- Effects of V2O5 on sinterability and microwave dielectric properties of NaCa4V5O17 ceramics

Guoguang Yao*, Yang Li, Jingjing Tan, Cuijin Pei, Yan Zhang and Jia Chen

School of Science, Xi’an University of Posts and Telecommunications, Xi’an 710121, China

The NaCa4V5O17

ceramics owing low sintering temperature had been prepared via conventional

solid state reaction method using V2O5 as vanadium

source. The sinterability, microwave dielectric characterisations and

compatibility with Ag were investigated. Pure phase NaCa4V5O17

with triclinic structure was confirmed by Rietveld refinement and Raman

spectrum. The permittivity (εr) and quality factor (Qxf)

values mainly depended on the relative density, whereas the temperature

coefficient of resonant frequency (τf) value was closely connected

with the tetrahedral distortion of V(1)O4. The NaCa4V5O17

ceramics sintered at 800 oС owned high densification and moderate microwave

dielectric performances under 10.7 GHz: εr = 9.5, Q×f = 34,200 GHz, τf

= -90.0 ppm/oС, but poor chemical compatibility with Ag paste.

Keywords: Ceramics, microwave dielectric properties, NaCa4V5O17, tetrahedral distortion

In the future 10 years, 5G wireless communications will

become the dominant wireless protocol for applications

like Artificial Intelligence and the Internet of Things [1].

The rapid evolution of 5G wireless communications gives rise to higher

requirement of microwave dielectric ceramics [2]. To address the requirements

of 5G wireless communications, the dielectric ceramics must satisfy following primary

dielectric characteristics: low εr (εr ≤ 10) to increase

signal transmission velocity, near-zero τf to ensure thermal stabilization at different operating temperatures, and

high Qxf or low dielectric loss to decrease the power dissipation [3, 4].

Meanwhile, low sintering temperatures should be ensured to meet low-temperature co-sintered ceramic technology, which

can be used to reduce the size of

electronic devices [5, 6]. Therefore, the dielectric materials

with superior performances and inherent lower sintering temperature received prodigious attention.

Recently, vanadium host compounds are followed with

interest once again since their low sintering temperature

and superior dielectric performances. Lots of vanadium-basic ceramics have been

investigated for LTCC substrate applications, for example Ca5Co4(VO4)6,

(CaBi)(MoV)O4, LiMgVO4, (Bi, Ce)VO4, etc

[7-11]. Quite recently, a novel NaCa4V5O17

compounds with triclinic structure had been fabricated by Xie et al. [12].

Later, Fang et al. [13] first presented the microwave dielectric performances

(er = 9.72, Q×f = 51,000 GHz, τf = -84 ppm/oС)

of NaCa4V5O17 ceramics. Considering the

microwave dielectric performances of the ceramics are strongly

depended on the craft parameters, including primary materials,

ball milling and sintering conditions etc. [14]. The variation in one or more

these parameters greatly influence the dielectric properties of such ceramics

[15]. However, there is no related microwave dielectric properties study about

NaCa4V5O17 ceramics using V2O5

as vanadium source. Here, we reported the effects V2O5,

as the vanadium source, on sinterability, microstructure, microwave dielectric

performances as well as compatibility with silver of NaCa4V5O17

ceramics.

We

fabricated NaCa4V5O17 samples through the

traditional solid-state route. V2O5 (99%), Na2CO3

(99.8%) and CaCO3 (99%) were weighed

according to stoichiometric NaCa4V5O17, and

then were ball milled for 8 h using alcohol and ZrO2 balls for

grinding media. The resultant milled powders were dried under 80 oC,

followed by presintered under 600 oC/4 h, and then regrinded for

further 8 h. The above presintered powders were mixed with 5wt % PVA,

granulated and sieved through a No. 80 sieve. The granules were pressed at 200

MPa into compacts (Ф10 mm×5 mm). These compacts were heated at 500 oC

for 2 h to exclude PVA, and then fired in air ambient under 750-850 oС

dwelling for 4 h.

The phase constitutions in sintered specimens had been

studied by X-ray powder diffraction (XRD, Smartlab, Japan) and

Raman spectra (Jobin Yvon, Longjumeau, France) equipped with He-Ne laser and an

output of 30 mW. Rietveld refinement of XRD patterns was carried out with the GSAS

program [16]. Microstructures of NaCa4V5O17

ceramics were observed through a scanning

electron microscope (SEM, Hitachi, Tokyo, Japan). Archimedes' principle was

carried out to determine the bulk densities. The εr and Qxf values

of samples were evaluated by resonant cavity method using Rohde & Schwarz

ZVB20 vector network analyzer under about 10-12 GHz. The τf value of

samples was calculated between 25 and 85 °C according to Reference

[17].

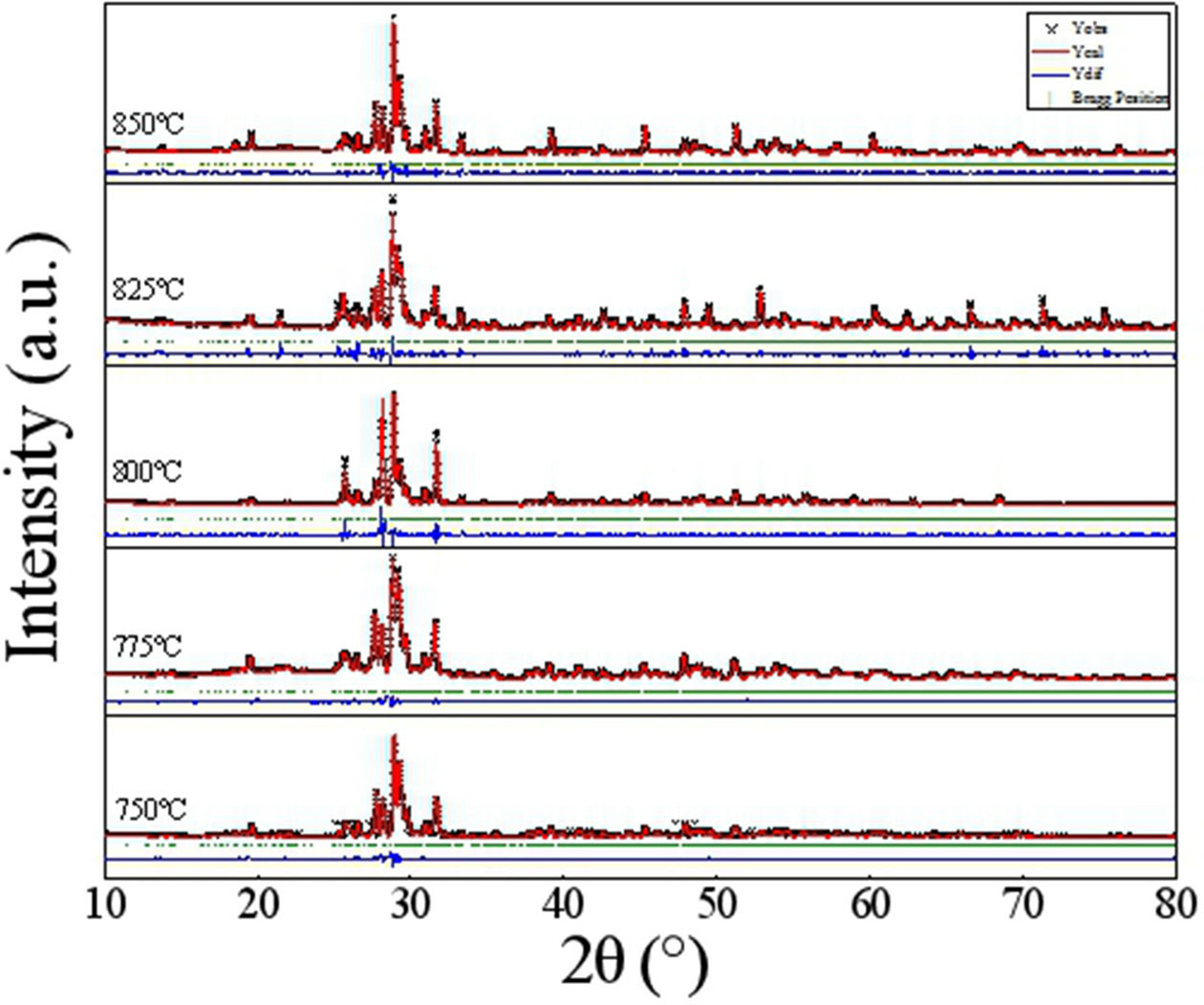

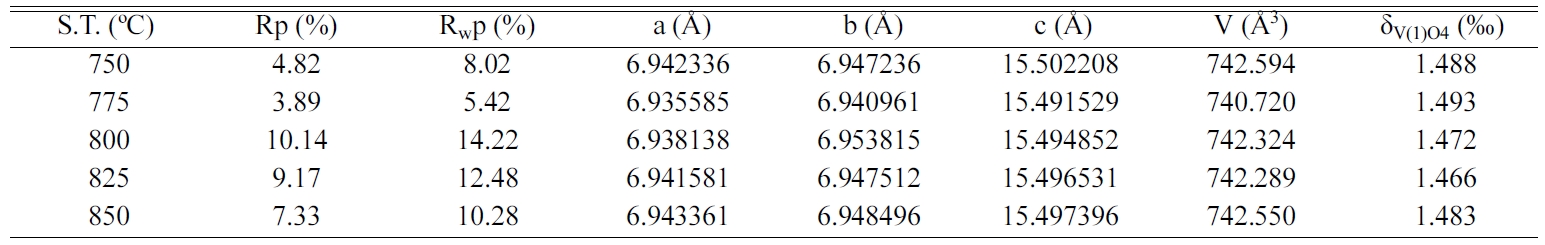

Fig. 1 exhibits the refined fit of NaCa4V5O17

sintered under diverse temperatures to their diffraction patterns. The

Rietveld refined lattice parameters, reliability factors

and V(1)O4 tetrahedral distortion for all specimens are enumerated

in Table 1. As shown in Fig. 1, the calculated XRD profiles

based on NaCa4V5O17 structural model closely

fitted those of experimental ones, indicating the NaCa4V5O17

ceramics crystallized in a triclinic structure with P-1(2)

space group. Pure phase NaCa4V5O17 without

an obvious secondary phase was obtained for all samples

sintered in the range of 750-850 oC. Moreover, as seen in Table

1, the achieved reliability factors (Rp, Rwp) are less than 15, suggesting the

refined results are credible. Meanwhile, no obvious changes of unit cell volume

were observed under different sintering temperatures.

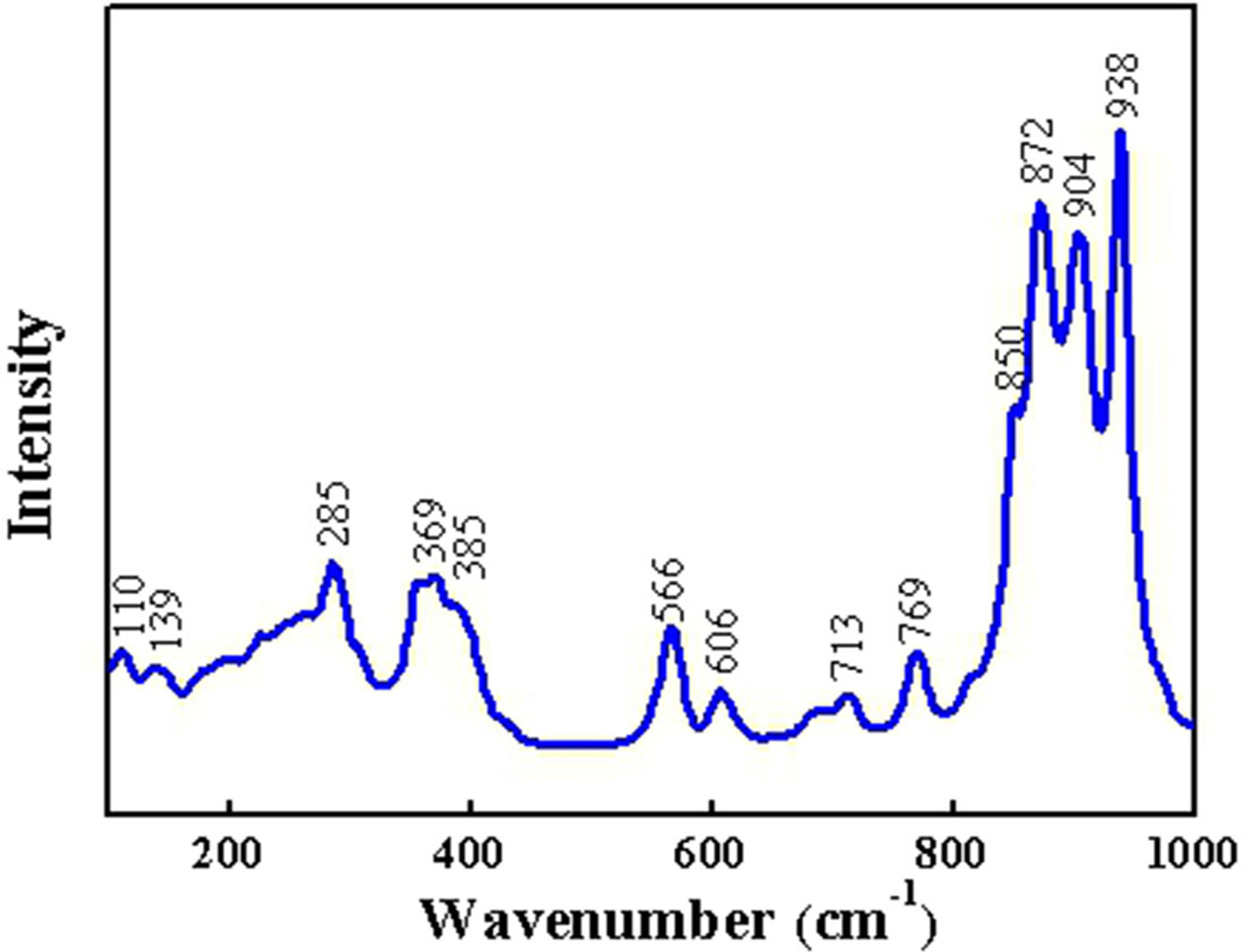

The Raman spectrum of NaCa4V5O17

sample fired under 800 oC is displayed in Fig. 2. Three

distinct regions of Raman modes can be distinguished. The first region located

at 900-940 cm-1

is associated with terminal V-O (V = O) symmetric stretching vibrations [12].

The second region located at 550-880 cm-1

is related to the V-O-V antisymmetric or symmetric stretching vibrations [18].

The third region below the 400 cm-1

is ascribed to the peripheral modes [19].

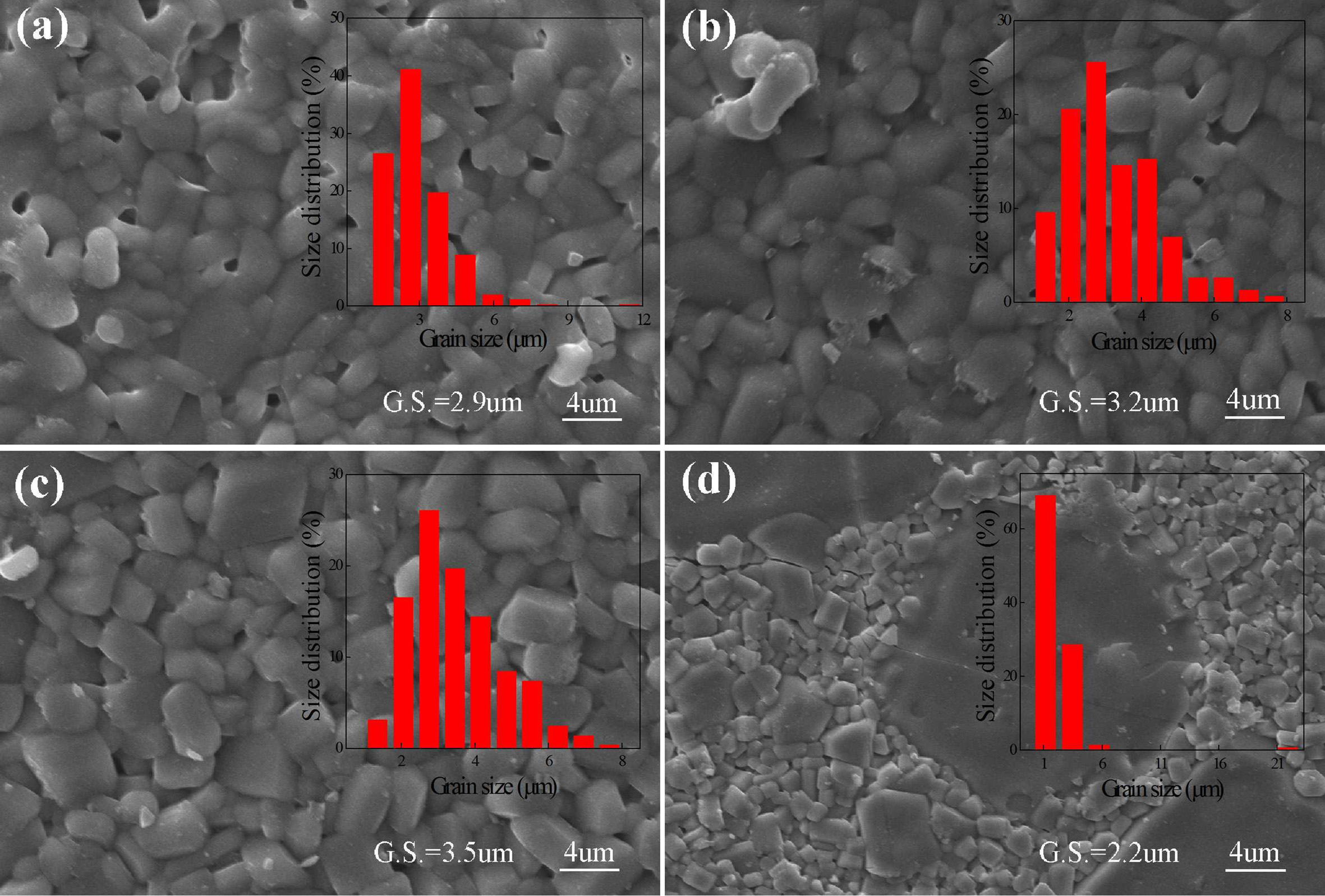

Fig. 3 gives the typical SEM micrographs of NaCa4V5O17

ceramics heated at distinct temperatures. From Figs. 3(a)-(c), the number of

residual open pores was reduced accompanied by average grain size growth with

an elevated temperature. And the 800 oC-sintered sample

presented a relative compact and uniform microstructure with a mean grain size

around 3.5 um, which is helpful to improve the dielectric properties of the

NaCa4V5O17 ceramics [20]. When the sintering

temperature rose to 825 oC, excessive grain growth, uneven

grain distribution and crack formed, these would deteriorate the dielectric

performances of the present ceramics [21].

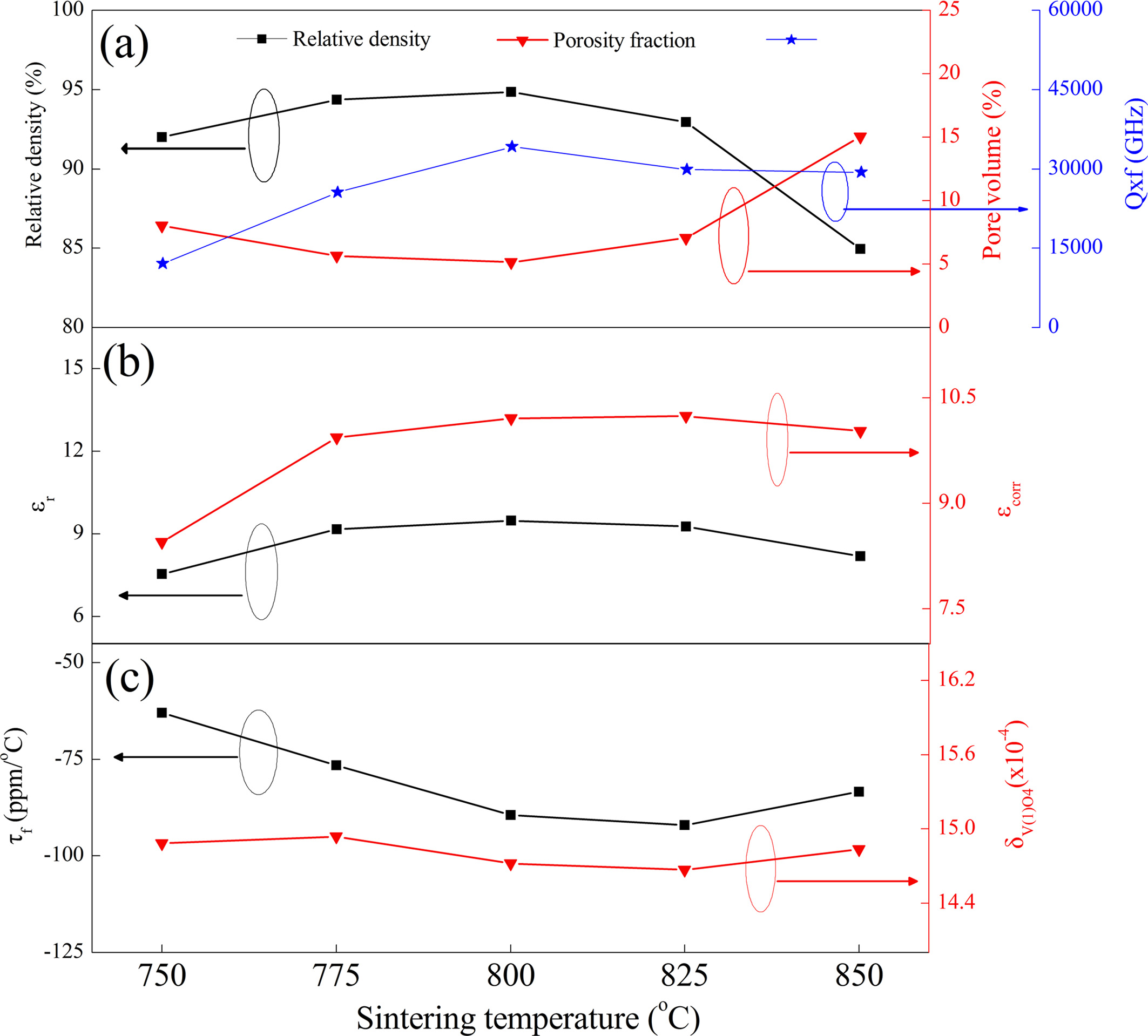

Fig. 4 presents the variations in relative density, pore volume,

microwave dielectric properties and tetrahedral distortion

of NaCa4V5O17 ceramics heated at 750-850 oC.

As shown in Fig. 4(a), the relative density was enhanced to the maximum (94.9%)

under 800 oC and thereafter declined with an elevated

temperature, which was agree with the above morphology analysis. In general,

the Qxf value at microwave region of dielectric ceramics is

predominated by extrinsic parameters like relative density, second phase and

oxygen vacancies [22-24]. Considering the similar variation tendency between

Qxf value and relative density of NaCa4V5O17

ceramics, suggesting the Q×f value was predominated by the relative density.

The εr is determined by density, dielectric polarizability and

molecular volume [25, 26]. For a given compounds, its εr mainly

depends on the relative density or porosity owing to the invariant dielectric

polarizabilities and chemical formula [26]. Therefore, the changes of εr

and εcorr of NaCa4V5O17 ceramics

exhibited a tendency inverse or similar to the variation in

porosity or relative density, and the corrected dielectric

constant (εcorr) was calculated according to reference [27]. It was

reported that the τf value could be determined by the distortion of oxygen

polyhedral and phase composition [28, 29], which was also well represented

in the present work. As seen in Fig. 4(c), the change of τf

of NaCa4V5O17 ceramics exhibited a tendency

similar to that of the variation of V(1)O4 tetrahedral

distortion (δV(1)O4), indicating the τf is

greatly affected by δV(1)O4. The δV(1)O4 calculated

based the Rietveld refinement data and Shannon equation [30]. It is

noted that the NaCa4V5O17 ceramics in our

cases possessed compatible εr (9.5) and τf

(-90.0 ppm/oC) but inferior Qxf (34,200 GHz) value than

that of NaCa4V5O17 (εr = 9.72, τf

= -84 ppm/oC, Qxf = 51,000 GHz) reported by Yin et al. [13], which

may be due to the different vanadium source and processing

conditions [31].

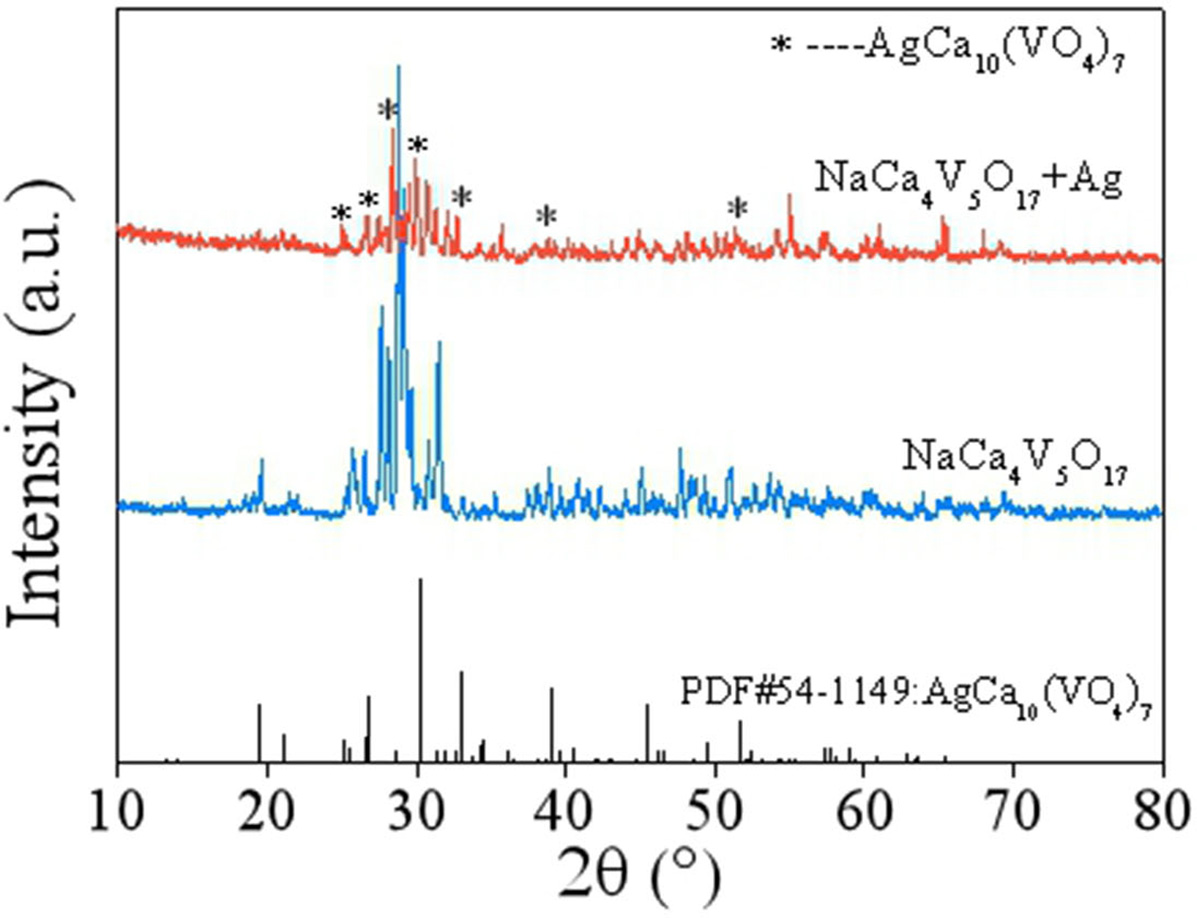

Fig. 5 depicts the XRD patterns of NaCa4V5O17

presintered powder with 20 wt% Ag powder co-fired under 800 oC. As

seen from Fig. 5, a new main phase AgCa10(VO4)7

(JCPDS#54-1149) formed except for NaCa4V5O17

phase, which was also not agree with the previous

report [13]. This result showed that a chemical reaction

between the basic phase NaCa4V5O17 and Ag

happened, which impeded its further application for LTCC.

|

Fig. 1 Rietveld refinement patterns of NaCa4V5O17 ceramics sintered at deferent temperatures. |

|

Fig. 2 Raman spectrum of NaCa4V5O17 ceramics sintered at 800 oC. |

|

Fig. 3 SEM micrographs of NaCa4V5O17 ceramics sintered at (a) 750 oС, (b) 775 oС, (c) 800 oС, (d) 825 oС. |

|

Fig. 4 Dependence of ρr, pore volume, εr, Qxf, τf and δV(1)O4 on the firing temperature of NaCa4V5O17 ceramics. |

|

Fig. 5 XRD patterns of NaCa4V5O17-20 wt% Ag mixture co-fired at 800 oC. |

|

Table 1 Rietveld refinement results and V(1)O4 tetrahedral distortion (δV(1)O4) of NaCa4V5O17 ceramics sintered at various temperatures. |

The NaCa4V5O17 ceramics

owing low firing temperature had been prepared via the route of

conventional solid state reaction. The impacts of V2O5 on

the sinterability, microwave dielectric characterizations as well as chemical compatibility

with Ag of present ceramics were

investigated. The XRD and Raman spectrum revealed that the NaCa4V5O17

ceramics crystallized in a triclinic structure with P-1(2) space group. The εr

and Qxf values were dominated by the relative density, whereas the τf

value was closely connected with the tetrahedral distortion of V(1)O4.

Typically, the 800 oС-sintered

NaCa4V5O17 ceramics owned moderate microwave dielectric performances at measured frequency of

10.7 GHz: er = 9.5, Q×f = 34,200 GHz, τf = -90.0 ppm/oС,

whereas its poor chemical compatibility with Ag paste affected its practical viability

for LTCC applications.

This study was financially supported by China Post-doctoral Science Foundation

(2015M582696), Shaanxi Province Postdoctoral Science Foundation, Education

Department of Shaan xi Province (18JK0711), Science and technology plan project

of Xi'an Bureau of Science and technology (GXYD17.19), and Innovation Funds of

Graduate Programs of Xi'an Post and Telecom-munications University (Grant Nos.

CXJJLA2018008, CXJJLD2019020).

- 1. Q.B. Lin, K.X. Song, and B. Liu, Ceram. Int. 46 (2020) 1171-1177.

-

- 2. H. Li, C.Y. Cai, Q.Y. Xiang, B. Tang, J. Xiao, and S.R. Zhang, Ceram. Int. 45 (2019) 23157-23163.

-

- 3. J.J. Bian, X.Q. Sun, and Y.R. Xie, J. Eur. Ceram. Soc. 39 (2019) 4139-4143.

-

- 4. W.B. Hong, L. Li, H. Yan, and X.M. Chen, J. Am. Ceram. Soc. 102 (2019) 5934-5940.

-

- 5. X.H. Ma, S.H. Kweon, S. Nahm, C.Y. Kang, and Y.S. Kim, J. Eur. Ceram. Soc. 37 (2017) 605-610.

-

- 6. A. Pirvaram, E. Taheri-Nassaj, W.Z. Lu, and W. Lei, J. Am. Ceram. Soc. 102 (2019) 5213-5222.

-

- 7. R. Naveenraj, E.K. Suresh, and J. Dhanya, Eur. J. Inorg. Chem. 2019 (2019) 949-955.

-

- 8. H.H. Guo, D. Zhou, L.X. Pang, and Z.M. Qi, J. Eur. Ceram. Soc. 39 (2019) 2365-2373.

-

- 9. G.G. Yao, P. Liu, X.G. Zhao, J.P. Zhou, and H.W. Zhang, J. Eur. Ceram. Soc. 34 (2014) 2983-2987.

-

- 10. H.H. Guo, D. Zhou, and W.F. Liu, J. Am. Ceram. Soc. 103 (2019) 423-431.

-

- 11. G.G. Yao, X.S. Hu, P. Liu, and J.G. Xu, J. Mater. Sci: Mater. Electron. 26 (2015) 1795-1798.

-

- 12. Z.Q. Xie, S.C. Cheng, S.W. Li, and H.Q. Ding, J. Solid. State. Chem. 269 (2019) 94-99.

-

- 13. C.Z. Yin, C.C. Li, L. Fang et al., J. Eur. Ceram. Soc. 40 (2020) 386-390.

-

- 14. Y.C. Liou, S.L. Yang, and S.Y. Chu, J. Alloy. Compd. 576 (2013) 161-169.

-

- 15. C.J. Pei, C.D. Hou, Y. Li, G.G. Yao, P. Liu, and H.W. Zhang, J. Alloy. Compd. 792 (2019) 46-49.

-

- 16. A.C. Larson and R.B. Von Dreele, Los Alamos National Laboratory Report LAUR 86 (2004)

-

- 17. G.G. Yao, C.D. Hou, C.J. Pei, and P. Liu, Ferroelectrics. 536 (2018) 156-161.

-

- 18. A. Sharma, M. Varshney, and K.H. Chae, Rsc. Adv. 8 (2018) 26423-26431.

-

- 19. E.K. Suresh, K. Prasad, N.S. Arun, and R. Ratheesh, J. Electron. Mater. 45 (2016) 2996-3002.

-

- 20. S.P. Wu, D.F. Chen, C. Jiang, Y.X. Mei, and Q. Ma, Mater. Lett. 91 (2013) 239-241.

-

- 21. J.B. Song, K.X. Song, J.S. Wei, H.X. Lin, and J.M. Xu, J. Alloy. Compd. 731 (2018) 264-270.

-

- 22. J.M. Kim, H.W. Jo, and E.S. Kim, Int. J. Appl. Ceram. Technol. 16 (2019) 2053-2059.

-

- 23. R.C. Pullar, S.J. Penn, I.M. Reaney, and N.M. Alford, J. Eur. Ceram. Soc. 29 (2009) 419-424.

-

- 24. S.B An, J. Jiang, J.Z. Wang, L. Gan, and T.J. Zhang, Ceram. Int. 46 (2020) 3960-3967.

-

- 25. C.J. Pei, G.G. Yao, and Z.Y. Ren, J. Ceram. Process. Res. 17 (2016) 681-684.

-

- 26. Y. Wang L.W. Shi, and W.S. Xia, Ceram. Int. 46 (2020) 6984-6986.

-

- 27. T. Hanai and Z. Kolloid, Kolloid-Zeitschrift. 171 (1960) 23-30.

-

- 28. K.M. Manu, K.A. Lazar, R. Ubic, and M.T. Sebastian, J. Am. Ceram. Soc. 96 (2013) 1504-1511.

-

- 29. G.G. Yao, J. Ceram. Process. Res. 16 (2015) 4144.

- 30. W.H. Baur, Acta. Crystallogr. Sect. B. 30 (1974) 1195-1215.

-

- 31. M. Li, A. Feteira, M.T. Lanagan, and C.A. Randall, J. Am. Ceram. Soc. 93 (2010) 4087-4095.

-

This Article

This Article

-

2020; 21(3): 338-342

Published on Jun 30, 2020

- 10.36410/jcpr.2020.21.3.338

- Received on Feb 16, 2020

- Revised on Mar 18, 2020

- Accepted on Mar 20, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Guoguang Yao

-

School of Science, Xi’an University of Posts and Telecommunications, Xi’an 710121, China

Tel : +86 29 88166089

Fax: +86 29 88166333 - E-mail: yaoguoguang@xupt.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.