- Characterization of metakaolin-based lightweight geopolymers with various foaming agents

Yoorim Rho and Seung-Gu Kang*

Department of Advanced Materials Science and Engineering, Kyonggi University, Suwon 16227, Korea

In this study, lightweight

foamed geopolymers based on metakaolin were synthesized and characterized. By

considering the compressive strength, density, and crystal phase of the

specimens according to the type and amount of forming agent, the possibility of

replacing Al powder, a foaming agent, with Si sludge in lightweight foamed

geopolymers was analyzed. The specimens foamed with Al powder had lower density

than those with Si sludge. However, the compressive strength of the former was

higher than that of the specimens foamed with Si sludge, owing to a more

uniform pore distribution and microstructure. Through this study, lightweight

foamed geopolymers having density of 0.36~1.05 g/cm3 and compressive

strength of 0.7~4.7 MPa can be prepared by controlling the process conditions

such as the amount of Si sludge added, alkali activator concentration, L/S

ratio, etc. The possibility of Si sludge replacing Al powder as a foaming agent

thus has been demonstrated. The lightweight foamed geopolymer fabricated in

this study can be applied to various fields as it can meet the required

physical properties according to the application.

Keywords: Geopolymer, Light Weight, Si Sludge, Metakaolin

Environmental problems caused by greenhouse gases have

occurred in almost all countries around the world since the 2000s. Carbon

dioxide, in particular, is a major greenhouse gas. Research to reduce carbon

dioxide emissions is being actively conducted around the world [1]. Currently,

Portland cement is widely used as a binding material in the construction and

civil engineering field. The cement manufacturing industry meanwhile consumes a

great deal of energy and emits enormous amounts of carbon dioxide gas during

the heat treatment of limestone (CaCO3) and the

combustion of fuel [2, 3]. Specifically, 0.4 to 1.0 tons of carbon

dioxide is discharged to produce one ton of cement, which accounts for 5-7% of

the total carbon dioxide generated by mankind [4, 5]. From this point of view,

geopolymers are attracting attention in the production of binders compared to

Portland cement concrete as greenhouse gas is rarely generated depending on the

weight value of reactive materials of feedstock (SiO2, NaOH, etc.)

[6, 7].

The term “geopolymer” refers to an inorganic polymer

synthesized by the chemical reaction of an alumino-silicate precursor with an

alkali solution [8]. It is generally prepared by reacting raw materials of rich

in Si and Al such as metakaolin with alkali activators such as sodium

hydroxide, potassium hydroxide or water glass [9-11]. Geopolymers consist of

three-dimensional polymer chains. When an alkali solution is brought into

contact with an alumino-silicate oxide as a raw material,

Si and Al ions are dissolved. The dissolved ions are

polymerized into AlO4 and SiO4 tetrahedral precursors

[12, 13]. The basic form of the polymer chain produced

by the polymerization of precursors is -Si-O-Si-O-Si-.

Na+ ions added to the chain as activators and Al3+ ions

are substituted at Si 4 + sites to form a network structure in the

form of -Si-O-Al (Na) -O-Si-. This network

structure finally generates a polymer structure in the form of Mn[-(Si-O2)z-Al-O]n-wH2O

by a complex reaction, where M is an alkali ion such as Na+, K+,

Li+, Ca2+, or Ba2+, Z is 1 to 3, and n is the

degree of polymerization. Because of this polymer structure, industrial waste

such as blast furnace slag and fly ash, which are mostly composed of Si and Al,

are highly applicable as geopolymer materials [14].

Geopolymers have the advantages of excellent mechanical

strength, heat resistance, and chemical resistance

[15]. Microstructure and mechanical properties of

geopolymer highly depends on its composition and curing routes, including type

of alkaline cation and its content, Si/Al ratio, M2O/H2O

ratio, M2O/SiO2 ratio, temperature,

and humidity, among others [16]. Recently, porous

geopolymers with intentional pores have attracted considerable

attention for application to high value-added fields such as thermal

insulation, soundproofing, and fire resistance [16]. On the other hand, the

weight reduction of the construction material has an economic advantage

because it reduces the weight-bearing burden on each

member composing a building. In addition, lightweight materials have low

thermal conductivity, which can be expected to provide thermal insulation [17,

18]. For this reason, research to reduce the weight of geopolymers by

containing a foaming agent in the manufacturing process have been actively

conducted.

In general, there are two common ways to create pores in

geopolymers. The first is to use chemical agents to create bubbles by chemical

reactions during geopolymer curing and to trap the bubbles in the specimen, and

the second is the use of foaming agents, which release the bubbles during

mechanical mixing of the geopolymer slurry [19, 20]. The porosity of the

lightweight geopolymer is highly dependent on the kind and

amount of foaming agent added. It is important to precisely

control the manufacturing conditions in order to prevent bubbles from

collapsing when the generated bubbles are brought into contact with each other

[21].

Al, H2O2, Zn, etc. have been used as

foaming agents. Recently, V. Medri et al. reported that foamed

geopolymers can be prepared through hydrogen gas generation by adding

various types of Si [22-24]. Like Al, a reactive metal powder, Si also reacts

with water and hydroxides in an alkaline environment to produce hydrogen gas

[20]. Reiva et al. reported the pore formation reaction of Si and Al [25].

First, the reaction between Si and alkali activator is shown in Eq. (1).

Si + 2NaOH + H2O → Na2SiO3

+ 2H2↑ (1)

The reactions Al and water or alkali reaction are shown in

Eq. (2), (3), and (4).

2Al + 6H2O → 2Al(OH)3 + 3H2↑ (2)

2Al + 3H2O → Al2O3 + 3H2↑ (3)

2Al + 2OH¯ + 6H2O → 2Al(OH)4¯ + 3H2↑ (4)

Si also has a similar reaction scheme in which gas is

generated by reacting with water or an alkali like Al, a conventional foaming

agent. Therefore, Si could be used as a foaming agent. In this

study, lightweight foamed geopolymers based on metakaolin were

synthesized and characterized. The goal of this study is to replace the

existing foaming agent Al with the waste resource Si sludge in

synthesizing lightweight foamed geopolymers. In

particular, by considering the compressive strength, density, and crystal phase

of the specimens according to the type and amount of forming agent, the

possibility of replacing Al powder with Si sludge was analyzed

Metakaolin was used as a raw material of the geopolymer.

The alkali activator used to activate the geopolymer reaction was sodium

hydroxide (Sodium Hydroxide, Duksan, Extra Pure Grade, 93-100%).

Alkali activators are prepared by mixing distilled water and

sodium hydroxide in a specific molarity. Si sludge used as a foaming agent

originates from the silicon wafer cutting process for semiconductors. The

particle size of Si sludge used was only 106㎛ or less obtained through the

grinding and sieving process. Al powder used as another foaming agent in this

study was 99.9% pure and had a particle size of less than 106㎛ like as Si

sludge.

Metakaolin and alkali activator were mixed in a bowl for

15 min to activate the geopolymer reaction. The mixed slurry was placed in a

5 x 5 x 5cm3 brass mold and

compressed with a hand compact. In the curing process, in order to prevent

cracking caused by rapid evaporation of water, the green body molded in the

mold was put in a zipper bag made of polyethylene together with the mold and

then cured at 70 °C for 24 h. After curing, the specimens were aged at

room temperature for 3 days.

The chemical composition and crystal phase of metakaolin

and the fabricated geopolymer were analyzed using XRF

(X-ray Fluorescence; SPECTRO 2000) and XRD(X-ray

Diffractometer; MiniFlex II, Rigaku, Japan),

respectively. The compressive strength of the produced geopolymer was measured

using a universal testing machine (UTM).

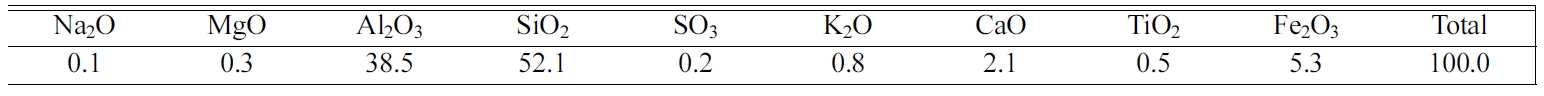

Table 1 shows the chemical composition of metakaolin

indicating that the contents of SiO2 and Al2O3

were 52.1 and 38.5 wt%, respectively. The Si:Al atomic ratio of metakaolin was

calculated as 1.14. Al and Si ions could be eluted when an alkaline activator

solution is contacted with the alumino-silicate materials, and they can be

cured to a dense solid by polycondensation. This process

is called a geopolymeric reaction. The geopolymeric

reaction might generate various polymers such as poly-sialate–siloxo,

poly-sialate–disiloxo, etc. relying upon the ratio of SiO2/Al2O3

in the batch [26].

The ratios of Si/Al of poly-sialates, poly-sialate–siloxo,

and poly-sialate–disiloxo are 1, 2, and 3, respectively. It is

crucial for the geopolymeric reaction to generate an ortho-sialate oligomer

with a Si/Al ratio = 1 because the rate of room temperature

polymerization of oligo-sialates was 100 to 1,000 times faster

than that of ortho-silicate or oligo-siloxo units [27]. Among the geopolymers

based on various industrial wastes, Si/Al = 17.5 was also reported [28].

Therefore, the present raw material, metakolin with a Si/Al

ratio = 1.14, can be considered to

be usable as a raw material of geopolymers.

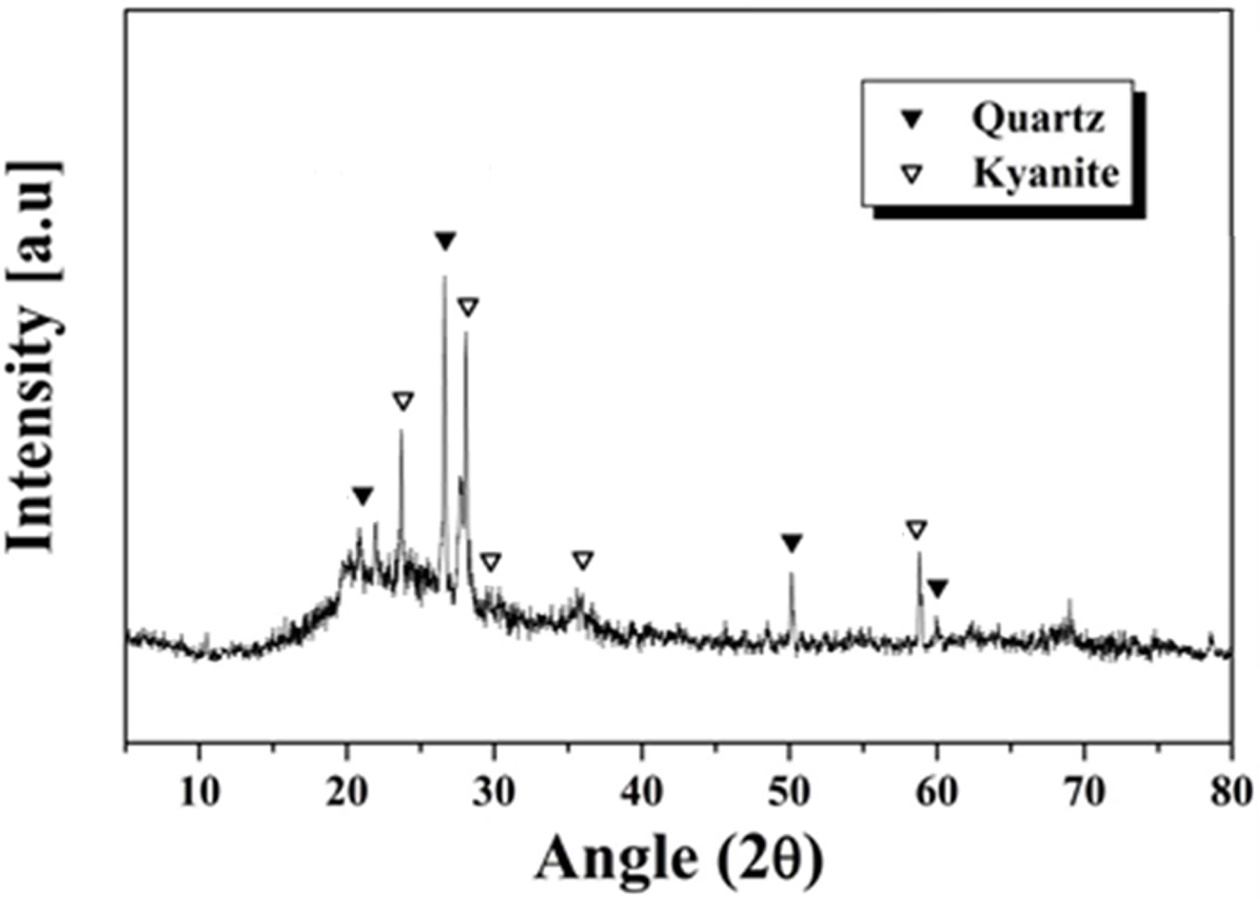

The crystal phase of metakaolin analyzed by XRD is shown

in Fig. 1. There were several phases. First, the large humps, indicating that

there was a significant amount of amorphous phase in the material. It can be

seen also that quartz (SiO2) and kyanite (Al2SiO5)

crystal phases also exist. The cations such as Si and Al could be dissolved out

from metakaolin when the metakaolin is brought into contact

with the alkali solution, owing to the presence of an

amorphous phase. It is, therefore, judged to be suitable as a raw material for

fabricating geopolymer.

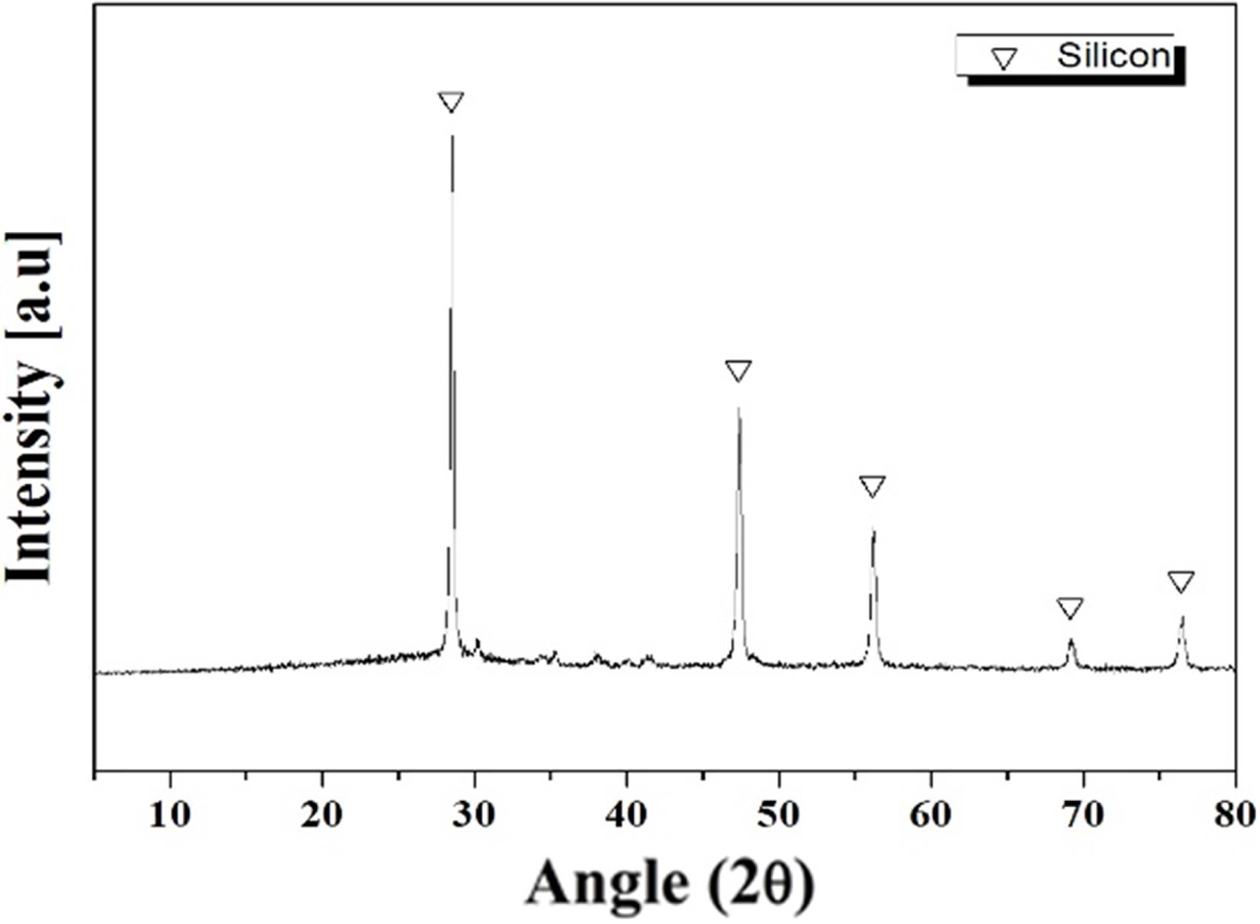

Si sludge is a waste resource emitted during the process

of manufacturing silicon wafers for solar cells and semiconductor modules.

During the process, about 40% of the silicon is produced as sludge-type waste

containing 2% Al2O3, a polishing powder used for

polishing Si wafers. Although the sludge contained 2% Al2O3

phase, the XRD analysis shows only Si crystal peaks, as in Fig. 2.

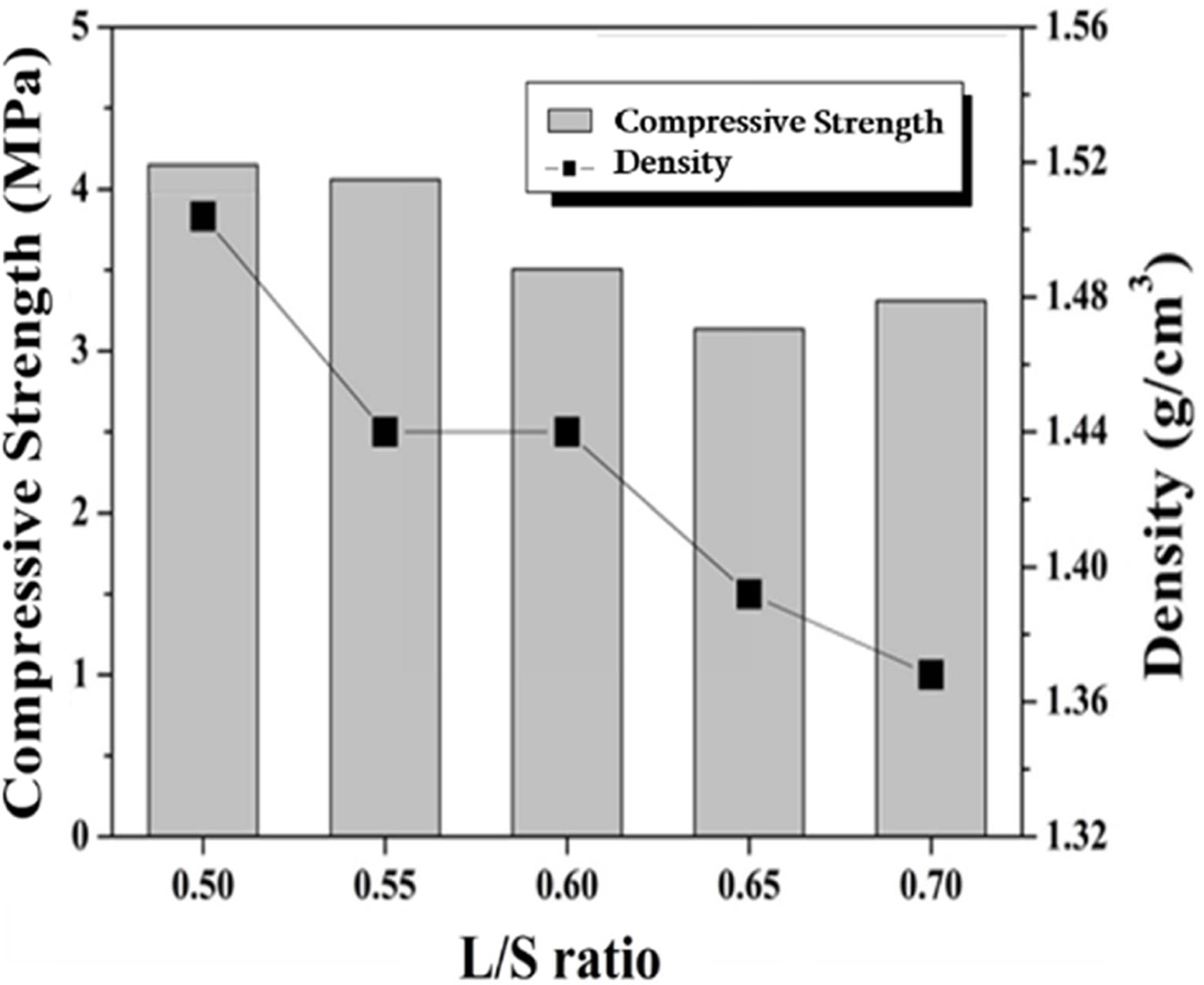

The compressive strength and density of specimens with a

liquid/solid ratio (L/S ratio) ranging from 0.5 to 0.7 were measured and the

results are shown in Fig. 3. No foaming agent was added, and the concentration

of alkali activator solution used was 9 M. The density decreases with the

amount of water because the space occupied by the excess water turned into

pores during the drying process. For example, the density of the specimen made

with L/S values of 0.5 and 0.7 were 1.5 and 1.37 g/cm3,

respectively. As the L/S ratio increased from 0.5 to

0.7, the compressive strength value decreased from 4.2 to

3.4 MPa, respectively, owing to a decrease in density with an increasing L/S

ratio. The specimens shown in Fig. 3 were dense geopolymers without use of a

foaming agent, but the compressive strength values were very low. This is

because the molar concentration of the alkali activator used in the specimen

preparation was too low. As will be mentioned later in Fig. 5,

for the best compressive strength specimens, the concentration of

the alkali activator should be 15 M.

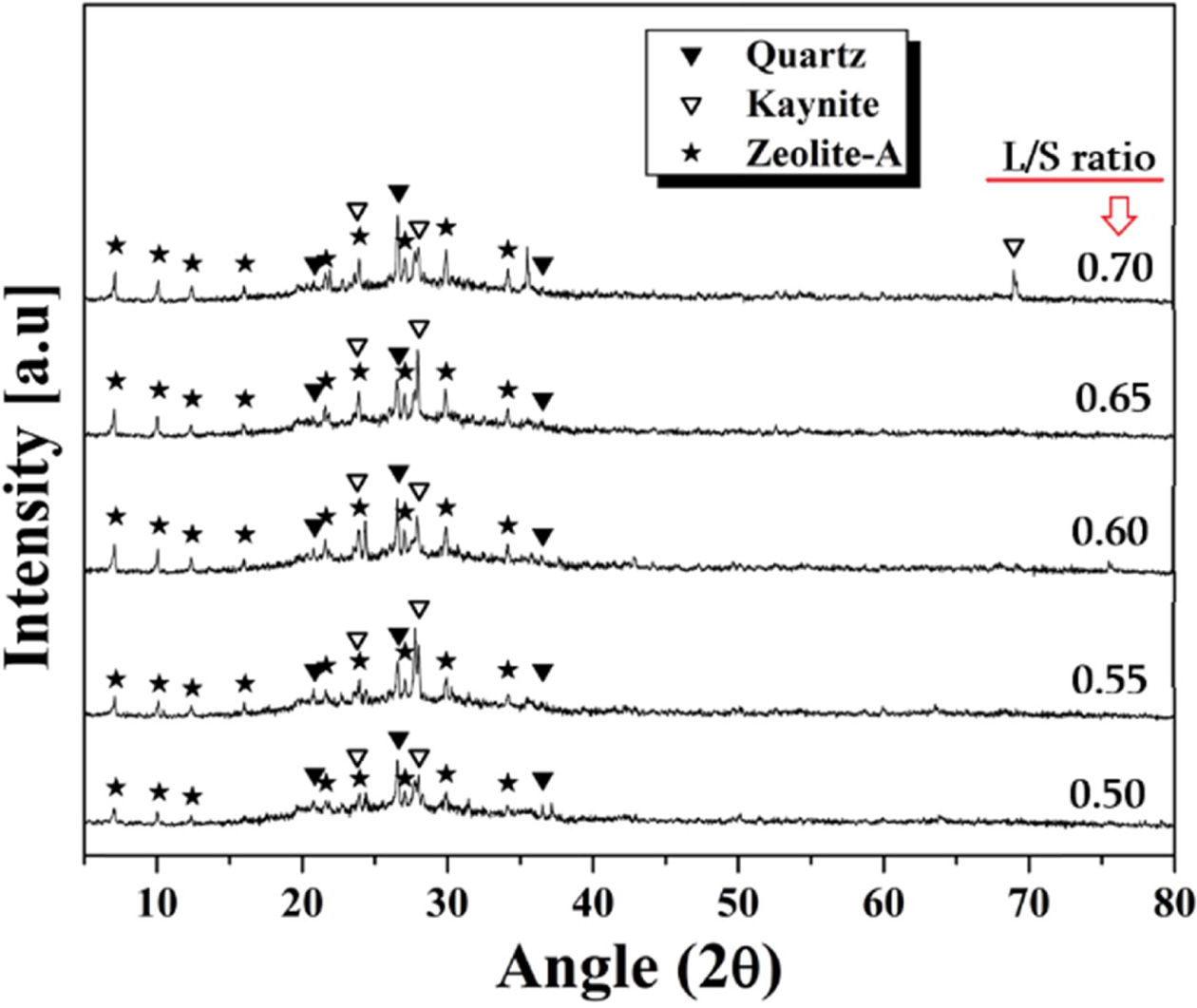

XRD analysis results of the specimens according to the

L/S ratio are shown in Fig. 4. Regardless of the manufacturing conditions,

quartz, kyanite, and zeolite-A crystal phases appeared in all specimens. Quartz

and kyanite originate from the starting material, metakaolin. The

zeolite phase, which is composed of alumino-silicate crystals,

has a chemical formula similar to Mn[-(Si-O2)z-Al-O]n-wH2O,

which is the structure of geopolymers. The existence of zeolite phases in the specimen

is known to be evidence that the geopolymeric reaction occurred. The

zeolite crystals usually can accommodate a wide variety of

cations, such as Na+, K+, Ca2+, Mg2+,

and others, being rather loosely held. The peak intensities of most of the

crystal phases did not change significantly

with the L/S ratio, and meanwhile the zeolite-A crystals showed a slight

increase in peak intensity with the L/S ratio. As the ions move faster in the

liquid phase, the higher the L/S ratio is, the easier the Al and Si ions will

be eluted. As a result, the geopolymer reaction took place vigorously through

the rich liquid phase, resulting in better generation of the zeolite phase.

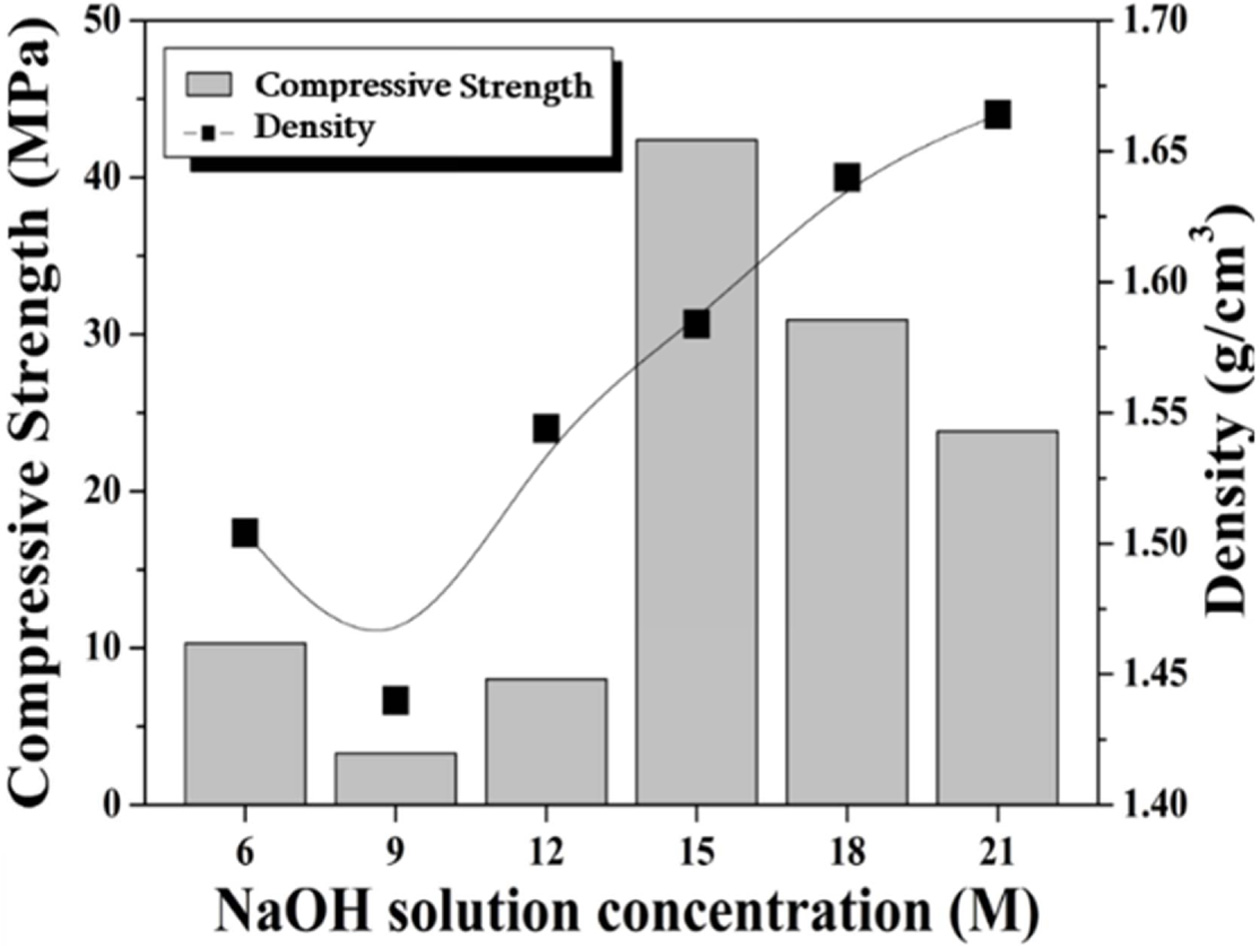

The effect of the alkali activator concentration upon the

compressive strength and density of the specimen prepared with a L/S ratio of

0.6 is shown in Fig. 5. The density of the specimen has a tendency to increase

with increasing activator concentration, except for the

specimen of 9 M NaOH. However, the compressive strength was

highest at 42 MPa when the concentration of the activator used was 15 M.

It is believed that excess alkali interfered with the geopolymer reaction with

an alkali activator of 15 M or more. The increase in the density with the

concentration of the alkaline solution is likely due to the composition of the

liquid phase. The liquid phase used in this study is a mixture of water and NaOH.

The resulting alkaline solution with high molarity is heavier

than pure water. Therefore, the higher the molar concentration of the alkaline solution

is, the higher the unit weight of the solution will be, and thus the density of

the specimen increases.

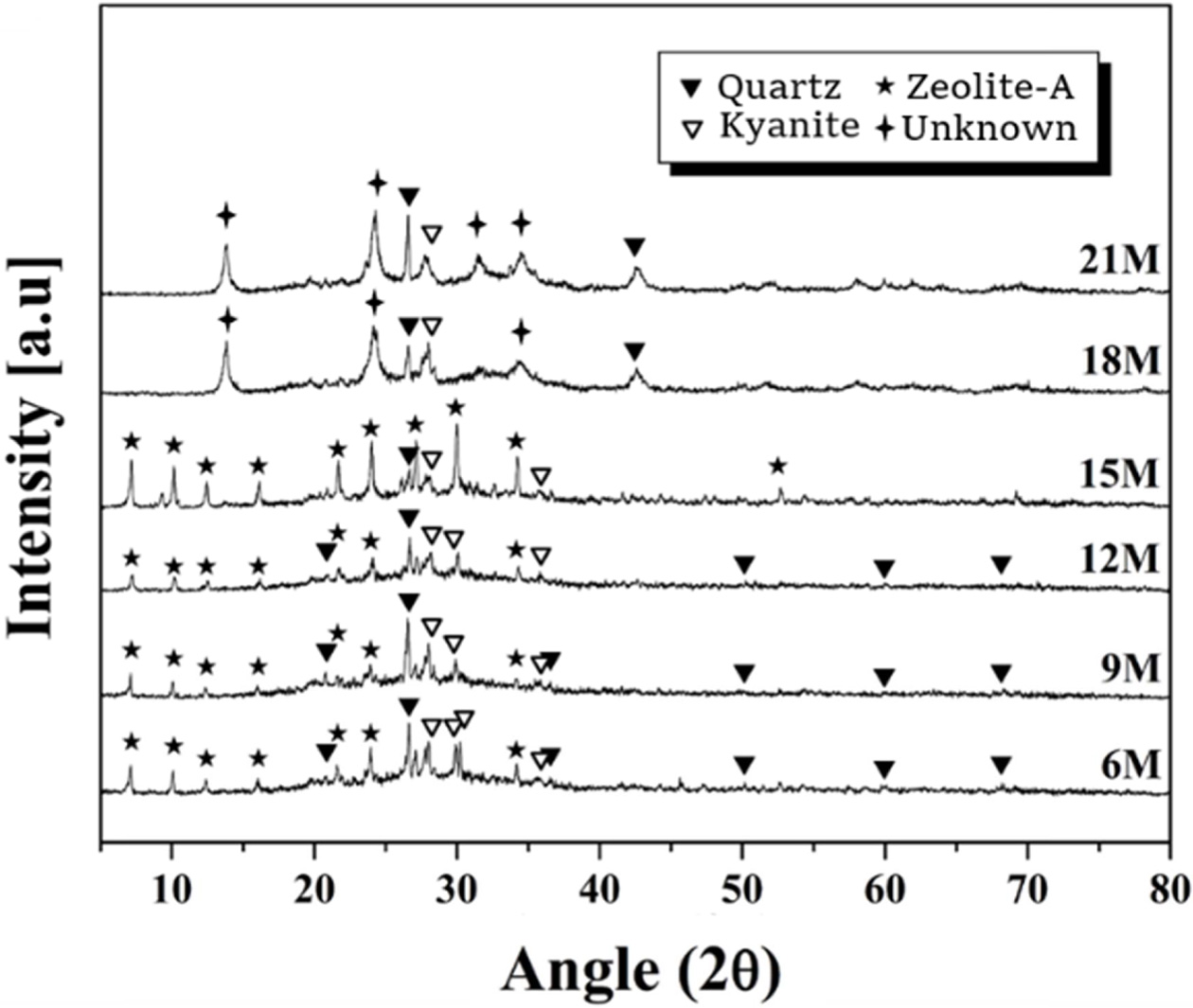

The XRD analysis results of the specimens prepared with

various molar concentrations of alkaline solution are shown in Fig. 6. The L/S

ratio used was 0.6. As mentioned earlier, quartz and kaynite originate from the

starting material, metakaolin, and the new phase generated by the geopolymeric

reaction is zeolite-A crystal. The peak intensity of the zeolite-A crystals

tended to increase with the molarity of the alkaline solution within the range

of 6-15 M, but the zeolite-A phase disappeared and unknown crystal peaks

appeared at a molarity of 18 M or more. As mentioned above, the presence of the

zeolite phase is evidence that a geopolymer reaction has taken place.

Therefore, the use of an alkaline solution with an excessive molar concentration

of 18 moles or more was found to interfere with the

geopolymer reaction.

Analyzing the XRD results in Fig. 5 with the com- pressive strength data in Fig. 6, it can

be seen that the compressive strength values increased with the zeolite

crystal peak intensity. Thus, it can be seen that the excess alkali activator

not only inhibits the geopolymer reaction but also produces an unknown

crystalline phase (possibly a Na-based crystalline phase). The

resulting unknown crystalline phase lowered the compressive strength

value of the specimen. Therefore, for preparing the

geopolymer in the present study, the optimum value of the alkaline solution

concentration was determined to be 15 M. However, it is thought that the

discussion of the exact relationship between the mechanical strength value and

the type of crystal phases formed identified by XRD results may be possible

when the additional experiments is performed.

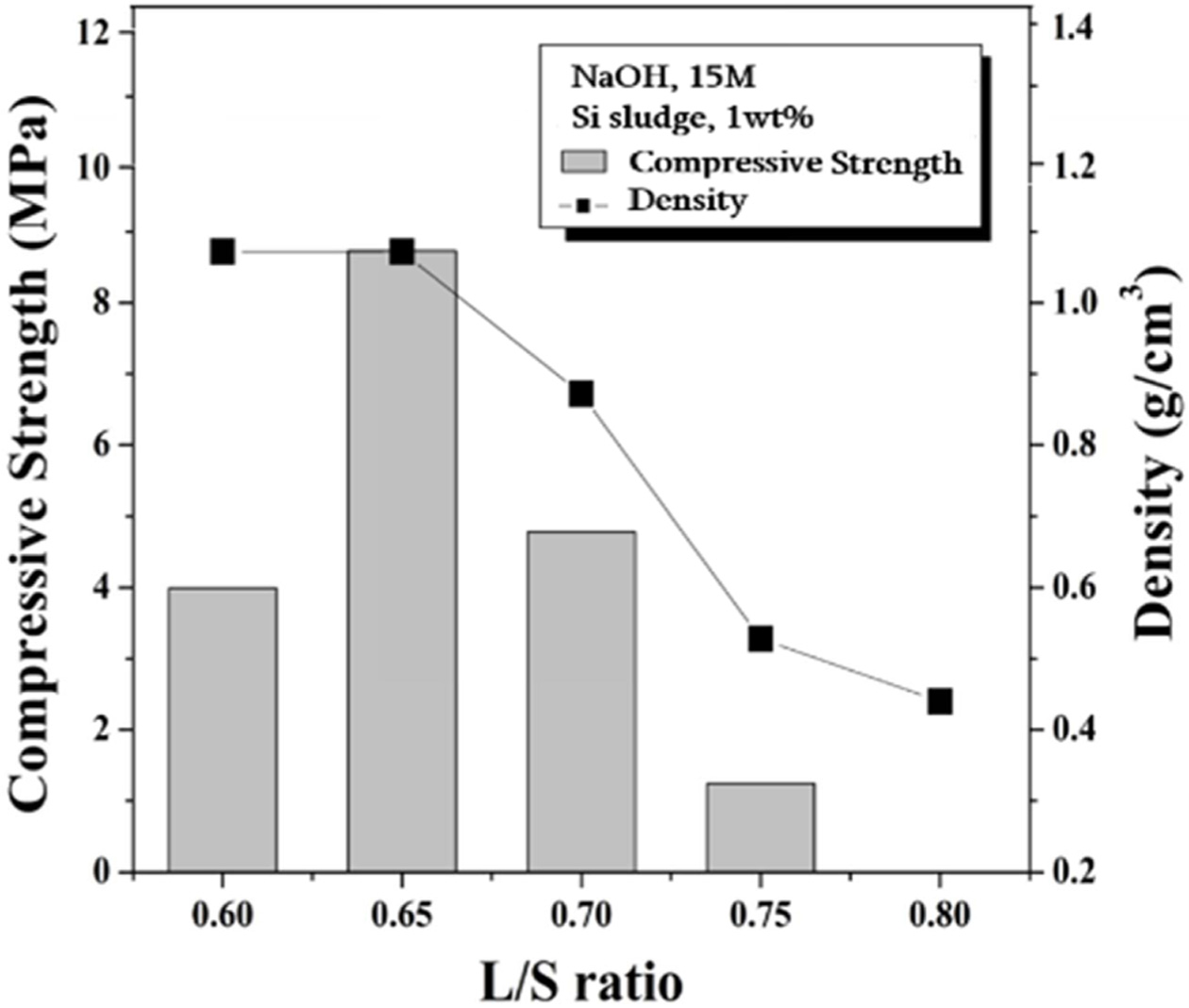

The compressive strength and density of foamed geopolymers

containing 1 wt% Si sludge and 15 M NaOH as a function of the L/S ratio

are shown in Fig. 7. The density decreased with the L/S ratio. Overall, a lightweight

specimen with a density of 0.35 to 1.1 g/cm3 was produced. As shown in Eq. (1), the Si sludge

generates hydrogen gas upon contact with water. The generated hydrogen gas is

trapped inside the geopolymer and expands to make the geopolymer into a porous

structure. As the amount of water in the geopolymer increases, the Si sludge

generates more bubbles, which ultimately reduces the density of the specimen.

The compressive strength of the specimens was 1.2-8.7 MPa in a L/S ratio

ranging from 0.6 to 0.8, with a maximum compressive strength at a L/S ratio of

0.65. When the L/S ratio is 0.6, the dissolution rate of the Si and Al ions is not high enough, and consequently the geopolymer reaction is suppressed

and the strength is considered to be low. The compressive strength of the

specimen decreased with the L/S ratio in a L/S ratio range of 0.7-0.8. The reason for this is that more

porous structures were produced as

the amount of water increased. In particular, the strength of specimen made

with an L/S ratio of 0.8 was too low to be measured by UTM.

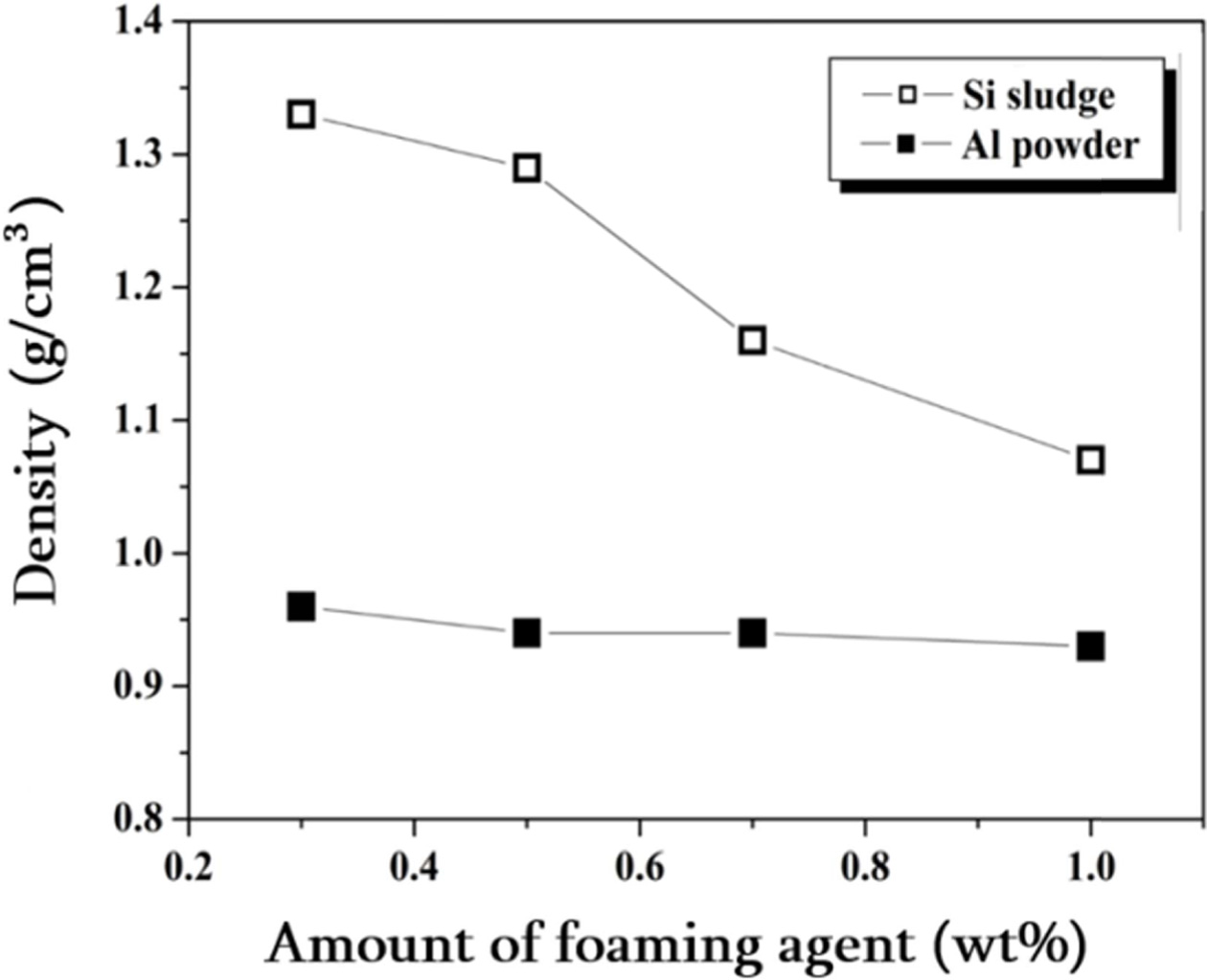

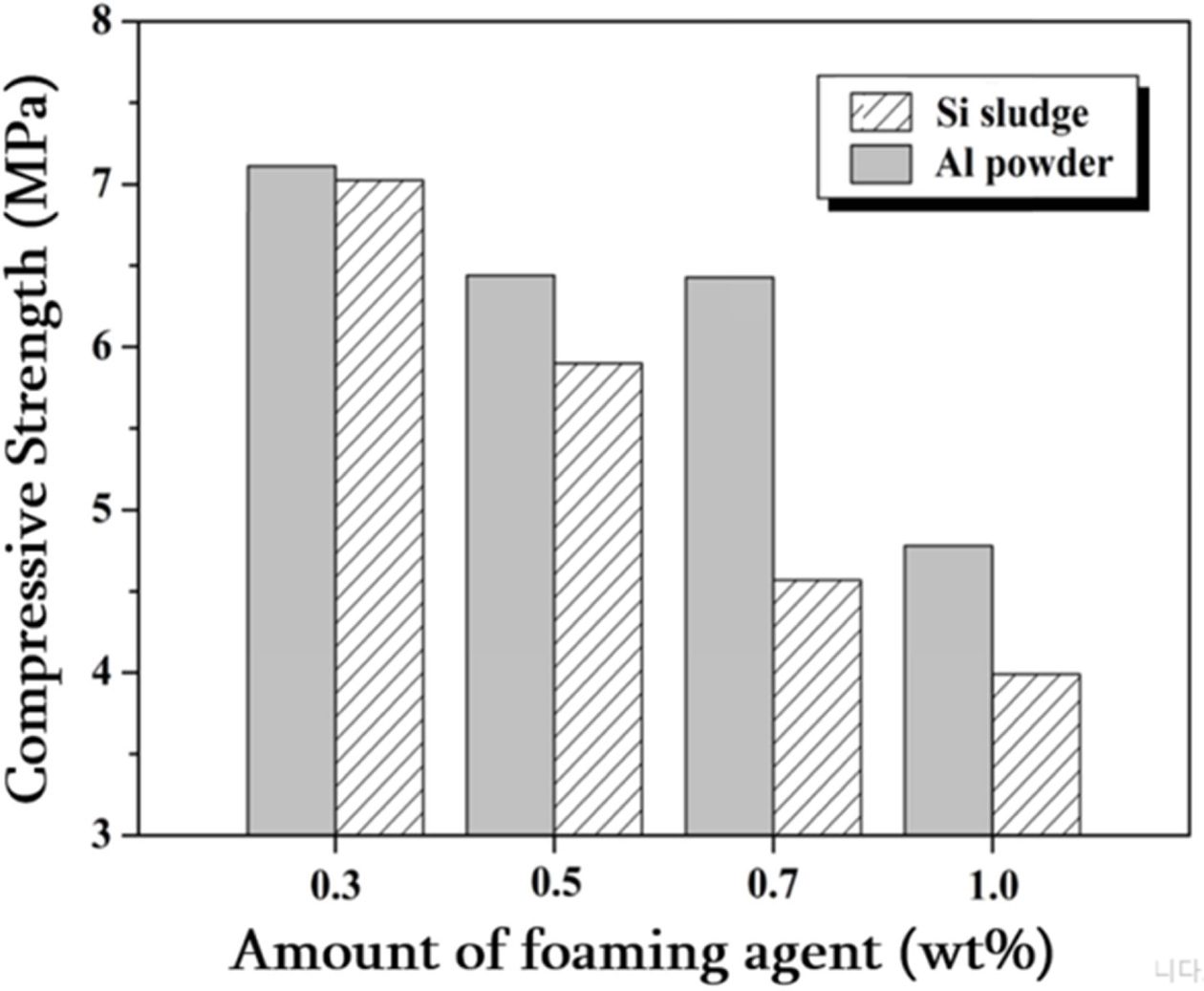

The density and compressive strength of lightweight foamed

geopolymer specimens prepared using two kinds of foaming agents, Al powder and

Si sludge, are shown in Figs. 8 and 9, respectively. The concentration of

alkali activator used when preparing the specimen was 15 M and

the L/S ratio was set at 0.65. The specimens foamed with Si

sludge had decreased density from 1.33 to 1.06 as the amount of Si

sludge added was increased within a range of 0.3-1.0 wt%. The specimens foamed

with Al powder had a lower density overall than the Si foamed specimens, and

the density change with the amount of Al powder added was not significant.

Regardless of the type of foaming agent, the compressive strength decreased as

the amount of foaming agent added increased. Overall, the compressive

strength of the Al powder-added specimens was higher than that of

the Si sludge-added specimens. In particular, in the case

of 0.7 wt% foaming agent added, the Al powder-added specimen showed 20.5%

higher com- pressive

strength than the Si sludge-added specimen. This is thought to be due to the

more uniform pore distribution and microstructure of the specimens made with Al

powder than those made with Si sludge, as shown in Fig. 10.

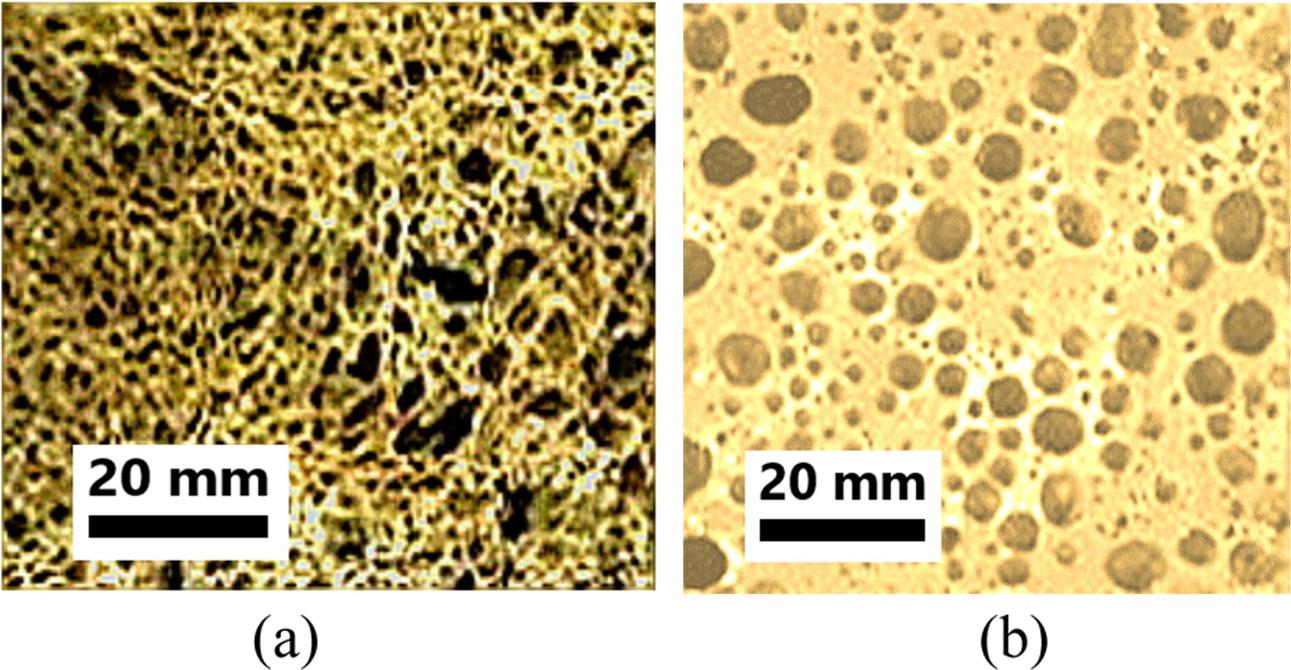

Fig. 10 shows photographs of specimens foamed with Al

powder (a) and Si sludge (b). The samples made of Al powder had larger pores

than those of the samples made of Si sludge. For this reason, the density of

specimens made of Al powder was lower than that of Si sludge. However, it can

be seen that the pore size distribution and microstructure of the

specimens prepared by Al powder are more uniform than

that of the specimens prepared by Si sludge. A non-uniform pore size

distribution and microstructure causes the specimen to degrade in terms of

compressive strength.

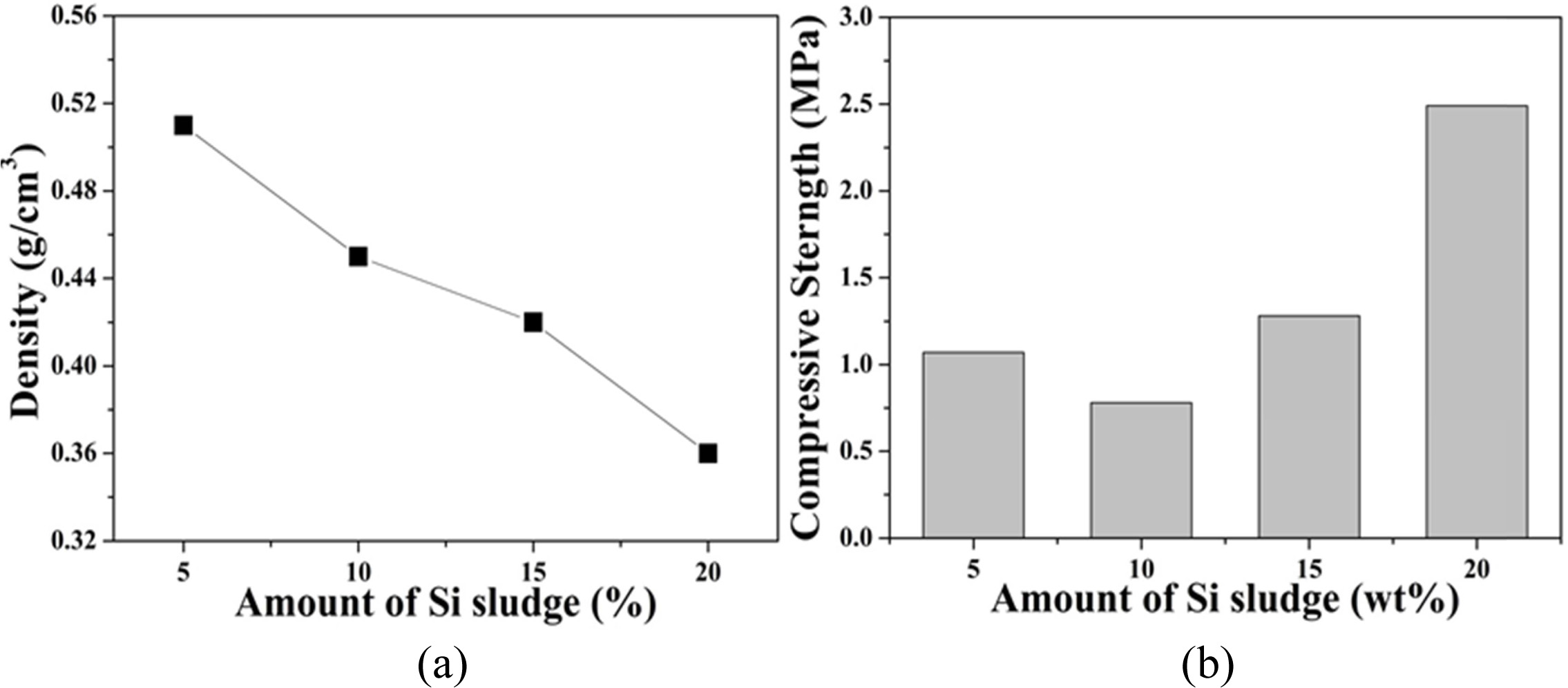

In order to investigate the effect of the large amount of

Si sludge addition on the weight reduction of the geopolymer, the density and

compressive strength of the specimens prepared with 5 to 20 wt% Si sludge were

measured and the results are shown in Fig. 11. The density of geopolymers

decreased with the amount of Si sludge added. For example, the densities of the

specimen made with 5 and 20 wt% of Si sludge addition were 0.51 and 0.36,

respectively. On the other hand, the compressive strength made with 5 wt% Si

sludge added was 1.1 MPa, but decreased to 0.8 MPa for the specimen with 10 wt%

Si sludge. However, when the added amount was more than 15%, the compressive

strength increased conversely with the Si sludge. For example, the compressive

strength of the specimen made with 20 wt% Si sludge was 2.5 MPa. The

reason why the compressive strength of the specimen made with the

foaming agent 15% or more is increased is that bubbles generated on the surface

escape easily from the specimen before the specimen is hardened. As a result,

the surface was denser than the interior. Of course, there are still many pores

inside the specimen, and thus the density decreases with the amount of blowing

agent. Due to densification of the surface, it is thought that the compressive

strength increased again in the specimen with more than 15 wt% of Si sludge.

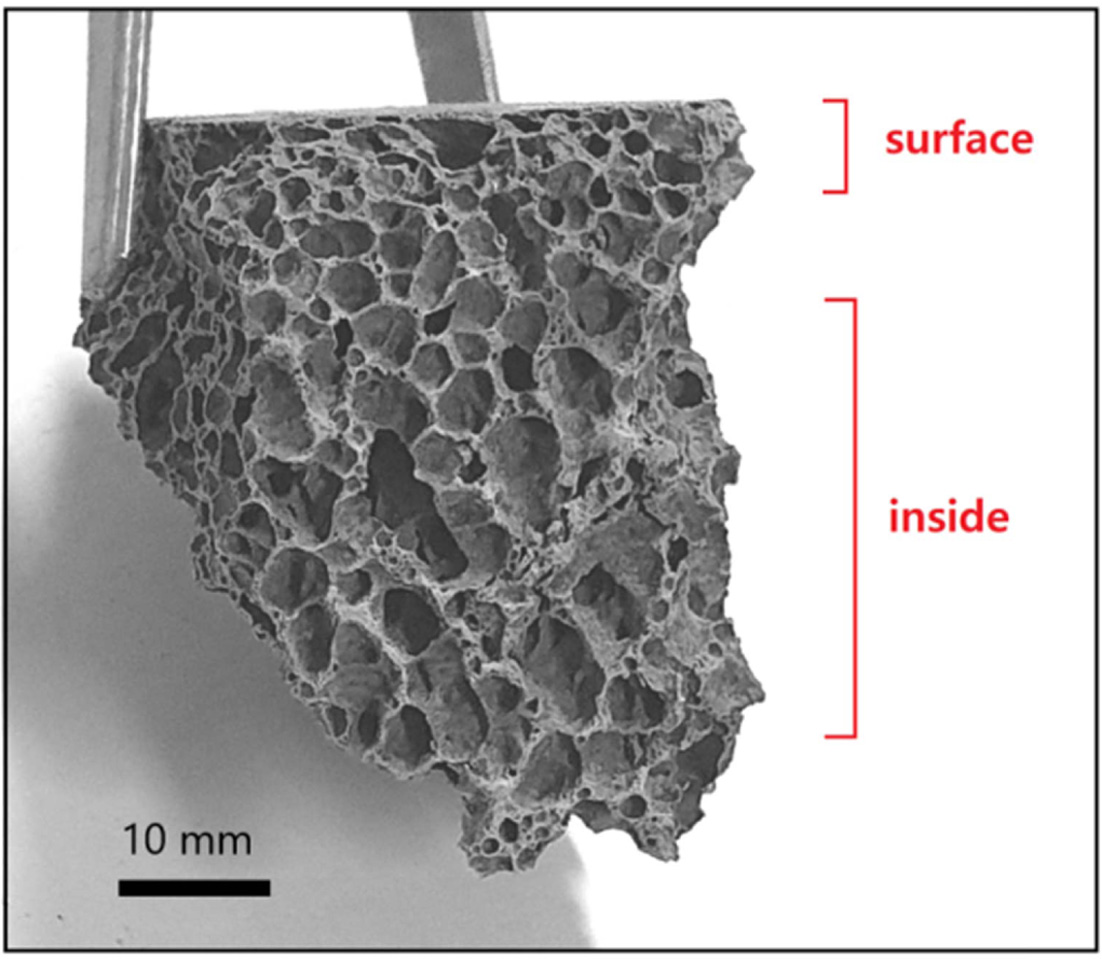

This phenomenon can be seen in Fig. 12. The pores near the surface of the

specimen are small, while the pores in the inner part are large.

As a result, it was possible to manufacture metakaolin-based

lightweight foamed geopolymers having compressive strength of

0.7-2.4 MPa and density of 0.51-0.36 by using 5-20 wt% of Si sludge instead of

Al powder as a foaming agent in this study.

|

Fig. 1 XRD pattern of metakaolin used as starting material for fabricating geopolymers. |

|

Fig. 2 XRD pattern of Si sludge used as forming agent. |

|

Fig. 3 Compressive strength and density of geopolymers made with various L/S ratios. Alkali activator concentration used was 9 M and no foaming agent was added. |

|

Fig. 4 XRD pattern of geopolymers made with various L/S ratios. Alkali activator concentration used was 9 M and no foaming agent was added. |

|

Fig. 5 Compressive strength and density of geopolymers made with various alkali solution concentrations. L/S ratio used was 0.6. |

|

Fig. 6 XRD pattern of geopolymers made with various alkali solution concentrations. L/S ratio used was 0.6. |

|

Fig. 7 Compressive strength and density of light weight geopolymers made with various L/S ratios. Alkali activator concentration used was 15 M, and amount of Si sludge added was 1.0 wt%. |

|

Fig. 8 Graph of density changes of light-weight geopolymers made of Si sludge and Al Powder. Alkali activator concentration used was 15 M, and the L/S ratio used was 0.65. |

|

Fig. 9 Compressive strength of light-weight geopolymers made of Si sludge and Al Powder. Alkali activator concentration used was 15 M, and the L/S ratio used was 0.65. |

|

Fig. 10 Optical photograph of light-weight geopolymers made of 0.5 wt% (a) Si sludge and (b) Al Powder. Alkali activator concentration was used 15 M, and the L/S ratio used was 0.65. |

|

Fig. 11 Physical properties of light-weight geopolymers made with various amounts of Si sludge; (a) density, and (b) compressive strength. Alkali activator concentration used was 15 M, and the L/S ratio used was 0.65. |

|

Fig. 12 Picture of fractured surface for foamed geopolymer made with 15 wt% Si sludge. |

In this study, experiments were carried out for the

purpose of replacing Al powder, which is used mainly in manufacturing

lightweight foamed geopolymer, with Si sludge produced as industrial waste, and

we have drawn the following conclusions.

1) The presence of zeolite crystalline phases generated

in metakaolin geopolymer specimens indicates that a geopolymeric reaction

occurred in the specimen.

2) As a higher L/S ratio is employed, the zeolite phase is

well formed due to the active geopolymer reaction caused by easy dissolution of

Al and Si ions. Considering formability and reactivity, an L/S ratio of 0.6 ~

0.65 is suitable for the production of metakaolin-based geopolymers.

3) Increasing the molarity of the alkali activator

increased the zeolite crystal peak in XRD analysis, but above 15 M, the excess

alkali inhibited the geopolymer reaction and the zeolite crystal phase

generation.

4) Partial densification was observed near the surface of

the specimen made with more than 15 wt% of Si sludge, resulting in an increase

in compressive strength.

5) By adding Si sludge in the place of Al powder, which is

a conventional foaming agent, it was possible to manufacture lightweight foamed

geopolymer based on metakaolin. By controlling the process conditions such as

the concentration of alkali activator, L/S ratio, and the amount of Si sludge

added, specimens with a density of 0.36 to 1.05 g/cm3 and

compressive strength of 0.7 to 4.7 MPa could be prepared.

This work was supported by Kyonggi University Research

Grant 2018.

- 1. Y. S. Kim and S. G. Kang, J. Korean Cryst. Growth Cryst. Technol. 24[1] (2014) 15-20.

-

- 2. J. J. Bang and S. G. Kang, J. Korean Cryst. Growth Cryst. Technol. 28[5] (2018) 199-205.

-

- 3. D.M.A. Huiskes, A. Keulen, Q.L. Yu, and H. J. H. Brouwers, Materials and Design, 89 (2016) 516-526.

-

- 4. E. Mohseni, M. J. Kazemi, K. Mahdi, B. Zehtab, and B. Abak, Constr. Build. Mater. 209 (2019) 532-540.

-

- 5. S. Top, H. Vapur, M. Altiner, D. Kaya, and A. Ekicibil, J. Mol. Struct. 1202 (2020) 127-136.

-

- 6. S. Mesgari, A. Akbarnezhad, and J. Z. Xiao, Constr. Build. Mater. 236 (2020) 117571.

-

- 7. B. C. McLellan, R. P. Williams, J. Lay, A. R. van, and G. D. Cordor, J. Cleaner Prod. 19 (2011) 1080-1090.

-

- 8. M. N. Rui, R. C. Pullar, and A. L. João, Prog. Mater. Sci.

-

- 9. T. A. Nour and H. A. Elsayed, HBRC Journal, 14 (2018) 159-164.

-

- 10. C. Yi, H. Ma, H. Chen, J. Wang, Shi Jing, Z. Li, and M. Yu, Const. Build. Mater. 187 (2018) 318-326.

-

- 11. Z. Peng, Y. Zheng, K. Wang, and J. Zhan, Compo. B Eng. 152 (2018) 79-95.

-

- 12. C. Shi, A. F. Jiménez, and A. Palom, Ceme. Concr. Res. 41 (2011) 750-763.

-

- 13. J. Davidovits, Alkakine Cements and Concretes, (1994) 131-149.

- 14. J. Davidovits, J. Therm. Anal 37 (1991), 1633-1656.

-

- 15. S. Quentin, Institut Géopolymère 4 (2015).

-

- 16. P. He, M. Wang, S. Fu, D. Jia, S.Yan, J. Yuan, J. Xu, P. Wang, and Y. Zhou, Ceram. Int, 42 (2016) 14416-14422.

-

- 17. W. Rickard, L. Vickers, and A. V. Riessen, App. Clay Sci, 73 (2013) 71-77.

-

- 18. W. Rickard, L. Vickers, and A. V. Riessen, App. Clay Sci. 73 (2012) 71.

-

- 19. K. B. Han, Kor. Const. Safety Association 33 (2005) 34.

-

- 20. F. Xu, G. Gu, W. Zhang, H. Wang, X. Huang, and J. Zhu, Cer. Int. 44 (2018) 19989-19997.

-

- 21. R. A. Aguilar, O. B. Díaz, and J. I. E. García, Const. Build. Mater. 24 (2010) 1166-1175.

-

- 22. S. J. Lee, E. M. An, and Y. H. Cho, J. Rec. Const. Resources. 4[4] (2016) 363-370.

-

- 23. Z. Zhang, J. L. Provis, A. Reid, and H. Wang, Const. Bldg. Mat. 56 (2014) 113.

-

- 24. V. Medri and A. Ruffini, Cer. Int. 38 (2012) 3351.

-

- 25. V. Medri, E. Papa, J. Dedecek, H. Jirglova, P. Benito, A. Vaccari, and E. Landi, Cer. Int. 39 (2013) 7657.

-

- 26. C. Leiva, Y. L. Galiano, C. Arenas, B. A. Fariñas, and C. F. Pereira, Waste Manag. 95 (2019) 504-512.

-

- 27. K. Pimraksaa, P. Chindaprasirt, A. Rungchet, K. Sagoe-Crentsil, and T. Sato, Mater. Sci. and Eng. A 528 (2011) 6616-6623.

-

- 28. M. North and T. Swaddle, Inorg. Chem. 39 (2000) 2661-2665.

-

- 29. S. Songpiriyakij, T. Kubprasit, C. Jaturapitakkul, and P. Chindaprasirt, Constr. Build. Mater. 24 (2010) 236-240.

-

This Article

This Article

-

2020; 21(S1): 74-80

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s74

- Received on Dec 30, 2019

- Revised on Apr 13, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Seung-Gu Kang

-

Department of Advanced Materials Science and Engineering, Kyonggi University, Suwon 16227, Korea

Tel : +82-10-5265-2681 - E-mail: sgkang@kgu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.