- Systematic experimental study for optimized hydrogen production of Ni/CeO2 prepared by incipient wetness impregnation technique

Shian Lia, Qiuwan Shena,* and Bengt Sundenb

aMarine Engineering College, Dalian Maritime University, Dalian, China

bDepartment of Energy Sciences, Lund University, Lund, Sweden

In this present work,

different supports (CeO2/ZrO2) and different Ni contents

based catalysts were prepared by incipient wetness impregnation method and

tested in the methane steam reforming (MSR) reaction. The prepared catalysts

were characterized by X-ray diffraction (XRD) and scanning electron microscope

(SEM). The XRD analysis confirmed the prepared Ni/CeO2 samples have

a pure crystal structure. In the catalytic tests, the effects of reactivity

temperature, different support, Ni loading content and the gas hourly space

velocity (GHSV) on hydrogen production performance were investigated

systematically. The results showed that the optimal reaction conditions for MSR

by Ni/CeO2 catalyst were as follows: 10 wt % Ni/CeO2,

750 oC, 1500 h-1. The stability test for 12 h

at 750 oC indicated that the chosen Ni/CeO2 catalyst

had excellent thermal stability.

Keywords: Hydrogen, Steam reforming, Ni, CeO2, Support

Nowadays, hydrogen is becoming an environmental friendly

energy source producing clean energy in an efficient way. Compared with new

energy sources such as solar energy and wind energy, hydrogen is a

secondary energy source that can be produced in a wide variety of

ways, such as photolysis of water, electrolysis of water, and hydrocarbon

reforming. The most mature hydrogen production technology is hydrocarbon

reforming. Com- pared

with hydrolyzed hydrogen production, hydrocarbon reforming

has the characteristics of low cost and high hydrogen production rate.

Methane is widely found in natural gas and biogas in

nature. Methane reforming is a widely used method in industries to convert

natural gas to H2 or syngas (H2+CO) [1-5]. According to

different reforming raw materials, it can be divided into partial oxidation of

methane [6], carbon dioxide reforming of methane [7, 8] and steam

reforming of methane [9, 10]. The methane steam

reforming reaction (MSR) is an endothermic reaction and is a fairly mature

industrial hydrogen production technology.

The reaction is represented by Eq. (1).

CH4 + H2O →

CO + 3H2 ΔH = +206.29

KJ/mol (1)

CO + H2O → CO2 + H2 ΔH = -41.19 KJ/mol (2)

This main reaction occurs at a high temperature, followed

by a water gas shift reaction (WGS) which produces CO2 (eq. (2)).

The methane steam reforming reaction is a complicated

process, which may involve multiple reactions. The reaction flows from the

surface of the catalyst by water vapor and methane under a high

temperature atmosphere. After the catalyst is catalyzed, H2

and CO are formed. CO2 will be generated when water is excessive.

The reaction is carried out under a certain pressure and high temperature.

In such a harsh environment, carbon deposition may occur.

Commonly used noble metal catalysts are Pt, Pd, and Rh.

The precious metal catalyst has a certain anti-carbon deposition performance,

and has better catalytic performance and stability than the general catalyst.

However, it is not widely used due to the expensive price.

It has been reported that noble metal catalysts such as

Rh, Ru, Pd and Pt have high activity, stability and carbon deposition

resistance [11-13]. Among many traditional metal catalysts, Ni-based catalysts

stand out due to their lower cost,good catalytic and higher stability

performance at high temperatures [14-16].

The support is one of the essential components of the

catalyst. It plays a very important role in the catalyst. One of its basic

functions is to support the active component.

The support determines the catalytic property of the system. For some specific reactions, besides affecting metal

dispersion and providing stability for metal particles, the support can also participate

in the reactions [17, 18]. Commonly used supports are γ-Al2O3,

CeO2, ZrO2, SiO2 and others. The support is

required to have high mechanical strength, large specific surface area and

strong anti-sintering ability. Due to its unique properties, cerium has been

widely used in heterogeneous catalysis [19].

Several studies have applied these materials for MSR and

concluded that the intermediate metal loadings produce the

best catalytic performance [20-22]. A series of nickel

catalysts with different metallic contents supported on CeO2 and ZrO2

were studied by Dong et al. [20]. They found that nickel loading of 15% wt is

optimal. Because it balances the two different catalytic activation points of

CH4 and H2O. In addition, Roh et al. studied the effect

of nickel content on a Ce-ZrO2/Al2O3 support

in MSR, and their results showed that with the nickel content of 12% wt.,

methane has the maximum conversion [21].

In the present study,

different supports (CeO2/ZrO2) and different Ni contents

are used to optimize their composition as catalyst for hydrogen production from

the MSR reaction. A series of synthesized catalysts were thoroughly

characterized by XRD and SEM. In addition, in order to evaluate the optimal

conditions of this process, the influence of the reactivity temperature,

different supports, Ni content and the gas hourly space velocity (GHSV) were

investigated to achieve a deeper understanding of Ni-based supported catalysts.

Samples

preparation

To prepare a catalyst using a wet incipient wetness

impregnation method, it is first necessary to measure the water absorption of

the support. Weigh a certain mass of the support in the beaker which is defined

as a, return the analytical balance to zero, add deionized water

to the fully immersed carrier with a plastic dropper, measure the

mass of deionized water to b, seal the beaker mouth at room temperature After

standing for 12 hours, the deionized water not absorbed by the carrier was

filtered off, and the mass was found to be m. Then the support water absorption

rate X is:

X = (b - m)/a*100% (1)

Preparation of different wt% Ni loadings catalysts

Ni(NO)3·6H2O having a corresponding

Ni loading amount was weighed into a beaker, and CeO2 was used as a

support. Deionized water was added to Ni(NO)3·6H2O according to the

measured water absorption rate of the support

to prepare a precursor solution. After the Ni(NO)3·6H2O

was completely dissolved, the precursor solution and the CeO2 were immersed, mixed vigorously with a stirrer for 20 min . Standing at room

temperature for 12 hours, then the composite was aged at 110 oC

for 12 h inside, taken out and ground, and finally calcined at 500 oC

for 5 h in a muffle furnace. The Ni loadings were 6.0 wt%, 8.0 wt%, 10.0

wt% and 12.0 wt% respectively.

Preparation of Ni-based catalysts with different supports

CeO2 and ZrO2 were used as carriers

to determine the water absorption rate, respectively. Two Ni(NO)3·6H2O

corresponding to 8.0 wt% Ni loading were weighed into different beakers

according to the water absorption rate of the support to Ni(NO)3·6H2O.

The deionized water is added to prepare the precursor solution, and the mass of

the two beakers is weighed. After the Ni(NO)3·6H2O is

completely dissolved, the precursor solution is impregnated with the two kinds

of carriers. A homogeneous mixture of the solution was obtained by stirring

with a magnetic stirrer for 20 min. Standing at room temperature for 12 h, then

the composite was aged at 110 oC for 12 h. And it was finally

calcined at 500 oC for 5 h by using a muffle furnace.

Evaluation

of catalytic activity

Test of the catalytic performance of the catalysts was

carried out in a fixed bed quartz reactor at atmospheric pressure in the

temperature range of 600 oC to 750 oC. The

catalyst (2g) was pretreated for 2 hours at 500 oC under

hydrogen stream. The reducing mixture gas was a composite of H2 and

Ar (H2: Ar=1:9, 300 mL/min) and brought in at a ramp rate of

10 oC/min from room temperature to 500 oC.

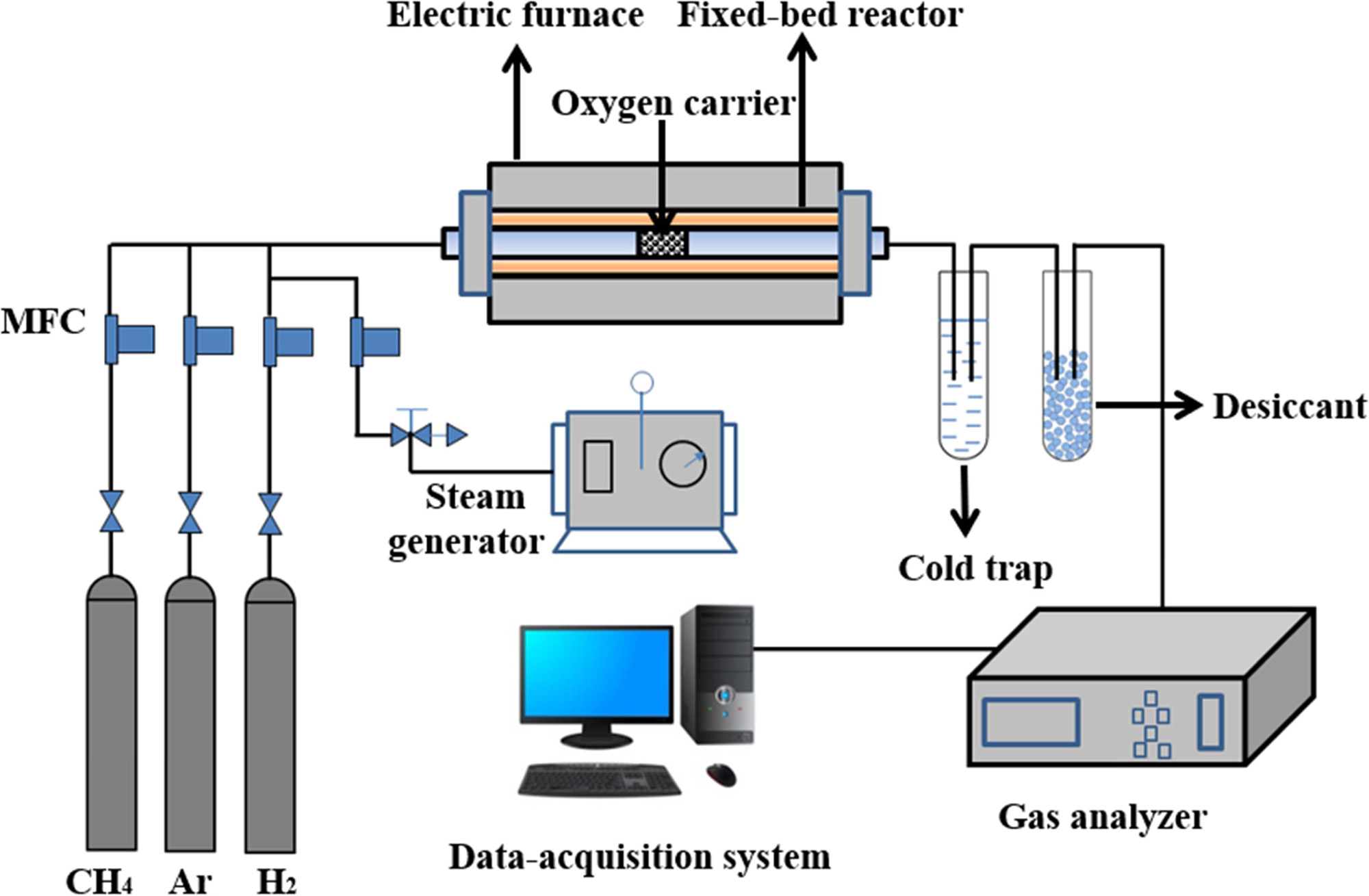

The schematic diagram of the fixed bed system is shown in

Fig. 1. The system consists of three parts: a feeding unit, a methane steam

reforming reactor and an analysis part. It is necessary to uniformly fill the

catalyst in the middle of the reactor before the reaction. First, a certain

amount of quartz sand is added to both ends of the flow channel. The particle size

of the quartz sand is close to that of the catalyst particles to avoid the

influence of internal diffusion, and then the catalyst sample is poured. The

quartz sand not only plays a supporting role, but also helps the gas in the

flow channel to be preheated. The outlet gases were detected online by a gas

analyzer (Gasboard 3100).

Samples

characterization

Powder X-ray diffraction data (XRD) were collected in the

Philips X’Pert PRO of PANalytical B.V. with Cu Kα radiation (λ= 0.1542 nm) and

a 2θ range of 10-90° to study the crystalline structure of the samples. The

morphologies of the synthesized catalysts were studied by scanning electron

microscopy (SEM, SUPRA 55 SAPPHIRE).

Samples

catalytic evaluation

Conversion of methane (XCH4) was calculated as

follows:

XCH4 ={[(nCH4)in-(nCH4)out]/(

nCH4)in}*100%

Hydrogen Selectivity (SH2) to the products was

determined as:

SH2(%) = (nH2)out/{(nH2)out + (nCO)out + (nCO2)out} * 100%

Hydrogen Yield (YH2) was determined as:

YH2 = SH2 * XCH4 * 100%

|

Fig. 1 Schematic diagram of the fixed bed system. |

Catalyst

characterizations

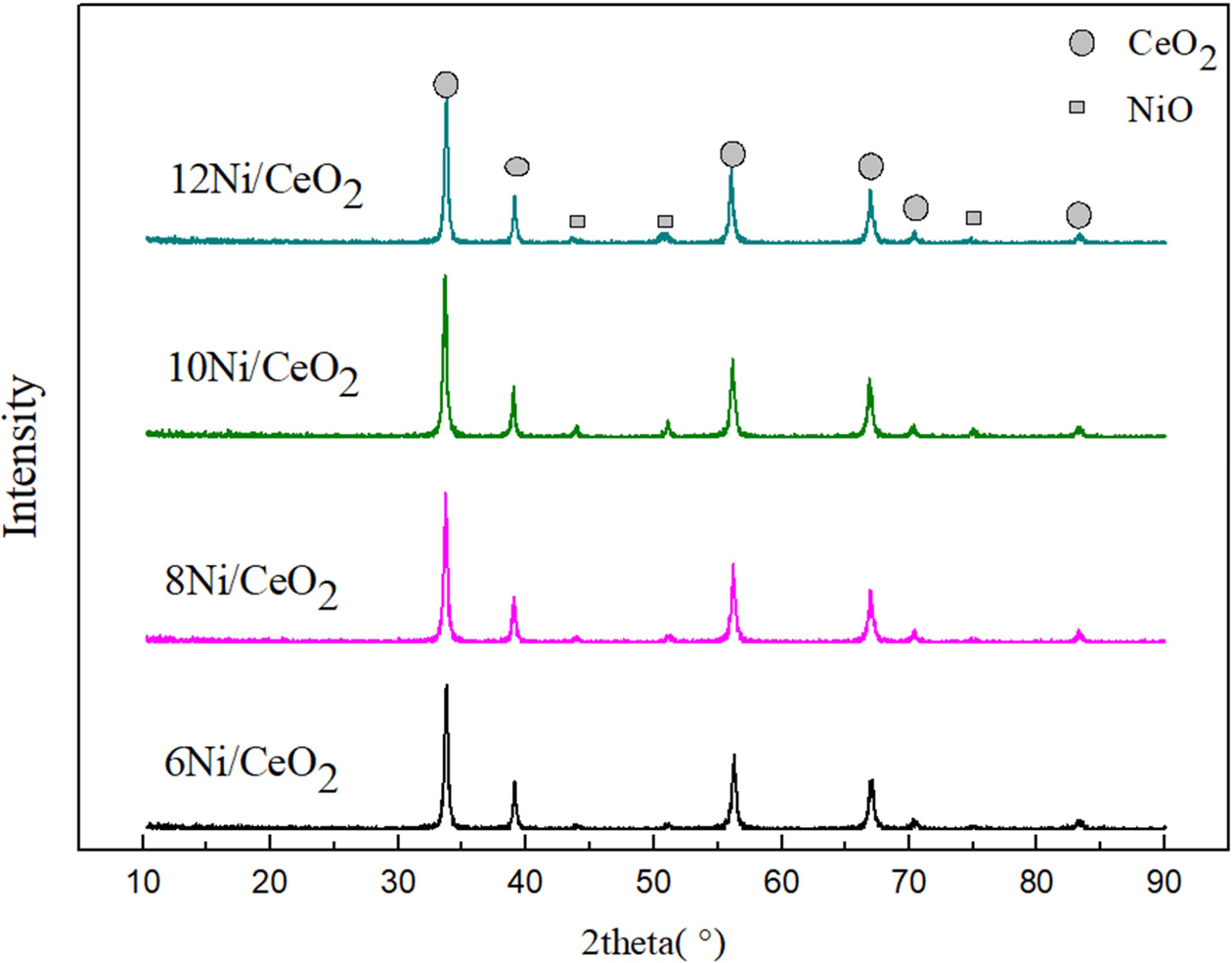

XRD diffraction result of the Ni/CeO2 with

different Ni loading of 6-12 wt% is displayed in Fig. 2. Compared

with standard cards in XRD database, the prepared Ni/CeO2

samples have a pure crystal structure. The diffraction peaks at 2θ = 37.4,

43.4 and 75.6° characterize the cubic NiO

phase (JCPDS file no.47-1049) [23, 24]. The

diffraction peaks corresponding to CeO2 at 2θ = 33.2, 56.6, 67.7,

and 83.7° are significantly increased.

Fig. 3 shows the morphology of the 10% Ni/CeO2

catalyst particles. It can be seen that the surface morphology of the carrier

CeO2 is porous, and NiO appears as a small particle with a size of

around 50 nm embedded in the CeO2 surface. The dispersion is

relatively high, and no agglomeration and sintering occur.

Catalytic

activity

Effect of different supports

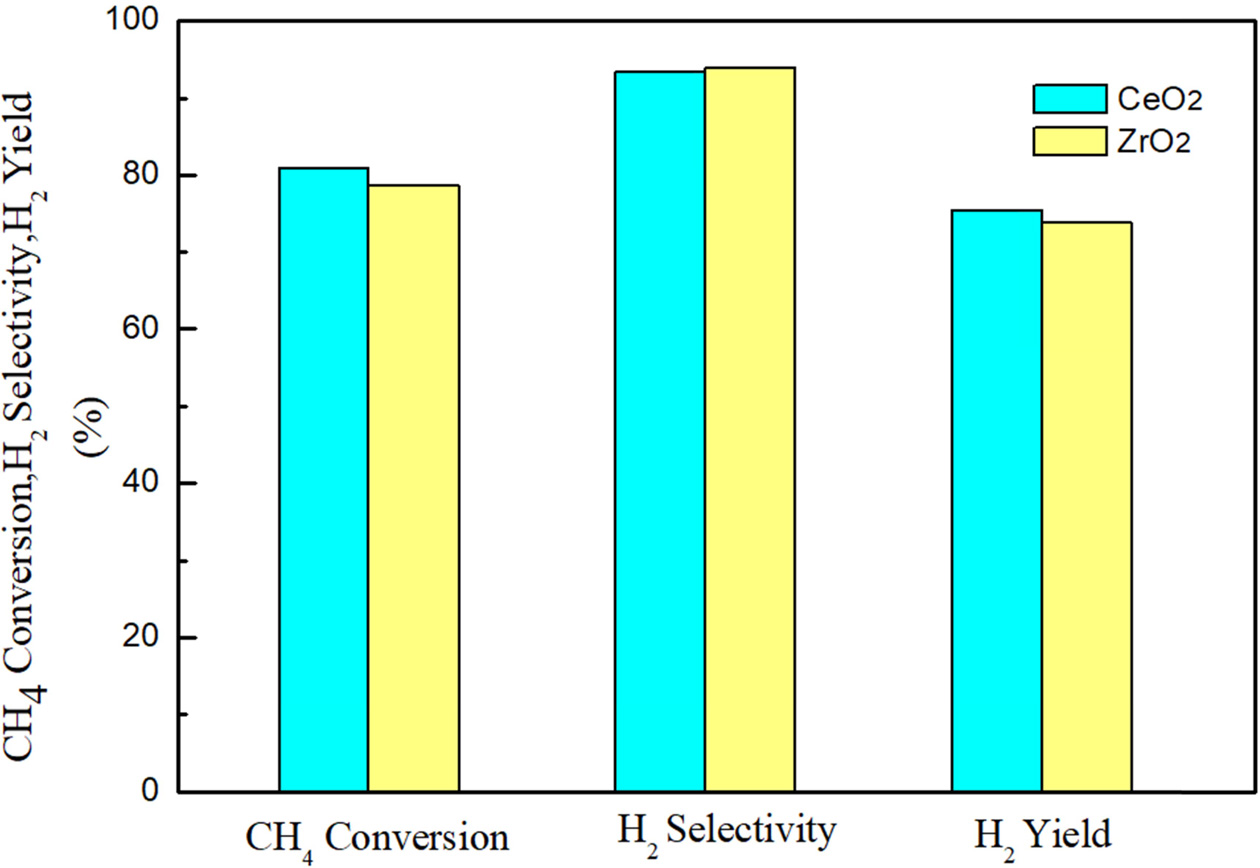

Effect of different supports on catalytic activity of

Ni-based catalysts was studied in the fixed-bed system. The experimental

reaction temperature was 750 oC, the water-carbon ratio n (H2O):

n (CH4) was 3, and the space velocity was 1,500 h-1.

According to Fig. 4, it can be seen that under this condition, the Ni/CeO2

has a methane conversion rate and a hydrogen yield of 80.9% and 75.6%,

respectively. In addition, for the Ni/ZrO2 catalysts, the CH4

conversion rate and the H2 generation rate of the catalyst were

78.6% and 73.8%, respectively. Therefore, the nickel-based catalyst with CeO2

as a support has better activity regardless of the methane conversion rate or

the hydrogen yield. In addition, the hydrogen generation rate is also

correlated with the hydrogen selectivity. The results show that the hydrogen

selectivity of the catalyst with CeO2 as the support is 93.4%, and

the hydrogen selectivity of the catalyst supported by ZrO2 is 93.9%.

The selectivity will be slightly larger than the former, but the overall

difference is small.

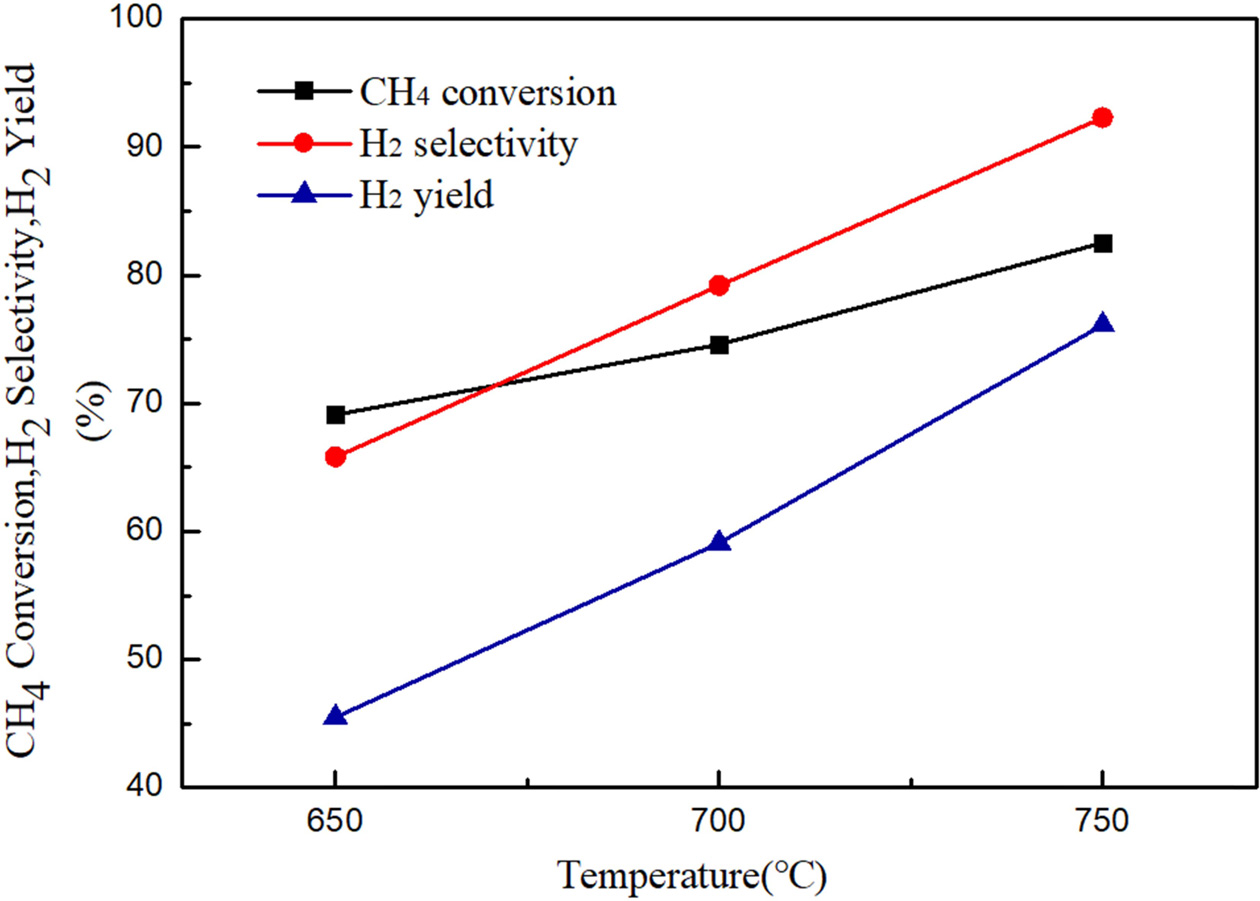

Effect of different reaction temperatures

The methane steam reforming reaction is an endothermic reaction

and should be carried out in a high temperature atmosphere.

A suitable temperature is favorable for the reaction to generate hydrogen and

carbon monoxide. When the temperature is too high, it will cause carbon

deposition in the methane cracking, and the active component Ni will also be

sintered, which will affect the catalytic performance and the high temperature

will also threaten the life of the experimental equipment. If the temperature

is too low, carbon monoxide will be decomposed to form carbon deposits, which

is the main cause of carbon deposition in the catalyst, which in turn affects

the catalytic performance. Therefore, the reaction

temperature is a very important reaction condition in the MSR

reaction.

Fig. 5 demonstrates the comparison of performance of 10%

Ni/CeO2 catalysts at reaction temperatures of 650 oC,

700 oC and 750 oC (n(H2O):n(CH4)

=3, a space velocity of 1,500 h-1).

According to Fig. 5, it is found that the CH4

conversion rate and the H2 generation

rate increase with the increase of temperature. The methane conversion rates

are 69.1%, 74.6% and 82.4% at the temperatures of 650 oC,

700 oC and 750 oC, respectively. The CH4

conversion rate increased by 5.5% when the temperature was raised from

650 oC to 700 oC, and the CH4

conversion rate increased by 7.8% when the temperature was raised from

700 oC to 750 oC. The rate of increase is more

obvious when the temperature is raised from 700 oC to 750 oC.

As for the hydrogen generation rate, the corresponding hydrogen generation

rates are 45.5%, 59.1%, and 76.1% at the temperatures of 650 oC,

700 oC and 750 oC, respectively. Therefore,

750 oC was selected as the optimal temperature for Ni/CeO2

catalysts. The reaction temperatures of the following experiments were set to

750 oC.

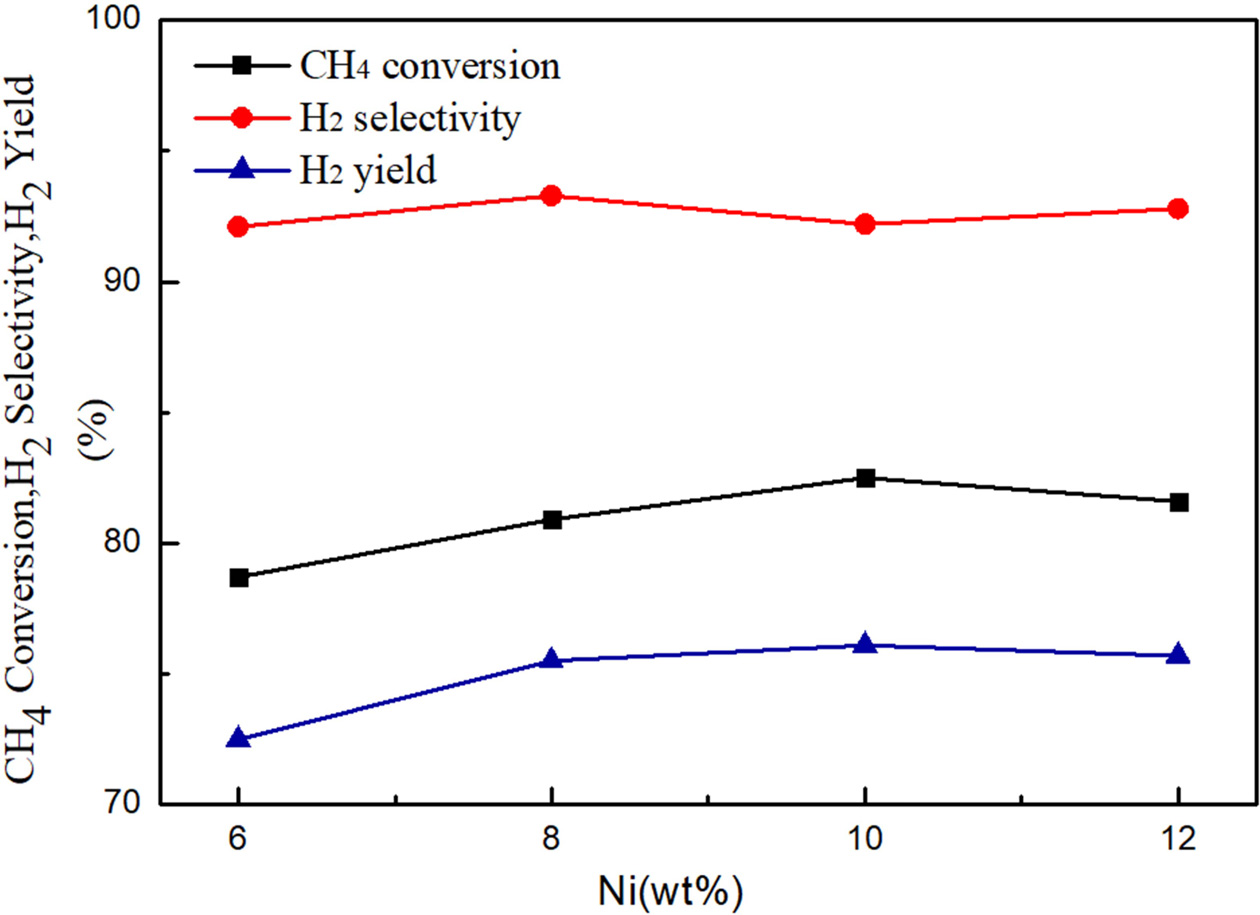

Effect of loading different amount of active components

Generally, the larger the active component loading at the

same mass of the catalysts, the larger the particle diameter of

the active component and the corresponding catalytic

performance will be better, but when the loading is

too large, the active component will aggregate. The active

component in this experiment is Ni, which is easy to bring to aggregation and

sintering. If the load is too large, it is easy to produce carbon deposits, resulting

in a decrease in catalyst performance. Therefore, a suitable

Ni loading amount on catalyst plays a crucial role in MSR.

This part mainly investigates the effect of loading of

different active components on performance of Ni/CeO2 with Ni

content of 6%, 8%, 10% and 12% respectively (at temperature of 750 oC;

n(H2O): n(CH4) =3; and GHSV = 1,500

h-1).

Fig. 5 shows the comparison of catalytic capability of 6% Ni/CeO2,

8% Ni/CeO2, 10% Ni/CeO2 and 12% Ni/CeO2 under

the same conditions.

As seen in Fig. 6, the CH4 conversion rate and

H2 yield are higher at the temperature of 750 oC.

The results indicate that the activity increases with the increase of Ni

loading from 6% to 10% and the reactivity decreases for the higher loading

content of 12% of Ni. The catalysts containing 10% Ni showed the

highest CH4 conversion rate and the H2 yield among

the samples. It can be seen that the CH4 conversion rate and the H2

generation rate have a significant increase in the Ni loading from 6% to 10%,

which is directly related to the increase of Ni loading, but when the Ni

loading is increased from 8% to 10%, the increase rate of hydrogen generation

rate in the range is less than 1%. It also can be seen that the hydrogen

selectivity decreases from 93.4% to 92.3% when the Ni loading is increased from

8% to 10%. When the Ni loading was continuously increased to 12%, it was found

that the CH4 conversion rate and the H2 yield were lower

than the Ni loading amount of 10%. The reason might be that the catalyst

agglomerates to produce agglomerates as the Ni loading becomes

larger. The carbon deposition reaction occurs to deteriorate the

catalytic performance.

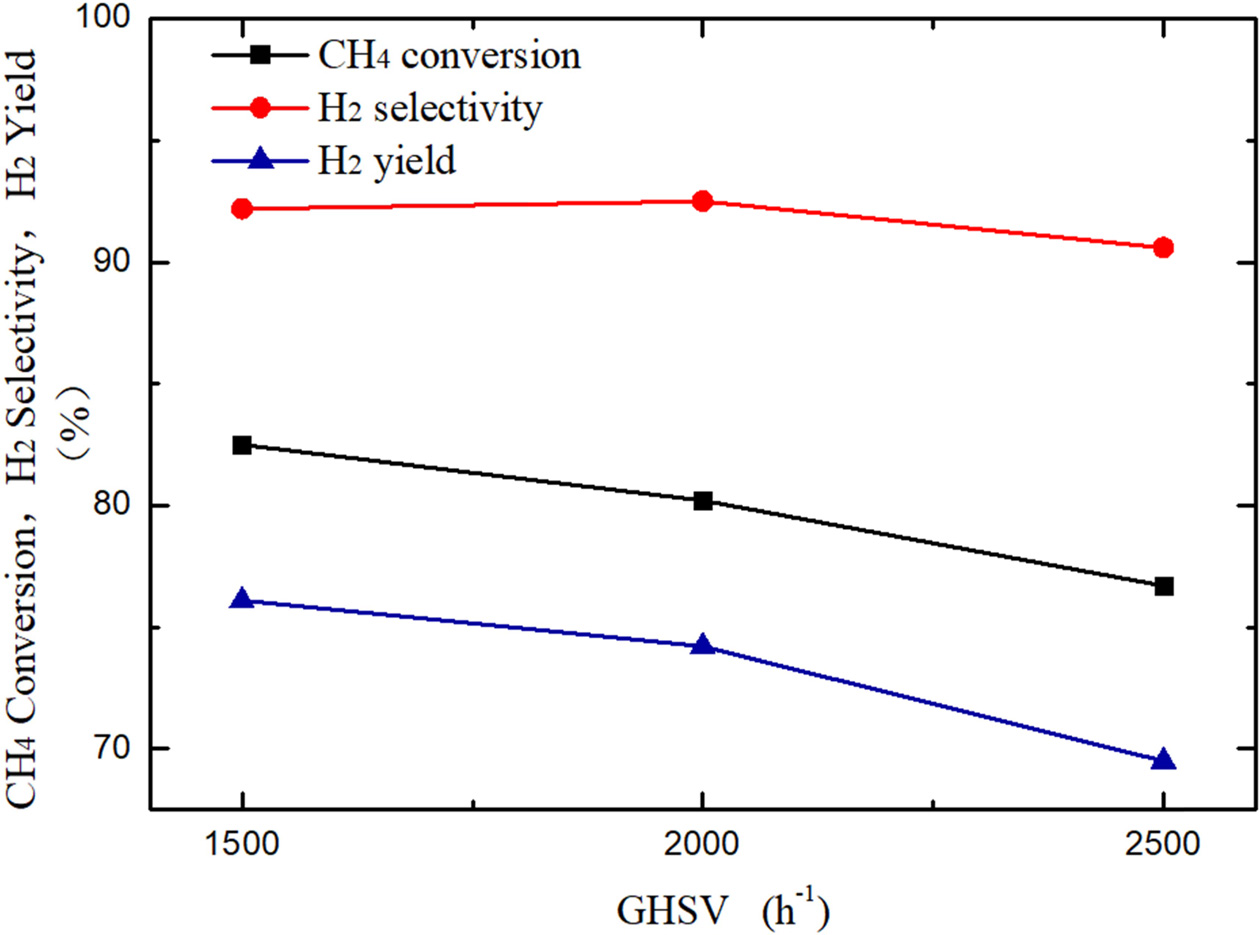

Effect of GHSV

Fig.

7 shows the catalytic performance comparison of methane steam reforming reactions with different GHSV of 1,500 h-1,

2,000 h-1

and 2,500 h-1,

respectively. Results show that the CH4

conversion of methane steam reforming reactions at GHSV of 1,500

h-1,

2,000 h-1 and

2,500 h-1 were

82.5%, 80.2%, and 76.7%, respectively. In addition, the hydrogen

yield decreased by 1.9% with the GHSV changed from 1,500 h-1

to 2,000 h-1 ,

while the hydrogen yield decreased by 4.7% from 2,000 h-1

to 2,500 h-1,

which is the same as that of the methane conversion. Overall, GHSV of 1,500 h-1

corresponds to the best performance of the catalyst among the

conditions.

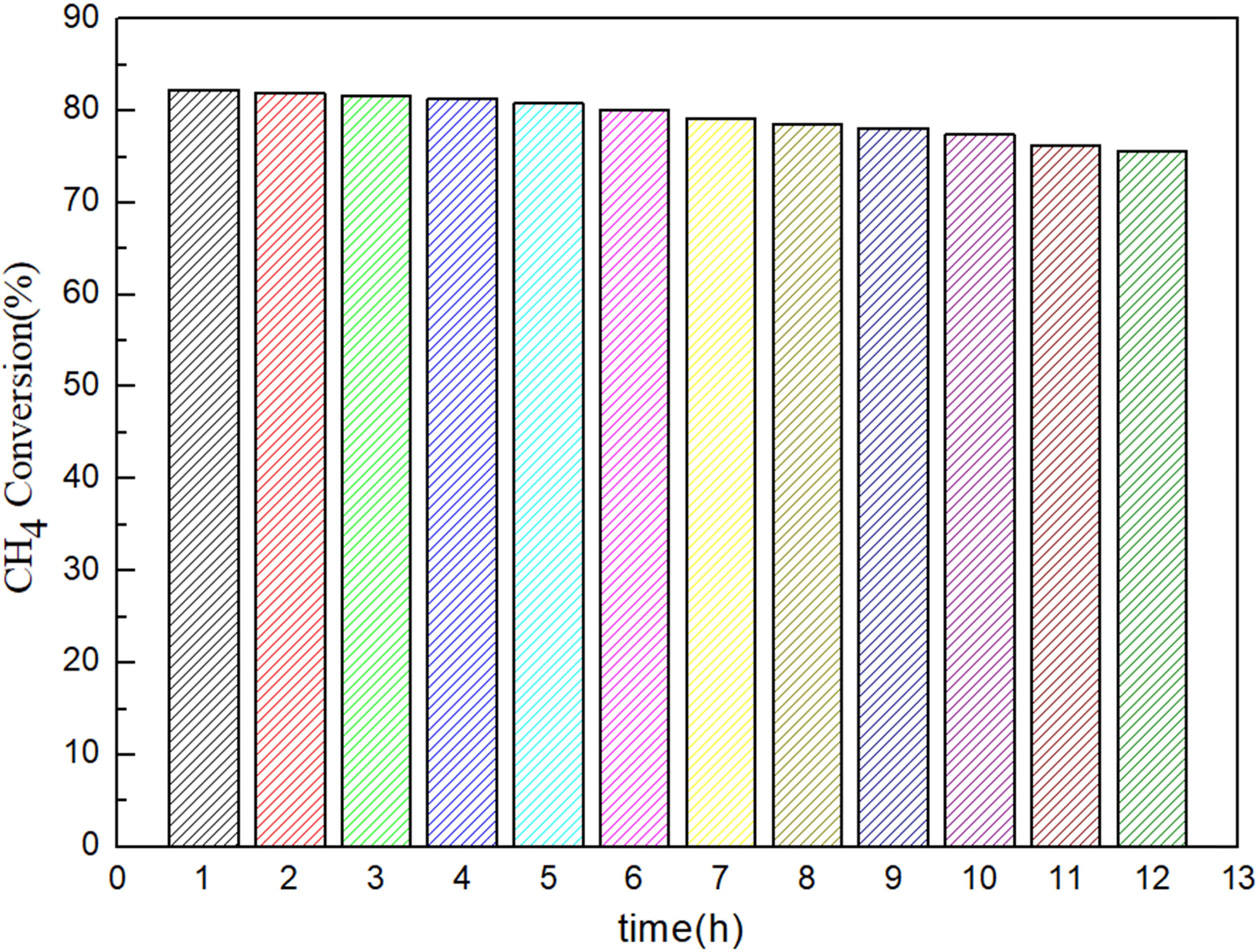

Stability tests

The methane conversion rate is an important parameter

for the stability of the catalyst. An experiment was conducted to evaluate the

stability of the catalyst at 750 oC for 12 h under flow

(10%Ni/CeO2, n(H2O): n(CH4) = 3, and GHSV =

1,500 h-1).

The experimental results are shown in Fig. 8. The catalytic activity remained

unchanged within 6 h, but the conversion of CH4 decreased slightly

(about 9%). This stability may be related to the small active NiO locations,

which are highly uniformly dispersed on the cerium support and have high

sintering resistance.

|

Fig. 2 XRD analysis of the Ni/CeO2 catalysts. |

|

Fig. 3 Results of Ni/CeO2 scanning electron microscopy with 10%Ni load. |

|

Fig. 4 Comparison of catalytic performance of and (n(H2O): n(CH4) = 3; GHSV = 1,500 h−1; T = 750 oC). |

|

Fig. 5 Methane conversion and H2 yield at different temperature (n(H2O):n(CH4) = 3, GHSV = 1,500 h−1). |

|

Fig. 6 Methane conversion and H2 yield/selectivity for different wt % Ni loading (n(H2O): n(CH4) = 3; T = 750 oC). |

|

Fig. 7 Effect of GHSV on methane conversion and H2 yield/selectivity of 10Ni/CeO2(n(H2O): n(CH4) = 3; T = 750 oC). |

|

Fig. 8 Stability of catalysts for10%Ni/CeO2, Reaction conditions: T = 750 oC, n(H2O): n(CH4) = 3, GHSV = 1,500 h−1. |

Ni/CeO2 Nanocrystalline catalysts with

different Ni loadings (6, 8, 10, and 12%) were synthesized by a wetness

impregnation method for the methane steam reforming (MSR) process. The

catalytic performance of Ni/CeO2 catalyst was studied. XRD results

approved the formation of the nanocrystalline of the prepared catalysts.

It was shown that the 10 wt% Ni/CeO2 provided

the optimal catalytic activity among the catalysts with different Ni loadings.

The optimal reaction conditions for MSR by Ni/CeO2 catalyst was as

follows: 10 wt %Ni/CeO2, 750 oC, 1,500 h-1.

The stability test for 12 h at 750 oC demonstrated excellent

thermal stability of the resulted Ni/CeO2 catalysts.

This work was supported by the National Natural Science

Foundation of China Funding (No. 51606013), China Postdoctoral Science

Foundation Funding (No. 2019M651097 and No. 2019M651094), Fundamental Research

Funds for the Central Universities of China (No. 3132019187,

No. 3132019191 and No. 3132019327), and Natural Science Foundation of Liaoning

Province (No. 2019-BS-026 and No. 2019-ZD-0154).

- 1. W. Cai, L. Ye, L. Zhang, Y. Ren, B. Yue, X. Chen, and H. He, Materials 7 (2014) 2340-2355.

-

- 2. I. Dincer and C. Acar, Int. J. Hydrog. Energy 40 (2010) 11094-110111.

-

- 3. J.Matos, M. Rosales, R. Demir-Cakan, and M.M. Titirici, Appl. Catal. Gen. 386 (2010) 140-146.

-

- 4. T.L. LeValley, A.R. Richard, and Fan, M., Int. J. Hydrog. Energy 39 (2014)16983-17000.

-

- 5. O.A. Seyma, Int. J. Hydrog. Energy 35 (2010) 12821-12828.

-

- 6. A.C.W. Koh, L. Chen, W.K. Leong, B.F.G. Johnson, T. Khimyak, and J. Lin, Int. J. Hydrog. Energy 32 (2007) 725-730.

-

- 7. M. Rezaei, S.M. Alavi, S. Sahebdelfar, P. Bai, X. Liu, and Z.F. Yan, Appl Catal, B. 77 (2008) 346-354.

-

- 8. M.S. Fan, A.Z. Abdullah, and S.Bhatia, Int. J. Hydrog. Energy 36 (2011) 4875-4886.

-

- 9. A. Sardar, J.A. Mohammed, G. Ahmed, A.K. Abdelmoneim, and K. Mahmoud, Int. J. Hydrog. Energy 41[48] (2016) 22876-22885.

-

- 10. V.K. Jaiswar, S. Katheria, G. Deo, and D. Kunzru, Int. J. Hydrog. Energy 27 (2017) 18968-18976.

-

- 11. A. Berman, R.K. Karn, and M. Epstein, Appl. Catal. Gen. 282[1-2] (2005) 73-83.

-

- 12. R. Craciun, W. Daniell, and H. Knozinger, Appl. Catal. Gen. 230 (2002) 53-68.

-

- 13. V.P. De Souza, D. Costa, D. Dos Santos, A.G. Sato, and J.M.C. BuenoInt. J. Hydrog. Energy 37[13] (2012) 9985-9993.

-

- 14. N. Salhi, C. Petit, A.C. Roger, A. Kienemann, S. Libs, and M.M. Bettahar, Catal. Today 113[3-4] (2006) 187-193.

-

- 15. X. Fang, X. Zhang, Y. Guo, M. Chen, W. Liu, and X. Xu, Int. J. Hydrog. Energy, 41 (2016) 11141-11153.

-

- 16. R. Martınez, E. Romero, C. Guimon, and R. Bilbao, Appl. Catal. Gen. 274[1-2] (2004)139-149.

-

- 17. M. Cargnello, P. Fornasiero, and R.J. Gorte, Catal. Lett. 142 (2012) 1043-1048.

-

- 18. M. Ahmadi, H. Mistry, and B.R. Cuenya, J. Phys. Chem. Lett. 7 (2016) 3519-3533.

-

- 19. T. Montini, M. Melchionna, M. Monai, and P. Fornasiero, Chem. Rev. 116 (2016) 5987-6041.

-

- 20. W.S. Dong, H.S. Roh, K.W. Jun, S.E. Park, and Y.S. Oh, Appl. Catal. A Gen. 226 (2002) 63-72.

-

- 21. H.S Roh, K.W. Jun, and S.E. Park, Appl. Catal. A Gen. 251 (2003) 275-283.

-

- 22. T.J. Huang and M.C. Huang, Chem. Eng. J. 145 (2008) 149-153.

-

- 23. G.R. Gavalas, C. Phichitkul, and G.E. Voecks, J. Catal. 88[1] (1984) 54-64.

-

- 24. A. Zhao, W. Ying, H. Zhang, H. Ma, and D. Fang, Int J. Chem. Mol. Mat. Metal Eng. 5[11] (2011) 1039-1043.

-

This Article

This Article

-

2020; 21(2): 263-268

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.263

- Received on Feb 10, 2020

- Revised on Mar 5, 2020

- Accepted on Mar 9, 2020

Services

Services

- Abstract

introduction

experimental

results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- Qiuwan Shen

-

Marine Engineering College, Dalian Maritime University, Dalian, China

Tel: +86-18624118015 Fax: +0411-84728659 - E-mail: shenqiuwan@dlmu.edu.cn

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.