameter 20 mm and hydraulic uniaxial

pressing machine were used in the formation of porcelain samples by using a semi

dry pressing technique and a pressure of 60 MPa, then temperature 110 ºC

was selected to dry the formed samples for five hours to eliminate the wetness

from the samples and temperatures 1,100 ºC and 1,200 ºC were selected

to sinter it with heating rate 5 ºC/min and soaking period 2 h, the

cooling of samples was finished in the furnace. Fig. 1 displays the sintered

samples.

Tests

The tests which were made for porcelain samples produced

were included the mechanical properties (hardness and fracture strength), the

physical properties (linear shrinkage, density, porosity and XRD) and thermal

properties (DTA), which were done as the following:

Mechanical

properties

Depending on ASTM standard (C 773-88) [17], fracture

strength of the samples was tested using general testing

machine. Fracture strength was determined from the following formula.

бf = L / CA (1)

where бf is a fracture strength

(MPa); L is an applied load up to fracture (N); CA is a cross

section area mm2.

Apparatus of digital microvickers hardness tester (TH-717) was utilized

to test Vickers hardness of porcelain samples according to ASTM standard C1327-90 by

use Vickers indentation manner by 9 kg load applied through 10 seconds

on a surfaces of the specimens. The equation

below was utilized to calculate

Vickers hardness values of porcelain samples [18].

HV = 1.854 × F/ d2 (2)

where HV is vickers hardness of the

samples (kg/mm2); F is an indentation load (kg); d is a half of the

indentation diagonal (mm).

Physical

properties

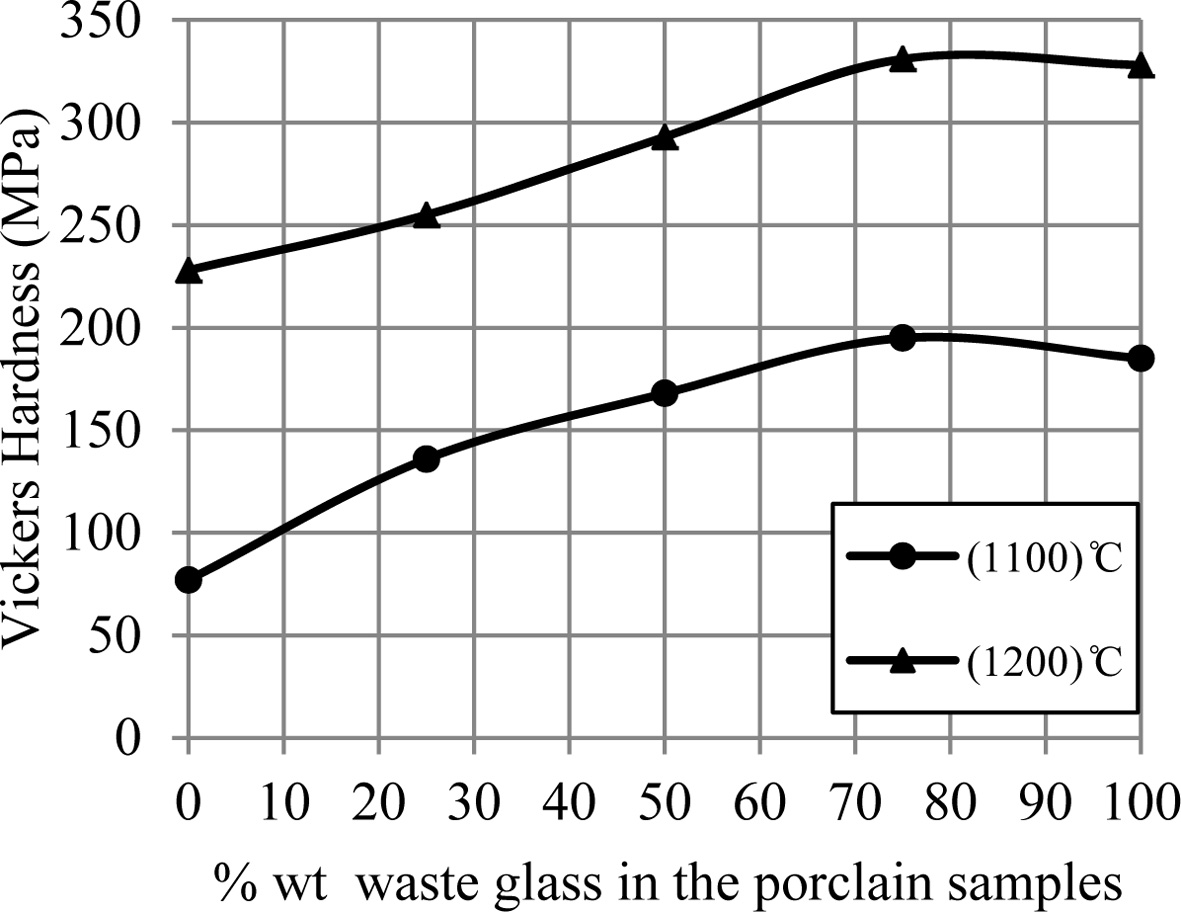

A linear shrinkage on firing of porcelain samples was

evaluated according to ASTM standard C326 by use the equation below [19].

where (L.S) is a linear shrinkage of

porcelain samples; D1 and D2 are the external diameter

for the samples before and after sintering process respectively.

Archimedes technique was utilized to measure the density

and porosity of porcelain samples which were measured according to (ASTM

C373-88) standard, and the formula below was utilized to find a bulk density of

porcelain samples [20, 21].

where D is the bulk density of

porcelain samples (g/cm3); Dwater is the water's

density (g/cm3); MD is the sample's dry mass (g); MP

is the sample's suspended mass (g); MS is the sample's

water-saturated mass (g).

Also the formula below was utilized to find an apparent

porosity of porcelain samples.

where Po = the percent of

apparent porosity of porcelain samples.

X-ray diffraction test was made for a powder of porcelain

specimens to detect a crystalline phases developed in porcelain samples

produced. A mortar and pestle were used to grind porcelain samples to get the

fine powder of samples which was tested by X-ray diffraction. A (SHIMADZU XRD –

6000) machine was utilized in this test to obtain the X-ray diffraction

patterns. An anode of Cu with voltage [40 kv] and current [30 mA] was utilized

to obtain the incessant scan mode using range (θ-2θ) as (20o - 70o),

a speed of the scan was (7o (θ)/min) and a size of the step was (2θ

=0.0200o)

Differential

thermal analysis (DTA)

Differential thermal analysis (DTA) was made to examine

the thermal changes for porcelain samples with and without an addition of the

waste glass for it. A fine powder of porcelain samples produced was used in

this test. Temperature range 0-800 oC was utilized to perform the

DTA analysis by the heating rate 5 oC/min. DTA-50 apparatus linked to

a program and control unit which shows a result of this test.

|

Fig. 1 The sintered samples: a group (A) at (1,100 ºC) and a group (B) at (1200 ºC). |

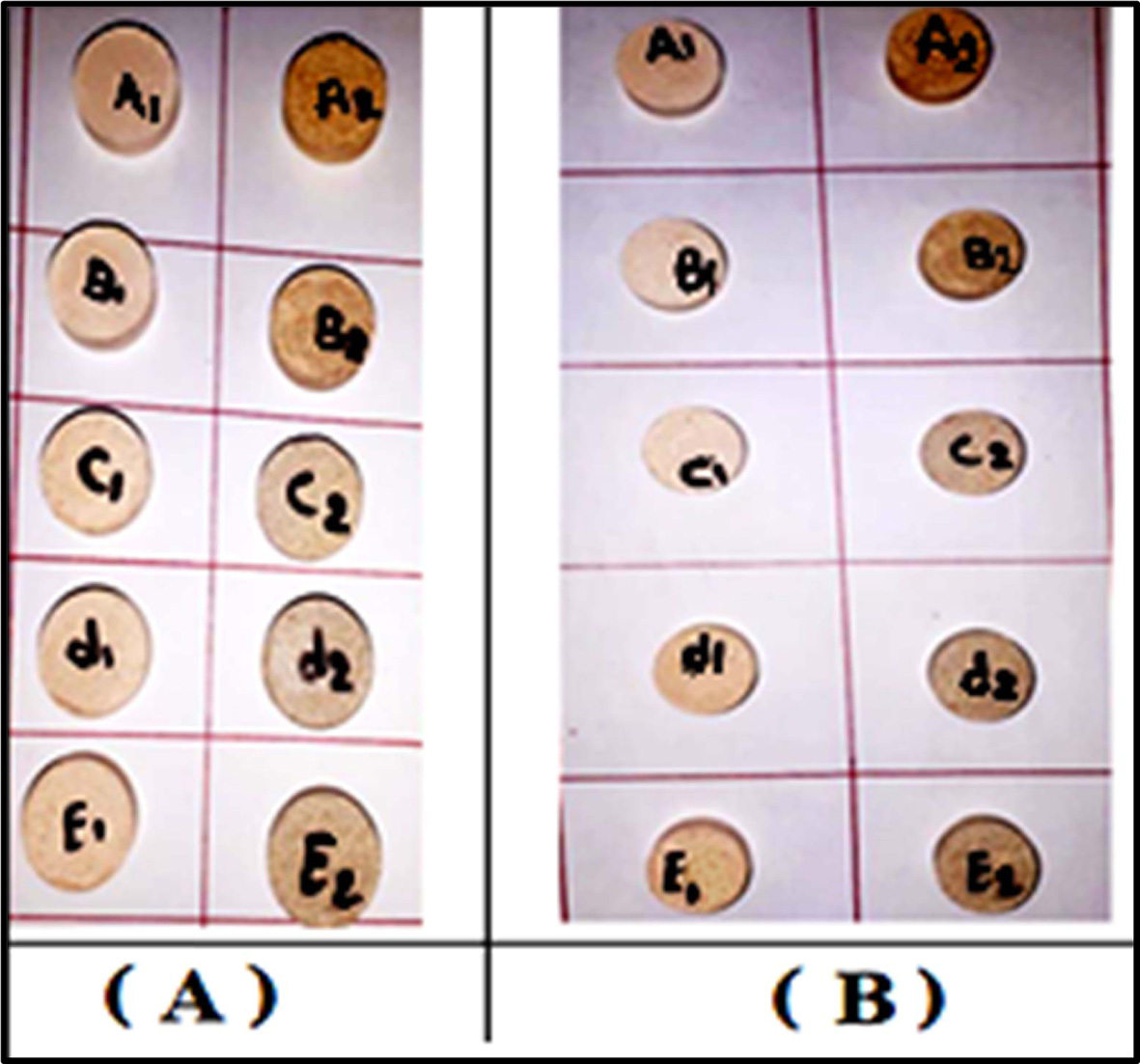

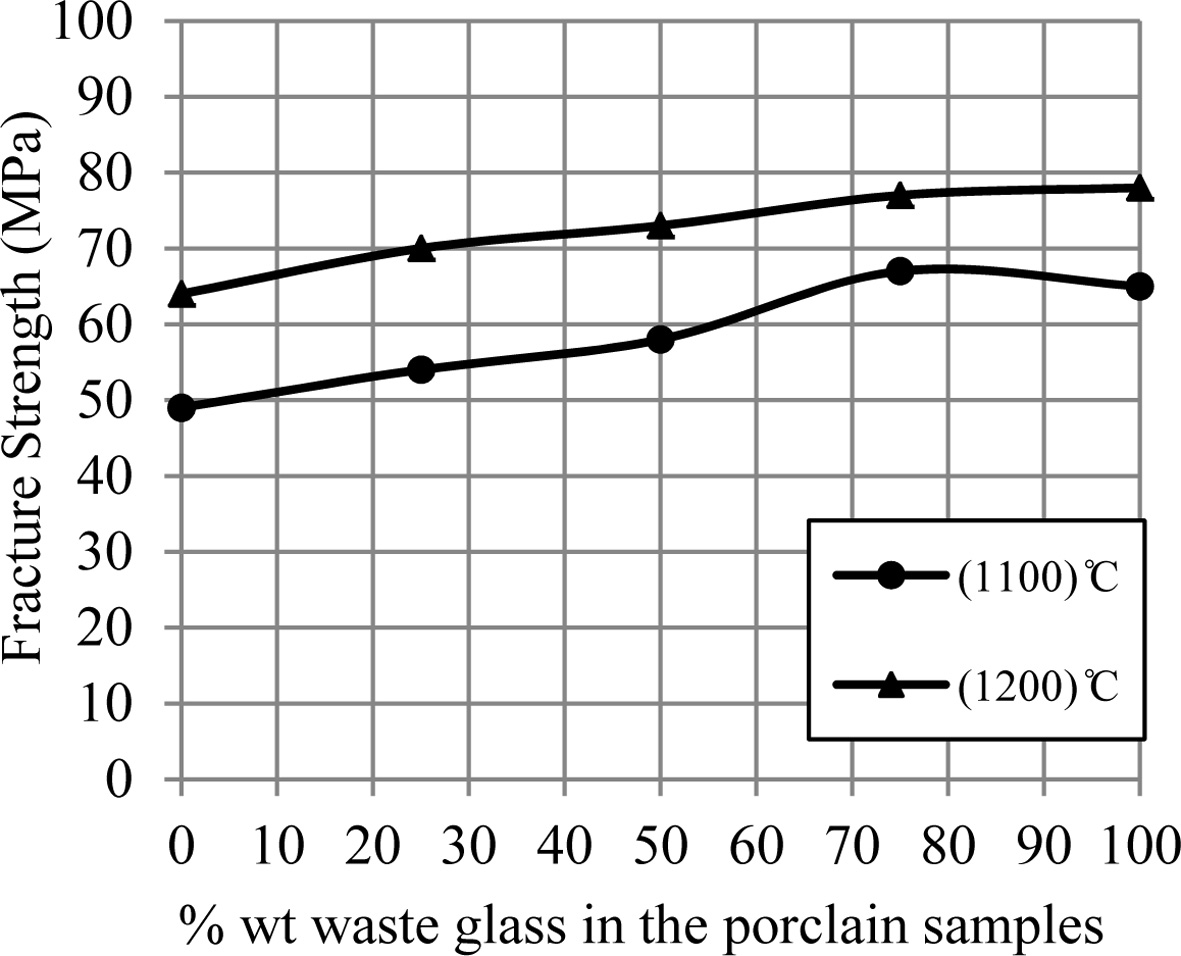

Fig. 2 displays the fracture strength for porcelain

samples. It can be showed that an increase of the fracture strength occurs by

an increase of the additive waste glass percentage. So the

samples' hardness increases by an increase of the additive waste glass

percentage, which is displayed in Fig. 3. This improvement in the mechanical

properties for porcelain specimens produced after an

addition of the waste glass for them was happened because of a formation of the

glassy phase in a matrix of porcelain specimens as a result of an existence of

the great quantity of the diverse fluxes (such as CaO, K2O and Na2O)

within a composition of the waste glass added, that leads to the decrease in

the pores among the substance's particles and the increase in the bond among them

that forms the more-rigid network,

consequently that improves the mechanical strength for porcelain samples [9,

15, 22, 23].

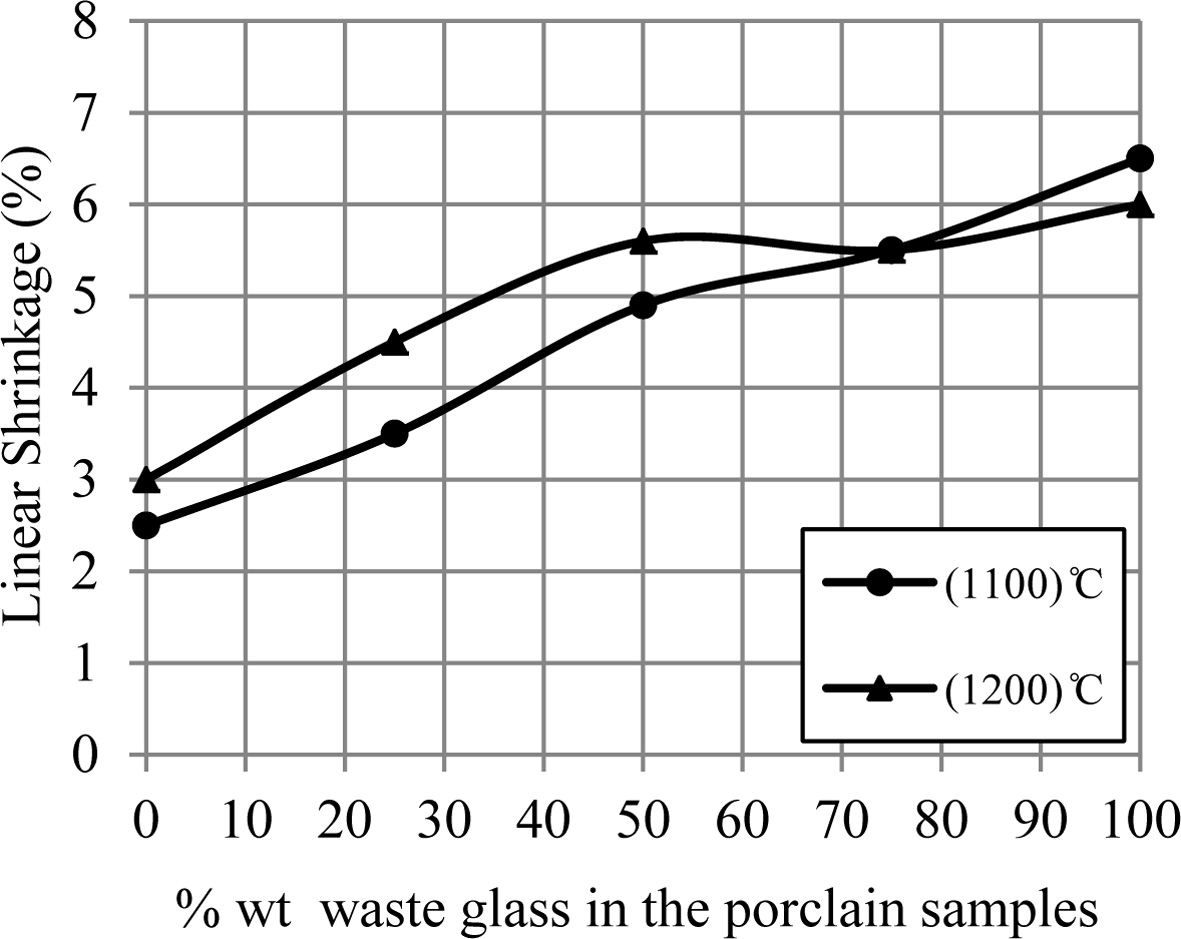

While Fig. 4 displays the linear shrinkage on firing for

porcelain samples. Each one of porcelain samples showed a linear shrinkage

within the range 2.5-6.5% for temperature 1,100 ºC and 1,200 ºC, where the

linear shrinkage values for porcelain specimens raise with an increase of the percentage

of additive waste glass. The samples at temperature 1,200 ºC and until 75%

wt. waste glass were more shrinkage than that at 1,100 ºC due to form of a

great amount of the liquid phase which fills the voids among the particle of

sample, that leads to decrease the total volume of sample (i.e. increase the

linear shrinkage for the samples) [24, 25]. For the samples with 75% waste

glass and up, an important reduction happened in the linear shrinkage values at

1,200 ºC which were a lower than that at 1,100 ºC. Usually, the

existence of liquid phase eases the sintering process of the samples, but a

presence of a great quantity of the low-density liquid phase causes the

swelling in porcelain specimens as happened in this state [9, 26, 27].

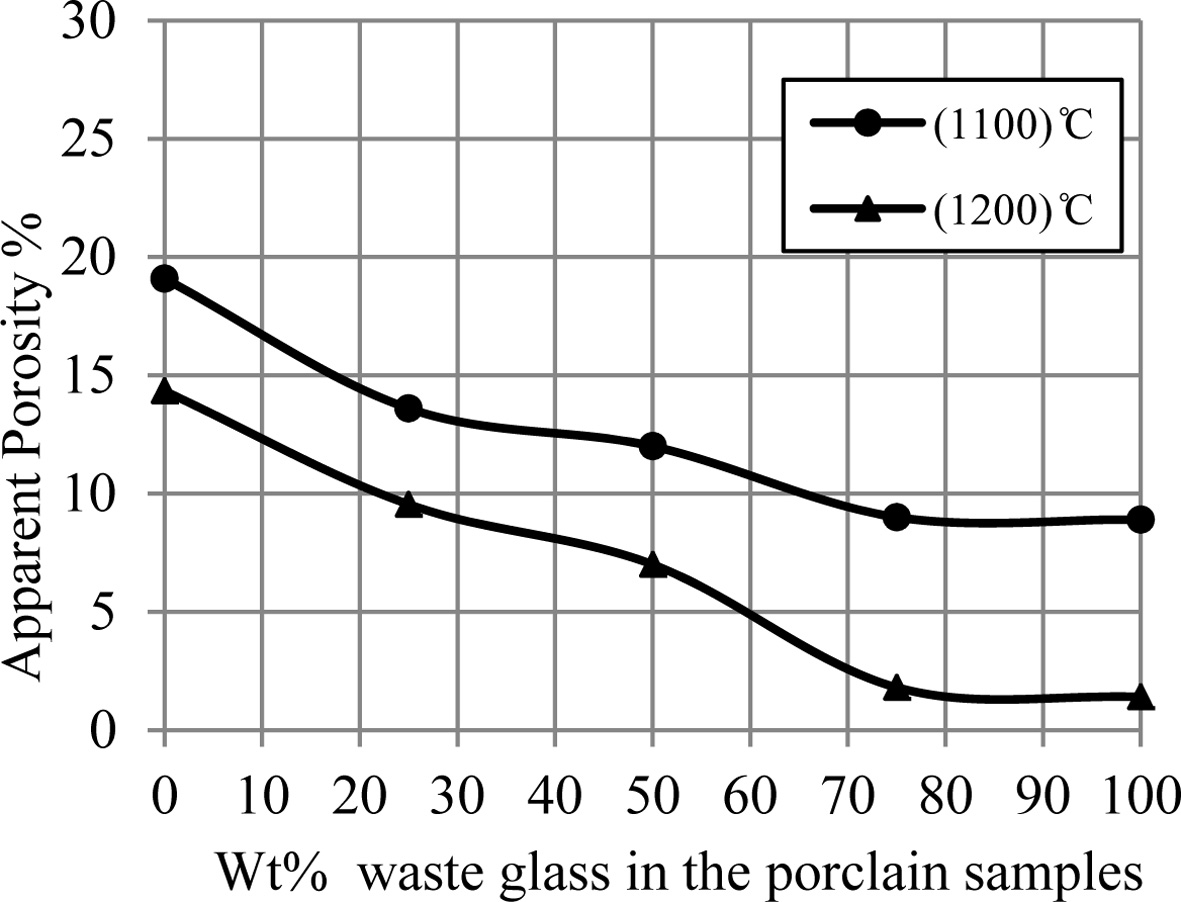

Fig. 5 displays an influence of the additive percentage

of waste glass on an apparent porosity of porcelain specimens. It can be showed

from this figure the decreasing in the porosity of samples with an increase of

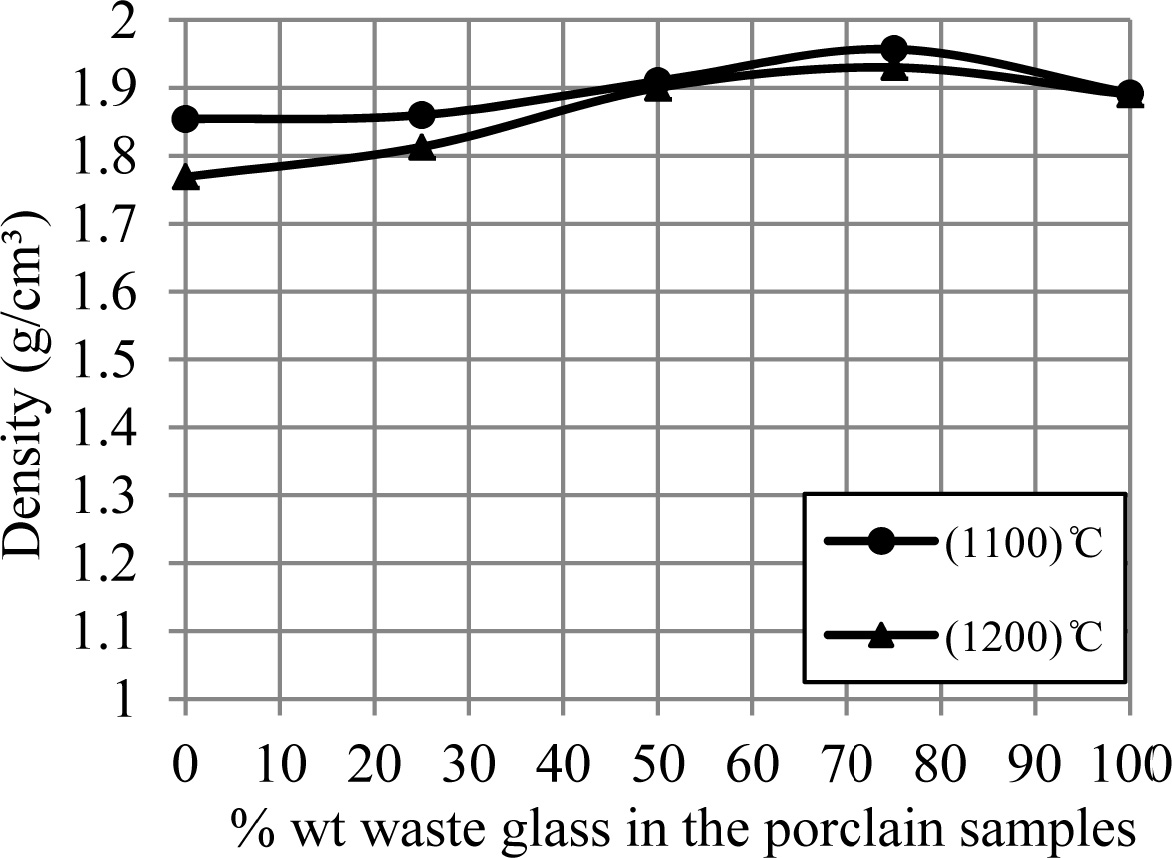

the additive percentage of waste glass. Whereas Fig. 6 displays an influence of

the additive percentage of waste glass on the bulk density of porcelain

specimens, where an increase of the additive percentage of waste glass leaded

to increase the density of samples. These increasing and decreasing in the

density and porosity of samples respectively can be happened because of the

liquid phase formed in a matrix of porcelain specimens for an

existence of the great quantity of the diverse fluxes (such as

CaO, K2O and Na2O) within a composition of the waste

glass added, which lead to the appearance of a large

amount of liquid phase that fills the voids among the

substance's particles and leads to the decrease in the pores in the sample

structure [15, 28], and because of a conversion of the remaining open porosity

to closed porosity [9, 29].

This increase in the density of samples continues to the

percent for waste glass 75% wt. of feldspar, after this percent the state is

contrary (i.e. the density of samples decreased), and addition to the bulk

density of samples at 1,200 ºC was a less than that at 1,100 ºC. This

is a result of the existence of a great amount of low-density

liquid phase leads to a swelling of porcelain specimens

[26, 27], and a result of the liquid phase formed at temperature upper than

1,200 ºC facilitates a liberation of the gas locked in the closed pores,

that causes a creation of the new open porosity [9, 30].

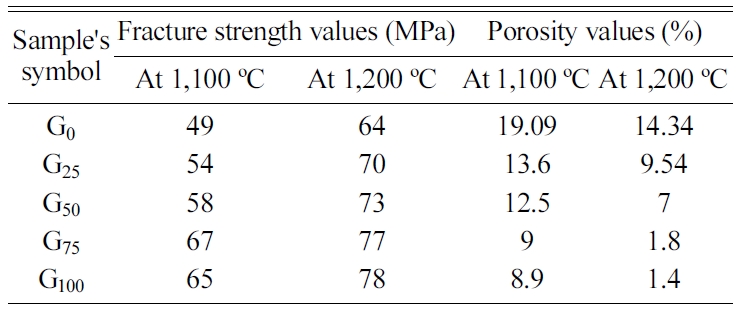

Table 2 displays the fracture strength and porosity values

of porcelain samples for the comparison between these

properties.

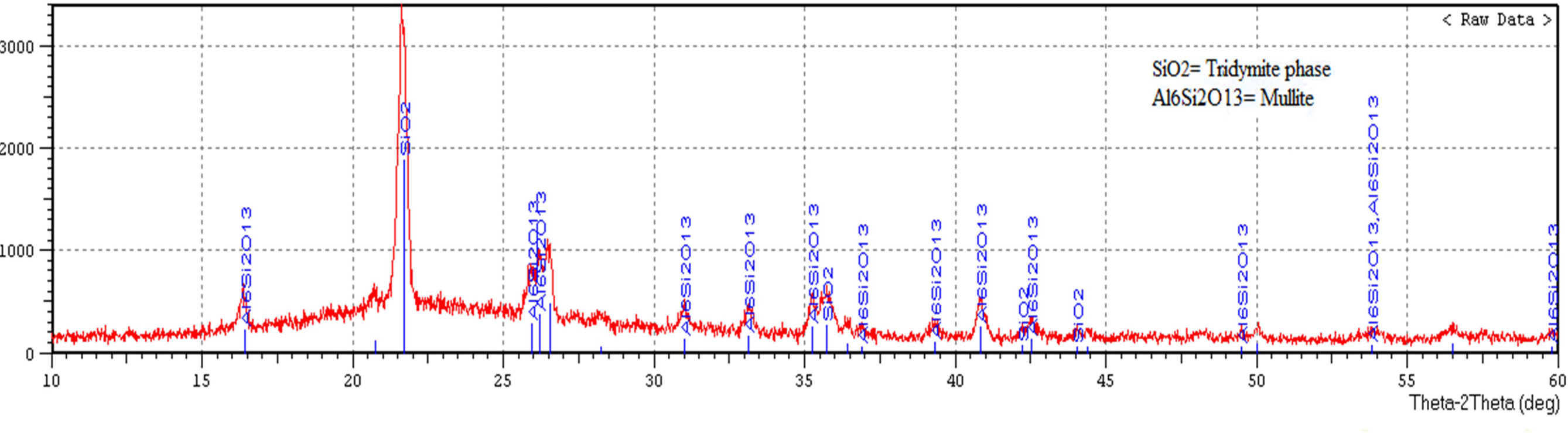

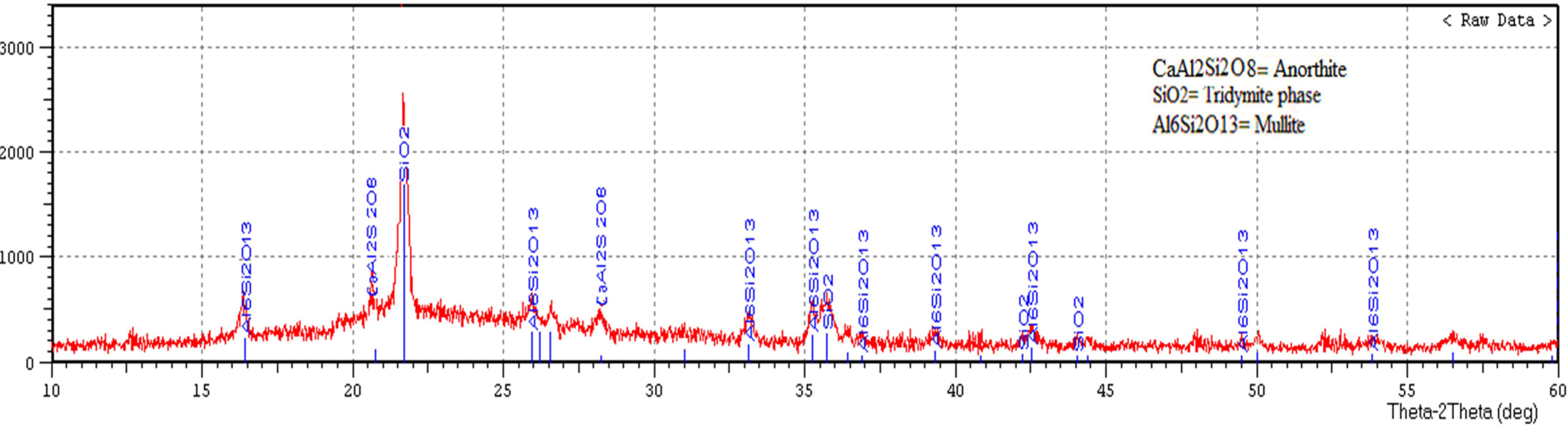

Fig. 7 displays X-ray diffraction pattern of porcelain

specimen produced without the addition of waste glass and fired at

(1,200 ºC), while Fig. 8 displays X-ray diffraction pattern of porcelain

specimen produced by the addition of waste glass 100% wt. of feldspar and fired

at (1,200 ºC). The main difference between these figures is an existence

of anorthite (CaAl2Si2O8) in Fig. 8, anorthite

is a rare phase in porcelain and its crystallization within a composition of

porcelain sample contained on the waste glass is a consequence of the existence

of (CaO) in the powder of soda-lime glass. Another difference is an existence

of mullite (2SiO2·3Al2O3)

in Fig. 7 more than that in Fig. 8 as a result of the utilization of soda-lime glass as a substitute of feldspar, which leads to an existence of the

glass phase composition, as well as

the low aluminum content in a

composition of the sample contained on the waste glass. The highest peak in both the two patterns represents another crystalline phase which is tridymite

phase (SiO2). The peak height proved the presence of a more amount of the tridymite phase in Fig. 7. These

differences between porcelain

samples produced in this study represent as

a peculiarity of the employment of soda-lime glass waste as a substitute of feldspar. This analysis agrees with the

way suggested by [9, 31, 32].

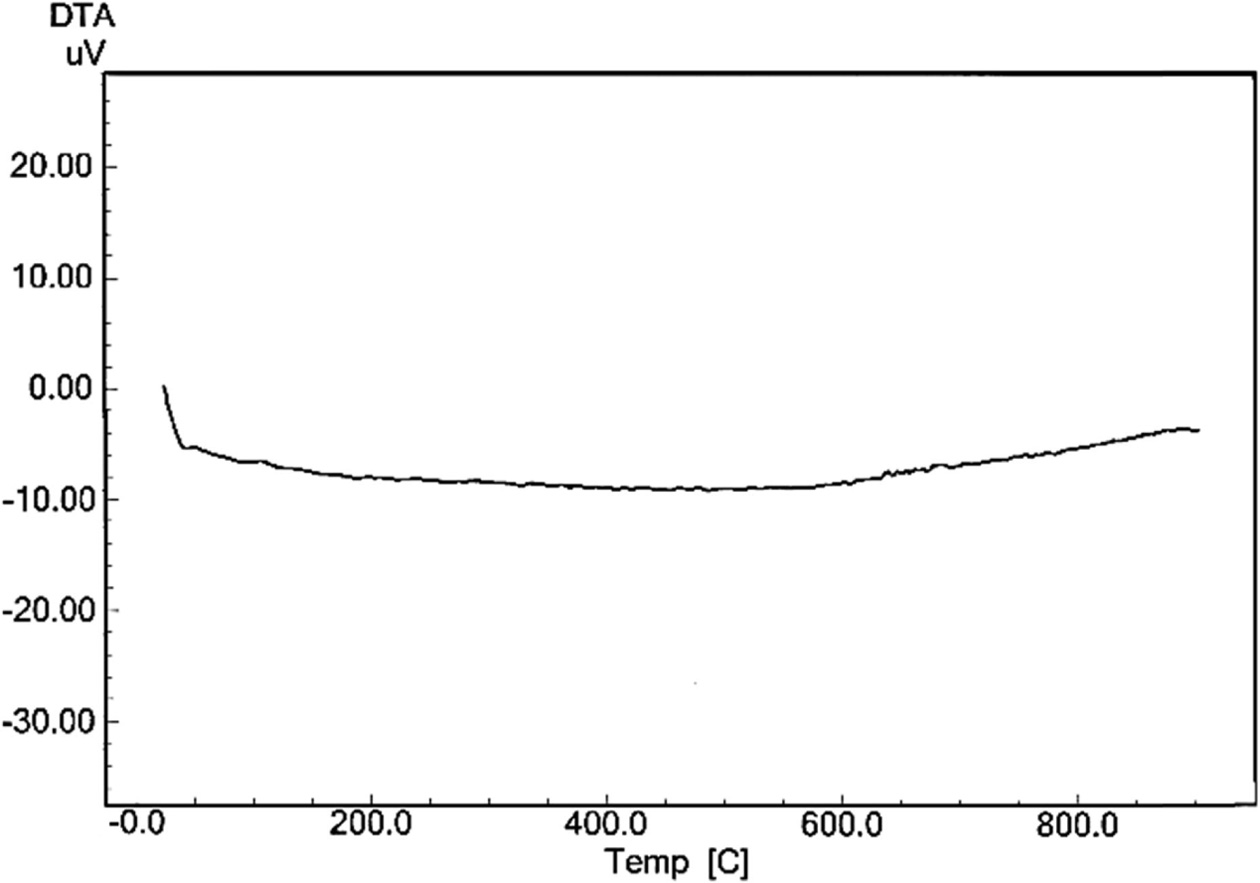

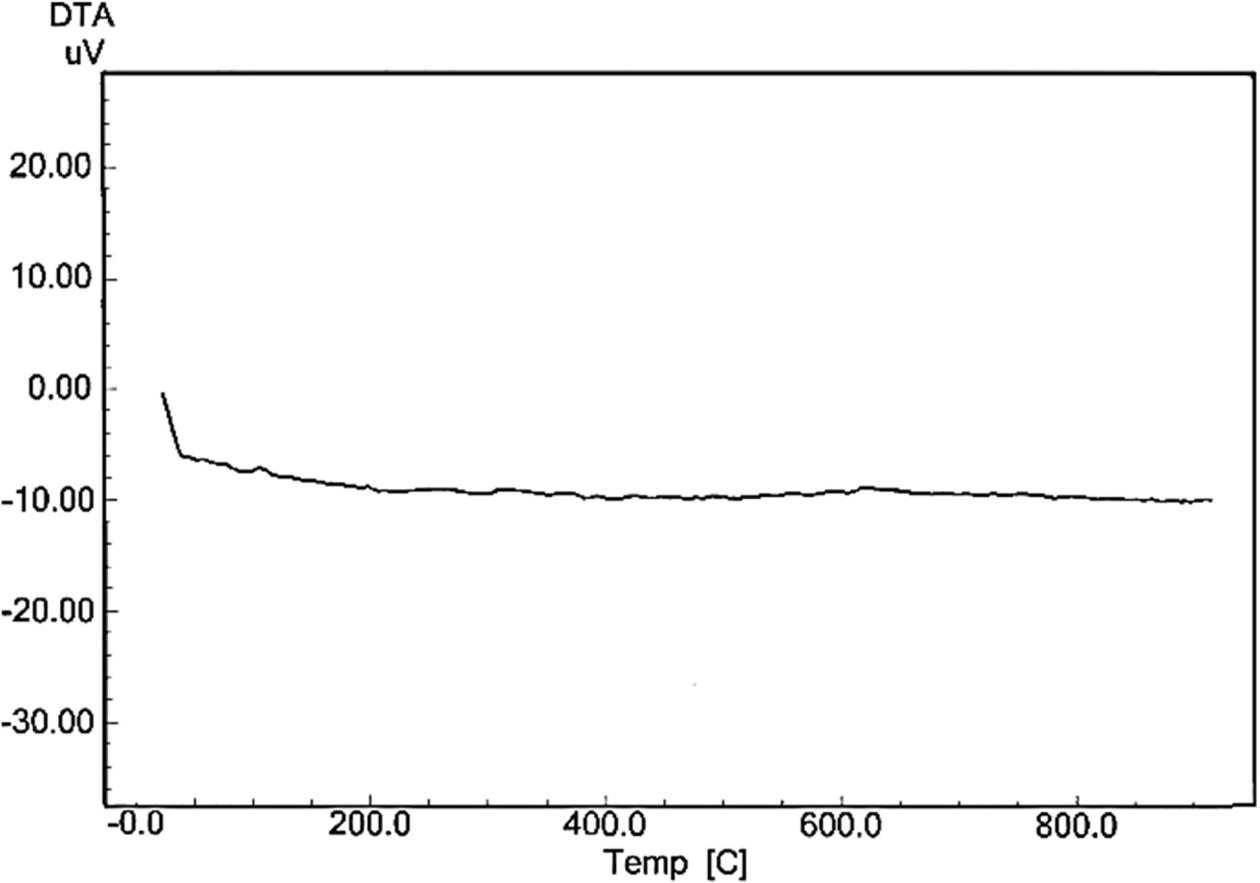

Finally, the (DTA) curve registered through heating for

porcelain sample produced without the addition of waste glass and fired at

(1,200 ºC) is exposed in Fig. 9, while Fig. 10 displays the (DTA) curve

for porcelain sample produced with the addition of waste glass 100% wt.

of feldspar and fired at (1,200 ºC). There was a clear difference between

the two curves after temperature (600 ºC), which

approximates from the glass transition temperature of soda-lime silica glass,

which be in the range 520-600 ºC [13]. An influence of an use of the waste

glass as a replacement of feldspar on the thermal behavior for porcelain samples

in this test was due to an existence of the great quantity of the diverse

fluxes (such as CaO, K2O and Na2O) within a composition

of the waste glass added, these fluxes facilitate the

sintering process for porcelain samples, and thus facilitating the formation

of phases since its glass transition temperature is low [28,

33, 34, 35].

|

Fig. 2 A change of fracture strength of porcelain samples with increase the percent of additive waste glass. |

|

Fig. 3 A change of hardness of porcelain samples with increase the percent of additive waste glass. |

|

Fig. 4 A change of linear shrinkage of porcelain samples with increase the percent of additive waste glass. |

|

Fig. 5 A change of apparent porosity of porcelain samples with increase the percent of additive waste glass. |

|

Fig. 6 A change of bulk density of porcelain samples with increase the percent of additive waste glass. |

|

Fig. 7 X-ray diffraction pattern of porcelain specimen produced without the addition of waste glass and fired at (1,200 ºC). |

|

Fig. 8 X-ray diffraction pattern of porcelain specimen produced by the addition of waste glass 100% wt. of feldspar and fired at (1,200 ºC). |

|

Fig. 9 The (DTA) curve for porcelain sample produced without the addition of waste glass and fired at (1,200 oC). |

|

Fig. 10 The (DTA) curve for porcelain sample produced with the addition of waste glass 100% wt. of feldspar and fired at (1,200 ºC). |

This study shows a possibility of replacement of the

feldspar used in porcelain industry with soda-lime waste glass as a flux, and

the percent of waste glass additive which gives the best properties of

porcelain samples is 75% wt. of feldspar. The linear shrinkage on firing and

density of porcelain specimens raise by an increase of

the additive percentage of waste glass. In the samples with 75% wt. waste glass

and up, a significant reduction in the linear shrinkage

values at 1,200 ºC to compare with that at 1,100 ºC, and the increase

in the density of samples converts to a decrease. While, the porosity of

specimens reduces by an increase of the additive percentage of waste glass. In

addition, the fracture strength and hardness of porcelain specimens increase by

an increase of the additive percentage of waste glass to them. X-ray

diffraction analysis proves an existence of crystalline phases in porcelain

matrix, which refers tridymite phase (SiO2) and mullite phase (2SiO2·3Al2O3)

for both the two states (i.e. with and without use of waste glass in porcelain

samples), so it shows a present of anorthite phase (CaAl2Si2O8)

in porcelain sample contained 100% waste glass of feldspar

and fired at 1,200 ºC. While, the difference between the DTA curves for

porcelain samples ensures that the use of waste glass as the replacement of

feldspar affects on the thermal behavior for these samples. Then, the

samples with 75% wt. waste glass give the best effect on the

properties of porcelain samples.

- 1. H.R. Fernandes, D.U. Tulyaganov, and J.M.F. Ferreira, J. Adv. Appl. Ceram. 108[1] (2009) 9-13.

-

- 2. A. Karamanov, J. Adv. Appl. Ceram. 108[1] (2009) 14-21.

-

- 3. I. Ponsot, R. Detsch, AR. Boccaccini, and E. Bernardo, J. Adv. Appl. Ceram. 114[Suppl. 1] (2015) S17-S25.

-

- 4. P.R. Monich, D. Desideri, and E. Bernardo, J. Adv. Appl. Ceram. 118[6] (2019) 366-371.

-

- 5. M.L. Antunes, A. Botignon de Sá, P.S. Oliveira, and E.C. Range, Cerâmica 65[Suppl.1] (2019) 1-6.

-

- 6. A. Karamanov, E. Karamanova, A. Ferrari, F. Ferrante, and M. Pelino, J. Ceram. Int. 32[7] (2006) 727-732.

-

- 7. A. Akkus and T. Boyraz, J. Ceram. Process. Res. 20[1] (2019) 54-58.

-

- 8. S. Bhattacharyya, S.K. Das, and N.K. Mitra, J. Bull. Mater. Sci. 28[5] (2005) 445-452.

-

- 9. B. Khaled, B. Abdelhafid, B. Hocine, and R. Maximina, Bol. Soc. Esp. Cerám. Vidr. 58[1] (2019) 28-37.

-

- 10. S. Wattanasiriwech and D. Wattanasiriwech, J. Ceram. Process. Res. 20[6] (2019) 643-648.

-

- 11. S. Radomír and V. Lucie, Int. J. Eng. Sci. 4[10] (2014) 49.

- 12. N. Ediza and A. Yurdakulb, J. Ceram. Process. Res. 10[6] (2009) 758-769.

- 13. S. Frank, in “The Corning Museum of Glass Education Dept. Education Coordinator” (The Corning Museum of Glass, 1998) p.82.

- 14. T. Tarnkamol and P.S. Guilherme, International Conference on Geology of Thailand: Towards Sustainable Development and Sufficiency Economy, (2014) 276.

- 15. Y. Pontikes, A. Christogerou, and G. Angelopoulos, Article in Glass Technology, 78 (2005) 54.

- 16. Ç. Koca, N. Karakus, N. Toplan, and H. Toplan, J. Ceram. Process. Res. 13[6] (2012) 693-698.

- 17. ASTM, C 773-88 (1988) 245.

- 18. M. Roy. The University of British Columbia, (2010) 89.

- 19. W.D. Kingery, H.K. Bowen, and D.R. Uhlmanm, in “Intro- duction to Ceramics, 2nd Edition” (John Wiley and Sons, 1975) p.1032.

- 20. G. Kaya, Ceram. Int. 39[1] (2013) 511-517.

-

- 21. ASTM, C 373 (1988) 195.

- 22. K. Nuntaporn, C. Benya, B. Warunee, and C. Parinya, J. Met., Mat. Min. 29[3] (2019) 71-75.

- 23. Y. Dong, X. Feng, Y. Ding, X. Liu, and G. Meng, J. Alloy. Compo. 460 (2008) 599-606.

-

- 24. O. Watanabe and S. Kato, in “Environmental Issues and Waste Management Technologies in the Ceramic and Nuclear Industries VI” (Am. Ceram. Soc., 2001) p.113-123.

- 25. B. Achiou, H. Elomari, M. Ouammou, A. Albizane, J. Bennazha, A. Aaddane, S.A. Younssi, and I. El Amrani El Hassani, J. Mater. Environ. Sci. 9[3] (2018) 1013-1021.

-

- 26. K. Kim and J. Hwang, J. Ceram. Int. 41[5] (2015) 7097-7102.

-

- 27. E. Bernardo and P.A. Bingham, J. Adv. Appl. Ceram. 110[1] (2011) 41-48.

-

- 28. I.M. Bakr, J. Adv. Appl. Ceram. 104[5] (2005) 243-248.

-

- 29. A. Ahmet and B. Tahsin, J. Ceram. Process. Res. 20[1] (2019) 54-58.

-

- 30. Y. Iqbal and W.E. Lee, J. Am. Ceram. Soc., 83[12] (2000) 3121-3127.

-

- 31. R.B. Saulo and P.B. Carlos, Mat. Res. 8[1] (2005) 67.

- 32. H.R. Fernandes and J.M.F. Ferreira, J. Eur. Ceram. Soc. 27[16] (2007) 4657-4663.

-

- 33. M. Heraiz, F. Sahnoune, H. Belhouchet, and N. Saheb, J. Optoelectron. Adv. Mater. 15[11-12] (2013) 1263-1267.

- 34. A.J. Souza, B.C.A. Pinheiro, and J.N.F. Holanda, J. Environ. Manage. 91[3] (2010) 685-689.

-

- 35. S.Y.R. Lopez, J.S. Rodriguez, and S.S. Sueyoshi, J. Ceram. Process. Res. 12[3] (2011) 228-232.

This Article

This Article

-

2020; 21(3): 371-377

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.371

- Received on Nov 29, 2019

- Revised on Mar 21, 2020

- Accepted on Mar 24, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Marwa Marza Salman

-

Faculty of Materials Engineering, Babylon University, Babylon, Iraq

Tel : +964-7809430850

Fax: +964-7809430850 - E-mail: marwamarzas@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.