- Nano bioactive HAP-nano bioresorbable β-TCP-PEG composite scaffolds and their biochemical activity for implant applications

K. Kalaa, M. Sundara Ganeasanb, V. Balasubramanib, J. Manovasukib, K. Valivittana, T.M. Sridharb and M.R. Kuppusamyc,*

aDepartment of Biotechnology, St. Peter’s University, Chennai 600054, India

bDepartment of Analytical Chemistry, University of Madras, Guindy Campus, Chennai-600025, India

cDepartment of Chemistry, RV Government Arts College, Chennai 603001, India

Recent efforts towards the

treatment of bone defects and diseases focus on the development of bone

scaffolds. Bioceramics provide strength, osteoconductivity and also imparts

flexibility and resorbability. In this study, the biodegradable composites were

fabricated using bioactive nano Hydroxyapatite (n-HAP) and bioresorbable nano β-Tricalcium

phosphate (n-β-TCP) taken in 1:1 proportion. The nano composite scaffolds were

synthesized using PEG (Poly Ethylene Glycol) by wet precipitation method. XRD

(X-ray diffraction) confirms the presence of crystalline structure of n-HAP and

n-β-TCP within the lattice. FESEM (Field Emission Scanning Electron Microscopy)

and EDS (Energy Dispersion X-ray Spectroscopy) confirms the micro porous nature

and the phase purity of the composite. Further, biochemical studies were

carried out using MG-63 Osteoblast cell line to evaluate their sustainability

after implantation. The viability of the cells and proliferation rate is

evaluated using 3-(4,5-dimethylthiazole-2-yl)-2,5-diphenyltetrazolium bromide

(MTT) with different concentration and different incubation period. The ALP

(Alkaline Phosphotase) test reveals that the composite favours bone

regeneration through apatite layer formation. Further studies were carried out

to explore the DPPH (1,1-diphenyl-2-picrylhydrazyl) activity on the composites

and results reveals that the composite have an ability to trap the free

radicals in the biological surroundings. The antimicrobial studies indicate

that the composites shows no major inhibitory effects towards the most common

bone affecting bacteria Staphylococcus aureus. The studies indicate that

the concentration range of the composite is ideal for bone growth and can be

used as substituents in the scaffold synthesis for normal and cancerous

patients.

Keywords: n-HAP, n-β-TCP, Poly ethylene glycol, composite, MTT assay, DPPH assay, ALP activity

Treatment of bone diseases and multiple fractures is a

great challenge and tissue engineering offers a solution to patch-up and heal

the damaged hard tissue by using biomaterials. Among several biomaterials that

are available biodegradable polymers have attracted researchers to study its

potential as an alternative to metallic implants [1]. These

biodegradable polymers are commonly used

as the biological substitutes for treatment of damaged

bone, drug delivery, repair of tissues and organs of the human body [2].

Biocompatibility is the primary property that any biomaterial should possess

during the selection of substituted biomaterials in order to provide a platform

for cell growth and proliferation. These biomaterials should actively interact

with the cell and activate the osseointegration process leading to new bone

deposition [3]. In recent studies, considerable attention has been given to HAP

based composite biomaterials. Since, it has specific properties such as biocompatibility,

biodegradability, an intrinsic antibacterial nature and

the ability to mold into various forms or geometries which is suitable for cell

growth and osteoconduction.

Bioactive ceramics (n-HAP) are widely used in scaffold

preparation. n-HAP on implantation in the human body has the ability to react

with physiological fluids. This bioceramic on further contact with the fluids

and tissues for a few days to weeks leads to the formation of new bone with

n-HAP layers [4, 5]

.

The composite materials on implantation provokes immune

response in the body which elicits a cascade mechanism in the biological

environment. This makes it necessary to evaluate the biological properties of

the composites along with their characterization to prove their

biological efficacy. This would help us to determine the

longevity of the implant [6]. The improper choice of the substituent materials

during scaffold preperation limits its biological application [7]. Even the

minute level of injury during restoration period affects the performance of the

scaffold. This may be due to the leakage of the toxic substances from the

scaffold into the biological fluids. This may induce inflammation at the

implant site [8]. To avoid such a situation, it is highly essential to carry

out the in vitro biochemical evaluation before the clinical studies. Hence, in

vitro biochemical screening is the best choice to evaluate the biocompatibility

and toxicity [9]

.

In

bone tissue engineering, the biological behaviour of the composites namely its

osteoconductivity, osteoinductivity and degradability would help us to

analyse the ability of the implant to induce bone growth in the biological surroundings. This could be accomplished in the

lab by carrying out in vitro testing with an appropriate cell line to study the

mechanism of interaction. In humans,

when the composites are implanted the

ions present in the body fluids surround the surface of the materials forming the ionic layers. This is

followed by the interaction with

protein that would support us to understand the osteoinduction process

[10]. In case of osteoconduction, the bone tissue grows around the internal pores of the scaffolds which would aid

the conduction process. The evaluation of osteoconduction property and

osteoinduction property helps us to assess the behavior of the scaffold after

implantation in the biological system.

This osteoconductivity can be measured

by taking into account the bone coverage area using optical or FESEM

analysis [11]. Biodegradability is the another important property by which the

materials get degraded once inserted inside

the body. The biodegradability of the

biomaterials would determine the osteoconductive nature of the surrounding

cells that are in contact with the physiological environment [12].

In the view of

osteoconduction and osteointegration requirement nano Hydroxyapatite which is a

chief mineral component of bone matrix was selected. It is the most appealing

inorganic constituents that is widely used for the bone regenerative medicine.

n-β-TCP is a bioactive material that posses good biocompatibility and

biodegradability. The degradable property of n-β-TCP ensures the release of

elements such as calcium and phosphorus at the site of implantation. n-β-TCP

has limited direct clinical application due to its brittle nature

and difficulty of obtaining various implant shapes. This

problem can be overcome by using it as a one of the materials

in composites [13]. Bioceramic composites are prepared

in nano dimensions by mixing one or more phases of ceramics with mainly

polymers or other biocompatible materials. The typical microstructures of nanoceramic

composites result in exceptional properties (biological,

mechanical, electrical and electronic etc.). These composites can be used as

bulk materials for structural applications or can be developed as coatings on

different substrates for various applications [14]. The composites can be

prepared with Polyethylene Glycol (PEG) which acts as an important

additive component and provides hydrophilicity to the composite [15]

.

Nano form of biomaterials is preferable due to its small

grain size and large surface area that promotes the interfacial interaction

with bone. Moreover, nano ceramics are widely used in scaffold preparation as

they pocess controlled rate of degradation which could exactly match with new

bone growth rate. This can be acheived by controlling the crystalline grain

size of the nano ceramics and thus improve the bone graft healing without any

complication [34]. Further, researchers have reported that nano HAP can

suppress the cancer cells without affecting the normal cells [30]

.

Nano Hydroxyapatite reinforced polyphenylene sulfide biocomposites

were reported to have good cell proliferation with MG-63 cells. It shows the

osteogenic differentiation with higher ALP activity [16]. In

designing the synthetic scaffolds for bone tissue engineering the

materials can be prepared in various physical forms such as

powders, pastes or granules and porous scaffolds [3].

Scaffolds should be resorbable with time in the human body

with gradual replacement by newly formed bone tissue

and should ensure a high protein-adsorption capacity. n-HAP is stable against

dissolution in body fluids, whereas n-β-TCP has a much higher resorption rate

compared to that of n-HAP. One can easily control the resorption rate by

varying the ratio of n-HAP/n-β-TCP composites [17, 18]. Selection of

polymer is critical for preparing the composite and it should be

evaluated for its toxic nature. The systemic screening of scaffolds by invitro

method is reported in literature [31]. Invitro cytotoxicity and biochemical tests

are most ideal, reliable, simple and help us

to evaluate the toxic nature of the scaffolds. These tests aids in screening

the bone deposition properties such as osteoconduction, cell viability, cell proliferation and bone

regeneration. These tests are carried

out using the osteoblast cell line.

Cell viability and cell proliferation can be evaluated

using MTT assay. In this study the viable nature of the cell is confirmed by

the active presence of mitocondrial dehydrogenase enzyme. This enzyme inturn

reduces MTT and promotes cell proliferation. The reduction of MTT is confirmed

by the colour change. The cell proliferation is further confirmed

using the growth curve [19]. Implant-material related

infection is common and this could arise during surgery. This infection may affect

not only the surgical sites but also other organs of the body through the

migration of pathological microorganisms during blood circulation [20]. The presence of bacterial infection at the implanted

site often shows a delayed wound

healing and may sometimes result in

revision surgery.

The main aim of this study is to prepare n-HAP/ n-β-TCP/PEG

nano composite using different ratios of the bioceramics and polymer. This

would be followed by the evaluation of the composite for biochemical and

biological behaviour to identify the suitable ratio for the scaffold

preparation. Since both n-HAP & n-β-TCP are the constituents of bone. In

order to impart the hydrophilicity and antifouling property the PEG added the

composite. These composites were evaluated using invitro studies which includes

cell viability, cell proliferation, antimicrobial

activity, alkaline phosphatase activity and antioxidant activity.

The scaffolds prepared using 1:1:5 ratio of n-HAP/n-β-TCP/PEG was found to show

good cell attachment with least toxicity.

Materials

Calcium Nitrate Tetrahydrate [Ca(NO3)2·4H2O],

Diammonium hydrogen Phosphate [(NH4)2HPO4],

Poly Ethylene Glycol 6000 [PEG], Conc. Ammonia, Ethanol were purchased from SRL

and Finar. All the chemicals were of analytical grade and used further without

purification.

Synthesis

of n-HAP/ n-β-TCP/ PEG composites

The n-HAP and n-β-TCP was synthesized based on the earlier

established procedure in the lab [21]. The powders were dried and sintered at

800 °C for 2 h in air atmosphere using a muffle furnace. PEG solution was

prepared separately with deionized water by using a magnetic stirrer for 2~3 h

to obtain a homogenious solution. Synthesized n-HAP/n-β-TCP was added into the

solution to make a n-HAP/n-β-TCP/PEG by adding different concentrations of the

powders (0.5:1:5,1:1:5 and 2:1:5) mixture. The polymer

n-HAP/n-β-TCP mixture was stirred for 10 hours with

stirrer until n-HAP/n-β-TCP was completely dispersed in the solution and then

this mixture was dried at 100 °C in an hot air oven.

Material Characterization studies of n-HAP/n-β-TCP/PEG composites

The synthesized n-HAP/n-β-TCP/PEG composite materials were

characterized using different analytical techniques. The crystal structural

properties of n-HAP/n-β-TCP/PEG composites were characterized using X-ray

diffractometer (XRD) (model, Rigaku Ultima IV) with Cu Kα (λ = 0.154 nm)

radiation and 2θ scanning range of 10-80°. The morphology of n-HAP/n-β-TCP/PEG

were analyzed using Field Emission Scanning Electron

Microscope (FESEM) (model, Carl Zesis Supra 55).

Biochemical study of n-HAP/n-β-TCP/PEG

composites

Cytotoxicity assay

The assay was performed based on the Mosmann, 1983

procedure [22]. For this assay MG-63 cell line was obtained

from NCCS, Pune. Cells were plated in 24-well plates (Nucleon,

Roskilde, Denmark) and incubated at 37 °C with 5% CO2

under humid conditions. After the cell reached the

confluence, the prepared samples at different concentration was added and

incubated for 24 h, 48 h and 72 h. After incubation, the samples of each

concentration were removed from the wells and washed with phosphate-buffered saline

(pH 7.4) or DMEM (Dulbecco's modified eagle medium) without serum 100 µL/well

(5 mg/ml) of 0.5% 3-(4, 5-dimethyl-2-thiazolyl)-2,5-diphenyl-tetrazolium

bromide (MTT) was added and incubated for 4 h. After incubation,

1ml of DMSO (Dimethyl sulfoxide) was added in all the wells. The absorbance at

570 nm was measured with UV- Spectrophotometer using DMSO as the

blank. Measurements were performed and the concentration required for a 50%

inhibition (IC50) was determined graphically. The percentage of cell

viability was calculated using the following formula:

The time period is extended to 24 h, 48 h and 72 h in

order to determine the cell proliferation rate. Graphs are plotted using the %

of Cell Viability at Y-axis and concentration of the sample in X-axis. Cell

control and sample control is included in each assay to compare the cell

viability assessments.

Antibacterial activity

Antibacterial activity is done using Kirby-Bauer disk

diffusion susceptibility test (2009). [25] Staphylococcus aureus, a

common bone affecting gram positive bacteria is used. The

pathogenic organism is made to grow on Mueller-Hinton agar (MHA) in the

presence of anti-microbial impregnated filter paper disks. The

growth of the organism around the disk is an indirect measure of the compound ability against the pathogen.

Antibacterial activity of the composites was determined by disc

diffusion method on MHA medium. The

medium is then poured into the petri dishes. The inoculum was spread over the

solidified solid plate with the help of sterile swab moistened with the

bacterial suspension. Ampicillin (20 μL/disc) is taken as positive control. The

disc was placed in MHA plates consisting of 20 μl of sample (Concentration:

1,000 μg, 750 μg and 500 μg). The plates were incubated at 37 °C for 24 h.

The diameter of zone of inhibition gives the antibacterial activity.

DPPH (2,2 diphenyl 1 picrylhydrazil) Assay

The DPPH assay was performed based on Molyneux, 2004

method [24]. The main characteristics of an antioxidant are its ability to trap

free radicals. Highly reactive free radicals like ROS (Reactive Oxygen Species)

and RNS (Reactive Nitrogen Species) found in biological systems form a wide

variety of sources. A rapid and simple inexpensive method to measure the

antioxidant supply of a sample involves the use of free radical 1,1 diphenyl 2

picryl hydrazyl (DPPH). Three test tubes were labeled as blank, standard and

test. First 3.7 mL of absolute methanol (Sigma Aldrich) is added to all the 3

test tubes. This was followed by addition of 100 µL of standard Butylated

hydroxy toluene (Sigma Aldrich) to the standard test tube. 100 µL of composite

mixture is added to the test tube labeled as test. 200 µL of fresh DPPH

solution is added to all the test tubes including blank. The test tubes are

allowed to incubate at room temperature under dark conditions and the readings

were taken at 1, 5 and 30 min respectively. The results are expressed as

radical scavenging activity.

The molecule of DPPH were characterized as a stable free

radical by delocalization of electrons. This forms a deep violet colour,

characterized by the absorption band in methanol solution centered at 520 nm.

The antioxidant property is confirmed by the change from violet

to yellow colour on addition of DPPH. This change of colour is occurs due to

the reduction of DPPH by picryl group.

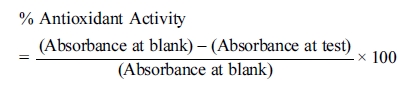

• The percentage of antioxidant

activity can be measured by,

Alkaline Phosphatase (ALP) assay

This assay was performed based on George N.Bowers,

Jr., and Robert B. McComb, 1966 procedure [23]. ALP at an

alkaline pH hydrolyses p-Nitrophenyl phosphatase to form

p-Nitrophenol and Phosphatase. The rate of formation of p-Nitrophenol is

measured as an increase in absorbance which is proportional to the ALP activity

in the sample.

The

buffer selected for this work is 2-amino-2-methyl-l-propanol (2A2M1P) (Sigma

Aldrich). The substrate, p-nitro phenyl

phosphate as the disodium salt, tetra hydrate (Sigma Aldrich). To evaluate the

ALP activity, the bio-composites were incubated in 0.5 mg/ml p-nitro phenol

phosphate in glycine buffer solution every five minutes a 90 µL aliquot of the

solution was removed and placed in 96 well plates containing 10 µL of a stop

solution. 0.1 M NaOH (Sodium hydroxide) (Aldrich chemical) and 0.1 M EDTA

(Ethylene diamine tetra acetic acid) (Aldrich chemical). The absorbance was

measured at 405 nm. The enzyme activity was calculated using formula.

Activity = A405 (Vreaction / Valiquot) / β

A405: Absorbance at 405, Vreaction:

Volume of reaction, Valiquot: Volume of aliquot, β: Extinction

coefficient for para nitro phenol, λ -18.5 at 405 nm.

ALP Activity in micromol/min (U/L)

= ΔA/min./18.75

× Test volume/Serum Volume × 1/Temperature factor

Where, 18.75 is mill molar absorptivity, Temperature at

30°C is consider as temperature factor is 1 ALP in U/L can be calculated as,

ALP Activity in U/L = ΔA/min. × 2754

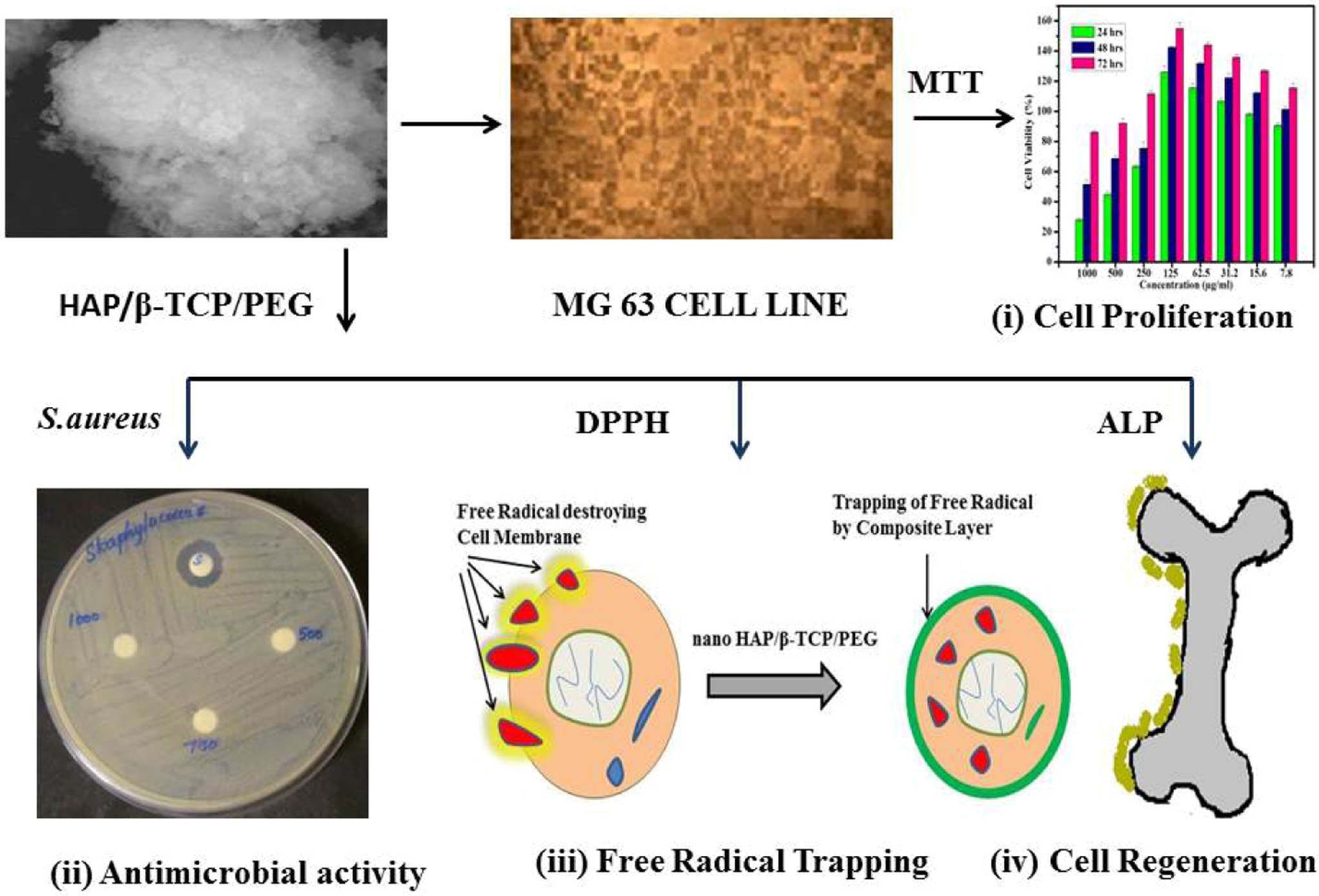

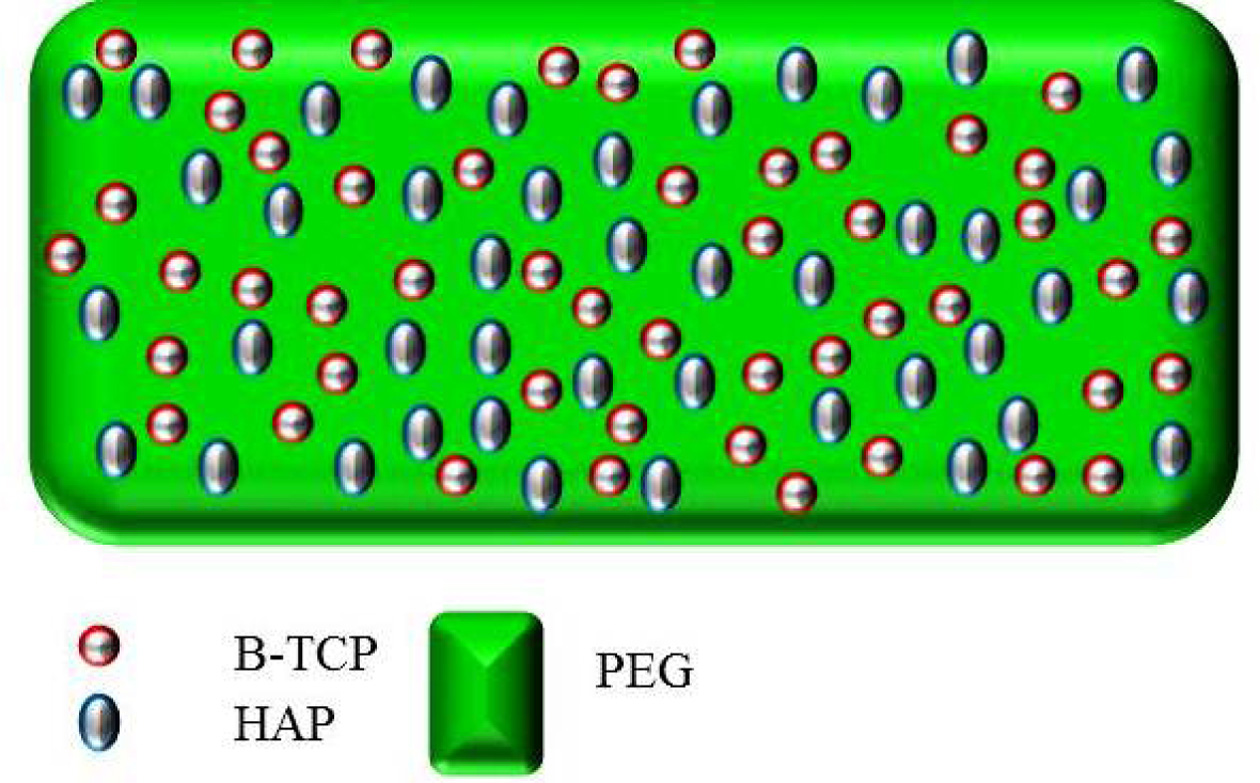

The overall summary of n-HAP/n-β-TCP/PEG com- posite is presented in Fig. 1 along

with the biochemical studies involving – (i) cell

proliferation (ii) antimicrobial activity (iii) Free radical trapping

(antioxidant) and (iv) cell regeneration (ALP activity) is given in Fig. 1.

|

Fig. 1 Schematic representation of n-HAP/n-β-TCP/PEG composite osteoblast cells and bacterial cell culture. |

Bioceramics such as n-HAP, n-β-TCP are commonly used in

new bone generation. But, in order to obtain the specific and desired

properties such us porosity, bioactivity, bio resorbability and

biocompatibility, researchers have prepared composites in which

different biomaterials can be combined based on the specific

property depending on the nature of their application [26]. In this concept,

the current work focus on the choice of the material composition which includes

Nano- Hydroxyapatite, Nano-β-Tricalcium phosphate, and

Polyethylene Glycol which posses the basic properties such as

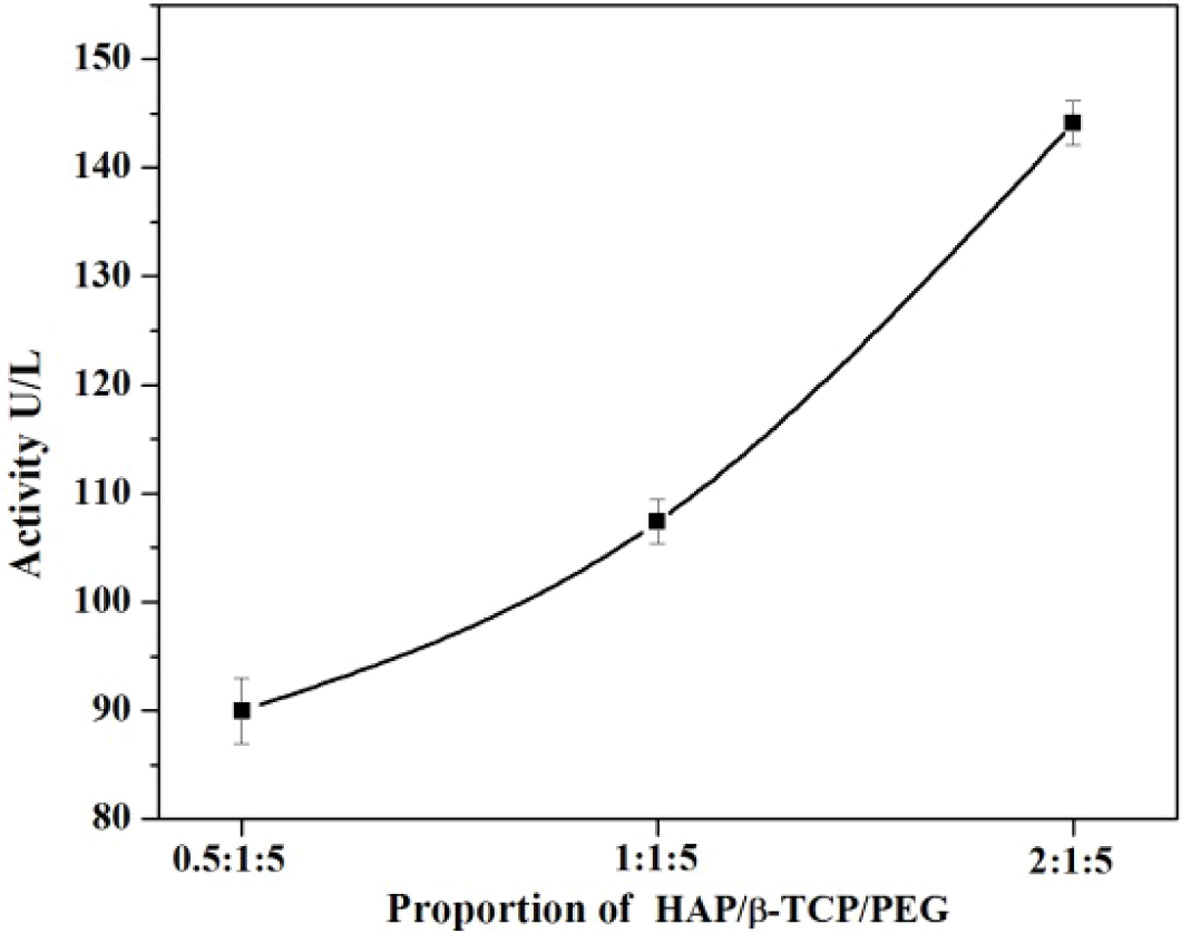

bioactivity, bioresorbability and hydrophilicity. The present work focuses on

the bone minerlization in scaffold materials, ALP activity which induces the

bone mineralization [27] was studied with the prepared scaffolds. The normal

value of ALP is 20-140 units per litre. If there is an increase or decrease in

the normal values it is termed as abnormality which leads to discomfort to the

patient [28]. Since, ALP is needed for the apatite formation the level should

be monitored and the values should not cross the maximum level. The report

suggests that the ALP can induce hydroxyapatite mineralization [29]. The

changes in ALP values of the composite would affect the formation of apatite

layers of new bone. Hence, n-HAP can be used in different proportion to

maintain the normal ALP activity. The study was further extended to select the

proportion of the components present in the composite. To fix the

concentration, three different proportions were taken in the composite mixture

of n-HAP/n-β-TCP/PEG . The proportion includes 1:1:5, 0.5:1:5, 2:1:5 which has

different concentration of n-HAP in n-HAP/n-β-TCP/PEG. The above proportions

were tried for different concentration to identify the concentration which can

be suitable for further studies. The changes in optical activity with changes

in the ratios of n-HAP/n-β-TCP/PEG is given in Fig. 2.

The ALP activity for the composite with n-HAP/n-β-TCP/PEG

in 0.5:1:5 ratio shows the ALP activity to be about

89.964. Different ratios of samples were prepared and tested

to obtain the highest ALP activity. As the ratio of n-HAP was increased from

0.5 to 2 the 2:1:5 composite shows an ALP activity of about 144.126 which is

normally higher than that of the optimum level that can be found in the blood.

For a n-HAP ratio of 1:1:5 the ALP was found to be 110.321. Hence, the current

study indicates that the n-HAP/n-β-TCP/PEG scaffold with 1:1:5 ratio has the

optimum and desired ALP activity and can be considered for further

intensive investigations.

Characterization study

of n-HAP/n-β-TCP/PEG composites

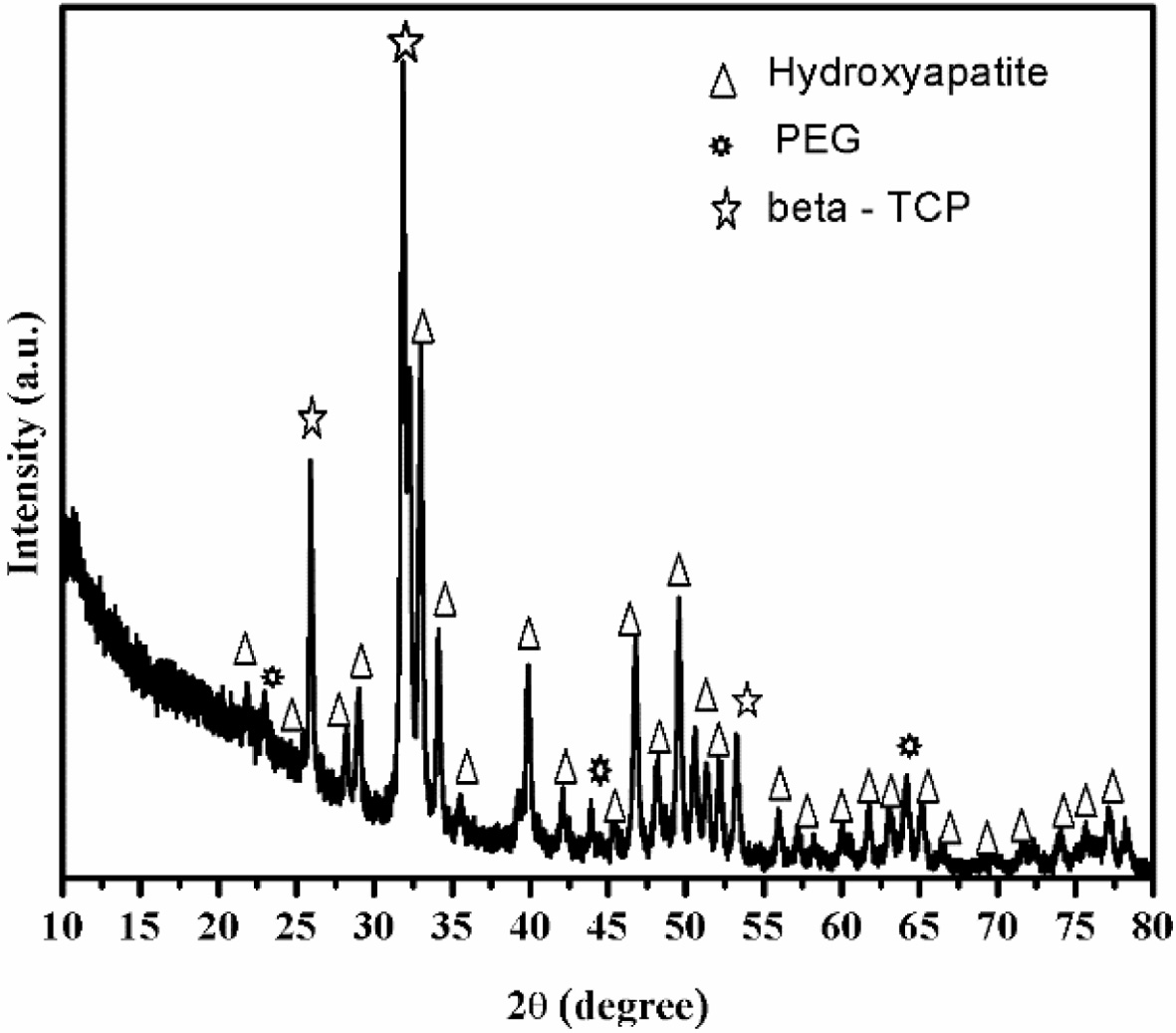

XRD analysis

Fig. 3 shows the XRD pattern of n-HAP/n-β-TCP/PEG

composites which shows that HAP and β-TCP exists as nano form

and present together in the composite. The peaks corresponding to nano HAP

powder were found at the reflections of (002), (102), (210), (211), (112),

(300), (202), (310), (311), (222), (213), (321), (004) and (510). The

crystalline nature of nano HAP can be established by the presence of

diffraction peaks with high intensities and minimal line broadening after

indexing the two theta values with JCPDS file no.9-0432. The observed patterns

clearly indicate that no structural transformation of mono phasic nano HAP

occurs. This indicate that the bioactivity would be preserved. The intensity

peaks are assigned to n-β-TCP were obtained at (024), (1010), (214), (300),

(0120), (220), (1016), (3012) and (4010). These, hkl indices were

compared with JCPDS file no.09-0169. The intensity

peaks for PEG were obtained at the XRD patterns indicates that the

addition of polymer to the sample do not affect the crystal structure of n-HAP

and β -TCP nanoparticles. PEG is observed to show XRD peaks at 23.328 and a few

minor peaks are observed, which is

consistent with data in previous report [33].

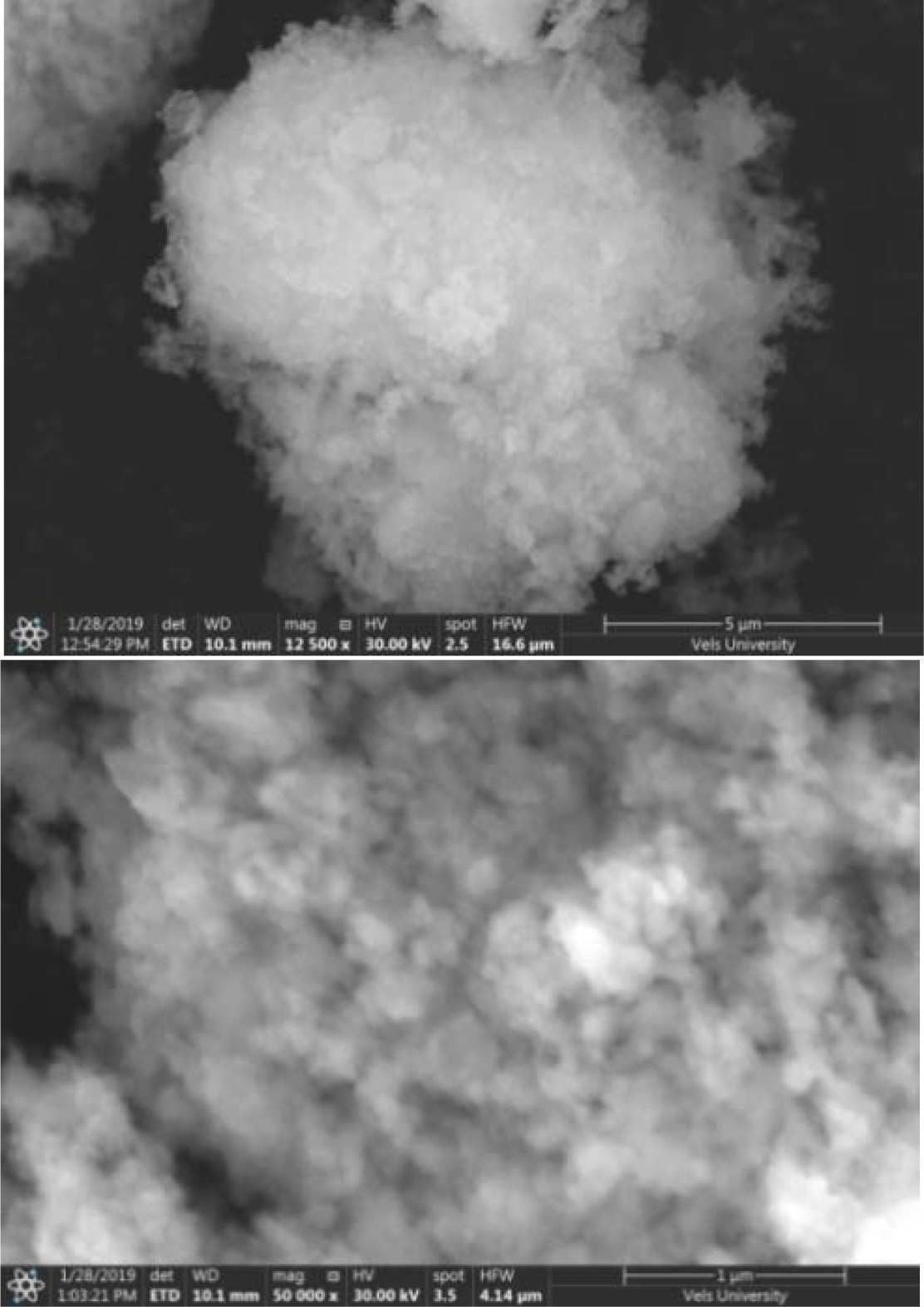

Field Emission Scanning Electron Microscope study (FESEM)

The

FESEM micrographic images of pure n-HAP/ n-β-TCP/PEG compositions are shown in Fig. 4. The FESEM image shows that particles are well agglomerated in the polymer matrix. The images show spherical particles of the ceramic to be embedded in PEG

indicating the composite nature of

the ceramics. The porosity of the samples were found to vary from 1.3 to 2%.

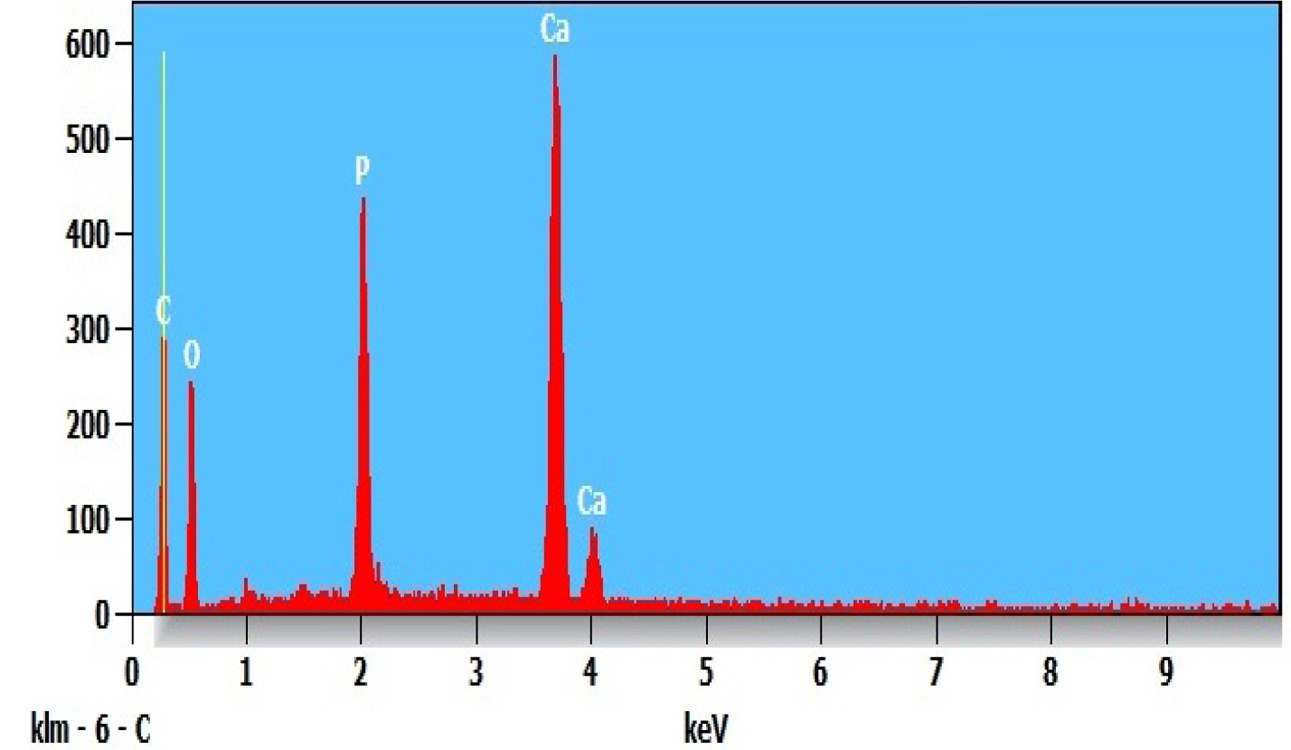

The EDS of n-HAP/n-β-TCP/PEG compositions shown in Fig. 5. This indicates the

presence of Ca, O, P and C in the nanocomposite which further confirms the

presence of n-HAP/n-β-TCP.

Biochemical study of n-HAP/n-β-TCP/PEG

composites

Cytotoxicity assay

The composite mixture prepared with n-HAP/n-β-TCP/PEG

(1:1:5) were taken in different dilutions. The linearity of MTT assay in the

MG-63 cells were plated out in doubling dilution using 0.1mL growth medium in

96 well plate. The MTT is added to all the cells immediately and the plates

were allowed to incubate at 37 °C for 4 h. The graph was plotted between the

obtained concentration and the percentage of

cell viability. The duration of

exposure is usually determined as the

time required for maximal damage occurs but is also influenced by the stability

of the composites. MTT is the most commonly used yellow colour substrate and

this converted into a dark blue formazan product when incubated with the live

cells. The viability percentage of the cells were measured

spectrophotometrically by the colour obtained after the addition of MTT [32].

The exposure time is prolonged to identify

the rate of proliferation of the cell.

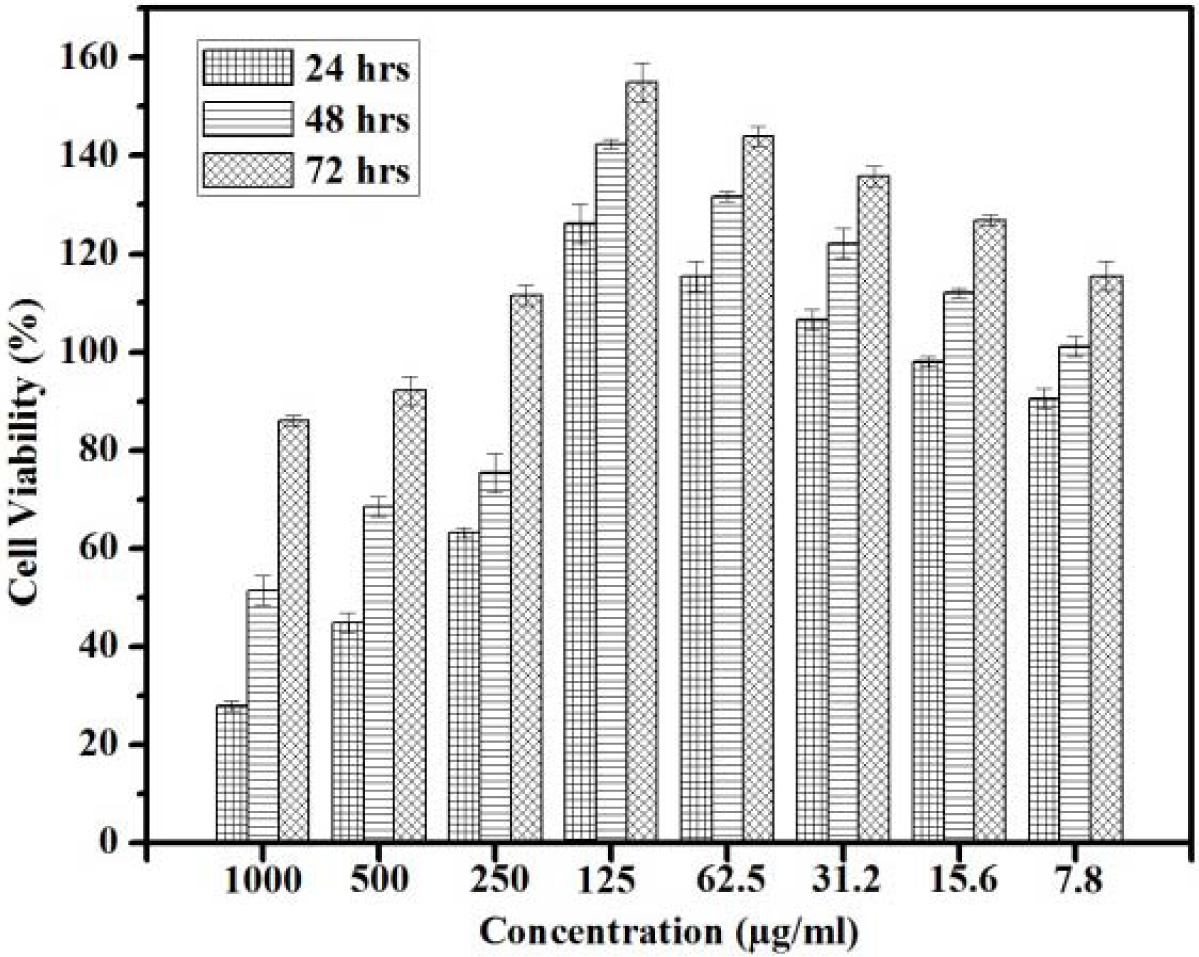

Fig. 6 indicates the percentage of cell viability IC50

that can be reached by the active cells after 24 h upto 250 µg/ml. This

indicates that the percentage of cell viability is found to be 50% and above.

The rate of cells were increased when the incuabtion time was extended to 72 h.

When the concentration increases the 50% of cell viability reached only in

extended period of incubation. When the concentration increases upto 1,000 µg/ml

the percentage of cell viability IC50 is found only after 48 h of

incubation. The proliferation of the cells are identified at different exposure

time. In all concentration when the time of exposure increases the rate of

proliferation increases The Fig. 6 shows that in each concentration 72 h peak

is higher than 48 h which inturn higher than 24 h. This suggests that when the

concentration increases to 500 μg/ml and 750 μg/ml, the increase in incubation

period is required to get better proliferation at 48 and 72 h respectively.

These results indicate that the level of cell viability

increases with time of exposure and it decreases with concentration. The cells

were allowed to proliferate for two to three population doubling times (PDTs)

in order to distinguish between cells that remain viable and are capable of

proliferation and those that remain viable cannot proliferate. The percentage

of surviving cells is then determined indirectly by MTT. The amount of MTT

formazan produced is directly proportional to the cell viability. The

proliferation of the cells were noticed from the concentration 125 μg/ml,

62.5 μg/ml, 31.5 μg/ml where the cell viability percentage is found to be

double and that confirms the population doubling through proliferation. Normally IC50 represents the con- centration of the composite materials that

is required for 50% of cell viability. This

50% viability is achieved at 1,000 μg/ml

and 500 μg/ml after 48 h of incubation.

The same 50% viability can be achieved in all other concentration (250, 500

and 750 μg/ml) after 24 h of incubation. Fig.

6 shows that IC50 can be seen upto 250 μg/ml concentrations with an

exposure time period ranging from 24 h, 48 h and 72 h. When the concentration is increased to 500 μg/ml and 1,000 μg/ml

the IC50 cannot be achieved in the initial time phase of 24 h and

this will get elicit only after the period of exposure 48 h and 72 h

respectively. This implies that at all the concentration the cells would

proliferate indicating that the sacffold is biocompatible. As the concentration range increases above 250 µg/ml it is

important to increase the incubation period for cell proliferation to take

place. The results indicate that the nano composite of n-HAP/n-β-TCP/PEG can be

used maximum of 250 μg/ml as the substituent for the scaffold preparation. The

concentration preferable for scaffold is found to be maximum at 250 μg/ml. As

the concentration crosses 250 μg/ml

the period of incubation should

increases.

Thus, it can be inferred that when the concentration exceeds,

the period of incubation also need to be increased for finding

both the cell viability and proliferation This assay suggest that the choice of

materials used in preperation of nano composite is good

to provoke the proliferation of cells. The scaffolds prepared indicate the

presence of osteoconduction property.

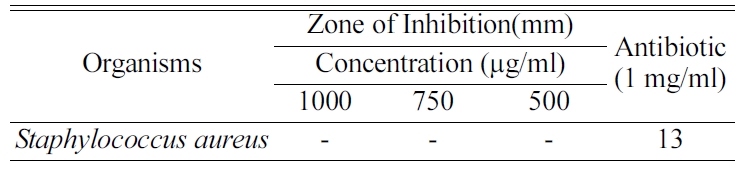

Antibacterial activity

Table 1 shows that no zone of inhibition was found at

different concentrations of 1,000 µg/ml, 750 µg/ml and 500 µg/ml and the

inhibition zone found only in the antibiotic amphicilline disc. The

composite materials were tested with Staphylococcus aureus which

is the common pathogen that induces the bone infection. The composite materials

of different concentration such as 1,000 µg/ml, 750 µg/ml and 500 µg/ml were placed in

a disc and the disc placed over the microbial environment.

The zone of inhibition was calculated by measuring the diameter of the

diffusion around the disc. This confirms that the composite does not show any

inhibition towards the Staphylococcus aureus. The inhibition is not found with the increase in

concentration.

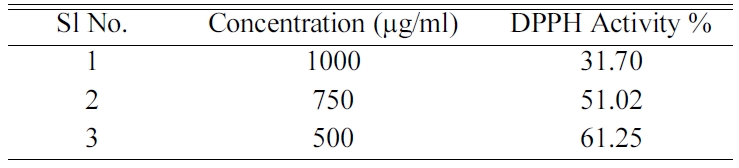

DPPH (2,2 diphenyl 1 picryl hydrazil) assay

Scientific evidence suggests that antioxidants reduce the

risk for chronic disease including cancer and heart diseases. The main

characteristics of an antioxidant are its ability to trap free radicals. The

antioxidant property of the composite n-HAP/n-β-TCP/PEG is measured with the

addition of 1,1 diphenyl 2 picrylhydrazyl (DPPH). The formation of reduced form

of DPPHH is due to the reaction of free radical with unpaired

electron of DPPH become reduced by capturing hydrogen ions which

was donated by the composite materials. The reduced state of DPPHH would form

yellow colour. The increase in the intensity of the colour confirms the higher

reducing activity and also more antioxidant property ie.

above 50% which is required for implantation inside the

biological medium.

Table 2 explains the activity of the DPPH for the

different concentration of the composite n-HAP/n-β-TCP/PEG. A decrease in the

acitivity of the composite was found with the increase in concentration of the

composite. The activity above 50% can be viewed only in 750 μg/ml and also

below that concentration. This study concludes that the DPPH property can be

good for the composite when the concentration range is less than 750 μg/ml is

used for the scaffold preparation.

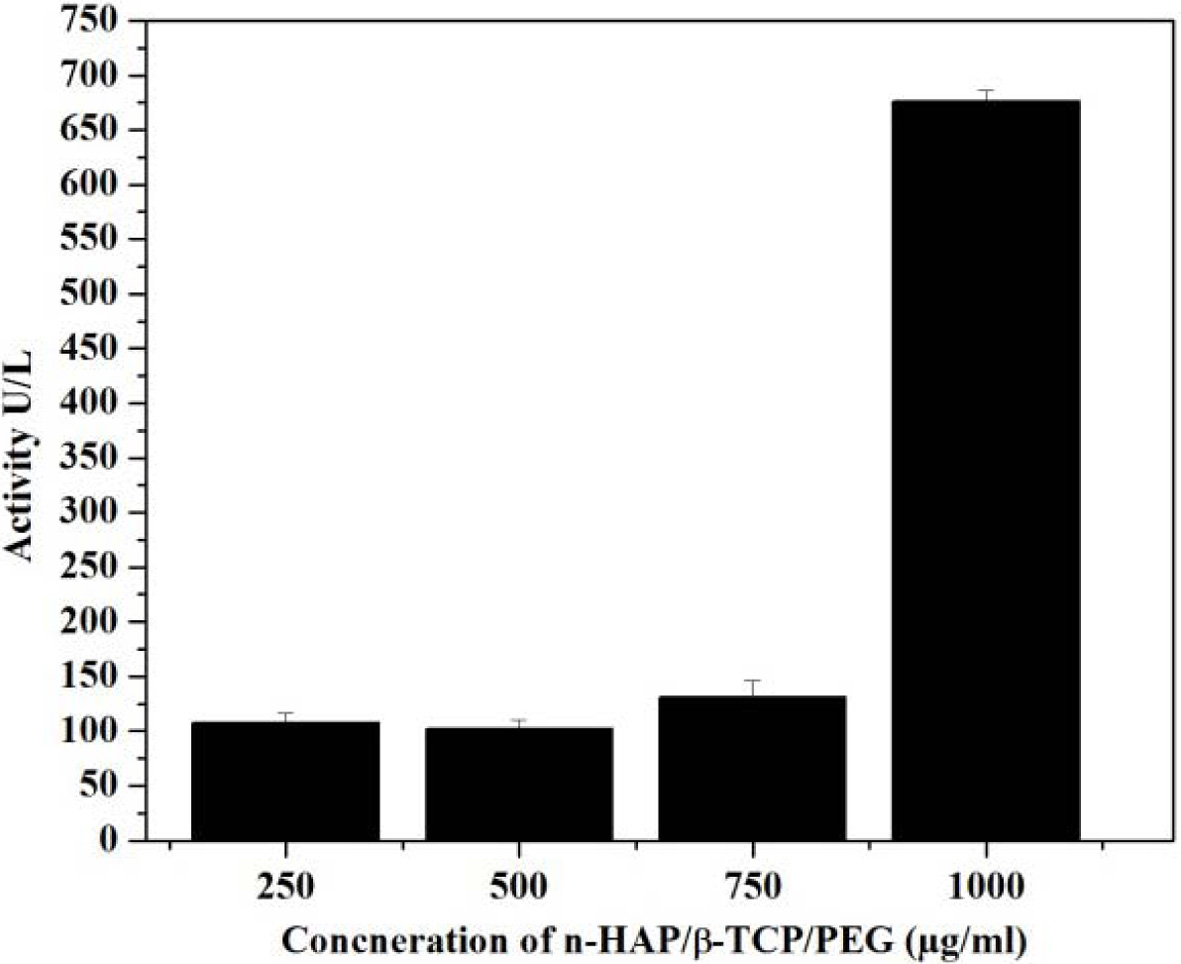

Alkaline phosphatase assay

The composites were further analysed for the bone

formation ability by using ALP activity. The analysis were taken for different

concentration of the n-HAP/n-β-TCP/PEG composites such as 1,000 µg/ml, 750

µg/ml, 500 µg/ml and 250 µg/ml respectively. The results were taken after 3

minutes incubation at the standard condition. The results indicate that ALP

activity of the composite increases when the concentration increases. This

is mainly due to the presence of increased levels of Alkaline phosphatase

enzyme in the hemolysis sample. The increase level leads to the breakdown of

the proteins in the body. This will convert more pyrophosphate to inorganic

phosphate which induces bone mineralization and this would in turn increase the

bone growth. Normally, healthy adult should have the ALP level 20-140 units per

litre (U/L) below and the above will leads to discomfort in healthy individual.

Since, ALP is need for the apatite formation the level should be monitored that

it should not cross the maximum level.

ALP Activity in U/L = ΔA/min. × 2754

The results of ALP activity are given in Fig. 9 indicate

that the concentration up to 750 μg/ml, the ALP level is increased and does not

cross the optimum level. These reports confirms that the n-HAP/n-β-TCP/PEG

composite can be used up to 750 μg/ml concentration as scaffold

for implantation.

Fig. 7 Fig. 8 Fig. 10

|

Fig. 2 Alkaline Phosphatase (ALP) activity at different proportion. |

|

Fig. 3 XRD pattern of n-HAP/n-β-TCP/PEG composites. |

|

Fig. 4 FESEM analysis of n-HAP/n-β-TCP/PEG composites. |

|

Fig. 5 Elemental analysis of n-HAP/n-β-TCP/PEG composites. |

|

Fig. 6 Cell viability at different concentration and different time period. |

|

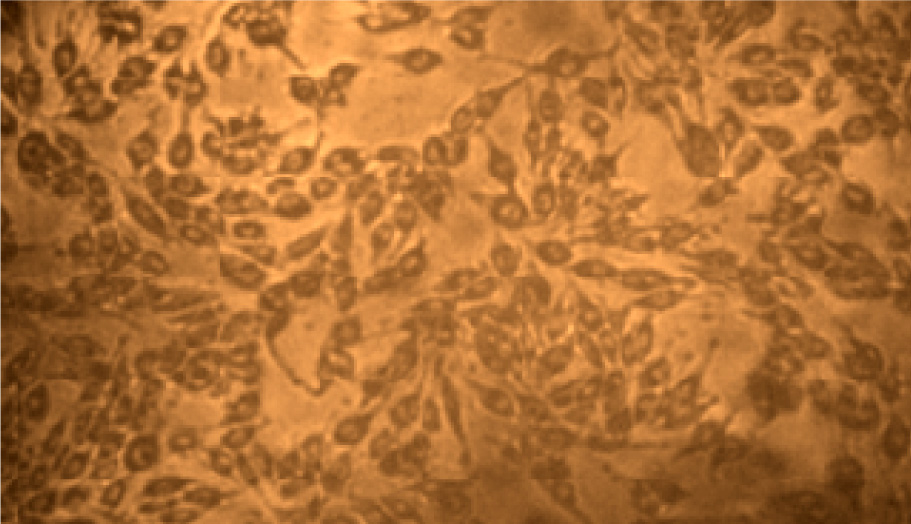

Fig. 7 MG-63- CELL LINE (40x ×100). |

|

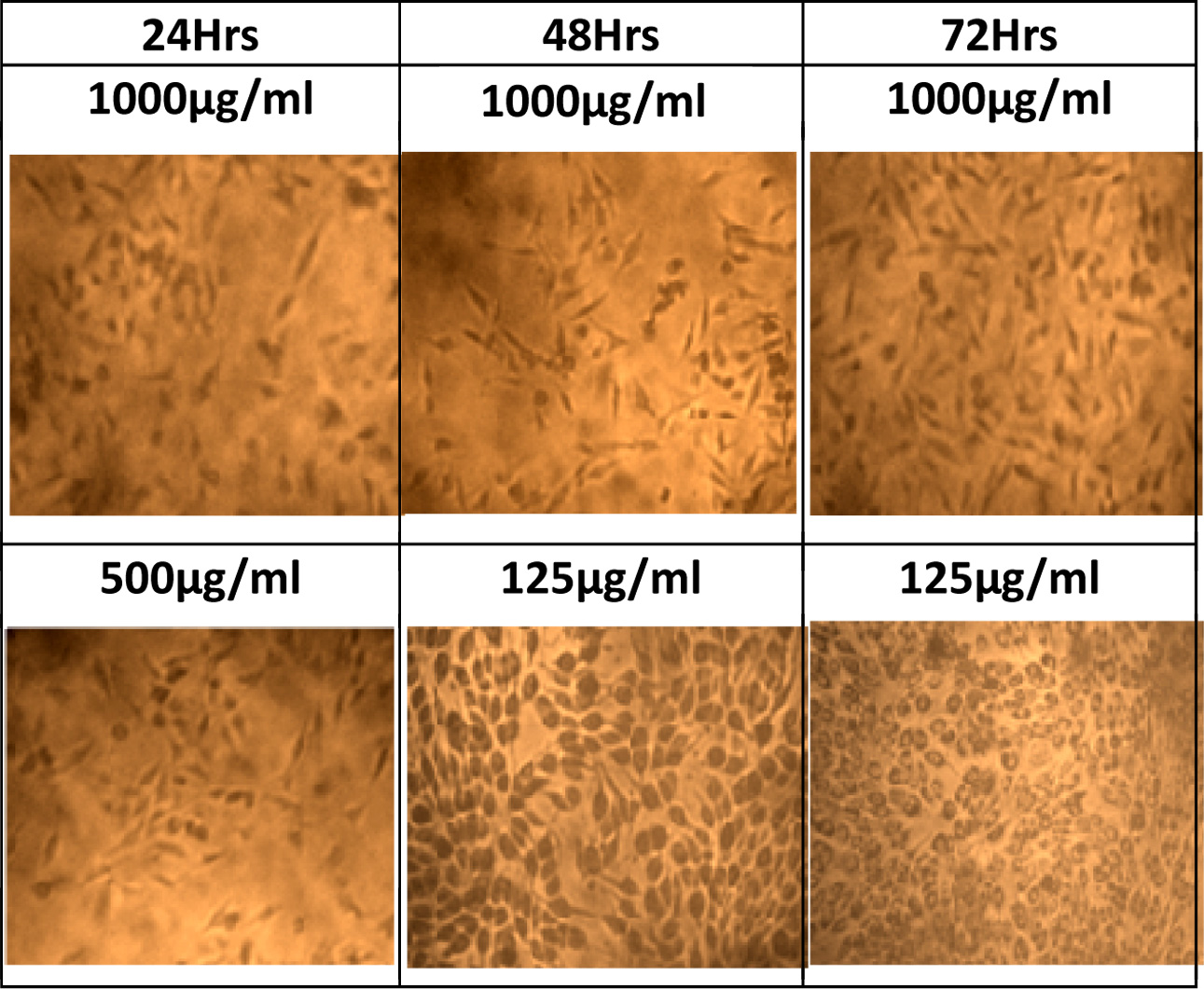

Fig. 8 Cell proliferation image at different concentration and time period. |

|

Fig. 9 Alkaline phosphatase activity of n-HAP/n-β-TCP/PEG composites. |

|

Fig. 10 Porous spongy structure of scaffold. |

n-HAP/n-β-TCP/PEG composites indicate better biochemical

and bioactivity performance at 1:1:5 proportion. The presence of

n-HAP/n-β-TCP crystalline phases were confirmed from XRD patterns.

FESEM analysis of the prepared composites indicates that the n-HAP and n-β-TCP

are embedded in the polymeric matrix. The elemental analysis further confirms

that the compsotion of nano composites. The biological studies of the

composites indicate its biocompatibility, cell proliferation, antioxidant,

toxicity and ALP activity. MTT assay confirms the MG-63 cells when adhered to

the composite mixture at different concentration shows better viability and

also proliferation at exponential phase. The concentration range preferable is

250 μg/ml to 750 μg/ml. To get better proliferation it is suggested that when

the concentration range exceeds 250 μg/ml the incubtion period should

increases. The DPPH assay confirms that the composite can be used for cancerous

patients due to its anti oxidant property that results in the trapping of free

radicals. The increased alkaline phosphatase enzyme can be seen in the required

concentration for the scaffold preperaed in the ratio of 1:1:5 indicating its

osteoconduction and osteoinduction nature.

This work was supported by UGC

SAP DRS-I (no. F.540/16/DRS-I/2016 (SAP-I)) program, Department of Analytical

Chemistry, University of Madras, Guindy Campus,Chennai-600 025

There are no conflicts of interest to declare.

- 1. M. Deng, S.G. Kumbar, Y. Wan, U.S. Toti, H.R. Allcock, and C.T. Laurencin, Soft Matter 6[14] (2010) 3119-3132.

-

- 2. G. Turnbull, J. Clarke, F. Picard, P. Riches, L. Jia, F. Han, B. Li, and W. Shu, Bioactive Materials 3[3] (2018) 278-314.

-

- 3. M. Bongio, J.J. Van Den Beucken, S.C. Leeuwenburgh, and J.A. Jansen, J. Mater. Chem. 20[40] (2010) 8747-8759.

-

- 4. X. Du, S. Fu, and Y. Zhu, J. Mater. Chem. 6[27] (2018) 4397-4412.

-

- 5. N. Eliaz and T.M. Sridhar, Cryst. Growth Des. 8[11] (2008) 3965-3977.

-

- 6. A. Regiel-Futyra, M. Kus-Liśkiewicz, V. Sebastian, S. Irusta, M. Arruebo, A. Kyzioł, and G. Stochel, RSC advances 7[83] (2017) 52398-52413.

-

- 7. P. Kumari and P. Majewski, J. Nanomater. (2013) 6.

-

- 8. P.J. VandeVord, H.W. Matthew, S.P. DeSilva, L. Mayton, B. Wu, and P.H. Wooley, P.J. VandeVord, H.W. Matthew, S.P. DeSilva, L. Mayton, B. Wu, and P.H. Wooley, J. Biomed. Mater. Res. 59[3] (2002) 585-590.

-

- 9. G. Thrivikraman, G. Madras, and B. Basu, RSC Advances 4[25] (2014) 12763-12781.

-

- 10. J. Lu, H. Yu, and C. Chen, RSC advances 8[4] (2018) 2015-2033.

-

- 11. P. Weiss, P. Layrolle, L.P. Clergeau, B. Enckel, P. Pilet, Y. Amouriq, G. Daculsi, and B. Giumelli, Biomaterials 28[22] (2007) 3295-3305.

-

- 12. J. Schnieders, U. Gbureck, E. Vorndran, M. Schossig, and T. Kissel, J. Biomed. Mater. Res., Part B 99[2] (2011) 391-398.

-

- 13. K.R. Mohamed, A.M. Mohamed, and H.H. Beherei, J. Genet. Eng. Biotechnol. 9[2] (2011) 111-119.

-

- 14. I.M. Low, in “Advances in Ceramic Matrix Composites” (Woodhead Publishing, 2018) p.27-48.

-

- 15. B. Chen, Y. Zhang, J. Zhang, L. Zhu, and H. Zhao, RSC Advances 9[32] (2019) 18688-18696.

-

- 16. Y. Deng, Y. Yang, Y. Ma, K. Fan, W. Yang, and G. Yin,. RSC Advances 7[1] (2017) 559-573.

-

- 17. G. Daculsi, O. Laboux, O. Malard, and P. Weiss, J. Mater. Sci.: Mater. Med. 14[3] (2003) 195-200.

-

- 18. R.Z. LeGeros, S. Lin, R. Rohanizadeh, D. Mijares, and J.P. LeGeros, J. Mater. Sci.: Mater. Med. 14[3] (2003) 201-209.

-

- 19. J. Van Meerloo, G.J. Kaspers, and J. Cloos, In Cancer cell culture (2011) 237-245.

-

- 20. F. Anagnostou, A. Debet, G. Pavon-Djavid, Z. Goudaby, G. Hélary, and V. Migonney, Biomaterials 27[21] (2006) 3912-3919.

-

- 21. S.P. Vinodhini, R. Manonmani, B. Venkatachalapathy, and T.M. Sridhar, RSC Advances 6[67] (2016) 62344-62355.

-

- 22. D. Gerlier and N. Thomasset, J. Immunol. Methods 94[1-2] (1986) 57-63.

-

- 23. G.N. Bowers and R.B. McComb, Clinical Chemistry 12[2] (1966) 70-89.

-

- 24. P. Molyneux and J. Songklanakarin, J. Sci. Technol. 26[2] (2004) 211-219.

- 25. J. Hudzicki, Kirby-Bauer disk diffusion susceptibility test protocol. (2009)

- 26. M.J.E. Paulo, M.A. dos Santos, B. Cimatti, N.F. Gava, M. Riberto, and E.E. Engel, Clinics 72[7] (2017) 449-453.

-

- 27. E.E. Golub and K. Boesze-Battaglia, Current opinion in Orthopaedics 18[5] (2007) 444-448.

-

- 28. U. Sharma, D. Pal, and R. Prasad, Indian J. Clin. Biochem. 29[3] (2014) 269-278.

-

- 29. M. Hui, S.Q. Li, D. Holmyard, and P.T. Cheng, Calcif. Tissue Int. 60[5] (1997) 467-472.

-

- 30. C. Gao, Y. Deng, P. Feng, Z. Mao, P. Li, B. Yang, J. Deng, Y. Cao, C. Shuai, and S. Peng, Int. J. Mol. Sci. 15[3] (2014) 4714-4732.

-

- 31. C. Ribeiro, V. Sencadas, D.M. Correia, and S. Lanceros-Méndez, Colloids Surf., B 136 (2015) 46-55.

-

- 32. S.D. Abel and S.K. Baird, Food chemistry 241 (2018) 70-78.

-

- 33. M.K. Barron, T.J. Young, K.P. Johnston, and R.O. Williams, AAPS PharmSciTech 4[2] (2003) 1-13.

-

- 34. M. Demirel and B. Aksakal, J. Ceram. Process. Res. 19[1] (2018) 5-10.

- 35. B.W. Lee and I.G. Hong, J. Ceram. Process. Res. 20[6] (2019) 655-659.

-

This Article

This Article

-

2020; 21(2): 240-248

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.240

- Received on Dec 13, 2019

- Revised on Feb 17, 2020

- Accepted on Feb 24, 2020

Services

Services

- Abstract

introduction

materials and methods

results and discussion

conclusion

- Acknowledgements

- Conflict of Interest

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- M.R. Kuppusamy

-

Department of Chemistry, RV Government Arts College, Chennai 603001, India

Tel : +91-44-2743 1257 - E-mail: kuppusmr@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.