- Experimental investigations of Co3O4, SiO2, cotton seed oil additive blends in the diesel engine and optimization by ANN-SVM process

A.P. Senthil Kumara, S. Yuvarajb,* and S. Janakic

aAssistant Professor, Department of Mechanical Engineering, PSG College of Technology, Coimbatore, India

bAssistant Professor, Department of Aeronautical Engineering, Sri Ramakrishna Engineering College, Coimbatore, India

cAssociate Professor, Department of Mechanical Engineering, SNS College of Technology, Coimbatore, India

The demand for alternative

fuel replaces the pure utilization of diesel fuel in the engines. Nano

additives and the biodiesel are introduced as the additives for reducing the

emission characteristics and fulfil the energy requirements. The main objective

of this research is to determine the emission characteristics of metal

additives and cottonseed added diesel. Three combinations of cobalt oxide

contributeto the fuel blend preparation, namely, cobalt oxide + cottonseed oil,

Cobalt oxide + silicon oxide and separate cobalt oxide in the diesel fuel. Such

combinations are mixed in the diesel fuel by adopting the method of ultrasonic

dispersed technique with three different proportions such as 25 ppm, 50 ppm and

100 ppm of Nano additives and B20, B40 and B60 blends of cottonseed oil. The

strategy of Artificial Neural Network-Support Vector Machine (ANN-SVM) is

applied to optimize and predict the better-reduced emission characteristics of

CO, HC and NOx through the mat lab platform. The testing is carried

out with five different load conditions such as 0, 25, 50, 75 and 100 N

and a constant compression ratio 17.5. Terminally, the comparison between

predicted and experimented values are also presented for determining the better

cobalt oxide fuel blend combinations with minimum emission outflow. The

combination of both additives such as silicon oxide and the cobalt oxide

proceeds better emission characteristics from both the predicted and the experimented

outcomes. In which, the predicted outcomes are 64.1% of NOx, 0.018%

of CO and 1.610% of HC.

Keywords: : Cobalt oxide, Cottonseed oil, Silicon oxide, Additives, ANN-SVM, Brake thermal efficiency

Energy plays a major role in the daily survival of humans

and certain sectors of power generation, transportation,

and industries. The vast demand for fossil fuels results in the

energy crisis due to its depleting and non-renewable behavior. In the

application of IC engines, itemits certain harmful gases while burning in the

engine [1]. The supreme emission characteristics are achieved on the basis of

proper combustion and performance behaviors of the engine [2]. The diesel

engine promotes better efficiency than the petrol engine and so, the diesel

engine performs as a prime mover application in several engineering fields. The

emission from the pure diesel fuel results the global warming disturbed air

quality and uncontrolled human health [3]. Carbon monoxide, hydrocarbon and

nitrous oxides are the major emission gases, which produced from the diesel

engine. Therefore, it is necessary to reduce the effect of such emission rates

by means of alternative fuels such as bio and nano fuel [4].

The need for alternative fuels from sustainable sources is increasing

and it also acts as a substitute for fossil fuels. The preservation of

the environment and sustainable development is achieved by the

utilization of an alternative fuel [5]. Many types of research are carried out

by the application of alternative fuels such as vegetable oil, certain oil

obtained from the seeds on diesel engines. The biodiesel and the nano additives

added diesel behaves less toxic and eco-friendly [6]. The biodiesel

incorporates complete industrial and commercial interest. It emits a

fewer amount of particulate emissions and

less quantity of unburnt carbon monoxide,

hydrocarbons and sulfur oxides etc. [7]. There are nearly 400 oil-bearing

plants are identified as the alternative additive agent for diesel, in which

soybean, cottonseed oil, peanut oil, safflower, sunflower, rapeseed

etc., are considered as major utilized oil.

The use of pure vegetable oils in the diesel may cause engine

problems such as fouling of the injector, incomplete

combustion, carbon deposited in the injector and poor

atomization of fuel. This is due to its certain worst characteristics such as

higher ranges of flash point, pour point, density and viscosity level [8]. Such

issues are overcome by the application of certain Nano metal additives. The

reduction of pollution range and the enhancement of combustion

efficiency are improved by the

application of fuel additives. The several metallics based

catalytic additive particles that contribute to the emission

controls are listed as copper, barium, manganese, iron etc.

[9]. Nanoparticles are added as the molecular form into the diesel and its

contribution todiesel fuel is actingas a most peculiar concept [10]. In the

recent advances, many types of research are carried out with the help of nano

additives to the diesel, biodiesel and its blends. The clogging action is also

prohibited with the help of nanoparticles because of its micron-sized particles

[11]. Silicon oxide is commonly used in the several

ceramics and the glass industries. It possesses better

behavior for minimizing the harmful gases from the emission rates [12]. In

addition to this, cobalt oxide plays a significant role inburning activities in

the combustion chamber. The nanoparticles of cobalt oxide

offer a perfect cycle life and high reversible capacity [13].

From the overall applied combinations, the process of

optimization promotes the precise outcome of the emissive characteristics.

Taguchi and ANOVA optimization processes are deeply utilized in several industrial

types of research [14]. Several algorithms are also contributed toprediction

and optimization purposes for different emission

characteristics of the fuel blend. ANN process is an enriched

utilized algorithm in several emission research applications [15,

16]. In this present work, three varieties of cobalt oxide combinationsare

blended in the base diesel fuel with three different proportions for analyzing

and minimize the emission characteristics of harmful gases. In addition to

this, the obtained experimental emission outcomes are

optimized and predicted with the assistance of the

ANN-SVM algorithm. Finally, a contrasting behavior is achieved for selecting

the optimal fuel additive combinations in between the experimental and the

predicted outcomes.

The emission characteristics such as NOX, HC, CO, CO2

are reduced in the combustion stage of biodiesel after the addition of ZnO

nanoparticles. Research work has been performed by Deepti Khatri

et al. [17] to reduce the formation of emission in a

diesel engine with the help of ZnO nanoparticles. Here, the ZnO nanoparticles are

added with diesel fuel at five various weights in between 5 to 25 mg. The

emission characteristics of ZnO nanoparticle blend biodiesel were analyzed

under six various loads such as 2 kW, 4 kW, 6 kW, 8 kW, 10 kW and 12 kW at 1500

rpm engine speed. Suresh Vellaiyan et al. [18] had performed an investigation

to reduce the emission of diesel with the help of ZnO incorporated water

emulsified soybean biodiesel. The experimentation was performed under the full

load condition of single-cylinder, natural aspirated, and four-stroke diesel

engines based on Taguchi L 16 array construction. According to the GRC and S/N

ratio, the emission characteristics of the fuel blend were analyzed. After the

addition of ZnO incorporated water emulsified soybean biodiesel with diesel,

the diesel engine performs well in terms of emission and workload. A waste

cooking oil (WCO)-based biodiesel was preferred by Cheruiyot et al. [19] to

reduce the emission characteristics of diesel. In which, the

preferred biodiesel blended with the diesel under 5 different

ratios named as B20, B40, B60, B80 and B100. Up to B60, the reduction rate

emission was increased, but after the blend range of B60, the reduction rate of

emission was reduced due to the viscosity property.

This research paper is sorted as follows: The existing

utilization of bio and Nanofuel from the different research papers are surveyed

in section 2. In section 3, the methodology, which proposed in this work, is

demonstrated with the flowchart representation. The utilized materials,

preparation of additive fuel blends and the methods used for the purpose of

optimization and prediction are briefly categorized in section 4. The

experimental results obtained from the testing of three proposed additive combinations

are provided in section 5. Terminally, section 6 concludes the presented work

with the attaining future scope.

The significant contribution of our proposed work is given

below:

> To develop an

alternative fuel blend toreplace the use of

pure diesel and minimize the emission characteristics.

> The

ANN-SVM algorithm contributes to identifying the

optimal fuel blend and forecasting the optimally selected

fuel blends on the basis of emission characteristics.

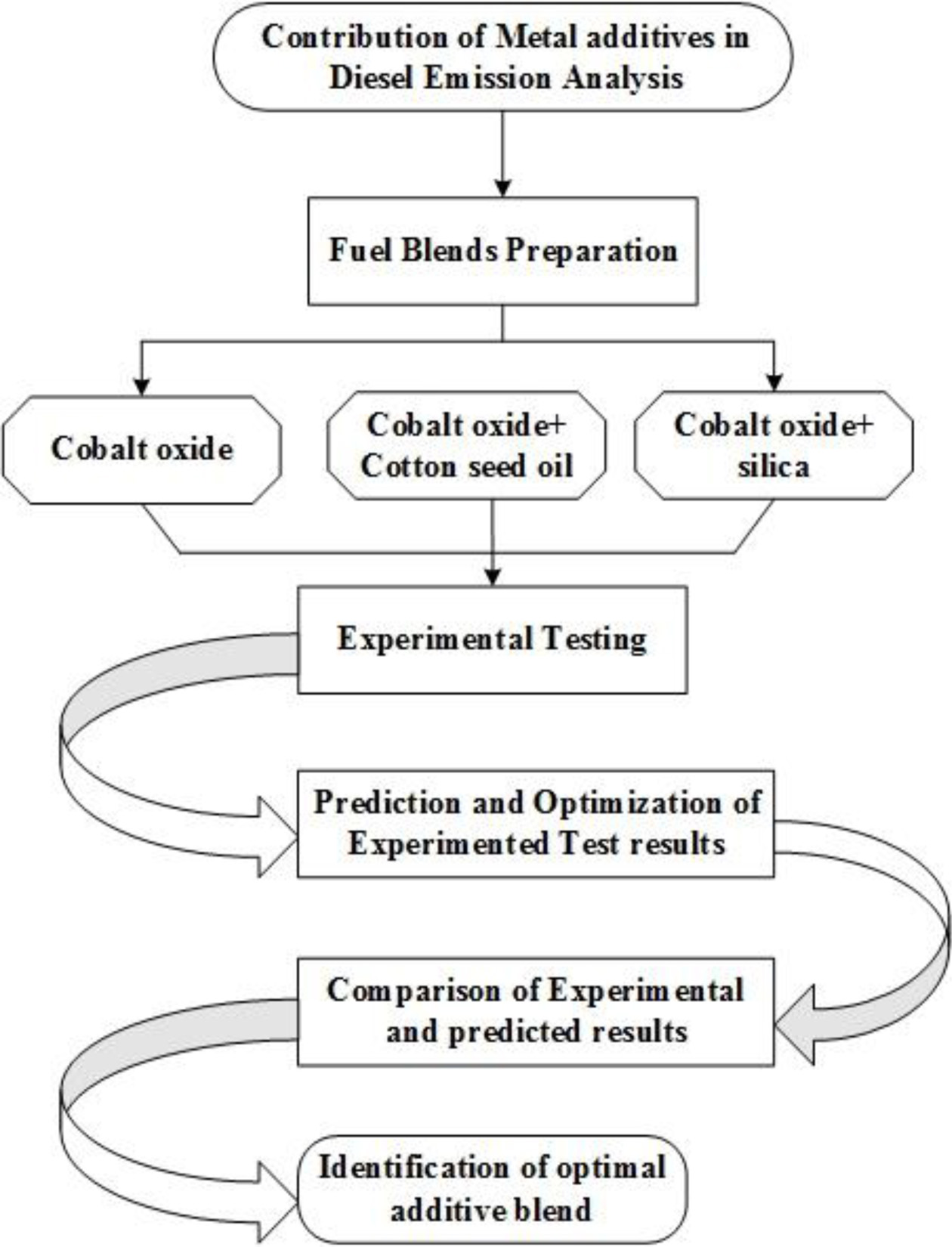

In the above flowchart, Fig. 1 demonstratesthat our

proposed fuel blend model. Initially, the diesel fuel is prepared by the mixing

of three different combinations of cobalt oxides in diesel fuel,

namely, cobalt oxide + silicon

oxide, cobalt oxide + cottonseed oil and separate cobalt

oxide by using the ultrasonically dispersed strategy. These

three combinations are added with three different proportions.

Then, in the middle stage, the prepared blends are

tested to determine the emission rates, such as CO, HC and

NOx. Finally, the experimental outcomes are optimized

and new outcomes are predicted via ANN-SVM algorithms. In addition to this, the

predicted gained outcomes are contrasted with the experimental outcomes to

assess the better emission ranges.

Test

engine and fuel preparation methods

In this paper, the influence of different cobalt oxide combinations

in diesel fuel is analyzed byavoiding certain design

modifications of the engine. The selection of materials, fuel blend separation

and working principles involved in the experiments are categorized by this

section.

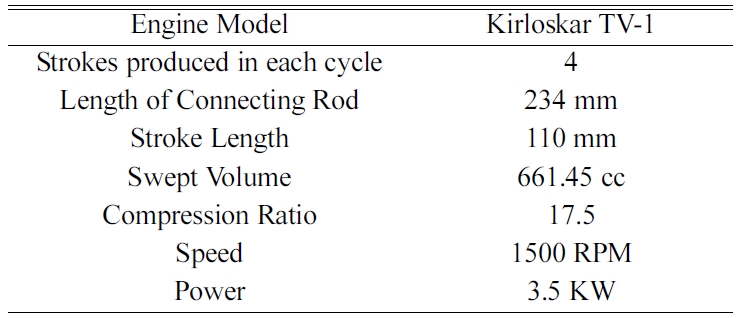

Materials and machines used Diesel engine

The Kirloskar TV-1 four-cylinder diesel engine is utilized

to test the prepared fuel blend combinations of diesel

additives namely, Co3O4+SiO2, Co3O4+cottonseed

oil and separate Co3O4.

The specifications of the utilized diesel engine are tabulated

in Table 1. The facilitation of loading activities and

measuring emission behaviors is accomplished by the Eddy current dynamometer

and AVL digital 444 analyzer. Both these devices are connected at the end of

the diesel engine.

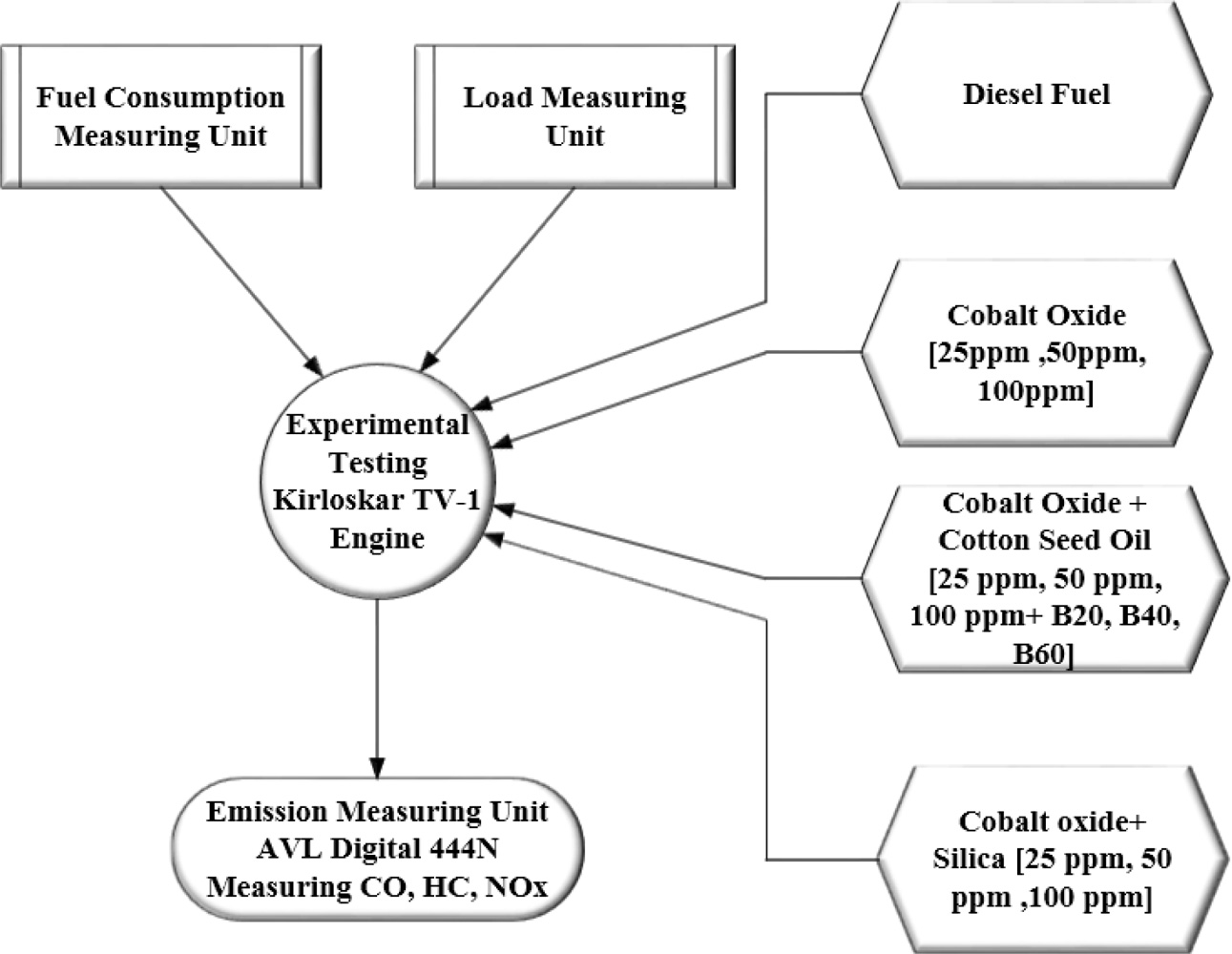

Testing procedures

Thetesting of proposed three different combinations of

additive added fuels are carried out with five distinct load conditions like 0,

25, 50, 75, and 100 N and with a constant compression ratio of 17.5. Three

different units are comprised of the diesel engine named fuel consumption unit,

load, and emission-measuring unit. The working activities, which involved in

the Kirloskar Tv-1 diesel engine are signified in Fig. 2. The fuel, which

ignited from the engine, is further measured by these mentioned units to

determine the emission characteristics.

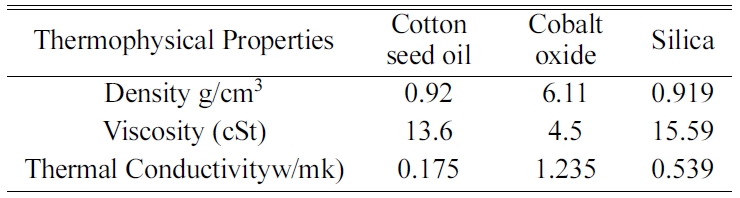

Additives

Cottonseed oil and two different nanoparticles such as

cobalt oxide and silica particles are added in the base diesel fuel for

enhancing the emission behaviors of the engine. Thecobalt oxide gives a better

clean burning and it reduces the emission rate of unburnt hydrocarbon. The

oxide content in the Co3O4 particles is response and

manage the burning behavior and diminishing the NOx generation. In

addition to this, two additional additives namely, cottonseed oil and silicon

oxide particles are separately added with the cobalt oxide. The cottonseed oil

and the silicon oxide particles achieve the minimum formation of harmful gases

when added with the cobalt oxide. Such additives are selected

on the basis of its boiling point and the size of the nanoparticles. The

preferred nano size of the particles is 6 nm to 8.5 nm. In addition to this,

the availability of the additive materials and its satisfied cost are also

considered as its major criteria. The thermo physical properties of the

utilized cottonseed oil and nano particles are listed in Table 2.

Fuel

blend preparation

The additives such as cobalt oxide, silicon oxide, and cottonseed

oil are added in the base diesel fuel with three prepared proportion of blends.

These entire combinations are leaded by the contribution of

cobalt oxide. So, both the nanoparticle (silicon oxide) and the bio agents (cottonseed

oil) are utilized with cobalt oxide throughout the paper.

• Cobalt

oxide (25 ppm, 50 ppm, 100 ppm)

• Cobalt

oxide + Cottonseed oil (25 ppm, 50 ppm, 100 ppm + B20, B40, B60)

• Cobalt

oxide + Silicon oxide (25 ppm, 50 ppm, 100 ppm)

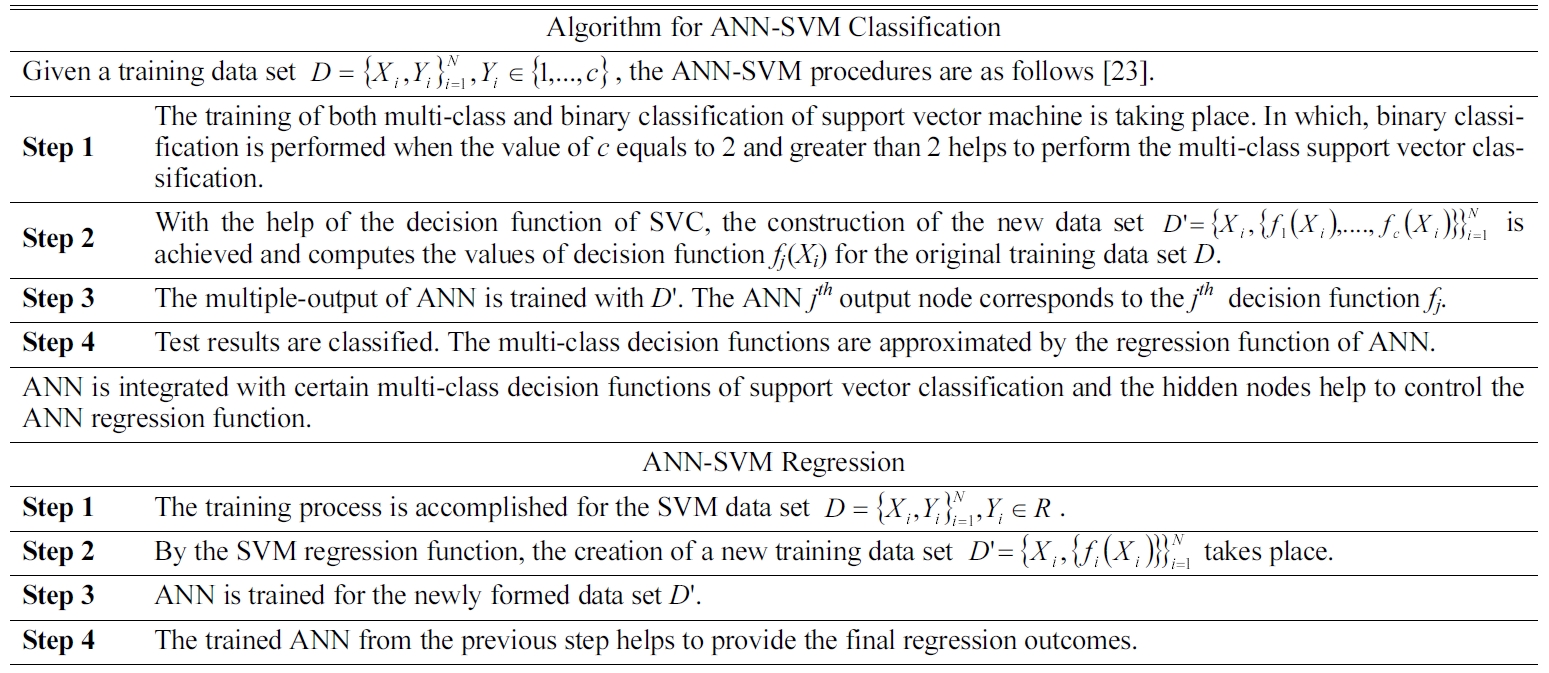

ANN-SVM prediction and optimization

The optimization and the prediction of the emission

performance of fuel blends are analyzed by using the ANN-SVM

strategy. This strategy optimizes and predicts the values

based on engine loading conditions and compression ratio. The supreme role of

the artificial neural network and support vector machine to

optimize the testing conditions and emissionbehaviours of the

blends and predict the performances for the optimally selected blends. Several

explicit issues are solved by an interlinked processing layer in the model of

ANN. In addition to this, SVM supports to supervising the classification and

regression techniques. The blend of ANN-SVM strategies quickens the prediction

and optimization process by fitting the several regression issues [20, 21]. The

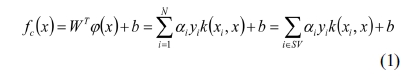

decision function of support vector classification (SVC) decision function is,

Where αi are the lagrange multipliers

which explain only the non-zero values and kernel function is denoted as k.

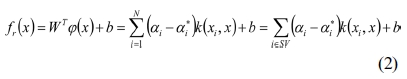

The regression function of the support vector machine

is expressed as,

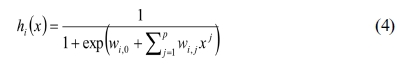

The nonlinear function hi based ANN

regression function f is defined as,

Where ith hidden node attains in the

hidden layer are denoted as hi and

wi denotes the weight.

Here, weight is mentioned wi,j, and jth

the input variable is denoted as xj. SVM eliminates the noise

from the dataset and the dataset is refined by train the ANN. ANN quickly

predicts the new data points and the prediction accuracy of both methods is the

same. There are two training phases in ANN-SVM and the first phase of SVM trains

the dataset.

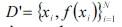

Here, xi it mentions the input feature

vector and yi mentions

the target output value. Based on the regression function or

the decision of trained SVM, obtains the function values  for

each data point xi. The input feature vector and the function

values are used to obtain the new refined dataset

for

each data point xi. The input feature vector and the function

values are used to obtain the new refined dataset  in the

second phase. The fitted function values are taken based on the training set

value of ANN. New data points are tested based on the regression function of

trained ANN and the classification problems are solved using ANN-SVM methods.

The given below table represents the regression function for the ANN-SVM

methods.

in the

second phase. The fitted function values are taken based on the training set

value of ANN. New data points are tested based on the regression function of

trained ANN and the classification problems are solved using ANN-SVM methods.

The given below table represents the regression function for the ANN-SVM

methods.

The above Table 3 shows the accompanying procedures

involved in the optimization and prediction of experimental outcomes. Both the

classification and regression problems involved in the experimental results are

solved with the assistance of ANN-SVM algorithms. In which, the

regression process is integrated with the

support vector and ANN classification decision functions to

optimize the associated problems.

|

Fig. 1 Fuel blend architecture. |

|

Fig. 2 Design of the experimental system. |

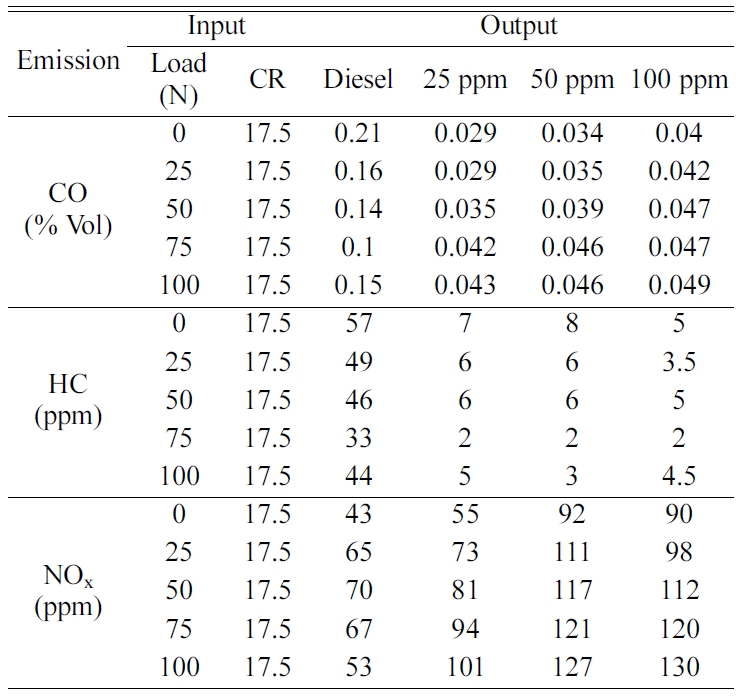

The emission performance of cobalt oxide combinations

in the diesel fuel is tabulated by means of input parameters. The load and

compression ratios are acting as the input parameters and the emission outflow

of CO, HC, and NOx are performed as output. In which, the

compression ratio is constantly set as 7.5 and the value of load differs from 0

N to 100 N. The ANN –SVM machine learning techniques help to optimize and

predict the three cobalt oxide blends in diesel fuel. The MAT lab simulation

software is utilized for enlarging the application of ANN-SVM. In addition to this,

the comparison of both experimented and predicted results are

signified in the final section.

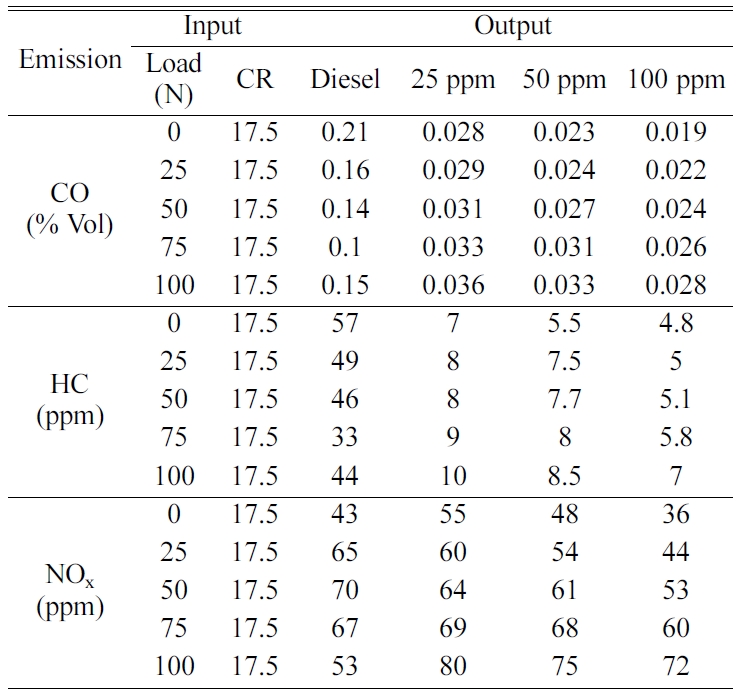

Table 4 signifies the emission rate of both normal and

cobalt oxide added diesel fuel adopted with five different load variations such

as 0, 25, 50, 75 and 100 N. In which, the emission rates of CO and HC are

optimal for the cobalt oxide added diesel and NOx emission rate is

minimum for the pure diesel fuel.

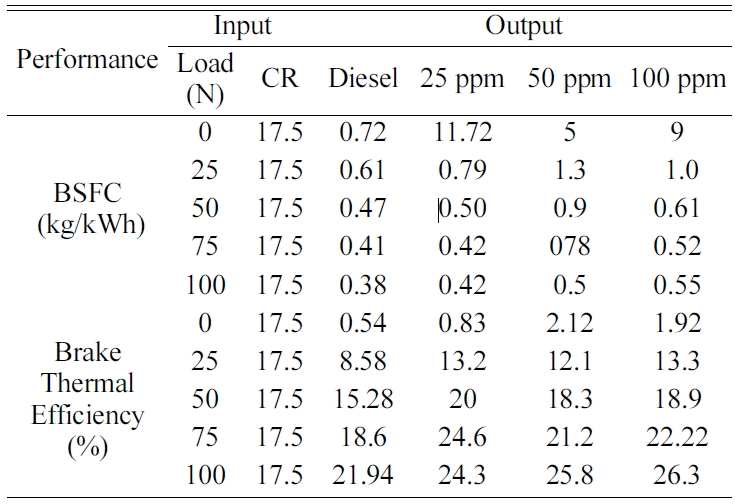

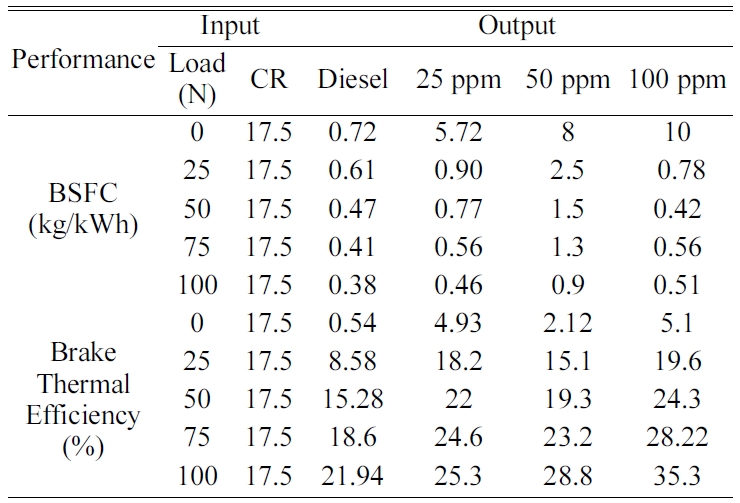

Table 5 displays the performance analysis of both pure

diesel and the cobalt oxide added diesel. The performance, such as brake specific

fuel consumption and the brake thermal efficiency are measured from the Co3O4

added biodiesel and the pure diesel. The table demonstrates that the increase

in load conditions increases the brake thermal efficiency and decreases the

brake specific fuel consumption.

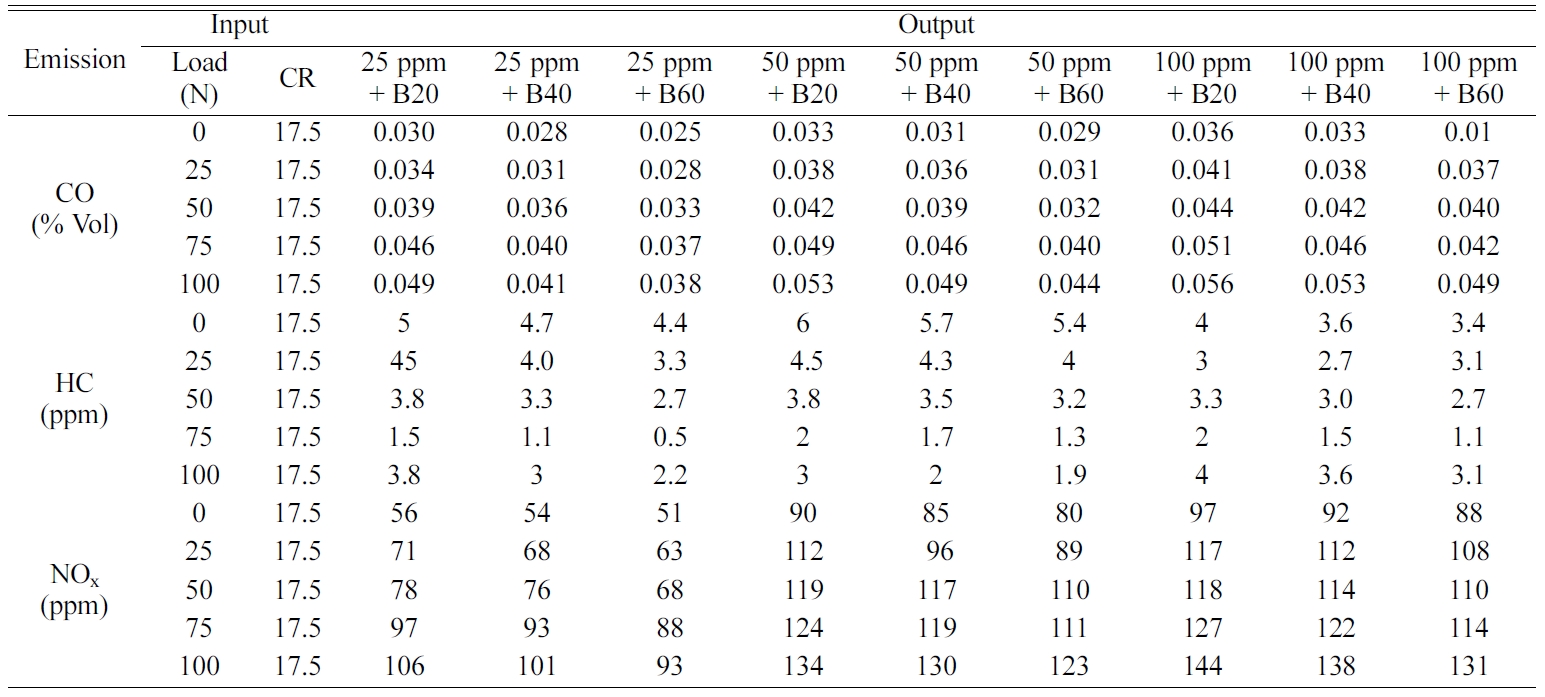

The emission behavior of cottonseed and cobalt oxide

are tabulated in Table 6 with three different proportions. The emission rate of

CO and HC is minimized according to the

increasing of loads and the NOx emission rate is increased

when the load increases. The emission characteristics of HC and CO are best in

the 100 ppm of cobalt oxide and B60 blends of cottonseed oil. The NOx emission

characteristics are optimal for the 25 ppm of cobalt oxide + B40 cottonseed oil

blend.

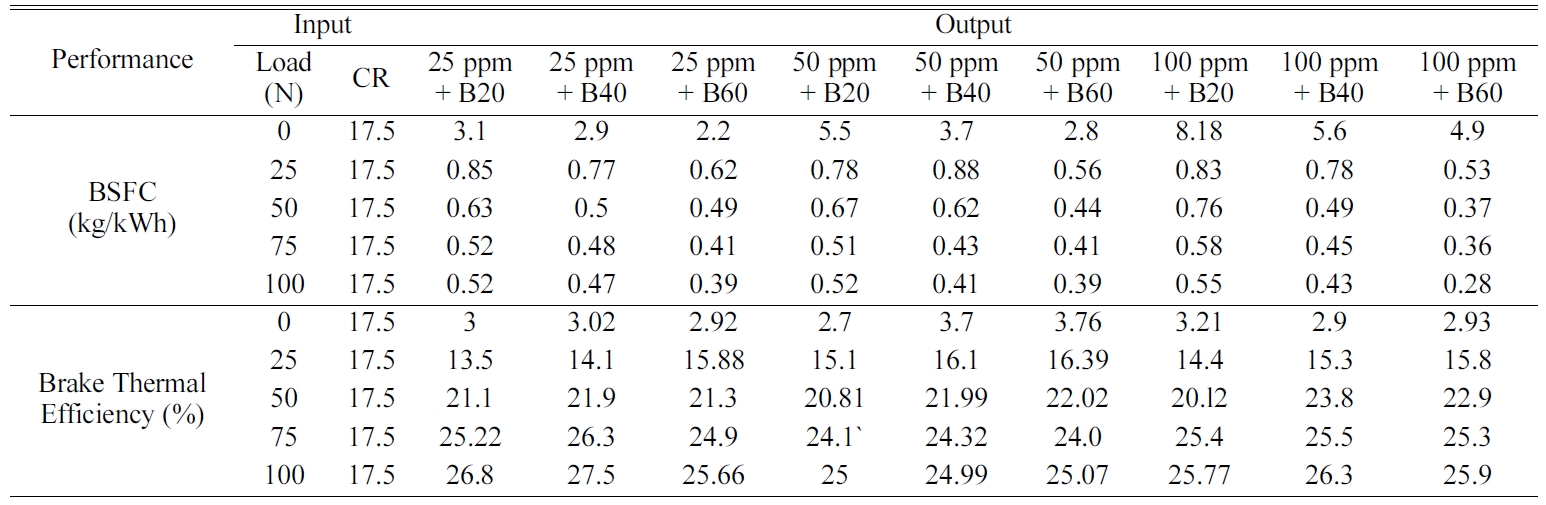

The

BSFC and BTE performances of both cobalt oxide and cottonseed oil added diesel

are indicated in Table 7. From the two discussed performances, the brake thermal efficiency is directly proportional

to the load condition and the brake

specific fuel consumption is decreased

with the increase of load conditions. The 100 ppm of cobalt oxide with a

B60 blend of cottonseedoil yields the optimal range for both performances.

Table 8 shows the emission characteristics of both

additives of cobalt oxide and silicon oxide particles added diesel.

The 100 ppm of both additives results in less amount

of emission characteristics of three different gases, namely CO, HC and NOx.

The load variations increased with the increase of emission rate of all these

mentioned emission gases.

The performance rate of both cobalt oxide and silicon

oxide in the diesel fuel are tabulated in the above table 9. At the 100 ppm

range, both the BSFC and BTE performances are optimal for the Co3O4

and SiO2 added diesel, in which it achieves the 35.3% of brake

thermal efficiency and it is greater than the pure diesel fuel, where the brake

thermal efficiency of diesel is 21.94%.

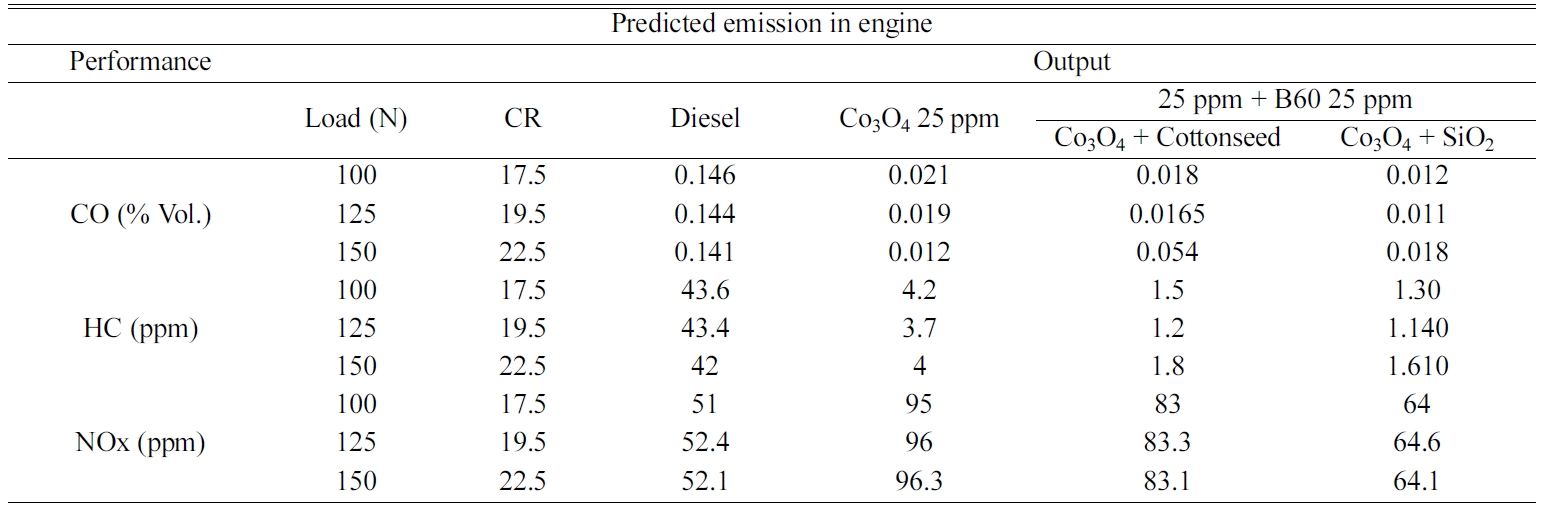

Predicted

results using ANN-SVM methods

The

optimization of experimental data and the prediction of data are achieved with

the help of ANN-SVM methods in MAT lab. The three different compression ratios of 17.5, 19.5, and 22.5 and load

conditions such as 100, 125 and 150 N are utilized for predicting the

emission rates. From the overall testing conditions, load at 150 N and compression

ratio of 22.5 promotes superior emission and performance characteristics.

Generally, the engine emits lesser emission rates

when using 25 ppm of cobalt oxide and silica combinations in the diesel fuel.

The predicted emission characteristics of pure diesel and different additives

added diesel are tabulated in the given Table 10.

The forecasted emission outcomes of three combinations

of cobalt oxide diesel blends are tabulated in Table 10. The predicted outcomes

are achieved by varying the three different load conditions, namely 100, 125

and 150 N and the various compression ratios suchas 17.5, 19.5 and 22.5. From

all the additive combinations, the cobalt oxide with silicon oxide blend in the

diesel promotes better emission characteristics when compared

with the other additive combinations. At the same time, the emission behavior

of NOx is better in the predicted results of pure diesel than the

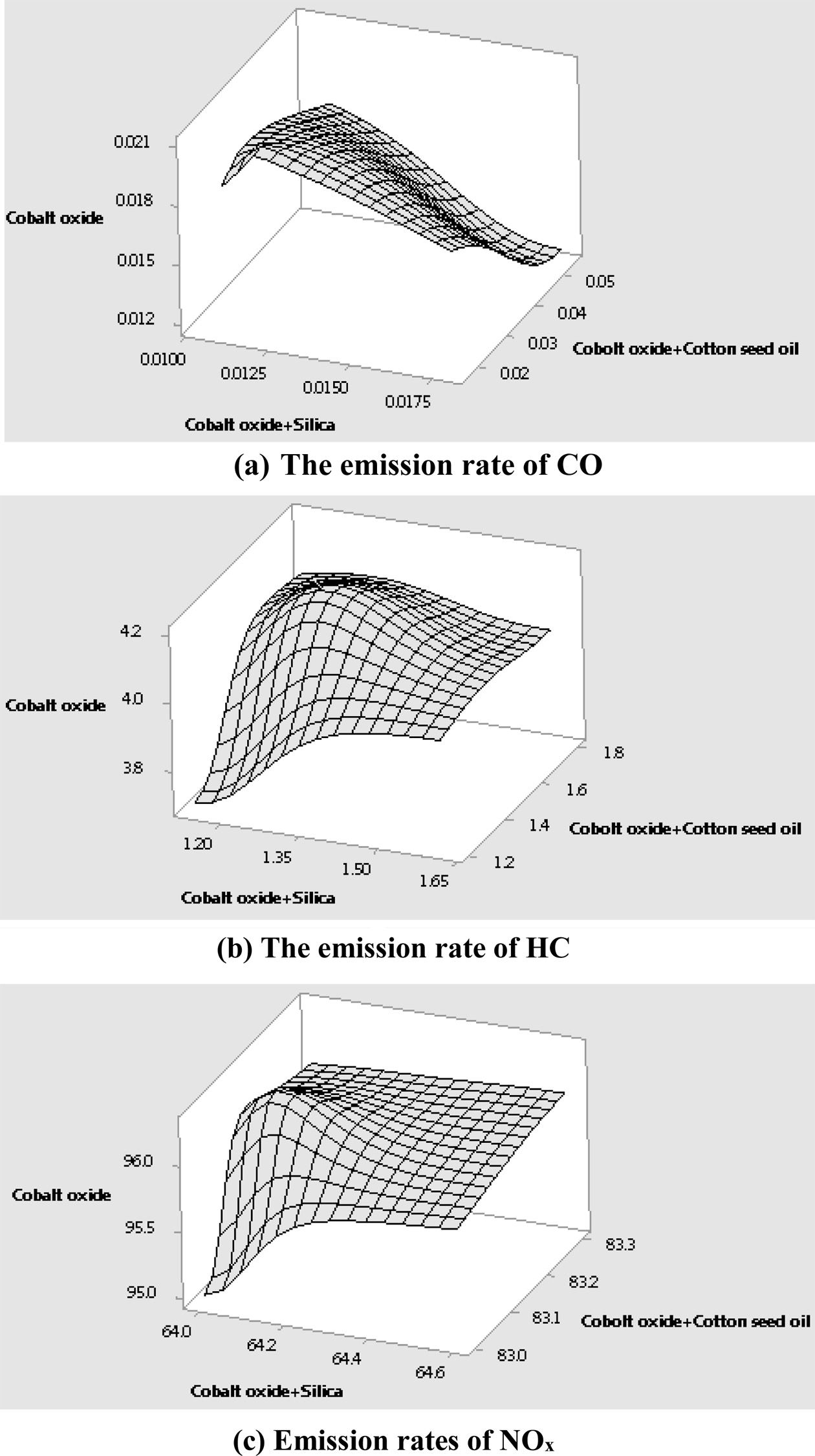

additive added alternative fuel. The emission characteristics of the three

proposed combinations of cobalt oxide are shown as wireframe graphical

representation in Fig. 3. From all these predicted results, the

emission gas of CO is yielded as very less amount and a large quantity of NOx

emission is created, when compared to the other emission gases. However,

when compared with the pure diesel fuel all the proposed additive combinations

produced a minimum amount of emission rates.

The conclusion is decided from the comparative analysis of

both the predicted and the experimented results. The whole proposed combinations

of cobalt oxide additives are optimized for the predicted results when

contrasted with the experimented values. Such comparative analysis is to be

discussed in the portion below.

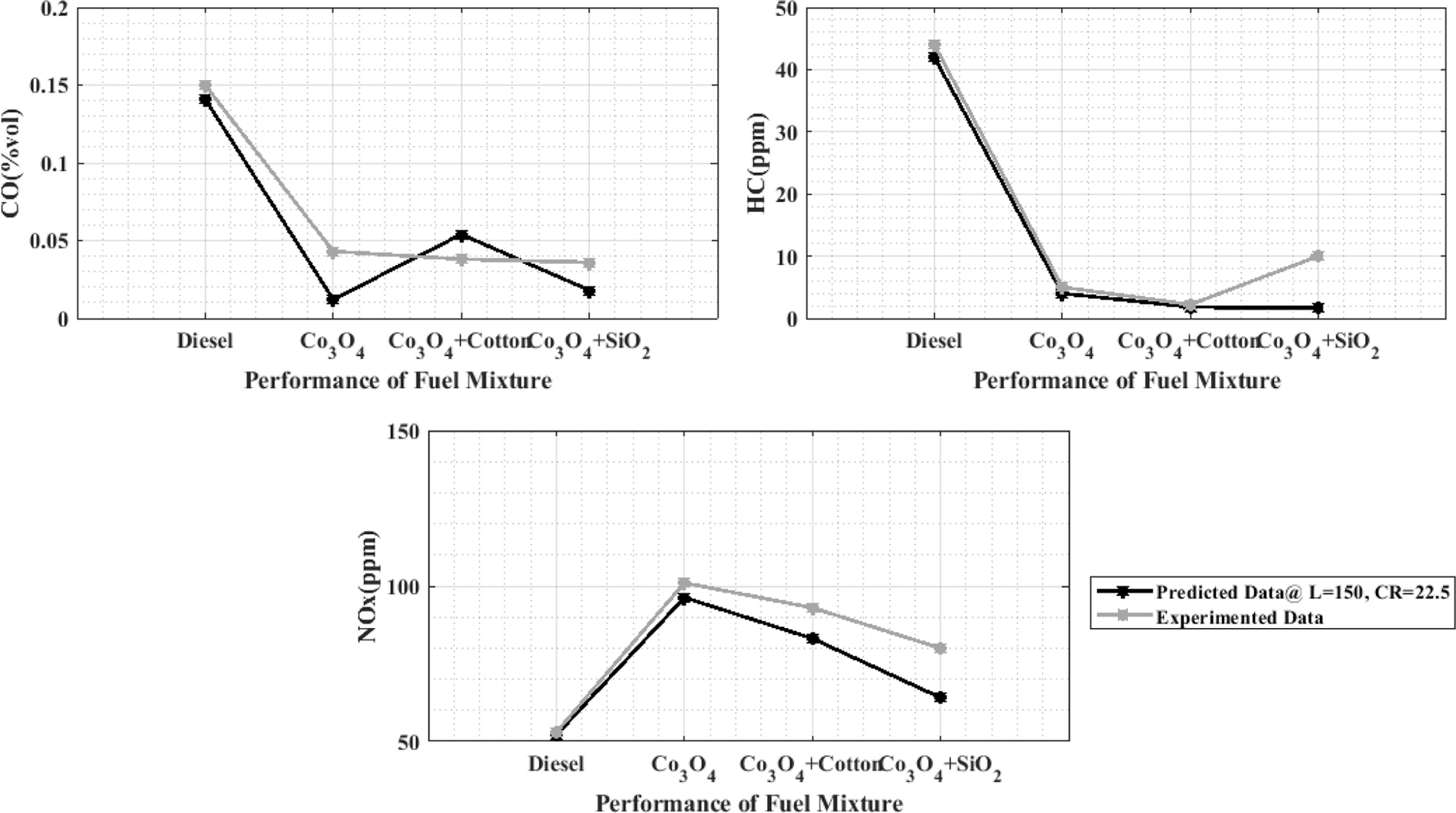

In Fig. 4, the optimal level of emission outflow obtained from

both the experimental and predicted results is depicted

in the form of graphical representation. The combinations of diesel additives

namely, cobalt oxide, cobalt oxide + cottonseed oil and cobalt oxide + silicon oxide are contrasted in this section. In

which, the emission behaviors of three different gases are separately

represented in the proceeded graph. In all these mentioned graphs, the predicted values of emission gases show optimal outcomes than the experimental

values. From the predicted results, the optimal values of HC and CO emission

rates are yielded from the blend of 25 ppm of silicon oxide + cobalt oxide in

the diesel fuel at the load of 125 N and the compression ratio of 22.5. The

predicted emission outcomes are 0.018% of CO, 64.1% of NOx and

1.610% of HC. In these input conditions, the emission rate of NOx is

minimum for the pure diesel fuel. When using copper oxide nano particles on the bio diesel blend, the

emission rates are more when compared

to our optimized fuel blend combination [22].

|

Fig. 3 Wireframe graphical representation for the predicted emission rates. |

|

Fig. 4 Comparison of experimental and predicted outcomes of engine emission rate. |

In this paper, the emission rates of diesel fuel are

reduced by adding three varieties of nano and bio-additives. The additive mixes

utilized in the diesel fuel are cobalt oxide, cobalt oxide + cottonseed oil and

cobalt oxide + silicon oxide particles. The emission test is achievedby the use

of diesel engine with five different load input conditions such as 0, 25, 50,

75, and 100 N and the constant compression ratio 7.5. The learning

algorithm of ANN-SVM is utilized to optimize and

forecast the experimental outcomes. From the test results, it

proved that the emission of HC and CO are favorable for our proposed blended

cobalt oxide combinations. However, the NOx emission rate is optimal

for pure diesel fuel. The supreme yields are obtained from the proportion rate

of 25 ppm of cobalt oxide and silicon oxide; and the blend B60 of

cottonseed oil. These emission characteristics are predicted for the

25 ppm of cobalt oxide and silicon oxide and B60 blend of

cottonseed oil with three different compression ratios such

as 17.5, 19.5 and 22.5. Similar to the experimental outcomes, the predicted

result reveals that the proposed combinations of cobalt oxide yield favorable

CO and HC emissions and the emission rate of NOx is optimal for

diesel fuel. From the predicted results, 25 ppm of Co3O4

and SiO2 and B60 blend of cottonseed oil promotes

minimum and optimal emission rates. Generally, at load conditions

150 N and the compression ratio of 22.5, the 25 ppm of Co3O4

+ SiO2 in the diesel fuel emits supreme behaviors such as 0.018% of

CO, 1.610% of HC and 64.1% of NOx. In the future, the work is

extended by utilizing different combinations of nano additives to the diesel

fuel for improving the emission characteristics of diesel engines. In

addition to this, various hybrid types of the algorithm are also

adopted to optimizing and predict the optimal emission characteristics.

The authors express their sincere gratitude to Sri

Ramakrishna Engineering College, Coimbatore and PSG College of Technology,

Coimbatore for providing the facilities for the conduct of the research.

- 1. A. Sanches-Pereira and M.F. Gómez, J. Cleaner Prod. 96[1] (2015) 452-466.

-

- 2. R.P. Bajpai and U. Chandrasekhar, in “Innovative Design and Development Practices in Aerospace and Automotive Engineering” (Springer, 2016) 231-238.

-

- 3. E. Ileri, A. Atmanli, and N. Yilmaz, J. Energy Inst. 89[4] (2016) 586-593.

-

- 4. M. Yunus, M.S. Alsoufi, and I. Hussain H., J. Alternate Energy Sources Technol. 7[2] (2016) 34-44.

- 5. J.S. Basha, J. Energy Inst. 91[2] (2018) 289-303.

-

- 6. G. Ramakrishnan, P. Krishnan, S. Rathinam, R. Thiyagu, and Y. Devarajan, Int. J. Green Energy 16[6] (2019) 435-441.

-

- 7. A. Devaraj, D. Yuvarajan, and I.V. Kanna, Int. J. Ambient Energy (2019) 1-5.

-

- 8. S. Marasri, P.P. Ewphun, P. Srichai, C. Charoenphonphanich, P. Karin, M. Tongroon, and H. Kosaka, Int. J. Automot. Technol. 20[3] (2019) 569-578.

- 9. A. Gharehghani, S. Asiaei, E. Khalife, B. Najafi and M. Tabetabaei, J Clean. Prod. 210 (2019) 1164-1170.

-

- 10. Y. Devarajan, D.B. Munuswamy, and A. Mahalingam, Heat Mass Transfer 55[6] (2019) 1641-1650.

-

- 11. G. Ramakrishnan, P. Krishnan, S. Rathinam, R. Thiyagu, and Y. Devarajan, Int. J. Green Energy 16[6] (2019) 435-441.

-

- 12. H.S. Lee, S.M. Koo, and J.W. Yoo, J. Ceram. Process. Res. 13[S2] (2012) 300-303.

- 13. S.E. Hashemi Amiri, M.R. Vaezi, and A. Esmaielzadeh Kandjani, J. Ceram. Process. Res. 12[3] (2011) 327-331.

- 14. M. Muqeem, A.F. Sherwani, M. Ahmad, and Z.A. Khan, Int. J. Heavy Veh. Syst. 26[1] (2019) 69-94.

-

- 15. P. Madane and R. Panua, Int J Computational Intelligence & IoT (IJCIIoT) 2[2] (2019) 522-528.

- 16. L. Chen and J. Ren, J. Air Transp. Manag. 68 (2018) 176-186.

-

- 17. D. Khatri, R. Goyal, A. Darad, A. Jain, S. Rawat, A. Khan, and A.T. Johnson, Clean Technol. Environ. Policy 21[7] (2019) 1485-1498.

-

- 18. S. Vellaiyan, A. Subbiah, and P. Chockalingam, Fuel 237[1] (2019) 1013-1020.

-

- 19. N.K. Cheruiyot, W.C. Hou, L.C. Wang, and C.Y. Chen, Chemosphere 235 (2019) 726-733.

-

- 20. A.H. Haghiabi, H.M. Azamathulla and A. Parsaie, ISH J of Hydraulic Engineering 23[1] (2017) 102-110.

-

- 21. S.H. Kang and S.Z. Cho, Expert Syst. Appl. 41[10] (2014) 4989-4995.

-

- 22. K. Kalaimurugan, S. Karthikeyan, M. Periyasamy, G. Mahendran, and T. Dharmaprabhakaran, Energ. Source. Part A: Recovery, Utilization, and Environmental Effects (2019) 1-16.

-

This Article

This Article

-

2020; 21(2): 217-225

Published on Apr 30, 2020

- 10.36410/jcpr.2020.21.2.217

- Received on Nov 20, 2019

- Revised on Jan 10, 2020

- Accepted on Jan 17, 2020

Services

Services

- Abstract

introduction

contribution of ceramics in bio diesel emission analysis

experimental results and discussion

conclusion

- Acknowledgements

- References

- Full Text PDF

Shared

Correspondence to

Correspondence to

- S. Yuvaraj

-

Assistant Professor, Department of Aeronautical Engineering, Sri Ramakrishna Engineering College, Coimbatore, India

Tel : +91 9976906912 Fax: +91-422-2461089 - E-mail: syuva91@gmail.com

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.

Copyright 2019 International Orgranization for Ceramic Processing. All rights reserved.