- Nano-crystallized glass-ceramic of BaO-TiO2-SiO2 system containing ZrO2

Byeong-Guk Kang and Seunggu Kang*

Department of Advanced Materials Science and Engineering, Kyonggi University, Suwon 16227, Korea

Fresnoite (Ba2TiSi2O8)

materials, which exhibit piezoelectricity, ferroelectricity, and nonlinear

optical properties, can be used as core materials for optical communication and

optical information processing devices. In this study, glass-ceramics with

nanometer size fresnoite crystal phase were prepared from BaO-TiO2-SiO2

(BTS) glass containing ZrO2 as a nucleating agent and their

microstructure, crystallization behavior, and photoluminescence properties were

analyzed. The heat treatment process for glass-ceramics was designed based

on data obtained by non-isothermal analysis using differential thermal analysis

(DTA). The crystal morphology and microstructure of the prepared specimens were

analyzed by X-ray diffraction analysis (XRD), optical microscopy (OM), and

field emission scanning electron microscopy (FE-SEM), respectively. The

luminescence properties of the specimens were analyzed by photoluminescence

(PL) measurements. When the BTS glass with 15 wt% ZrO2 (15Z)was heat

treated at 1,015 oC, a dendritic structure by gathering very

small spherical crystalline phases of 10-30 nm was formed. In addition, when

the 15Z was excited by light of 309 nm wavelength, strong light of 469 nm

wavelength was emitted, and this light appeared to be blue light close to white

in the Commission International de l'Eclairage (CIE) diagram.

Keywords: Glass-ceramic, Fresnoite, Nano-crystal, Photoluminescence

Glass-ceramic is a composite material in which crystals

are dispersed in a vitreous matrix. When the glass specimen is subjected to

sufficient thermal energy required for nucleation and crystal growth,

glass-ceramic is formed. Glass-ceramic has completely new electrical, optical,

mechanical, and chemical properties due to the crystalline phase produced in

the matrix as compared to the parent glass. In order to produce a glass-ceramic

having high functionality, the target crystal phase should be precipitated in a

vitreous state. For this purpose, the temperature and time of heat treatment in

the nucleation and crystal growth process must be strictly controlled.

Generally, it is known that nuclei generated in a glass-ceramic

do not grow epitaxially during crystal growth[1].

There are some glass compositions capable of forming nuclei

by themselves. However, in general, when a glass-ceramic is

manufactured, a nucleating agent is added to the glass-ceramic or droplets

induced by a liquid/liquid phase separation phenomenon in the glass serve as

nuclei. When the nuclei thus produced are subjected to heat

treatment at a high temperature, crystallization occurs to

precipitate target crystals [2]. Typical nucleating agents used in the

crystallization process include ZrO2, TiO2, P2O5,

CaF2, Cr2O3, Fe2O3, etc

[3]. TiO2 and ZrO2 nucleating agents are predominantly

used in silicate-based glasses. However, it is known that the addition of TiO2

decreases the crystallization temperature of the parent glass and the addition

of ZrO2 increases the crystallization temperature. Reben et al. also

published an interesting result that the addition of TiO2 to CRT

(Cathode Ray Tube) glass powder induces surface crystallization behavior, not

bulk crystallization [4]. Wondraczekw

et al. established optimal crystallization conditions by selecting TiO2

and ZrO2 to produce β-quartz crystal phases of 100 nm or less in LAS

(Li2O-Al2O3-SiO2) glass [5]. In

addition, by adding ZrO2 to the glass composition, Duke et al.

produced β-quartz crystals uniformly, thereby obtaining high transparency and

low expansion rate. Therefore, ZrO2 and TiO2 has been

widely conducted as nucleating agent [6].

On the other hand, it is known that fresnoite (Ba2TiSi2O8)

crystals exhibit piezoelectricity, ferroelectricity, and nonlinear optical

characteristics. When fresnoite is irradiated with ultraviolet light, blue

light is emitted due to Ti4+ ions present in the square-pyramidal

TiO5 structure. Recently, fresnoite-based glass-ceramics have been

attracting interest. Fresnoite-based glass-ceramics can be

applied to optical devices such as optical switches and optical

waveguides [7-11]. Lee et al. studied the fluorescence properties of BaO-TiO2-SiO2

(BTS) as a function of the ratio of K2O/BaO. Lee contended that the

degree of crystallinity and the PL intensity of glass-ceramics without K2O

are high, but that the degree of crystallinity and the photoluminescence (PL)

intensity decrease with an increasing K2O/BaO ratio [12].

Although various studies have been carried out on fresnoite-based

glass-ceramics exhibiting PL characteristics, it

is difficult to find any studies to induce bulk crystallization by adding the

ZrO2 nucleating agent. Therefore, in this study, ZrO2 was

added to BTS glass to induce bulk crystallization behavior, and also controlled to produce only nanaometer-sized fresnoite

crystal phase. Finally, the microstructure and the crystal phase of the

prepared glass-ceramic were analyzed and the results

were discussed in relation to the luminescence properties.

The starting materials were BaCO3 (Kojundo

Chemical Co., 99%), TiO2 (Kojundo Chemical Co., 99.9%),

SiO2 (Kojundo Chemical Co., 99.9%), and ZrO2 (Junsei

Chemical Co., 99%). The composition of the mother glass was fixed to BaO : TiO2

: SiO2 = 26: 13: 61 (mol%), which is

higher in the amount of SiO2 than the composition of the fresnoite

(Ba2TiSi2O8) phase, to

generate fresnoite crystals on the glassy matrix

in which SiO2 is the main component. To prepare

the glass-ceramic, ZrO2 was added to the mother glass in the range

of 0 to 15 wt%. The batch powder was pulverized and mixed with zirconia balls

as milling media for 24 h and then melted in an alumina crucible at 1,450 oC

for 1 h in an electric furnace. The melt obtained was quenched by pouring into

a graphite mold. The obtained glass was pulverized to a size of 45 μm or less

and then subjected to differential thermal analysis (DTA, STA S1500, Scinco

Co., Korea) at a heating rate of 5 oC/min to analyze the

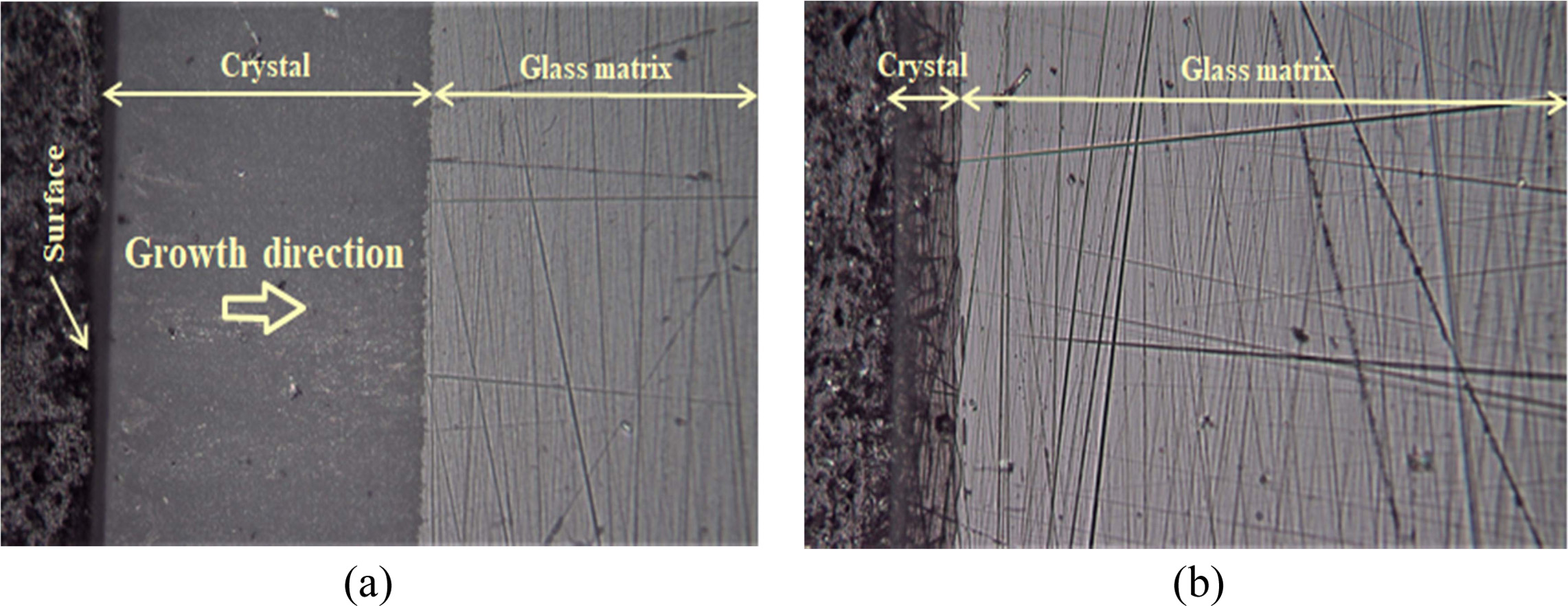

crystallization mechanism. Table 1 shows the heat treatment process conditions

for glass-ceramics manufacturing based on the data obtained from the DTA

results. The crystalline phase of the glass-ceramic was confirmed by X-ray

diffraction analysis (XRD, Pan'alytical, X'pertpro, Netherlands), and the

crystallization behavior was con- firmed by optical microscopy

(OM, ME-33, Daemyoung Optical Co., Korea). The nanoscale

microstructure was confirmed with a field emission scanning electron microscope

(FE-SEM, S-4800, HITACHI Co., Korea). Before the observation, the fractured

surface of the glass-ceramic was polished by SIC sandpaper and

etched with 1 wt% hydrofluoric acid (HF) for 30 seconds. Luminescence

properties of glass-ceramics were observed by

photoluminescence and photoluminescence excitation

spectroscopies (PL and PLE, Darsa-5000, PSI Co., Korea) at room temperature. A

500 W xenon lamp was used as the excitation source and the emitted light was analyzed

using the Commission International de l'Eclairage (CIE)

diagram.

|

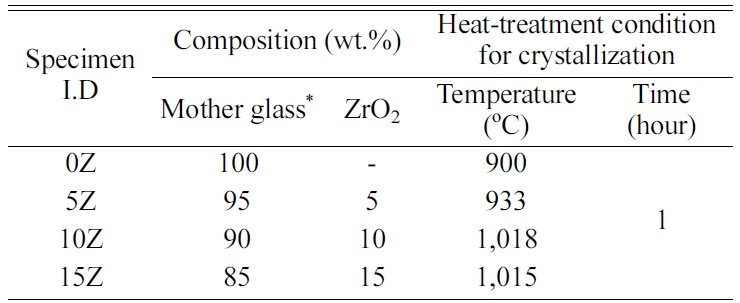

Table 1 One-step heat-treatment condition for fresnoite-based glass-ceramics. |

*Composition of mother glass is BaO: TiO2 : SiO2 = 26 : 13 : 61 (mol%) |

DTA analysis was performed on glass prepared by

substituting 0, 5, 10, and 15 wt% of nucleating agent ZrO2 in BTS

glass powder. The results are shown in Fig. 1. The maximum crystal growth

temperature (TP) is found to be 940 oC for the

mother glass (0Z), 973 oC for the 5Z specimen, 1,058 oC

for the 10Z specimen, and 1,045 oC for the 15Z specimen. That

is, when the ZrO2 substitution amount is in the range of 0-15 wt%, the TP value increases with the ZrO2

substitution amount, showing the highest value at 10% ZrO2, and decreases

when the ZrO2 substitution amount is over 10%.

Reben reported that the addition of ZrO2 as a nucleating agent to

fresnoite glass-ceramic tends to increase the crystal growth temperature [4]. However, when ZrO2

was replaced at more than 15wt% in this study, TP decreased. An

accurate interpretation of this tendency is expected to require additional

research.

We often have found that when glass-ceramics are

manufactured, the crystals grow beyond micrometer size due to too long heat

treatment or excessively high temperature than maximum crystal growth

temperature (Tp) obtained from DTA.

Therefore, glass was heated at a temperature of 40 oC

lower than Tp to produce a nano-sized fresnoite crystal phase. As shown

in Fig. 1, heat-treatment temperatures of the 0Z, 5Z, 10Z and 15Z specimens

were 900 oC, 933 oC, 1,018 oC

and 1,015 oC, respectively.

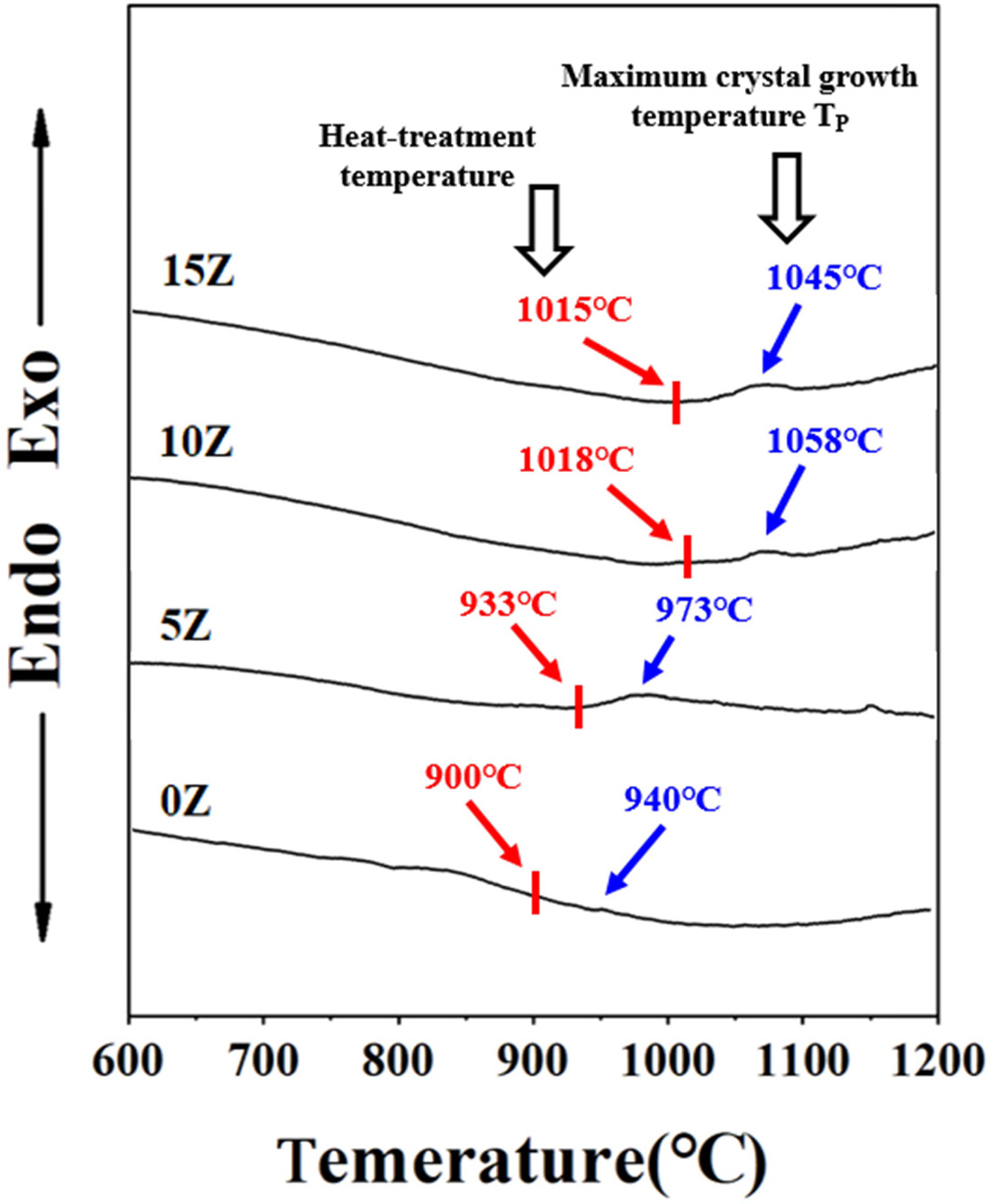

A graph of the XRD analysis results of the glass-ceramic

prepared according to the ZrO2 substitution amount is shown in Fig.

2. All glass-ceramics showed no or weak crystal

peaks, whereas the strong peaks for fresnoite crystals were formed in the specimen containing 10% ZrO2. The SiO2

might involve in the formation of both the

SiO2-based crystal phase and the amorphous matrix due to the

excessive amount of SiO2 added

compared to the stoichiometric fresnoite (Ba2TiSi2O8)

composition. Liu argued that when excess ZrO2

was added to the glass-ceramic, it would no longer function as a nucleating

agent but as a network former to strengthen the glass network,

and thus inhibits crystal growth [13]. Thus, the decrease in crystal peak intensity

of the 15Z specimen in the XRD graph is

believed to be due to the excess ZrO2 amount, acting as a

glass former rather than as a nucleating agent, as claimed by Liu.

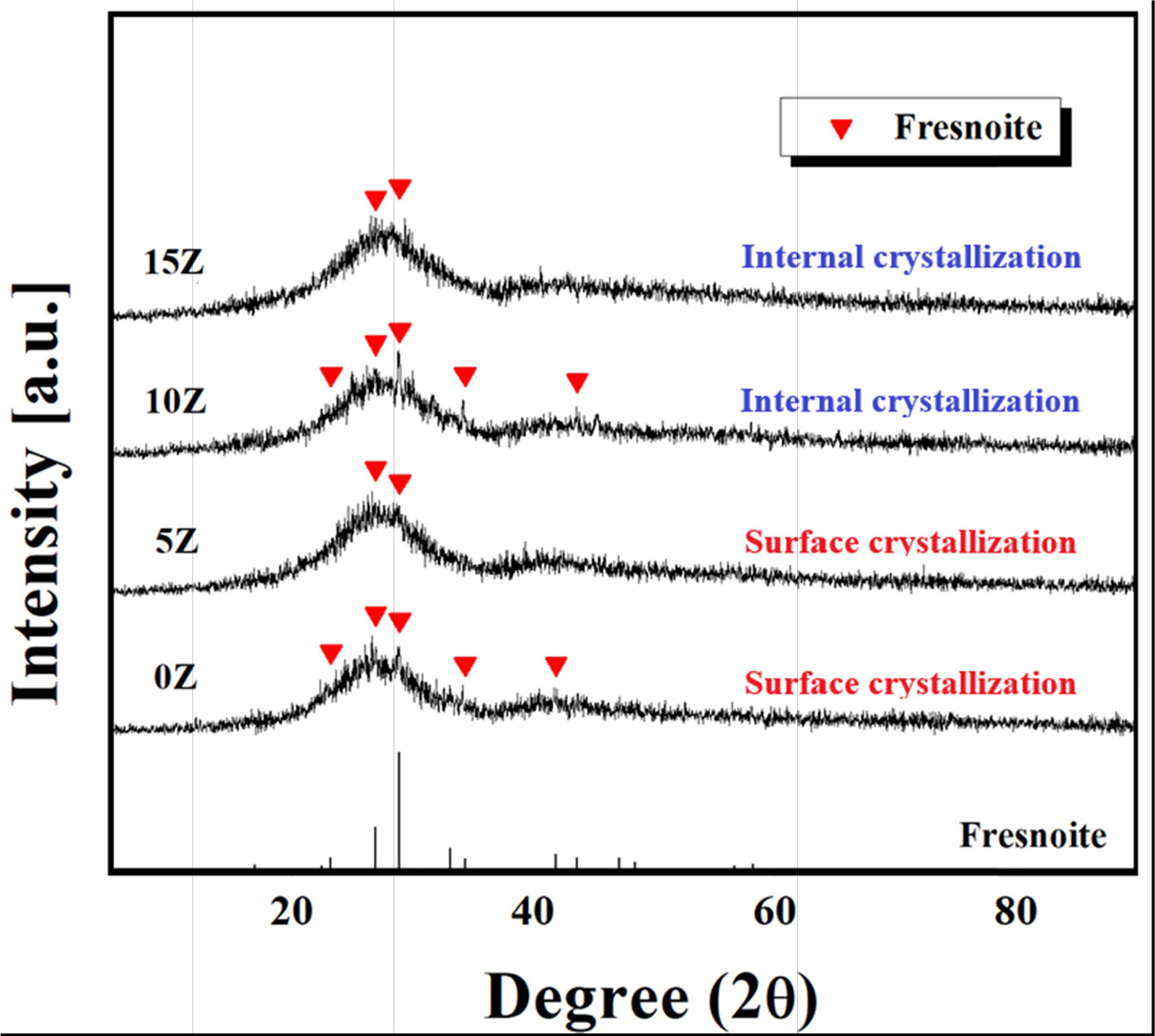

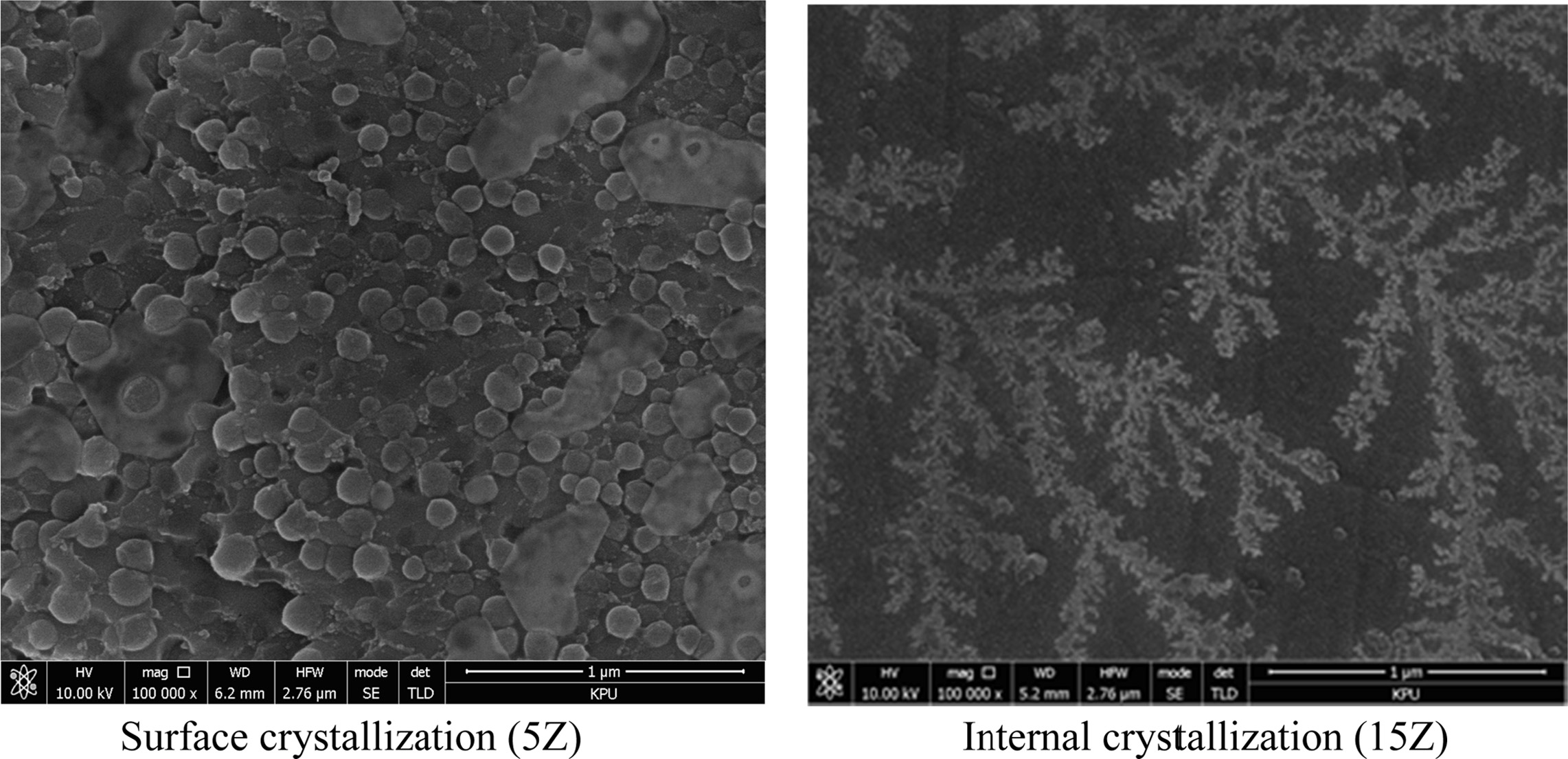

Also, as can be seen from the vertical section image shown in Fig. 3, surface crystallization phenomenon occurred in 0Z and 5Z specimens. Both specimens produced thick crystals on the surface, the thicknesses of surface crystal

of 217 μm and 46 μm, respectively. Due to the low hardness of the glass matrix, the crystal layer was

polished cleanly, whereas the glass matrix had many polishing marks. On the

other hand, in 10Z and 15Z specimens, no crystal layer

was observed on the surface, indicating that internal

crystallization occurred.

The microstructure of glass-ceramics prepared according

to the amount of ZrO2 substitution was observed by FE-SEM and the

results are shown in Fig. 4. The microstructure of the surface crystal part of

the 5Z specimen, magnified 50,000 times by SEM, was filled with spherical

crystals of 80-120 nm in size. On the other hand, the 15Z specimen

showed a dendrite-shaped crystal phase

composed of very small spherical particles of 10~30 nm

in size.

Wisniewski et al.

reported that several mechanisms are involved in the growth of

fresnoite crystals. Relatively slow growing crystals

form spherical or polygonal crystals, and

relatively fast growing crystals form dendrites [14-16]. In this study, the amount of ZrO2 added

determines the internal or surface crystallization, indicating that the crystallization rate varies

depending on the amount of ZrO2 added, and eventually the crystal

phase changes.

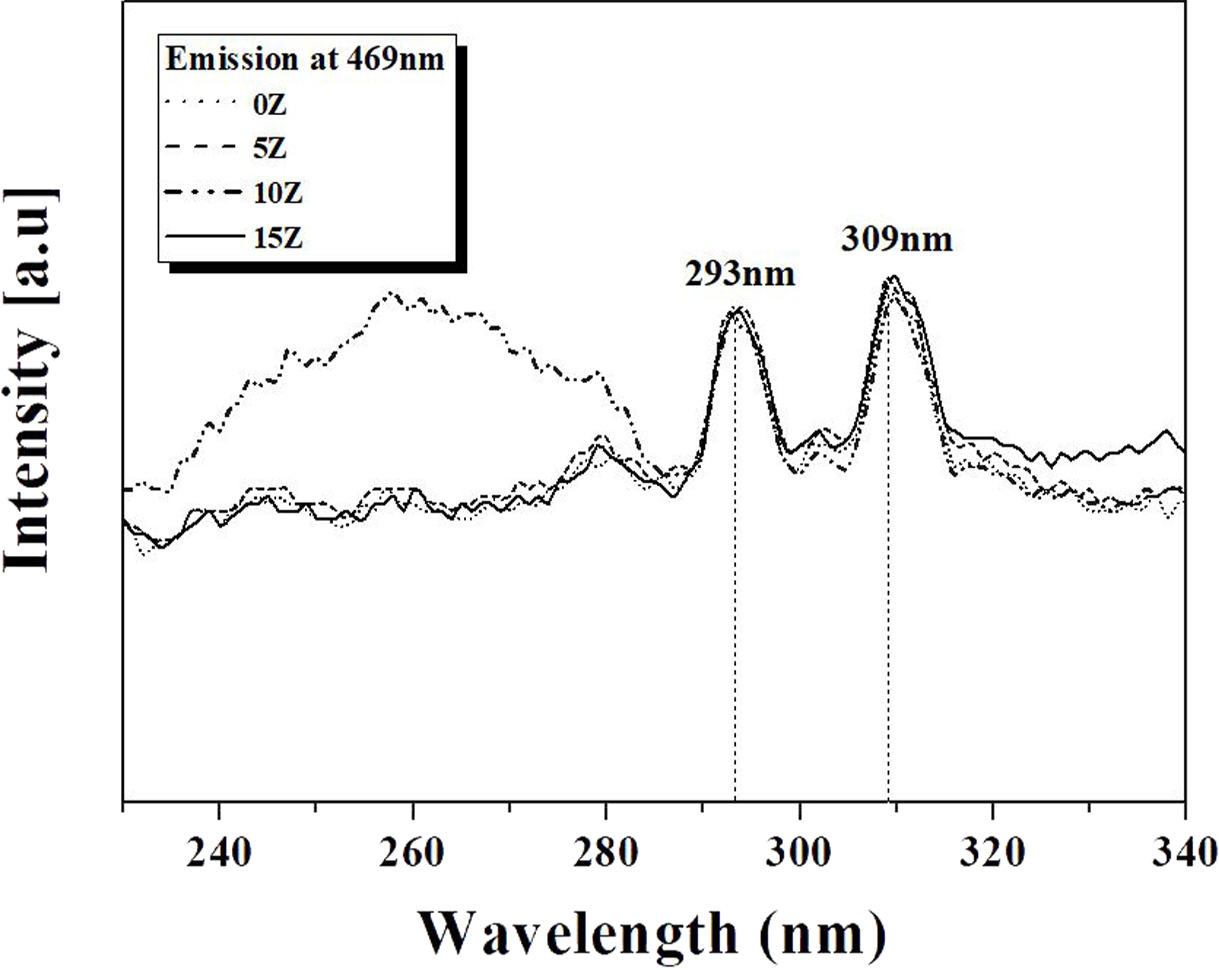

Photoluminescence excitation (PLE) and photo- luminescence

(PL)

analyses were performed to analyze the light emission characteristics of the

glass-ceramics prepared

according to the amount of ZrO2 added,

and the results are shown in Figs. 5 and 6, respectively. When

the light of 309 nm wavelength is irradiated to the glass ceramic specimen, the

light of 469 nm wavelength is emitted most as shown in Fig. 5. Therefore, when

analyzing the luminescence characteristics of the specimen prepared in this

study, 309 nm light was used as excitation light.

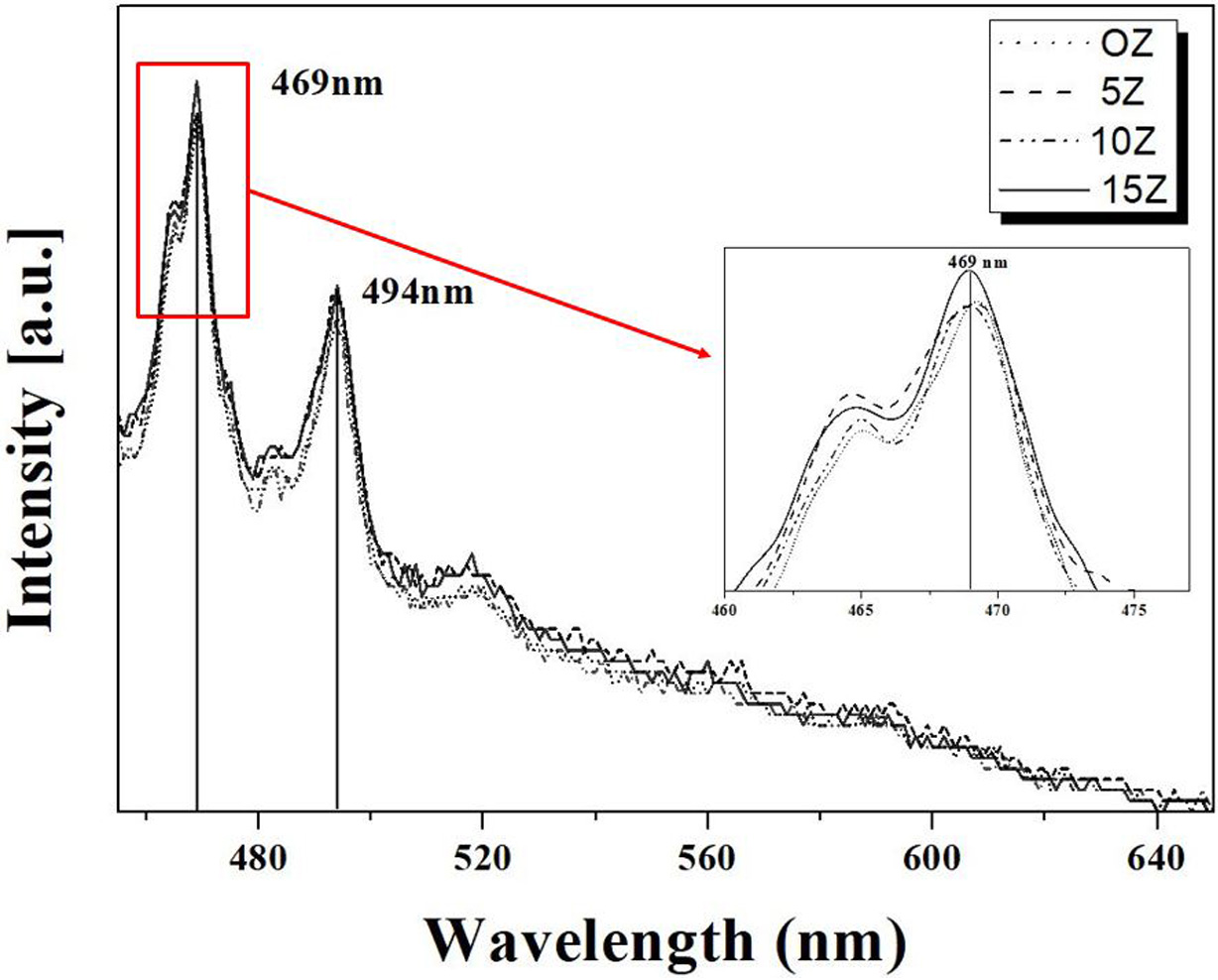

The PL spectra emitted from the glass-ceramics were shown

in Fig. 6 as a function of amount of ZrO2 added. The PL

characteristics of the fresnoite crystal phase are due to the crystal

structure, and when UV light is excited, blue-white light is emitted in the

400-600 nm wavelength range due to the structure of the pyrosilicate

groups (Si2O7) and the square pyramidal groups (TiO2)

[17]. The PL intensities at 469 nm of the 0Z, 5Z and 10Z samples were similar,

but the intensity of the 15Z specimens was the highest among the specimens

prepared in this study. It can be seen that as the amount of

the nucleating agent added increased, the PL intensity increased

overall, and the 15Z specimen showed the best PL properties. As a result, it

can be seen that ZrO2, which acts as a nucleating agent, has a

direct effect on the crystallization of Fresnoite crystals exhibiting PL properties

and has been a factor in improving PL properties.

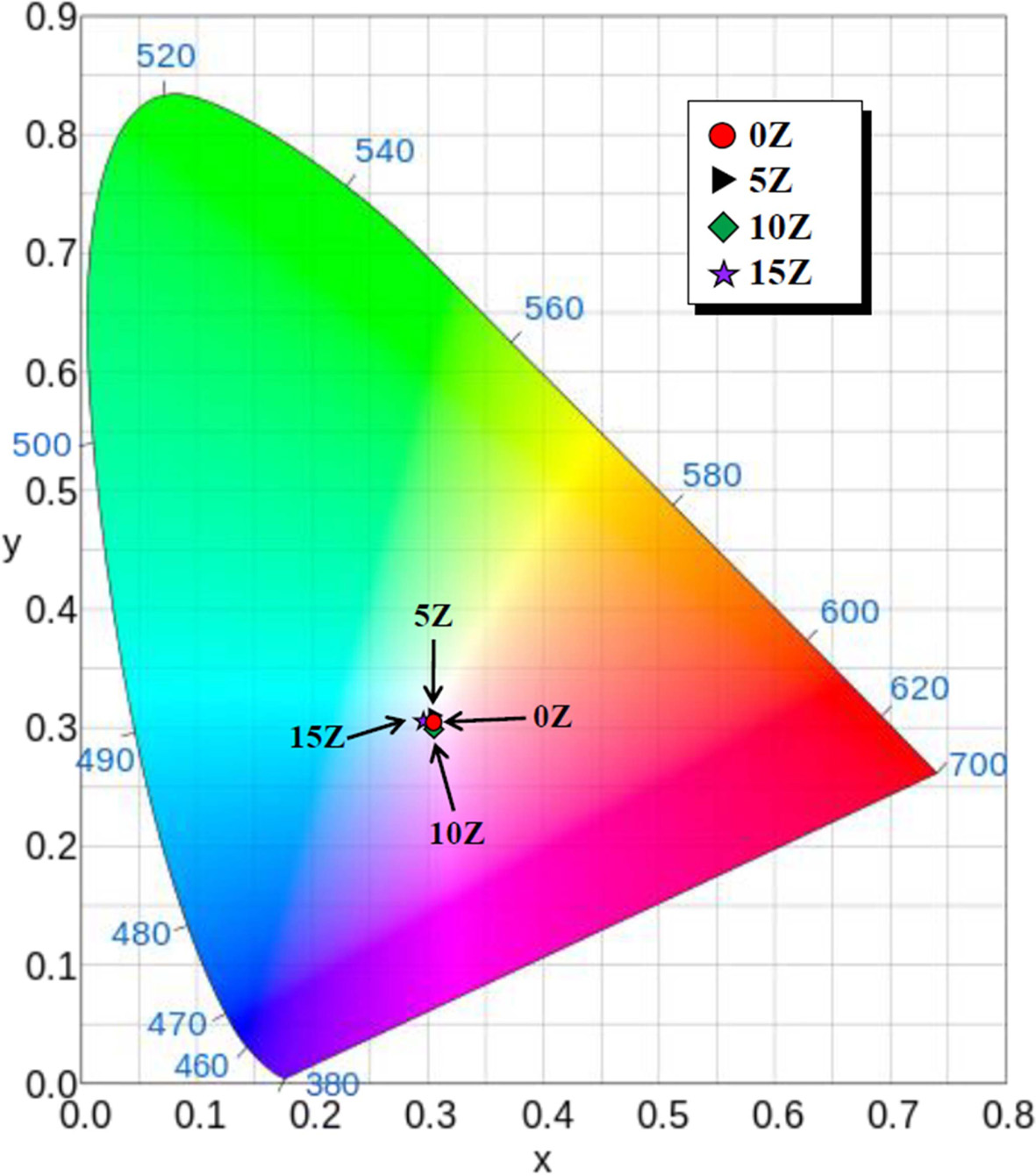

The color of PL spectra of the prepared specimen is

indicated in the CIE color coordinates, as shown in Fig. 7. The PLs of all the

specimens had similar color coordinates, appearing in blue light close to

white.

|

Fig. 1 DTA graph of glass according to amount of ZrO2 added. |

|

Fig. 2 XRD graph of glass-ceramics according to amount of ZrO2 added. |

|

Fig. 3 The cross-section of glass-ceramics observed magnified 200 times with an optical microscope; (a) 0Z and (b) 5Z. |

|

Fig. 4 Microstructure of glass-ceramics according to amount of ZrO2 added observed by SEM. |

|

Fig. 5 PLE spectra of fresnoite-based glass-ceramics. |

|

Fig. 6 PL spectra of fresnoite-based glass-ceramics according to amount of ZrO2 added. The excitation light used has wavelength of 309 nm. |

|

Fig. 7 CIE diagram of light emitted from glass-ceramics with varying amounts of ZrO2 added. |

In this paper, glass-ceramics of BaO : TiO2 : SiO2

= 26 : 13 : 61 (mol%) composition containing 0-15 wt% of ZrO2 as nucleating agent were prepared and its phase identification, microstructure observation and PL analysis were performed. All glass-ceramics showed no or weak crystal peaks, whereas the

strong peaks for fresnoite crystals were formed in the specimen containing 10% ZrO2. The surface

crystallization phenomenon occurred in

0Z and 5Z specimens, meanwhile, in 10Z and 15Z specimens, an internal crystallization occurred. The microstructure of the surface crystal part of the 5Z

specimen was filled with spherical crystals of 80~120 nm in size.

On the other hand, the 15Z specimen showed a

dendrite-shaped crystal phase composed of very small spherical

particles of 10~30 nm in size, indicating that the

amount of ZrO2 added determines the internal or surface

crystallization and the

crystallization rate.

When

the specimens were excited with 309 nm light, all the glass-ceramic specimens emitted 469 nm wavelength light. The

light emission intensity was highest in the 15Z specimen, and the emitted light

showed blue color light close to

white in the Commission International de l'Eclairage (CIE) diagram.

It was possible to produce nano-sized fresnoite-based

glass-ceramics by substituting the nucleating agent ZrO2 into

BaO-TiO2-SiO2 glass having an excellent PL property.

This work was supported by Kyonggi University Research

Grant 2018.

- 1. L. Vladislavova, M. Kracker, T. Zscheckel, C. Thiemeand, and C. Rüssel, Solid State Sci. 78 (2018) 107-115.

-

- 2. G.H. Beall and L.R. Pinckney, J. Am. Ceram. Soc. 82[1] (1999) 5-16.

-

- 3. C.C. Chou, K.C. Feng, I.P. Raevski, H. Chen, C.Y. Tsao, P.Y. Chen, C.S. Chen, C.A. Lu, and C.S. Tu, Mater. Res. Bull. 96 (2017) 66-70.

-

- 4. M. Reben, M. Kosmal, M. Ziąbka, P. Pichniarczyk, and I. Grelowska, J. Non. Cryst. Solids. 425 (2015) 118-123.

-

- 5. L. Wondraczek and P. Pradeau, J. Am. Ceram. Soc. 91 (2008) 1945-1951.

-

- 6. D. A. Duke and G. A. Chase, Applied Optics. 7[5] (1968) 813-818.

-

- 7. A.D. Pablos-Martín, A. Herrmann, C. Patzig, B. Oberleiter, T. Rainer, and Th. Höche, J. Non. Cryst. Solids. 488 (2018) 44-51.

-

- 8. Y. Takahashi, K. Kitamura, Y. Benino, T. Fujiwara, and T. Komatsu, Appl. Phys. Lett. 86 (2005) 1-3.

-

- 9. A. Muller, M. Lorenz, K. Brachwitz, J. Lenzner, K. Mittwoch, W. Skorupa, M. Grundmanna, and T. Hoche, Cryst. Eng. Comm. 13 (2011) 6377-6385.

-

- 10. K. Shinozaki, T. Honma, and T. Komatsu, Mater. Res. Bull. 46[6] (2011) 922-928.

-

- 11. L.L. Martín, P. Haro-González, I.R. Martín, D. Puerto, J. Solís, J.M. Cáceres, and N.E. Capuj, Opt. Mater. 33[2] (2010) 186-190.

-

- 12. H.K. Lee, E.S. Yoo, S.J. Chae, and W.H. Kang, J. Korean Ceram. Soc. 43[9] (2006) 569-574.

-

- 13. S. Liu, J. Wang, J. Ding, H. Hao, L. Zhao, and S. Xia., Ceram. Int. 45[3] (2019) 4003-4008.

-

- 14. W. Wisniewski, K. Thieme, and C. Rüssel, Prog. Mater. Sci. 98 (2018) 68-107.

-

- 15. E. Boulay, C. Ragoen, H. Idrissi, D. Schryvers, and S. Godet, J. Non. Cryst. Solids. 384 (2014) 61-72.

-

- 16. W. Wisniewski, M. Patschger, and C. Rüssel, Sci. Rep. 3[3558] (2013) 1-6.

-

- 17. G. Blasse, J. Inorg. Nucl. Chem. 41[5] (1979) 639-641.

-

This Article

This Article

-

2020; 21(S1): 58-62

Published on May 31, 2020

- 10.36410/jcpr.2020.21.S1.s58

- Received on Dec 26, 2019

- Revised on Apr 13, 2020

- Accepted on May 4, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusions

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Seunggu Kang

-

Department of Advanced Materials Science and Engineering, Kyonggi University, Suwon 16227, Korea

Tel : +82-10-5265-2681 - E-mail: sgkang@kgu.ac.kr

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.